A Comparative Study of the Diffuse-Interface Model and Sharp-Interface Model in the Soldering Related Wetting Spreading Systems

Abstract

1. Introduction

2. Experimental Procedure and Wetting Kinetics

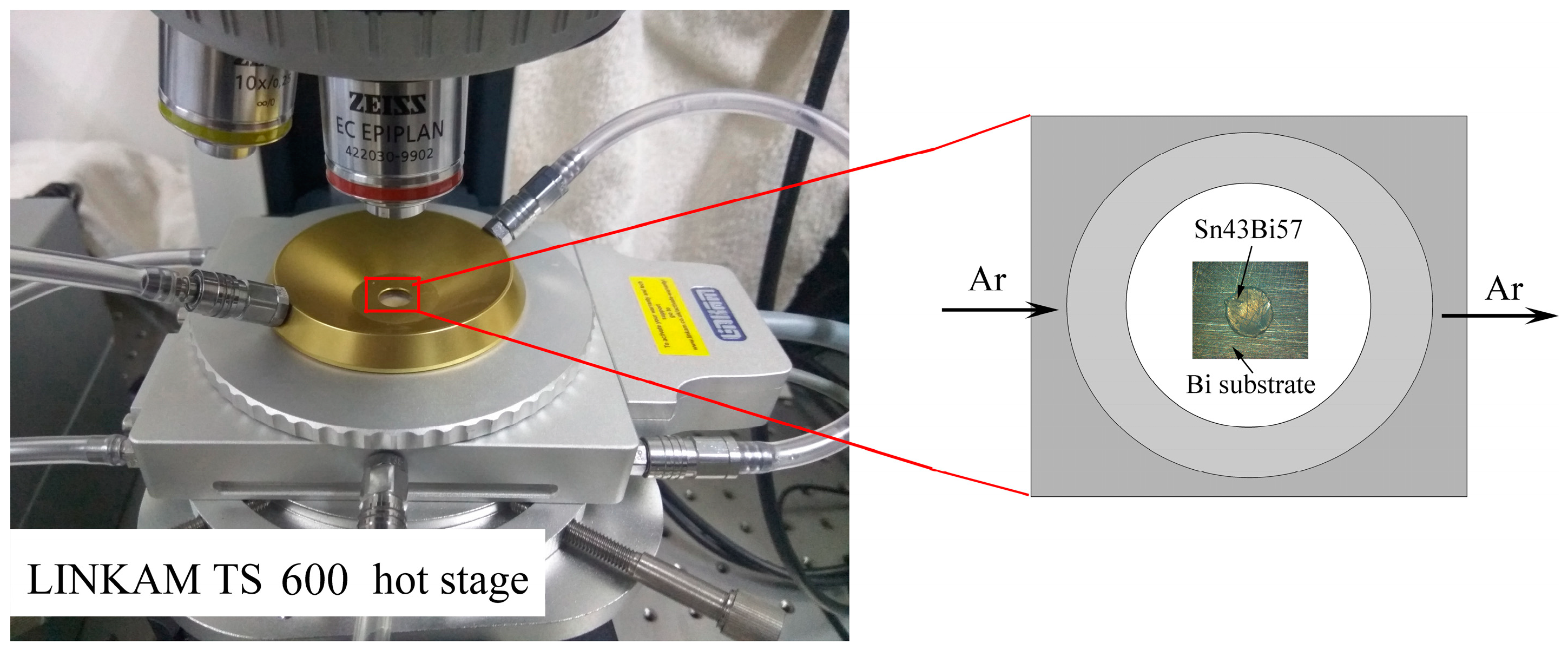

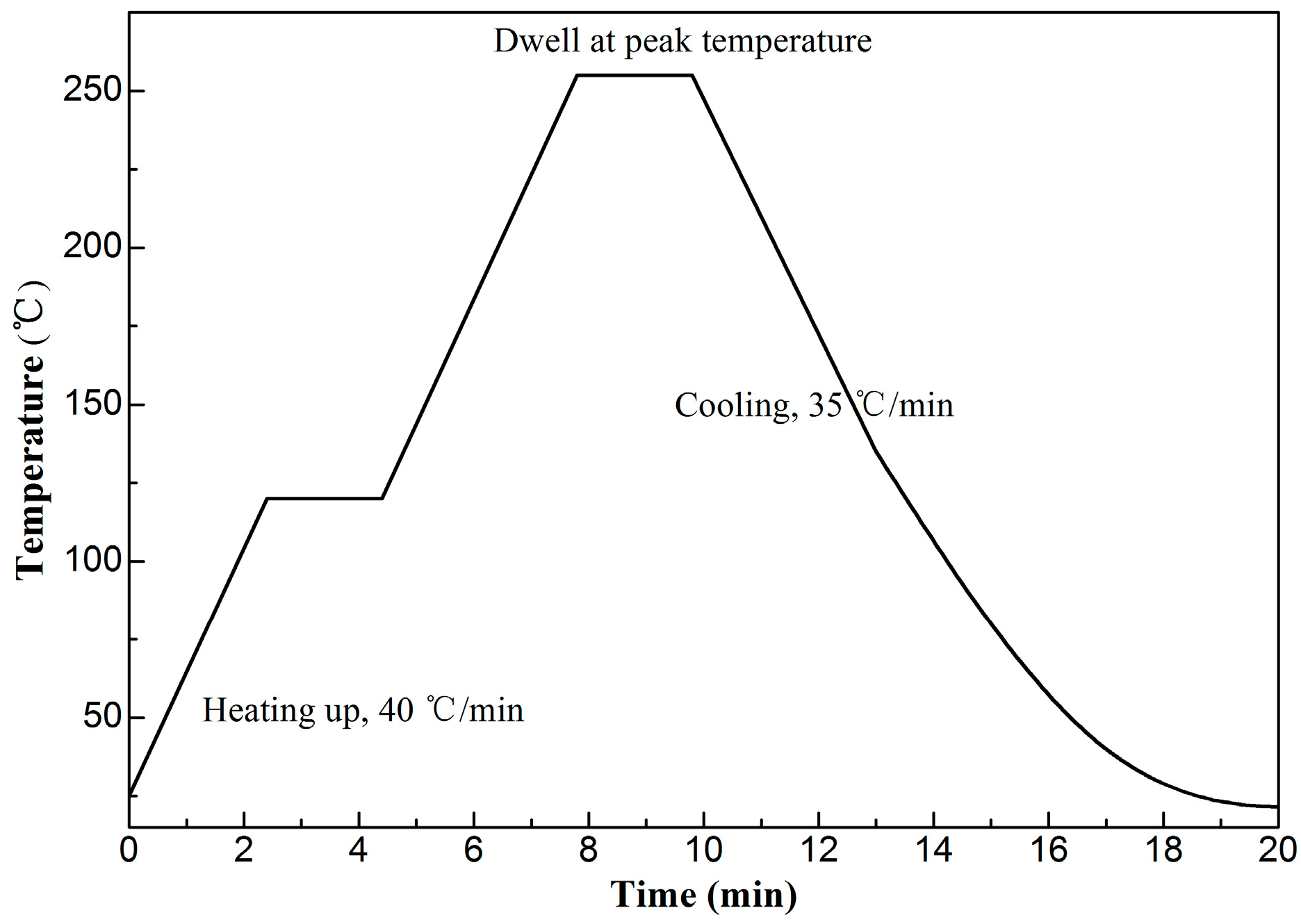

2.1. Experimental Procedure

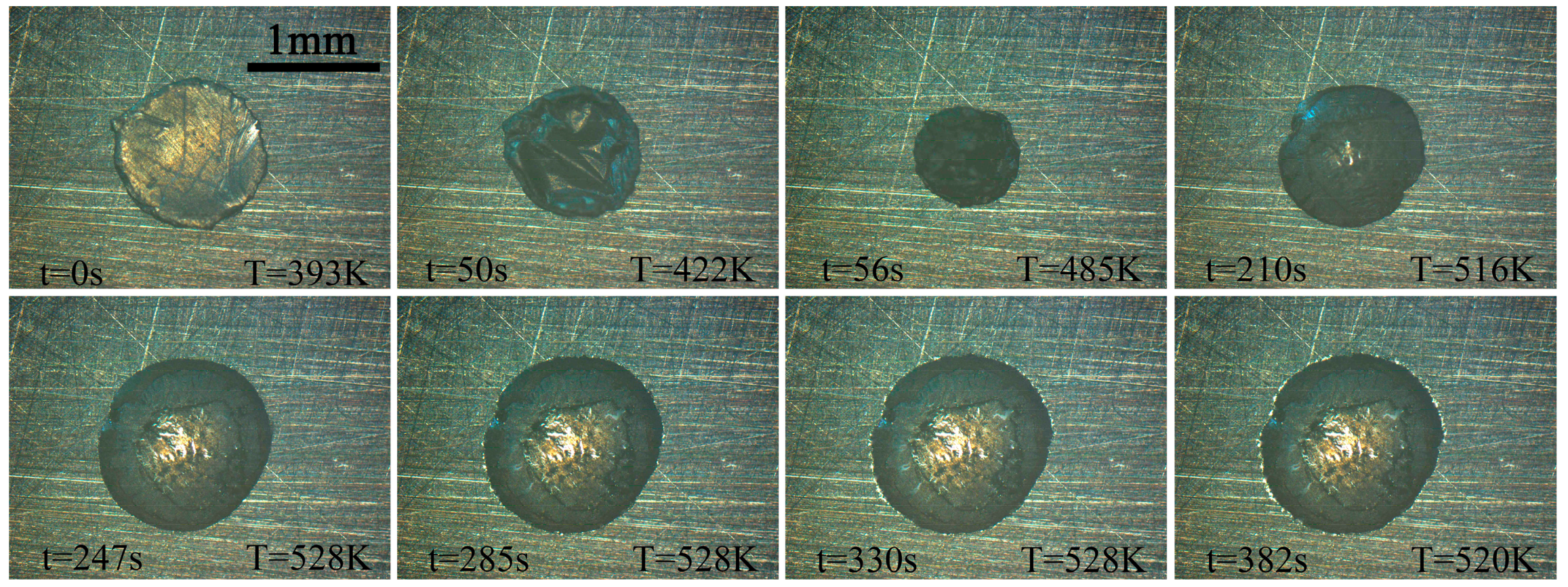

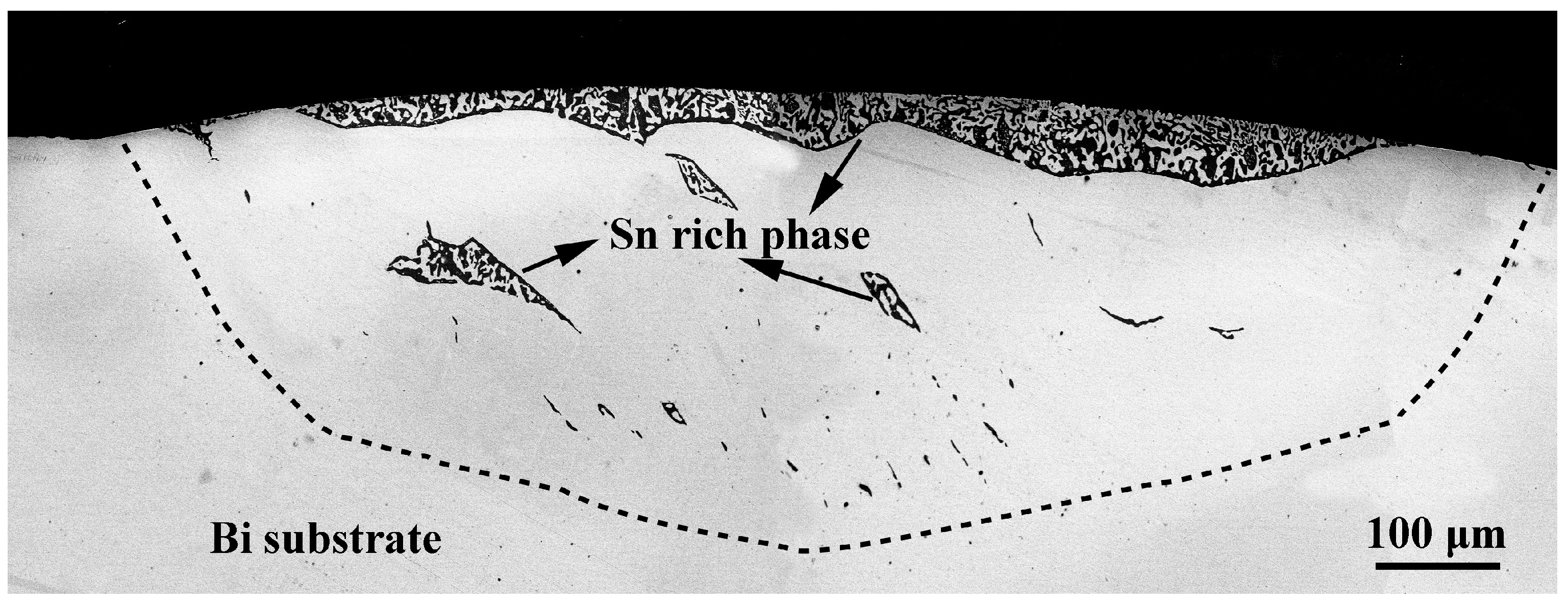

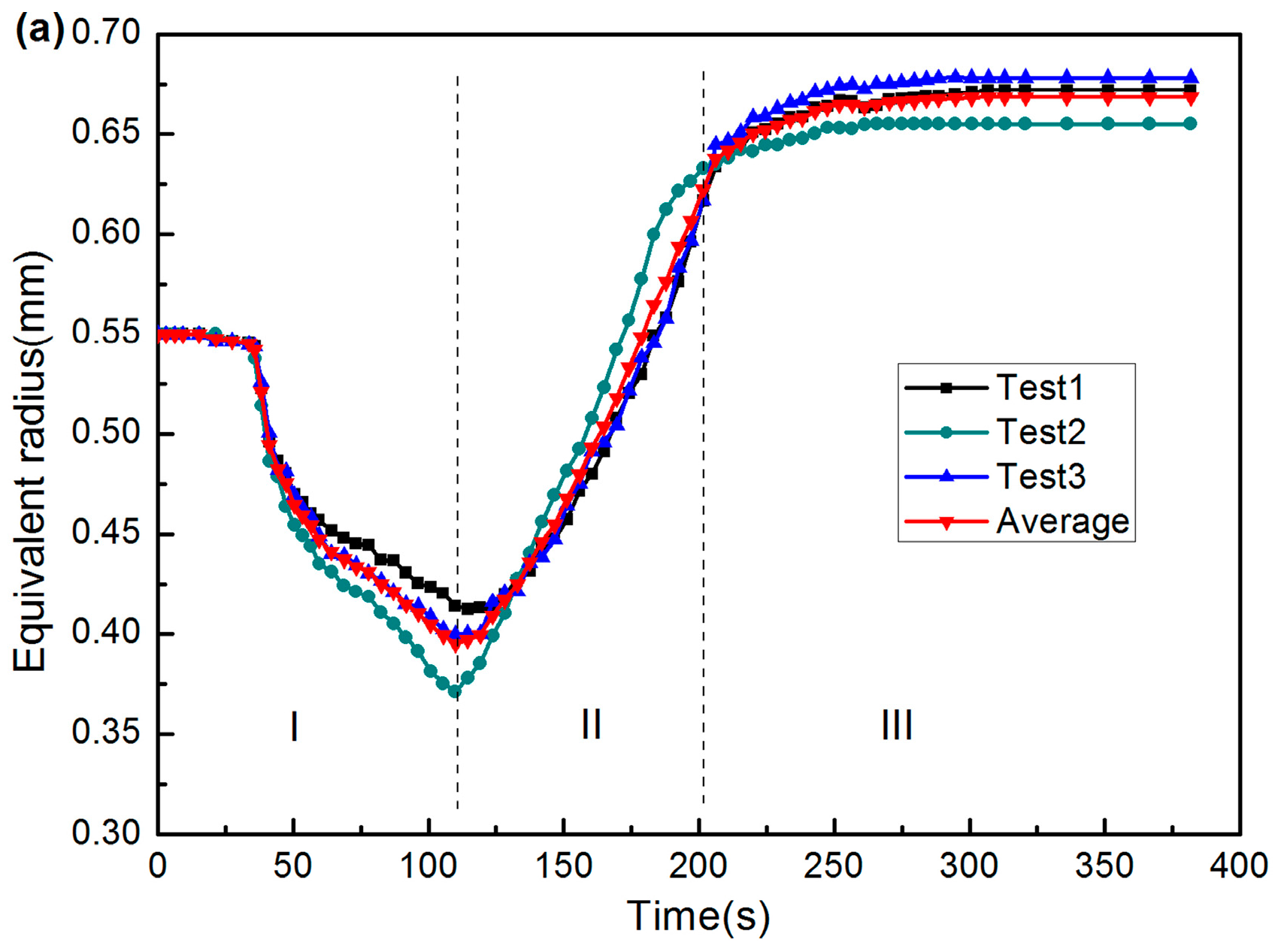

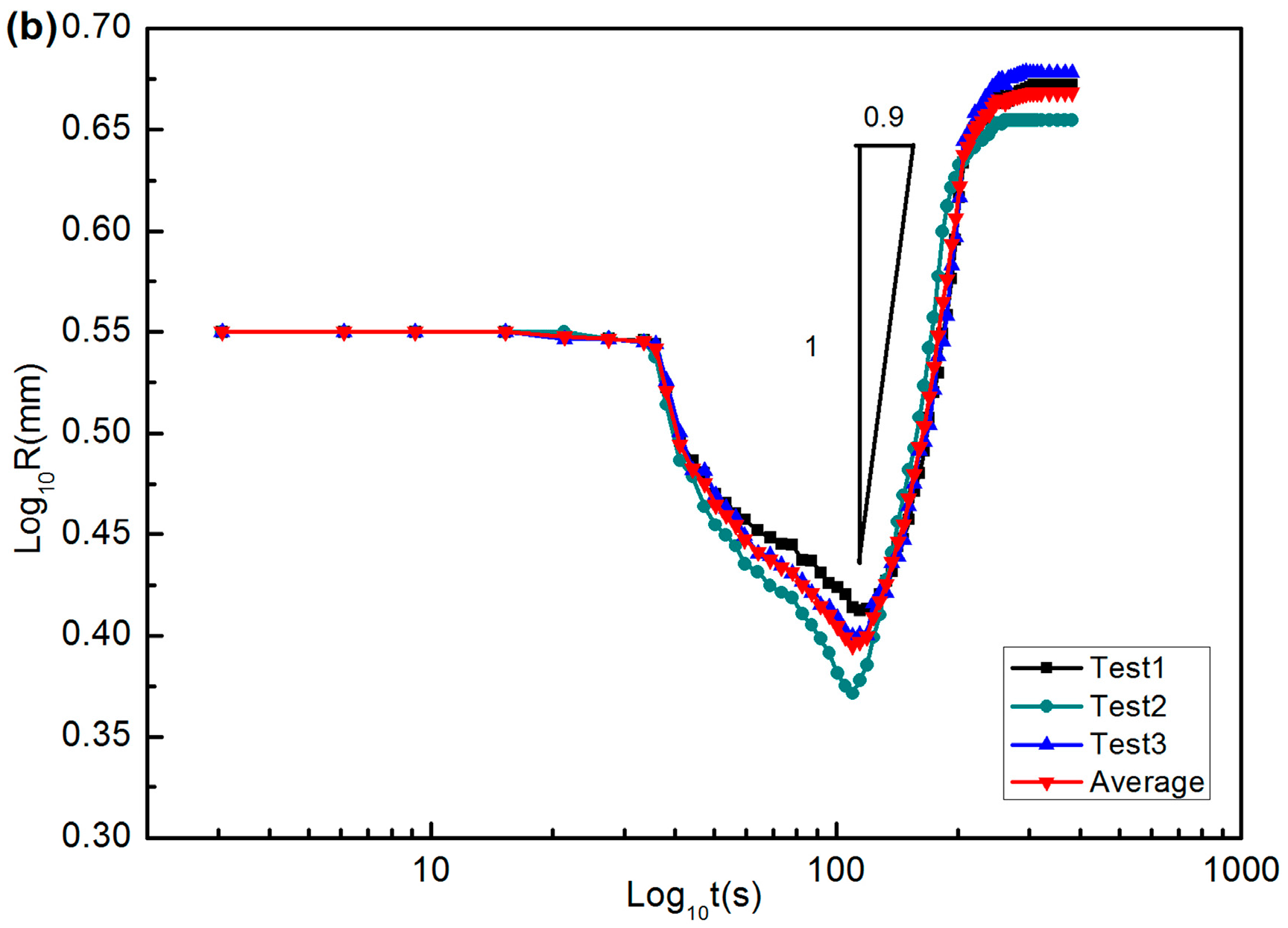

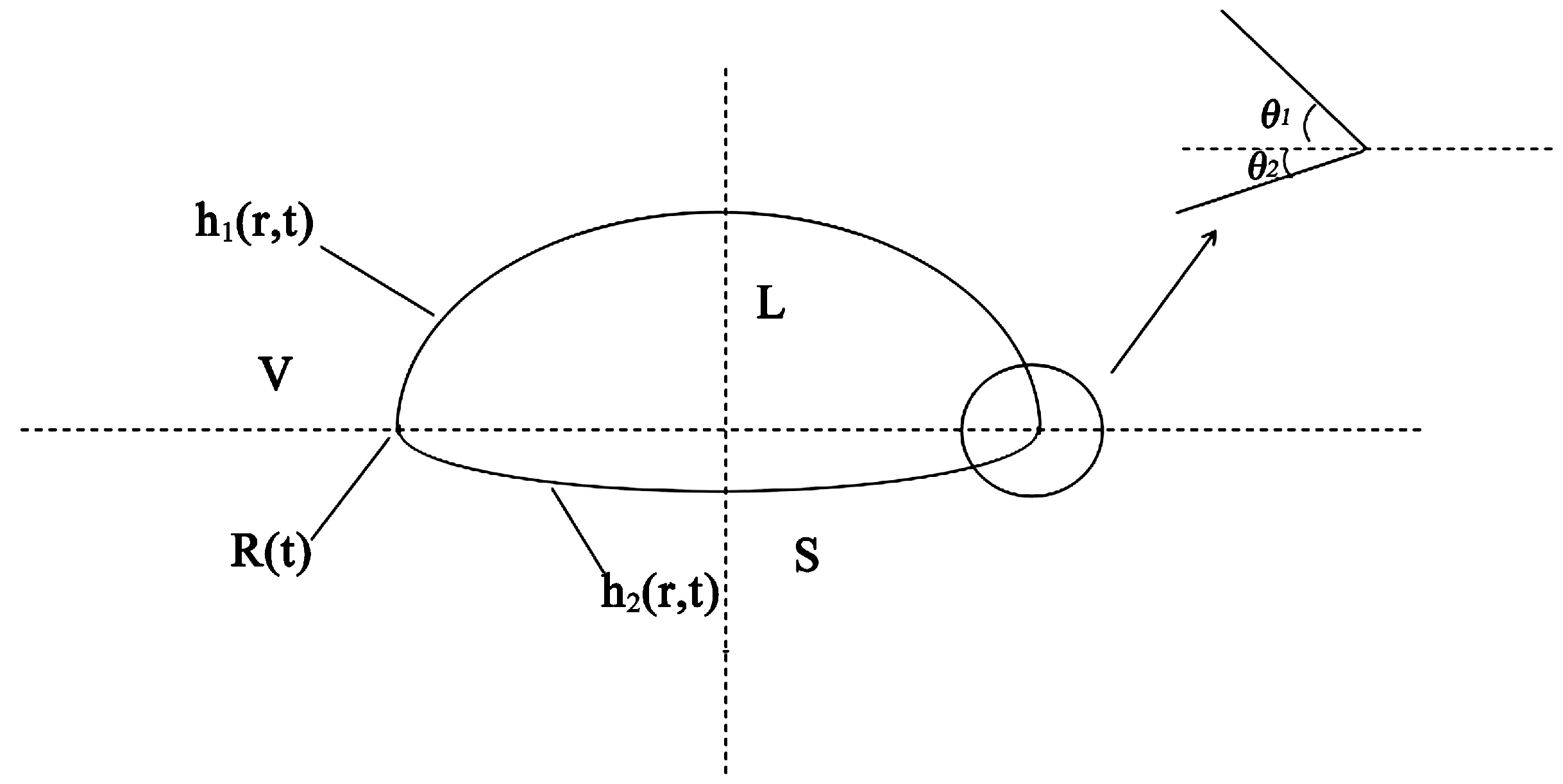

2.2. Results and Wetting Kinetics

3. The Differences and Relations between the Sharp-Interface and Diffuse-Interface

3.1. The Differences between the Basic Theories

3.2. The Relations between the Basic Theories

4. The Sharp-Interface Model and Diffuse-Interface Model in the Practical Applications

4.1. Practical Application of Sharp-Interface Model

4.2. Practical Application of Diffuse-Interface Model

5. Comparison of the Simulation Results Based on the Two Interface Models

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dezellus, O.; Eustathopoulos, N. Fundamental issues of reactive wetting by liquid metals. J. Mater. Sci. 2010, 45, 4256–4264. [Google Scholar] [CrossRef]

- Li, Y.L.; Wang, Z.L.; Long, W.F.; Lei, M.; Hu, X.W. Wetting kinetics and spreading phenomena of Sn-35Bi-1Ag solder on different substrates. J. Mater. Sci. Mater. Electron. 2018, 29, 13914–13924. [Google Scholar] [CrossRef]

- Liu, W.; Sekulic, D.P. Capillary driven molten metal flow over topographically complex substrates. Langmuir 2011, 27, 6720–6730. [Google Scholar] [CrossRef] [PubMed]

- Tanner, L.H. The spreading of silicone oil drops on horizontal surfaces. J. Phys. D Appl. Phys. 1979, 12, 1473. [Google Scholar] [CrossRef]

- Eustathopoulos, N.; Voytovych, R. The role of reactivity in wetting by liquid metals: A review. J. Mater. Sci. 2016, 51, 425–437. [Google Scholar] [CrossRef]

- Landry, K.; Rado, C.; Voitovich, R.; Eustathopoulos, N. Mechanisms of reactive wetting: The question of triple line configuration. Acta Mater. 1997, 45, 3079–3085. [Google Scholar] [CrossRef]

- Mortensen, A.; Drevet, B.; Eustathopoulos, N. Kinetics of diffusion-limited spreading of sessile drops in reactive wetting. Scr. Mater. 1997, 36, 645–651. [Google Scholar] [CrossRef]

- Ding, H.; Spelt, P.D.M. Wetting condition in diffuse interface simulations of contact line motion. Phys. Rev. E 2007, 75, 046708. [Google Scholar] [CrossRef]

- Liu, H.R.; Gao, P.; Ding, H. Fluid–structure interaction involving dynamic wetting: 2D modeling and simulations. J. Comput. Phys. 2017, 348, 45–65. [Google Scholar] [CrossRef]

- Khatavkar, V.V.; Anderson, P.D.; Meijer, H.E.H. Capillary spreading of a droplet in the partially wetting regime using a diffuse-interface model. J. Fluid Mech. 2007, 572, 367–387. [Google Scholar] [CrossRef]

- Jacqmin, D. Contact-line dynamics of a diffuse fluid interface. J. Fluid Mech. 2000, 402, 57–88. [Google Scholar] [CrossRef]

- Leo, P.H.; Lowengrub, J.S.; Jou, H.J. A diffuse interface model for microstructural evolution in elastically stressed solids. Acta Mater. 1998, 46, 2113–2130. [Google Scholar] [CrossRef]

- Subhedar, A.; Steinbach, I.; Varnik, F. Modeling the flow in diffuse interface methods of solidification. Phys. Rev. E 2015, 92, 023303. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Liu, F.; Herlach, D.M. Kinetics of triple-junctions in eutectic solidification: A sharp interface model. J. Mater. Sci. 2015, 50, 176–188. [Google Scholar] [CrossRef]

- Theillard, M.; Gibou, F.; Pollock, T. A sharp computational method for the simulation of the solidification of binary alloys. J. Sci. Comput. 2015, 63, 330–354. [Google Scholar] [CrossRef]

- Anderson, D.M.; McFadden, G.B.; Wheeler, A.A. Diffuse-interface methods in fluid mechanics. Annu. Rev. Fluid. Mech. 1998, 30, 139–165. [Google Scholar] [CrossRef]

- Collins, J.B.; Levine, H. Diffuse interface model of diffusion-limited crystal growth. Phys. Rev. B 1985, 31, 6119. [Google Scholar] [CrossRef] [PubMed]

- Galenko, P.; Jou, D. Diffuse-interface model for rapid phase transformations in nonequilibrium systems. Phys. Rev. E 2005, 71, 046125. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Liu, F.; Zhai, H.; Wang, K. Application of the maximal entropy production principle to rapid solidification: A sharp interface model. Acta Mater. 2012, 60, 1444–1454. [Google Scholar] [CrossRef]

- Warren, J.A.; Boettinger, W.J.; Roosen, A.R. Modeling reactive wetting. Acta Mater. 1998, 46, 3247–3264. [Google Scholar] [CrossRef]

- Yin, L.; Murray, B.T.; Singler, T.J. Dissolutive wetting in the Bi–Sn system. Acta Mater. 2006, 54, 3561–3574. [Google Scholar] [CrossRef]

- Su, S.; Yin, L.; Sun, Y.; Murray, B.T.; Singler, T.J. Modeling dissolution and spreading of Bi–Sn alloy drops on a Bi substrate. Acta Mater. 2009, 57, 3110–3122. [Google Scholar] [CrossRef]

- Chen, L.Q. Phase-field models for microstructure evolution. Annu. Rev. Mater. Res. 2002, 32, 113–140. [Google Scholar] [CrossRef]

- Drolet, F.; Elder, K.R.; Grant, M.; Kosterlitz, J.M. Phase-field modeling of eutectic growth. Phys. Rev. E 2000, 61, 6705. [Google Scholar] [CrossRef] [PubMed]

- Loginova, I.; Odqvist, J.; Amberg, G.; Ågren, J. The phase-field approach and solute drag modeling of the transition to massive γ→α transformation in binary Fe-C alloys. Acta Mater. 2003, 51, 1327–1339. [Google Scholar] [CrossRef]

- Warren, J.A.; Boettinger, W.J. Prediction of dendritic growth and microsegregation patterns in a binary alloy using the phase-field method. Acta Mater. 1995, 43, 689–703. [Google Scholar] [CrossRef]

- Huh, J.Y.; Hong, K.K.; Kim, Y.B.; Kim, K.T. Phase field simulations of intermetallic compound growth during soldering reactions. J. Electron. Mater. 2004, 33, 1161–1170. [Google Scholar] [CrossRef]

- Hong, K.K.; Huh, J.Y. Phase field simulations of morphological evolution and growth kinetics of solder reaction products. J. Electron. Mater. 2006, 35, 56–64. [Google Scholar] [CrossRef]

- Villanueva, W.; Granhagen, K.; Amberg, G.; Ågren, J. Multicomponent and multiphase modeling and simulation of reactive wetting. Phys. Rev. E 2008, 77, 056313. [Google Scholar] [CrossRef]

- Villanueva, W.; Boettinger, W.J.; Warren, J.A.; Amberg, G. Effect of phase change and solute diffusion on spreading on a dissolving substrate. Acta Mater. 2009, 57, 6022–6036. [Google Scholar] [CrossRef]

- Eustathopoulos, N. Dynamics of wetting in reactive metal/ceramic systems. Acta Mater. 1998, 46, 2319–2327. [Google Scholar]

- Zhao, H.; Nalagatla, D.R.; Sekulic, D.P. Wetting kinetics of eutectic lead and lead-free solders: Spreading over the Cu Surface. J. Electron. Mater. 2009, 38, 284–291. [Google Scholar] [CrossRef]

- De Gennes, P.G. Wetting: Statics and dynamics. Rev. Mod. Phys. 1985, 57, 827. [Google Scholar] [CrossRef]

- Asthana, R.; Sobczak, N. Wettability, spreading, and interfacial phenomena in high-temperature coatings. JOM-e 2000, 52, 1–19. [Google Scholar]

- Yu, X.; Yang, J.; Yan, M.; Hu, X.W.; Li, Y.L. Kinetics of wetting and spreading of AgCu filler metal over Ti–6Al–4V substrates. J. Mater. Sci. 2016, 51, 10960–10969. [Google Scholar] [CrossRef]

- Qin, R.S.; Bhadeshia, H.K. Phase field method. Mater. Sci. Technol. 2010, 26, 803–811. [Google Scholar] [CrossRef]

- Elder, K.R.; Grant, M.; Provatas, N.; Kosterlitz, J.M. Sharp interface limits of phase-field models. Phys. Rev. E 2001, 64, 021604. [Google Scholar] [CrossRef] [PubMed]

- Caginalp, G.; Xie, W. Phase-field and sharp-interface alloy models. Phys. Rev. E 1993, 48, 1897. [Google Scholar] [CrossRef]

- Song, X.G.; Cao, J.; Wang, Y.F.; Feng, J.C. Effect of Si3N4-particles addition in Ag-Cu-Ti filler alloy on Si3N4/TiAl brazed joint. Mater. Sci. Eng. A 2011, 528, 5135–5140. [Google Scholar] [CrossRef]

- Yue, P.; Zhou, C.; Feng, J.J. Sharp-interface limit of the Cahn-Hilliard model for moving contact lines. J. Fluid Mech. 2010, 645, 279–294. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, G.; Zhang, J.; Lei, M.; Li, Y.; Li, X. A Comparative Study of the Diffuse-Interface Model and Sharp-Interface Model in the Soldering Related Wetting Spreading Systems. Metals 2019, 9, 944. https://doi.org/10.3390/met9090944

Liu G, Zhang J, Lei M, Li Y, Li X. A Comparative Study of the Diffuse-Interface Model and Sharp-Interface Model in the Soldering Related Wetting Spreading Systems. Metals. 2019; 9(9):944. https://doi.org/10.3390/met9090944

Chicago/Turabian StyleLiu, Guanpeng, Jianyang Zhang, Min Lei, Yulong Li, and Xuewen Li. 2019. "A Comparative Study of the Diffuse-Interface Model and Sharp-Interface Model in the Soldering Related Wetting Spreading Systems" Metals 9, no. 9: 944. https://doi.org/10.3390/met9090944

APA StyleLiu, G., Zhang, J., Lei, M., Li, Y., & Li, X. (2019). A Comparative Study of the Diffuse-Interface Model and Sharp-Interface Model in the Soldering Related Wetting Spreading Systems. Metals, 9(9), 944. https://doi.org/10.3390/met9090944