Development of Novel AlSi10Mg Based Nanocomposites: Microstructure, Thermal and Mechanical Properties

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

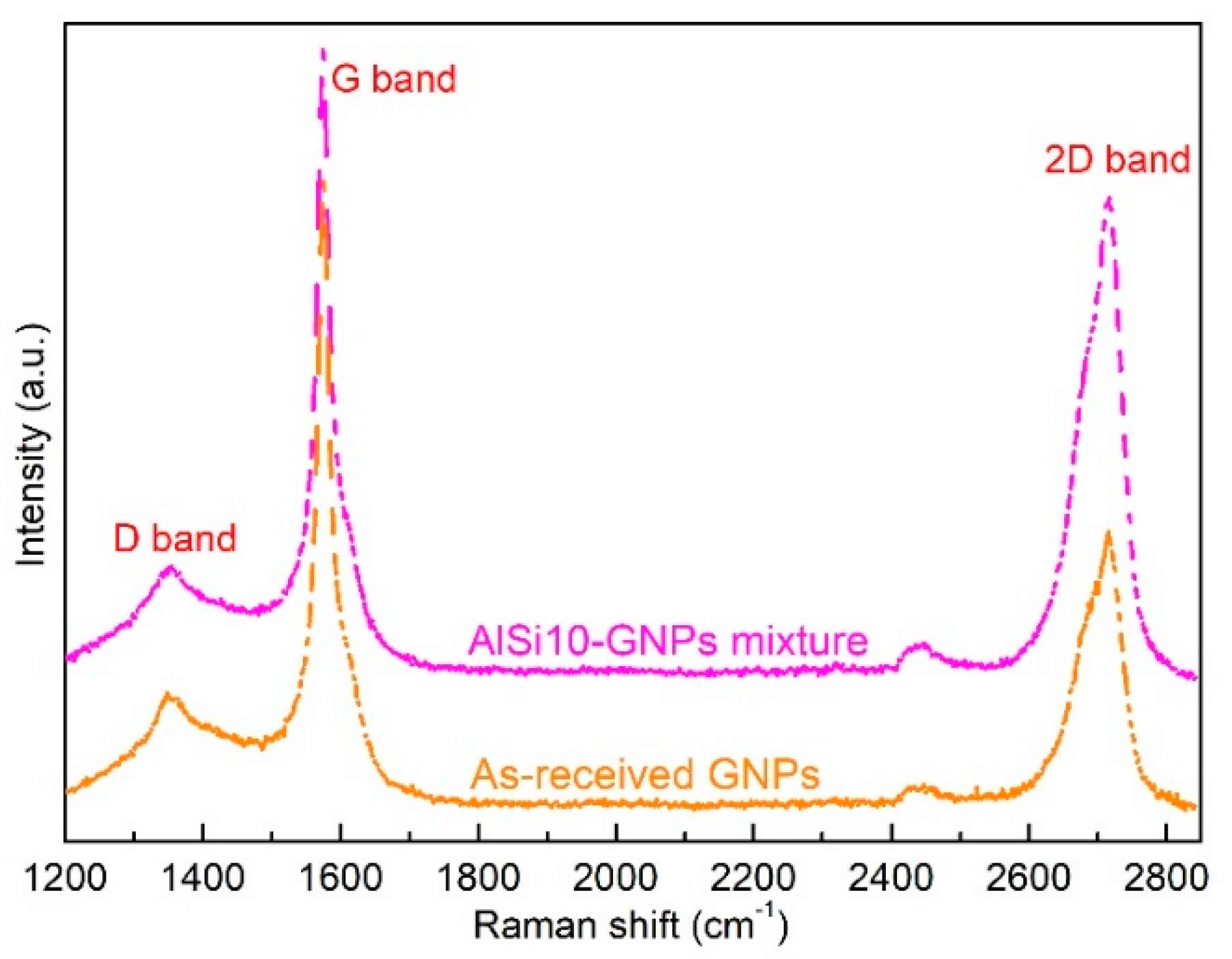

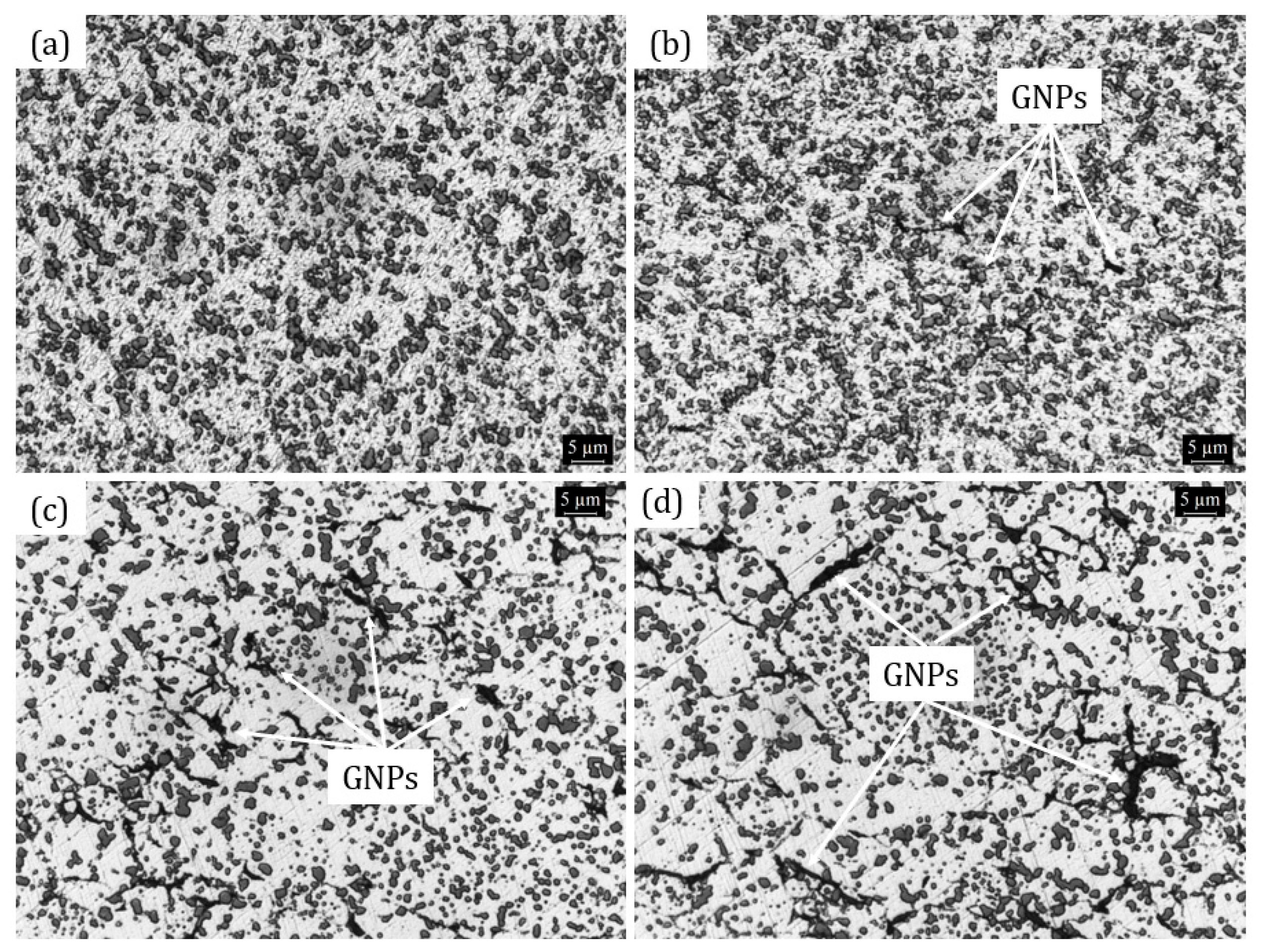

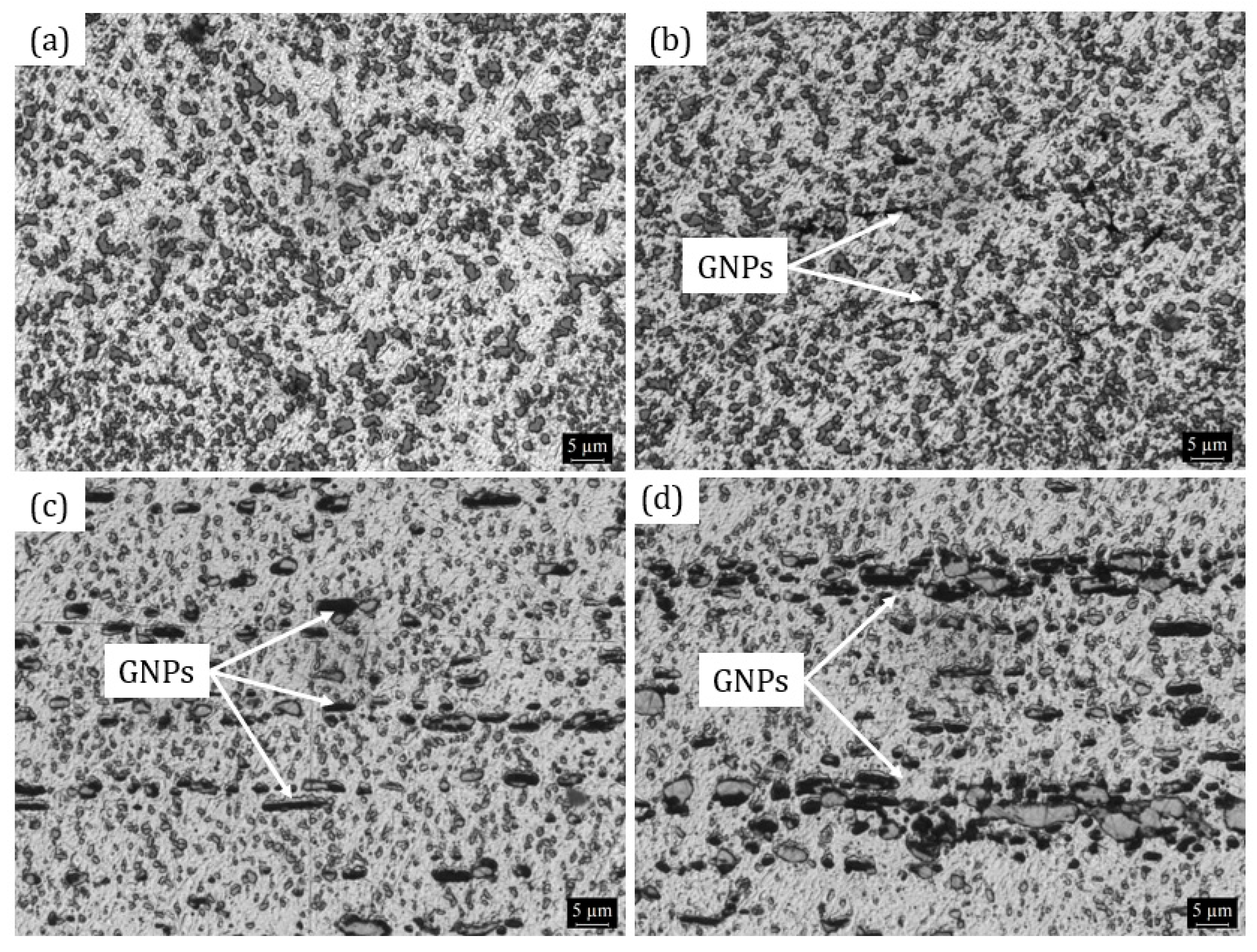

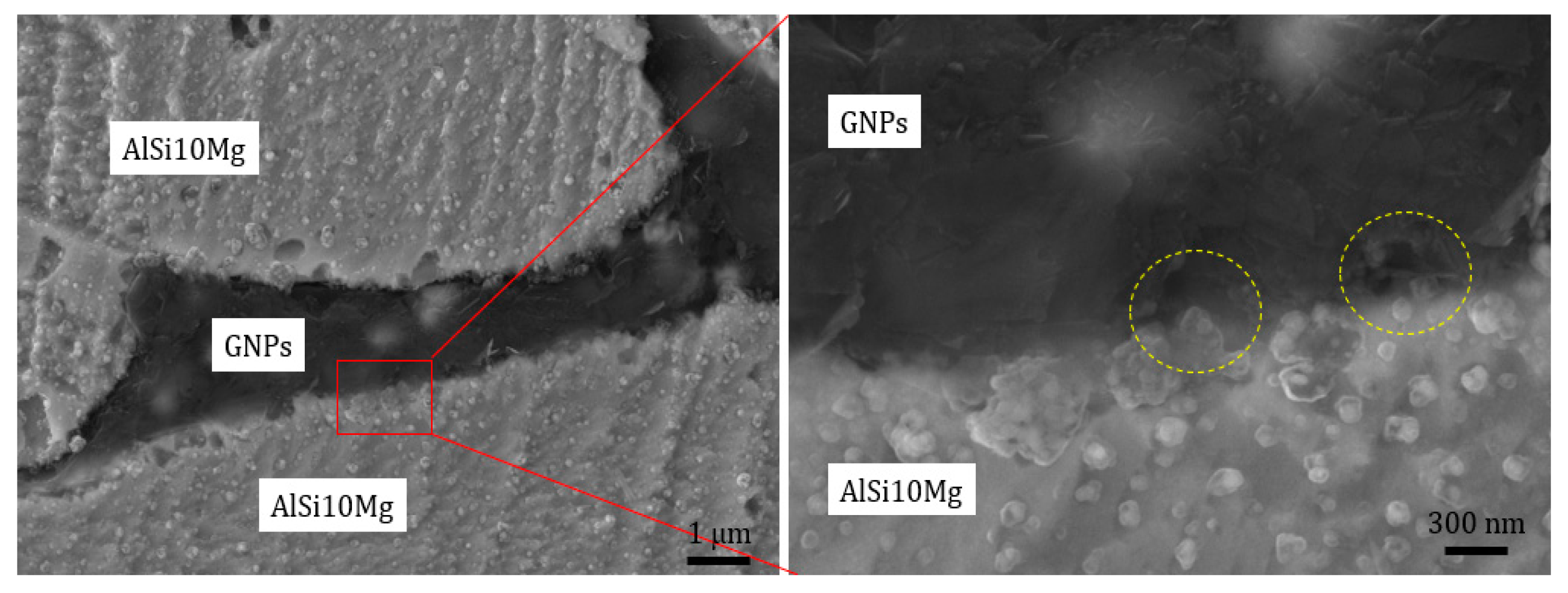

3.1. Microstructure Characterization

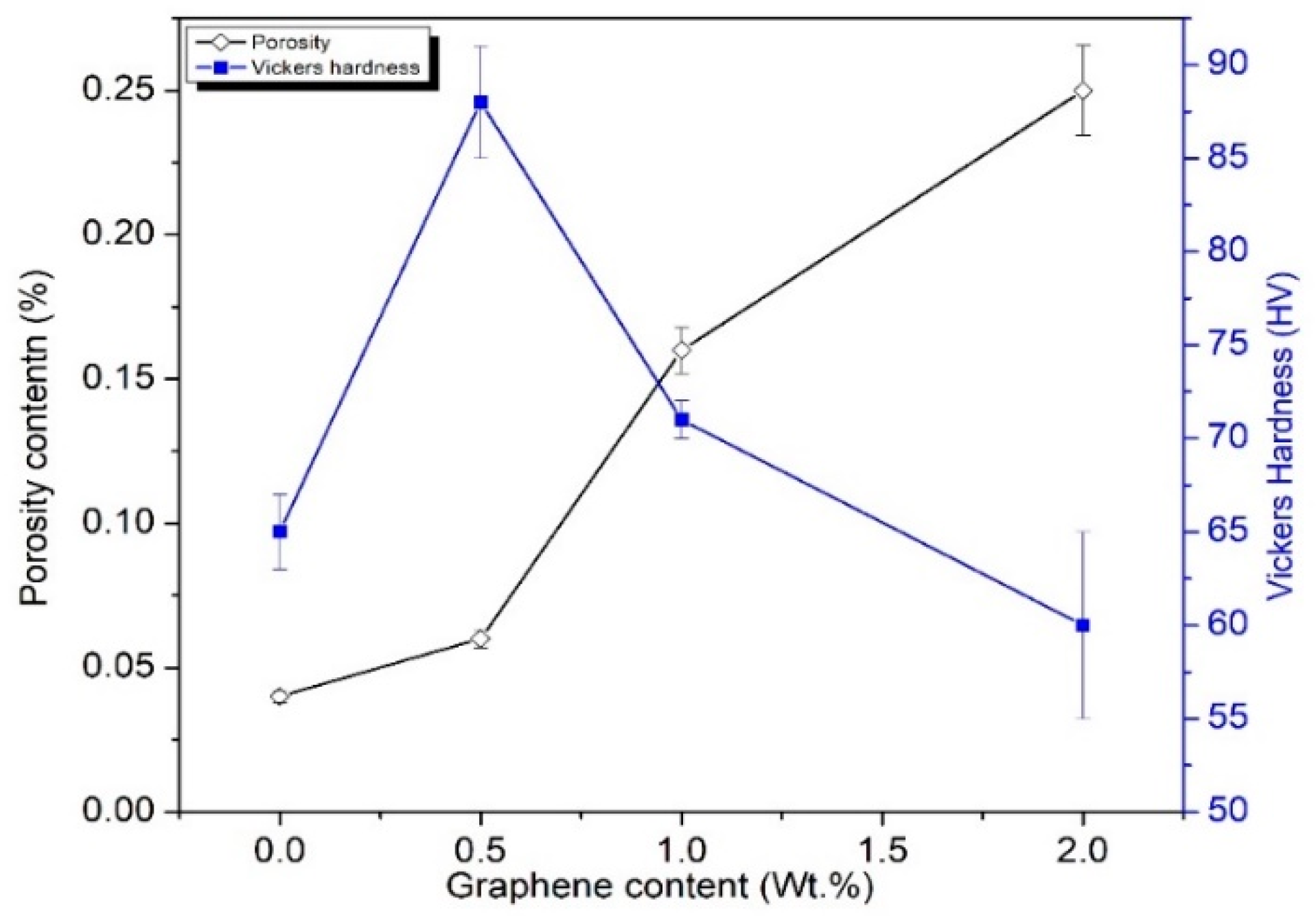

3.2. Mechanical Properties Evaluation

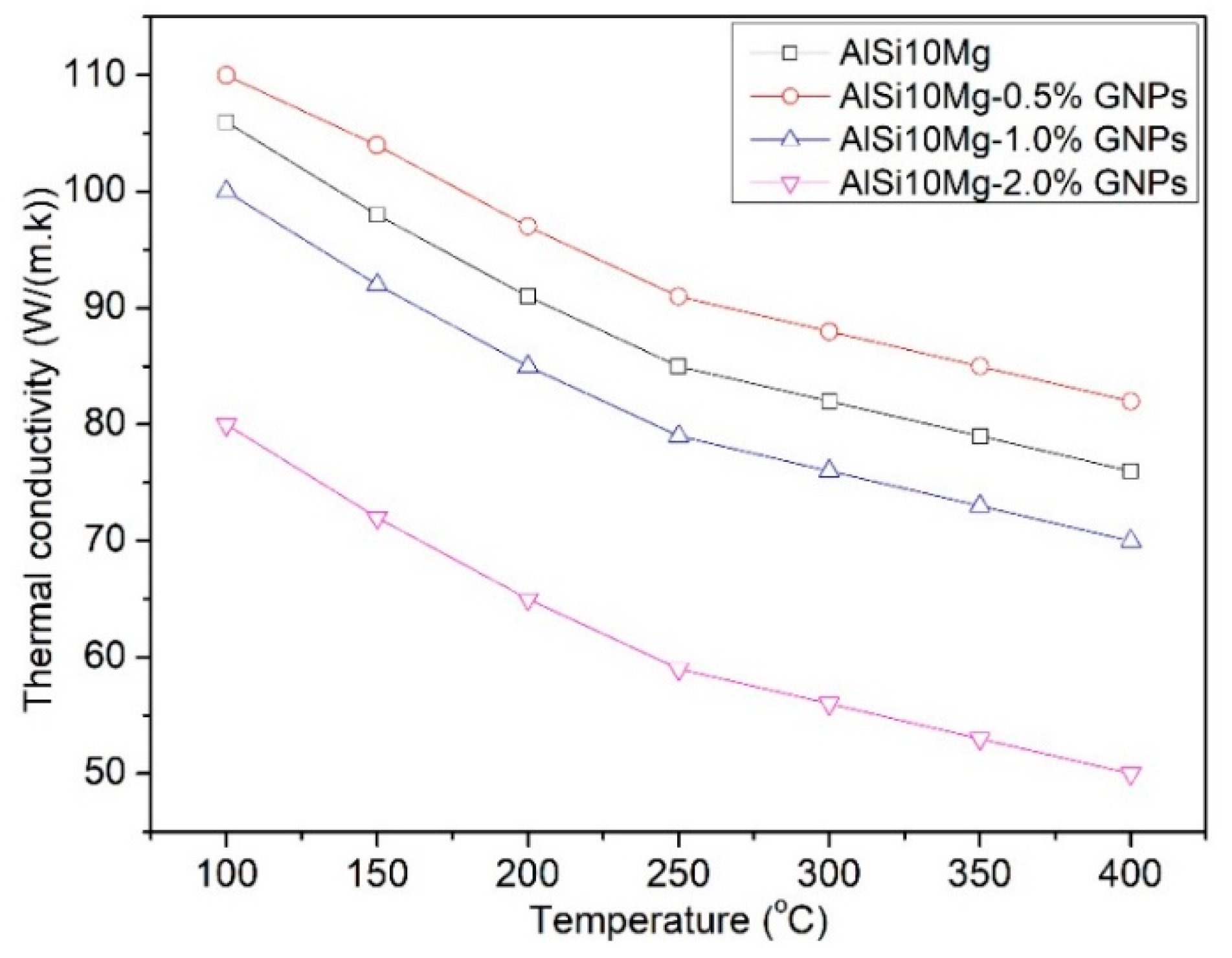

3.3. Thermal Properties

4. Conclusions

- Wet mixing method has a great potential to be used as a mixing method to homogeneously disperse a low quantity of GNPs within the AlSi10Mg matrix.

- In the mixing of AlSi10Mg/GNPs, there is a critical threshold for the quantity of GNPs that should be considered, in such a way that after this critical quantity GNPs start to for agglomerates and deteriorate the final properties of nanocomposites.

- By increasing the quantity of GNPs, the residual porosity content increases dramatically.

- Grain refinement is one of the significant effects of graphene addition on the microstructure of AlSi10Mg/GNPs nanocomposites and plays a key role in the strengthening of the nanocomposites through the Hall-Petch strengthening effect.

- In-depth microstructural investigations revealed that the interfacial bonding between AlSi10Mg and GNPs is one of the weakest types interfaces, which is called mechanical interlocking.

- The effect of GNPs addition on mechanical characteristics (UTS, YS, FS and hardness) of AlSi10Mg was investigated. It was found that the AlSi10Mg nanocomposites with 0.5 wt.% GNPs presented the highest hardness and UTS, which could be associated with the grain refinement as the primary strengthening mechanism.

- Surprisingly, AlSi10Mg–1 and 2% GNPs nanocomposites presented lower mechanical properties with respect to the un-reinforced AlSi10Mg alloy, which might be as a consequence of GNP agglomeration and higher porosity content.

- The same trend of mechanical properties is also achieved in the thermal conductivity of the nanocomposites in which, at the low quantity of GNPs, the thermal conductivity of the nanocomposite increased slightly, whereas at higher GNPs contents, their thermal conductivities deteriorated.

- The interfacial thermal resistance of the AlSi10Mg/GNPs was estimated via the acoustic mismatch model (AMM) model, and the outcome shows that the interfacial resistance between AlSi10Mg/GNPs is slightly higher than Al/GNPs.

Author Contributions

Funding

Conflicts of Interest

References

- Geim, A.K.; Novoselov, K.S. The rise of graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef] [PubMed]

- Balandin, A.A.; Ghosh, S.; Bao, W.; Calizo, I.; Teweldebrhan, D.; Miao, F.; Lau, C.N. Superior thermal conductivity of single-layer graphene. Nano Lett. 2008, 8, 902–907. [Google Scholar] [CrossRef] [PubMed]

- Saboori, A.; Moheimani, S.K.; Pavese, M.; Badini, C.; Fino, P. New nanocomposite materials with improved mechanical strength and tailored coefficient of thermal expansion for electro-packaging applications. Metals 2017, 7, 536. [Google Scholar] [CrossRef]

- Faccio, R.; Denis, P.A.; Pardo, H.; Goyenola, C.; Álvaro, W. Mechanical properties of graphene nanoribbons. J. Phys. Condens. Matter. 2009, 21, 285–304. [Google Scholar] [CrossRef] [PubMed]

- Stankovich, S.; Dikin, D.A.; Dommett, G.H.B.; Kohlhaas, K.M.; Zimney, E.J.; Stach, E.A.; Piner, R.D.; Nguyen, S.T.; Ruoff, R.S. Graphene-based composite materials. Nature 2006, 442, 282–286. [Google Scholar] [CrossRef] [PubMed]

- Saboori, A.; Pavese, M.; Badini, C.; Fino, P. A novel approach to enhance the mechanical strength and electrical and thermal conductivity of Cu-GNP nanocomposites. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2018, 49, 333–345. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Wang, C.M.; Cheng, Y.; Xiang, Y. Mechanical properties of bilayer graphene sheets coupled by sp3 bonding. Carbon 2011, 49, 4511–4517. [Google Scholar] [CrossRef]

- Hong, N.; Zhan, J.; Wang, X.; Stec, A.A.; Hull, T.R.; Ge, H.; Xing, W.; Song, L.; Hu, Y. Enhanced mechanical, thermal and flame retardant properties by combining graphene nanosheets and metal hydroxide nanorods for Acrylonitrile–Butadiene–Styrene copolymer composite. Compos. Part. A Appl. Sci. Manuf. 2014, 64, 203–210. [Google Scholar] [CrossRef]

- Hu, K.; Kulkarni, D.D.; Choi, I.; Tsukruk, V.V. Graphene-polymer nanocomposites for structural and functional applications. Prog. Polym. Sci. 2014, 39, 1934–1972. [Google Scholar] [CrossRef]

- Wang, K.; Wang, Y.; Fan, Z.; Yan, J.; Wei, T. Preparation of graphene nanosheet/alumina composites by spark plasma sintering. Mater. Res. Bull. 2011, 46, 315–318. [Google Scholar] [CrossRef]

- Walker, L.S.; Marotto, V.R.; Rafiee, M.A.; Koratkar, N.; Corral, E.L. Toughening in graphene ceramic composites. ACS Nano 2011, 5, 3182–3190. [Google Scholar] [CrossRef] [PubMed]

- Kim, W.J.; Lee, T.J.; Han, S.H. Multi-layer graphene/copper composites: Preparation using high-ratio differential speed rolling, microstructure and mechanical properties. Carbon 2014, 69, 55–65. [Google Scholar] [CrossRef]

- Chen, L.; Zhao, Y.; Hou, H.; Zhang, T.; Liang, J.; Li, M.; Li, J. Development of AZ91D magnesium alloy-graphene nanoplatelets composites using thixomolding process. J. Alloys Compd. 2019, 778, 359–374. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, K.; Zhang, M. Fabrication and properties of Ni-modified graphene nanosheets reinforced Sn-Ag-Cu composite solder. J. Alloys Compd. 2019, 781, 761–772. [Google Scholar] [CrossRef]

- Jagannadham, K. Volume fraction of graphene platelets in copper-graphene composites. Met. Mater. Trans. A 2013, 44, 552–559. [Google Scholar] [CrossRef]

- Saboori, A.; Pavese, M.; Badini, C.; Fino, P. A novel Cu-GNPs nanocomposite with improved thermal and mechanical properties. Acta Met. Sin. English Lett. 2018, 31, 148–152. [Google Scholar] [CrossRef]

- Saboori, A.; Pavese, M.; Badini, C.; Fino, P. Effect of sample preparation on the microstructural evaluation of Al-GNPs nanocomposites. Met. Microstruct. Anal. 2017, 6, 619–622. [Google Scholar] [CrossRef]

- Shao, P.; Yang, W.; Zhang, Q.; Meng, Q.; Tan, X.; Xiu, Z.; Qiao, J.; Yu, Z.; Wu, G. Microstructure and tensile properties of 5083 Al matrix composites reinforced with graphene oxide and graphene nanoplates prepared by pressure infiltration method. Compos. Part A Appl. Sci. Manuf. 2018, 109, 151–162. [Google Scholar] [CrossRef]

- Rashad, M.; Pan, F.; Tang, A.; Asif, M. Effect of graphene nanoplatelets addition on mechanical properties of pure aluminum using a semi-powder method. Prog. Nat. Sci. Mater. Int. 2014, 24, 101–108. [Google Scholar] [CrossRef]

- Wang, J.; Li, Z.; Fan, G.; Pan, H.; Chen, Z.; Zhang, D. Reinforcement with graphene nanosheets in aluminum matrix composites. Scr. Mater. 2012, 66, 594–597. [Google Scholar] [CrossRef] [Green Version]

- Saboori, A.; Pavese, M.; Badini, C.; Fino, P. Microstructure and thermal conductivity of Al-graphene composites fabricated by powder metallurgy and hot rolling techniques. Acta Metall. Sin. English Lett. 2017, 30, 675–687. [Google Scholar] [CrossRef]

- Saboori, A.; Novara, C.; Pavese, M.; Badini, C.; Giorgis, F.; Fino, P. An investigation on the sinterability and the compaction behavior of aluminum/graphene nanoplatelets ( GNPs ) prepared by powder metallurgy. J. Mater. Eng. Perform. 2017, 26, 993–999. [Google Scholar] [CrossRef]

- Rashad, M.; Pan, F.; Hu, H.; Asif, M.; Hussain, S.; She, J. Enhanced tensile properties of magnesium composites reinforced with graphene nanoplatelets. Mater. Sci. Eng. A 2015, 630, 36–44. [Google Scholar] [CrossRef]

- Bartolucci, S.F.; Paras, J.; Rafiee, M.A.; Rafiee, J.; Lee, S.; Kapoor, D.; Koratkar, N. Graphene–aluminum nanocomposites. Mater. Sci. Eng. A 2011, 528, 7933–7937. [Google Scholar] [CrossRef]

- Rashad, M.; Pan, F.; Asif, M.; Tang, A. Powder metallurgy of Mg–1%Al–1%Sn alloy reinforced with low content of graphene nanoplatelets (GNPs). J. Ind. Eng. Chem. 2014, 20, 4250–4255. [Google Scholar] [CrossRef]

- Saboori, A.; Dadkhah, M.; Fino, P.; Pavese, M. An overview of metal matrix nanocomposites reinforced with graphene nanoplatelets; Mechanical, electrical and thermophysical properties. Metals 2018, 8, 423. [Google Scholar] [CrossRef]

- Saboori, A.; Moheimani, S.K.; Dadkhah, M.; Pavese, M.; Badini, C.; Fino, P. An overview of key challenges in the fabrication of metal matrix nanocomposites reinforced by graphene nanoplatelets. Metals 2018, 8, 172. [Google Scholar] [CrossRef]

- Chu, K.; Liu, Z.; Jia, C.; Chen, H.; Liang, X.; Gao, W. Thermal conductivity of SPS consolidated Cu/diamond composites with Cr-coated diamond particles. J. Alloy. Compd. 2010, 490, 453–458. [Google Scholar] [CrossRef]

- Kandemir, S. Effect of graphene nanoplatelets reinforcement on the microstructure and mechanical properties of AlSi10Mg alloy. GU J. Sci. Part C 2018, 6, 177–187. [Google Scholar]

- Saboori, A.; Casati, R.; Zanatta, A.; Pavese, M.; Badini, C.; Vedani, M. Effect of Graphene nanoplatelets on microstructure and mechanical properties of AlSi10Mg nanocomposites produced by hot extrusion. Powder Metall. Met. Ceram. 2018, 56, 647–655. [Google Scholar] [CrossRef]

- Ferguson, J.B.; Sheykh-Jaberi, F.; Kim, C.-S.; Rohatgi, P.K.; Cho, K. On the strength and strain to failure in particle-reinforced magnesium metal-matrix nanocomposites (Mg MMNCs). Mater. Sci. Eng. A 2012, 558, 193–204. [Google Scholar] [CrossRef]

- Luster, J.W.; Thumann, M.; Baumann, R. Mechanical properties of aluminium alloy 6061–Al2O3 composites. Mater. Sci. Technol. 1993, 9, 853–862. [Google Scholar] [CrossRef]

- Aikin, R.M.; Christodoulou, L. The role of equiaxed particles on the yield stress of composites. Scr. Metall. Mater. 1991, 25, 9–14. [Google Scholar] [CrossRef]

- Swartz, E.T.; Pohl, R.O. Thermal boundary resistance. Rev. Mod. Phys. 1989, 61, 605. [Google Scholar] [CrossRef]

- Dewar, B.; Nicholas, M.; Scott, P.M. The solid phase bonding of copper, nickel and some of their alloys to diamonds. J. Mater. Sci. 1976, 11, 1083–1090. [Google Scholar] [CrossRef]

- Xue, C.; Bai, H.; Tao, P.F.; Wang, J.W.; Jiang, N.; Wang, S.L. Thermal conductivity and mechanical properties of flake graphite/Al composite with a SiC nano-layer on graphite surface. Mater. Des. 2016, 108, 250–258. [Google Scholar] [CrossRef]

- Schmidt, A.J.; Collins, K.C.; Minnich, A.J.; Chen, G. Thermal conductance and phonon transmissivity of metal-graphite interfaces. J. Appl. Phys. 2010, 107, 104–107. [Google Scholar] [CrossRef]

| Al | Si | Fe | Cu | Mn | Mg | Ni | Zn | Pb | Sn | Ti |

|---|---|---|---|---|---|---|---|---|---|---|

| Balance | 9–11 | ≤0.56 | ≤0.05 | ≤0.43 | ≤0.2–0.45 | ≤0.05 | ≤0.11 | ≤0.05 | ≤0.05 | ≤0.15 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moheimani, S.K.; Dadkhah, M.; Saboori, A. Development of Novel AlSi10Mg Based Nanocomposites: Microstructure, Thermal and Mechanical Properties. Metals 2019, 9, 1000. https://doi.org/10.3390/met9091000

Moheimani SK, Dadkhah M, Saboori A. Development of Novel AlSi10Mg Based Nanocomposites: Microstructure, Thermal and Mechanical Properties. Metals. 2019; 9(9):1000. https://doi.org/10.3390/met9091000

Chicago/Turabian StyleMoheimani, Seyed Kiomars, Mehran Dadkhah, and Abdollah Saboori. 2019. "Development of Novel AlSi10Mg Based Nanocomposites: Microstructure, Thermal and Mechanical Properties" Metals 9, no. 9: 1000. https://doi.org/10.3390/met9091000

APA StyleMoheimani, S. K., Dadkhah, M., & Saboori, A. (2019). Development of Novel AlSi10Mg Based Nanocomposites: Microstructure, Thermal and Mechanical Properties. Metals, 9(9), 1000. https://doi.org/10.3390/met9091000