Tensile Behavior and Deformation Mechanism of Fe-Mn-Al-C Low Density Steel with High Strength and High Plasticity

Abstract

:1. Introduction

2. Experimental

3. Results and Discussion

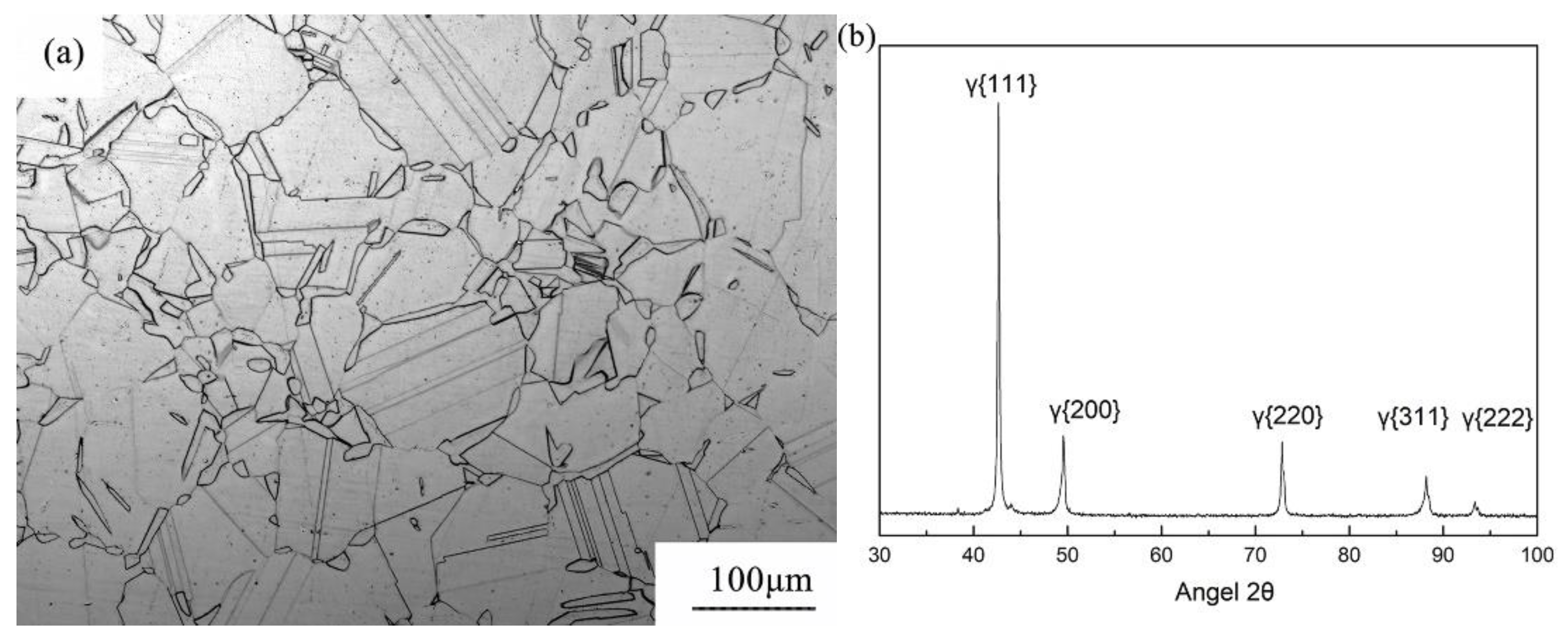

3.1. Initial Microstructure and Stacking Fault Energy of the Steel

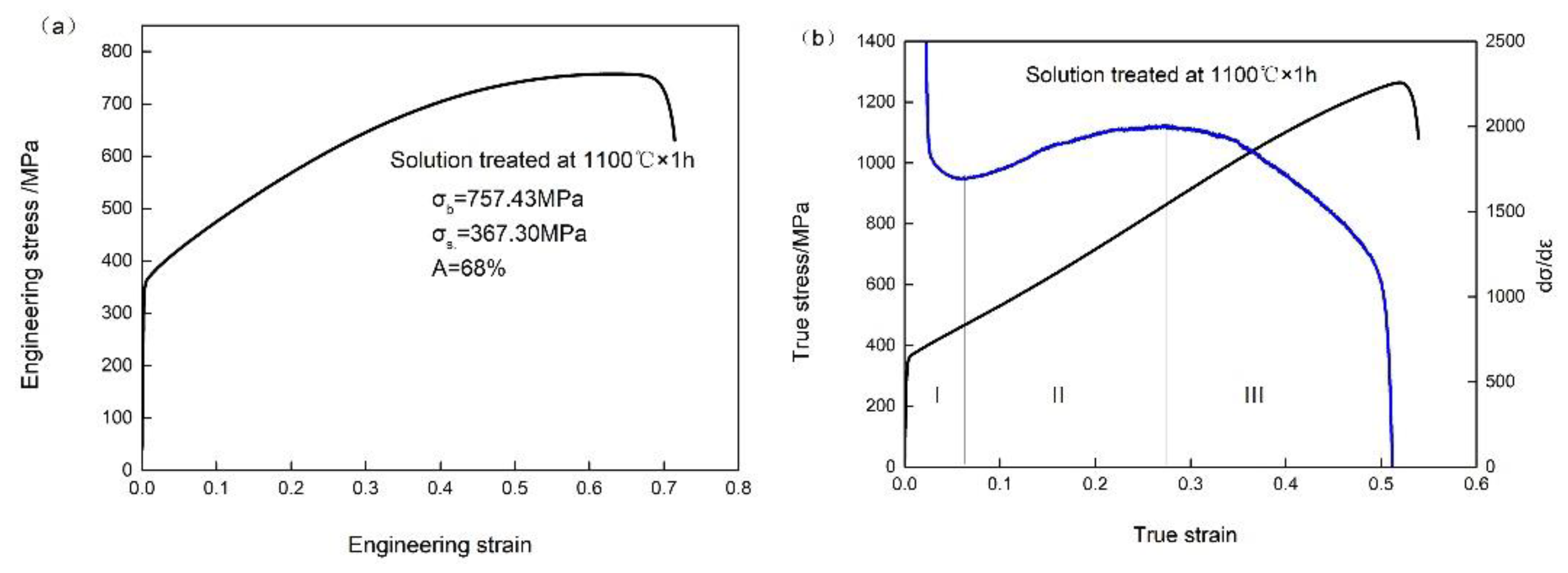

3.2. Mechanical Properties

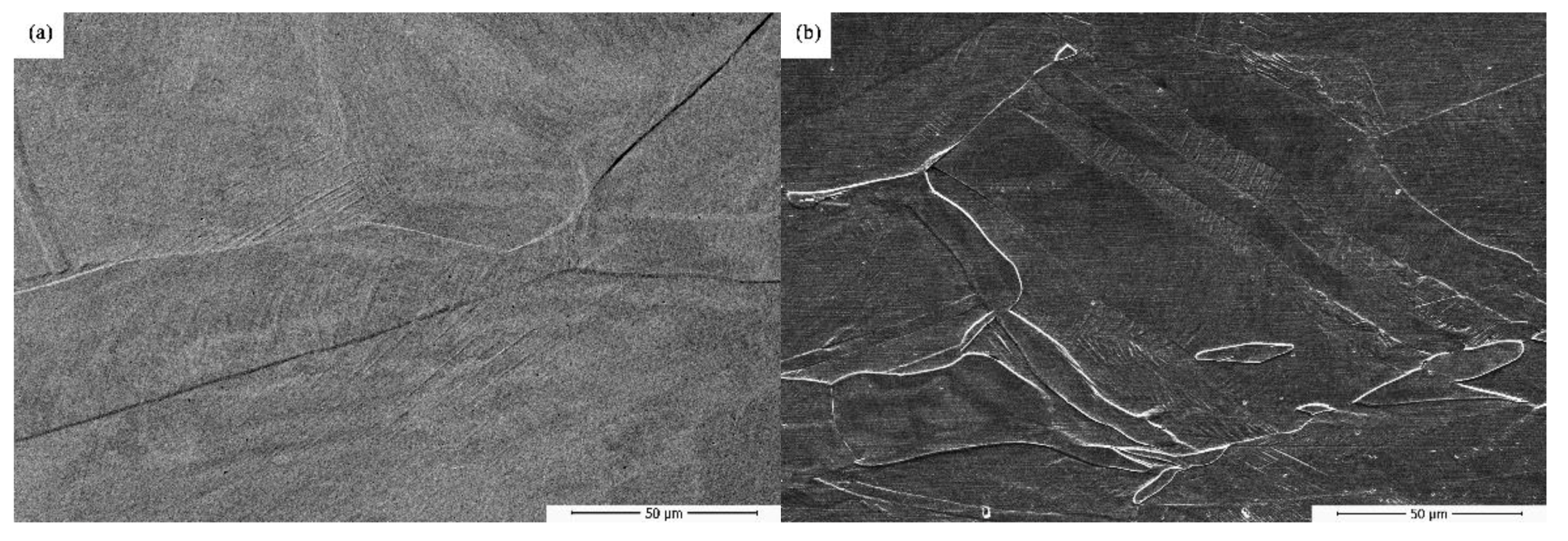

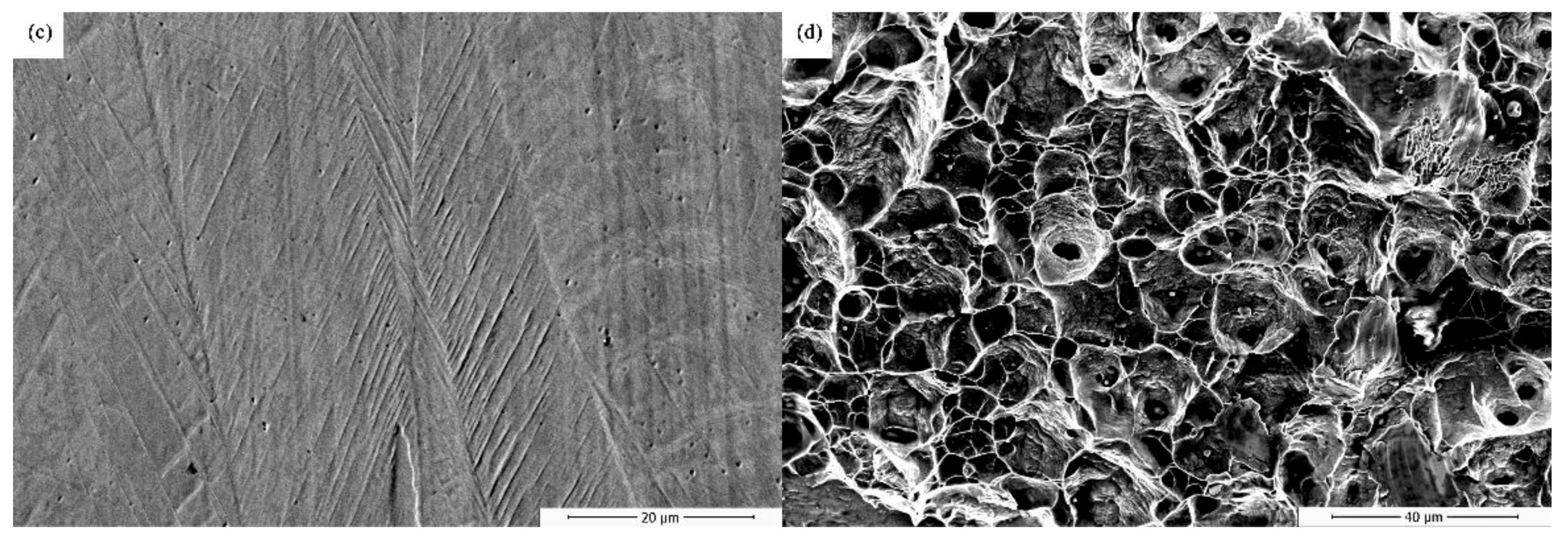

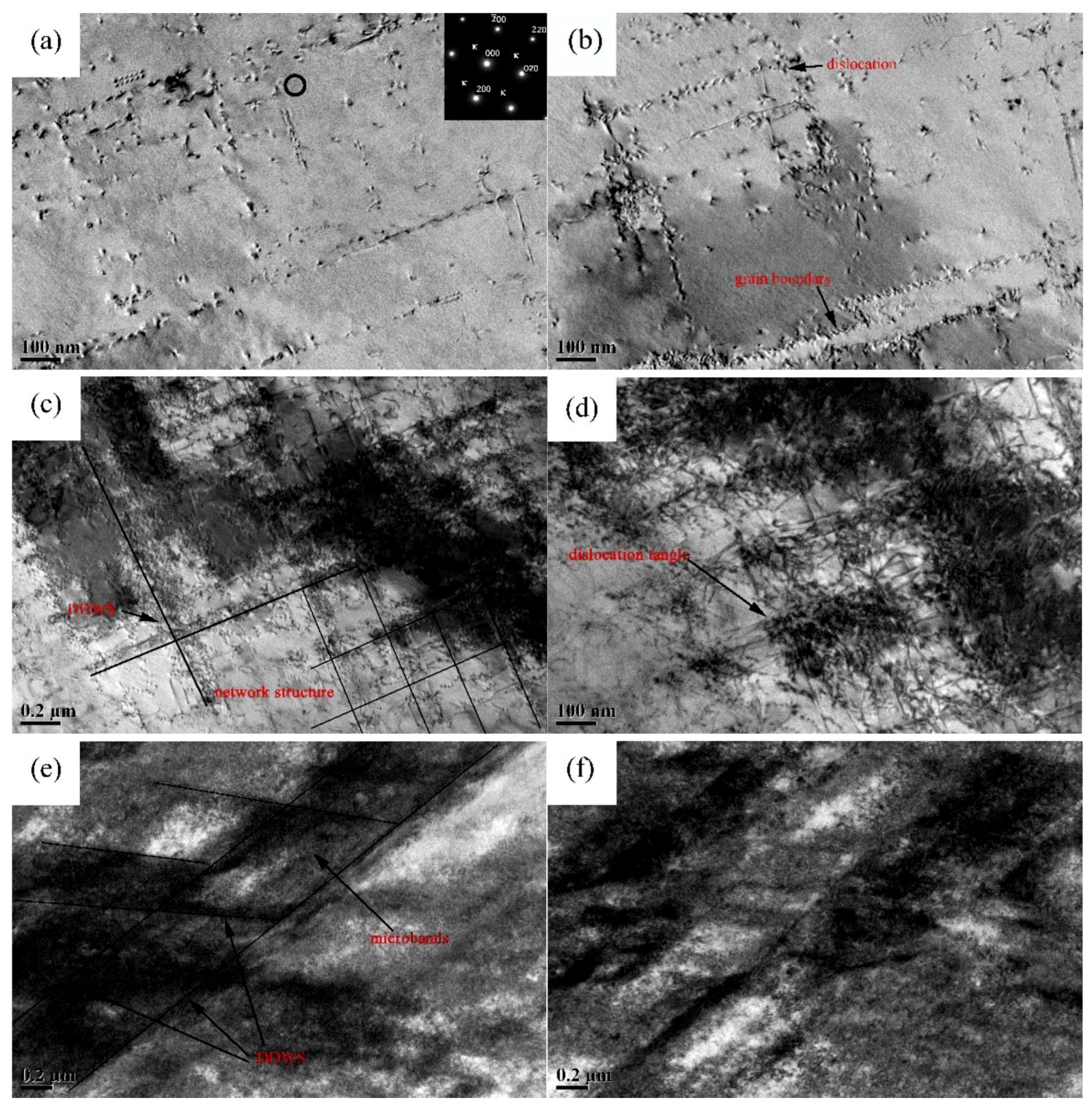

3.3. Deformation Structure with Increasing Strain

4. Conclusions

- Fe-22.8Mn-8.48Al-0.86C steel after solid treatment at 1100 °C for 1 h was austenitic with annealing twins through the austenite grain. The experimental steel possesses excellent comprehensive mechanical properties, with a high strength of 757.43 MPa and an elongation of 68%. With the increase of strain, the working hardening rate is on the rise uninterruptedly during tensile deformation before plastic collapse;

- and of the present Fe-22.8Mn-8.48Al-0.86C steel at room temperature were estimated as 71.5 mJ/m2 and 910.1 J/mol. During the tensile deformation, amounts of slip parallel bands formed on austenite matrix. The density of the slip bands increased, and then slip bands in different directions crossed with the increase of strain.

- The steel shows characteristics of typical glide during the deformation. Dislocation multiplied at low deformation, dislocations tangled and dense dislocation walls formed at middle deformation. As the deformation increased, microbands formed and intersected. The work-hardening mechanism of the test steel changed gradually from dislocation reinforcing to microbands reinforcing.

Author Contributions

Funding

Conflicts of Interest

References

- Tang, D.; Mi, Z.-L.; Chen, Y.-L. Technology and research and development of advanced automobile steel abroad. J. Iron. Steel 2005, 40, 1–5. [Google Scholar]

- Cai, Z.H.; Ding, H.; Misra, R.D.K.; Kong, H.; Wu, H.Y. Unique impact of ferrite in influencing austenite stability and deformation behavior in a hot-rolled Fe-Mn-Al-C steel. Mater. Sci. Eng., A. 2014, 595, 86–91. [Google Scholar] [CrossRef]

- Kim, H.; Suh, D.W.; Kim, N.J. Fe-Al-Mn-C lightweight structural alloys: a review on the microstructures and mechanical properties. Sci. Technol. Adv. Mater. 2013, 14, 014205. [Google Scholar] [CrossRef] [PubMed]

- Yoo, J.D.; Park, K.T. Microband-induced plasticity in a high Mn-Al-C light. Mater. Sci. Eng., A. 2008, 496, 417–424. [Google Scholar] [CrossRef]

- Chen, S.; Rana, R.; Haldar, A.; Ranjit, K.R. Current state of Fe-Mn-Al-C low density steels. Prog. Mater. Sci. 2017, 89, 345–391. [Google Scholar] [CrossRef]

- Allain, S.; Chateau, J.P.; Bouaziz, O.; Migot, S.; Gueton, N. Correlations between the calculated stacking fault energy and the plasticity mechanisms in Fe-Mn-C alloys. Mater. Sci. Eng., A. 2004, 387, 158–162. [Google Scholar] [CrossRef]

- Park, K.T.; Kim, G.; Kim, S.K.; Lee, S.W.; Hwang, S.W.; Lee, C.S. On the transitions of deformation modes of fully austenitic steels at room temperature. Met. Mater. Int. 2010, 16, 1–6. [Google Scholar] [CrossRef]

- Canadinc, D.; Sehitoglu, H.; Maier, H.J.; Chumlyakov, Y.I. Strain hardening behavior of aluminum alloyed Hadfield steel single crystals. Acta Mater. 2005, 53, 1831–1842. [Google Scholar] [CrossRef]

- Hirth, J.P. Thermodynamics of stacking faults. Metall. Trans. 1970, 1, 2367. [Google Scholar]

- Choi, K.; Seo, C.H.; Lee, H.; Kim, S.K.; Kwak, J.H.; Chin, K.G.; Park, K.T.; Kim, N.J. Effect of aging on the microstructure and deformation behavior of austenite base lightweight Fe-28Mn-9Al-0.8C steel. Scr. Mater. 2010, 63, 1028–1031. [Google Scholar] [CrossRef]

- Chang, K.M.; Chao, C.G.; Liu, T.F. Excellent combination of strength and ductility in an Fe-9Al-28Mn-1.8C alloy. Scr. Mater. 2010, 63, 162–165. [Google Scholar] [CrossRef]

- Kimura, Y.; Handa, K.; Hayashi, K.; Mishima, Y. Microstructure control and ductility improvement of the two-phase γ-Fe/κ-(Fe, Mn)3AlC alloys in the Fe-Mn-Al-C quaternary system. Intermetallics 2004, 12, 607–617. [Google Scholar] [CrossRef]

- Gutierrez-Urrutia, I.; Raabe, D. Influence of Al content and precipitation state on the mechanical behavior of austenitic high-Mn low-density steels. Scr. Mater. 2013, 68, 343–347. [Google Scholar] [CrossRef]

- Park, K.T. Tensile deformation of low-density Fe-Mn-Al-C austenitic steels at ambient temperature. Scr. Mater. 2013, 68, 375–379. [Google Scholar] [CrossRef]

- Hughes, D.A. Microstructural evolution in a non-cell forming metal: Al-Mg. Acta Metall. Mater. 1993, 41, 1421–1430. [Google Scholar] [CrossRef]

- Yang, F.; Song, R.; Li, Y.; Sun, T.; Wang, K.K. Tensile deformation of low density duplex Fe-Mn-Al-C steel. Mater. Des. 2015, 76, 32–39. [Google Scholar] [CrossRef]

| Mn | Al | C | Fe |

|---|---|---|---|

| 22.8 | 8.48 | 0.86 | Bal. |

| Parameters | Value and Functions |

|---|---|

| 2.94 × 10−5 (mol/m2) | |

| 9 (mJ/m2) | |

| –2243.38 + 4.309 T (J/mol) | |

| –1000 + 1.123 T (J/mol) | |

| 2800 + 5 T (J/mol) | |

| –22,166 (J/mol) | |

| 2180 + 532 ( − ) (J/mol) | |

| 3339 (J/mol) | |

| 42,500 (J/mol) | |

| 26,910 (J/mol) | |

| 0.7 + 0.62 – 0.64– 4 | |

| 0.62 – 4 | |

| 250ln() – 475 – 6.2 + 720 (K) | |

| 58 (K) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pang, J.; Zhou, Z.; Zhao, Z.; Tang, D.; Liang, J.; He, Q. Tensile Behavior and Deformation Mechanism of Fe-Mn-Al-C Low Density Steel with High Strength and High Plasticity. Metals 2019, 9, 897. https://doi.org/10.3390/met9080897

Pang J, Zhou Z, Zhao Z, Tang D, Liang J, He Q. Tensile Behavior and Deformation Mechanism of Fe-Mn-Al-C Low Density Steel with High Strength and High Plasticity. Metals. 2019; 9(8):897. https://doi.org/10.3390/met9080897

Chicago/Turabian StylePang, Jingyu, Zhanming Zhou, Zhengzhi Zhao, Di Tang, Juhua Liang, and Qing He. 2019. "Tensile Behavior and Deformation Mechanism of Fe-Mn-Al-C Low Density Steel with High Strength and High Plasticity" Metals 9, no. 8: 897. https://doi.org/10.3390/met9080897

APA StylePang, J., Zhou, Z., Zhao, Z., Tang, D., Liang, J., & He, Q. (2019). Tensile Behavior and Deformation Mechanism of Fe-Mn-Al-C Low Density Steel with High Strength and High Plasticity. Metals, 9(8), 897. https://doi.org/10.3390/met9080897