Development on a Prediction Model for Experimental Condition of Flexibly Reconfigurable Roll Forming Process

Abstract

1. Introduction

2. Experiment

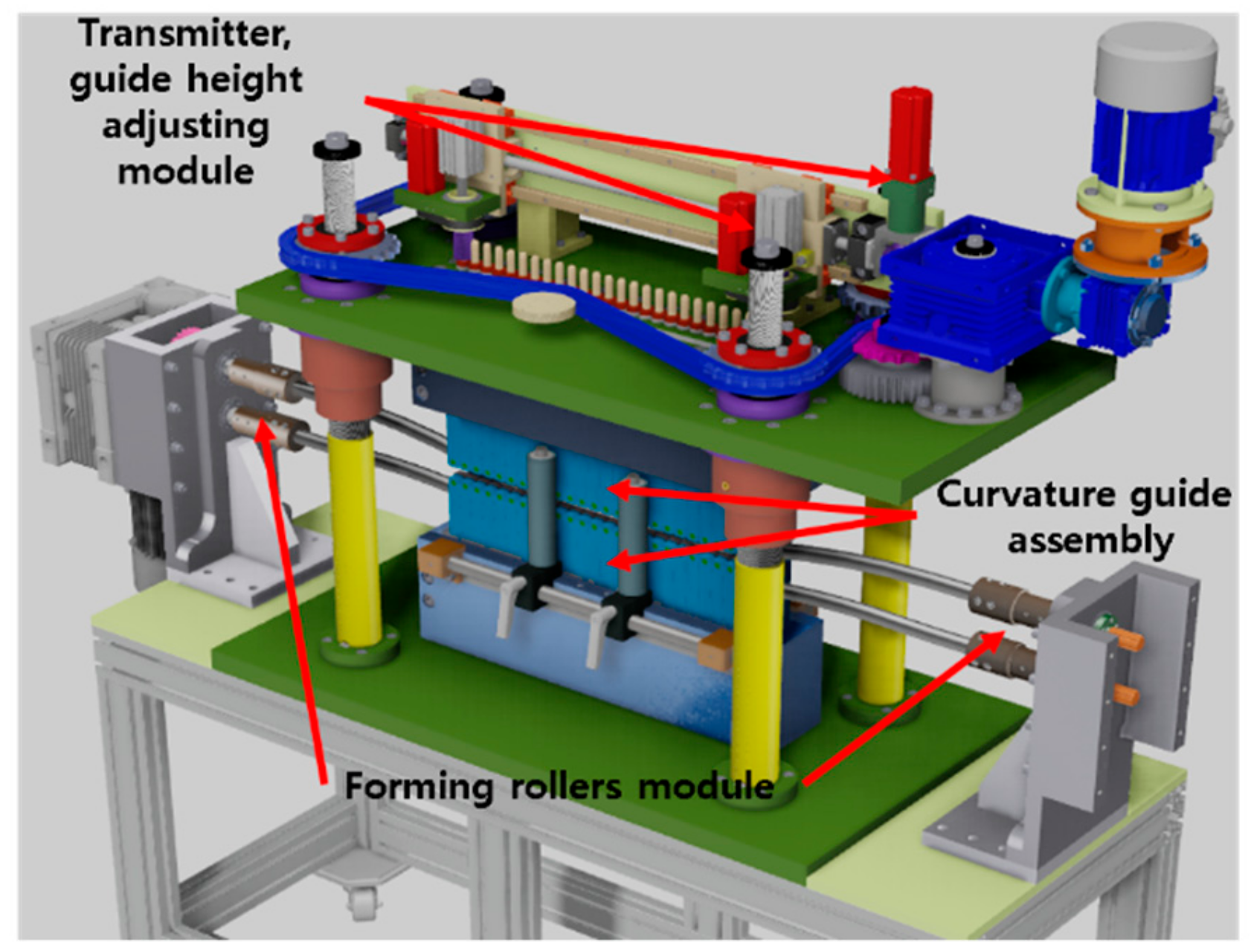

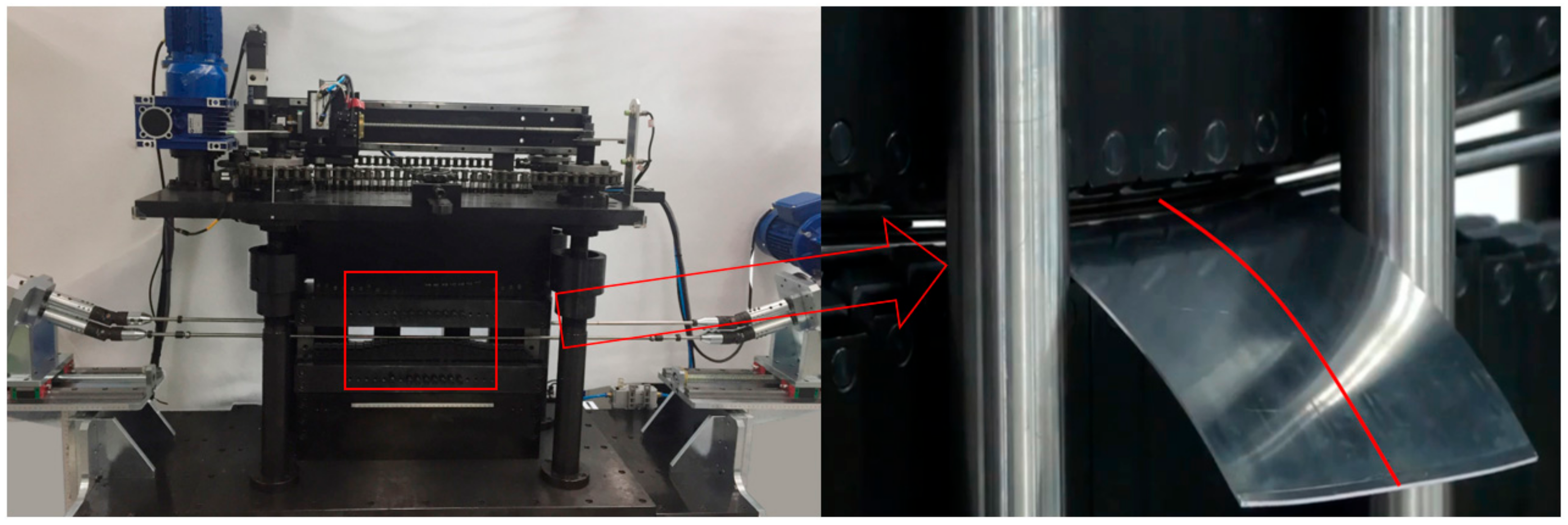

2.1. FRRF Equipment

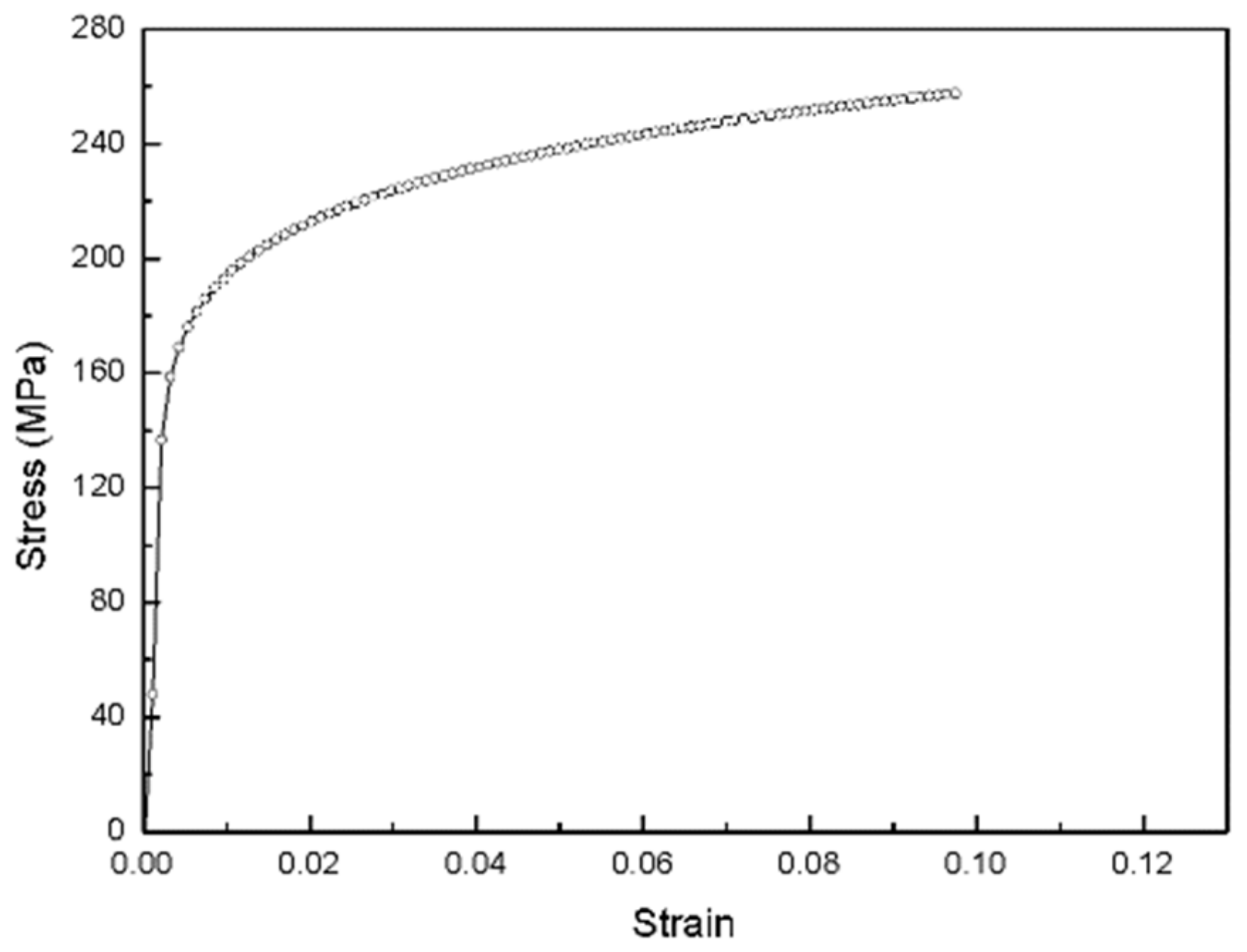

2.2. Experiment Conditions

3. Experimental Results and Regression Model

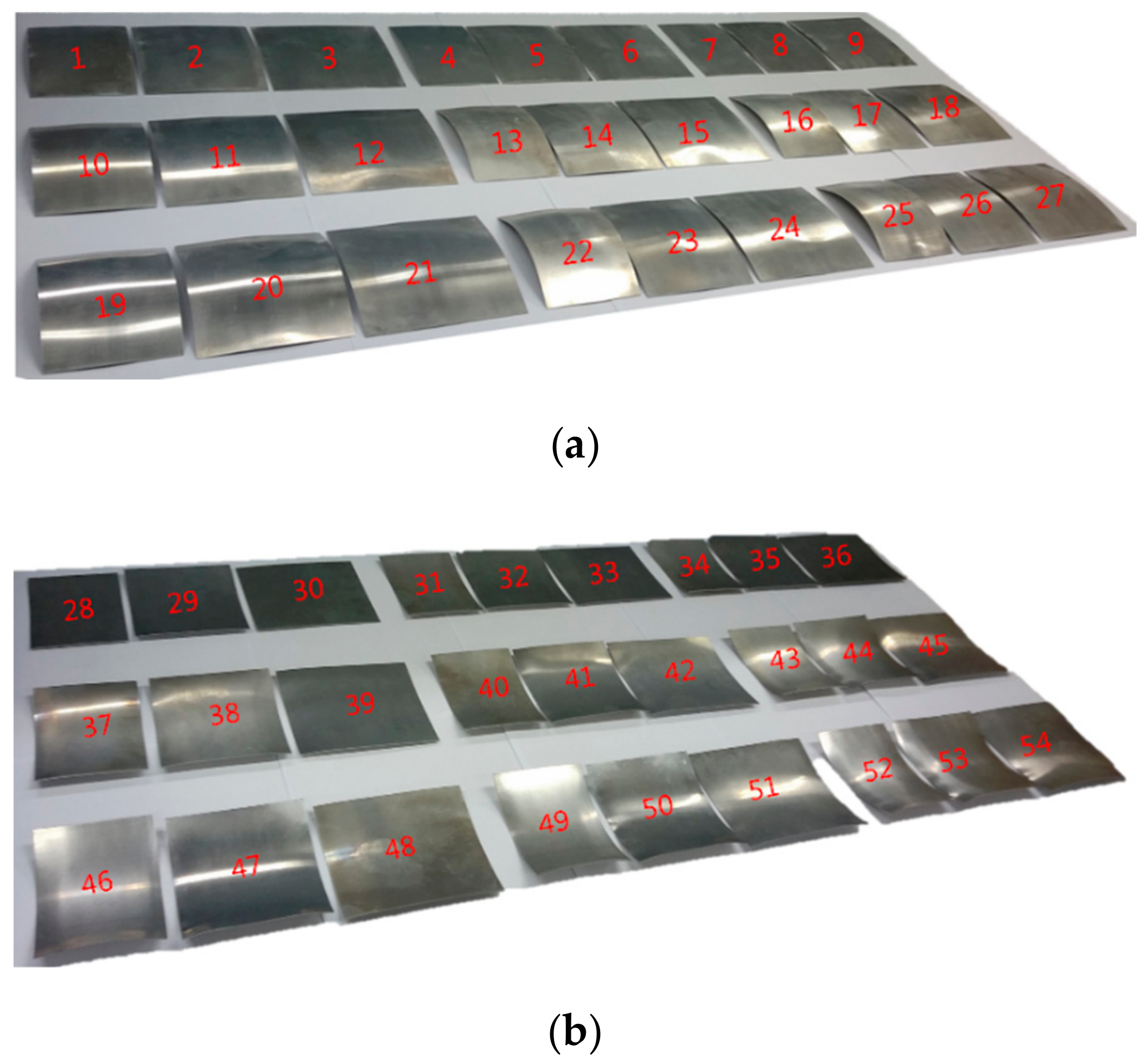

3.1. Experimental Results

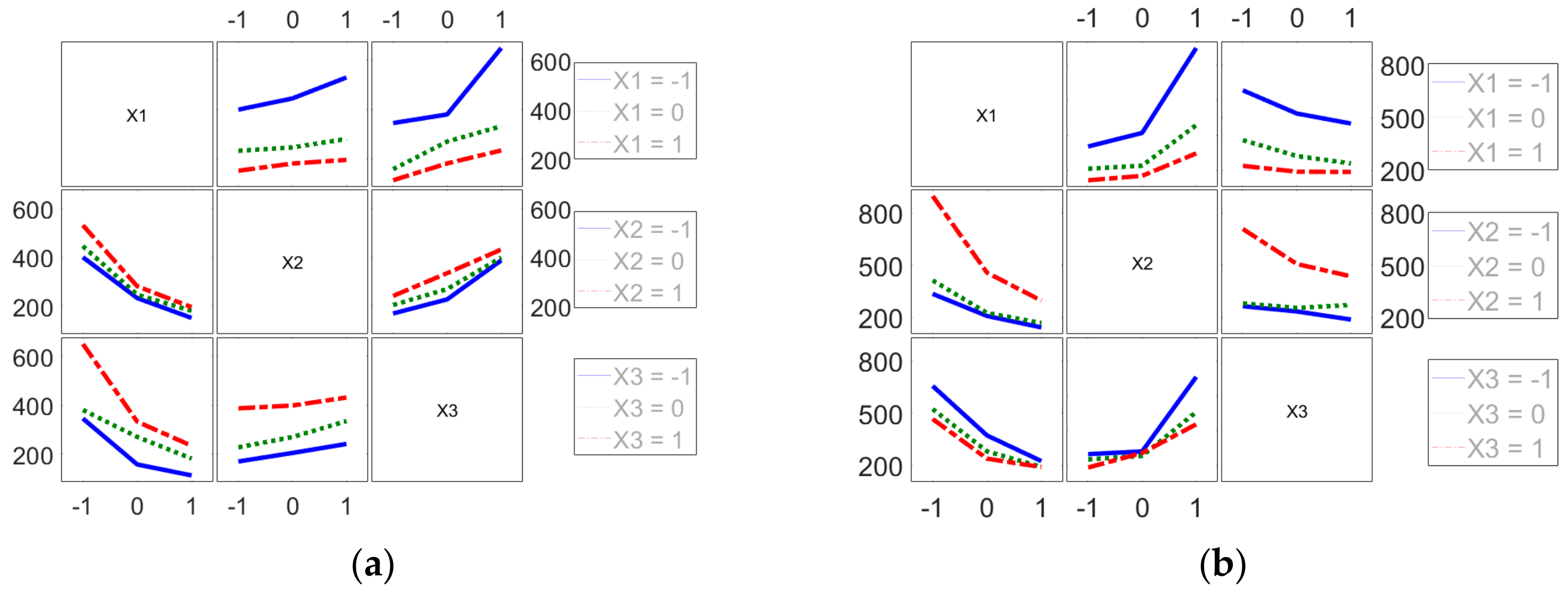

3.2. Regression Analysis Model

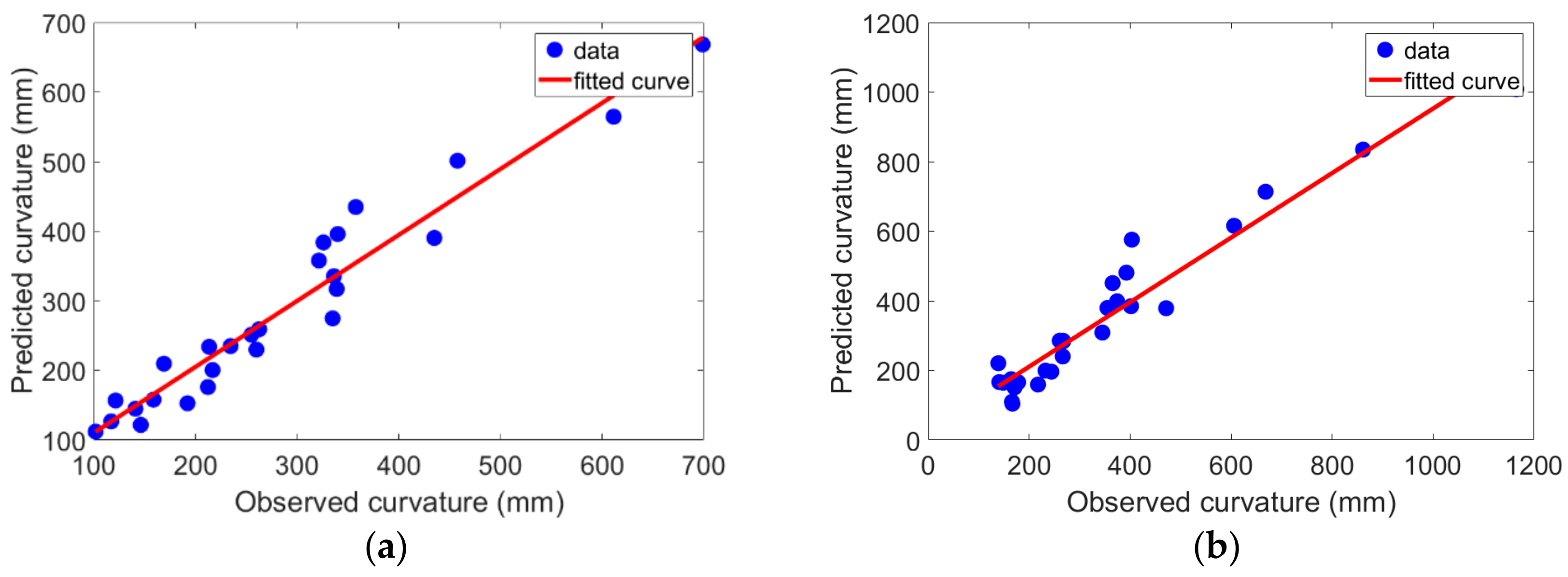

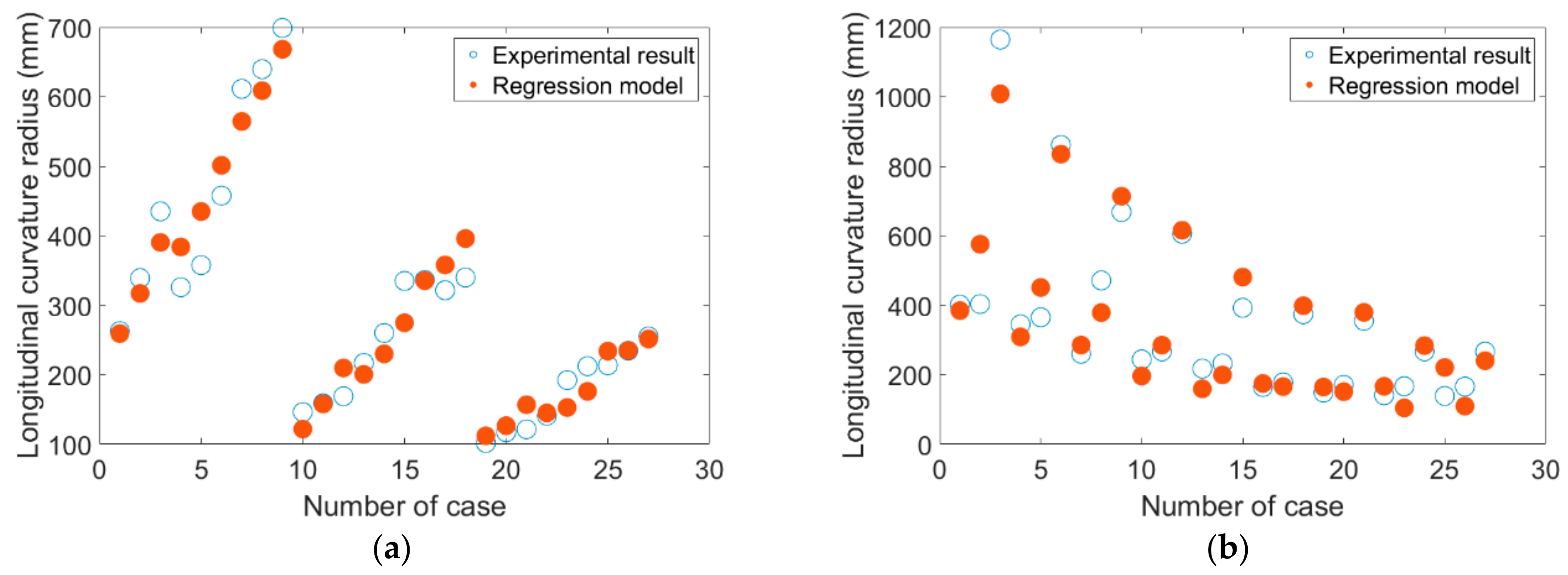

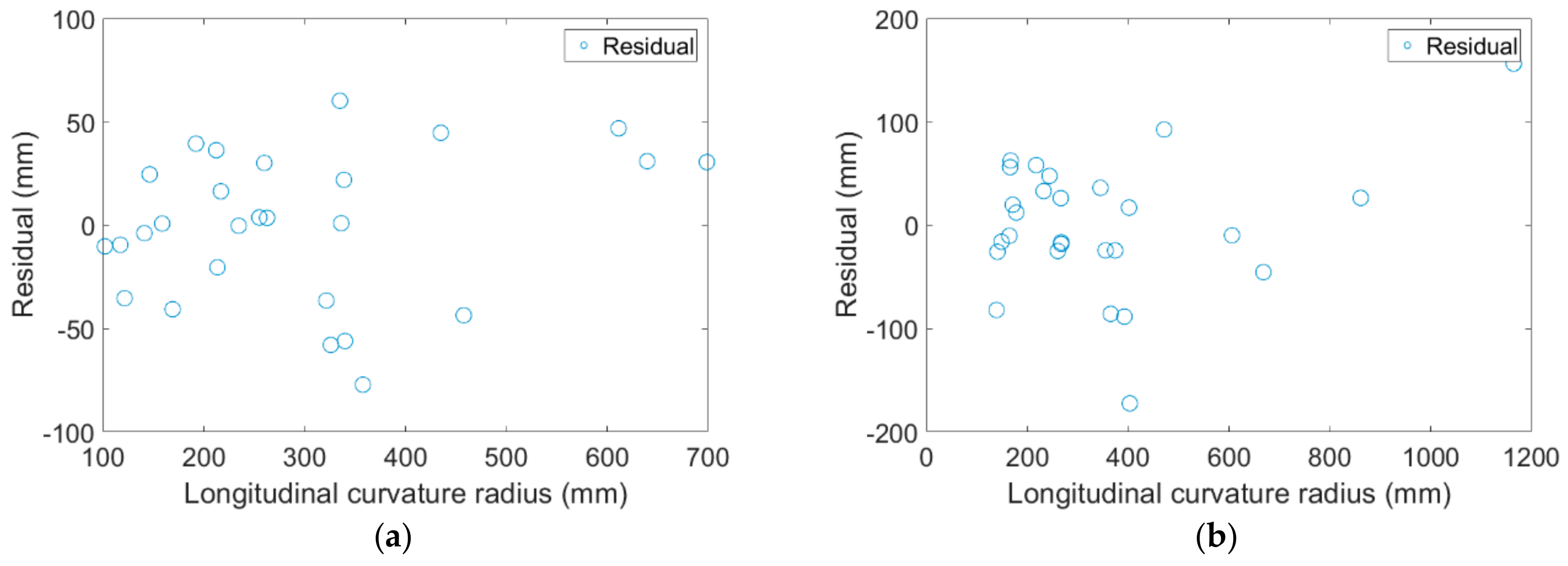

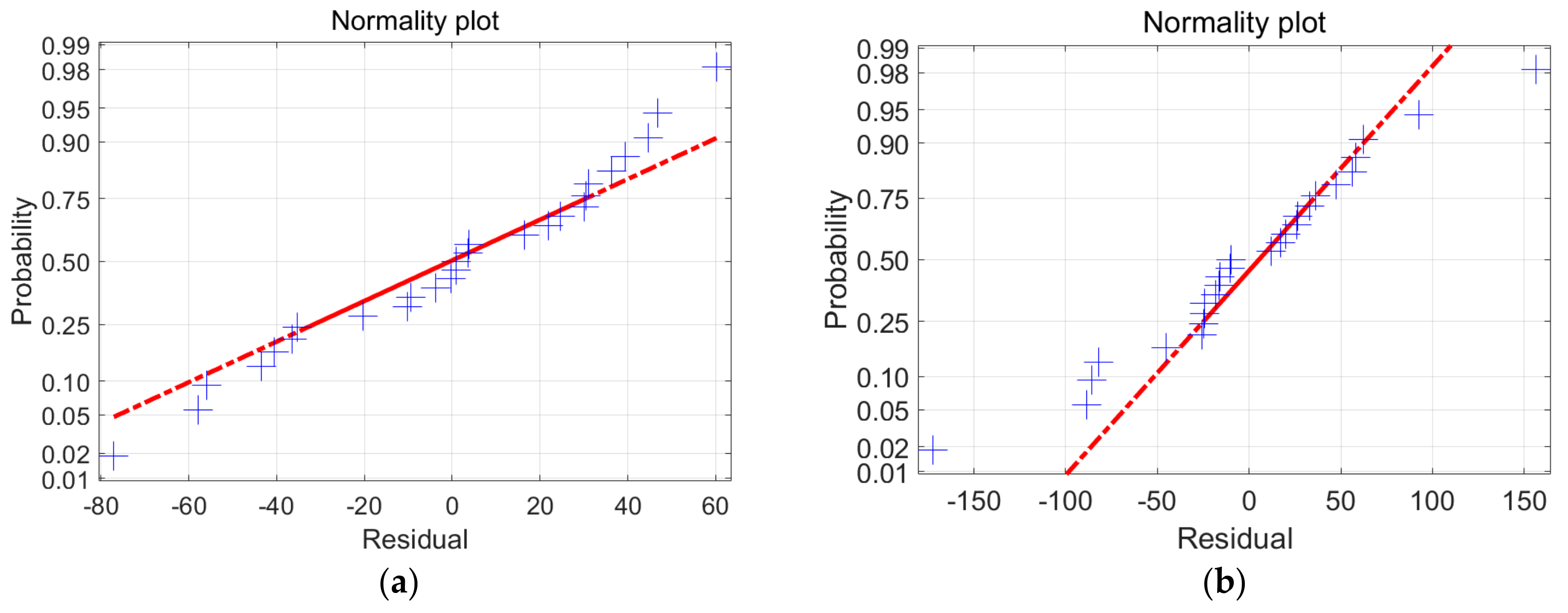

3.3. Goodness-of-Fit of the Regression Model

4. Application for Experiment Condition Deduction

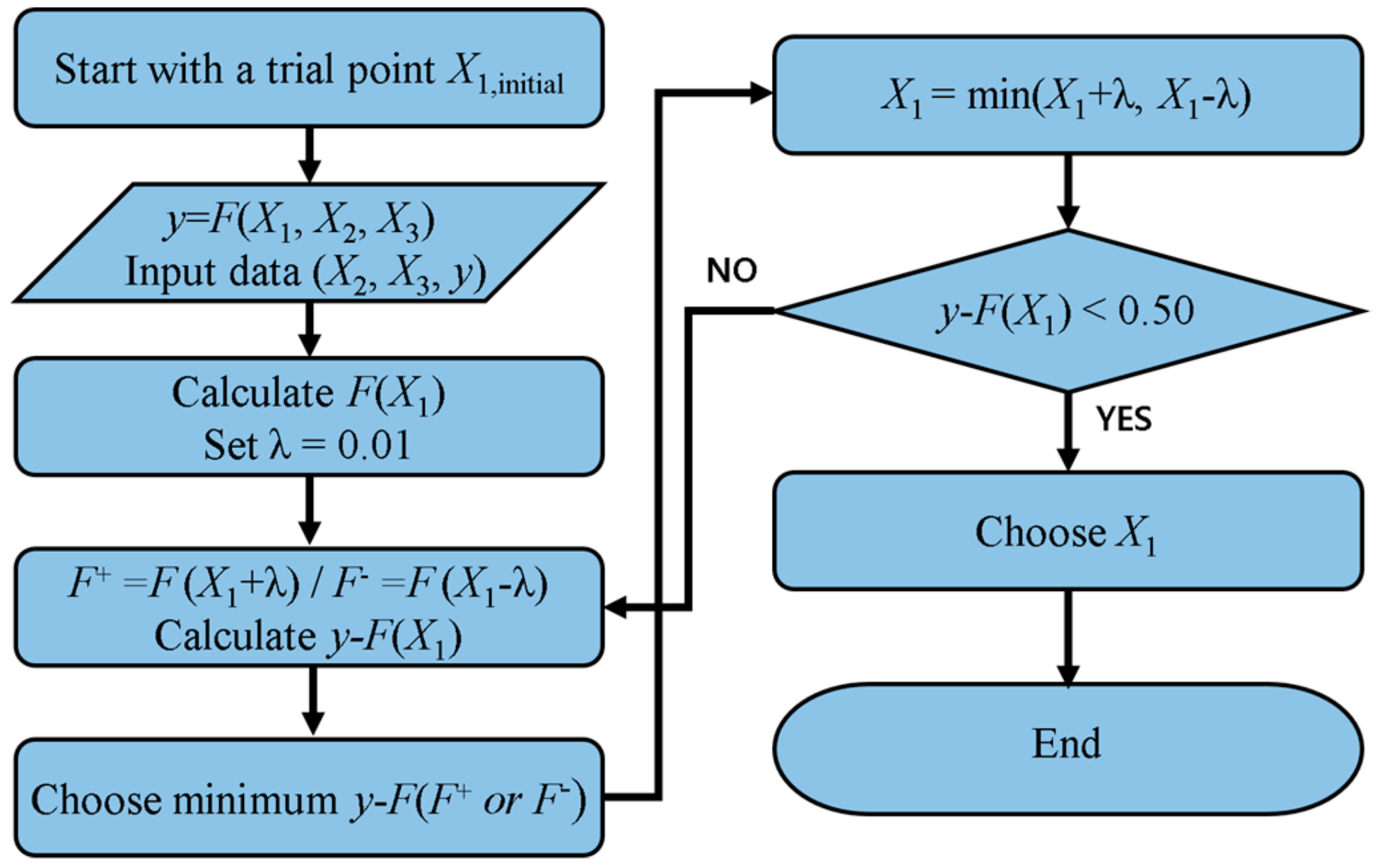

4.1. Conversions for a Prediction Model

4.2. Assumptions Underlying the Experimental Characteristics

5. Conclusions

- (1)

- To utilize experimental results in the regression model, a three-level, three-factor full factorial design was used. The experiments were conducted using the FRRF apparatus. The maximum compression value, radius of curvature in the transverse direction, and width of the blank were selected as the input parameters, and the radius of curvature in the longitudinal direction of in the FRRF process was the dependent variable. The radius of curvature values in the longitudinal direction, for the experimental samples, was obtained using a 3D scanner.

- (2)

- Regression analysis was conducted using the experimental results as the sample data. A polynomial, nonlinear regression model was used, and a goodness-of-fit test was conducted to confirm the validity of the model. R-squared values, NRMSE, and residual data were examined. The test results fitted well with the experimental data; thus, the regression model was confirmed to follow the trend of the experimental results.

- (3)

- From the completed regression model, it was concluded that it was possible to predict the results of the FRRF process. The optimization for converting the regression model was carried out to deduce the compression characteristics for forming the target surface. The compression conditions for the actual target surface might also be determined by using the converted regression model. This study thus confirms the feasibility of statistically predicting the curvature produced by the FRRF process. Future progress will focus on further research to evaluate the effects of physical properties on the FRRF process, conducted using different materials.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Olsen, B.A. Die Forming of Sheet Metal Using Discrete Surfaces. Master’s Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 1981. [Google Scholar]

- Zhang, Q.; Wang, Z.; Dean, T. The mechanics of multi-point sandwich forming. Int. J. Mach. Tools Manuf. 2008, 48, 1495–1503. [Google Scholar] [CrossRef]

- Yan, Y.; Wang, H.; Li, Q.; Qian, B.; Mpofu, K. Simulation and experimental verification of flexible roll forming of steel sheets. Int. J. Adv. Manuf. Technol. 2014, 72, 209–220. [Google Scholar] [CrossRef]

- Li, M.; Cai, Z.; Sui, Z.; Yan, Q. Multi-point forming technology for sheet metal. J. Mater. Process. Technol. 2002, 129, 333–338. [Google Scholar] [CrossRef]

- Heo, S.C.; Seo, Y.H.; Park, J.W.; Ku, T.W.; Kim, J.; Kang, B.S. Application of flexible forming process to gull structure forming. J. Mech. Sci. Technol. 2010, 24, 137–140. [Google Scholar] [CrossRef]

- Park, J.W.; Kim, J.; Kim, K.H.; Kang, B.S. Numerical and experimental study of stretching effect on flexible forming technology. Int. J. Adv. Manuf. Technol. 2014, 73, 1273–1280. [Google Scholar] [CrossRef]

- Abebe, M.; Park, J.W.; Kim, J.; Kang, B.S. Numerical verification on formability of metallic alloys for skin structure using multi-point die-less forming. Int. J. Precis. Eng. Manuf. 2017, 18, 263–272. [Google Scholar] [CrossRef]

- Quan, G.Z.; Ku, T.W.; Kang, B.S. Improvement of formability for multi-point bending process of AZ31B sheet material using elastic cushion. Int. J. Precis. Eng. Manuf. 2011, 12, 1023–1030. [Google Scholar] [CrossRef]

- Abebe, M.; Park, J.W.; Kang, B.S. Reliability-based robust process optimization of multi-point dieless forming for product defect reduction. Int. J. Adv. Manuf. Technol. 2017, 89, 1223–1234. [Google Scholar] [CrossRef]

- Yoon, J.S.; Son, S.E.; Song, W.J.; Kim, J.; Kang, B.S. Study on flexibly-reconfigurable roll forming process for multi-curved surface of sheet metal. Int. J. Precis. Eng. Manuf. 2014, 15, 1069–1074. [Google Scholar] [CrossRef]

- Kang, B.S.; Yoon, J.S. Mold-less Pate Forming Apparatus with Flexible Rollers. PCT Patent PCT/KR2013/007642, 27 August 2013. [Google Scholar]

- Liu, P.; Ku, T.W.; Kang, B.S. Shape error prediction and compensation of three-dimensional surface in flexibly-reconfigurable roll forming. J. Mech. Sci. Technol. 2015, 29, 4387–4397. [Google Scholar] [CrossRef]

- Kim, H.H.; Yoon, J.S.; Kim, J.; Kang, B.S. Feasibility Study on Flexibly Reconfigurable Roll Forming Process for Sheet Metal and Its Implementation. Adv. Mech. Eng. 2014, 6, 958925. [Google Scholar]

- Yoon, J.S.; Kim, J.; Kang, B.S. Deformation analysis and shape prediction for sheet forming using flexibly reconfigurable roll forming. J. Mater. Process. Technol. 2016, 233, 192–205. [Google Scholar] [CrossRef]

- Park, J.W.; Yoon, J.; Lee, K.; Kim, J.; Kang, B.S. Rapid prediction of longitudinal curvature obtained by flexibly reconfigurable roll forming using response surface methodology. Int. J. Adv. Manuf. Technol. 2017, 91, 3371–3384. [Google Scholar] [CrossRef]

- Yoon, J.; Park, J.; Son, S.; Kim, H.; Kim, J.; Kang, B. Development of a Flexibly-reconfigurable Roll Forming Apparatus for Curved Surface Forming. Trans. Mater. Process. 2016, 25, 161–168. [Google Scholar] [CrossRef]

- Son, S.; Yoon, J.; Kim, J.; Kang, B. Effect of Shape Design Variables on Flexibly-Reconfigurable Roll Forming of Multi-curved Sheet Metal. Trans. Mater. Process. 2014, 23, 103–109. [Google Scholar] [CrossRef][Green Version]

- Myers, R.H.; Montgomery, D.C.; Anderson-cook, C.M. Response Surface Methodology—Process and Product Optimization Using Designed Experiments, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2009; pp. 13–62. [Google Scholar]

| Variables | Level |

|---|---|

| Maximum compression value | 2% |

| 6% | |

| 10% | |

| Width of blank | 100 mm |

| 125 mm | |

| 150 mm | |

| Curvature radius of transvers direction | 1000 mm |

| 1500 mm | |

| 2000 mm |

| Material Property | Value | Unit |

|---|---|---|

| Young’s modulus | 70.30 | GPa |

| Poisson’s ratio | 0.33 | - |

| Yield strength | 176.00 | MPa |

| Ultimate strength | 260.00 | MPa |

| Density | 2.68 | g/cm3 |

| Number of Case | Maximum Compression Value X1 | Curvature Radius of Transverse Direction X2 (mm) | Width of the Blank X3 (mm) | Result y (mm) |

|---|---|---|---|---|

| 1 | 2.0 | 1000 | 100 | 262.8 |

| 2 | 2.0 | 1500 | 100 | 339.0 |

| 3 | 2.0 | 2000 | 100 | 435.1 |

| 4 | 2.0 | 1000 | 125 | 326.0 |

| 5 | 2.0 | 1500 | 125 | 357.8 |

| 6 | 2.0 | 2000 | 125 | 457.8 |

| 7 | 2.0 | 1000 | 150 | 611.4 |

| 8 | 2.0 | 1500 | 150 | 639.7 |

| 9 | 2.0 | 2000 | 150 | 698.9 |

| 10 | 6.0 | 1000 | 100 | 146.4 |

| 11 | 6.0 | 1500 | 100 | 158.8 |

| 12 | 6.0 | 2000 | 100 | 169.1 |

| 13 | 6.0 | 1000 | 125 | 217.0 |

| 14 | 6.0 | 1500 | 125 | 260.1 |

| 15 | 6.0 | 2000 | 125 | 335.0 |

| 16 | 6.0 | 1000 | 150 | 336.3 |

| 17 | 6.0 | 1500 | 150 | 321.5 |

| 18 | 6.0 | 2000 | 150 | 340.0 |

| 19 | 10.0 | 1000 | 100 | 101.9 |

| 20 | 10.0 | 1500 | 100 | 117.3 |

| 21 | 10.0 | 2000 | 100 | 121.5 |

| 22 | 10.0 | 1000 | 125 | 141.1 |

| 23 | 10.0 | 1500 | 125 | 192.3 |

| 24 | 10.0 | 2000 | 125 | 212.4 |

| 25 | 10.0 | 1000 | 150 | 213.6 |

| 26 | 10.0 | 1500 | 150 | 234.7 |

| 27 | 10.0 | 2000 | 150 | 255.1 |

| Number of Case | Maximum Compression Value X1 | Curvature Radius of Transverse Direction X2 (mm) | Width of the Blank X3 (mm) | Result y (mm) |

|---|---|---|---|---|

| 28 | 2.0 | 1000 | 100 | 401.7 |

| 29 | 2.0 | 1500 | 100 | 403.3 |

| 30 | 2.0 | 2000 | 100 | 1164.7 |

| 31 | 2.0 | 1000 | 125 | 345.0 |

| 32 | 2.0 | 1500 | 125 | 365.4 |

| 33 | 2.0 | 2000 | 125 | 861.2 |

| 34 | 2.0 | 1000 | 150 | 260.6 |

| 35 | 2.0 | 1500 | 150 | 471.3 |

| 36 | 2.0 | 2000 | 150 | 668.2 |

| 37 | 6.0 | 1000 | 100 | 244.0 |

| 38 | 6.0 | 1500 | 100 | 267.1 |

| 39 | 6.0 | 2000 | 100 | 605.9 |

| 40 | 6.0 | 1000 | 125 | 217.6 |

| 41 | 6.0 | 1500 | 125 | 232.4 |

| 42 | 6.0 | 2000 | 125 | 392.6 |

| 43 | 6.0 | 1000 | 150 | 164.6 |

| 44 | 6.0 | 1500 | 150 | 178.2 |

| 45 | 6.0 | 2000 | 150 | 374.2 |

| 46 | 10.0 | 1000 | 100 | 148.6 |

| 47 | 10.0 | 1500 | 100 | 171.1 |

| 48 | 10.0 | 2000 | 100 | 355.2 |

| 49 | 10.0 | 1000 | 125 | 140.9 |

| 50 | 10.0 | 1500 | 125 | 166.9 |

| 51 | 10.0 | 2000 | 125 | 267.3 |

| 52 | 10.0 | 1000 | 150 | 138.9 |

| 53 | 10.0 | 1500 | 150 | 165.9 |

| 54 | 10.0 | 2000 | 150 | 266.4 |

| Regression Coefficient | Value (Convex Shape) | Value (Saddle Shape) |

|---|---|---|

| 230.0 | 199.4 | |

| −141.0 | −173.3 | |

| 63.9 | 78.3 | |

| 100.0 | −59.6 | |

| 28.0 | 26.2 | |

| 37.1 | 160.8 | |

| 7.7 | 120.8 | |

| −45.9 | 38.8 | |

| −6.8 | −48.9 | |

| −21.6 | −102.2 |

| Number of Case | Estimated Result yi (mm) | Percent Error | Number of Case | Estimated Result yi (mm) | Percent Error |

|---|---|---|---|---|---|

| 1 | 262.8 | 1.4 | 28 | 384.7 | 4.4 |

| 2 | 339.0 | 6.5 | 29 | 575.7 | 42.7 |

| 3 | 435.1 | 10.3 | 30 | 1008.3 | 13.4 |

| 4 | 326.0 | 17.8 | 31 | 308.9 | 10.5 |

| 5 | 357.8 | 21.5 | 32 | 451.1 | 23.4 |

| 6 | 457.8 | 9.5 | 33 | 834.8 | 3.1 |

| 7 | 611.4 | 7.7 | 34 | 285.5 | 9.6 |

| 8 | 639.7 | 4.8 | 35 | 378.8 | 19.6 |

| 9 | 698.9 | 4.4 | 36 | 713.7 | 6.8 |

| 10 | 146.4 | 16.8 | 37 | 196.4 | 19.5 |

| 11 | 158.8 | 0.5 | 38 | 285.2 | 6.8 |

| 12 | 169.1 | 24.0 | 39 | 615.7 | 1.6 |

| 13 | 217.0 | 7.6 | 40 | 159.5 | 26.7 |

| 14 | 260.1 | 11.6 | 41 | 199.4 | 14.2 |

| 15 | 335.0 | 18.0 | 42 | 481.0 | 22.5 |

| 16 | 336.3 | 0.3 | 43 | 174.9 | 6.2 |

| 17 | 321.5 | 11.3 | 44 | 166.0 | 6.9 |

| 18 | 340.0 | 16.5 | 45 | 398.7 | 6.5 |

| 19 | 101.9 | 10.0 | 46 | 164.7 | 10.8 |

| 20 | 117.3 | 8.1 | 47 | 151.4 | 11.5 |

| 21 | 121.5 | 29.0 | 48 | 379.6 | 6.9 |

| 22 | 141.1 | 2.7 | 49 | 166.6 | 18.2 |

| 23 | 192.3 | 20.5 | 50 | 104.4 | 37.5 |

| 24 | 212.4 | 17.1 | 51 | 283.7 | 6.2 |

| 25 | 213.6 | 9.5 | 52 | 220.9 | 59.0 |

| 26 | 234.7 | 0.1 | 53 | 109.8 | 33.8 |

| 27 | 255.1 | 1.5 | 54 | 240.3 | 9.8 |

| Summary of Fit | Convex Shape | Saddle Shape |

|---|---|---|

| R-squared value | 0.9482 | 0.9273 |

| Normalized root mean square error (NRMSE) | 0.0595 | 0.0615 |

| Maximum percent error | 29.0 | 59.0 |

| Minimum percent error | 0.1 | 1.6 |

| Mean percent error | 10.7 | 16.2 |

| Mean residual | 2.0527 × 10−7 | 5.7370 × 10−14 |

| Number of Case | Curvature Radius of Transverse Direction X2 (mm) | Width of the Blank X3 (mm) | Curvature Radius of Longitudinal Direction y (mm) |

|---|---|---|---|

| 1 | 1111.9 | 105.3 | 258.0 |

| 2 | 1099.6 | 124.5 | 176.6 |

| 3 | 1948.8 | 137.4 | 572.7 |

| 4 | 1332.2 | 104.4 | 141.0 |

| 5 | 1843.4 | 117.3 | 468.3 |

| 6 | 1652.2 | 111.6 | 401.9 |

| 7 | 1767.9 | 144.3 | 323.3 |

| 8 | 1239.8 | 131.1 | 526.0 |

| 9 | 1508.7 | 148.0 | 360.3 |

| 10 | 1431.7 | 125.5 | 245.4 |

| Number of Case | Curvature Radius of Transverse Direction X2 (mm) | Width of the Blank X3 (mm) | Curvature Radius of Longitudinal Direction y (mm) |

|---|---|---|---|

| 11 | 1405.1 | 102.9 | 498.6 |

| 12 | 1554.2 | 146.2 | 374.0 |

| 13 | 1890.9 | 124.1 | 527.1 |

| 14 | 1218.7 | 113.4 | 149.6 |

| 15 | 1308.7 | 138.6 | 213.5 |

| 16 | 1022.2 | 126.7 | 317.3 |

| 17 | 1118.7 | 121.0 | 127.9 |

| 18 | 1609.7 | 131.1 | 394.9 |

| 19 | 1696.2 | 103.6 | 463.3 |

| 20 | 1837.5 | 112.7 | 690.7 |

| Number of Case | Deduced Compression Value X1 (%) | Deduced Curvature Radius of Longitudinal Direction y’ (mm) | Curvature Radius of Longitudinal Direction y (mm) | Difference |

|---|---|---|---|---|

| 1 | 2.67 | 257.8 | 258.0 | 0.21 |

| 2 | 6.99 | 176.6 | 176.6 | 0.06 |

| 3 | 1.97 | 572.7 | 572.7 | 0.08 |

| 4 | 6.55 | 141.2 | 141.0 | 0.20 |

| 5 | 1.56 | 468.3 | 468.3 | 0.07 |

| 6 | 1.72 | 402.1 | 401.9 | 0.28 |

| 7 | 6.43 | 323.5 | 323.3 | 0.17 |

| 8 | 0.87 | 525.6 | 526.0 | 0.38 |

| 9 | 5.70 | 360.4 | 360.3 | 0.03 |

| 10 | 5.50 | 245.5 | 245.4 | 0.12 |

| Number of Case | Deduced Compression Value X1 (%) | Deduced Curvature Radius of Longitudinal Direction y’ (mm) | Curvature Radius of Longitudinal Direction y (mm) | Difference |

|---|---|---|---|---|

| 11 | 2.07 | 498.9 | 498.6 | 0.27 |

| 12 | 2.51 | 373.9 | 374.0 | 0.11 |

| 13 | 4.27 | 527.3 | 527.1 | 0.23 |

| 14 | 6.59 | 149.7 | 149.6 | 0.10 |

| 15 | 4.08 | 213.5 | 213.5 | 0.08 |

| 16 | 1.82 | 317.2 | 317.3 | 0.12 |

| 17 | 7.18 | 127.7 | 127.9 | 0.24 |

| 18 | 3.19 | 394.5 | 394.9 | 0.32 |

| 19 | 4.61 | 463.1 | 463.3 | 0.14 |

| 20 | 2.63 | 690.9 | 690.7 | 0.22 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, J.-W.; Kim, J.; Kang, B.-S. Development on a Prediction Model for Experimental Condition of Flexibly Reconfigurable Roll Forming Process. Metals 2019, 9, 896. https://doi.org/10.3390/met9080896

Park J-W, Kim J, Kang B-S. Development on a Prediction Model for Experimental Condition of Flexibly Reconfigurable Roll Forming Process. Metals. 2019; 9(8):896. https://doi.org/10.3390/met9080896

Chicago/Turabian StylePark, Ji-Woo, Jeong Kim, and Beom-Soo Kang. 2019. "Development on a Prediction Model for Experimental Condition of Flexibly Reconfigurable Roll Forming Process" Metals 9, no. 8: 896. https://doi.org/10.3390/met9080896

APA StylePark, J.-W., Kim, J., & Kang, B.-S. (2019). Development on a Prediction Model for Experimental Condition of Flexibly Reconfigurable Roll Forming Process. Metals, 9(8), 896. https://doi.org/10.3390/met9080896