Initial β Grain Size Effect on High-Temperature Flow Behavior of Tb8 Titanium Alloys in Single β Phase Field

Abstract

1. Introduction

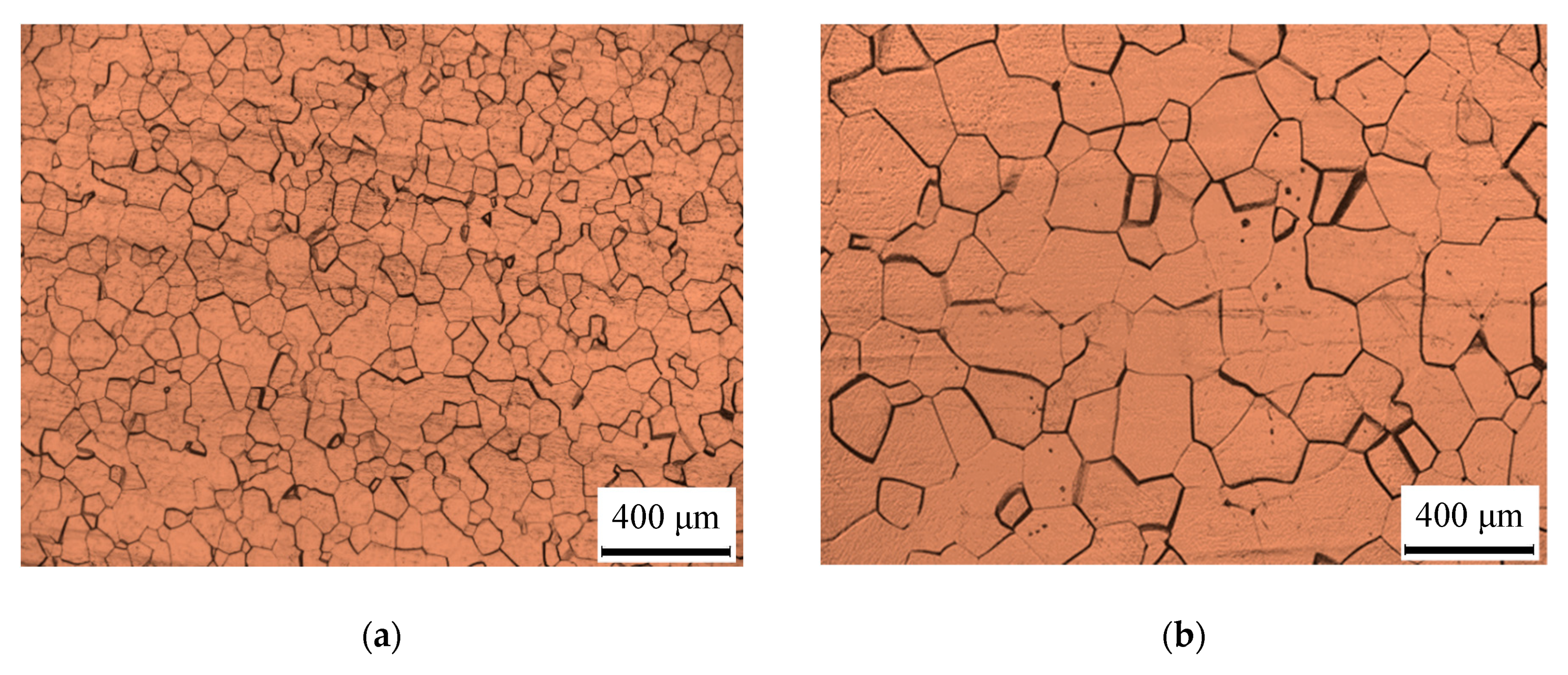

2. Experiments

3. Results and Discussion

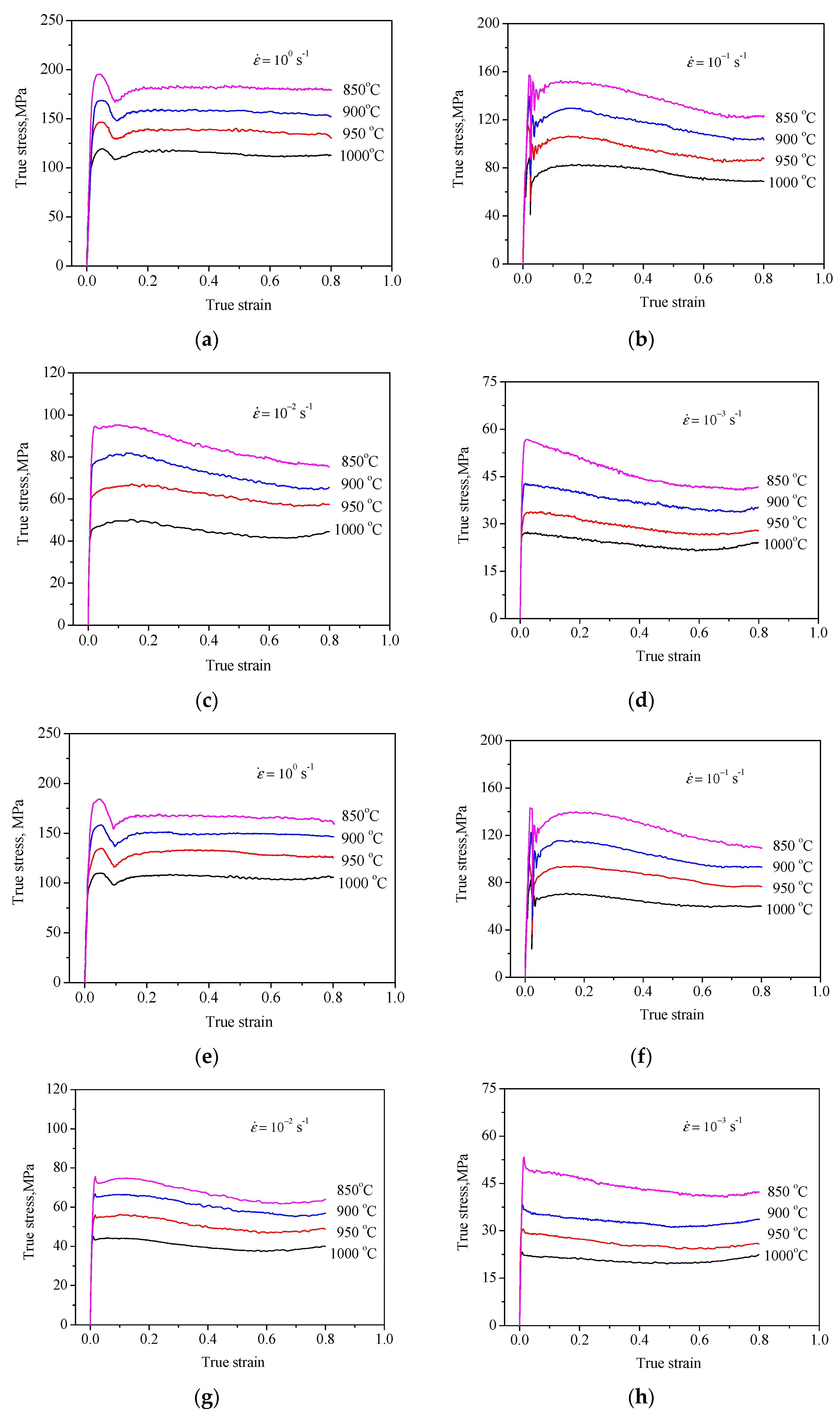

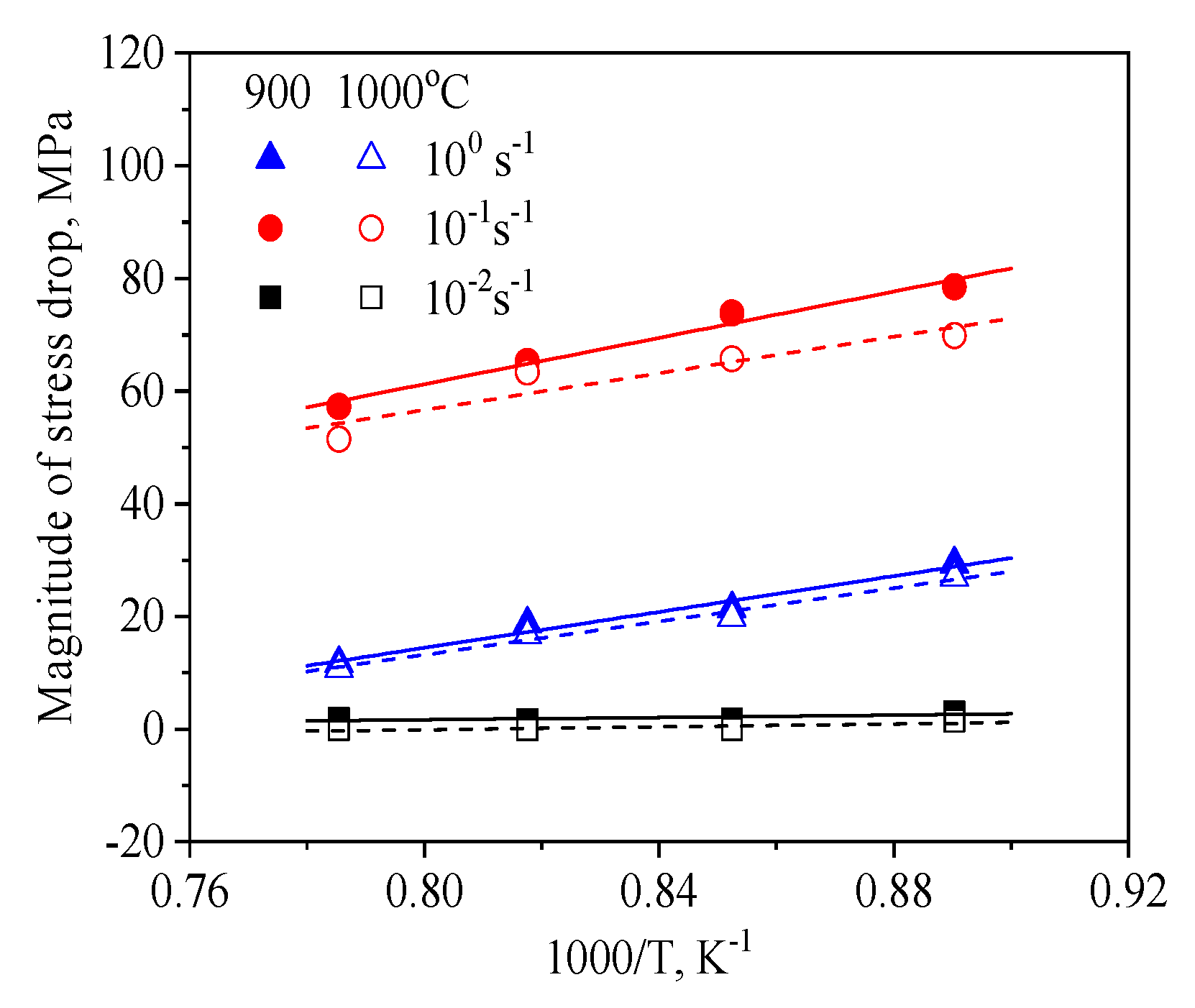

3.1. Flow Curves

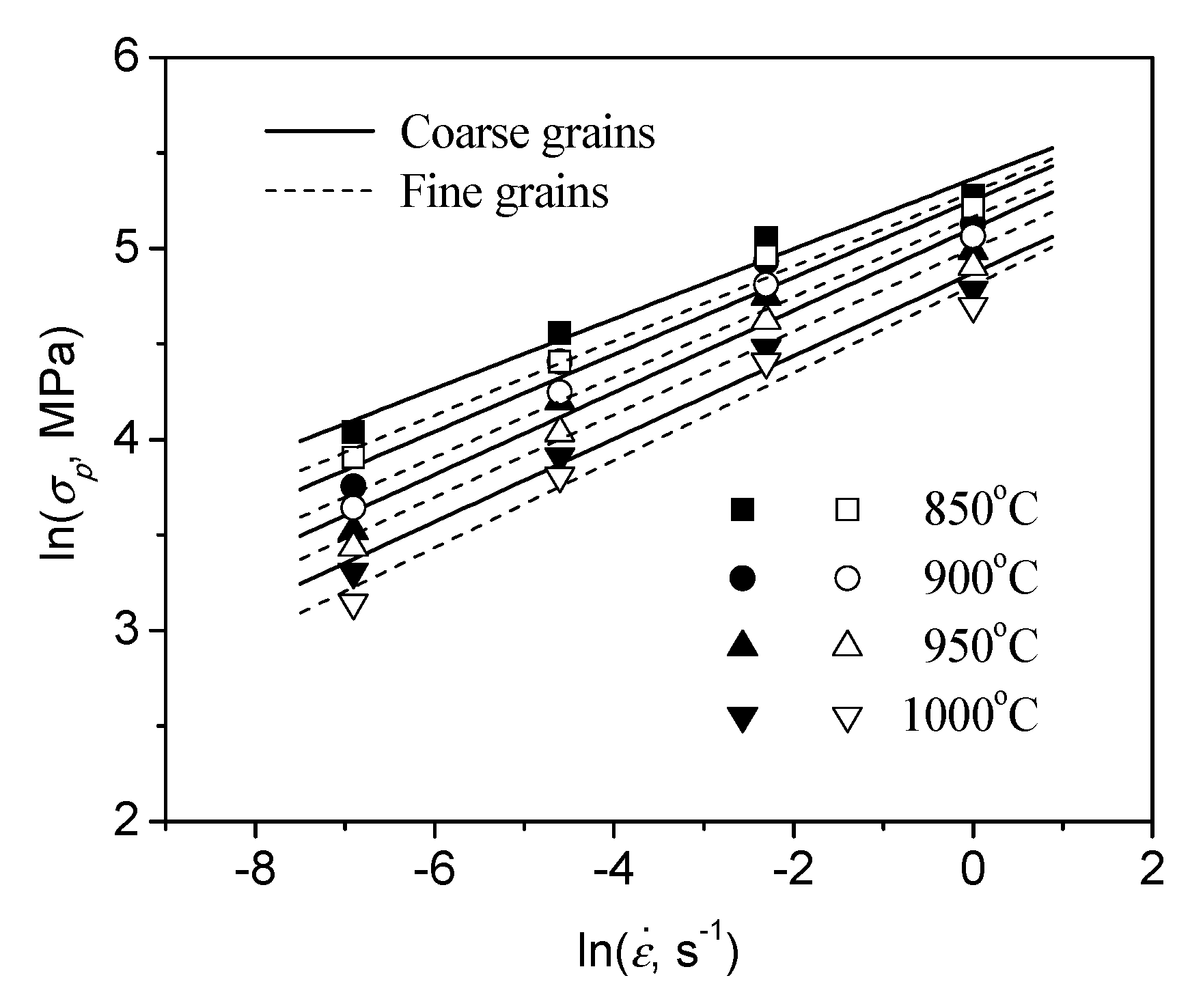

3.2. Constitutive Equations Analysis of TB8 Titanium Alloys

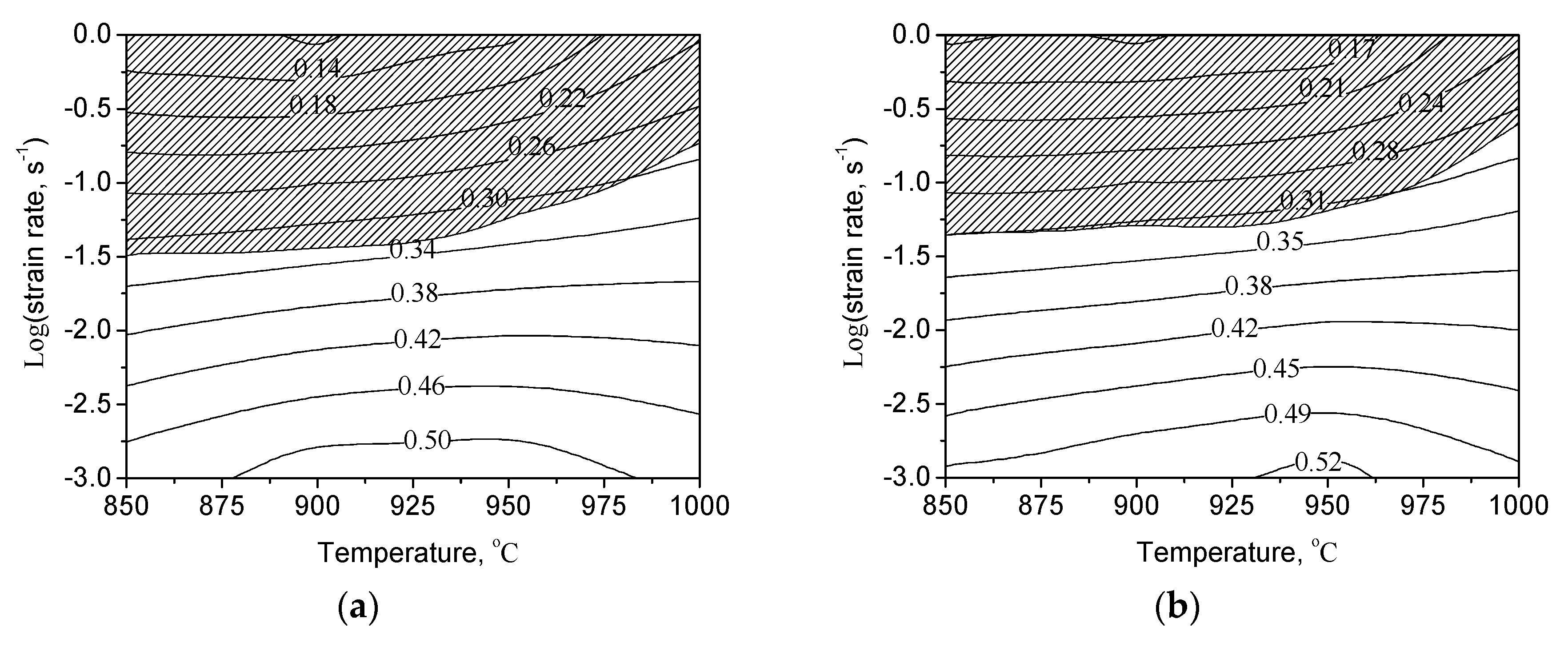

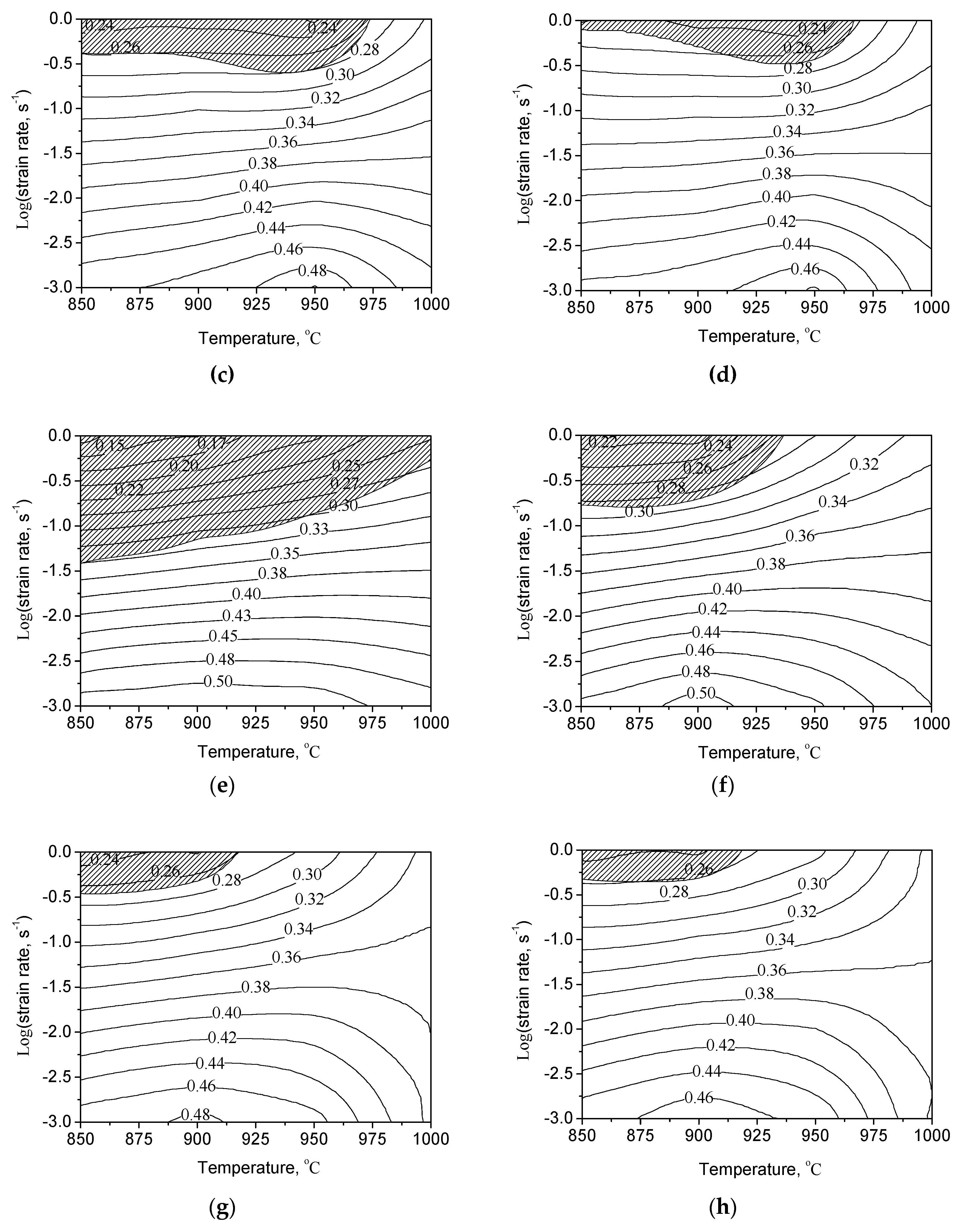

3.3. Processing Maps

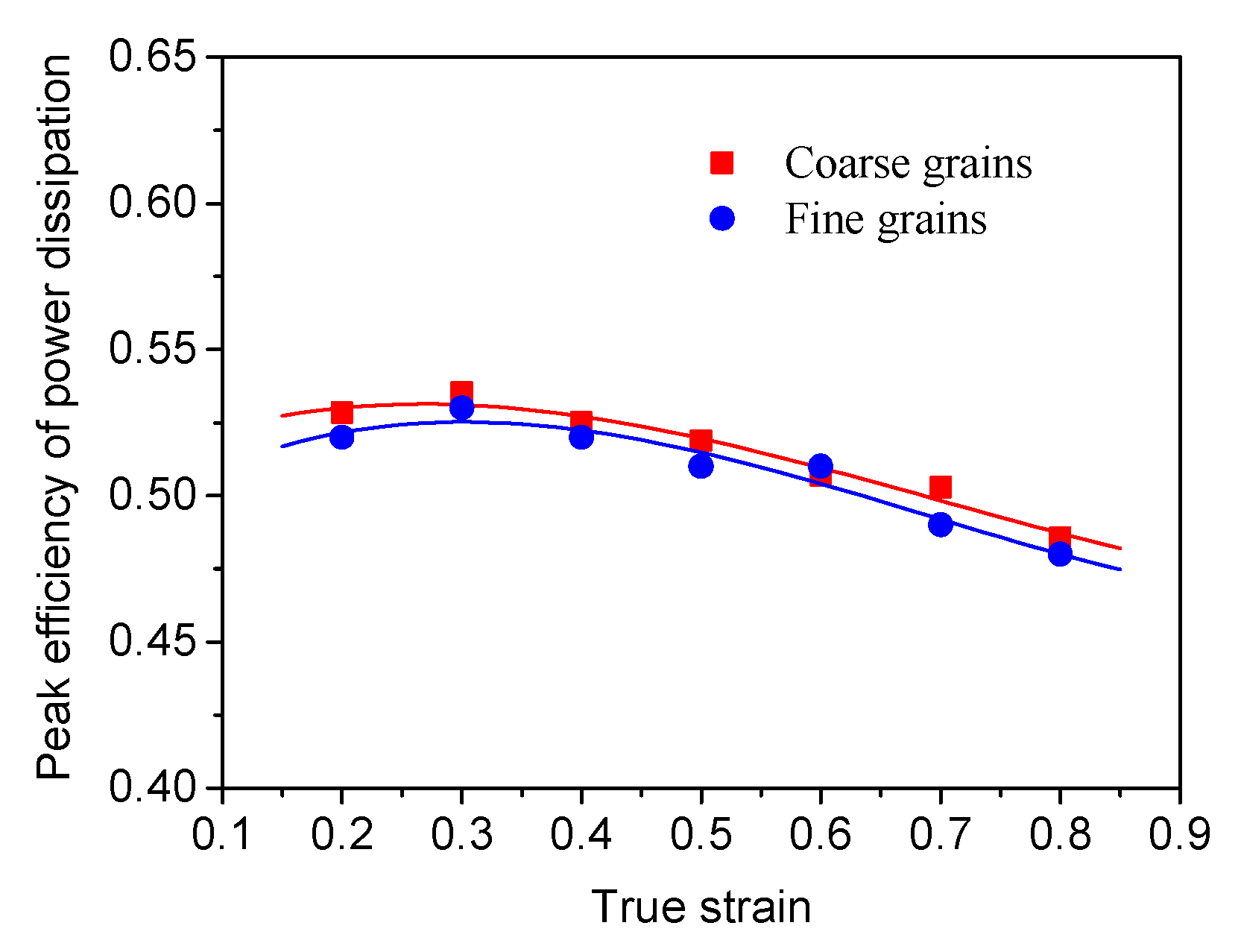

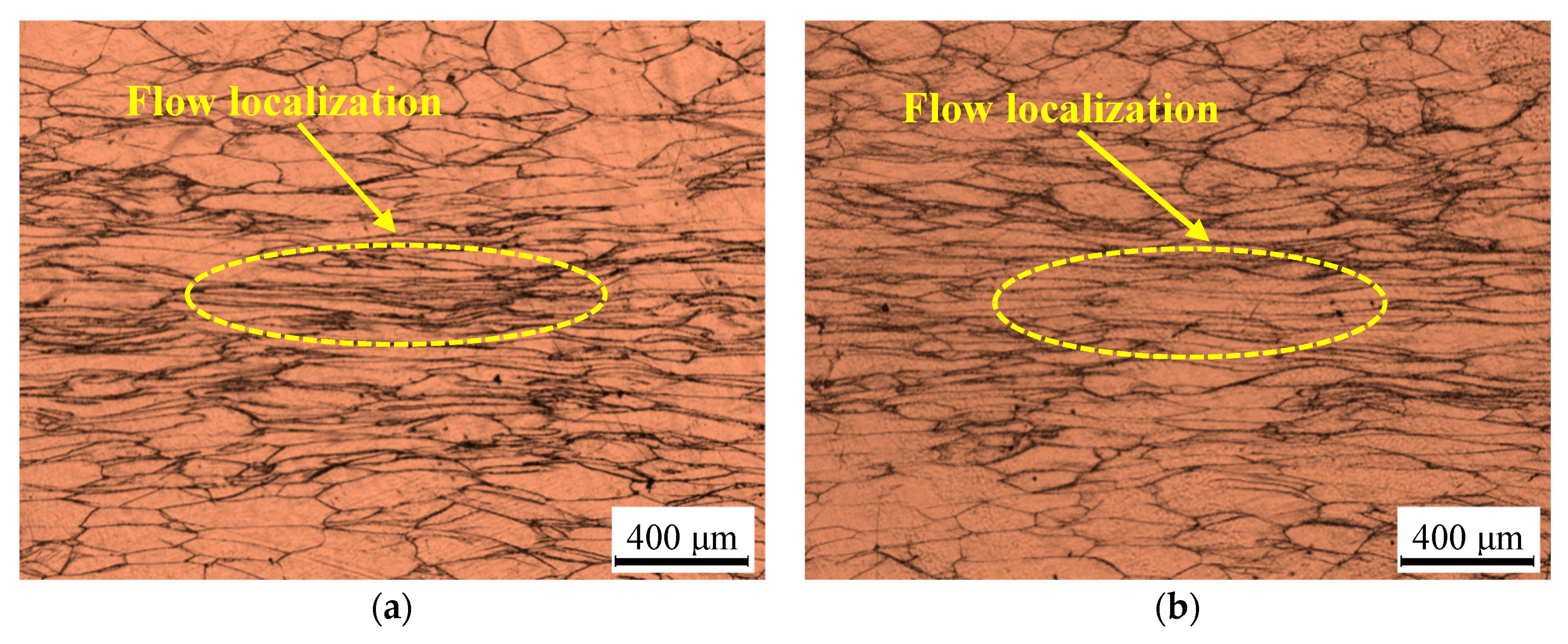

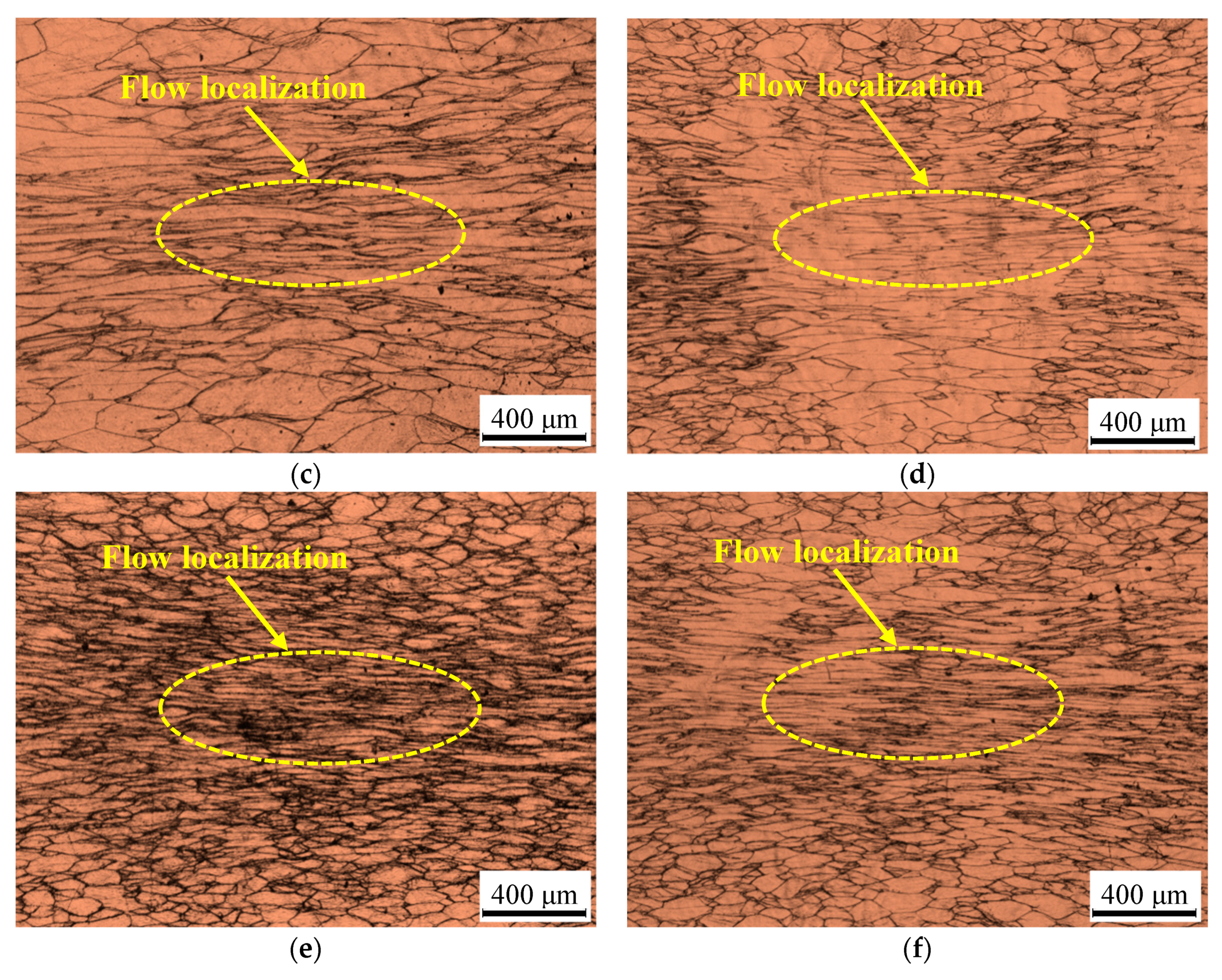

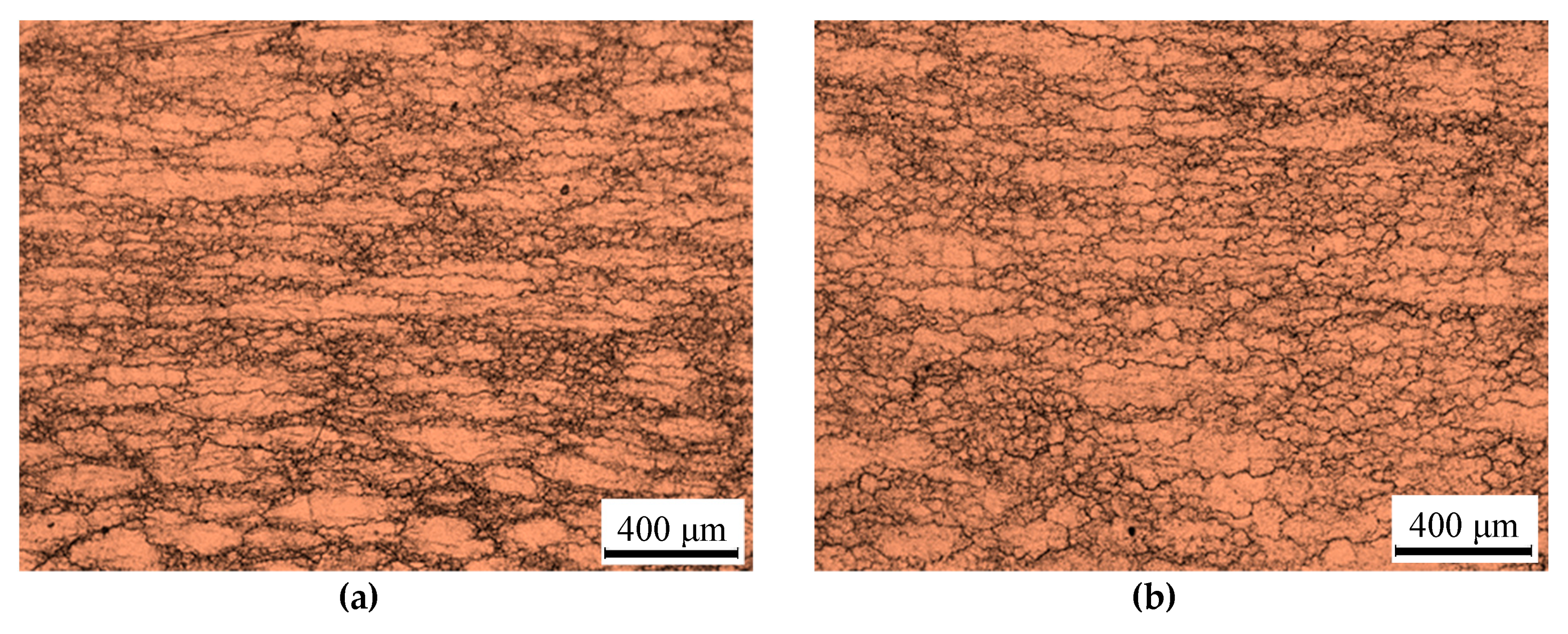

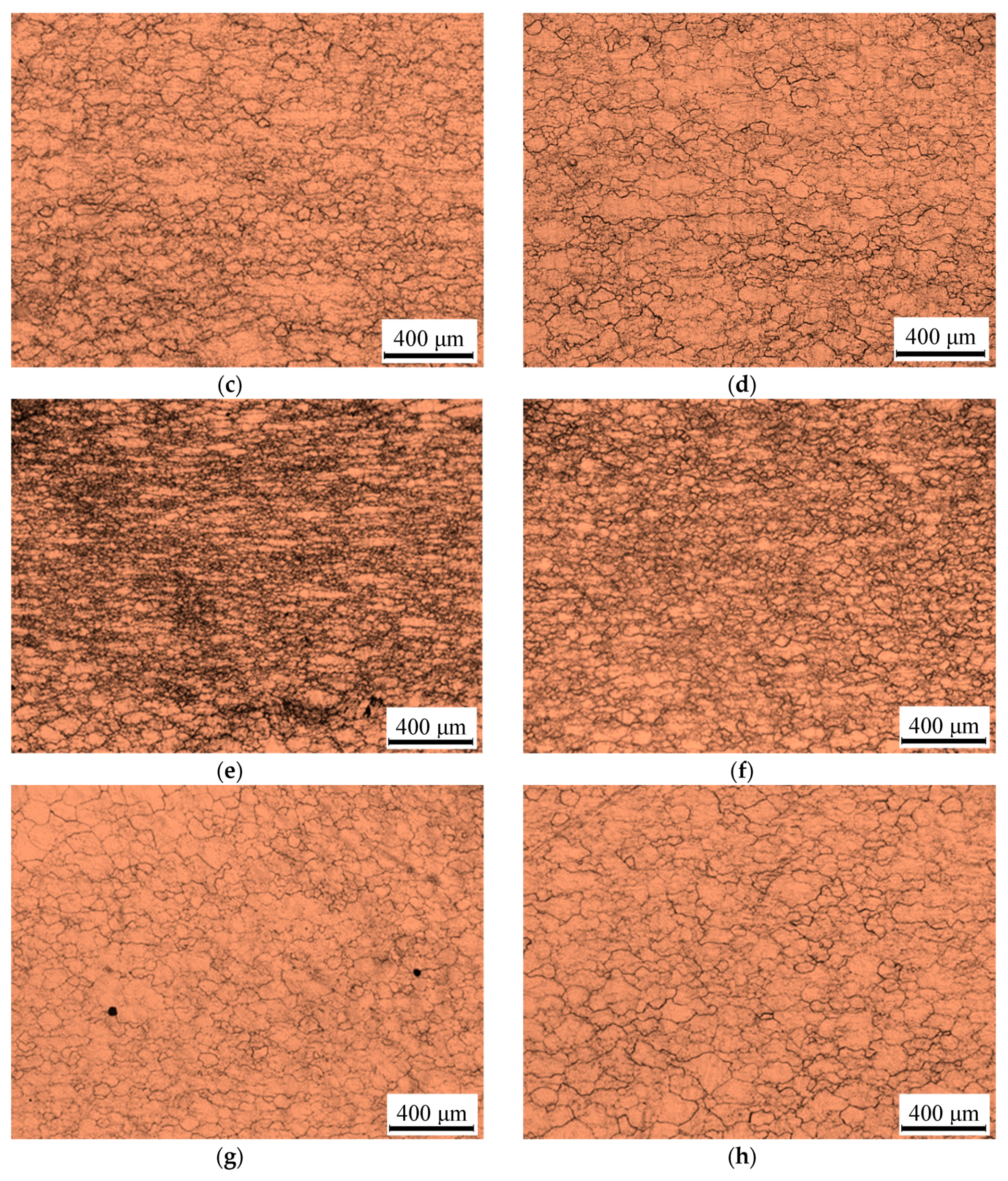

3.4. Deformation Microstructure of TB8 Titanium Alloys

4. Conclusions

- At the strain rates of 100 and 10−1 s−1, a significant phenomenon of stress drop was visible at the beginning stage of deformation for TB8 titanium alloys with fine-grained and coarse-grained structure. The flow stress firstly raised to a maximum value, and subsequently attained a plateau at 100 s−1, whereas a slight decrease at 10−1 s−1. Only dynamic recovery occurs under these deformation conditions. When the strain rate is 10−3 s−1, the flow curves of TB8 titanium alloys showed a typical characteristic of dynamic recrystallization.

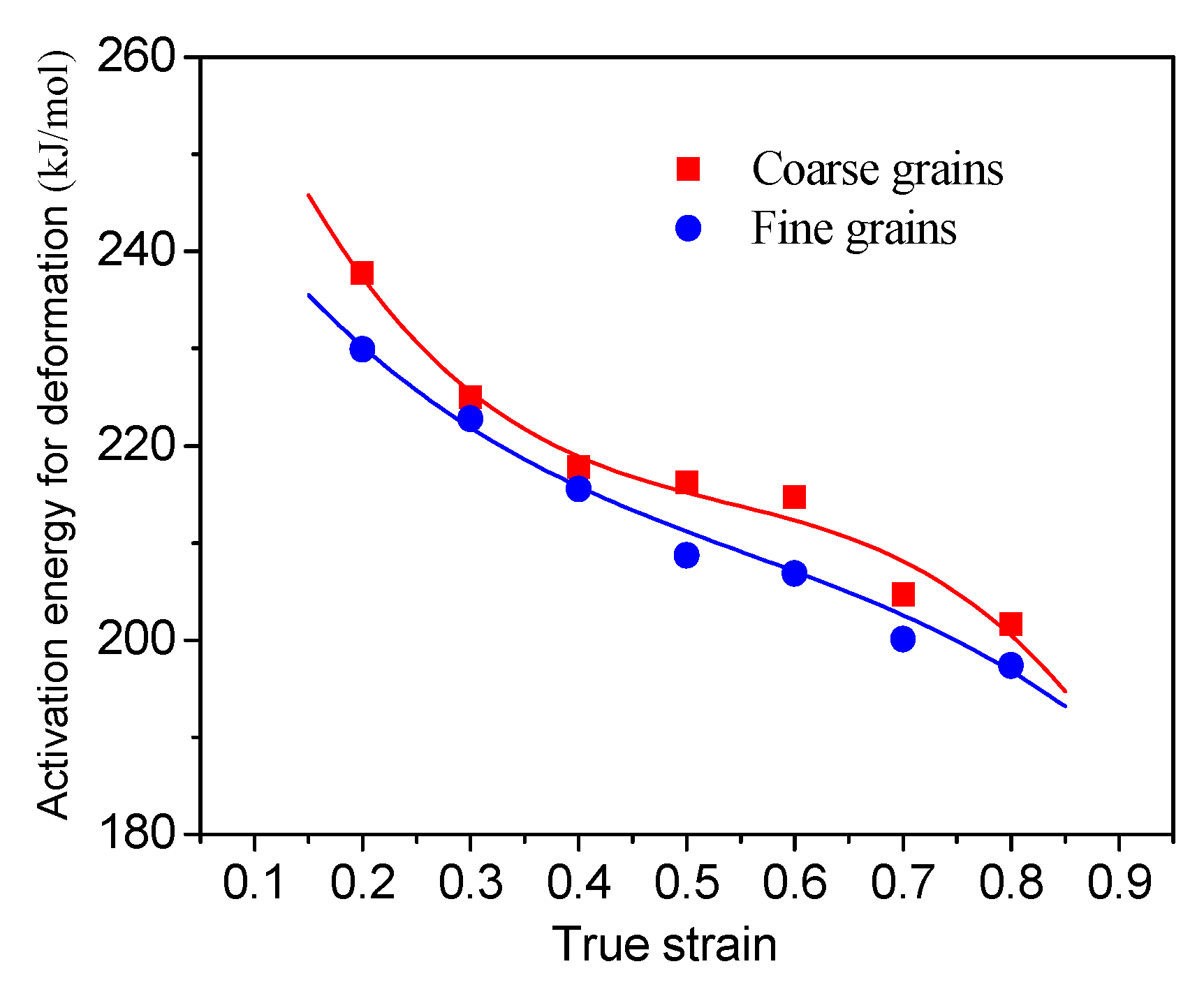

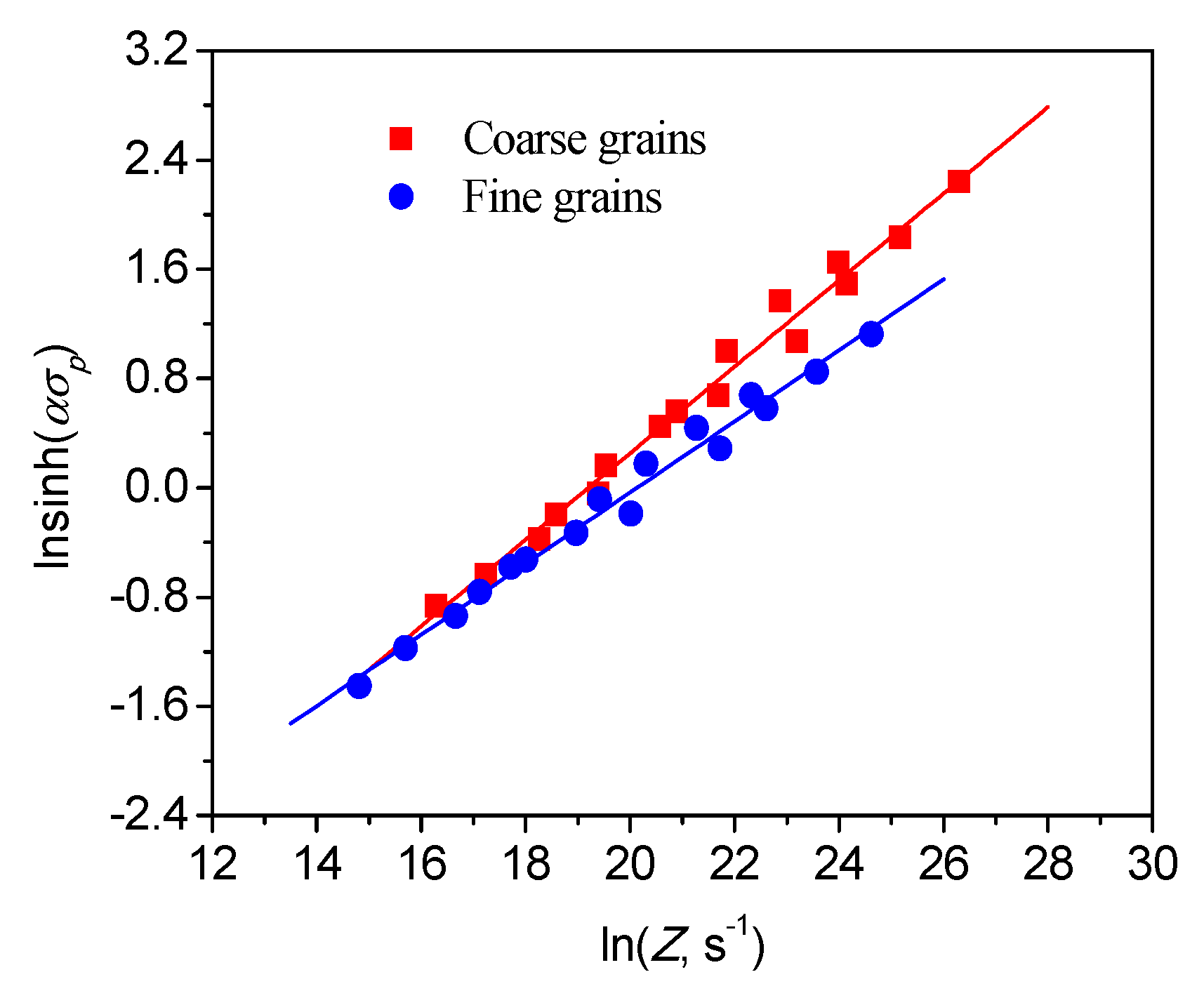

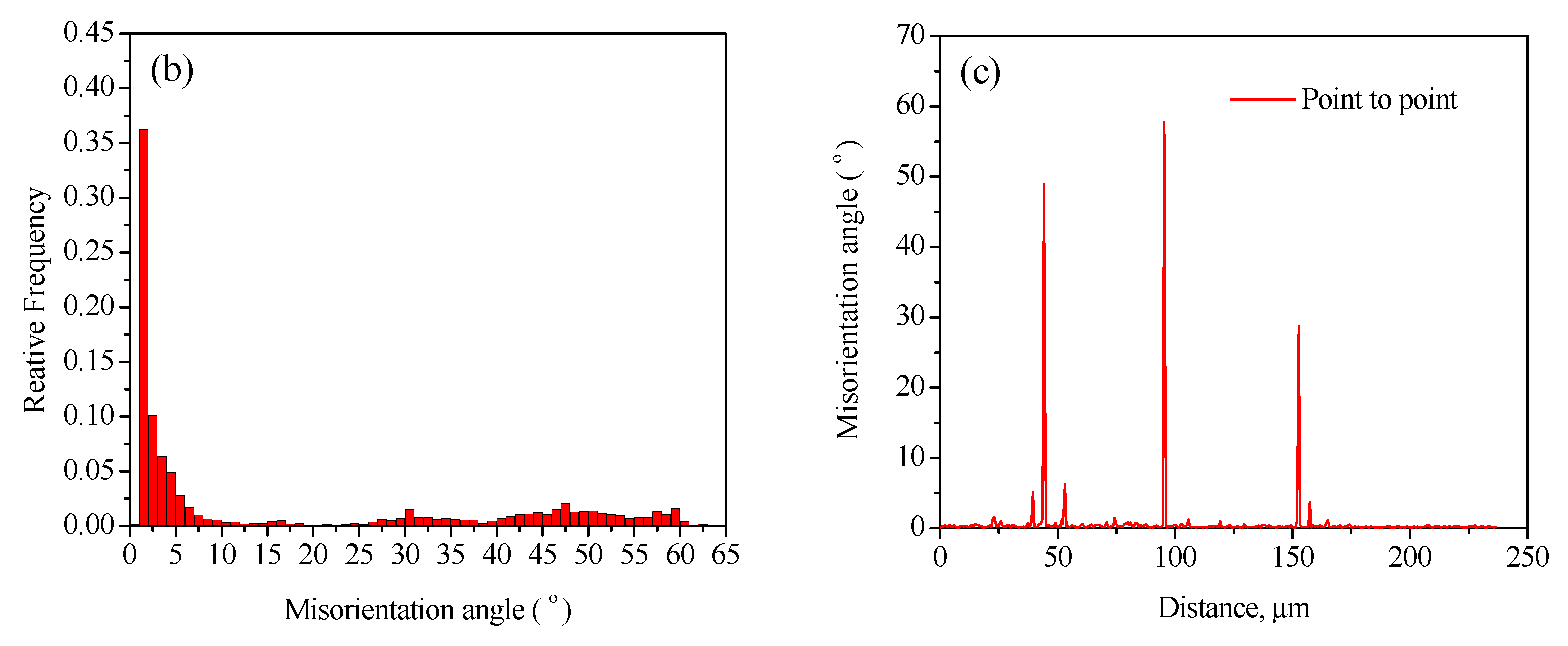

- The values of α, A, n, and Q were computed at various strains, according to the received experimental data for TB8 titanium alloys with two different grain sizes. The value of Q all declined gradually with the rising of strain. At a given strain, the value of Q for the fine-grained alloy is lower than that for the coarse-grained alloy, which indicates that the fine initial grain size is beneficial to the plastic deformation of the alloy during hot processing.

- The relationship between , and can be described by the hyperbolic-sine Arrhenius-type equation as follows:For TB8 titanium alloy with fine grain structure,For TB8 titanium alloy with coarse grain structure,

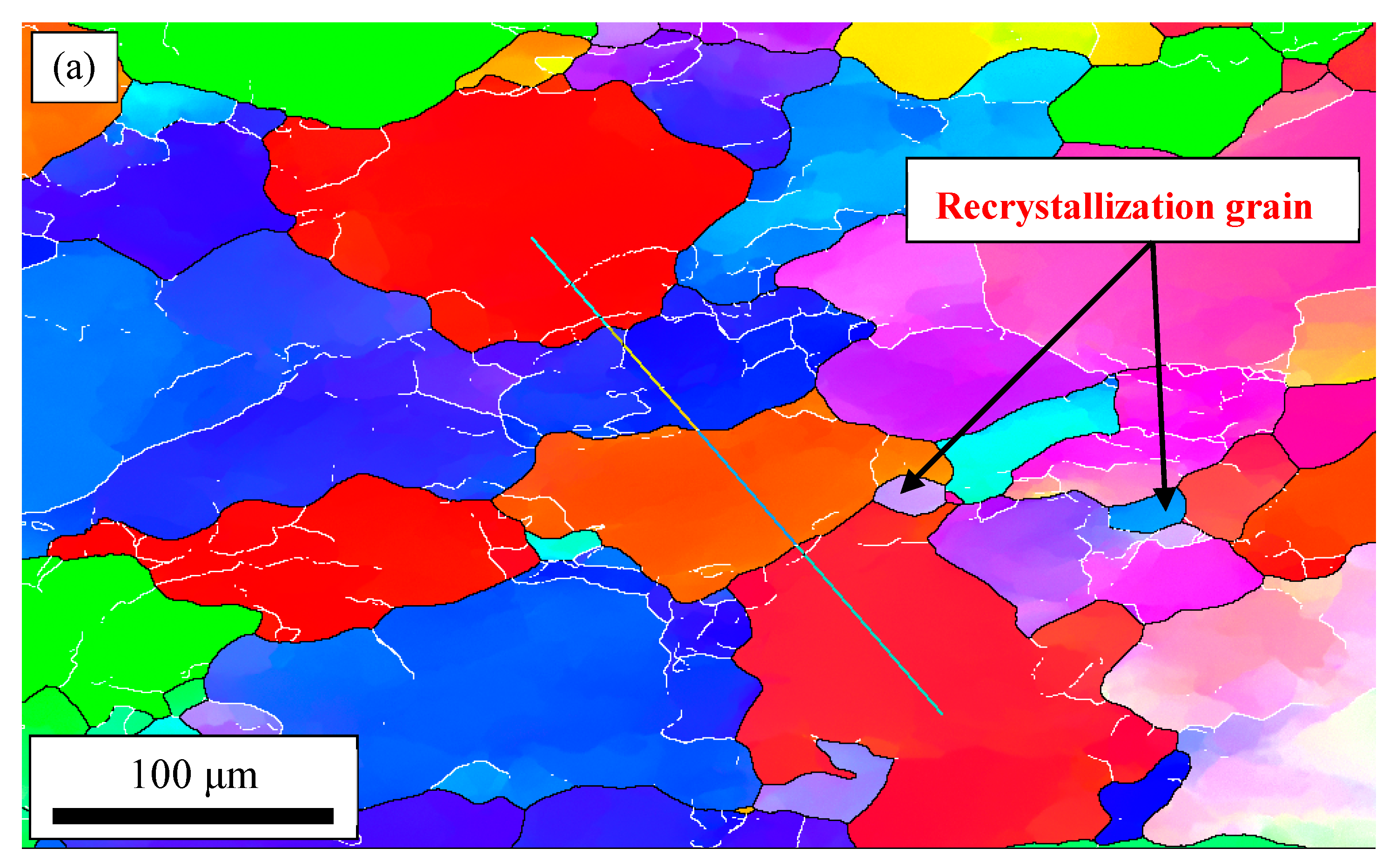

- At the strain of 0.2, the dynamic recrystallization only occurred in the local region of initial grain boundaries during hot deformation for the TB8 titanium alloy with fine-grained structure. The volume fraction of low angle grain boundaries was accounted for 65.7%. The largest orientation gradient was located at the distance of approximate 5–10 µm from the grain boundaries and the misorientation angle was approximately 4–6°.

- The processing maps of TB8 titanium alloys with two different grain sizes were established. The optimum processing parameters of the fine- and coarse-grained alloy for hot working were measured to be 900 °C/10−3 s−1 and 950 °C/10−3 s−1, respectively. The hot deformation mechanism in these regions with a peak value of η is mainly the dynamic recrystallization of β phase.

Author Contributions

Funding

Conflicts of Interest

References

- Boyer, R.R.; Briggs, R.D. The use of β titanium alloys in the aerospace industry. J. Mater. Eng. Perform. 2005, 14, 681–685. [Google Scholar] [CrossRef]

- Balasubrahmanyam, V.V.; Prasad, Y.V.R.K. Deformation behaviour of beta titanium alloy Ti-10V-4.5Fe-1.5Al in hot upset forging. Mater. Sci. Eng. A 2002, 336, 150–158. [Google Scholar] [CrossRef]

- Li, Y.H.Z.; Ou, X.Q.; Ni, S.; Song, M. Deformation behaviors of a hot rolled near-β Ti-5Al-5Mo-5V-1Cr-1Fe alloy. Mater. Sci. Eng. A 2019, 742, 390–399. [Google Scholar] [CrossRef]

- Xu, T.W.; Li, J.S.; Zhang, F.S.; Wang, F.Y.; Liu, X.H.; Feng, Y. Microstructure Evolution during Cold-Deformation and Aging Response after Annealing of TB8 Titanium Alloy. Rare Met. Mater. Eng. 2016, 45, 575–580. [Google Scholar] [CrossRef]

- Tang, B.; Tang, B.; Han, F.B.; Yang, G.J.; Li, J.S. Microstructure Evolution during Cold-Deformation and Aging Response after Annealing of TB8 Titanium Alloy. J. Alloy. Compd. 2013, 565, 1–5. [Google Scholar]

- Baufeld, B.; Biest, O.V.D.; Gault, R. Mechanical properties of Ti-6Al-4V specimens produced by shaped metal deposition. Sci. Technol. Adv. Mater. 2009, 10, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Baufeld, B.; Biest, O.V.D.; Gault, R. Additive manufacturing of Ti-6Al-4V components by shaped metal deposition: Microstructure and mechanical properties. Mater. Des. 2010, 31, 106–111. [Google Scholar] [CrossRef]

- Zhu, Y.C.; Zeng, W.D.; Liu, J.L.; Zhao, Y.Q.; Zhou, Y.G.; Yu, H.Q. Effect of processing parameters on the hot deformation behavior of as-cast TC21 titanium alloy. Mater. Des. 2012, 33, 264–272. [Google Scholar] [CrossRef]

- Peng, W.W.; Zeng, W.D.; Wang, Q.J.; Zhao, Q.Y.; Yu, H.Q. Effect of processing parameters on hot deformation behavior and microstructural evolution during hot compression of as-cast Ti60 titanium alloy. Mater. Sci. Eng. A 2014, 593, 16–23. [Google Scholar] [CrossRef]

- Liu, Y.H.; Ning, Y.Q.; Yao, Z.K.; Guo, H.Z. Hot deformation behavior of Ti-6.0A-7.0Nb biomedical alloy by using processing map. J. Alloy. Compd. 2014, 587, 183–189. [Google Scholar] [CrossRef]

- Zhang, Z.X.; Qu, S.J.; Feng, A.H.; Shen, J.; Chen, D.L. Hot deformation behavior of Ti-6Al-4V alloy: Effect of initial microstructure. J. Alloy. Compd. 2017, 718, 170–181. [Google Scholar] [CrossRef]

- Long, S.; Xia, Y.F.; Hu, J.C.; Zhang, J.S.; Zhou, J.; Zhang, P.; Cui, M.L. Hot deformation behavior and microstructure evolution of Ti-6Cr-5Mo-5V-4Al alloy during hot compression. Vacuum 2019, 160, 171–180. [Google Scholar] [CrossRef]

- El Wahabi, M.; Gavard, L.; Montheillet, F.; Cabrera, J.M.; Prado, J.M. Effect of initial grain size on dynamic recrystallization in high purity austenitic stainless steels. Acta Mater. 2005, 53, 4605–4612. [Google Scholar] [CrossRef]

- Rezaei Ashtiani, H.R.; Parsa, M.H.; Bisadi, H. Effects of initial grain size on hot deformation behavior of commercial pure aluminum. Mater. Des. 2012, 42, 478–485. [Google Scholar] [CrossRef]

- Oudin, A.; Barnett, M.R.; Hodgson, P.D. Grain size effect on the warm deformation behaviour of a Ti-IF steel. Mater. Sci. Eng. A 2004, 367, 282–294. [Google Scholar] [CrossRef]

- Barnett, M.R.; Beer, A.G.; Atwell, D.; Oudin, A. Influence of grain size on hot working stresses and microstructures in Mg-3Al-1Zn. Scr. Mater. 2004, 51, 19–24. [Google Scholar] [CrossRef]

- Barnett, M.R.; Keshavarz, Z.; Beer, A.G.; Atwell, D. Influence of grain size on the compressive deformation of wrought Mg-3Al-1Zn. Acta Mater. 2004, 52, 5093–5103. [Google Scholar] [CrossRef]

- Yang, Y.B.; Zhang, Z.M.; Li, X.B.; Wang, Q.; Zhang, Y.H. The effects of grain size on the hot deformation and processing map for 7075 aluminum alloy. Mater. Des. 2013, 51, 592–597. [Google Scholar] [CrossRef]

- Tan, Y.B.; Yang, L.H.; Duan, J.L.; Liu, W.C.; Zhang, J.W.; Liu, R.P. Effect of initial grain size on the hot deformation behavior of 47Zr-45Ti-5Al-3V alloy. J. Nucl. Mater. 2014, 454, 413–420. [Google Scholar] [CrossRef]

- Duan, Y.P.; Ping, L.I.; Xue, K.M.; Zhang, Q.; Wang, X.X. Flow behavior and microstructure evolution of TB8 alloy during hot deformation process. Trans. Nonferrous Met. Soc. China 2007, 17, 1199–1204. [Google Scholar] [CrossRef]

- Tang, B.; Tang, B.; Han, F.B.; Li, J.S.; Yang, G.J. Hot Deformation Behavior of TB8 Alloy near the β-Transus. Rare Met. Mat. Eng. 2013, 42, 1761–1766. [Google Scholar]

- Philippart, I.; Rack, H.J. High temperature dynamic yielding in metastable Ti-6.8Mo- 4.5Fe-1.5Al alloy. Mater. Sci. Eng. A 1998, 243, 196–200. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Seetharaman, V.; Weiss, I. Flow behavior and globularization kinetics during hot working of Ti-6Al-4V with a colony alpha microstructure. Mater. Sci. Eng. A 1999, 263, 257–271. [Google Scholar] [CrossRef]

- Ma, X.; Zeng, W.D.; Xu, B.; Sun, Y.; Xue, C.; Han, Y.F. Characterization of the hot deformation behavior of a Ti-22Al-25Nb alloy using processing maps based on the Murty criterion. Intermetallics 2012, 20, 1–7. [Google Scholar] [CrossRef]

- Park, C.H.; Kim, J.H.; Hyun, Y.T.; Yeom, J.T.; Reddy, N.S. The origins of flow softening during high-temperature deformation of a Ti-6Al-4V alloy with a lamellar microstructure. J. Alloy. Compd. 2014, 582, 126–129. [Google Scholar] [CrossRef]

- Peng, W.W.; Zeng, W.D.; Wang, Q.J.; Yu, H.Q. Characterization of high-temperature deformation behavior of as-cast Ti60 titanium alloy using processing map. Mater. Sci. Eng. A 2013, 571, 116–122. [Google Scholar] [CrossRef]

- Yuan, H.; Liu, W.C. Effect of the δ phase on the hot deformation behavior of Inconel 718. Mater. Sci. Eng. A 2005, 408, 281–289. [Google Scholar] [CrossRef]

- Coryell, S.P.; Findley, K.O.; Mataya, M.C. Evolution of Microstructure and Texture During Hot Compression of a Ni-Fe-Cr Superalloy. Metall. Mater Trans. A 2012, 43, 633–649. [Google Scholar] [CrossRef]

- Narayana Murty, S.V.S.; Nageswara Rao, B. On the flow localization concepts in the processing maps of titanium alloy Ti–24Al–20Nb. J. Mater. Process. Technol. 2000, 104, 103–109. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K.; Seshacharyulu, T.; Medeiros, S.C.; Frazier, W.G. Influence of oxygen content on the forging response of equiaxed (α + β) preform of Ti-6Al-4V: Commercial vs. ELI grade. J. Mater. Process. Technol. 2001, 108, 320–327. [Google Scholar] [CrossRef]

- Atwell, D.L.; Barnett, M.R.; Hutchinson, W.B. The effect of initial grain size and temperature on the tensile properties of magnesium alloy AZ31 sheet. Mater. Sci. Eng. A 2012, 549, 1–6. [Google Scholar] [CrossRef]

- Verlinden, B.; Driver, J.; Samajdar, I.; Doherty, D. Thermo-Mechanical Processing of Metallic Materials; Elsevier: Amsterdam, The Netherlands, 2007. [Google Scholar]

- Sellars, C.M.; Tegart, W.J.M. Relationship between strength and structure in deformation at elevated temperatures. Mem. Sci. Rev. Metall. 1966, 63, 731–746. [Google Scholar]

- Cai, J.; Li, F.G.; Liu, T.Y.; Chen, B.; He, M. Constitutive equations for elevated temperature flow stress of Ti-6Al-4V alloy considering the effect of strain. Mater. Des. 2011, 32, 1144–1151. [Google Scholar] [CrossRef]

- Radovi, N.; Drobnjak, D. Effect of Interpass Time and Cooling Rate on Apparent Activation Energy for Hot Working and Critical Recrystallization Temperature of Nb-microalloyed Steel. ISIJ Int. 1999, 39, 575–582. [Google Scholar] [CrossRef][Green Version]

- Lee, W.S.; Lin, M.T. The effects of strain rate and temperature on the compressive deformation behaviour of Ti-6Al-4V alloy. J. Mater. Process Technol. 1997, 71, 235–246. [Google Scholar] [CrossRef]

- Weissa, I.; Semiatin, S.L. Thermomechanical processing of beta titanium alloys-an overview. Mater. Sci. Eng. A 1998, 243, 46–65. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K.; Gegel, H.L.; Doraivelu, S.M.; Malas, J.C.; Morgan, J.T.; Lark, K.A.; Barker, D.R. Modeling of dynamic material behavior in hot deformation: Forging of Ti-6242. Metall. Trans. A 1984, 15, 1883–1892. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K. Author’s reply: Dynamic materials model: Basis and principles. Metall. Mater. Trans. A 1996, 27, 235–236. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K.; Seshacharyulu, T. Modelling of hot deformation for microstructural control. Int. Mater. Rev. 1998, 43, 243–258. [Google Scholar] [CrossRef]

- Seshacharyulu, T.; Medeiros, S.C.; Frazier, W.G.; Prasad, Y.V.R.K. Hot working of commercial Ti-6Al-4V with an equiaxed α-β microstructure: Materials modeling considerations. Mater. Sci. Eng. A 2000, 284, 184–194. [Google Scholar] [CrossRef]

- Peng, X.N.; Guo, H.Z.; Shi, Z.F.; Qin, C.; Zhao, Z.L.; Yao, Z.K. Study on the hot deformation behavior of TC4-DT alloy with equiaxed α+β starting structure based on processing map. Mater. Sci. Eng. A 2014, 605, 80–88. [Google Scholar] [CrossRef]

- Sivakesavam, O.; Rao, I.S.; Prasad, Y.V.R.K. Processing map for hot working of as cast magnesium. Mater. Sci. Technol. 1993, 9, 805–810. [Google Scholar]

- Srinivasan, N.; Prasad, Y.V.R.K. Characterisation of dynamic recrystallisation in nickel using processing map for hot deformation. Mater. Sci. Technol. 1992, 8, 206–212. [Google Scholar] [CrossRef]

- Ravichandran, N.; Prasad, Y.V.R.K. Dynamic recrystallization during hot deformation of aluminum: A study using processing maps. Metall. Trans. 1991, 22, 2339–2348. [Google Scholar] [CrossRef]

- Tan, Y.B.; Ma, Y.H.; Zhao, F. Hot deformation behavior and constitutive modeling of fine grained Inconel 718 superalloy. J. Alloy. Compd. 2018, 741, 85–96. [Google Scholar] [CrossRef]

- Wan, Z.P.; Hu, L.X.; Sun, Y.; Wang, T.; Li, Z. Hot deformation behavior and processing workability of a Ni-based alloy. J. Alloy. Compd. 2018, 769, 367–375. [Google Scholar] [CrossRef]

- Li, H.Z.; Wang, H.J.; Li, Z.; Liu, C.M.; Liu, H.T. Flow behavior and processing map of as-cast Mg-10Gd-4.8 Y-2Zn-0.6 Zr alloy. Mater. Sci. Eng. A 2010, 528, 154–160. [Google Scholar] [CrossRef]

- Lu, S.Q.; Li, X.; Wang, K.L.; Dong, X.J.; Fu, M.W. High temperature deformation behavior and optimization of hot compression process parameters in TC11 titanium alloy with coarse lamellar original microstructure. Trans. Nonferrous Met. Soc. China 2013, 23, 353–360. [Google Scholar] [CrossRef]

| Mo | Al | Nb | Si | Fe | C | N | O | H | Ti |

|---|---|---|---|---|---|---|---|---|---|

| 14.5 | 2.9 | 2.85 | 0.19 | 0.07 | 0.02 | 0.02 | 0.09 | 0.002 | Bal |

| Fine- Grained | σp | Strain | ||||||

|---|---|---|---|---|---|---|---|---|

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | ||

| Q, kJ/mol | 234.72 | 229.92 | 222.78 | 215.53 | 208.73 | 206.86 | 200.10 | 197.35 |

| n | 3.20 | 3.21 | 3.15 | 3.12 | 3.12 | 3.14 | 3.72 | 3.84 |

| A, s−1 | 1.3 × 108 | 1.1 × 108 | 6.1 × 107 | 3.4 × 107 | 1.9 × 107 | 2.6 × 107 | 5.9 × 107 | 4.4 × 107 |

| α | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 | 0.01 | 0.01 |

| Coarse- Grained | σp | Strain | ||||||

|---|---|---|---|---|---|---|---|---|

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | ||

| Q, kJ/mol | 245.56 | 237.78 | 224.96 | 217.78 | 216.19 | 214.72 | 204.72 | 201.64 |

| n | 3.16 | 3.24 | 3.17 | 3.13 | 3.11 | 3.12 | 3.72 | 3.82 |

| A, s−1 | 2.2 × 108 | 1.3 × 108 | 4.2 × 107 | 2.4 × 107 | 2.4 × 107 | 2.4 × 107 | 6.2 × 107 | 4.5 × 107 |

| α | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 | 0.01 | 0.01 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Q.; Ma, M.; Tan, Y.; Xiang, S.; Zhao, F.; Liang, Y. Initial β Grain Size Effect on High-Temperature Flow Behavior of Tb8 Titanium Alloys in Single β Phase Field. Metals 2019, 9, 891. https://doi.org/10.3390/met9080891

Yang Q, Ma M, Tan Y, Xiang S, Zhao F, Liang Y. Initial β Grain Size Effect on High-Temperature Flow Behavior of Tb8 Titanium Alloys in Single β Phase Field. Metals. 2019; 9(8):891. https://doi.org/10.3390/met9080891

Chicago/Turabian StyleYang, Qiuyue, Min Ma, Yuanbiao Tan, Song Xiang, Fei Zhao, and Yilong Liang. 2019. "Initial β Grain Size Effect on High-Temperature Flow Behavior of Tb8 Titanium Alloys in Single β Phase Field" Metals 9, no. 8: 891. https://doi.org/10.3390/met9080891

APA StyleYang, Q., Ma, M., Tan, Y., Xiang, S., Zhao, F., & Liang, Y. (2019). Initial β Grain Size Effect on High-Temperature Flow Behavior of Tb8 Titanium Alloys in Single β Phase Field. Metals, 9(8), 891. https://doi.org/10.3390/met9080891