Continuous Electron Beam Post-Treatment of EBF3-Fabricated Ti–6Al–4V Parts

Abstract

1. Introduction

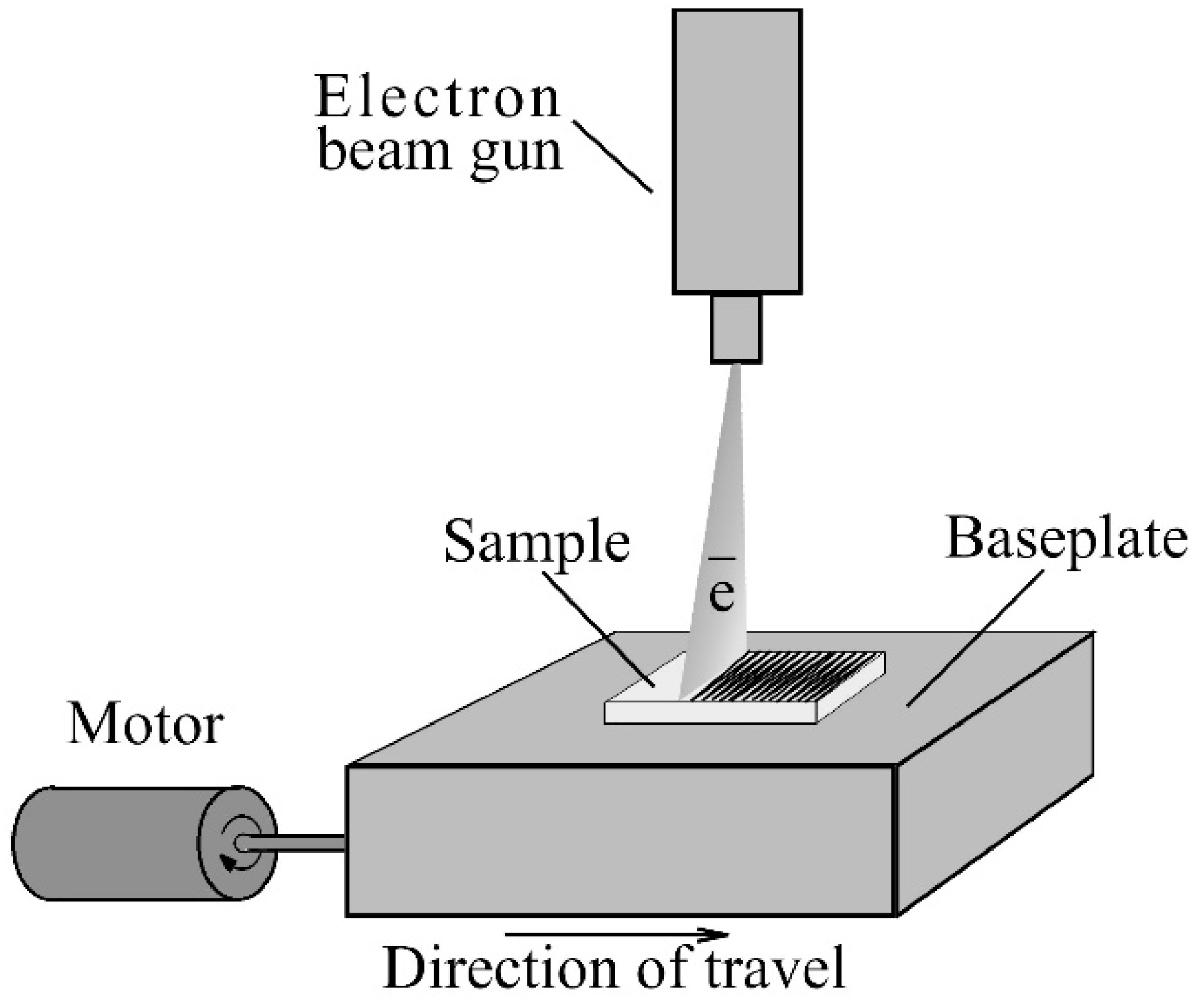

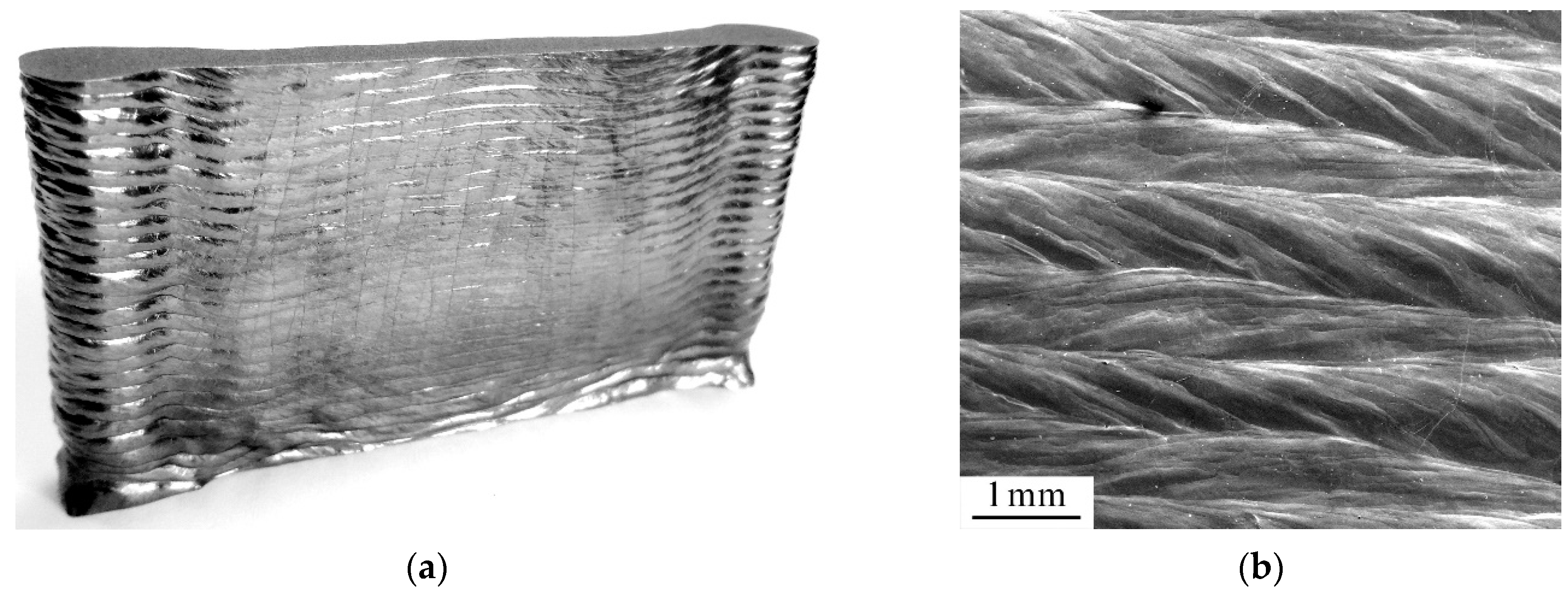

2. Materials and Methods

3. Results

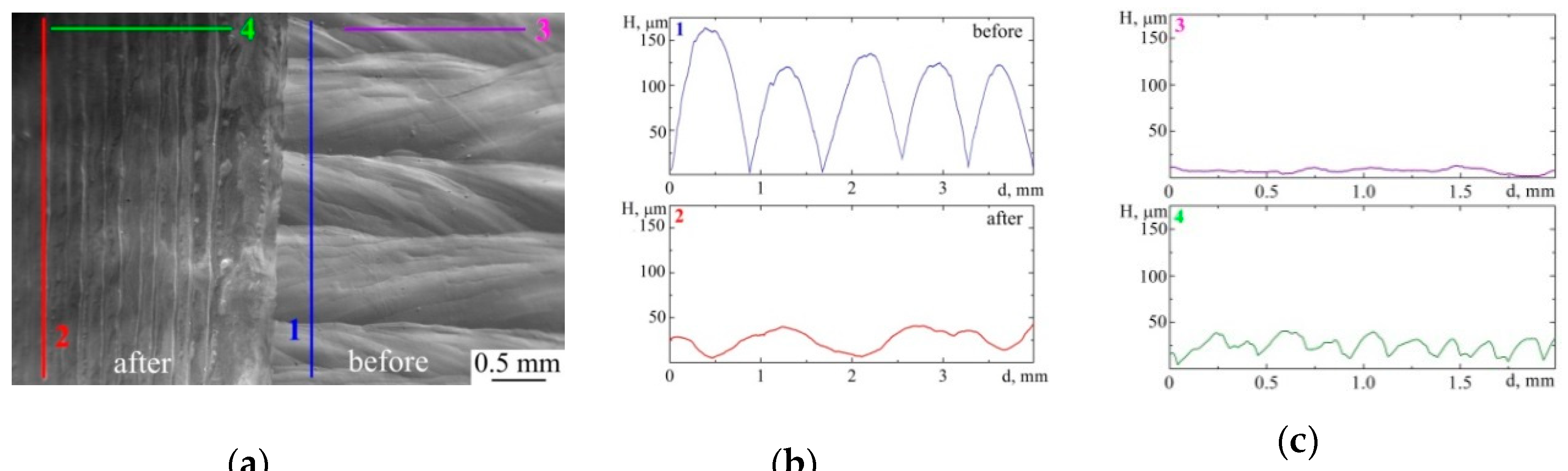

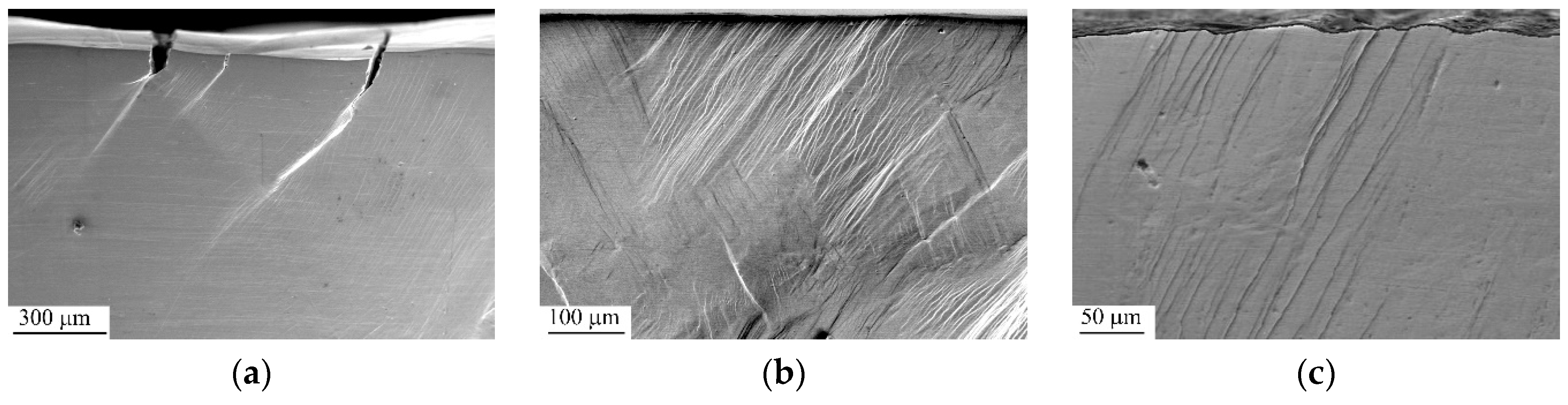

3.1. Surface Finish

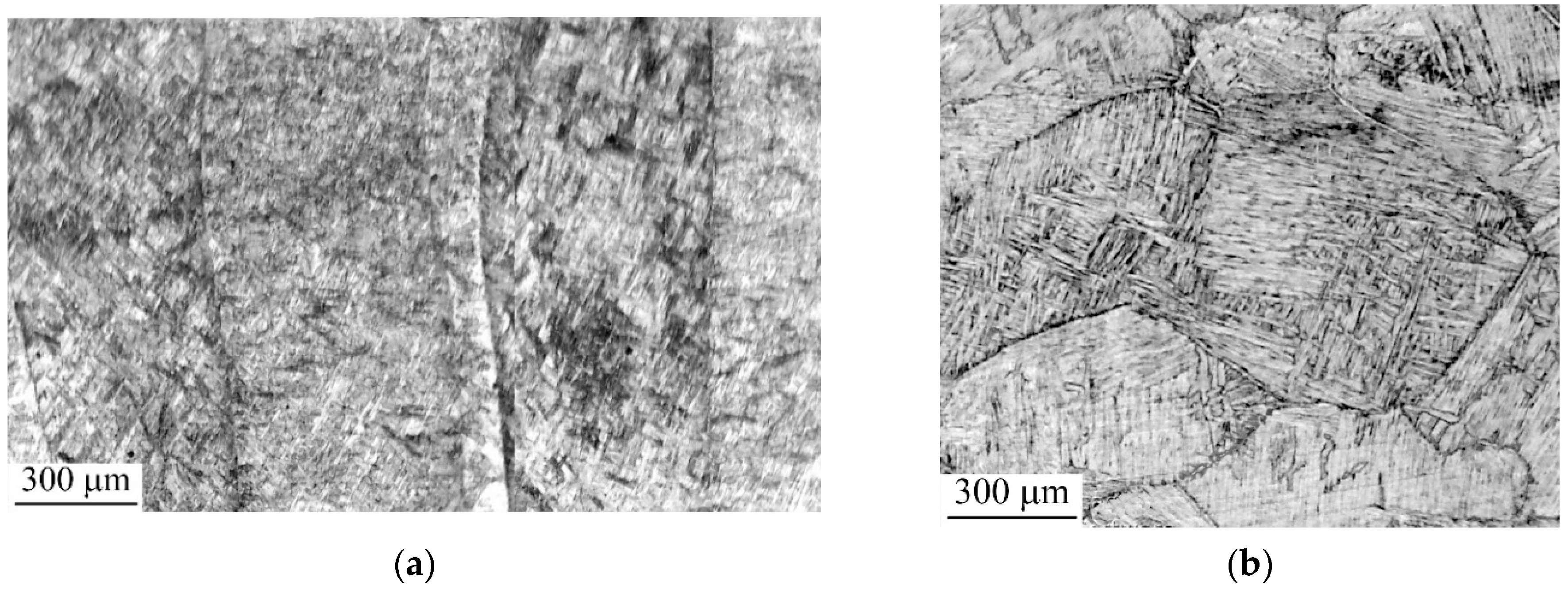

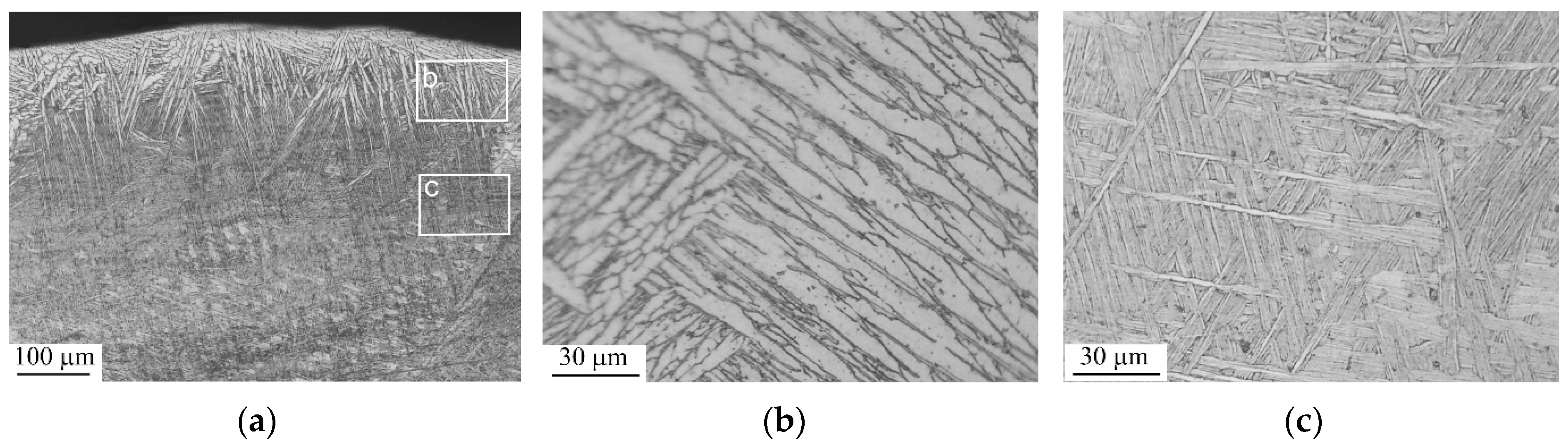

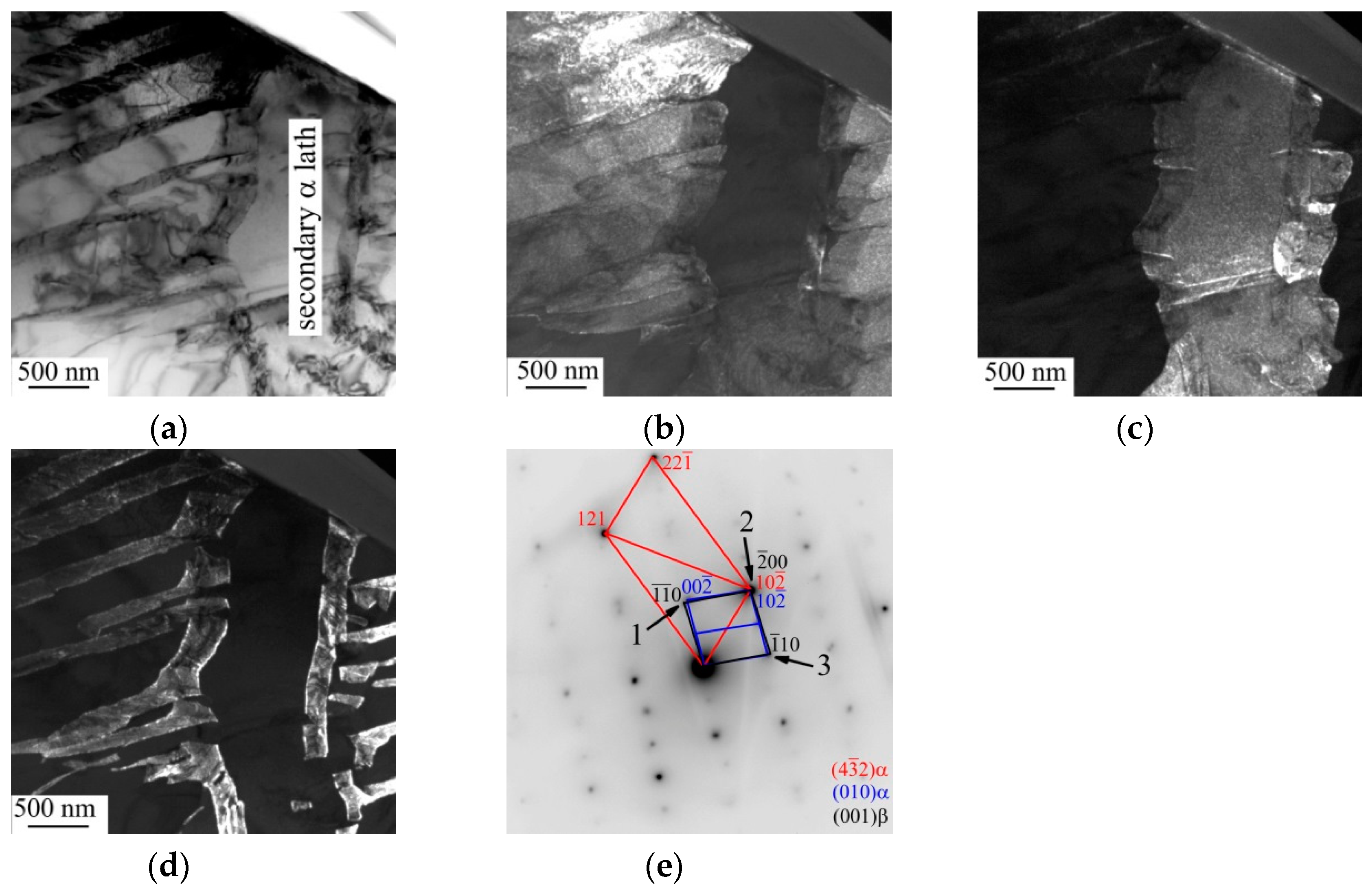

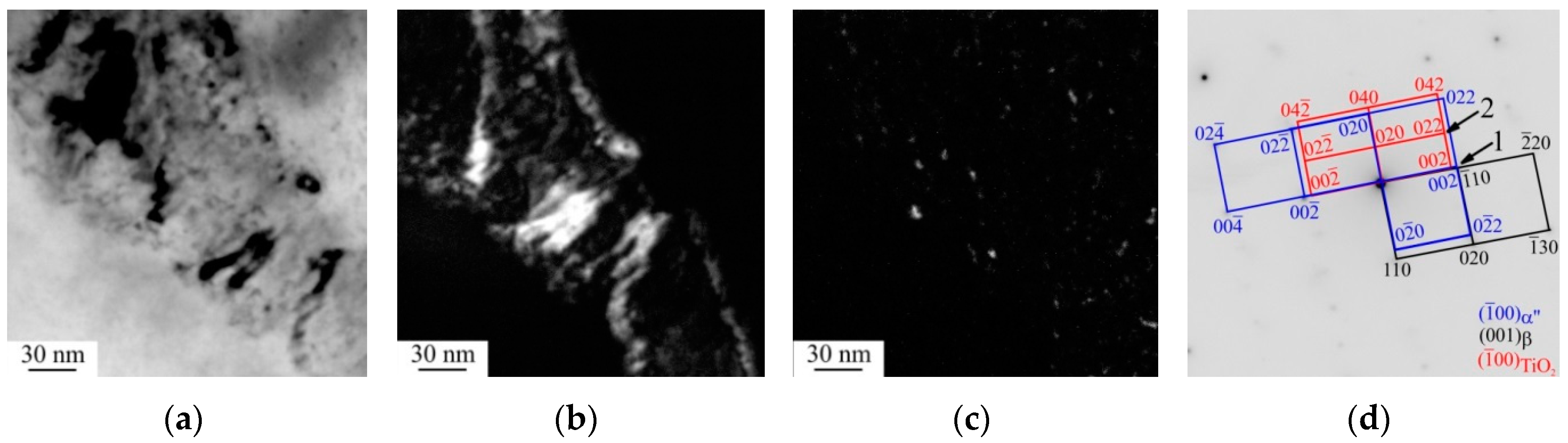

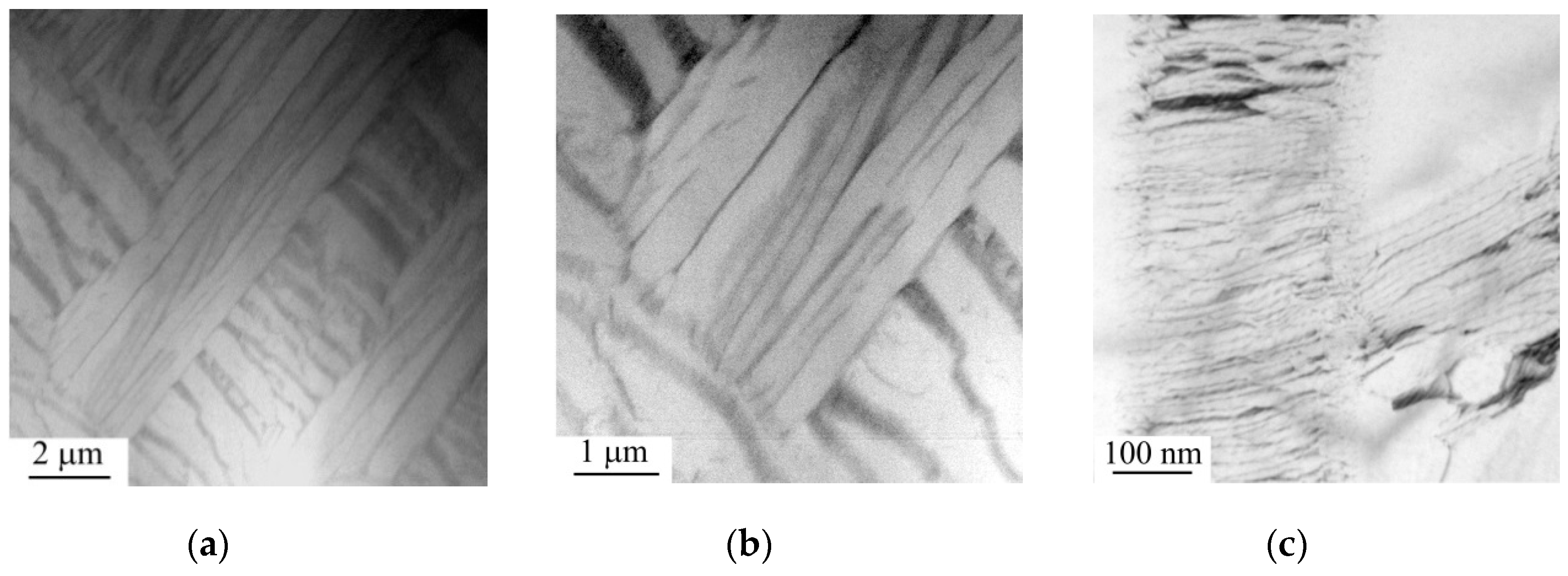

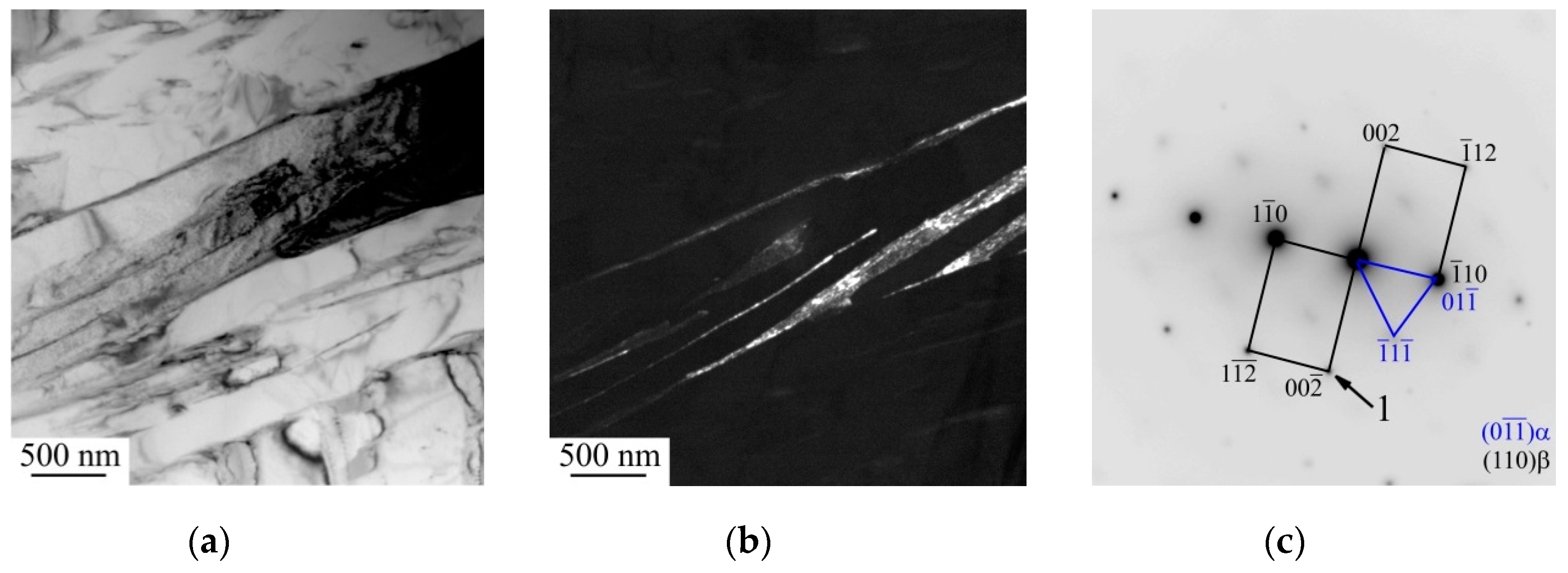

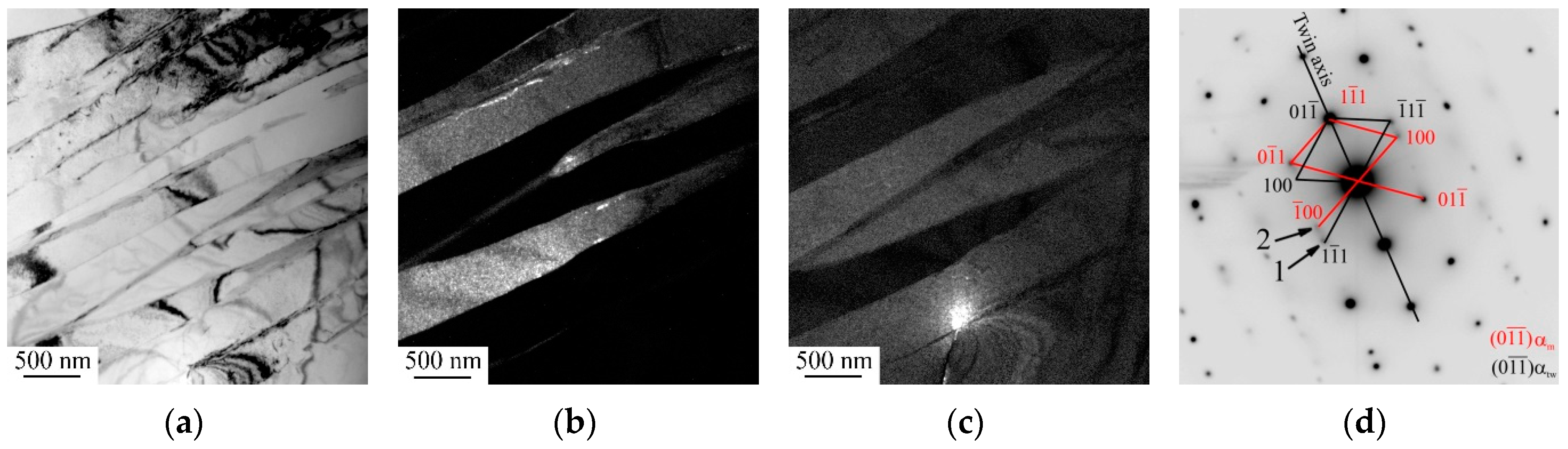

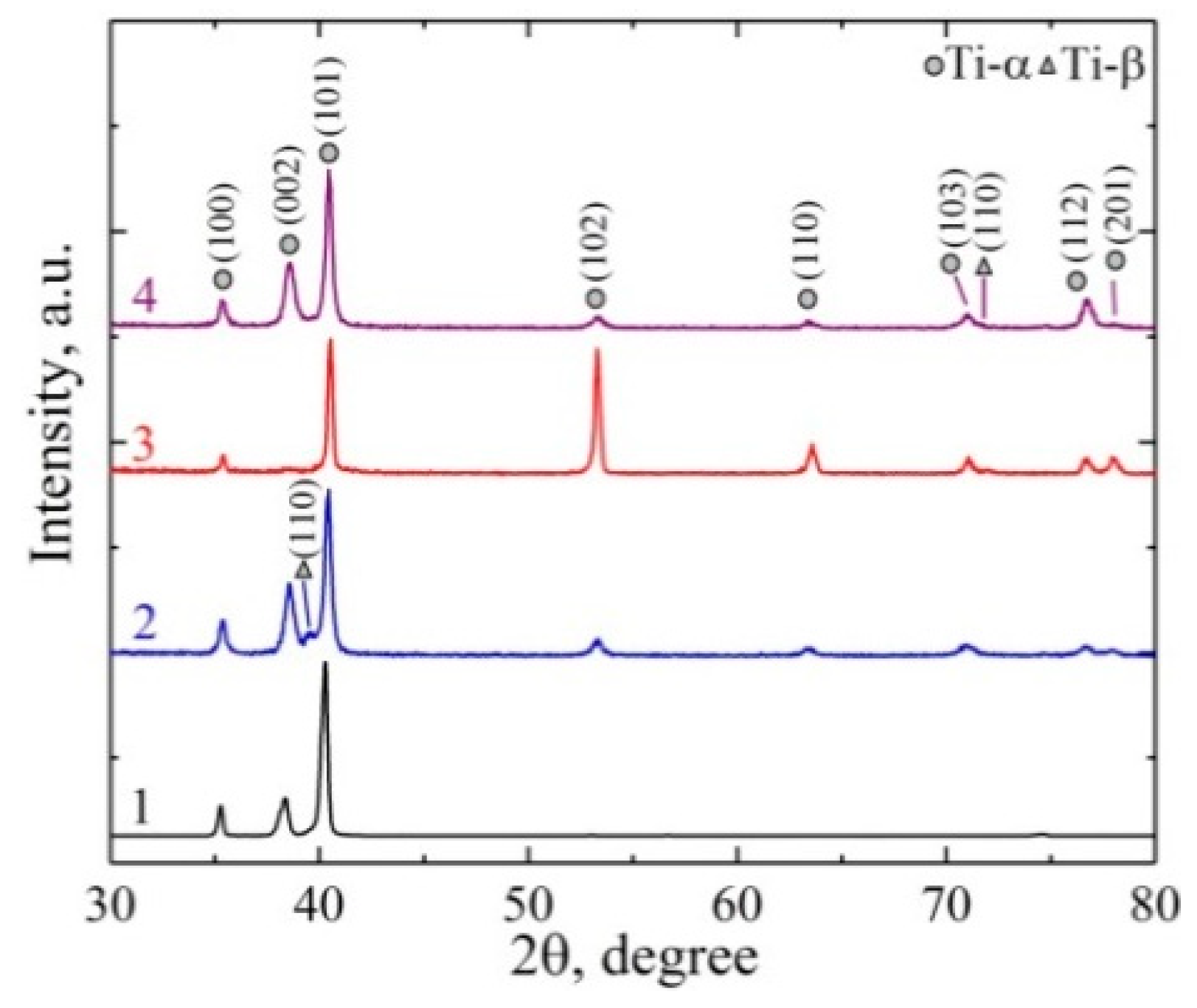

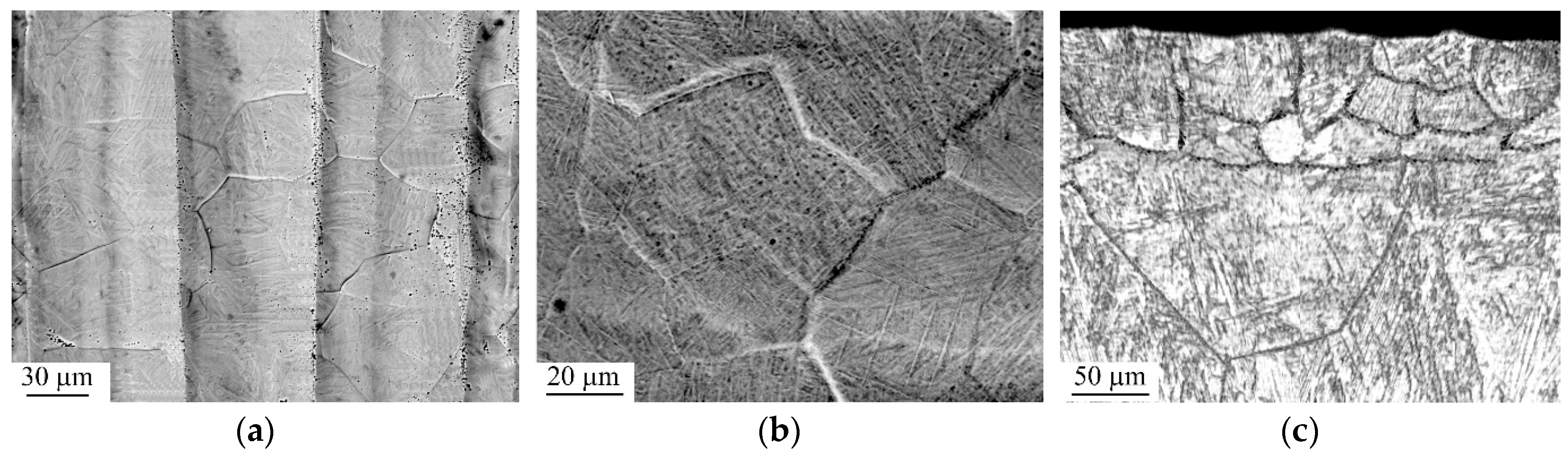

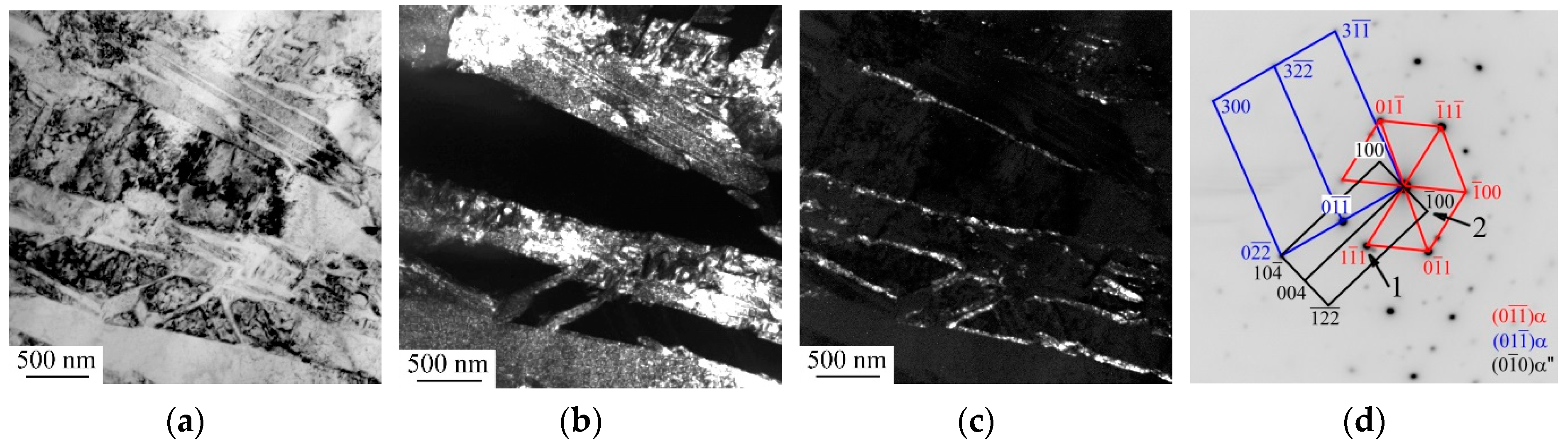

3.2. Microstructure

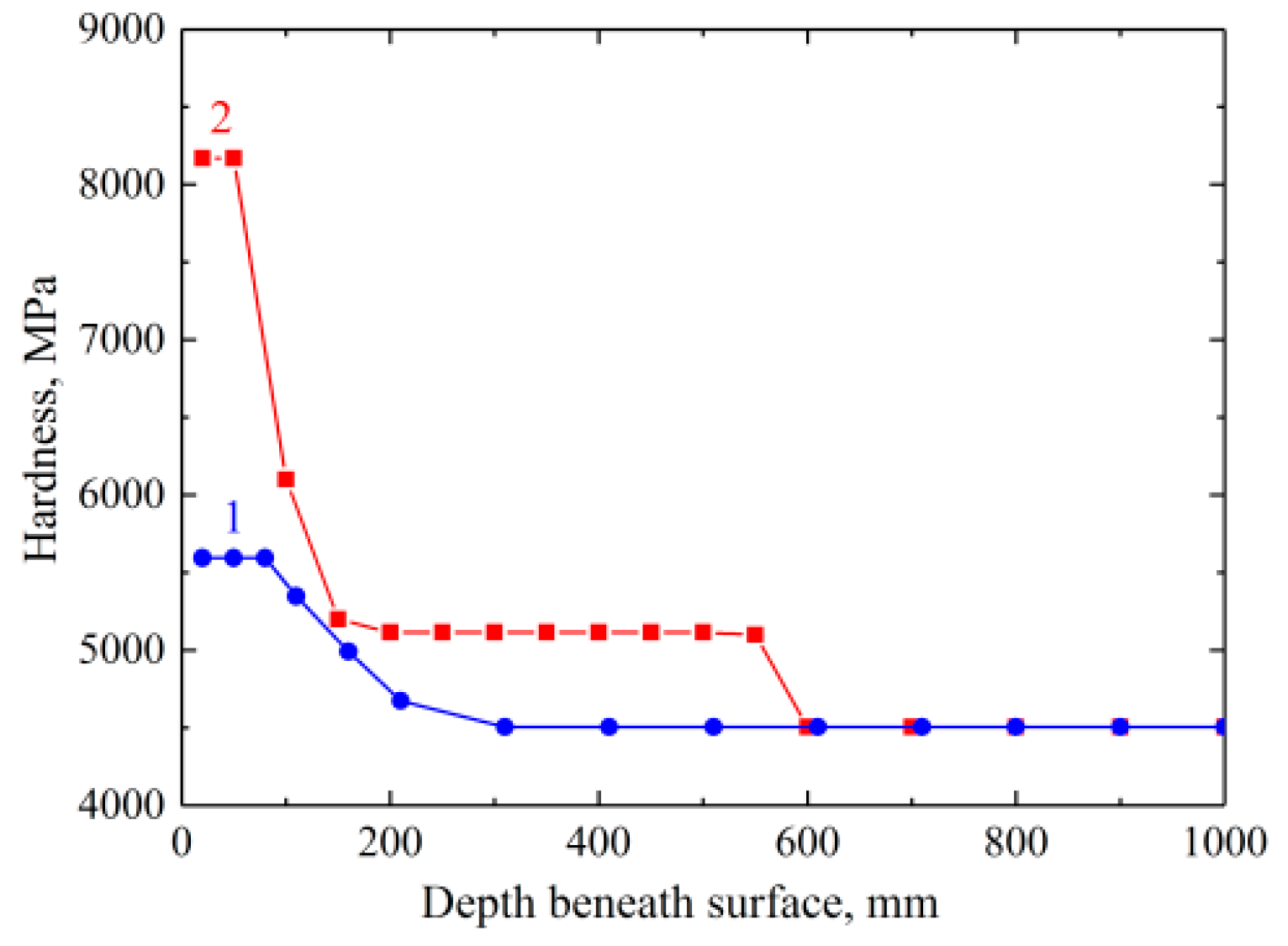

3.3. Microhardness

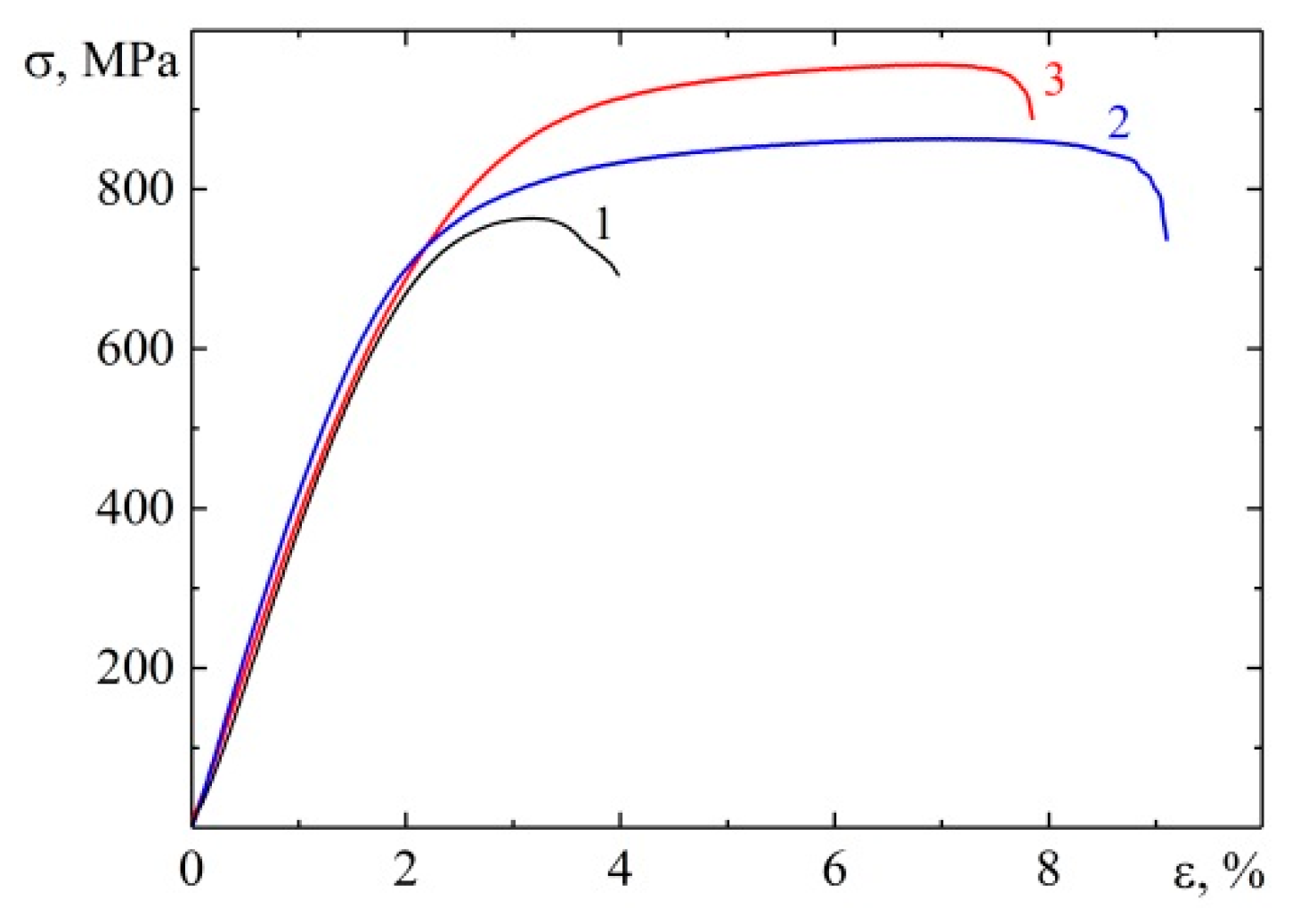

3.4. Strain Response during Tensile Test

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. Wire-feed additive manufacturing of metal components: Technologies, developments and future interests. Int. J. Adv. Manuf. Technol. 2015, 81, 465–481. [Google Scholar] [CrossRef]

- Liu, Q.; Wang, Y.; Zheng, H.; Tang, K.; Li, H.; Gong, S. Wire feeding based laser additive manufacturing TC17 titanium alloy. Mater. Technol. 2016, 31, 108–114. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Krakhmalev, P.; Yadroitsava, I. Selective laser melting of Ti6Al4V alloy for biomedical applications: Temperature monitoring and microstructural evolution. J. Alloys Compd. 2014, 583, 404–409. [Google Scholar] [CrossRef]

- Riedlbauer, D.; Scharowsky, T.; Singer, R.F.; Steinmann, P.; Körner, C.; Mergheim, J. Macroscopic simulation and experimental measurement of melt pool characteristics in selective electron beam melting of Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2017, 88, 1309–1317. [Google Scholar] [CrossRef]

- Zalameda, J.N.; Burke, E.R.; Hafley, R.A.; Taminger, K.M.; Domack, C.S.; Brewer, A.; Martin, R.E. Thermal imaging for assessment of electron-beam freeform fabrication (EBF3) additive manufacturing deposits. In Proceedings of the Thermosense: Thermal Infrared Applications XXXV.; International Society for Optics and Photonics, Baltimore, MD, USA, 30 April–2 May 2013; Volume 8705, p. 87050M. [Google Scholar]

- Hague, R.; Campbell, I.; Dickens, P. Implications on design of rapid manufacturing. Proceedings of the Institution of Mechanical Engineers, Part C. J. Mech. Eng. Sci. 2003, 217, 25–30. [Google Scholar] [CrossRef]

- Salmi, M.; Huuki, J.; Ituarte, I.F. The ultrasonic burnishing of cobalt-chrome and stainless steel surface made by additive manufacturing. Prog. Addit. Manuf. 2017, 2, 31–41. [Google Scholar] [CrossRef]

- AlMangour, B.; Yang, J.-M. Improving the surface quality and mechanical properties by shot-peening of 17-4 stainless steel fabricated by additive manufacturing. Mater. Des. 2016, 110, 914–924. [Google Scholar] [CrossRef]

- Sato, M.; Takakuwa, O.; Nakai, M.; Niinomi, M.; Takeo, F.; Soyama, H. Using Cavitation Peening to Improve the Fatigue Life of Titanium Alloy Ti-6Al-4V Manufactured by Electron Beam Melting. Mater. Sci. Appl. 2016, 7, 181. [Google Scholar] [CrossRef][Green Version]

- Kumbhar, N.N.; Mulay, A.V. Post Processing Methods used to Improve Surface Finish of Products which are Manufactured by Additive Manufacturing Technologies: A Review. J. Inst. Eng. 2018, 99, 481–487. [Google Scholar] [CrossRef]

- Farayibi, P.K.; Abioye, T.E.; Murray, J.W.; Kinnell, P.K.; Clare, A.T. Surface improvement of laser clad Ti–6Al–4V using plain waterjet and pulsed electron beam irradiation. J. Mater. Process. Technol. 2015, 218, 1–11. [Google Scholar] [CrossRef][Green Version]

- Pogrebnyak, A.D.; Proskurovskii, D.I. Modification of Metal Surface Layer Properties Using Pulsed Electron Beams. Phys. Status Solidi a 1994, 145, 9–49. [Google Scholar] [CrossRef]

- Zenker, R. Electron Beam Surface Technologies. In Encyclopedia of Tribology; Wang, Q.J., Chung, Y.-W., Eds.; Springer US: Boston, MA, USA, 2013; pp. 923–940. ISBN 978-0-387-92897-5. [Google Scholar]

- Noyan, I.C.; Cohen, J.B. Residual Stress: Measurement by Diffraction and Interpretation; Springer: Berlin/Heidelberg, Germany, 2013; ISBN 978-1-4613-9570-6. [Google Scholar]

- Agius, D.; Kourousis, K.I.; Wallbrink, C. A Review of the As-Built SLM Ti-6Al-4V Mechanical Properties towards Achieving Fatigue Resistant Designs. Metals 2018, 8, 75. [Google Scholar] [CrossRef]

- Lütjering, G.; Williams, J.C. Titanium. In Engineering Materials and Processes, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2007; ISBN 978-3-540-71397-5. [Google Scholar]

- Lütjering, G. Influence of processing on microstructure and mechanical properties of (α+β) titanium alloys. Mater. Sci. Eng. A 1998, 243, 32–45. [Google Scholar] [CrossRef]

- Rae, W.; Lomas, Z.; Jackson, M.; Rahimi, S. Measurements of residual stress and microstructural evolution in electron beam welded Ti-6Al-4V using multiple techniques. Mater. Charact. 2017, 132, 10–19. [Google Scholar] [CrossRef]

- Vilaro, T.; Colin, C.; Bartout, J.D. As-Fabricated and Heat-Treated Microstructures of the Ti-6Al-4V Alloy Processed by Selective Laser Melting. Metall. Mater. Trans. A 2011, 42, 3190–3199. [Google Scholar] [CrossRef]

- de Formanoir, C.; Martin, G.; Prima, F.; Allain, S.Y.P.; Dessolier, T.; Sun, F.; Vivès, S.; Hary, B.; Bréchet, Y.; Godet, S. Micromechanical behavior and thermal stability of a dual-phase α+α′ titanium alloy produced by additive manufacturing. Acta Mater. 2019, 162, 149–162. [Google Scholar] [CrossRef]

- Pushilina, N.; Panin, A.; Syrtanov, M.; Kashkarov, E.; Kudiiarov, V.; Perevalova, O.; Laptev, R.; Lider, A.; Koptyug, A. Hydrogen-Induced Phase Transformation and Microstructure Evolution for Ti-6Al-4V Parts Produced by Electron Beam Melting. Metals 2018, 8, 301. [Google Scholar] [CrossRef]

- Kazantseva, N.; Krakhmalev, P.; Thuvander, M.; Yadroitsev, I.; Vinogradova, N.; Ezhov, I. Martensitic transformations in Ti-6Al-4V (ELI) alloy manufactured by 3D Printing. Mater. Charact. 2018, 146, 101–112. [Google Scholar] [CrossRef]

- Landau, P.; Venkert, A.; Rittel, D. Microstructural Aspects of Adiabatic Shear Failure in Annealed Ti6Al4V. Metall. Mater. Trans. A 2009, 41, 389. [Google Scholar] [CrossRef]

- Wang, L.; Lu, W.; Qin, J.; Zhang, F.; Zhang, D. Texture and superelastic behavior of cold-rolled TiNbTaZr alloy. Mater. Sci. Eng. A 2008, 491, 372–377. [Google Scholar] [CrossRef]

- Sadeghpour, S.; Abbasi, S.M.; Morakabati, M. Deformation-induced martensitic transformation in a new metastable β titanium alloy. J. Alloys Compd. 2015, 650, 22–29. [Google Scholar] [CrossRef]

- Yang, J.; Yu, H.; Yin, J.; Gao, M.; Wang, Z.; Zeng, X. Formation and control of martensite in Ti-6Al-4V alloy produced by selective laser melting. Mater. Des. 2016, 108, 308–318. [Google Scholar] [CrossRef]

- Edwardson, S.P.; Griffiths, J.; Dearden, G.; Watkins, K.G. Temperature gradient mechanism: Overview of the multiple pass controlling factors. Phys. Procedia 2010, 5, 53–63. [Google Scholar] [CrossRef]

- Shiomi, M.; Osakada, K.; Nakamura, K.; Yamashita, T.; Abe, F. Residual Stress within Metallic Model Made by Selective Laser Melting Process. CIRP Ann. 2004, 53, 195–198. [Google Scholar] [CrossRef]

- Li, C.; Liu, Z.Y.; Fang, X.Y.; Guo, Y.B. Residual Stress in Metal Additive Manufacturing. Procedia CIRP 2018, 71, 348–353. [Google Scholar] [CrossRef]

- Buchbinder, D.; Meiners, W.; Pirch, N.; Wissenbach, K.; Schrage, J. Investigation on reducing distortion by preheating during manufacture of aluminum components using selective laser melting. J. Laser Appl. 2013, 26, 012004. [Google Scholar] [CrossRef]

- Ali, H.; Ma, L.; Ghadbeigi, H.; Mumtaz, K. In-situ residual stress reduction, martensitic decomposition and mechanical properties enhancement through high temperature powder bed pre-heating of Selective Laser Melted Ti6Al4V. Mater. Sci. Eng. A 2017, 695, 211–220. [Google Scholar] [CrossRef]

- Zhang, X.D.; Zou, J.X.; Weber, S.; Hao, S.Z.; Dong, C.; Grosdidier, T. Microstructure and property modifications in a near α Ti alloy induced by pulsed electron beam surface treatment. Surf. Coat. Technol. 2011, 206, 295–304. [Google Scholar] [CrossRef]

- Zenker, R. Structure and Properties as a Result of Electron Beam Surface Treatment. Adv. Eng. Mater. 2004, 6, 581–588. [Google Scholar] [CrossRef]

- Fu, Y.; Hu, J.; Shen, X.; Wang, Y.; Zhao, W. Surface hardening of 30CrMnSiA steel using continuous electron beam. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2017, 410, 207–214. [Google Scholar] [CrossRef]

- Rotshtein, V.P.; Proskurovsky, D.I.; Ozur, G.E.; Ivanov, Y.F.; Markov, A.B. Surface modification and alloying of metallic materials with low-energy high-current electron beams. Surf. Coat. Technol. 2004, 180–181, 377–381. [Google Scholar] [CrossRef]

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Wu, S.Q.; Lu, Y.J.; Gan, Y.L.; Huang, T.T.; Zhao, C.Q.; Lin, J.J.; Guo, S.; Lin, J.X. Microstructural evolution and microhardness of a selective-laser-melted Ti–6Al–4V alloy after post heat treatments. J. Alloys Compd. 2016, 672, 643–652. [Google Scholar] [CrossRef]

- Puebla, K.; Murr, L.E.; Gaytan, S.M.; Martinez, E.; Medina, F.; Wicker, R.B. Effect of Melt Scan Rate on Microstructure and Macrostructure for Electron Beam Melting of Ti-6Al-4V. Mater. Sci. Appl. 2012, 03, 259. [Google Scholar] [CrossRef]

- Committee, A.I.H. Properties and Selection: Nonferrous Alloys and Special-Purpose Materials; ASM International: Novelty, OH, USA, 1990; ISBN 978-0-87170-378-1. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Panin, A.; Kazachenok, M.; Perevalova, O.; Martynov, S.; Panina, A.; Sklyarova, E. Continuous Electron Beam Post-Treatment of EBF3-Fabricated Ti–6Al–4V Parts. Metals 2019, 9, 699. https://doi.org/10.3390/met9060699

Panin A, Kazachenok M, Perevalova O, Martynov S, Panina A, Sklyarova E. Continuous Electron Beam Post-Treatment of EBF3-Fabricated Ti–6Al–4V Parts. Metals. 2019; 9(6):699. https://doi.org/10.3390/met9060699

Chicago/Turabian StylePanin, Alexey, Marina Kazachenok, Olga Perevalova, Sergey Martynov, Alexandra Panina, and Elena Sklyarova. 2019. "Continuous Electron Beam Post-Treatment of EBF3-Fabricated Ti–6Al–4V Parts" Metals 9, no. 6: 699. https://doi.org/10.3390/met9060699

APA StylePanin, A., Kazachenok, M., Perevalova, O., Martynov, S., Panina, A., & Sklyarova, E. (2019). Continuous Electron Beam Post-Treatment of EBF3-Fabricated Ti–6Al–4V Parts. Metals, 9(6), 699. https://doi.org/10.3390/met9060699