Mixing Phenomenon and Flow Field in Ladle of RH Process

Abstract

1. Introduction

2. Experiments

2.1. Similarity Principle

2.1.1. Geometric Similarity

2.1.2. Dynamic Similarity

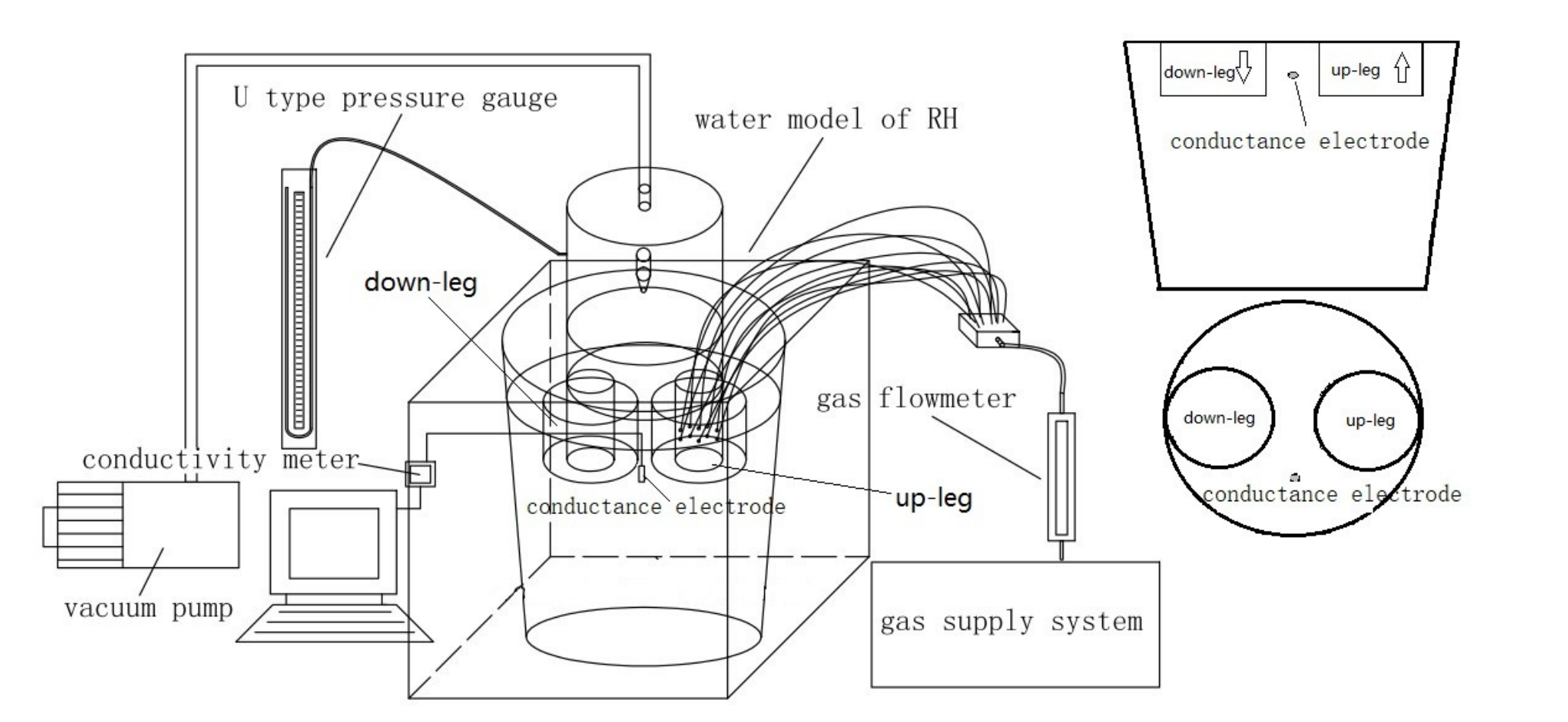

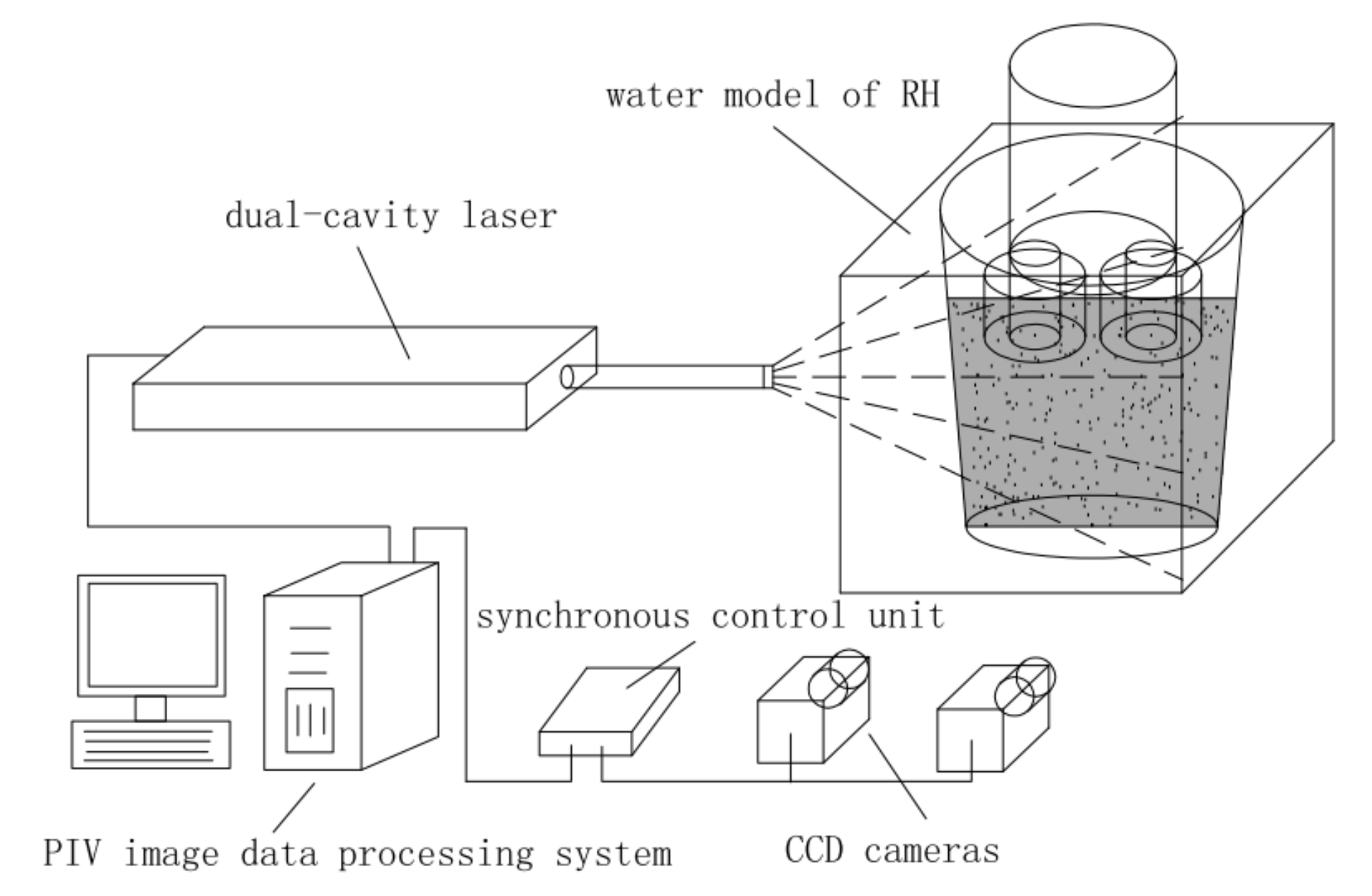

2.2. Experimental Apparatus and Method

2.2.1. Experiment of Mixing

2.2.2. PIV System

3. Results

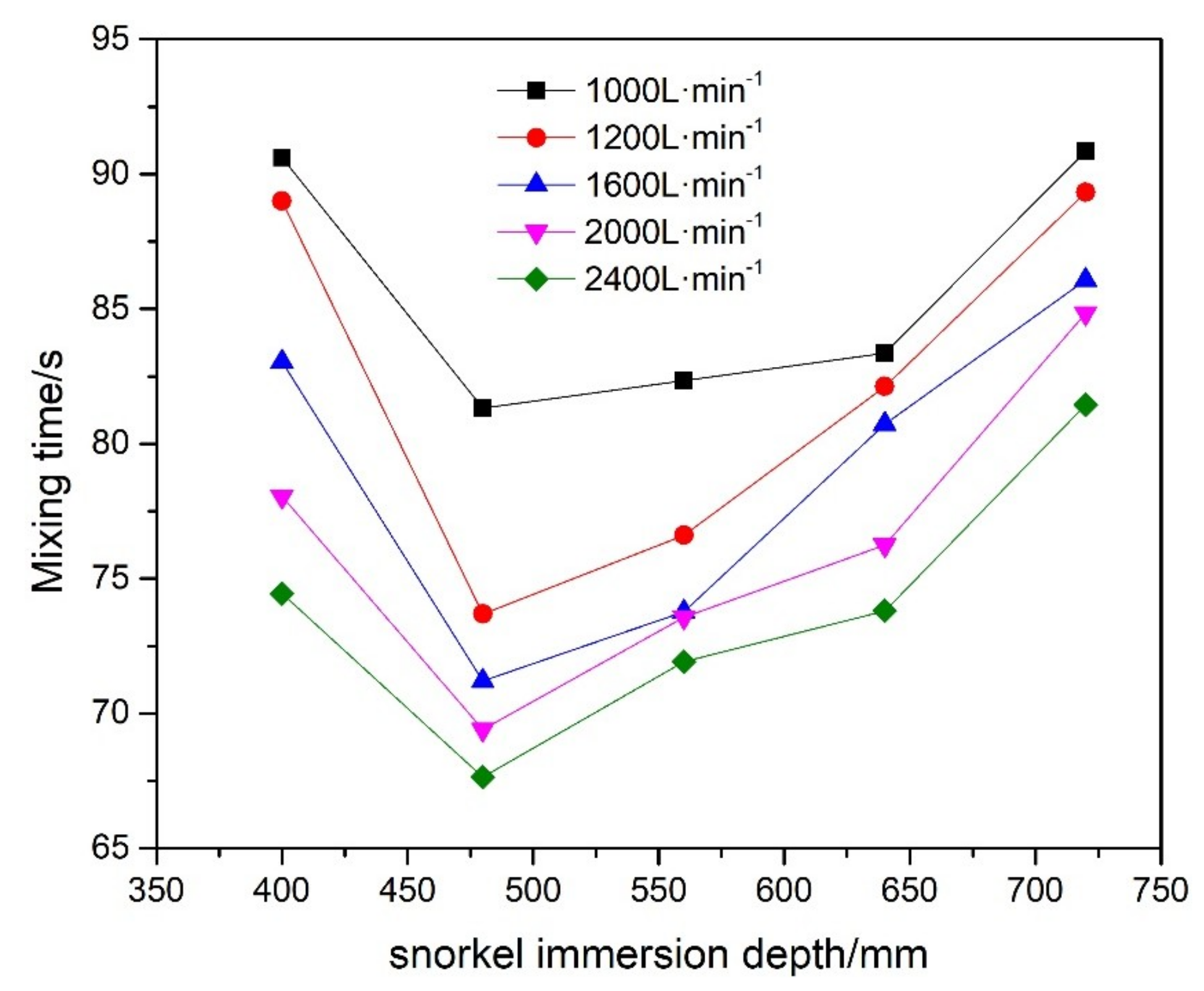

3.1. Effect of Gas Flow Rate and Snorkel Immersion Depth on Mixing Time

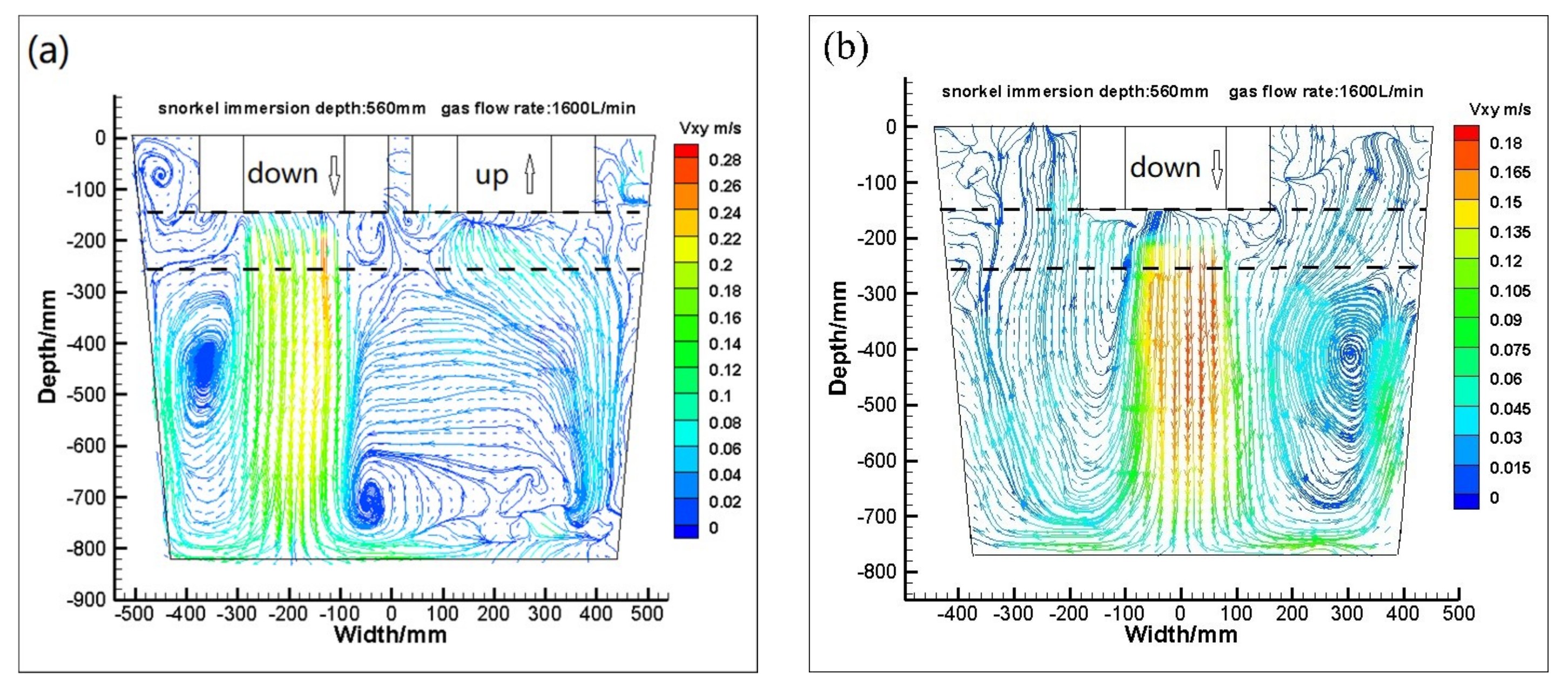

3.2. Characteristics of RH Ladle Flow Field

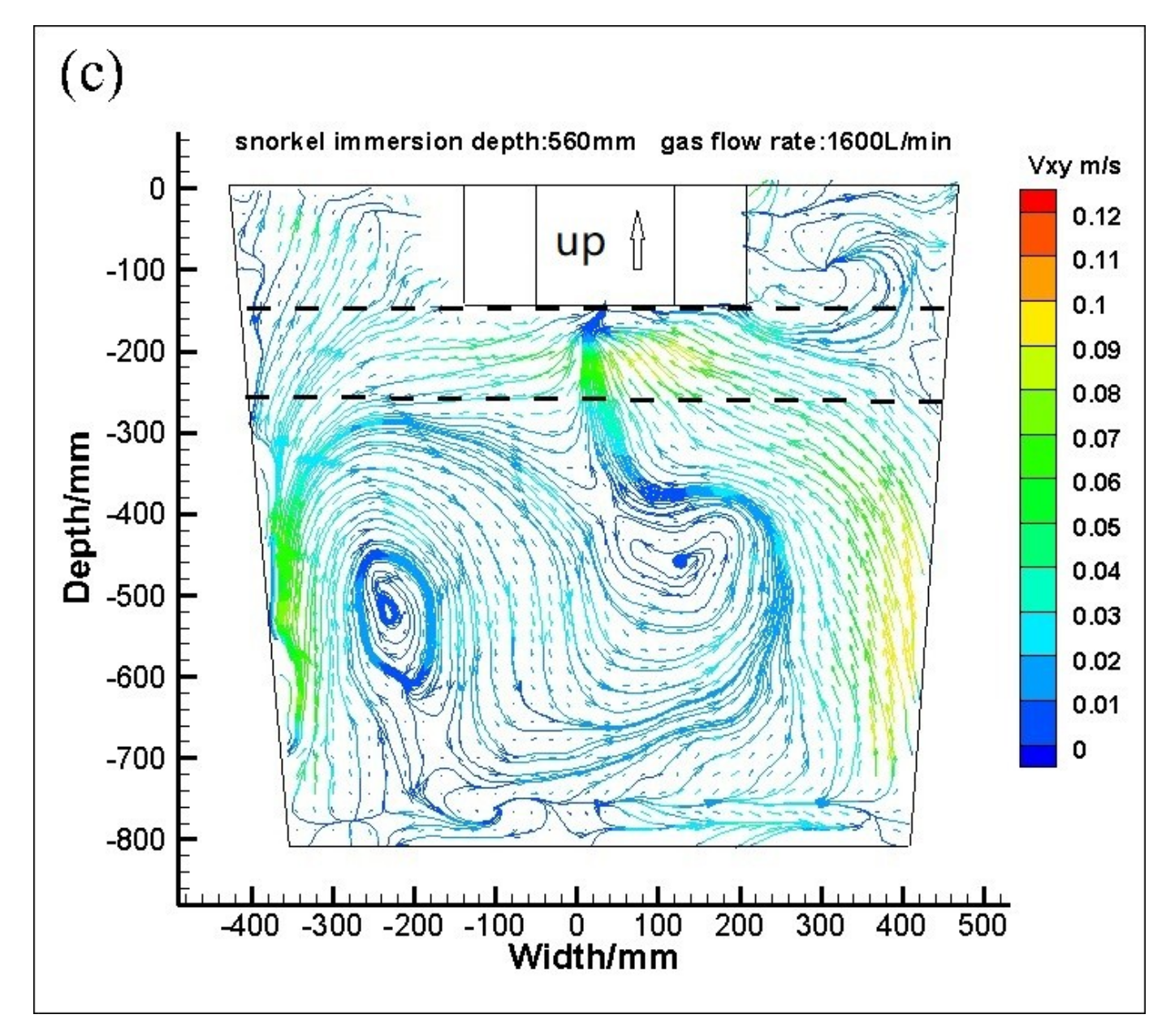

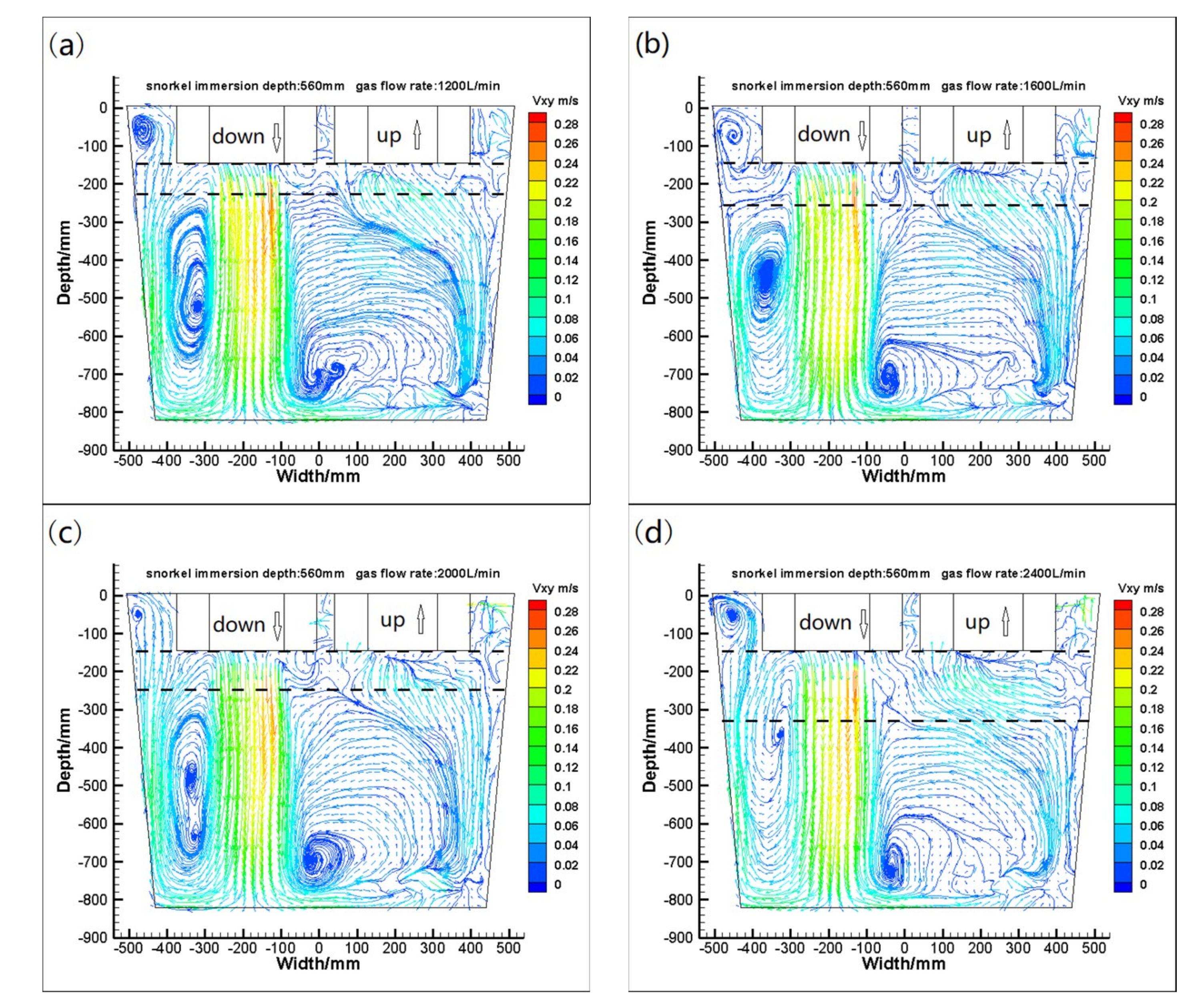

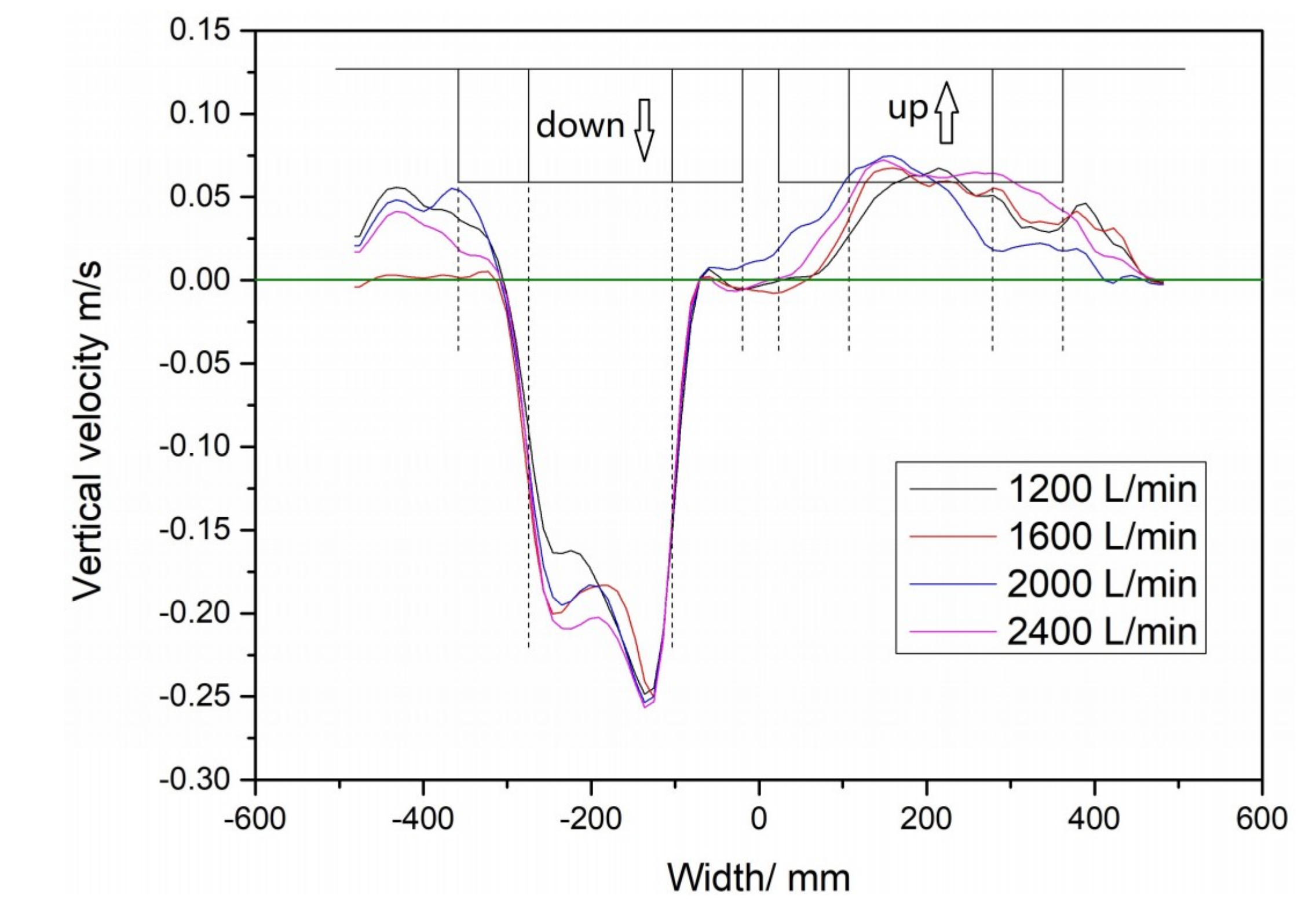

3.3. RH Ladle Flow Field under Different Gas Flow Rate

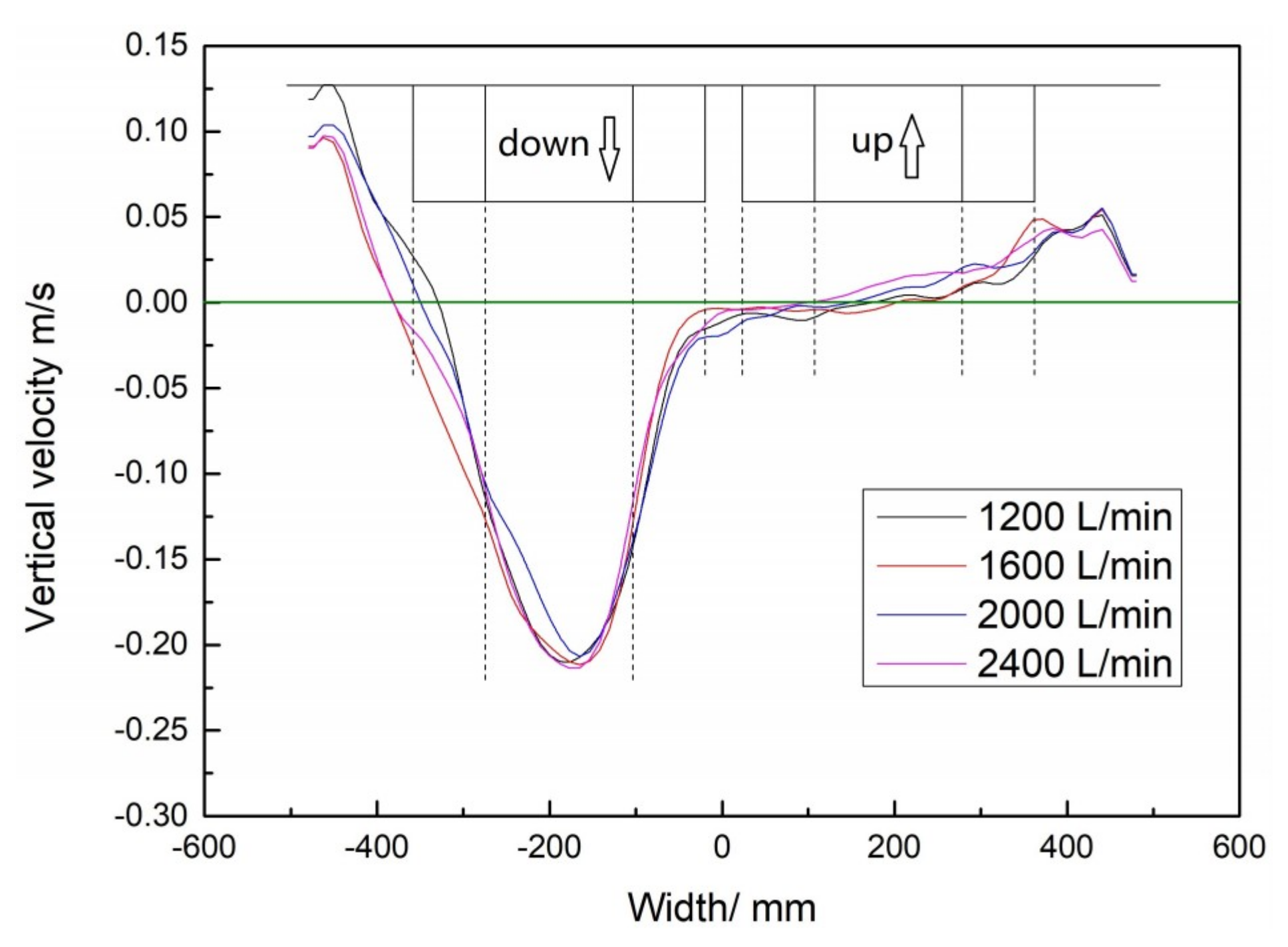

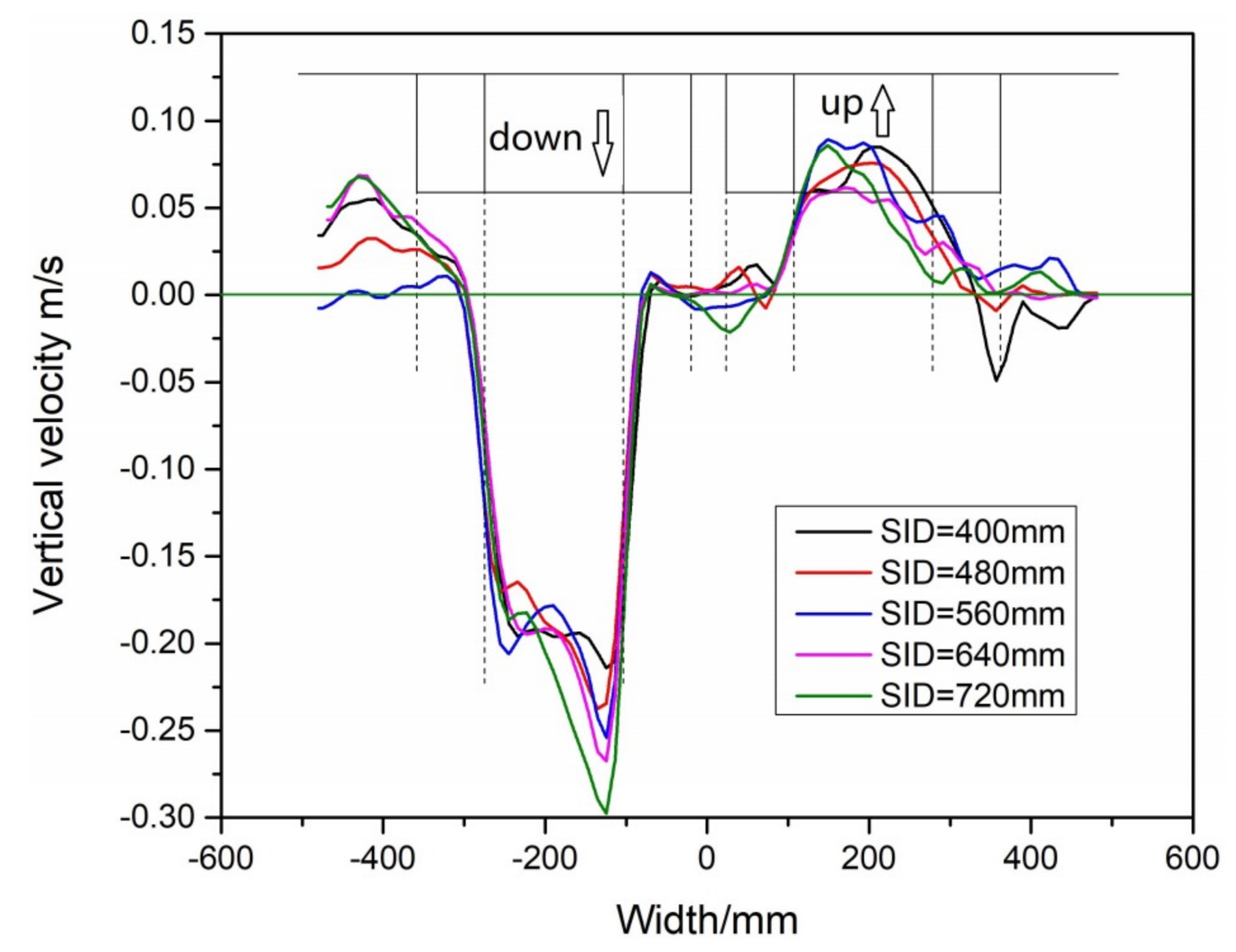

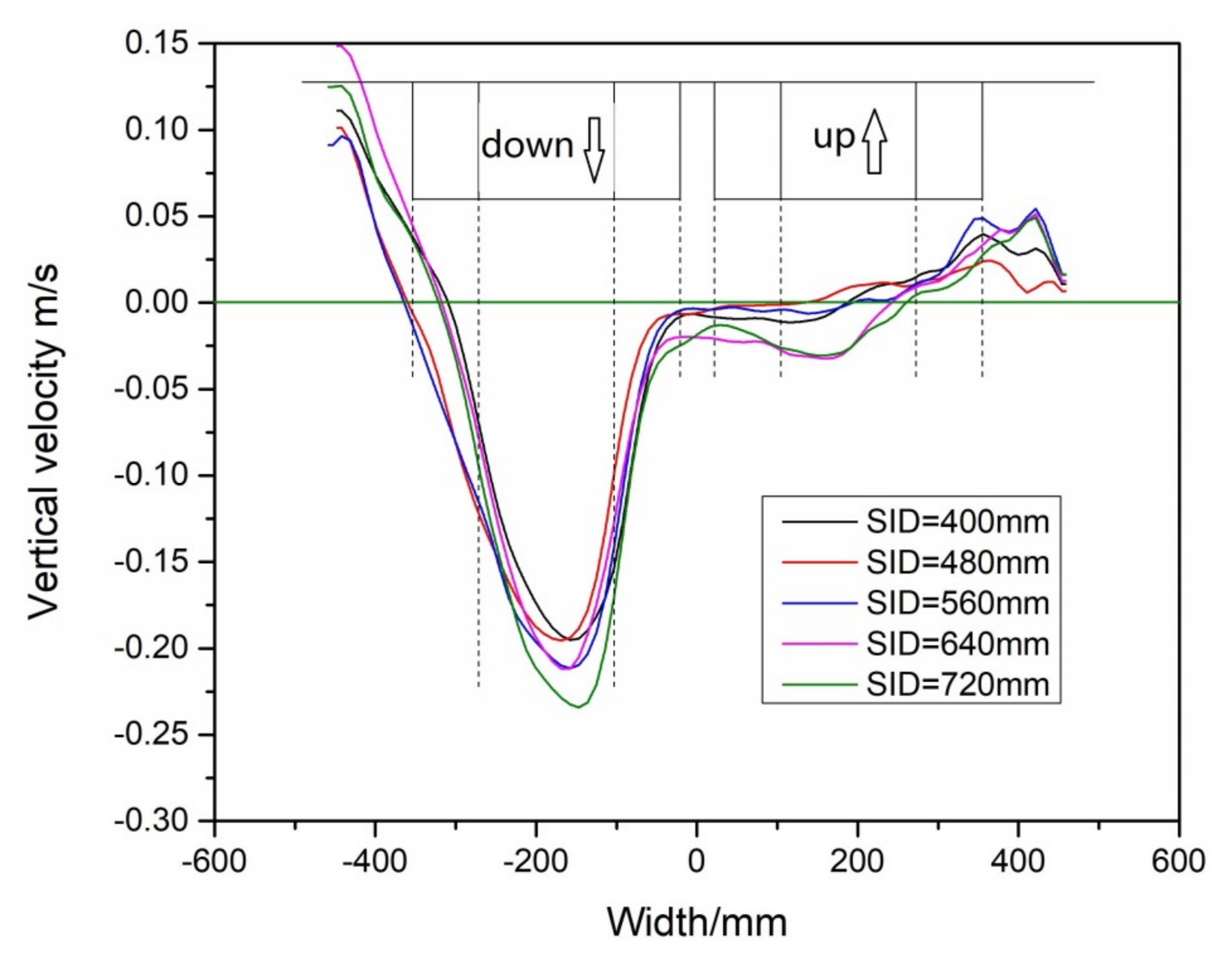

3.4. RH Ladle Flow Field under Different SIDs

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ajmani, S.K.; Dash, S.K.; Chandra, S.; Bhanu, C. Mixing evaluation in the RH process using mathematical modelling. ISIJ Int. 2004, 44, 82–89. [Google Scholar]

- Yamaguchi, K.; Kishimoto, Y.; Sakuraya, T.; Fujii, T.; Aratani, M.; Nishikawa, H. Effect of fefining conditions for ultra low carbon steel on decarburization reaction in RH degasser. ISIJ Int. 1992, 32, 126–135. [Google Scholar]

- Geng, D.Q.; Lei, H.; He, J.C. Effect of traveling magnetic field on flow, mixing, decarburization and inclusion removal during RH refining process. ISIJ Int. 2012, 52, 1036–1044. [Google Scholar] [CrossRef]

- Kato, Y.; Nakato, H.; Fujii, T.; Ohmiya, S.; Takatori, S. Fluid flow in ladle and its effects on decarburization rate in RH degasser. ISIJ Int. 1993, 33, 1088–1094. [Google Scholar]

- Ai, X.G.; Bao, Y.P.; Jiang, W.; Liu, J.H.; Li, P.H.; Li, T.Q. Periodic flow characteristics during RH vacuum circulation refining. Int. J. Miner. Metall. Mater. 2010, 17, 17–21. [Google Scholar] [CrossRef]

- Mukherjee, D.; Shukla, A.K.; Senk, D.G. Cold Model-Based Investigations to Study the Effects of Operational and Nonoperational Parameters on the Ruhrstahl–Heraeus Degassing Process. MMTB 2017, 48, 763–771. [Google Scholar] [CrossRef]

- Lin, L.; Bao, Y.P.; Yue, F.; Zhang, L.Q.; Qu, H.L. Physical model of fluid characteristics in RH-TOP vacuum refining process. Int. J. Miner. Metall. Mater. 2012, 19, 483–489. [Google Scholar] [CrossRef]

- Nakanishi, K.; Szekely, J.; Chang, C. Experiments and theoretical investigation of mixing phenomena in the RH-vacuum process. Ironmak. Steelmak. 1975, 2, 115–124. [Google Scholar]

- Zhang, L.F.; LI, F. Investigation on the fluid flow and Mixing phenomena in a Ruhrstahl-Hereaus (RH) steel degasser using physical modeling. JOM 2014, 66, 1227–1240. [Google Scholar] [CrossRef]

- Niu, D.L.; Ma, D.G.; Yang, J.; Xu, M.R.; Wang, Z. Characteristics of the dead zones in RH desgasser with simulation methods. Mater. Sci. Forum 2015, 817, 755–763. [Google Scholar] [CrossRef]

- Chen, G.J.; He, S.P. Mixing behavior in the RH degasser with bottom gas injection. Vacuum 2016, 130, 48–55. [Google Scholar] [CrossRef]

- Kishan, P.A.; Dash, S.K. Mixing time in RH ladle with upleg size and immersion depth: A new correlation. ISIJ Int. 2007, 47, 1549–1551. [Google Scholar] [CrossRef][Green Version]

- Zhu, B.H.; Chattopadhyay, K.; Hu, X.P.; Zhang, B.; Liu, Q.C. Optimization of sampling location in the ladle during RH vacuum refining process. Vacuum 2018, 152, 30–39. [Google Scholar] [CrossRef]

- Li, F.; Zhang, L.F.; Liu, Y.; Li, Y.L. Study of Mixing Phenomena during RH Refining Using Water Modeling. TMS (The Minerals, Metals & Materials Society) 2014, 57, 459–466. [Google Scholar]

- Ling, H.T.; Guo, C.B.; Conejo, A.N.; Li, F.; Zhang, L.F. Effect of snorkel shape and number of nozzles on mixing phenomena in the RH process by physical modeling. Metall. Res. Technol. 2017, 114, 111–123. [Google Scholar] [CrossRef]

- Pieprzyca, J.; Merder, T.; Saternus, M.; Michalek, K. Physical modelling of the steel flow in RH apparatus. Arch. Metall. Mater. 2015, 60, 1861–1864. [Google Scholar] [CrossRef]

- He, S.; Chen, G.; Guo, C. Investigation of mixing and slag layer behaviours in the RH degasser with bottom gas injection by using the VOF–DPM coupled model. Ironmak. Steelmak. 2017, 44, 1–6. [Google Scholar] [CrossRef]

- Geng, D.Q.; Lei, H.; He, J.C. Numerical simulation of the multiphase flow in the Rheinsahl-Heraeus (RH) system. MMTB 2009, 41, 234–247. [Google Scholar] [CrossRef]

- Tsujino, R.; Nakashima, J.; Hirai, M.; Sawada, I. Numerical analysis of molten steel flow in ladle of RH process. ISIJ Int. 1989, 29, 589–595. [Google Scholar]

- Liu, C.; Duan, H.J.; Zhang, L.F. Modeling of the melting of aluminum particles during the RH refining process. Metals 2019, 9, 442. [Google Scholar] [CrossRef]

| Main Parameters | Ladle/mm | Vacuum Chamber/mm | Snorkels/mm | |||||

|---|---|---|---|---|---|---|---|---|

| Upper Internal Diameter | Lower Internal Diameter | Height | Liquid Level | Internal Diameter | External Diameter | Internal Diameter | Length | |

| Prototype | 3884 | 3222 | 4060 | 3300 | 2138 | 1294 | 650 | 1075 |

| Model | 971 | 805.5 | 1015 | 825 | 534.5 | 323.5 | 162.5 | 268.75 |

| SID (mm) | Outlet Pressure (Pa) | Gas Flow Rate (L/min) | K | |||

|---|---|---|---|---|---|---|

| Prototype | Model | Prototype | Model | Prototype | Model | |

| 400 | 100 | 92,407 | 101,006.5 | 1000 | 36.67 | 0.03667 |

| 480 | 120 | 97,895 | 101,202.5 | 1200 | 42.79 | 0.03566 |

| 560 | 140 | 103,383 | 101,398.5 | 1600 | 55.57 | 0.03473 |

| 640 | 160 | 108,871 | 101,594.5 | 2000 | 67.76 | 0.03388 |

| 720 | 180 | 114,359 | 101,790.5 | 2400 | 79.42 | 0.03309 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, K.; Cui, H.; Wang, R.; Liu, Y. Mixing Phenomenon and Flow Field in Ladle of RH Process. Metals 2019, 9, 886. https://doi.org/10.3390/met9080886

Zhang K, Cui H, Wang R, Liu Y. Mixing Phenomenon and Flow Field in Ladle of RH Process. Metals. 2019; 9(8):886. https://doi.org/10.3390/met9080886

Chicago/Turabian StyleZhang, Kaitian, Heng Cui, Rudong Wang, and Yang Liu. 2019. "Mixing Phenomenon and Flow Field in Ladle of RH Process" Metals 9, no. 8: 886. https://doi.org/10.3390/met9080886

APA StyleZhang, K., Cui, H., Wang, R., & Liu, Y. (2019). Mixing Phenomenon and Flow Field in Ladle of RH Process. Metals, 9(8), 886. https://doi.org/10.3390/met9080886