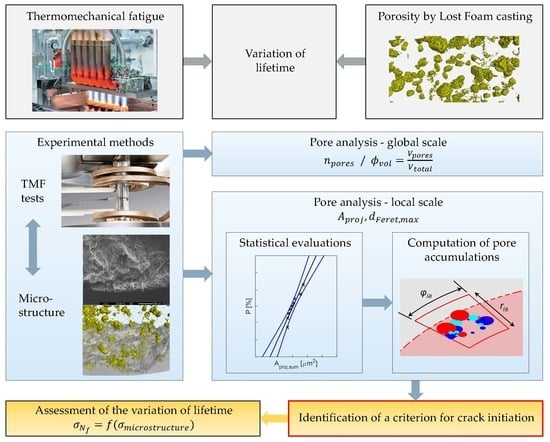

Thermomechanical Fatigue of Lost Foam Cast Al–Si Cylinder Heads—Assessment of Crack Origin Based on the Evaluation of Pore Distribution

Abstract

1. Introduction

2. Materials and Methods

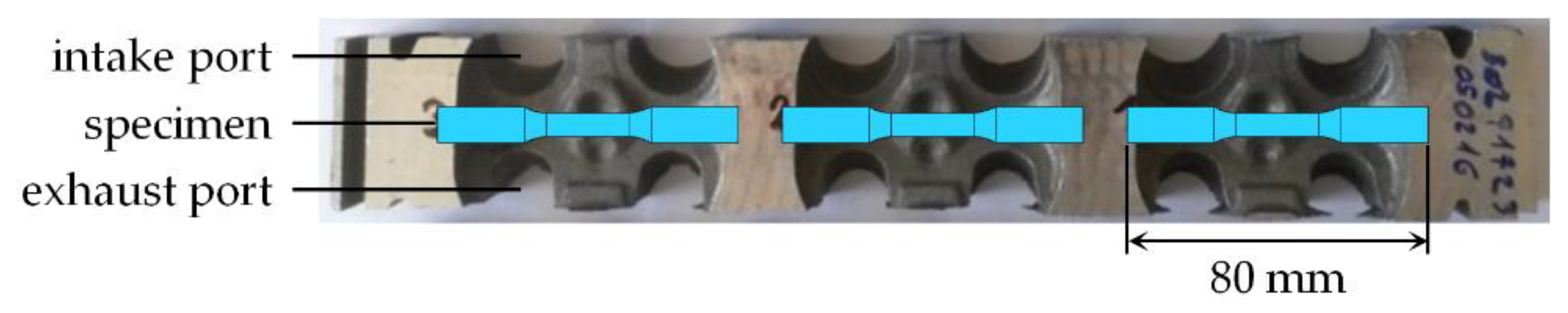

2.1. Material

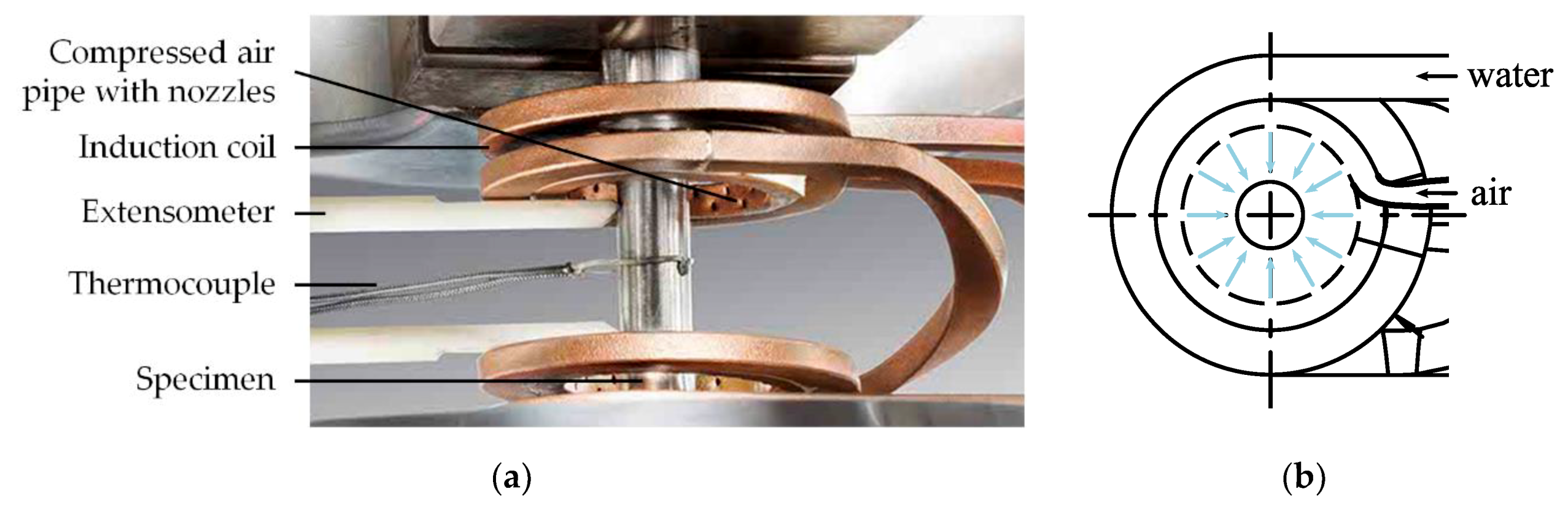

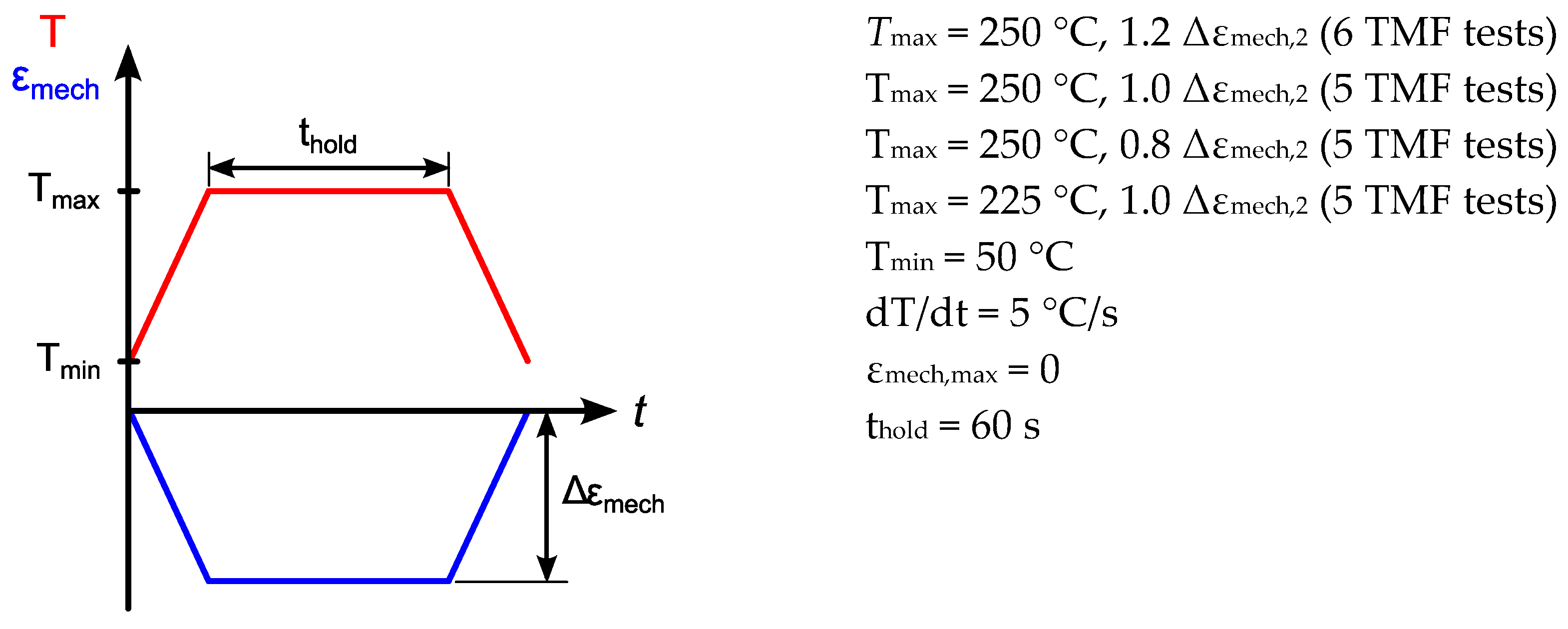

2.2. TMF Tests

2.3. Microstructure Analyses

3. Experimental Results

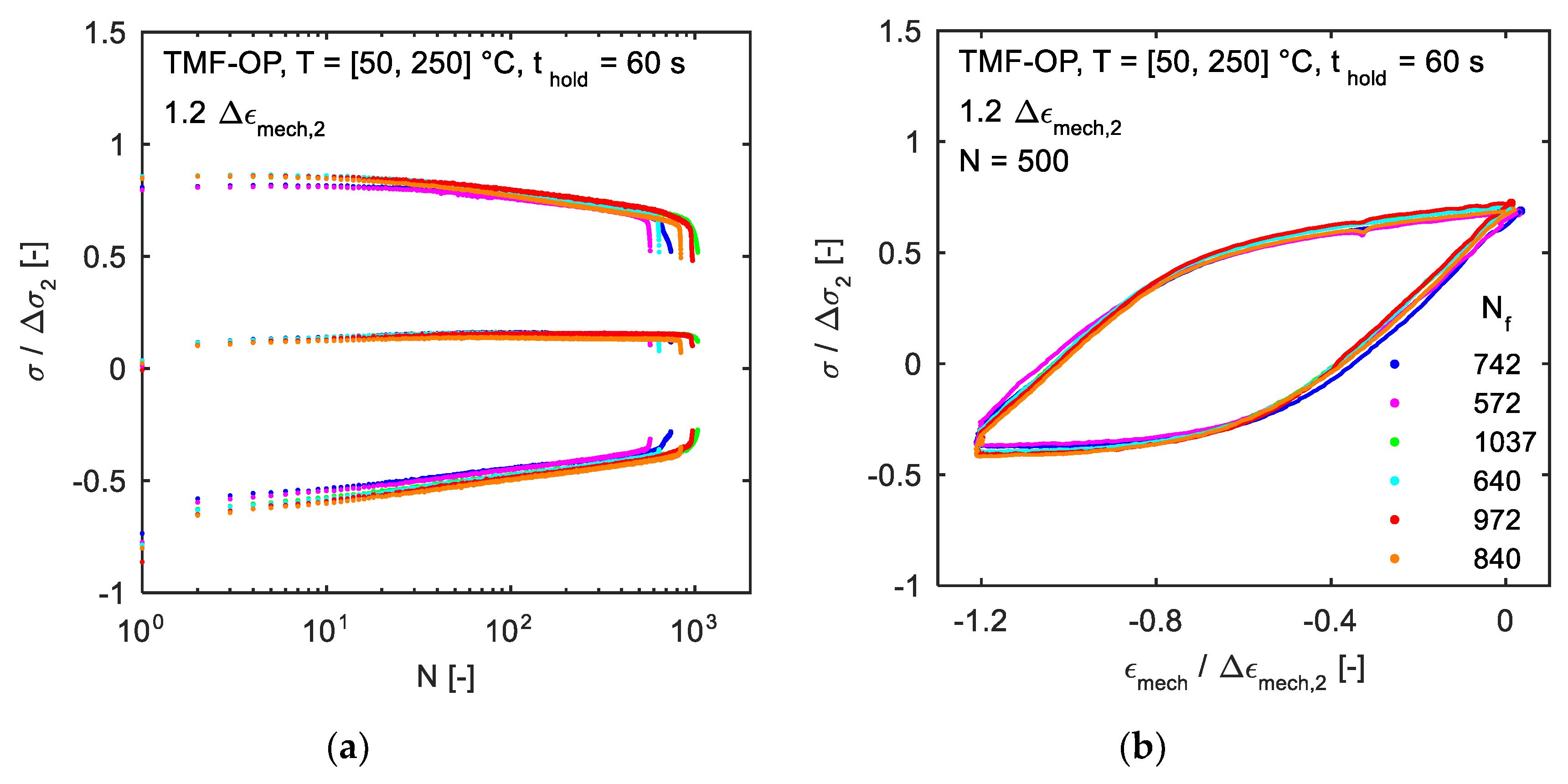

3.1. TMF Tests

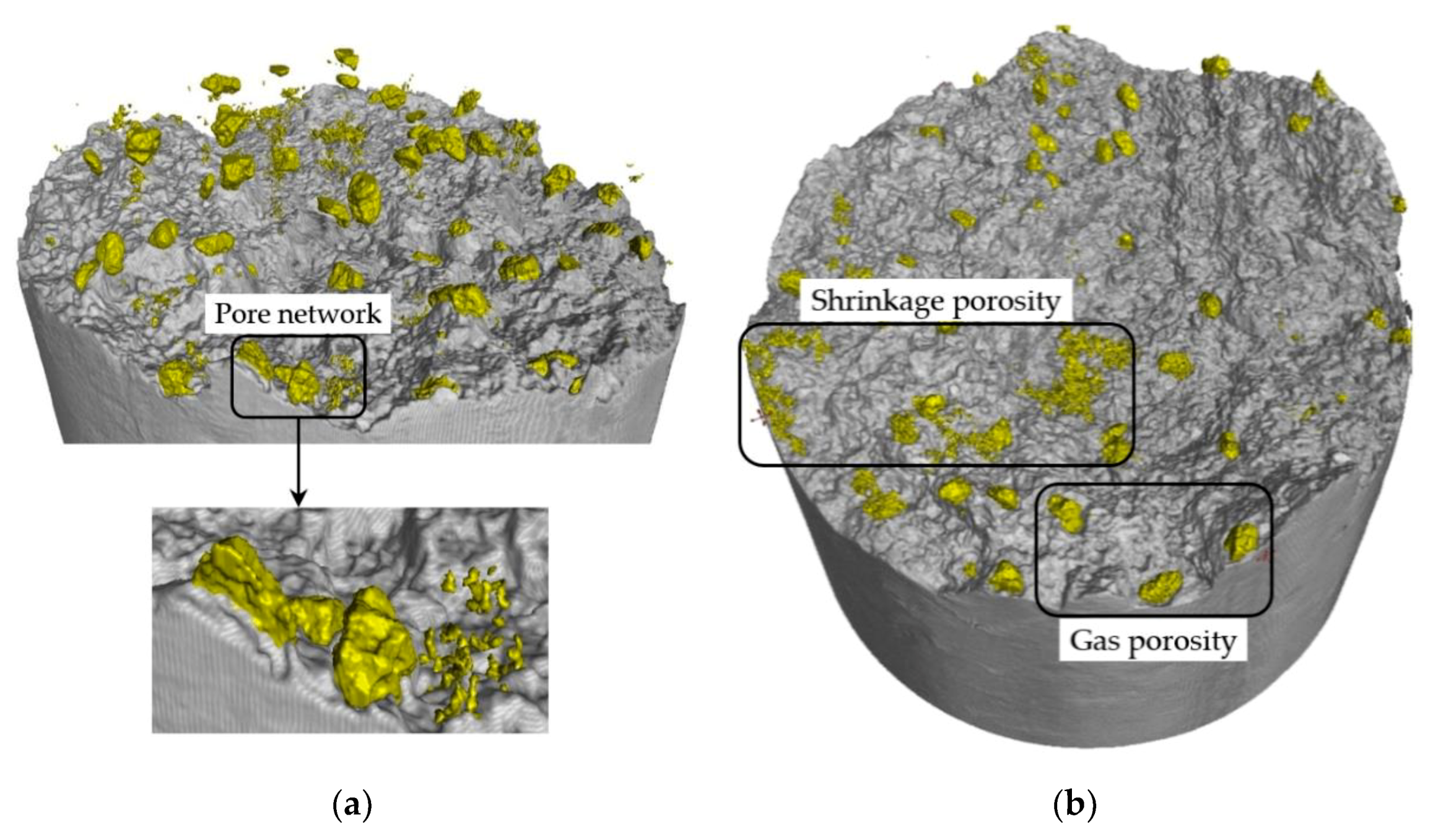

3.2. Microstructure Results

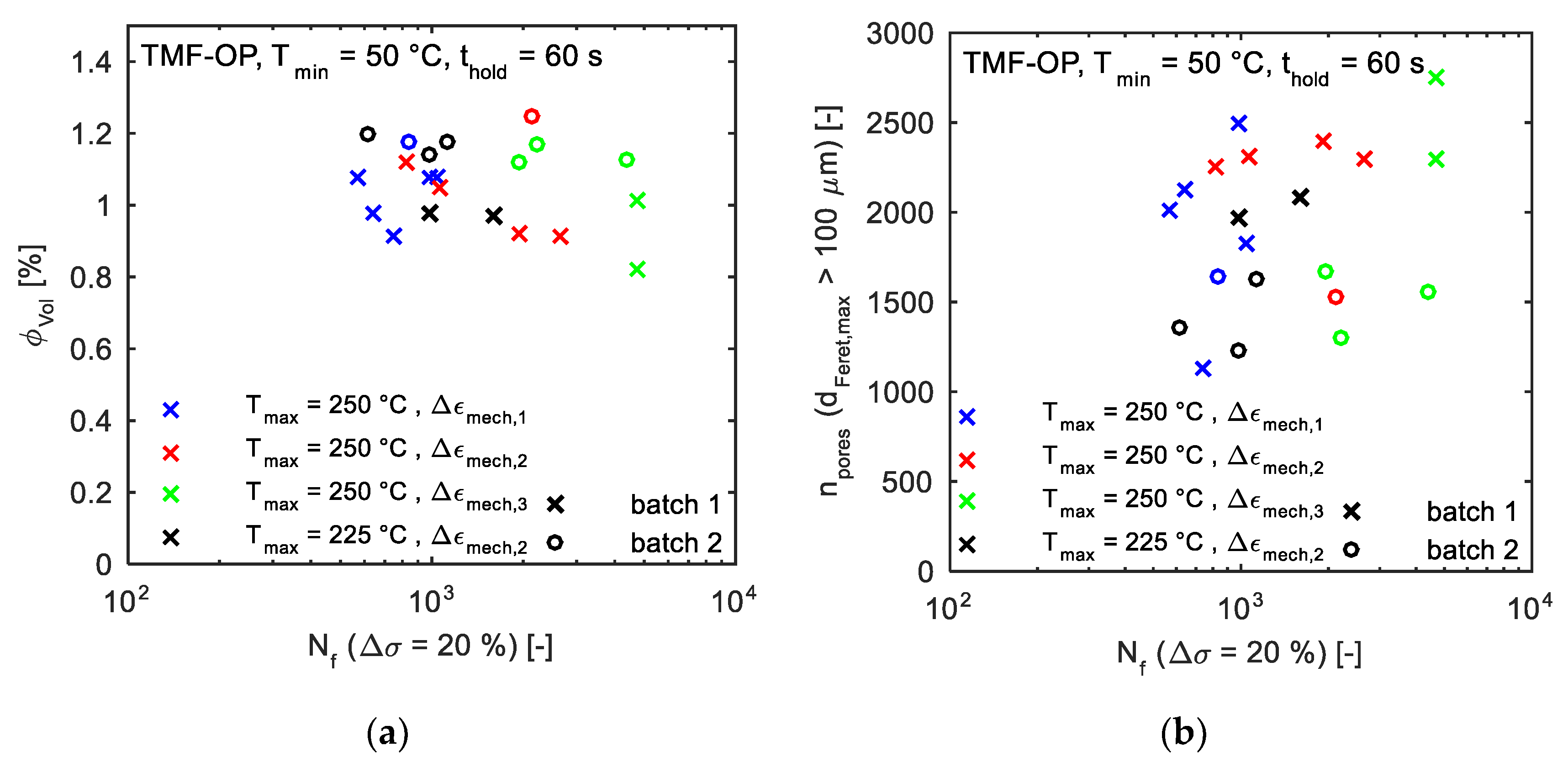

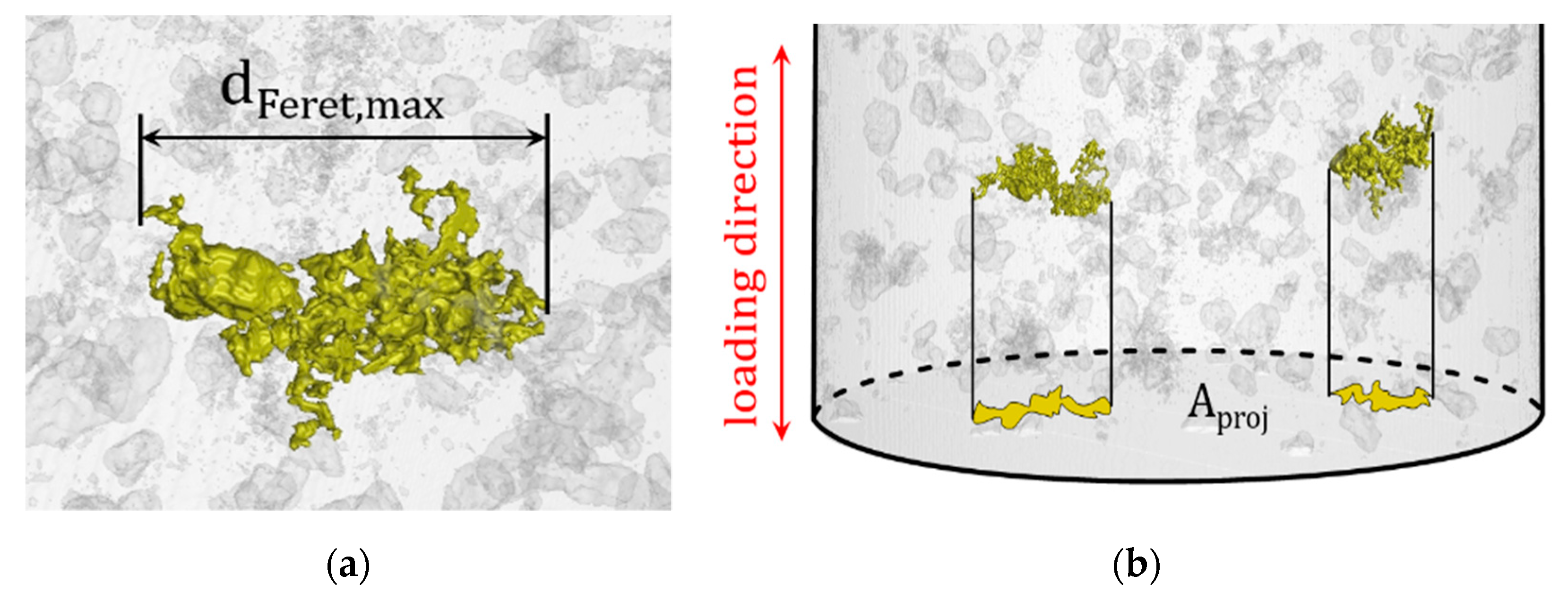

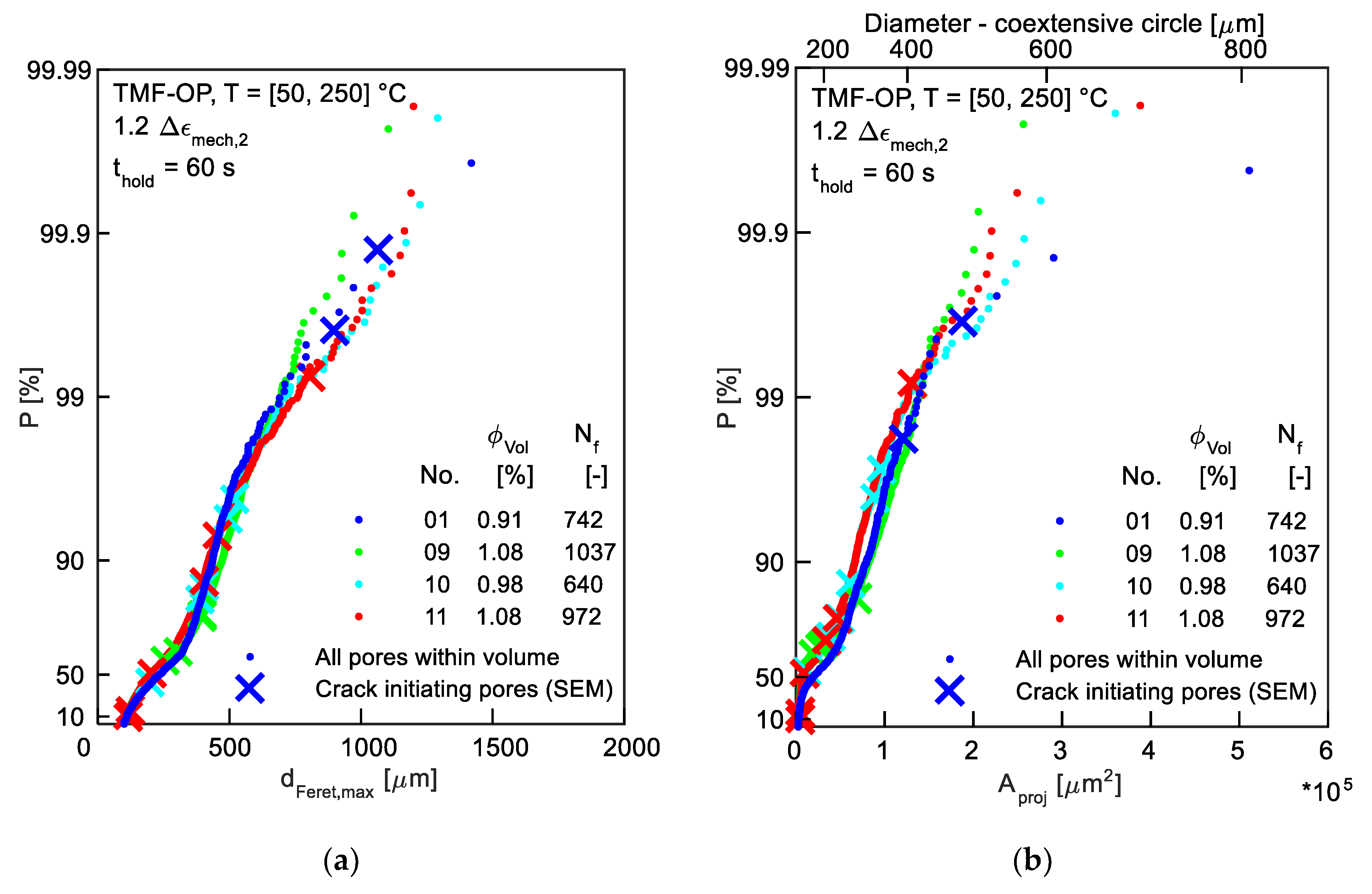

3.3. Pore Analysis on a Global Scale

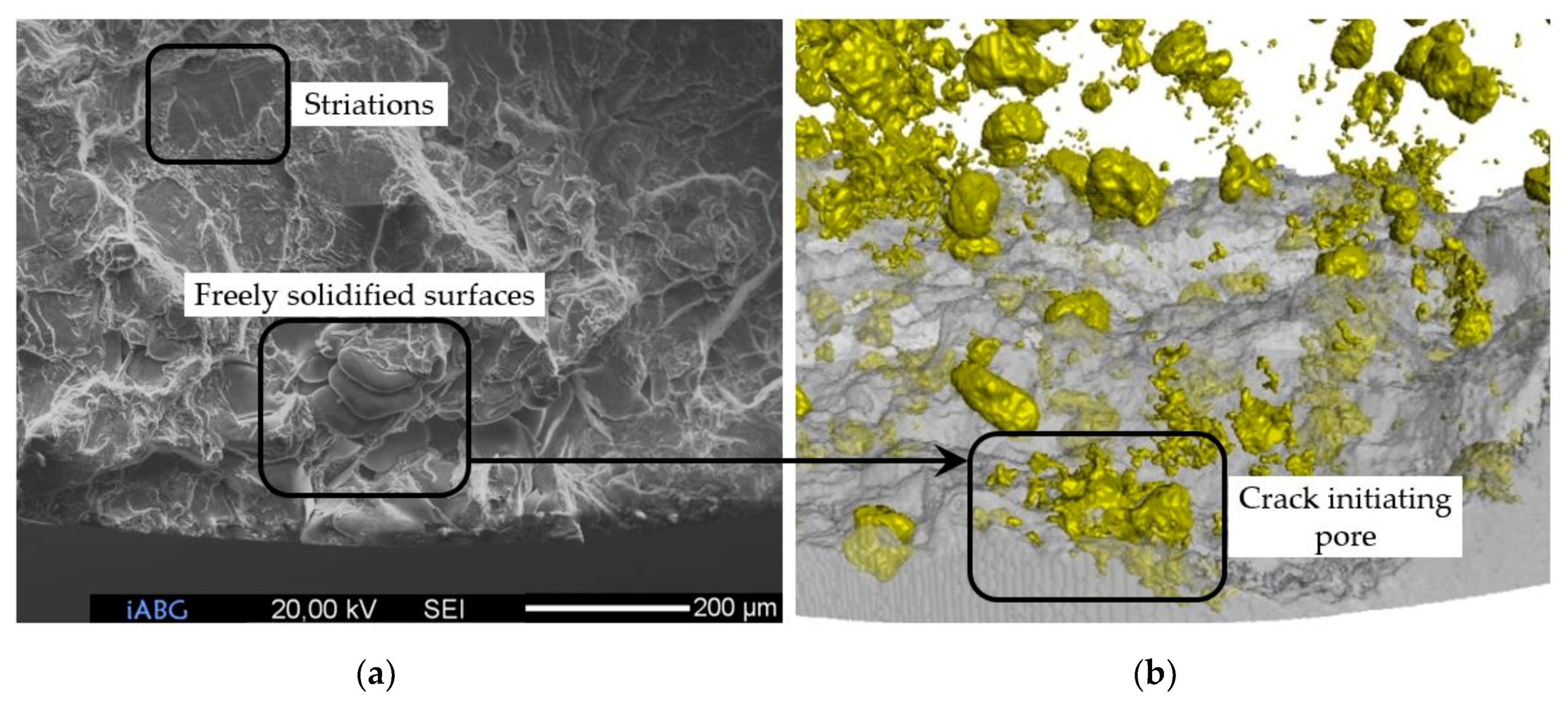

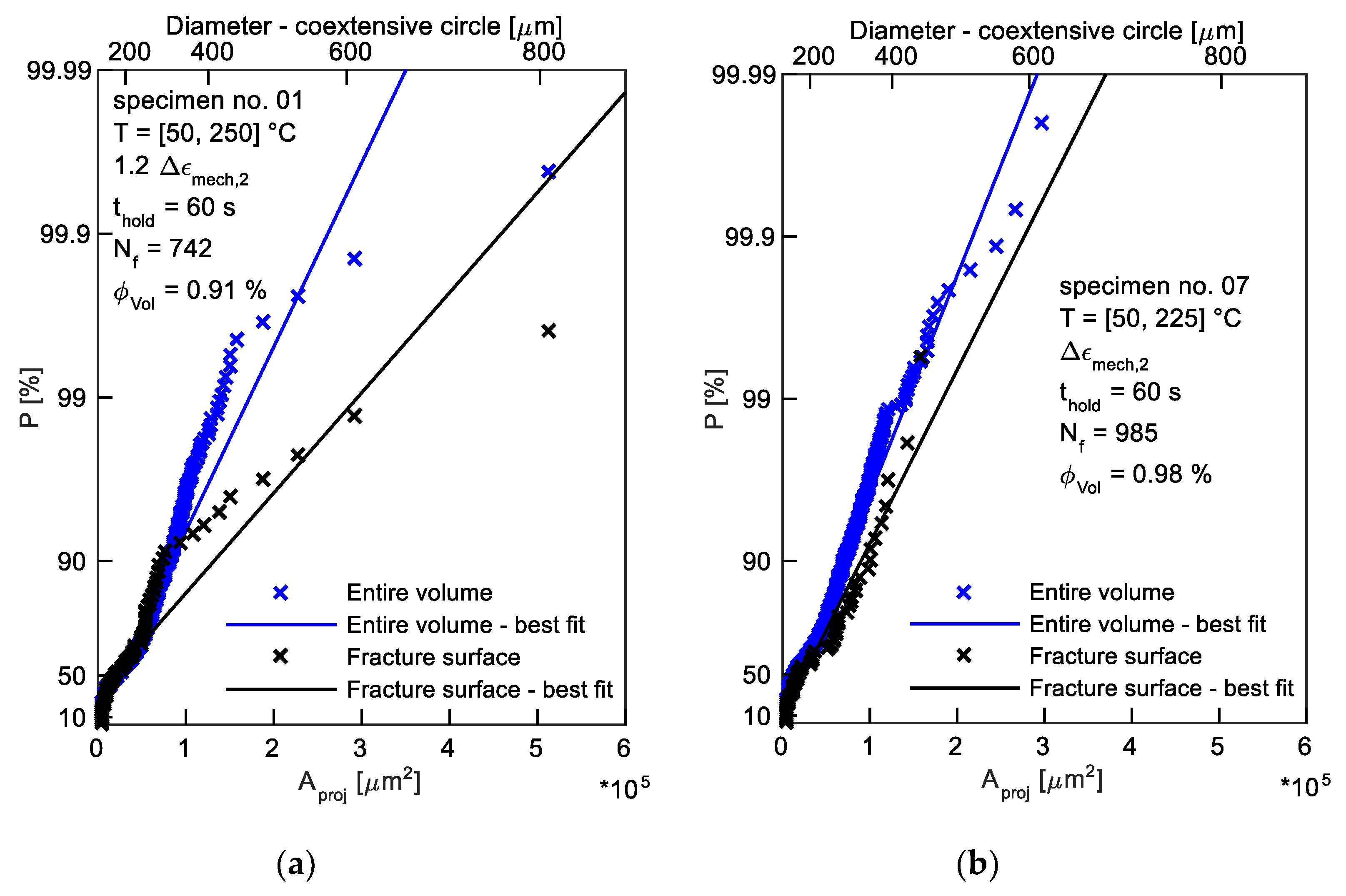

3.4. Pore Analysis on a Local Scale

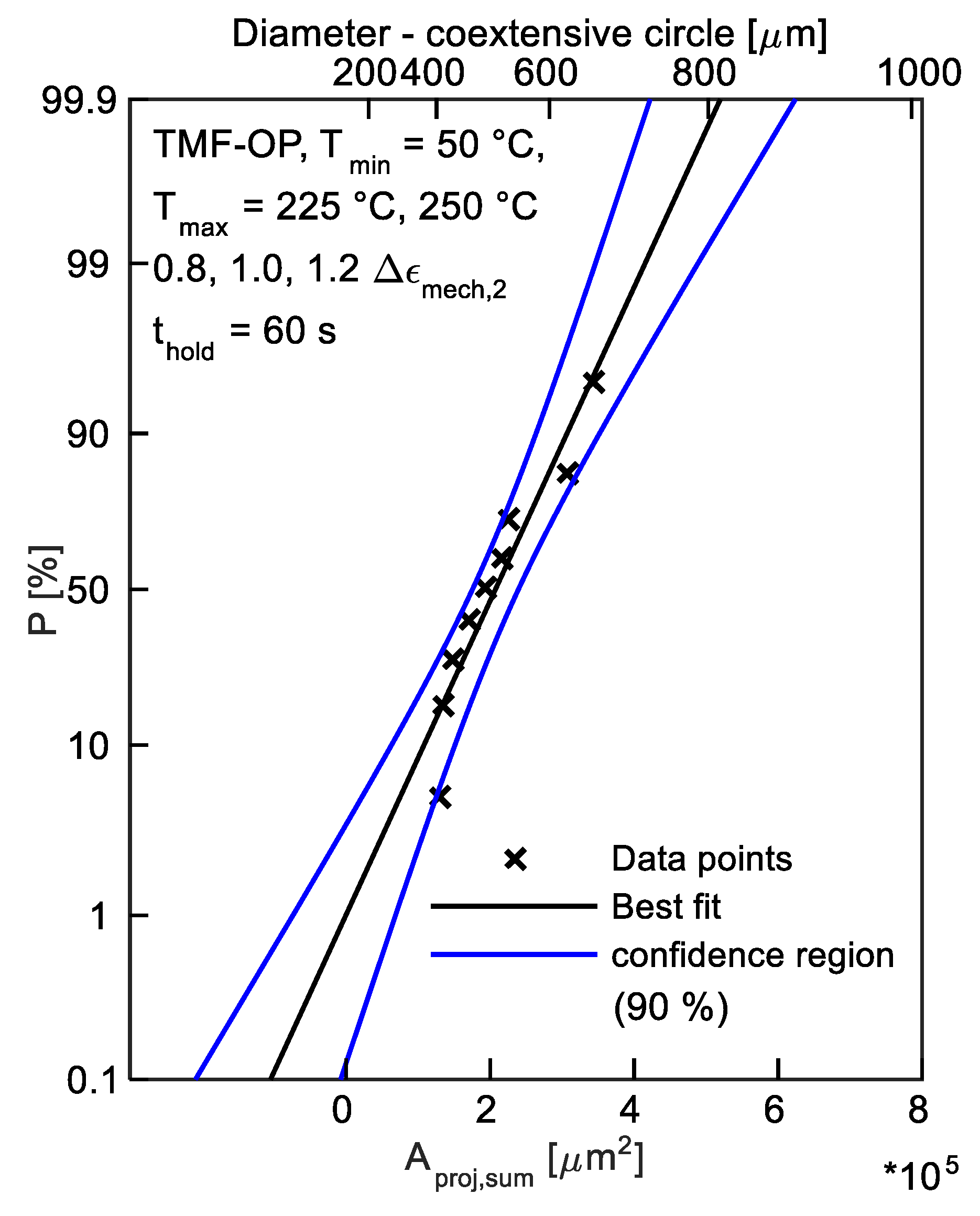

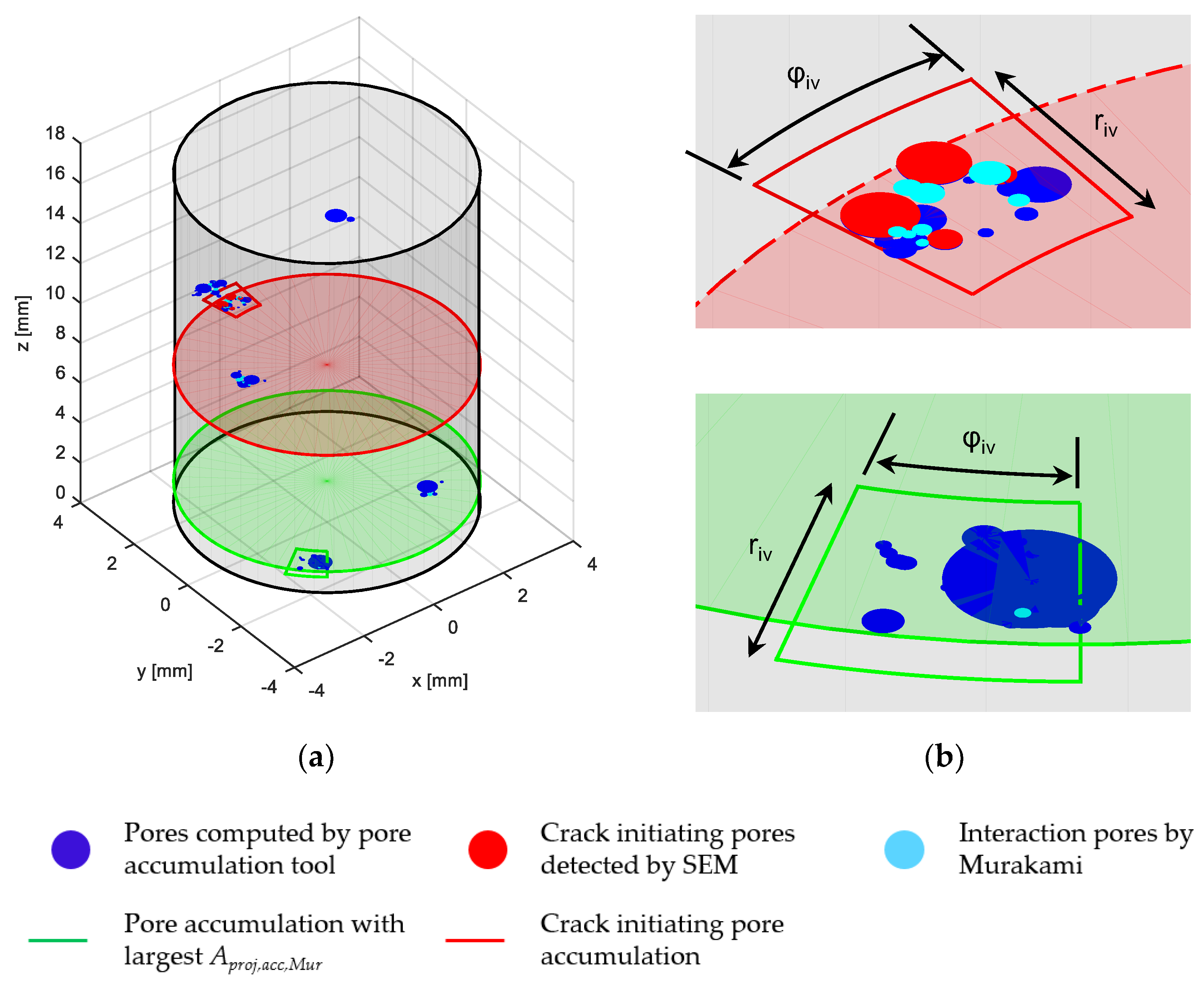

4. Computation of Pore Accumulations

4.1. Method of Computation

4.2. Results of Computation of Pore Accumulations

5. Conclusions

- The positive mean stress in the TMF tests is caused by the out-of-phase loading condition and cyclic softening by ageing of the material.

- Large shrinkage and gas pores, caused by the lost foam production process, are crucial for crack initiation.

- Crack-initiating pores and pore networks have a small distance to the specimen surface and a large projected area to the plane perpendicular to loading direction.

- On a global scale, the pore volume fraction and number of pores do not correlate with the lifetime.

- On a local scale, statistical evaluation of single pores implied that pore accumulations are crucial for crack initiation.

- For most specimens, the computation of pore accumulations is suitable for crack origin assessment because it improves the predictive accuracy compared to the exclusive consideration of single pores.

- There is no further improvement of the predictive accuracy by consideration of interaction of pores by Murakami [9] because the projected area of the accumulated pores is much larger than the area between the pores.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Hirsch, J. Aluminium in Innovative Light-Weight Car Design. Mater. Trans. 2011, 52, 818–824. [Google Scholar] [CrossRef]

- Thalmair, S.; Thiele, J.; Fischersworring-Bunk, A.; Ehart, R.; Guillou, M. Cylinder Heads for High Power Gasoline Engines—Thermomechanical Fatigue Life Prediction. SAE Tech. Pap. 2006, 548–555. [Google Scholar] [CrossRef]

- Grieb, M. Untersuchung von Aluminiumgusslegierungen auf Thermomechanische und HCF Ermüdung und Verbesserung der Lebensdauervorhersage; VDI-Verlag: Düsseldorf, Germany, 2010; ISBN 978-3-18-374205-9. [Google Scholar]

- Geffroy, P.-M.; Lakehal, M.; Goñi, J.; Beaugnon, E.; Heintz, J.-M.; Silvain, J.-F. Thermal and mechanical behavior of Al-Si alloy cast using magnetic molding and lost foam processes. Metall. Mater. Trans. A 2006, 37, 441–447. [Google Scholar] [CrossRef]

- Tabibian, S.; Charkaluk, E.; Constantinescu, A.; Oudin, A.; Szmytka, F. Behavior, damage and fatigue life assessment of lost foam casting aluminum alloys under thermo-mechanical fatigue conditions. Procedia Eng. 2010, 2, 1145–1154. [Google Scholar] [CrossRef][Green Version]

- Boileau, J.M.; Allison, J.E. The effect of solidification time and heat treatment on the fatigue properties of a cast 319 aluminum alloy. Metall. Mater. Trans. A 2003, 34, 1807–1820. [Google Scholar] [CrossRef]

- Wang, L.; Limodin, N.; El Bartali, A.; Witz, J.-F.; Seghir, R.; Buffiere, J.-Y.; Charkaluk, E. Influence of pores on crack initiation in monotonic tensile and cyclic loadings in lost foam casting A319 alloy by using 3D in-situ analysis. Mater. Sci. Eng. A 2016, 673, 362–372. [Google Scholar] [CrossRef]

- Dezecot, S.; Maurel, V.; Buffiere, J.-Y.; Szmytka, F.; Koster, A. 3D characterization and modeling of low cycle fatigue damage mechanisms at high temperature in a cast aluminum alloy. Acta Mater. 2017, 123, 24–34. [Google Scholar] [CrossRef]

- Murakami, Y. Metal Fatigue: Effects of Small Defects and Nonmetallic Inclusions; Elsevier: Amsterdam, The Netherlands, 2002; ISBN 978-0-08-049656-6. [Google Scholar]

- Masuo, H.; Tanaka, Y.; Morokoshi, S.; Yagura, H.; Uchida, T.; Yamamoto, Y.; Murakami, Y. Effects of Defects, Surface Roughness and HIP on Fatigue Strength of Ti-6Al-4V Manufactured by Additive Manufacturing. Procedia Struct. Integr. 2017, 7, 19–26. [Google Scholar] [CrossRef]

- Åman, M.; Okazaki, S.; Matsunaga, H.; Marquis, G.B.; Remes, H. The effect of interacting small defects on the fatigue limit of a medium carbon steel. Procedia Struct. Integr. 2016, 2, 3322–3329. [Google Scholar] [CrossRef]

- Beretta, S.; Murakami, Y. Statistical Analysis of Defects for Fatigue Strength Prediction and Quality Control of Materials. Fatigue Fract. Eng. Mater. Struct. 1998, 21, 1049–1065. [Google Scholar] [CrossRef]

- Wilson, P.; Saintier, N.; Palin-Luc, T.; Bergamo, S. Isothermal fatigue damage mechanisms at ambient and elevated temperature of a cast Al-Si-Cu aluminium alloy. Int. J. Fatigue 2019, 121, 112–123. [Google Scholar] [CrossRef]

- Romano, S.; Brandão, A.; Gumpinger, J.; Gschweitl, M.; Beretta, S. Qualification of AM parts: Extreme value statistics applied to tomographic measurements. Mater. Des. 2017, 131, 32–48. [Google Scholar] [CrossRef]

- Beretta, S.; Anderson, C.; Murakami, Y. Extreme value models for the assessment of steels containing multiple types of inclusion. Acta Mater. 2006, 54, 2277–2289. [Google Scholar] [CrossRef]

- Charkaluk, E.; Constantinescu, A.; Szmytka, F.; Tabibian, S. Probability density functions: From porosities to fatigue lifetime. Int. J. Fatigue 2014, 63, 127–136. [Google Scholar] [CrossRef]

- Rödling, S.; Fröschl, J.; Hück, M.; Decker, M. Influence of non-metallic inclusions on acceptable HCF design properties. Mater. Test. 2011, 53, 455–462. [Google Scholar] [CrossRef]

- Boileau, J.M.; Allison, J.E. The Effect of Porosity Size on the Fatigue Properties in a Cast 319 Aluminum Alloy; SAE International: Warrendale, PA, USA, 2001. [Google Scholar]

- Wagner, M.; Decker, M.; Hoyer, M.; Riva, M.; Christ, H.-J. Experimental and Computational Investigations of a Lost Foam Cast Aluminium-Silicon Alloy under Thermomechanical Loading; German Association for Materials Research and Testing E.V.: Dresden, Germany, 2017; pp. 405–410. [Google Scholar]

| Specimen No. | Pore Accumulations | Single Pores | ||

|---|---|---|---|---|

| Placement of Crack-Initiating Pore Accumulation in the Descending Order of the Computed Pore Accumulations | Placement of Largest Crack-Initiating Pore Detected by SEM in the Descending Order of Single Pores | |||

| Aproj,acc | Aproj,acc,Mur | |||

| 01 | 1 | 1 | < | 2 |

| 02 | 6 | 5 | < | 6 |

| 04 | 3 | 3 | < | 79 |

| 06 | 7 | 9 | < | 37 |

| 07 | 32 | 35 | > | 8 |

| 08 | 2 | 4 | > | 1 |

| 09 | 26 | 12 | < | 149 |

| 10 | 4 | 4 | < | 25 |

| 11 | 4 | 6 | < | 6 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wagner, M.; Mösenbacher, A.; Eiber, M.; Hoyer, M.; Riva, M.; Christ, H.-J. Thermomechanical Fatigue of Lost Foam Cast Al–Si Cylinder Heads—Assessment of Crack Origin Based on the Evaluation of Pore Distribution. Metals 2019, 9, 821. https://doi.org/10.3390/met9080821

Wagner M, Mösenbacher A, Eiber M, Hoyer M, Riva M, Christ H-J. Thermomechanical Fatigue of Lost Foam Cast Al–Si Cylinder Heads—Assessment of Crack Origin Based on the Evaluation of Pore Distribution. Metals. 2019; 9(8):821. https://doi.org/10.3390/met9080821

Chicago/Turabian StyleWagner, Martin, Andreas Mösenbacher, Marion Eiber, Martin Hoyer, Marco Riva, and Hans-Jürgen Christ. 2019. "Thermomechanical Fatigue of Lost Foam Cast Al–Si Cylinder Heads—Assessment of Crack Origin Based on the Evaluation of Pore Distribution" Metals 9, no. 8: 821. https://doi.org/10.3390/met9080821

APA StyleWagner, M., Mösenbacher, A., Eiber, M., Hoyer, M., Riva, M., & Christ, H.-J. (2019). Thermomechanical Fatigue of Lost Foam Cast Al–Si Cylinder Heads—Assessment of Crack Origin Based on the Evaluation of Pore Distribution. Metals, 9(8), 821. https://doi.org/10.3390/met9080821