Enhancement of Fatigue Endurance by Al-Si Coating in Hot-Stamping Boron Steel Sheet

Abstract

1. Introduction

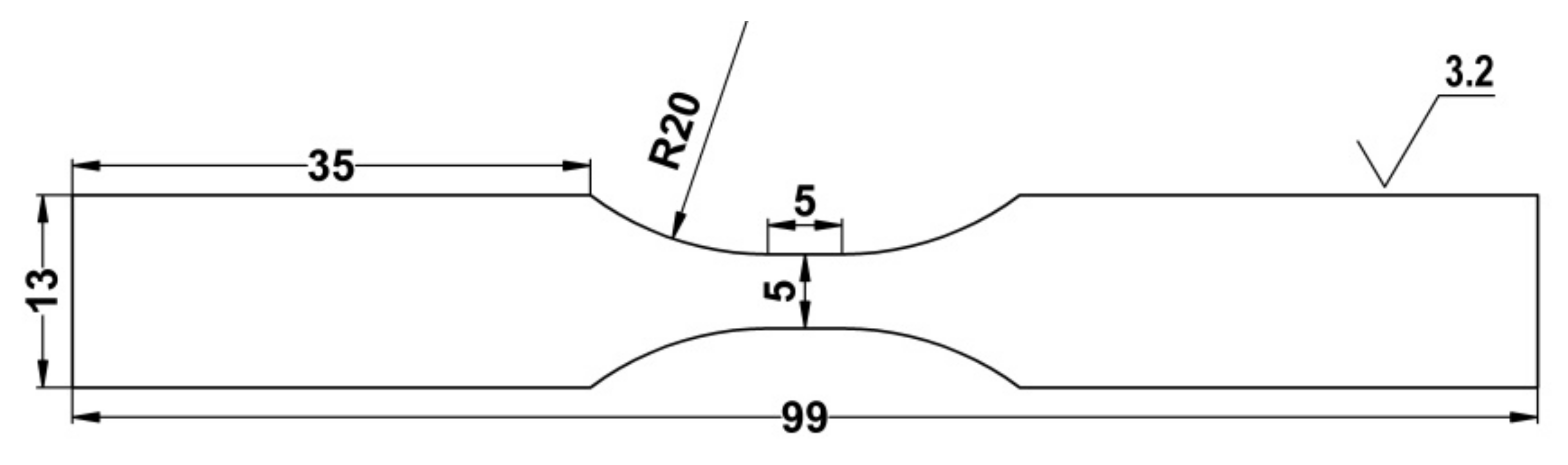

2. Experimental Procedures

3. Results and Discussion

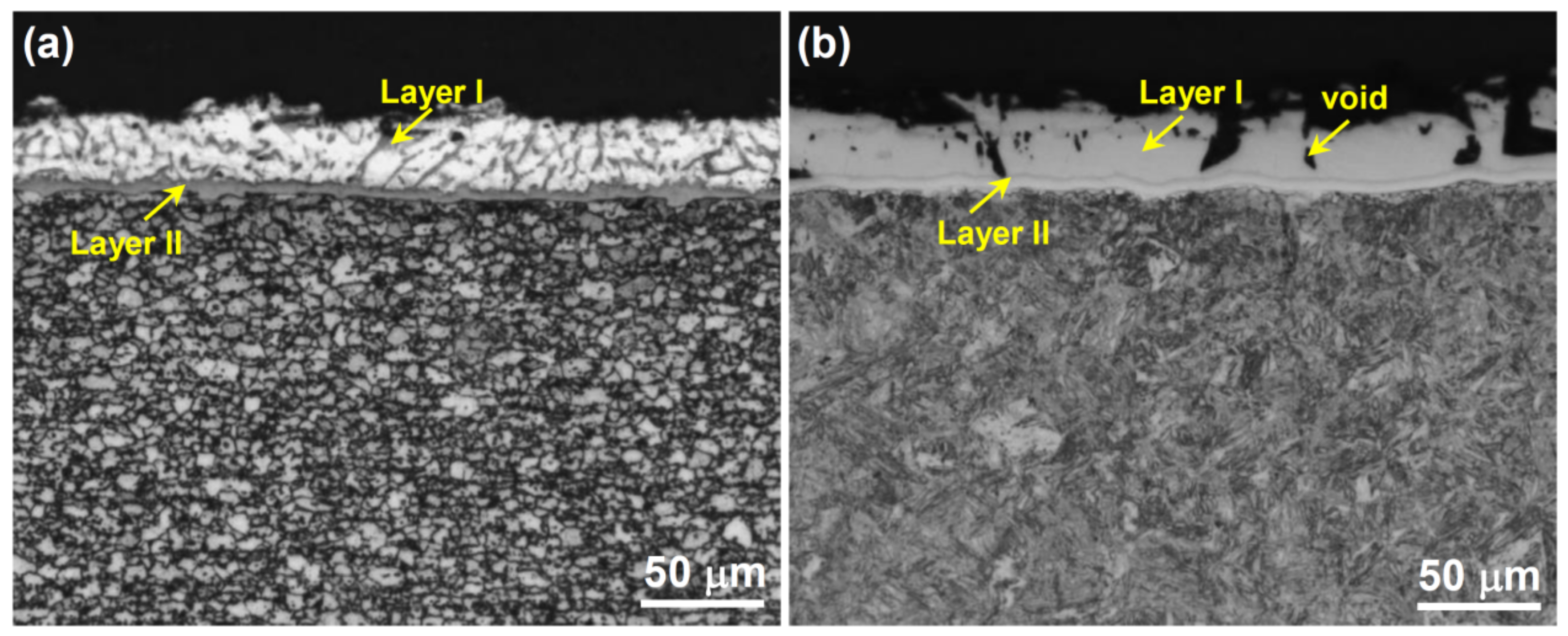

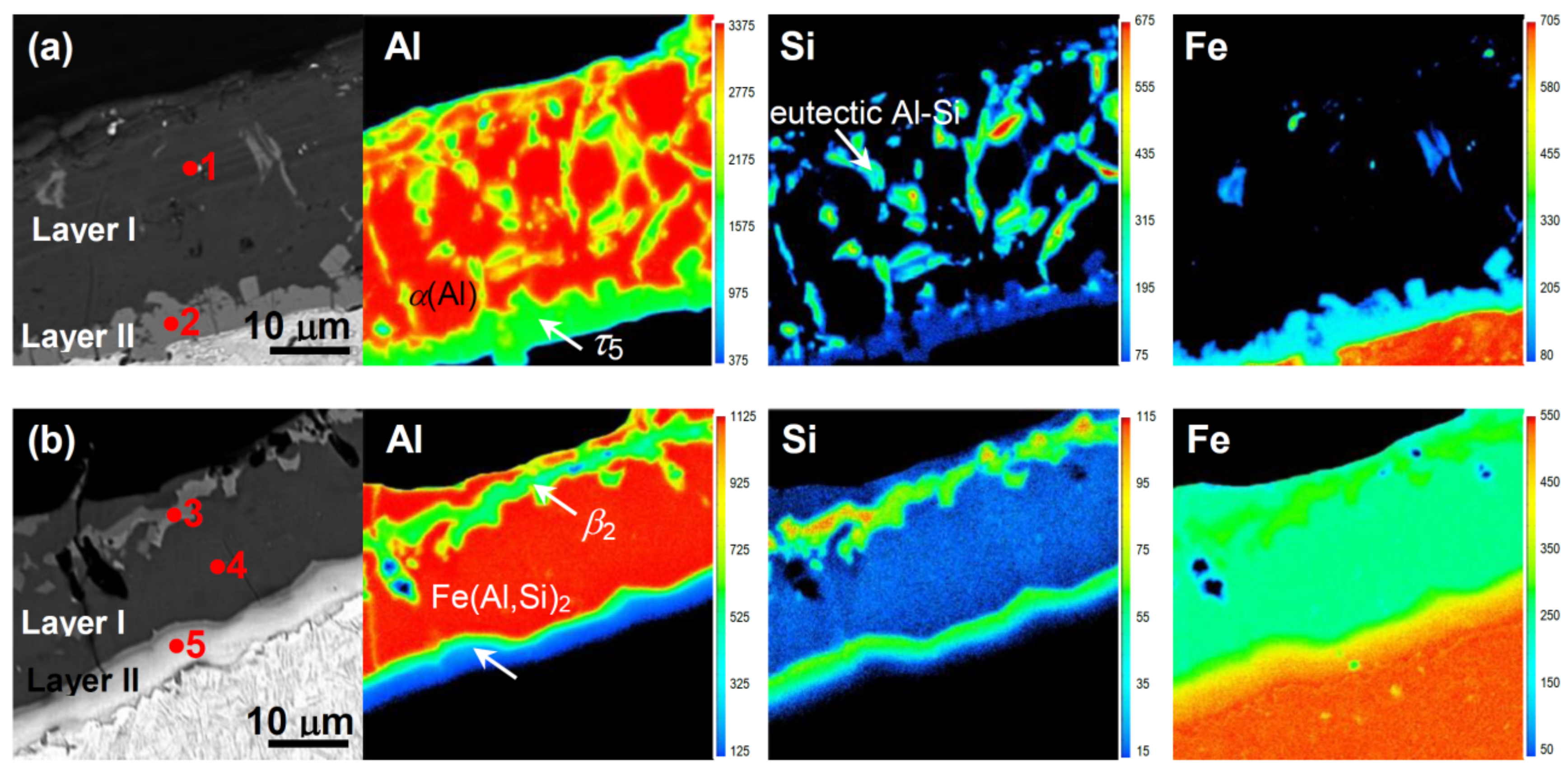

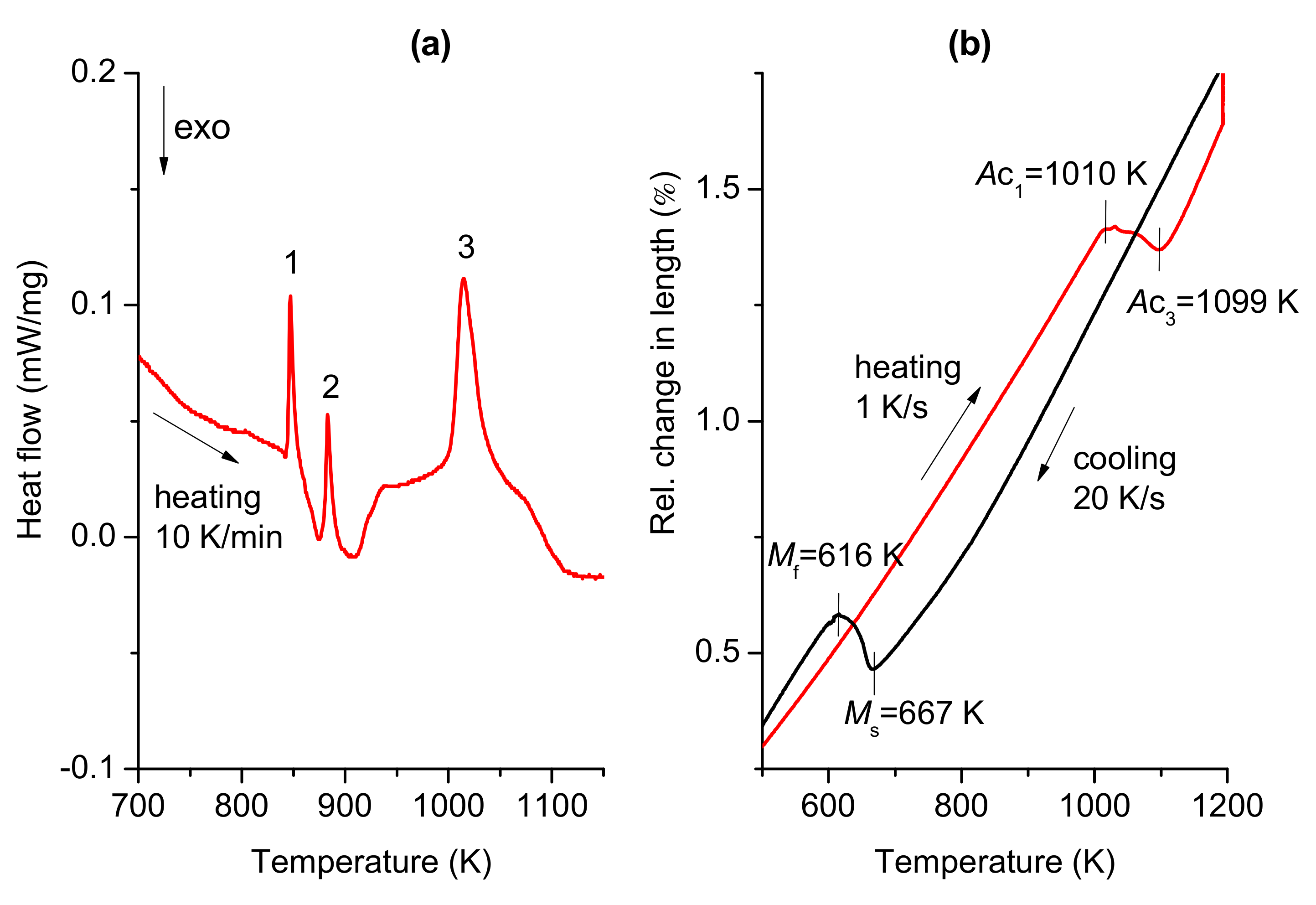

3.1. Al-Si Coating

3.2. High-Cycle Fatigue Behavior

4. Conclusions

- (1)

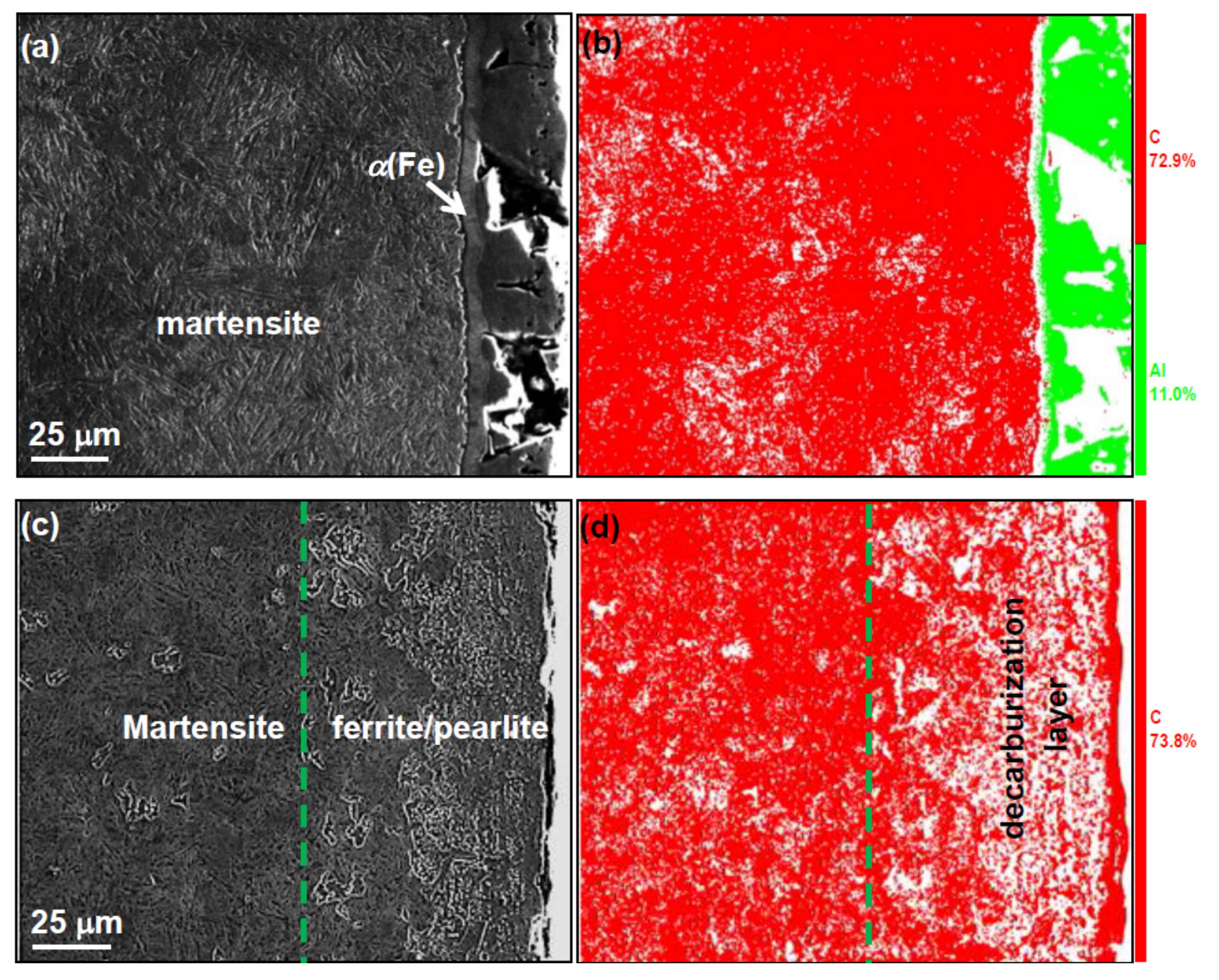

- The phases of the as-received Al-Si coating were α(Al), eutectic Al-Si, and τ5. After hot stamping at 1193 K, Fe(Al,Si)2, β2 and α(Fe), phases formed and some voids/cracks appeared inside the coating. The Al-Si coating effectively prevented the occurrence of near-surface decarburization during high-temperature hot stamping.

- (2)

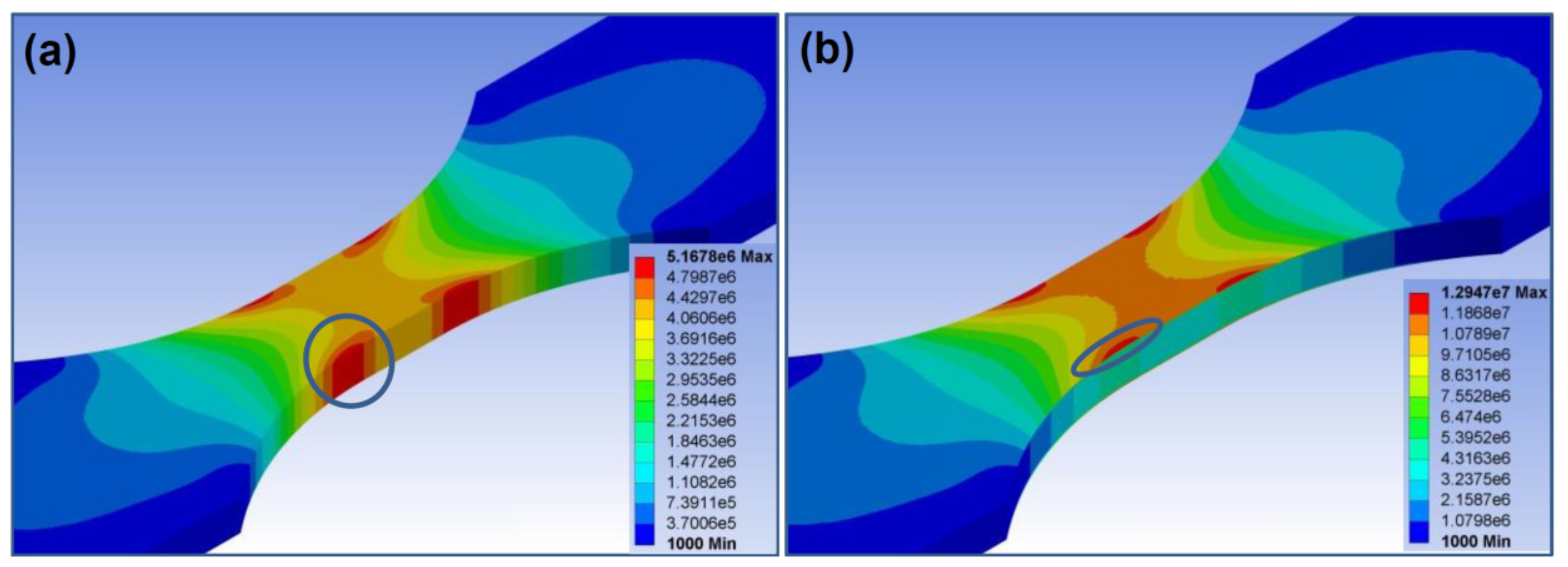

- The endurance limit of the hot-stamped coated steel sheet was 370 MPa compared to 305 MPa for the uncoated sheet under 107 fully reversed tension-compression loading cycles. Both specimens were classified as the surface-induced transgranular fatigue fracture.

- (3)

- The high-cycle fatigue cracks were generated from the decarburization layer in the uncoated sheet, whereas for the coated sheet, the cracks were initiated at wire-cutting surfaces.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Merklein, M.; Wieland, M.; Lechner, M.; Bruschi, S.; Ghiotti, A. Hot stamping of boron steel sheets with tailored properties: A review. J. Mater. Process. Tech. 2016, 228, 11–24. [Google Scholar] [CrossRef]

- Li, N.; Lin, J.; Balint, D.S.; Dean, T.A. Modelling of austenite formation during heating in boron steel hot stamping processes. J. Mater. Process. Tech. 2016, 237, 394–401. [Google Scholar] [CrossRef]

- Mori, K.; Bariani, P.F.; Behrens, B.-A.; Brosius, A.; Bruschi, S.; Maeno, T.; Merklein, M.; Yanagimoto, J. Hot stamping of ultra-high strength steel parts. CIRP Ann. 2017, 66, 755–777. [Google Scholar] [CrossRef]

- Abdulhay, B.; Bourouga, B.; Dessain, C. Experimental and theoretical study of thermal aspects of the hot stamping process. Appl. Therm. Eng. 2011, 31, 674–685. [Google Scholar] [CrossRef]

- Shao, Z.; Lin, J.; Ganapathy, M.; Dean, T. Experimental and modelling techniques for hot stamping applications. Procedia Manuf. 2018, 15, 6–13. [Google Scholar] [CrossRef]

- Nakagawa, Y.; Mori, K.; Yashima, S.; Kaido, T. Springback behaviour and quenchability in hot stamping of thick sheets. Procedia Manuf. 2018, 15, 1071–1078. [Google Scholar] [CrossRef]

- George, R.; Bardelcik, A.; Worswick, M.J. Hot forming of boron steels using heated and cooled tooling for tailored properties. J. Mater. Process. Tech. 2012, 212, 2386–2399. [Google Scholar] [CrossRef]

- Bariani, P.F.; Bruschi, S.; Ghiotti, A.; Turetta, A. Testing formability in the hot stamping of HSS. CIRP Ann. 2008, 57, 265–268. [Google Scholar] [CrossRef]

- Karbasian, H.; Tekkaya, A.E. A review on hot stamping. J. Mater. Process. Tech. 2010, 210, 2103–2118. [Google Scholar] [CrossRef]

- Neumann, R.; Schuster, S.; Gibmeier, J.; Böhlke, T. Two-scale simulation of the hot stamping process based on a Hashin-Shtrikman type mean field model. J. Mater. Process. Tech. 2019, 267, 124–140. [Google Scholar] [CrossRef]

- Lu, Y.; Peer, A.; Abke, T.; Kimchi, M.; Zhang, W. Subcritical heat affected zone softening in hot-stamped boron steel during resistance spot welding. Mater. Design 2018, 155, 170–184. [Google Scholar] [CrossRef]

- Li, X.D.; Chang, Y.; Wang, C.Y.; Hu, P.; Dong, H. Comparison of the hot-stamped boron-alloyed steel and the warm-stamped medium-Mn steel on microstructure and mechanical properties. Mater. Sci. Eng. A 2017, 679, 240–248. [Google Scholar] [CrossRef]

- Xing, Z.W.; Bao, J.; Yang, Y.Y. Numerical simulation of hot stamping of quenchable boron steel. Mater. Sci. Eng. A 2019, 499, 28–31. [Google Scholar] [CrossRef]

- Fan, D.W.; Kim, H.S.; De Cooman, B.C. A review of the physical metallurgy related to the hot press forming of advanced high strength steel. Steel Res. Int. 2009, 80, 241–248. [Google Scholar] [CrossRef]

- Mori, K.; Ito, D. Prevention of oxidation in hot stamping of quenchable steel sheet by oxidation preventive oil. CIRP Ann. 2009, 58, 267–270. [Google Scholar] [CrossRef]

- Allély, C.; Dosdat, L.; Clauzeau, O.; Ogle, K.; Volovitch, P. Anticorrosion mechanisms of aluminized steel for hot stamping. Surf. Coat. Tech. 2014, 238, 188–196. [Google Scholar] [CrossRef]

- Fan, D.W.; De Cooman, B.C. State-of-the-knowledge on coating systems for hot stamped parts. Steel Res. Int. 2012, 83, 412–433. [Google Scholar] [CrossRef]

- Zhang, J.; Jiang, S.; Zhang, Q.; Liu, C. Effect of temperature on microstructure and formability of Al-10 mass% Si coatings. J. Iron. Steel Res. Int. 2016, 23, 270–275. [Google Scholar] [CrossRef]

- Pelcastre, L.; Hardell, J.; Rolland, A.; Prakash, B. Influence of microstructural evolution of Al-Si coated UHSS on its tribological behaviour against tool steel at elevated temperatures. J. Mater. Process. Tech. 2016, 228, 117–124. [Google Scholar] [CrossRef]

- Windmann, M.; Röttger, A.; Theisen, W. Phase formation at the interface between a boron alloyed steel substrate and an Al-rich coating. Surf. Coat. Tech. 2013, 226, 130–139. [Google Scholar] [CrossRef]

- Dosdat, L.; Petitjean, J.; Vietoris, T.; Clauzeau, O. Corrosion resistance of different metallic coatings on press-hardened steels for automotive. Steel Res. Int. 2011, 82, 726–733. [Google Scholar] [CrossRef]

- Ighodaro, O.L.; Biro, E.; Zhou, Y.N. Comparative effects of Al-Si and galvannealed coatings on the properties of resistance spot welded hot stamping steel joints. J. Mater. Process. Tech. 2016, 236, 64–72. [Google Scholar] [CrossRef]

- Chang, J.K.; Lin, C.S.; Wang, W.R.; Cheng, W.J. Microstructural evaluation and property change of 5 wt pct Al-Zn coating on press hardening steel during austenitization. Metall. Mater. Trans. A 2018, 49, 3715–3728. [Google Scholar] [CrossRef]

- Kondratiuk, J.; Kuhn, P.; Labrenz, E.; Bischoff, C. Zinc coatings for hot sheet metal forming: Comparison of phase evolution and microstructure during heat treatment. Surf. Coat. Tech. 2011, 205, 4141–4153. [Google Scholar] [CrossRef]

- Kondratiuk, J.; Kuhn, P. Tribological investigation on friction and wear behaviour of coatings for hot sheet metal forming. Wear 2011, 270, 839–849. [Google Scholar] [CrossRef]

- Alibakhshi, E.; Akbarian, M.; Ramezanzadeh, M.; Ramezanzadeh, B.; Mahdavian, M. Evaluation of the corrosion protection performance of mild steel coated with hybrid sol-gel silane coating in 3.5 wt.% NaCl solution. Prog. Org. Coat. 2018, 123, 190–200. [Google Scholar] [CrossRef]

- Lee, C.W.; Choi, W.S.; Cho, Y.R.; De Cooman, B.C. Microstructure evolution of a 55 wt.% Al-Zn coating on press hardening steel during rapid heating. Surf. Coat. Tech. 2005, 281, 35–43. [Google Scholar] [CrossRef]

- Gui, Z.X.; Wang, K.; Zhang, Y.S.; Zhu, B. Cracking and interfacial debonding of the Al-Si coating in hot stamping of pre-coated boron steel. Appl. Surf. Sci. 2014, 316, 595–603. [Google Scholar] [CrossRef]

- Yao, S.J.; Feng, L.; Yang, D.L.; Han, D.X.; Liu, Y.; Li, Q.Q.; Guo, J.H.; Chao, B.J. A potential hot stamping process for microstructure optimization of 22MnB5 steels characterized by asymmetric pre-rolling and one- or two-step pre-heating. J. Mater. Process. Tech. 2018, 254, 100–107. [Google Scholar] [CrossRef]

- Golling, S.; Frómeta, D.; Casellas, D.; Jonsén, P. Influence of microstructure on the fracture toughness of hot stamped boron steel. Mater. Sci. Eng. A 2019, 743, 529–539. [Google Scholar] [CrossRef]

- Ganapathy, M.; Li, N.; Lin, J.; Bhattacharjee, D. Investigation of a new hot stamping process with improved formability and productivity. Procedia Eng. 2017, 207, 771–776. [Google Scholar] [CrossRef]

- Lara, A.; Picas, I.; Casellas, D. Effect of the cutting process on the fatigue behaviour of press hardened and high strength dual phase steels. J. Mater. Process. Tech. 2013, 213, 1908–1919. [Google Scholar] [CrossRef]

- Majumdar, S.; Bhattacharjee, D.; Ray, K.K. Mechanism of fatigue failure in interstitial-free and interstitial-free high-strength steel sheets. Scripta Mater. 2011, 64, 288–291. [Google Scholar] [CrossRef]

- Zhao, P.; Cheng, C.; Gao, G.; Hui, W.; Misra, R.D.K.; Bai, B.; Weng, Y. The potential significance of microalloying with niobium in governing very high cycle fatigue behavior of bainite/martensite multiphase steels. Mater. Sci. Eng. A 2016, 650, 438–444. [Google Scholar] [CrossRef]

- Park, S.H.; Lee, C.S. Relationship between mechanical properties and high-cycle fatigue strength of medium-carbon steels. Mater. Sci. Eng. A 2017, 690, 185–194. [Google Scholar] [CrossRef]

- Hou, H.; Li, H.; He, L.; Tang, B. Analysis of phase transformation and blanking accuracy of B1500HS steel during hot blanking. Procedia Eng. 2017, 207, 1528–1533. [Google Scholar] [CrossRef]

- Sun, Y.M.; Wu, L.J.; Tan, C.W.; Zhou, W.L.; Chen, B.; Song, X.G.; Zhao, H.Y.; Feng, J.C. Influence of Al-Si coating on microstructure and mechanical properties of fiber laser welded 22MnB5 steel. Opt. Laser Technol. 2019, 116, 117–127. [Google Scholar] [CrossRef]

- Fan, D.W.; Kim, H.S.; Oh, J.K.; Chin, K.G.; Cooman, B.C. Coating degradation in hot press forming. ISIJ Int. 2010, 50, 561–568. [Google Scholar] [CrossRef]

- Maitra, T.; Gupta, S.P. Intermetallic compound formation in Fe–Al–Si ternary system: Part II. Mater. Charact. 2003, 49, 293–311. [Google Scholar] [CrossRef]

- Tavoosi, M. The Kirkendall void formation in Al/Ti interface during solid-state reactive diffusion between Al and Ti. Surf. Interfaces 2017, 9, 196–200. [Google Scholar] [CrossRef]

- Haque, A.; Shekhar, S.; Narayana Murty, S.V.S.; Ramkumar, J.; Kar, K.; Mondal, K. Fabrication of controlled expansion Al-Si composites by pressureless and spark plasma sintering. Adv. Powder Technol. 2018, 29, 3427–3439. [Google Scholar] [CrossRef]

- Grauer, S.J.; Caron, E.J.F.R.; Chester, N.L.; Wells, M.A.; Daun, K.J. Investigation of melting in the Al-Si coating of a boron steel sheet by differential scanning calorimetry. J. Mater. Process. Tech. 2015, 216, 89–94. [Google Scholar] [CrossRef]

- Deirmina, F.; Peghini, N.; AlMangour, B.; Grzesiak, D.; Pellizzari, M. Heat treatment and properties of a hot work tool steel fabricated by additive manufacturing. Mater. Sci. Eng. A 2019, 753, 109–121. [Google Scholar] [CrossRef]

- Namklang, P.; Uthaisangsuk, V. Description of microstructures and mechanical properties of boron alloy steel in hot stamping process. J. Manuf. Process. 2016, 21, 87–100. [Google Scholar] [CrossRef]

- Mercier, D.; Lesage, J.; Decoopman, X.; Chicot, D. Eddy currents and hardness testing for evaluation of steel decarburizing. NdT&E Int. 2006, 39, 652–660. [Google Scholar] [CrossRef]

- Ren, C.X.; Wang, D.Q.; Wang, Q.; Guo, Y.S.; Zhang, Z.J.; Shao, C.W.; Yang, H.J.; Zhang, Z.F. Enhanced bending fatigue resistance of a 50CrMnMoVNb spring steel with decarburized layer by surface spinning strengthening. Int. J. Fatigue 2019, 124, 277–287. [Google Scholar] [CrossRef]

- Zhao, X.J.; Wang, H.Y.; Guo, J.; Liu, Q.Y.; Zhao, G.T.; Wang, W.J. The effect of decarburized layer on rolling contact fatigue of rail materials under dry-wet conditions. Eng. Fail. Anal. 2018, 91, 58–71. [Google Scholar] [CrossRef]

- Van Hall, S.N.; Findley, K.O.; Freis, A.K. Improved self-pierce rivet performance through intentional decarburization. J. Mater. Process. Tech. 2018, 251, 350–359. [Google Scholar] [CrossRef]

- Fan, Y.; Zhao, X.; Liu, Y. Research on fatigue behavior of the flash welded joint enhanced by ultrasonic peening treatment. Mater. Design 2016, 94, 515–522. [Google Scholar] [CrossRef]

| C | Si | Mn | P | S | Ni | Mo | Al | B | Cr | Ti | Cu |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.23 | 0.25 | 1.35 | 0.015 | 0.006 | 0.028 | 0.04 | 0.04 | 0.003 | 0.19 | 0.03 | 0.016 |

| Element | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Fe | 0.2 | 21.0 | 51.3 | 33.5 | 85.0 |

| Al | 94.6 | 69.3 | 35.5 | 63.6 | 10.9 |

| Si | 5.2 | 9.7 | 13.2 | 2.9 | 4.1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Tan, N.; Xu, Z.; Luo, Z.; Han, K.; Zhai, Q.; Zheng, H. Enhancement of Fatigue Endurance by Al-Si Coating in Hot-Stamping Boron Steel Sheet. Metals 2019, 9, 722. https://doi.org/10.3390/met9070722

Li Y, Tan N, Xu Z, Luo Z, Han K, Zhai Q, Zheng H. Enhancement of Fatigue Endurance by Al-Si Coating in Hot-Stamping Boron Steel Sheet. Metals. 2019; 9(7):722. https://doi.org/10.3390/met9070722

Chicago/Turabian StyleLi, Yuqiang, Ning Tan, Zhishuai Xu, Zhiping Luo, Ke Han, Qijie Zhai, and Hongxing Zheng. 2019. "Enhancement of Fatigue Endurance by Al-Si Coating in Hot-Stamping Boron Steel Sheet" Metals 9, no. 7: 722. https://doi.org/10.3390/met9070722

APA StyleLi, Y., Tan, N., Xu, Z., Luo, Z., Han, K., Zhai, Q., & Zheng, H. (2019). Enhancement of Fatigue Endurance by Al-Si Coating in Hot-Stamping Boron Steel Sheet. Metals, 9(7), 722. https://doi.org/10.3390/met9070722