1. Introduction

Machining is a major manufacturing process in the engineering industry. The quality of a product is largely dependent on the accuracy and consistency of the machining processes used for the production of the parts. Although in the last few decades, some entirely new machining processes have been developed—such as ultrasonic machining, thermal metal removal processes, electrochemical material removal processes, and laser machining processes, which differ from the conventional machining processes—conventional metal cutting operations are still the most widely used fabrication processes, and this is the reason why it is still essential to develop a fundamental understanding of metal cutting processes.

In general, machining consists of both cutting and abrasive processes that are mostly complimentary. In spite of the fact that conventional metal cutting processes are chip-forming processes, chip control has been overlooked in the manufacturing processes for a long time. However, along with the automation of manufacturing processes, machining chip control becomes an essential issue in machining operations in order to carry out the manufacturing processes efficiently and smoothly, especially in today’s unmanned machining systems. It can be said that the material removal from a workpiece using machining is based on a degradation of material cohesion realized in a controlled way.

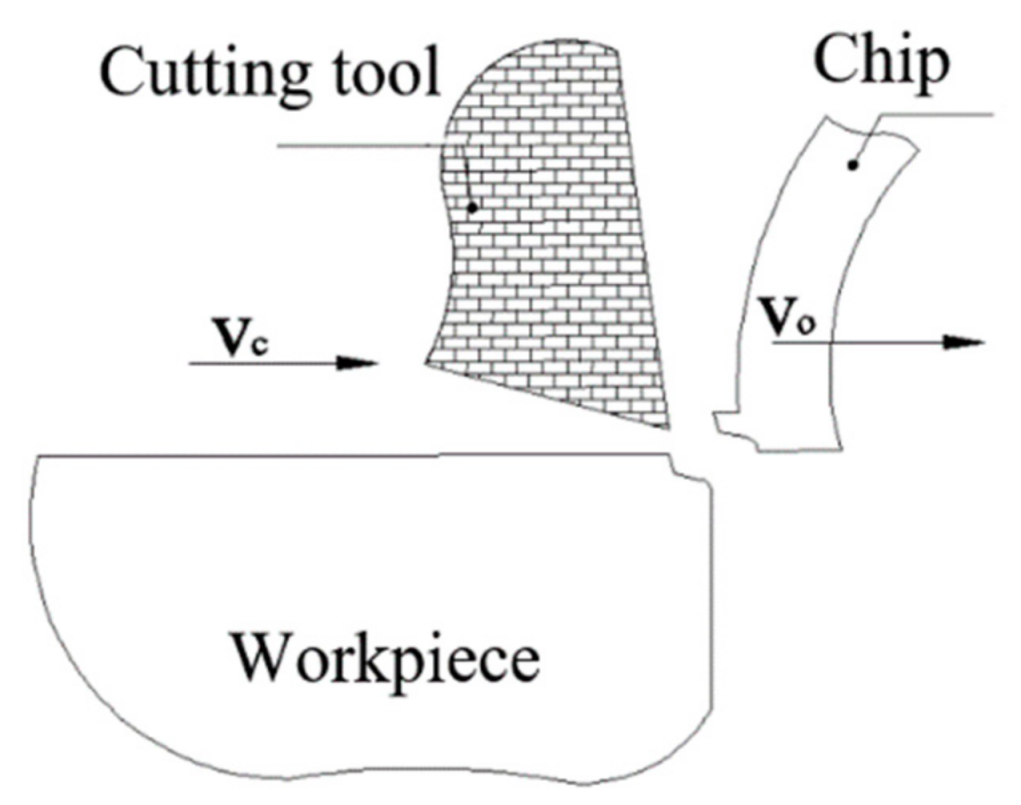

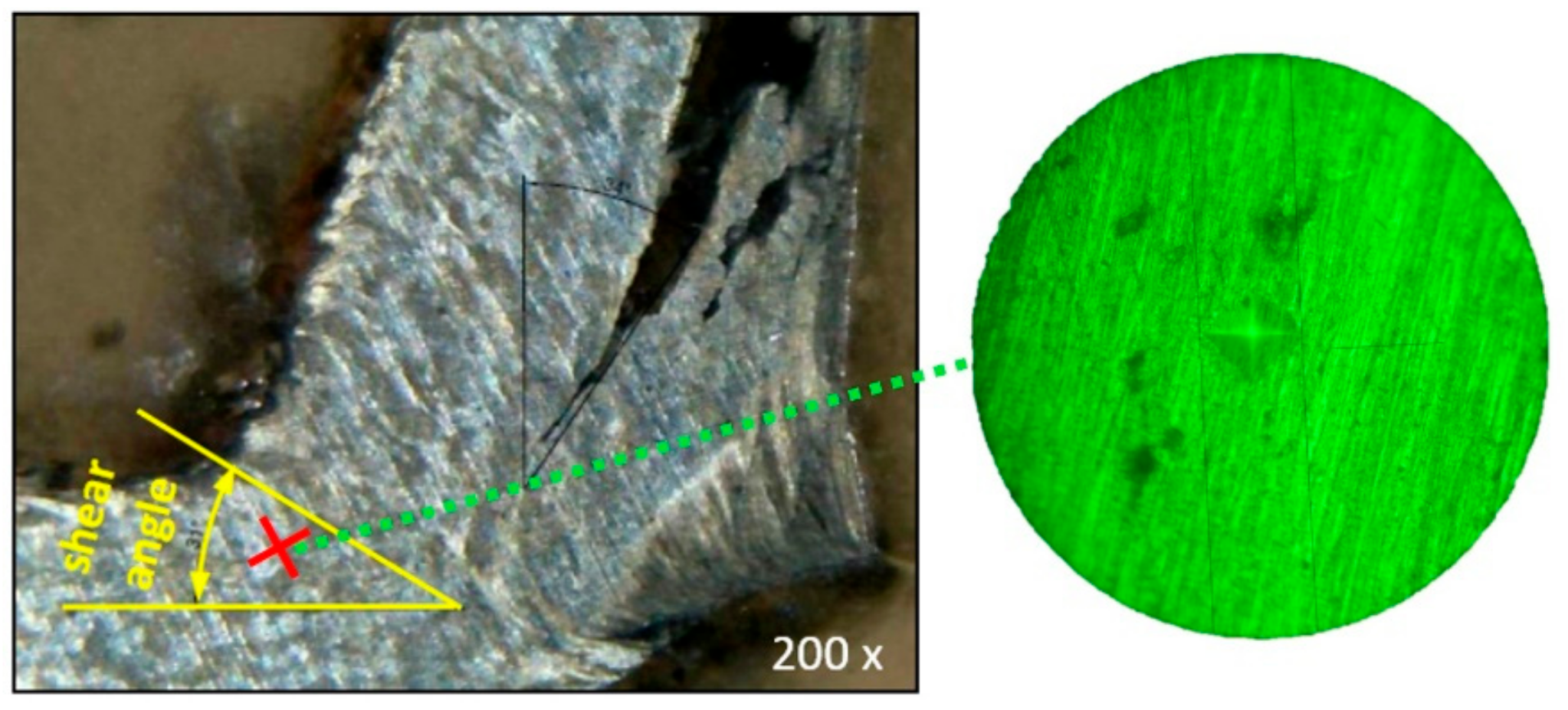

Chip removal produces technically and scientifically interesting material responses. In single point cutting, the process concentrates the mechanical power of a machine tool into creating the small volumes of the workpiece by forcing a hard-cutting tool with a small edge radius through an outer layer of the workpiece material. The tribological conditions at the tool–chip interface can result in macroscopic welding of the material to the cutting tool, and dissolution of the tool elements into the chip. The geometry of the deformation zones and the resulting microstructures in the workpiece depend on the geometrical and tribological interaction of the cutting tool with the workpiece material. Further understanding of fundamentals of chip formation is motivated by the desire for higher material removal rates, longer tool life, tighter tolerances, and improved quality of machined surfaces.

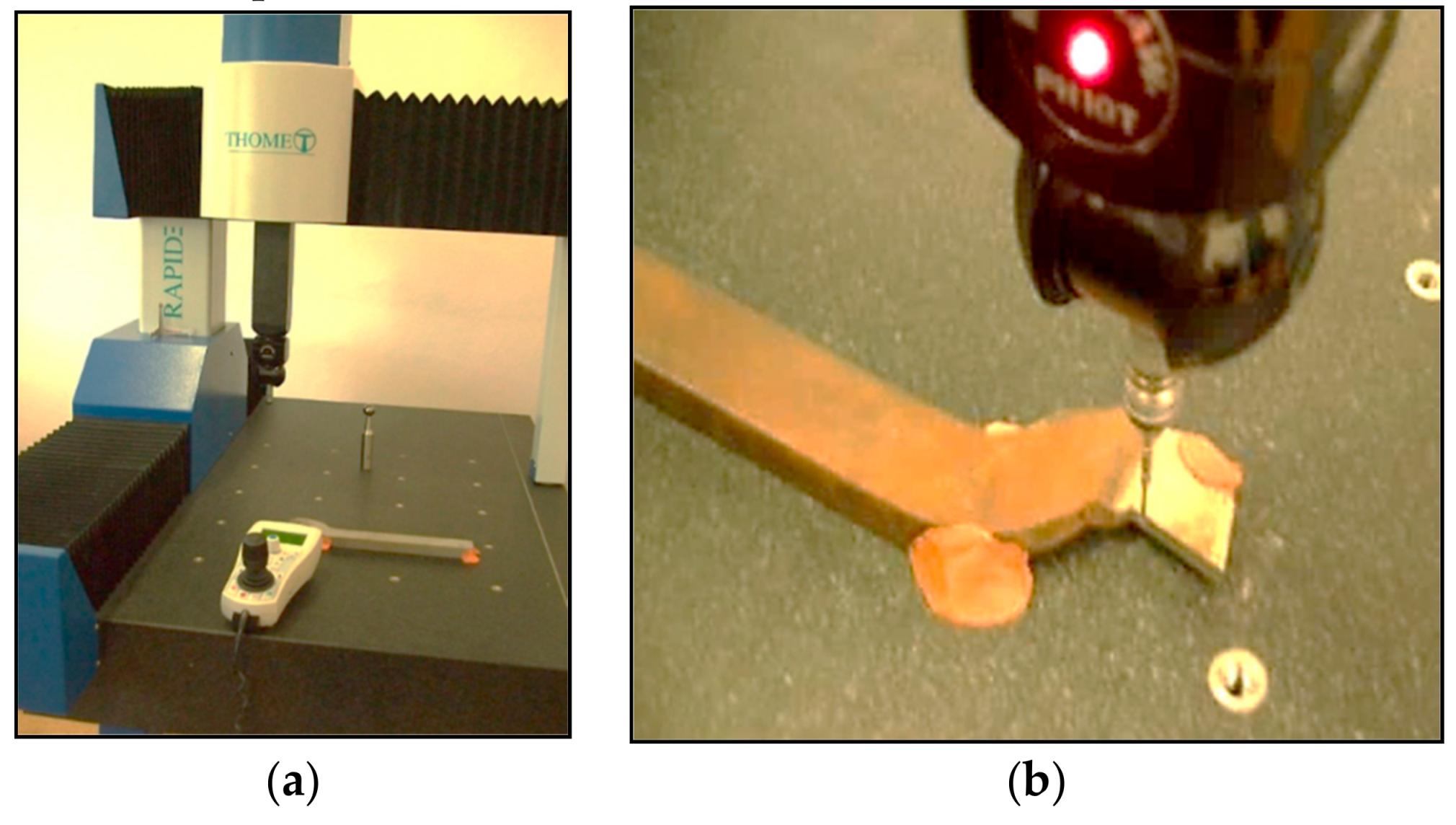

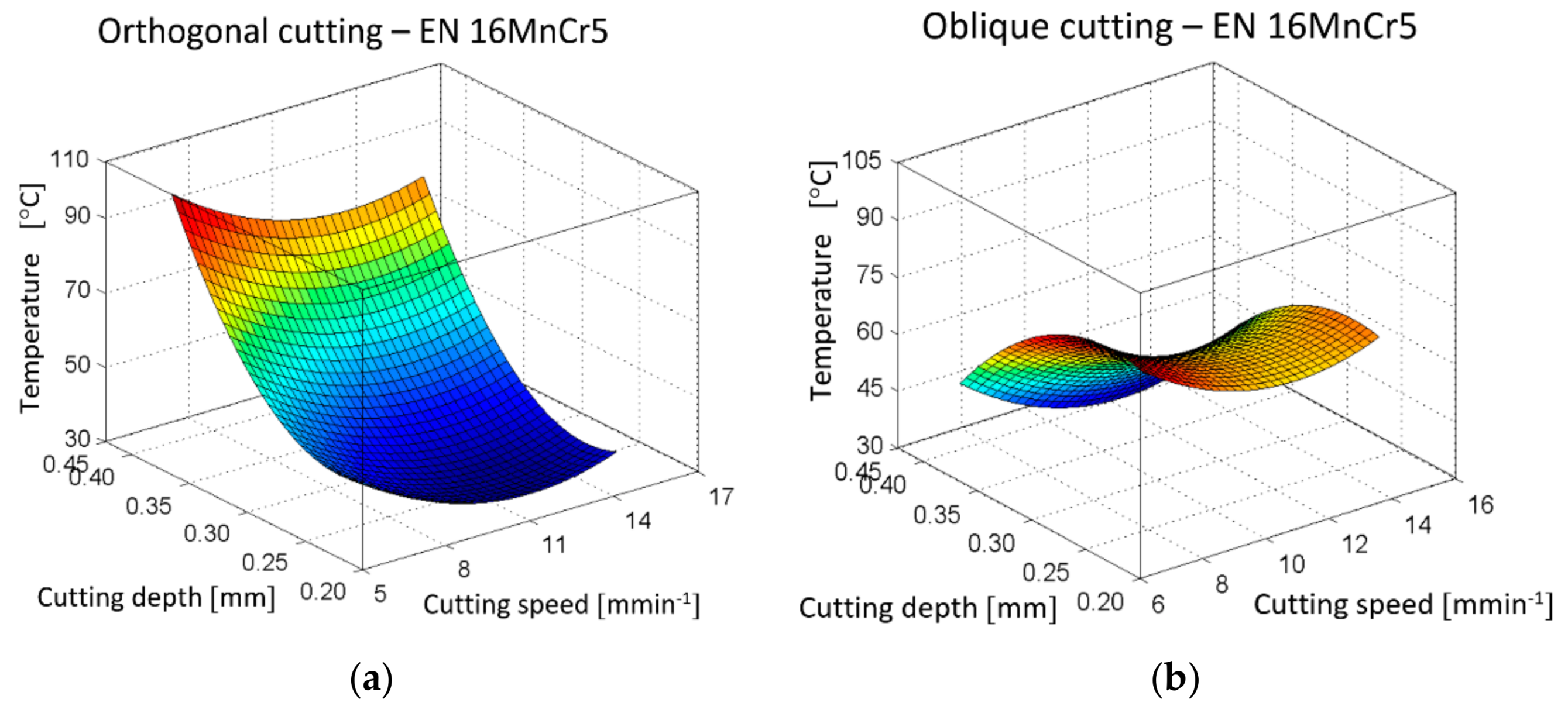

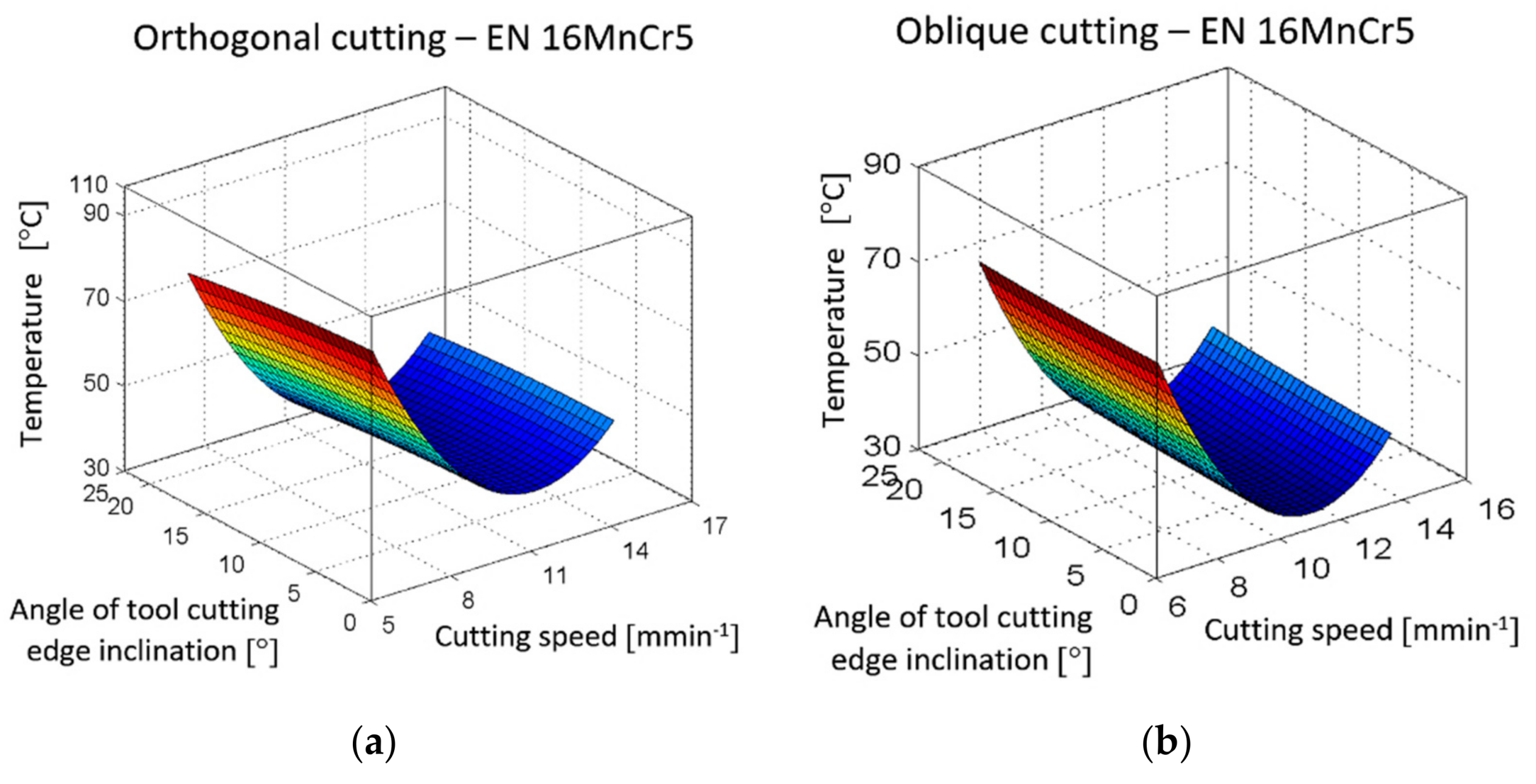

The goal of this article is to study some aspects of chip formation in the orthogonal and oblique slow-rate machining of EN 16MnCr5 steel. For the experimental comparative study, planing operation has been selected, by which the main sliding motion was performed by a workpiece. The main reason why this technology has been chosen is because chip formation is visible to the naked eye, in contrast to inward flanging (as another type of slow-rate machining), where the chip-forming process is hidden within the workpiece. For this reason, it has also been possible to measure the temperature in the cutting zone that is generated by the planing tool. The next factor was that restoring the cutting ability of the planing tools produced from high-speed steel by sharpening—according to the required parameters—was considerably easier when compared to turning tools.

Chip flow is only a part of chip space movement. To understand the chip formation mechanism, it is necessary to study other parameters that have an effect on the chip formation, and there are still many challenging issues to deal with.

Through the experimental measurements carried out in this study, different information has been gathered to help obtain a thorough understanding of the chip formation process at relatively low cutting speeds.

2. State of the Art

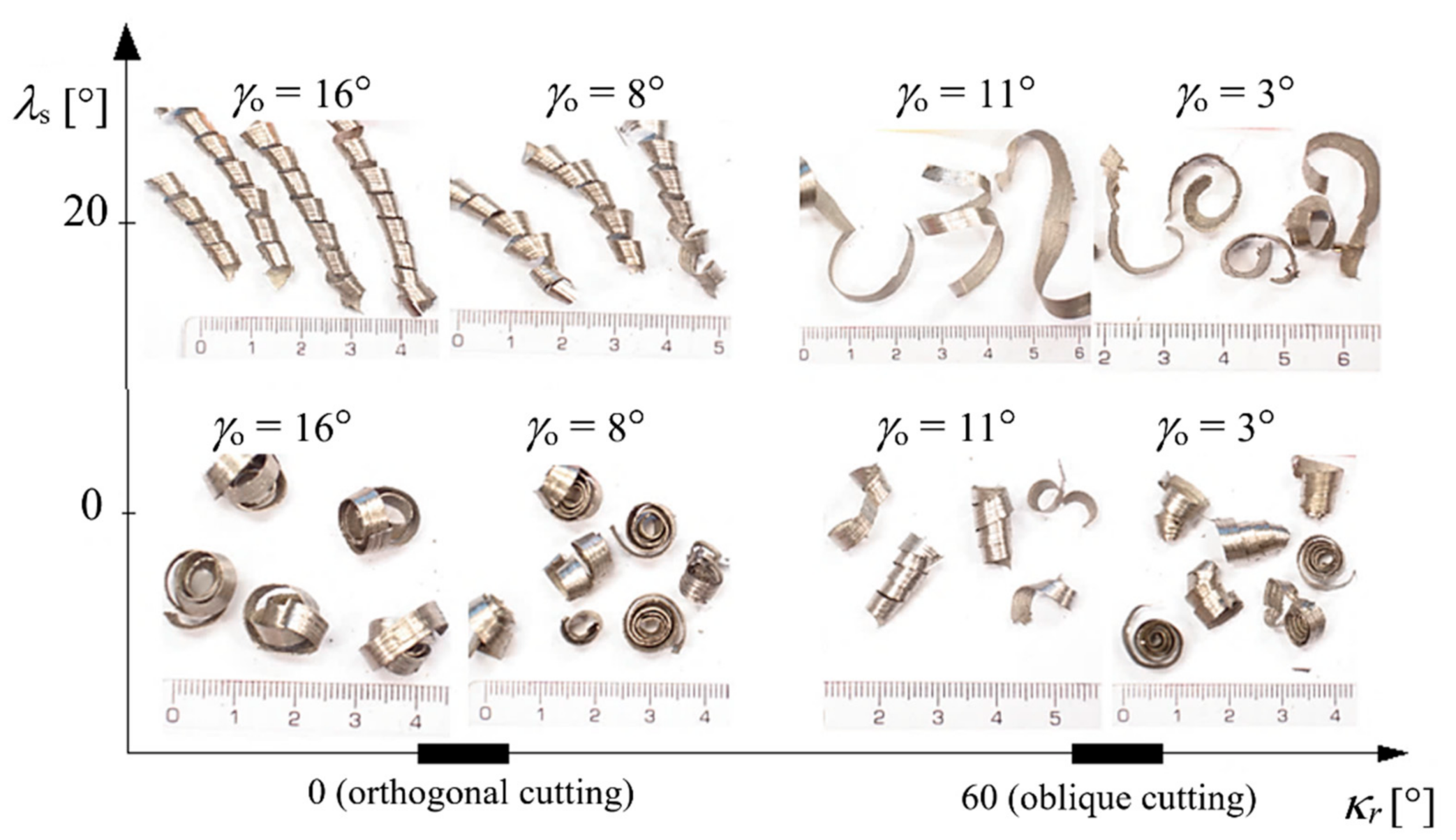

Chip machining is a complex process in which several mechanisms which are working simultaneously and interacting with each other. This process is greatly affected by material properties, cutting conditions, tool geometry, and machine tool dynamics. In any machining operation, the material is removed from the workpiece in the form of chips, the nature of which differs from operation to operation. As the form and dimensions of a chip from any process can reveal a lot of information about the nature and loyalty of process, the analysis of chips in the process of chip formation, by tear formation, is very important.

A lot of work has been conducted on chip flow angle research during the last few decades, and there are many methods for calculating of the chip flow angle. The investigation of chip flow began with modeling over plane rake face tools. Merchant [

1] and Shaffer and Lee [

2] have used plasticity theory to attempt to obtain a unique relationship between the chip shear plane angle, the tool rake angle, and the friction angle between the chip and the tool. Palmer [

3] presented shear zone theory by allowing for variation in the flow stress for a work-hardening material. Von Turkovich [

4] investigated the significance of work material properties and the cyclic nature of the chip formation process in metal cutting. Okushima [

5] considered that chip flow is not influenced by cutting speed and chip flow should be the summation of elemental flow angles over the entire length of the cutting edge. Slip-line field theory is widely applied in chip formation research and some slip-line field models are presented [

6,

7,

8]. Another chip flow model was presented by Young [

9], assuming Stabler’s flow rule, with validity for infinitesimal chip width, and the directions of elemental friction forces summed up to obtain the direction of chip flow.

During machining, material is removed from the workpiece, where it flows out in the form of chips. After flowing out, the chip curls either naturally or through contact with obstacles. If the material strain exceeds the material breaking strain, the chip will break. Chip flow, chip curl, and chip breaking are three main areas of chip control research [

10].

According to Toulfatzis et al. [

11], an improved chip breaking capability is directly connected with lower cutting tool wear rates. The width of the chips varies according to the different depths of cut employed during the various machining experiments. Chip segmentation is of pivotal importance since it facilitates the machining ergonomics and scrap removal without damaging workpiece surface quality and ensures the safety of the working personnel.

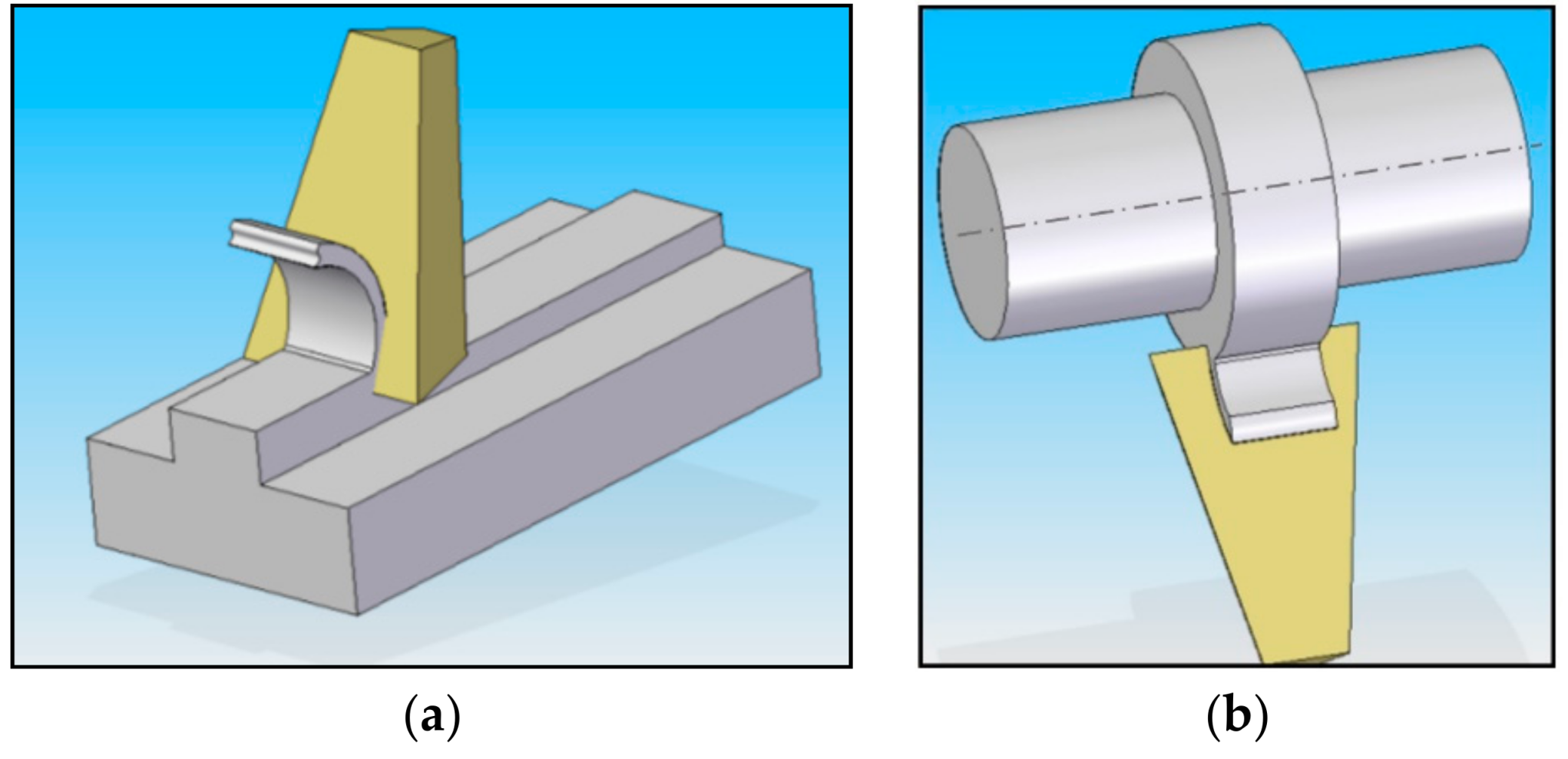

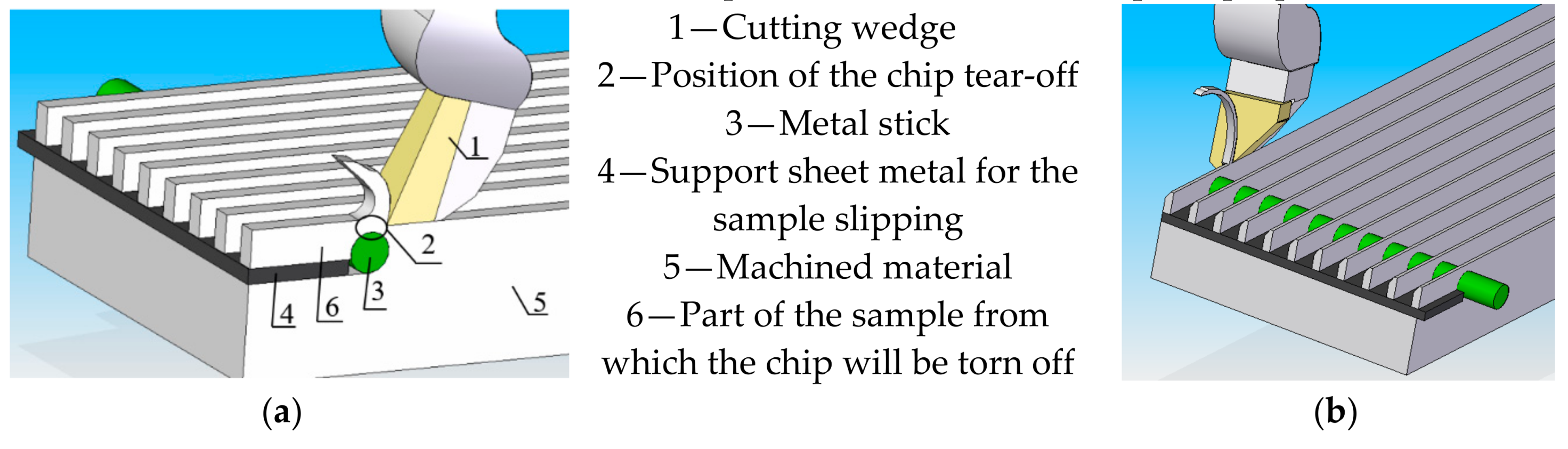

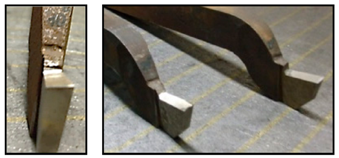

To study the chip characteristics, it is necessary to specify the type of machining by which the chip is forming. There are two different types of cutting: orthogonal (

Figure 1a) and oblique (

Figure 1b). Orthogonal cutting is a type of metal cutting in which the cutting edge of the wedge shape cutting tool is perpendicular to the direction of tool motion. In this cutting, the cutting edge is wider than the width of the cut. This cutting type is also known as 2D cutting because the force developed during the cutting can be plotted on a plane or can be represented by a 2D coordinate.

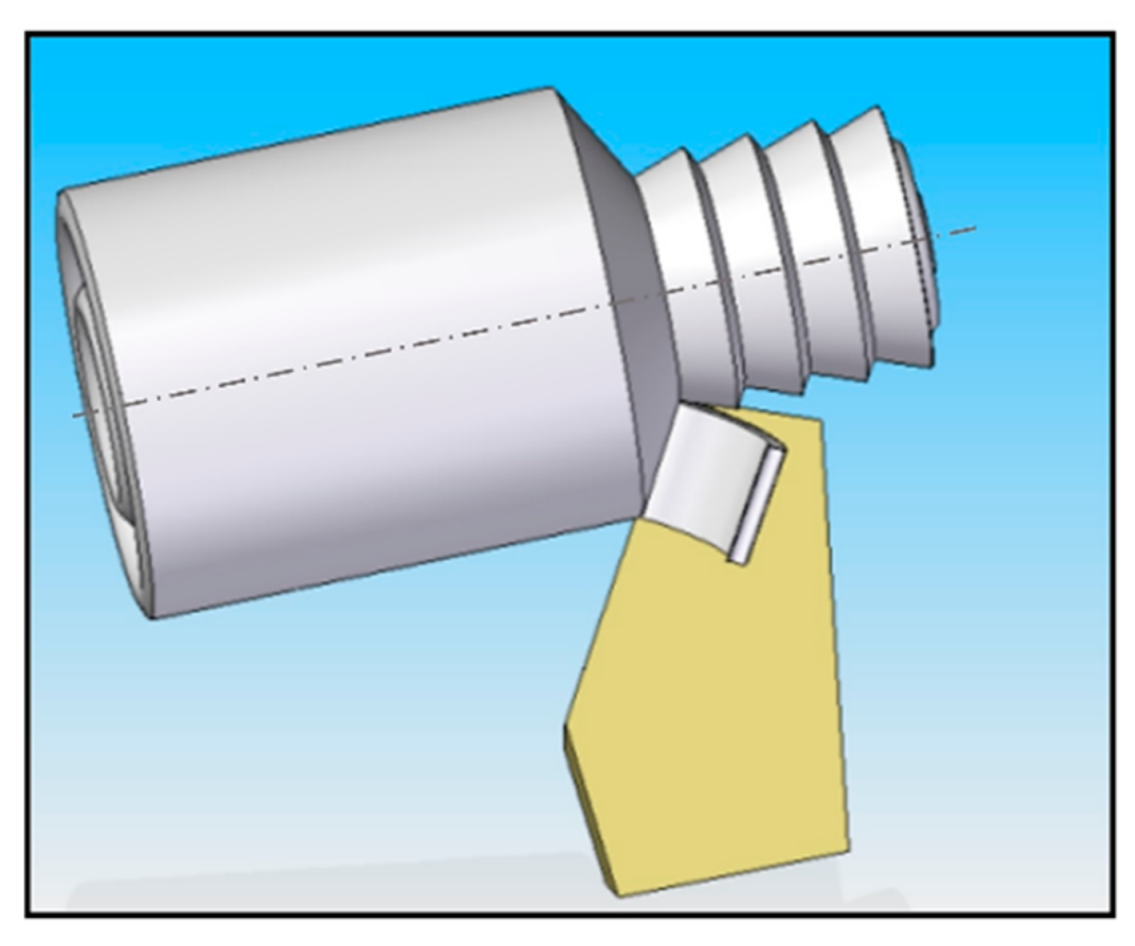

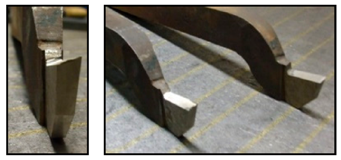

However, orthogonal cutting is only a particular case of oblique cutting and, as such, any analysis of orthogonal cutting can be applied to oblique cutting. Oblique cutting (

Figure 2) is a common type of three-dimensional cutting used in the machining process [

12].

In this type of machining, the cutting edge of the wedge shape makes an angle, except for the right angle, to the direction of tool motion. This will affect the cutting conditions and is also known as 3D cutting because the cutting force developed during the cutting process cannot be represented by 2D coordinates and 3D coordinates must be used to represent it.

One of the most important parameters of oblique cutting is the chip flow angle. Stabler [

13] stated that the chip flow angle is very close to the angle of obliquity. This rule has been accepted by many researchers and it has been considered to be a good predictor of the chip flow angle, e.g., as stated in [

14,

15,

16]. However, Stabler’s rule does not take into account the mechanics of the cutting process, such as the influence of the shear angle and friction. In some special cases, it can cause larger errors. Luk [

17] investigated the effect of cutting parameters on a chip flow angle and their study has been verified by Lin and Oxley [

18] within their experimental investigation. Also, Russel and Brown [

19] confirmed the influence of the normal rake angle on the chip flow. Shamoto and Altintas [

20] developed a model for shear angle prediction in oblique cutting where the shear angle is specified by two components of the resultant force and by the chip flow angle. Moufki together with his colleagues [

21] calculated the chip flow angle supposing that the friction force is collinear to the chip flow direction on the tool rake face. The effect of nose radius on the chip flow angle has been studied by investigators Usui [

22] and Wang [

23] using an iterative energy minimization method.

The chip characteristics during the milling process by varying the feed rates and the types of materials used were investigated by Prasetyo [

24].

Chip morphology and microstructure were also studied by Hernández [

25] in dry machining, where the influence of cutting speed and feed rate on various geometric chip parameters was carried out when cutting Ti6Al4V alloy.

Various methods by many researchers have been used to study chip geometry. Some of them analyzed chip geometry from an analytical point of view, resulting in the formulation of some theoretical models [

26,

27,

28]. However, in these cases, many simplifications had to be made with regard to the complexity of the chip formation process and, hence, some of the real, practically obtained results have not correspond to the predictions of various parameters to set up a chip geometry, and the results were inaccurate [

29,

30,

31]. Next, analyses of the chip formation used numerical models (finite element method, FEM) to simulate the chip generation process [

32,

33,

34,

35]. These models require a very good and precise definition of the boundary conditions; otherwise, the models are incomplete and vague [

36,

37].

Many of the studies that analyze the influence of one or two cutting parameters on chip geometry can be found in which the measured data were processed using four major statistical methods: regression, factor analysis, stochastic processes, and contingency table analysis [

38,

39,

40,

41,

42]. Salem [

43] and his coauthors have studied the chip formation at the machining of a hardened alloy X160CrMoV12-1 to obtain the optimal cutting conditions and to observe the different chip formation mechanisms. For the sake of simplicity, ANOVA (ANalysis Of VAriance) was used in this study to determine the influence of cutting parameters.

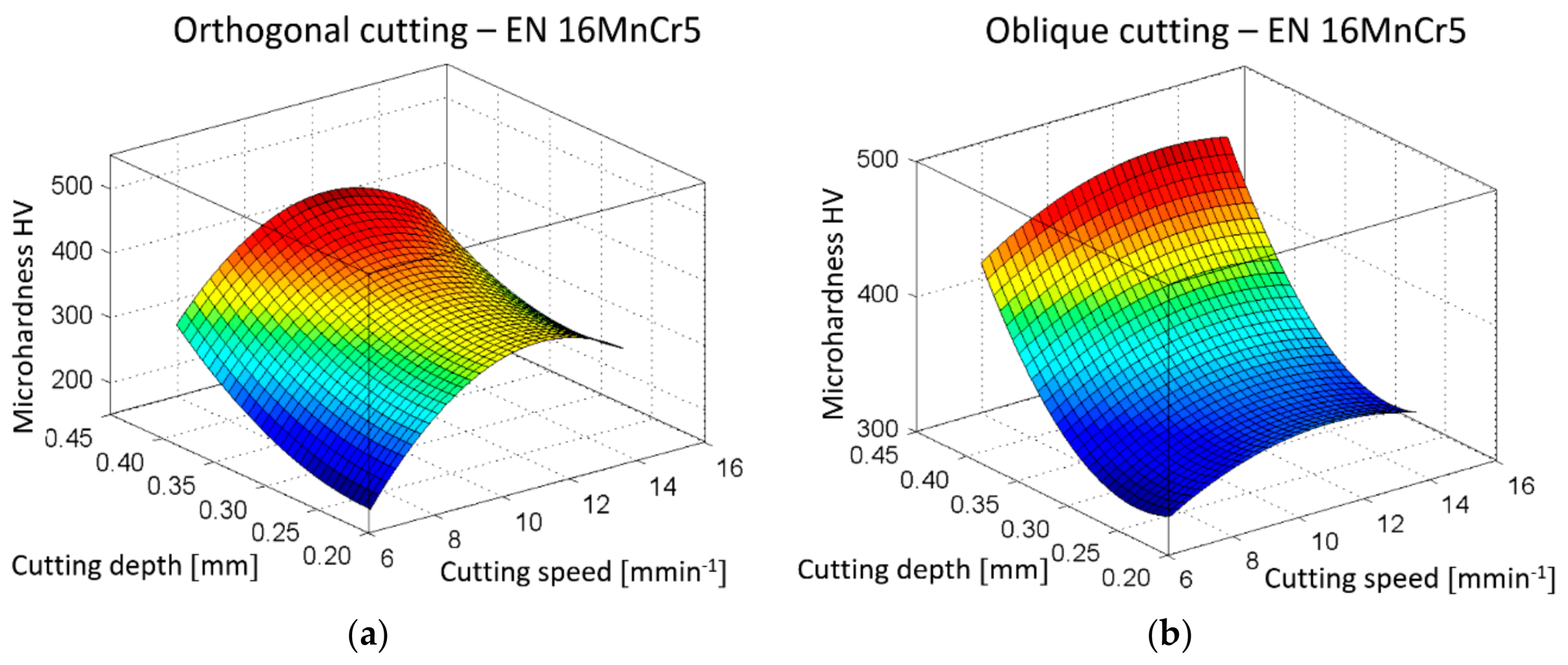

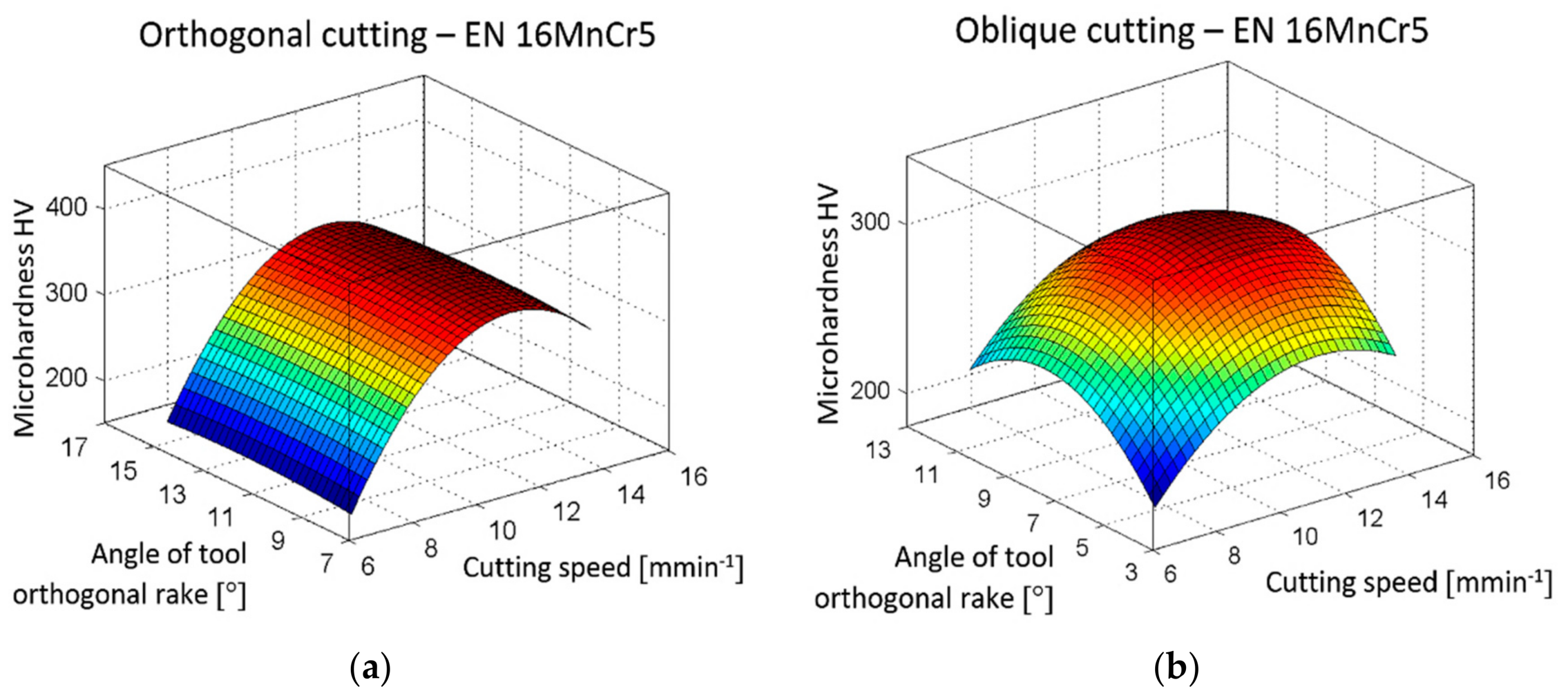

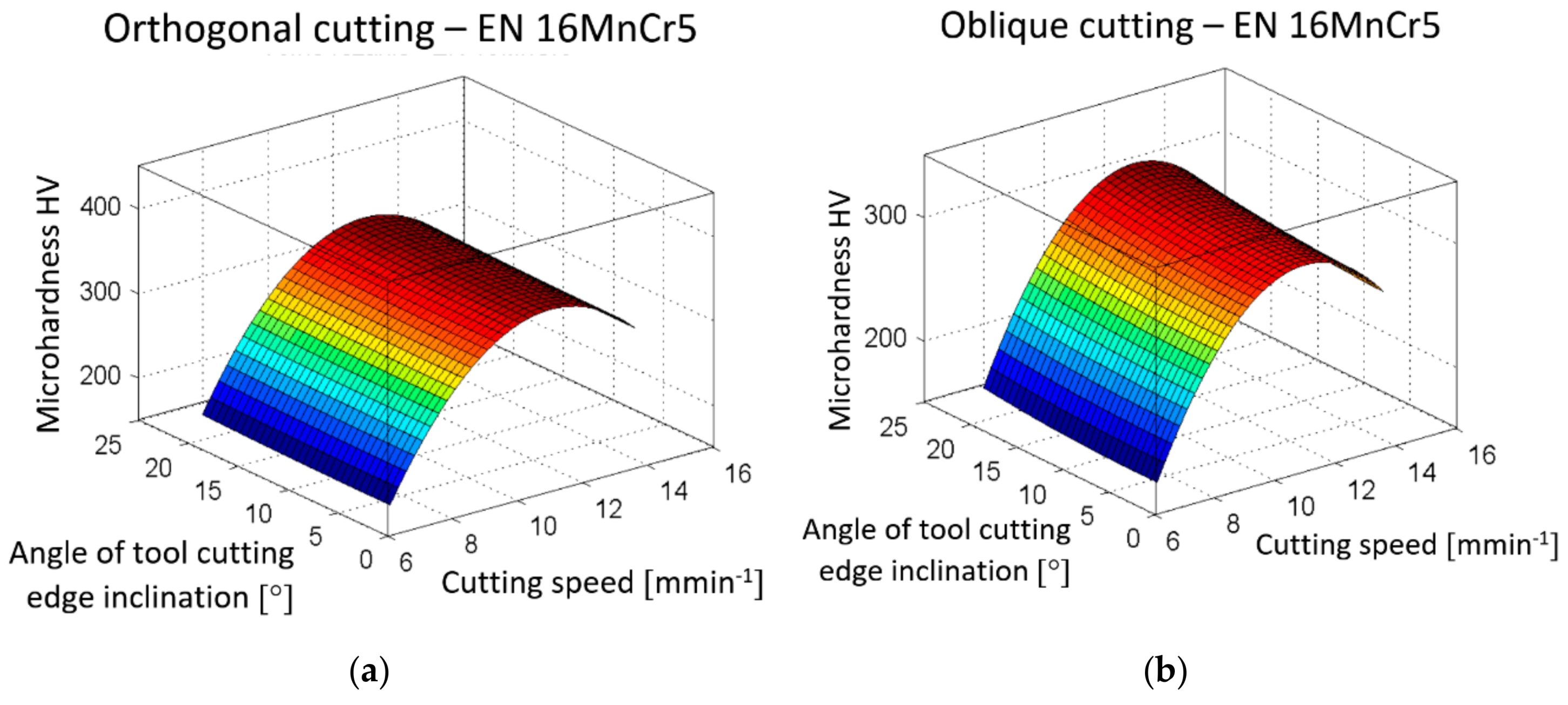

Currently, research of chip formation at slow-rate machining has been concerned with the influence of one or two factors on microhardness or temperature at chip root. Only a few studies have focused on chip formation in EN 16MnCr5 steel machining. The novelty of the presented study lies in the following: This research is more complex, while still considering the mutual connections among the four factors influencing chip forming in the cutting of EN 16MnCr5 steel in combination with observing and comparing the significance and influence of each individual factor in orthogonal and oblique cutting. For this reason, a three-level planned experiment was used for statistical evaluation of the obtained data. Based on the experimental study, several parametric models have also been developed that allow for the prediction of different temperatures or microhardness evolution at a chip root as a function of input parameters (cutting speed, cutting depth, and two geometry angles and of a tool λs and γo). Hereby, a new method of obtaining chip roots has been designed. The new method can be used to prevent changes in the microstructure of material by demonstrating a non-deformed and thermally uninfluenced chip root.