Connection Status Research of the Resistance Spot Welding Joint Based on a Rectangular Terminal Electrode

Abstract

:1. Introduction

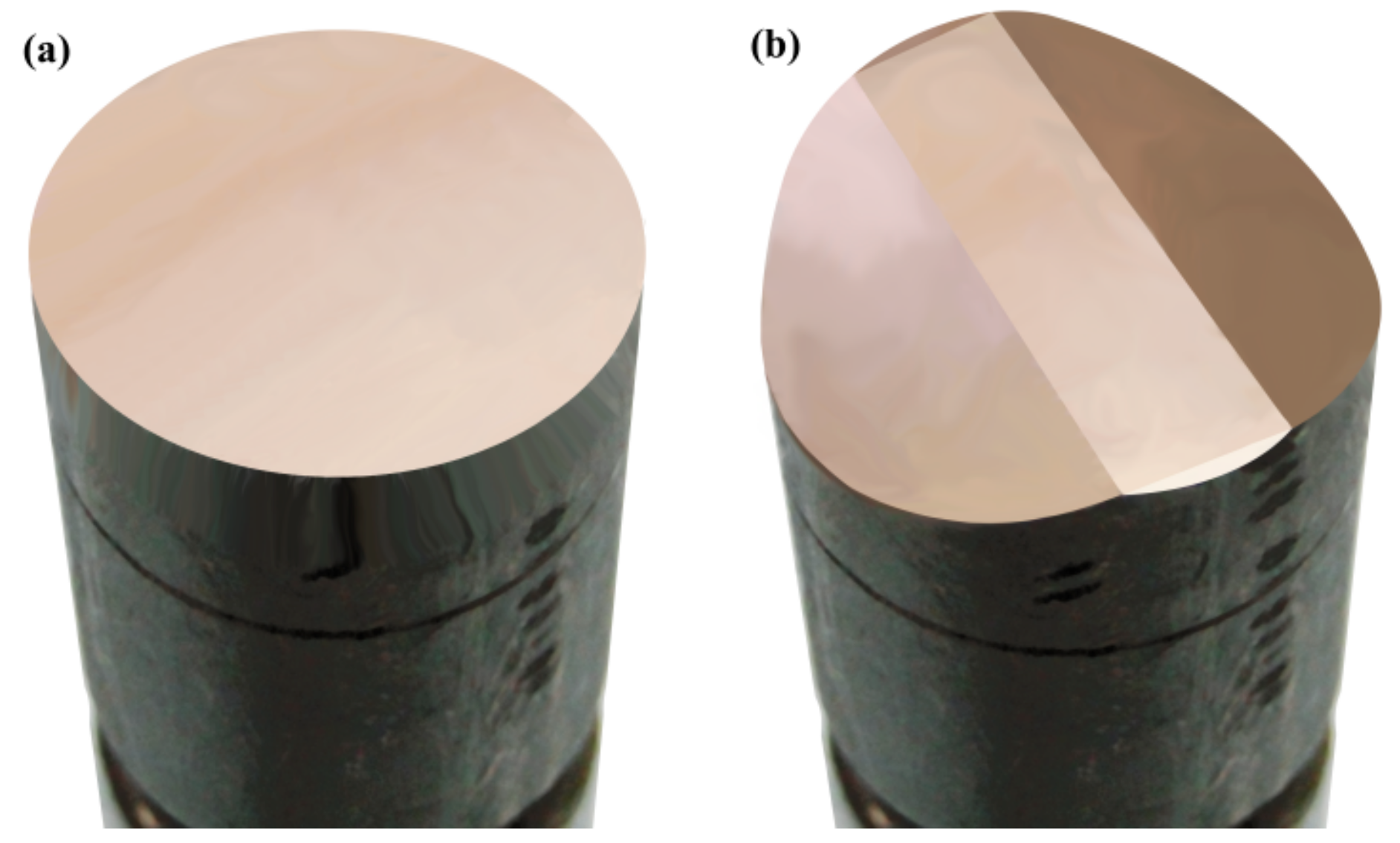

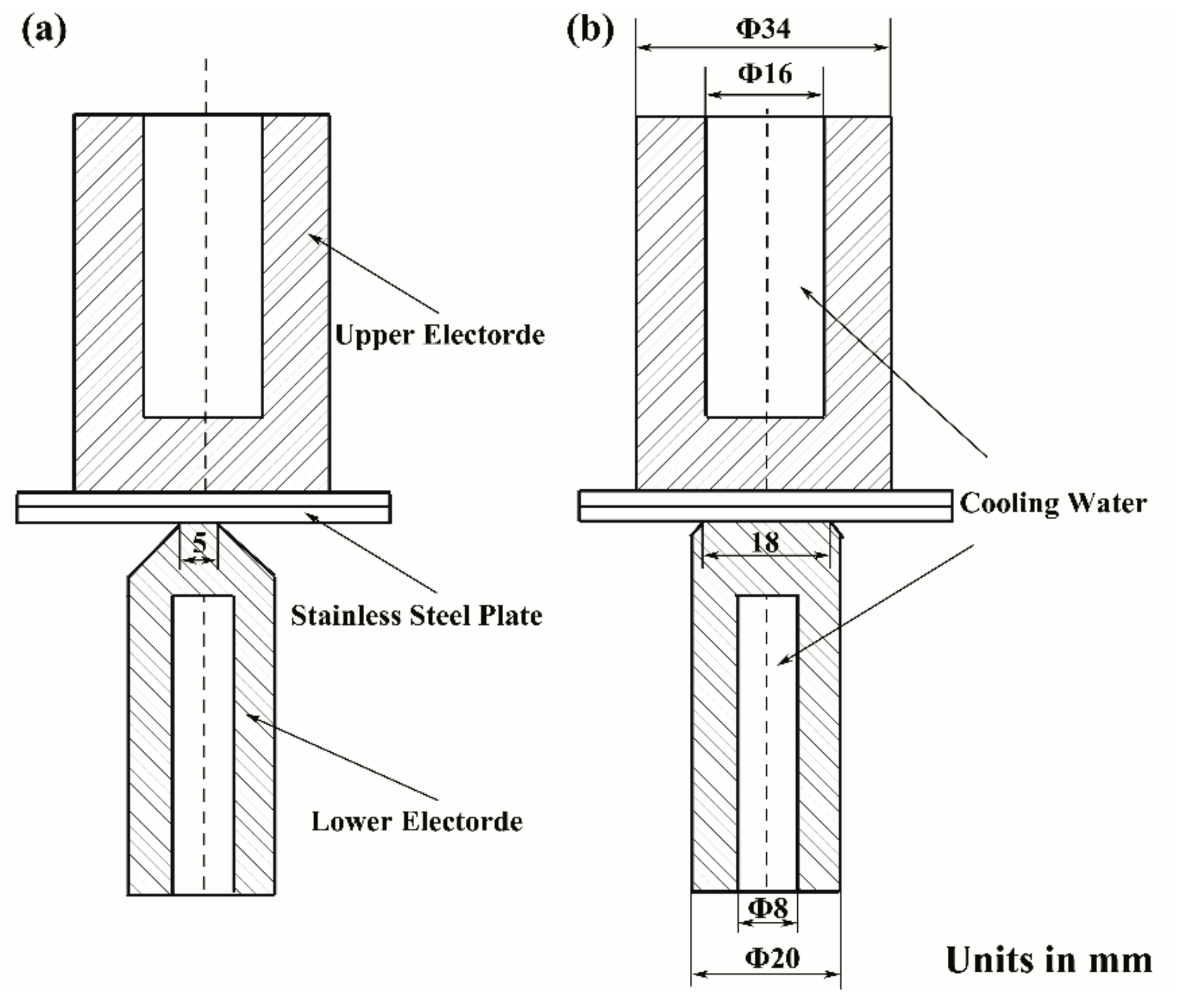

2. Materials and Experimental Conditions

2.1. Experimental Materials and Sample Dimensions

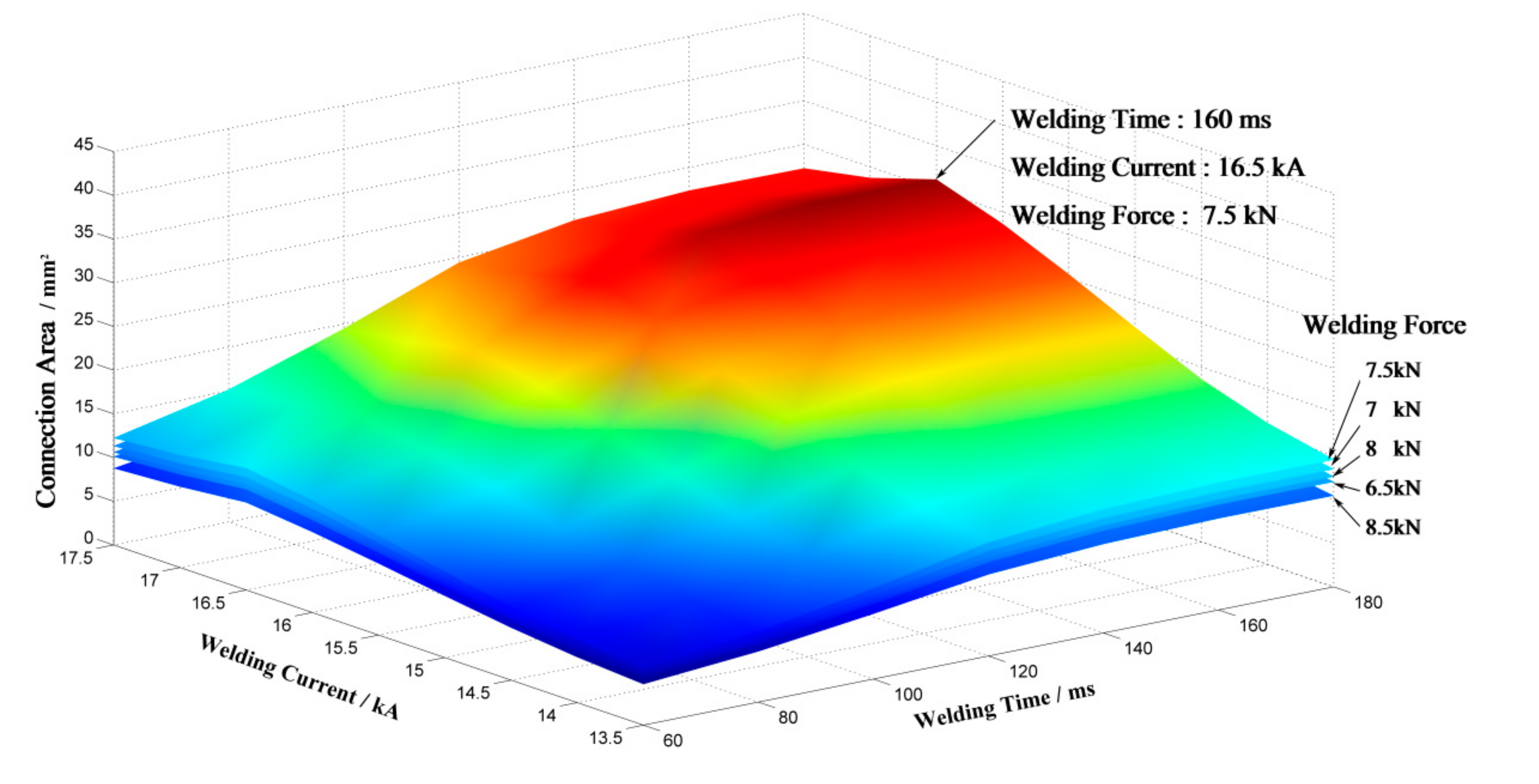

2.2. Welding Parameters

3. Results and Discussion

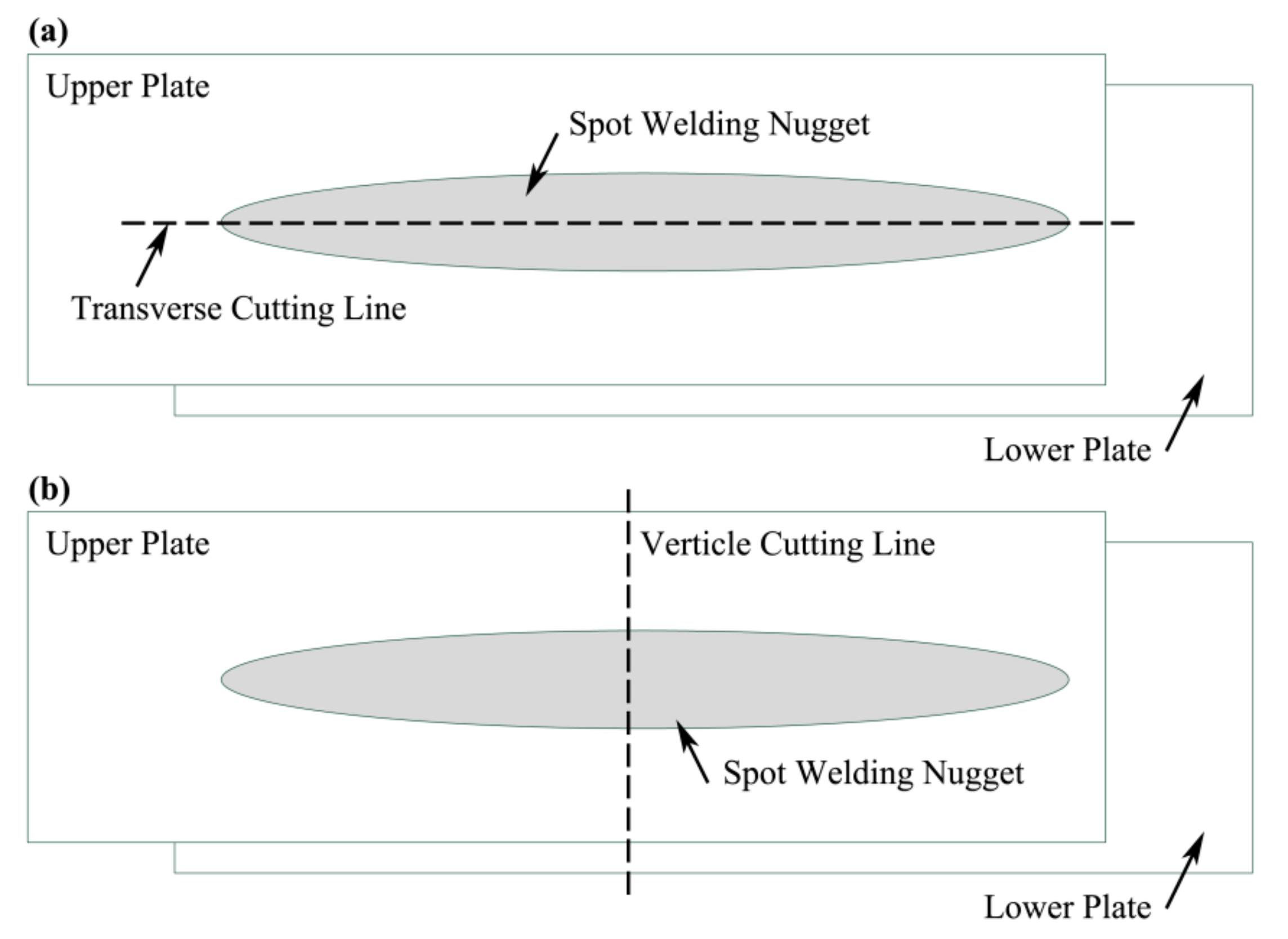

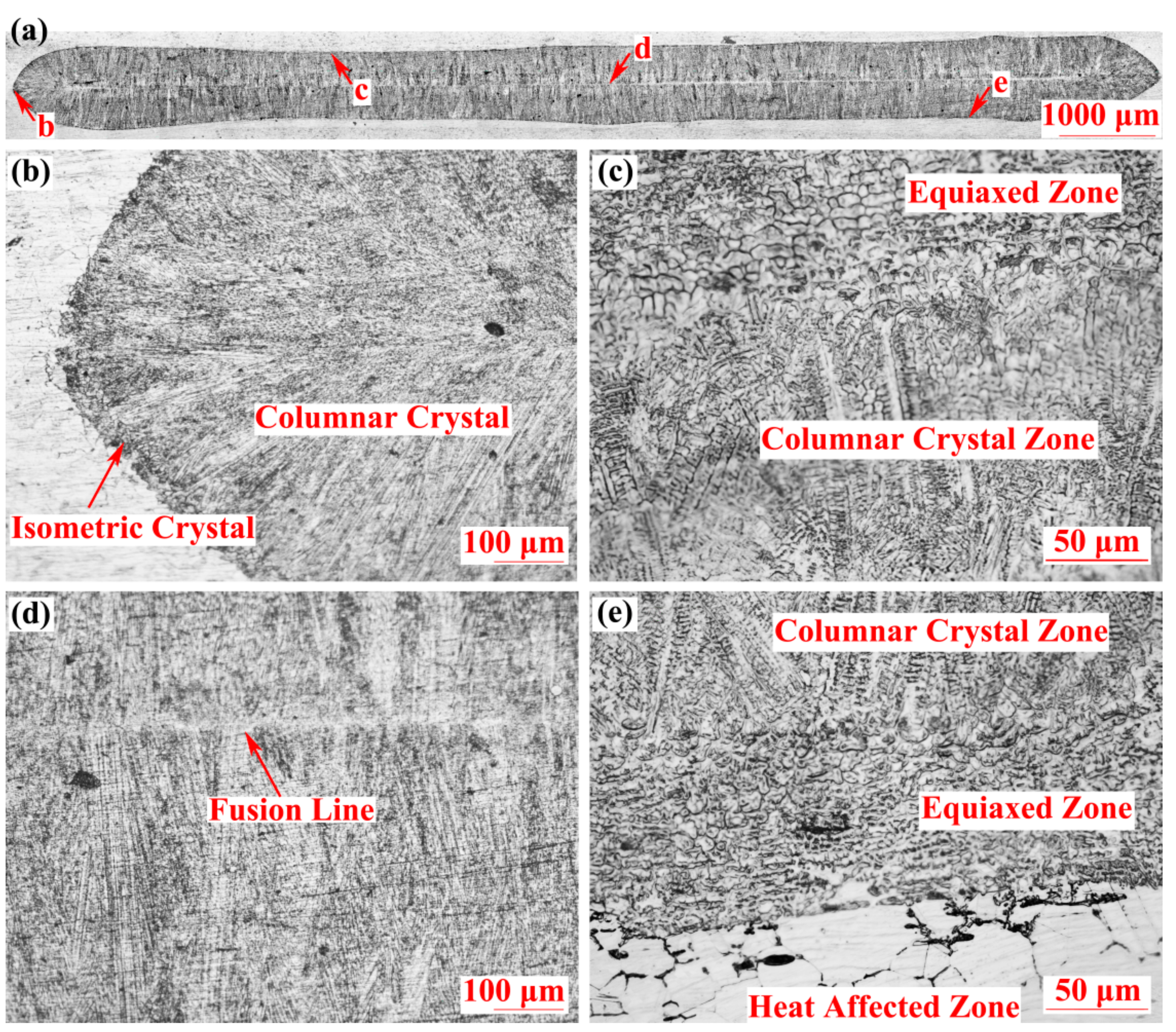

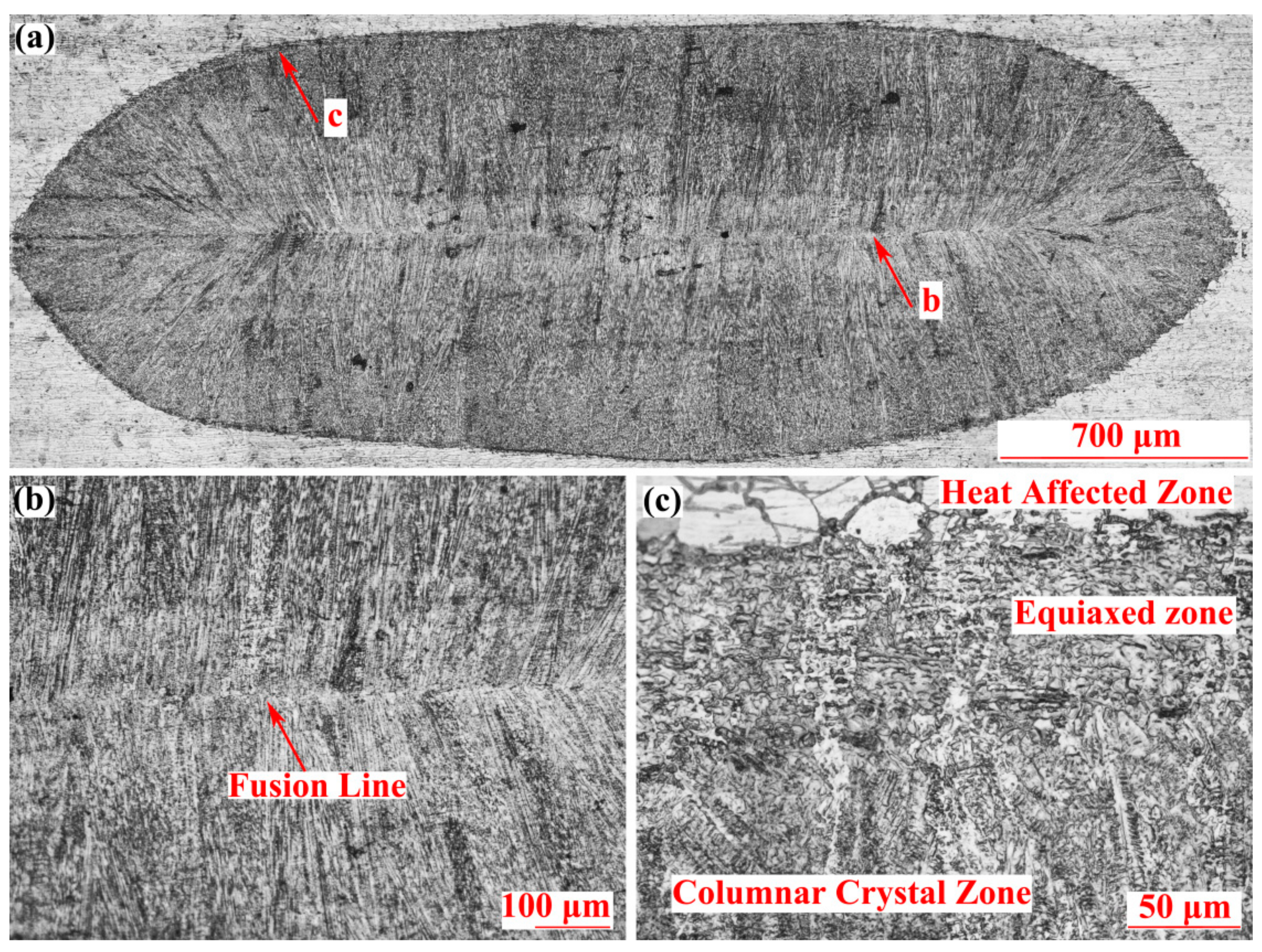

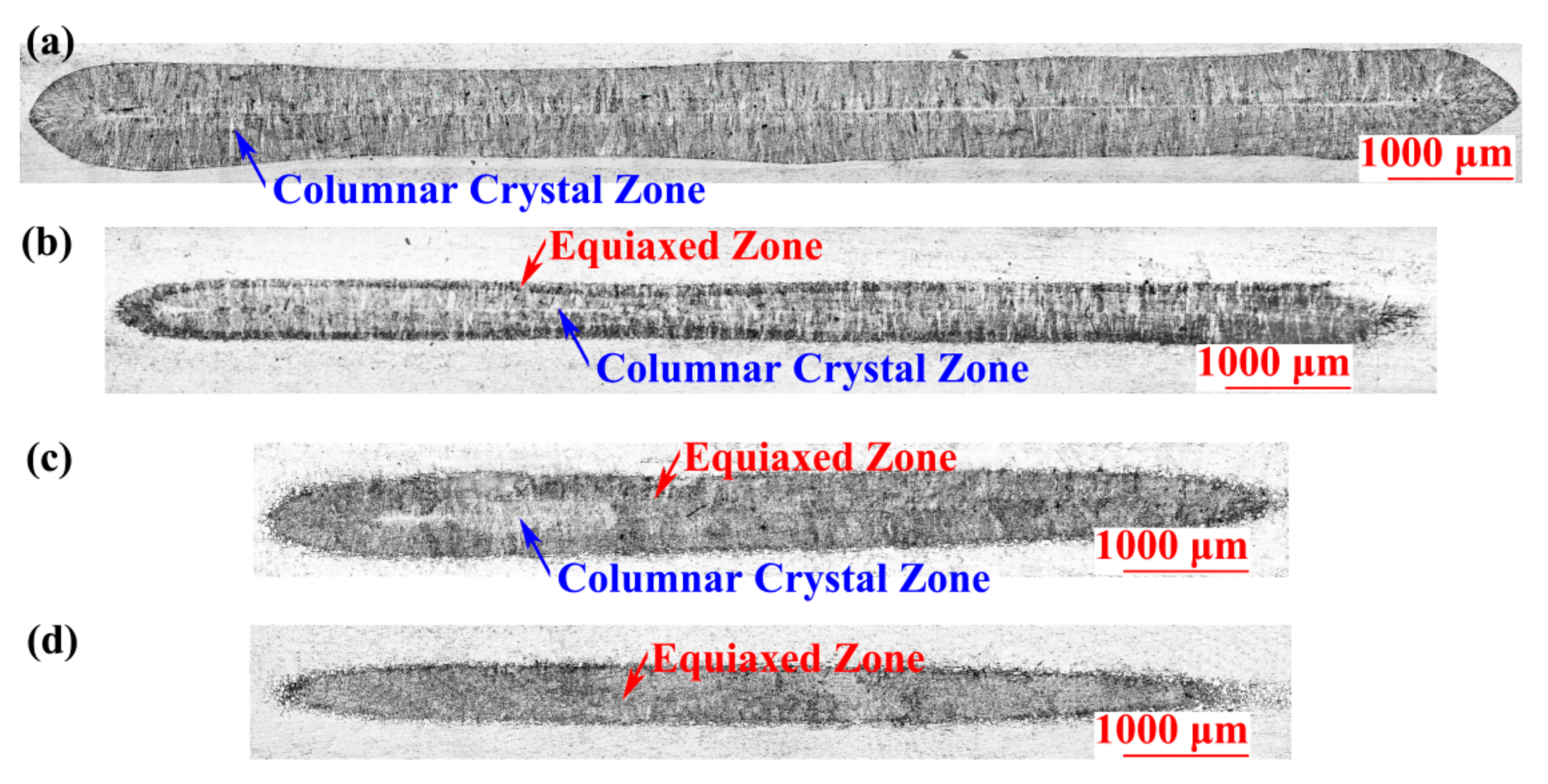

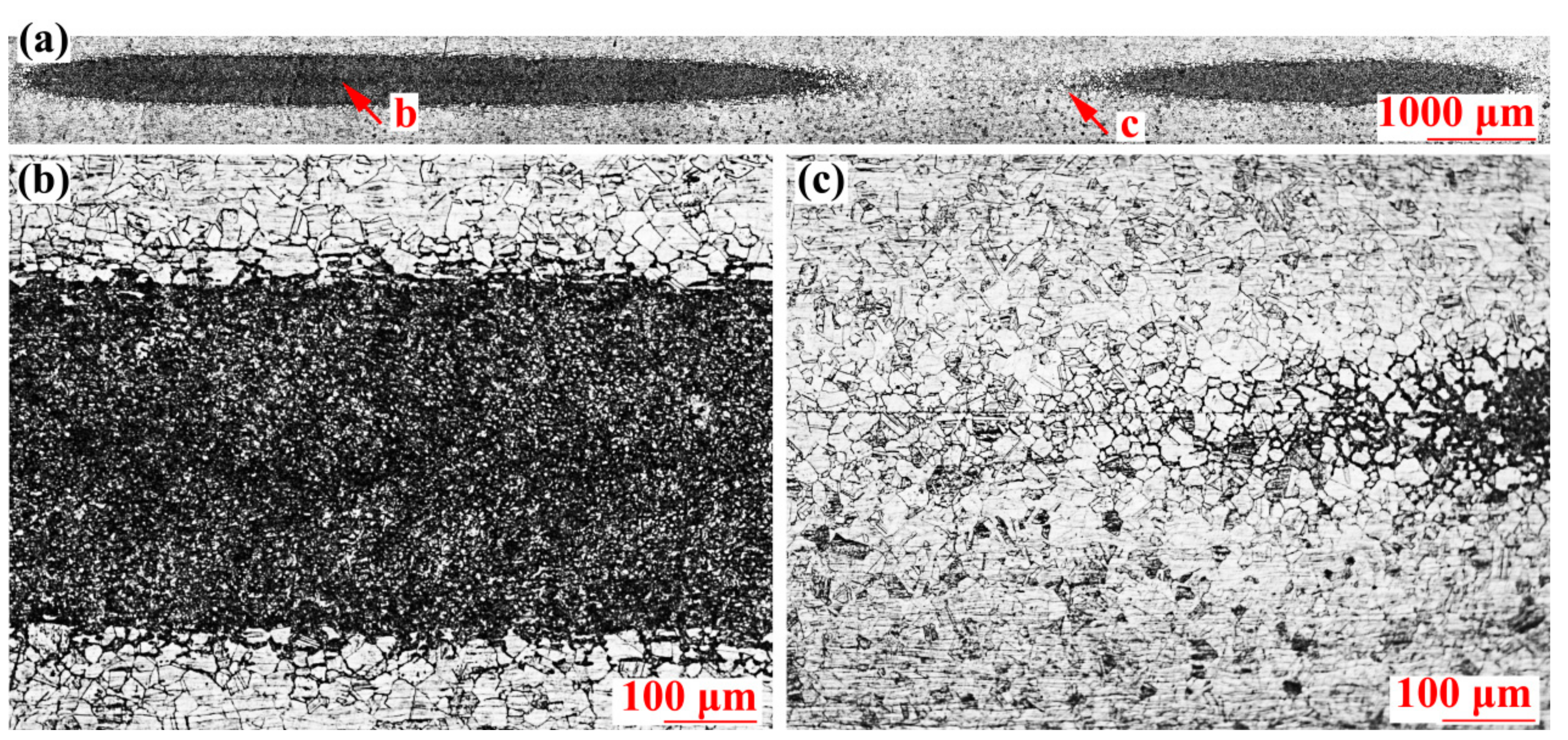

3.1. Metallographic Morphology of the Well-Connected RSW Joints

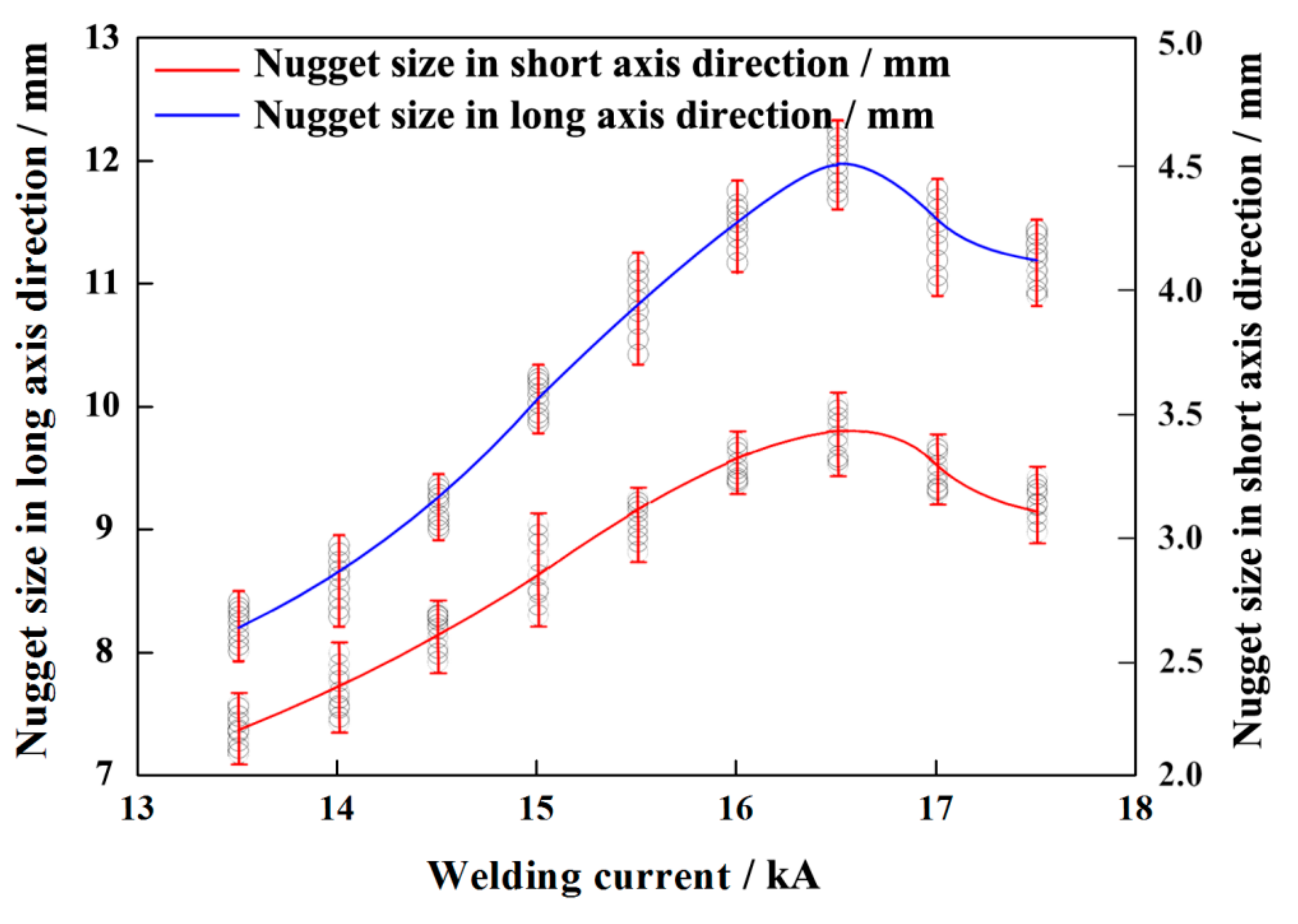

3.2. Influence of Welding Current on the RSW Nuggets

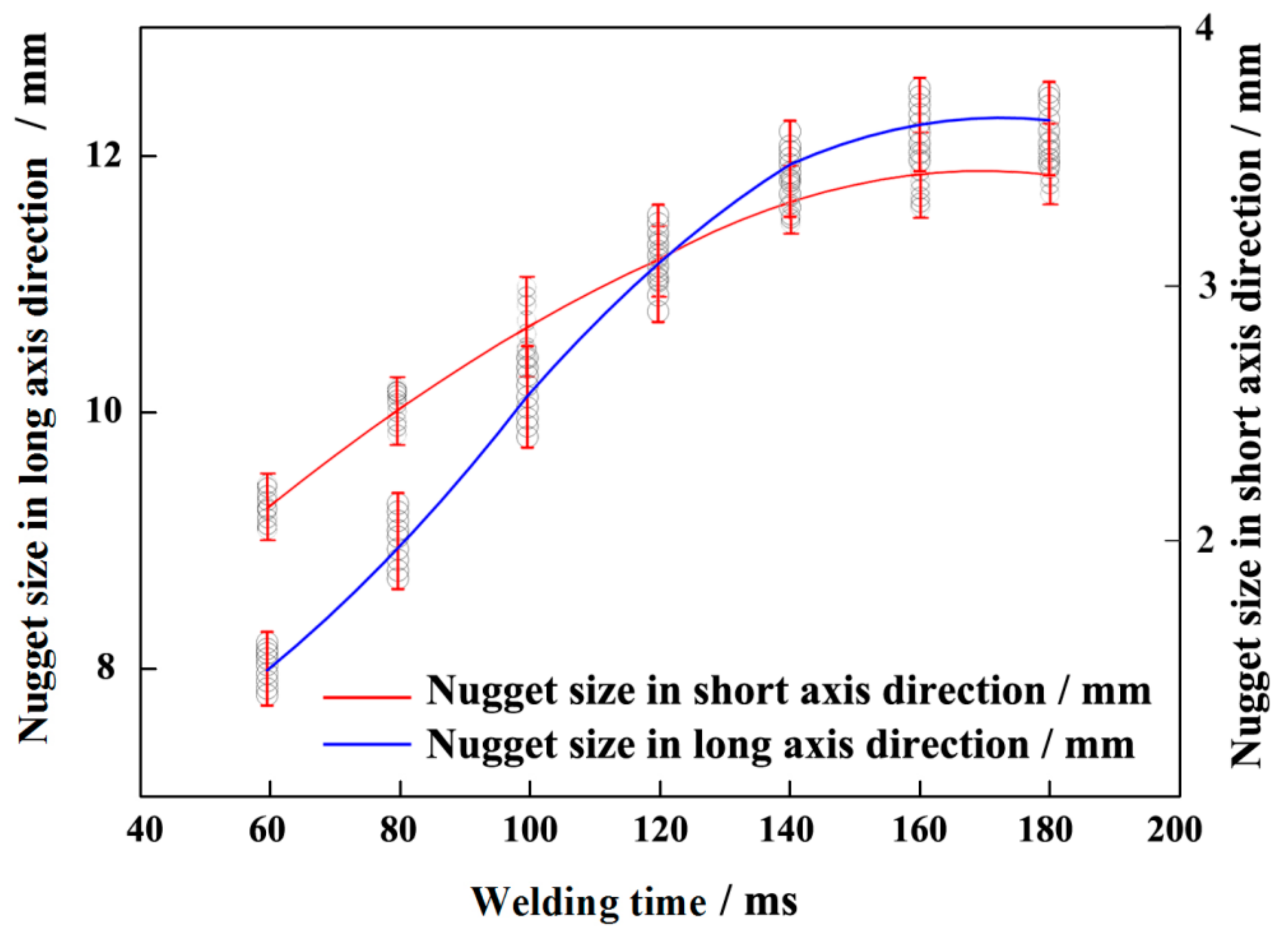

3.3. Influence of Welding Time on the RSW Nuggets

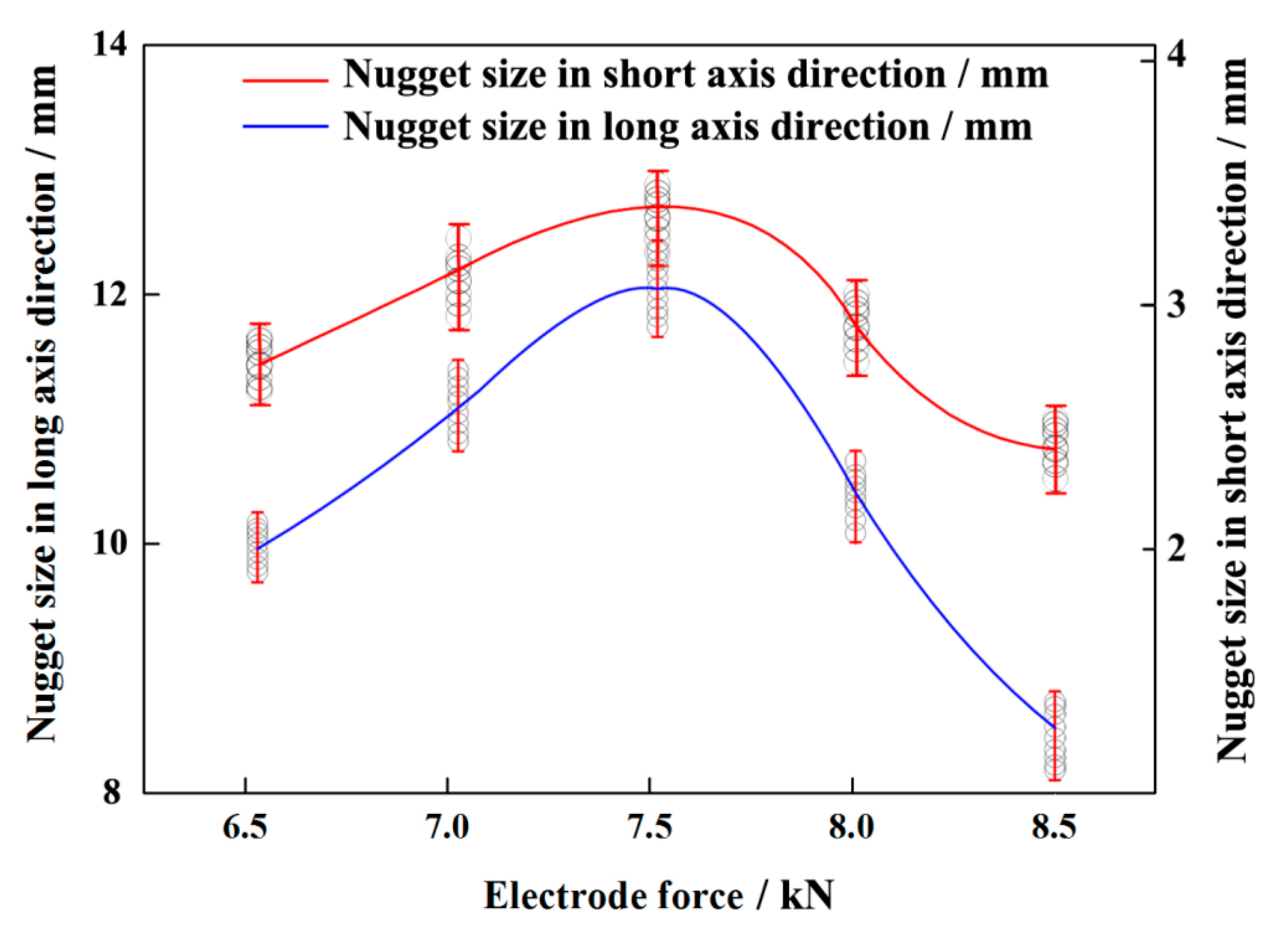

3.4. Influence of Welding Pressure on the RSW Nuggets

4. Conclusions

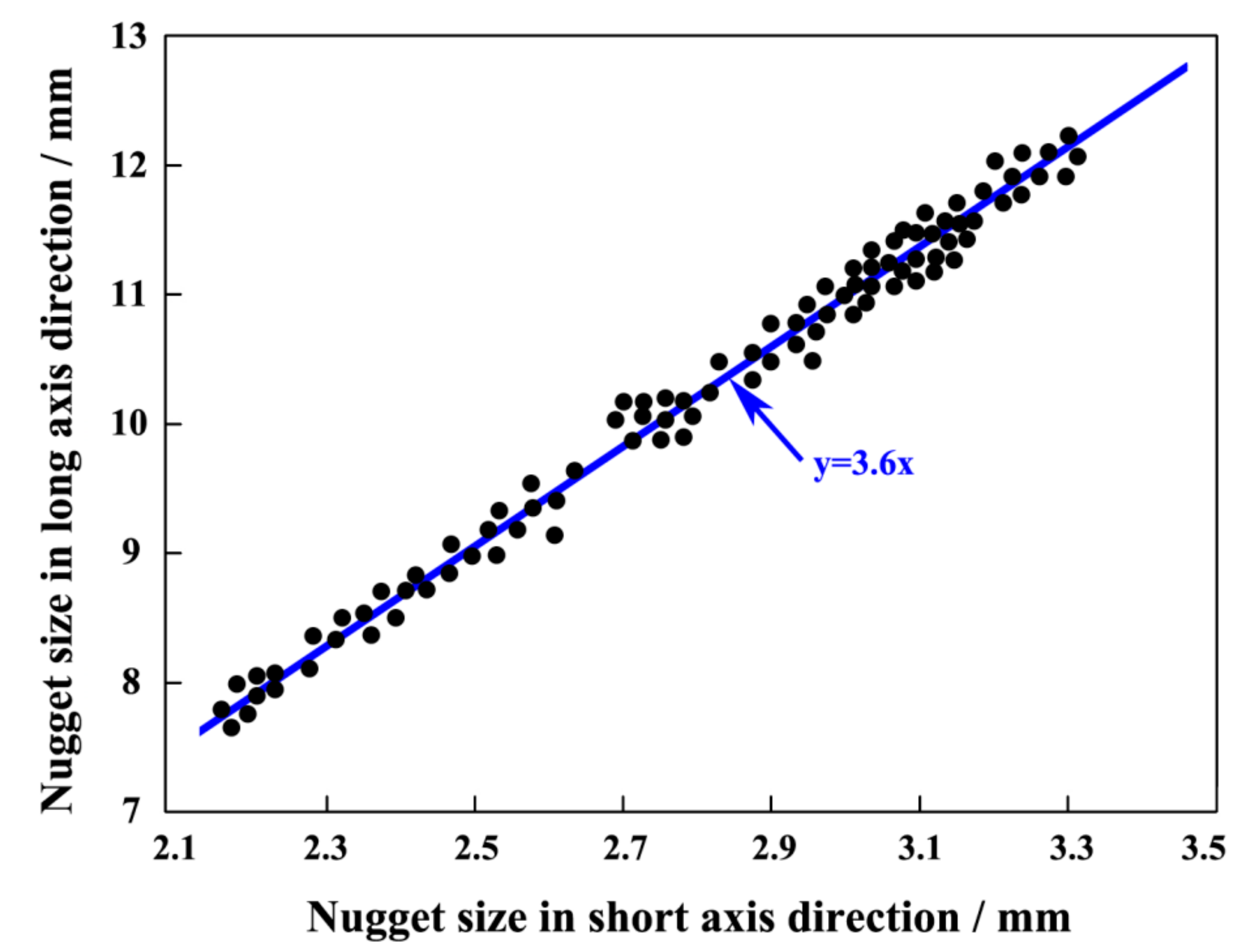

- Elliptical welding joints can be obtained on stainless steel plates by RSW with rectangular terminal electrode. There is a proportional relation between the nugget’s dimensions on the long axis and the short axis, and the nugget’s dimension ratio of the long and short axis is generally close to that of the long and short sides of the rectangular terminal electrode.

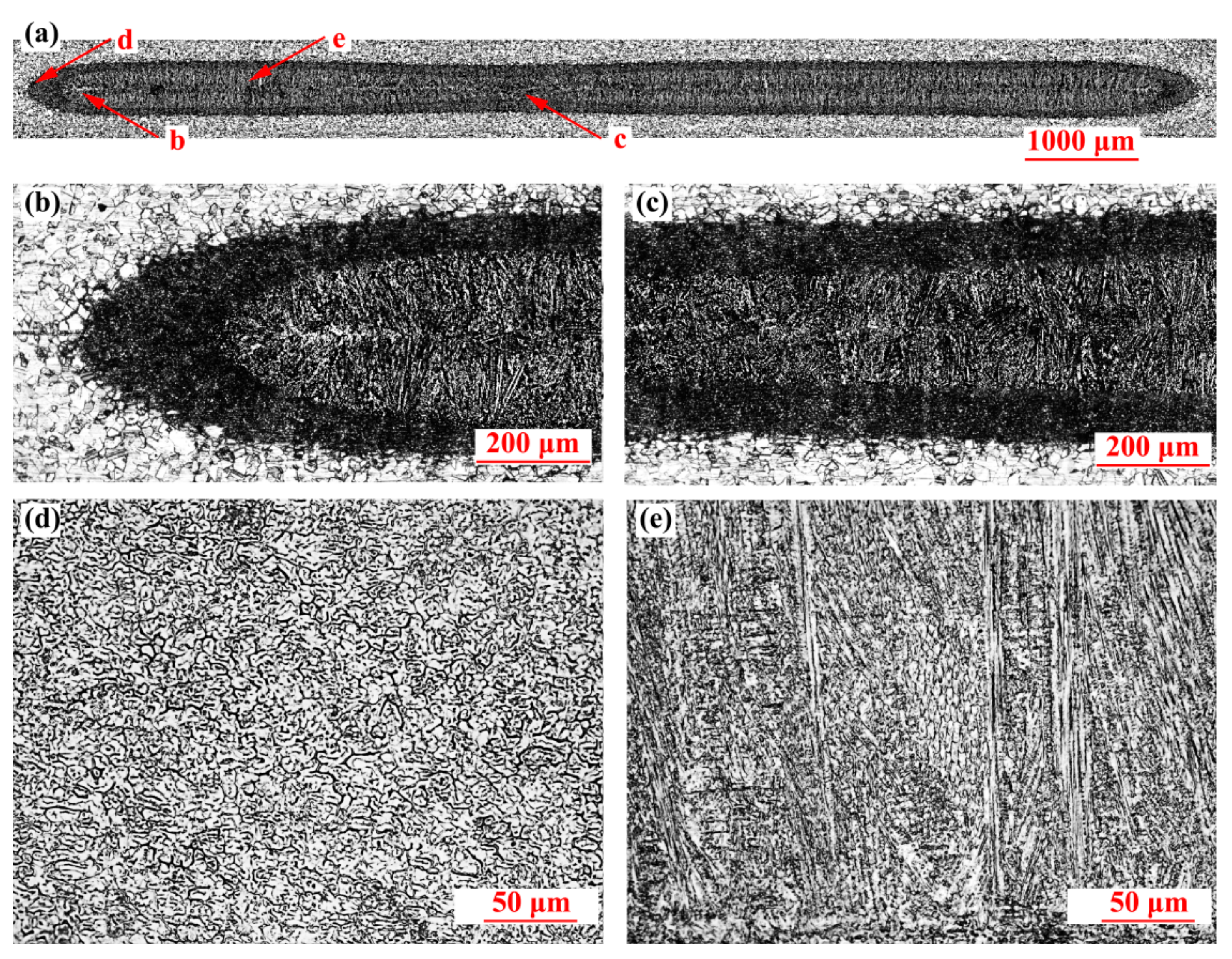

- The electrode terminal area can be used as an input to roughly estimate welding current density and the welding current range can be settled according to this. With the welding current increase, the RSW nugget’s dimensions of the long axis increase first and then decrease. When the nugget dimension reaches the peak value, the nuggets are mostly composed of regular columnar crystal and have a typical spot welded joint morphology. When the welding current decreases, the nugget dimensions decrease and the width of the equiaxed zone increases gradually. When the welding current is too small, the columnar crystal zone at the central of the nugget disappears, and the nugget is completely composed of isometric crystals.

- With the increase in welding time, the RSW nuggets dimensions increase first and then remain steady. The long welding time generally does not cause splash during the welding process.

- The electrode terminal area can be used as an input to roughly estimate welding pressure range. With the welding pressure increase, the RSW nuggets dimensions of long axis increase first and then decrease. When the welding pressure is too high, it is easy to produce welding joints with small nugget dimensions and large heat affected zone. When the welding pressure is too small, it is easy to produce a unique joint with two adjacent nuggets.

Author Contributions

Funding

Conflicts of Interest

References

- Ramazani, A.; Mukherjee, K.; Abdurakhmanov, A.; Abbasi, M.; Prahl, U. Characterization of microstructure and mechanical properties of resistance spot welded DP600 steel. Metals 2015, 5, 1704–1716. [Google Scholar] [CrossRef]

- Bhole, S.D.; Ma, C.; Khan, M.S.; Chen, D.L. A study of spot welding of advanced high strength steels for automotive applications. J. Iron Steel Res. Int. 2011, 18, 724–729. [Google Scholar]

- Bina, M.H.; Jamali, M.; Shamanian, M.; Sabet, H. Investigation on the resistance spot-welded austenitic/ferritic stainless steel. Int. J. Adv. Manuf. Tech. 2014, 75, 1371–1379. [Google Scholar] [CrossRef]

- Zhang, H.; Hou, Y.; Zhang, J.; Wang, F. A new method for nondestructive quality evaluation of the resistance spot welding based on the radar chart method and the decision tree classifier. Int. J. Adv. Manuf. Technol. 2015, 78, 841–851. [Google Scholar] [CrossRef]

- Jou, M. Real time monitoring weld quality of resistance spot welding for the fabrication of sheet metal assemblies. J. Mater. Process. Technol. 2003, 132, 102–113. [Google Scholar] [CrossRef]

- Qiao, Z.; Li, H.; Li, L.; Ran, X.; Feng, L. Microstructure and properties of spot welded joints of hot-stamped ultra-high strength steel used for automotive body structures. Metals 2019, 9, 285. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, F.; Xi, T.; Zhao, J.; Wang, L.; Gao, W. A novel quality evaluation method for resistance spot welding based on the electrode displacement signal and the Chernoff faces technique. Mechan. Syst. Signal Process. 2015, 62–63, 431–443. [Google Scholar] [CrossRef]

- Kahraman, N. The influence of welding parameters on the joint strength of resistance spot welded titanium sheets. Mater. Des. 2007, 28, 420–427. [Google Scholar] [CrossRef]

- Zou, J.; Zhao, Q.; Chen, Z. Surface modified long-life electrode for resistance spot welding of Zn-coated steel. J. Mater. Process. Tech. 2009, 209, 4141–4146. [Google Scholar] [CrossRef]

- Saeed, A.M.; Zuhailawati, H.; Ismail, A.B.; Samad, Z.; Ariga, T. Weldability of titanium and nickel with alloy filler addition and different electrodes tip shapes by using micro spot brazing method. Int. J. Adv. Manuf. Technol. 2014, 73, 591–599. [Google Scholar] [CrossRef]

- Qiu, R.; Zhang, Z.; Zhang, K.; Shi, H.; Ding, G. Influence of welding parameters on the tensile shear strength of aluminum alloy joint welded by resistance spot welding. J. Mater. Eng. Perform. 2011, 20, 355–358. [Google Scholar] [CrossRef]

- Jia, Q.; Liu, L.; Guo, W.; Peng, Y.; Zou, G.; Tian, Z.; Zhou, Y.N. Microstructure and tensile-shear properties of resistance spot-welded medium Mn steel. Metals 2018, 8, 48. [Google Scholar] [CrossRef]

- Tutar, M.; Aydin, H.; Bayram, A. Effect of weld current on the microstructure and mechanical properties of a resistance spot-welded TWIP steel sheet. Metals 2017, 7, 519. [Google Scholar] [CrossRef]

- Fan, Q.; Xu, G.; Wang, T. The influence of electrode tip radius on dynamic resistance in spot welding. Int. J. Adv. Manuf. 2018, 95, 3899–3904. [Google Scholar] [CrossRef]

- Liang, C.P.; Liu, X.H.; Bai, Y.W. Effect of electrode force change on spot weld quality of AHSS using servo gun. Adv. Mater. Res. 2011, 189–193, 3359–3363. [Google Scholar] [CrossRef]

- Podrzaj, P.; Polajnar, I.; Diaci, J.; Kariz, Z. Expulsion detection system for resistance spot welding based on a neural network. Meas. Sci. Technol. 2004, 15, 592–598. [Google Scholar] [CrossRef]

- Cho, Y.; Rhee, S. New technology for measuring dynamic resistance and estimating strength in resistance spot welding. Meas. Sci. Technol. 2000, 11, 1173–1178. [Google Scholar] [CrossRef]

- Banerjee, P.; Sarkar, R.; Pal, T.K.; Shome, M. Effect of nugget size and notch geometry on the high cycle fatigue performance of resistance spot welded DP590 steel sheets. J. Mater. Process. Technol. 2016, 238, 226–243. [Google Scholar] [CrossRef]

- Zhou, K.; Cai, L. Online nugget diameter control system for resistance spot welding. Int. J. Adv. Manuf. 2013, 68, 2571–2588. [Google Scholar] [CrossRef]

- Peng, J.; Fukumoto, S.; Brown, L.; Zhou, N. Image analysis of electrode degradation in resistance spot welding of aluminium. Sci. Technol. Weld. Join. 2004, 9, 331s–336s. [Google Scholar] [CrossRef]

- Varbai, B.; Sommer, C.; Szabó, M.; Tóth, T.; Májlinger, K. Shear tension strength of resistant spot welded ultra high strength steels. Thin Wall Struct. 2019, 142, 64–73. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, G.; Jing, W.; Wang, C. The research for resistance spot welding with rectangular electrode. In Proceedings of the International Conference on Mechatronics and Automation, Changchun, China, 9–12 August 2009. [Google Scholar]

| C | Si | Mn | P | S | Ni | Cr | N |

|---|---|---|---|---|---|---|---|

| ≤0.08 | ≤1.00 | ≤2.50 | ≤0.035 | ≤0.030 | 7.00–10.500 | 18.00–20.00 | 0.01–0.25 |

| Hardness (HV) | Yield Strength (N/mm2) | Tensile Strength (N/mm2) | Elongation (%) |

|---|---|---|---|

| >169 | >275 | >550 | >35 |

| Type of Electrode | Dimensions of Electrode (mm) | Welding Current (kA) | Welding Time (ms) | Welding Pressure (kN) |

|---|---|---|---|---|

| Ordinary circular electrode | Ф 5 (upper) + Ф 34 (lower) | 5.5–6.5 | 100–160 | 3.0–4.0 |

| Rectangular terminal electrode | 5 × 18 (upper) + Ф 34 (lower) | 13.5–17.5 | 60–180 | 6.5–8.5 |

| Welding Current (kA) | Welding Time (ms) | Welding Pressure (kN) |

|---|---|---|

| 13.5 | 60 | 6.5 |

| 14 | 80 | 7 |

| 14.5 | 100 | 7.5 |

| 15 | 120 | 8 |

| 15.5 | 140 | 8.5 |

| 16 | 160 | |

| 16.5 | 180 | |

| 17 | ||

| 17.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Wei, L.; Xu, G.; Wang, C. Connection Status Research of the Resistance Spot Welding Joint Based on a Rectangular Terminal Electrode. Metals 2019, 9, 659. https://doi.org/10.3390/met9060659

Zhang X, Wei L, Xu G, Wang C. Connection Status Research of the Resistance Spot Welding Joint Based on a Rectangular Terminal Electrode. Metals. 2019; 9(6):659. https://doi.org/10.3390/met9060659

Chicago/Turabian StyleZhang, Xiaoqi, Lingbo Wei, Guocheng Xu, and Chunsheng Wang. 2019. "Connection Status Research of the Resistance Spot Welding Joint Based on a Rectangular Terminal Electrode" Metals 9, no. 6: 659. https://doi.org/10.3390/met9060659

APA StyleZhang, X., Wei, L., Xu, G., & Wang, C. (2019). Connection Status Research of the Resistance Spot Welding Joint Based on a Rectangular Terminal Electrode. Metals, 9(6), 659. https://doi.org/10.3390/met9060659