Functionally Graded SS 316L to Ni-Based Structures Produced by 3D Plasma Metal Deposition

Abstract

1. Introduction

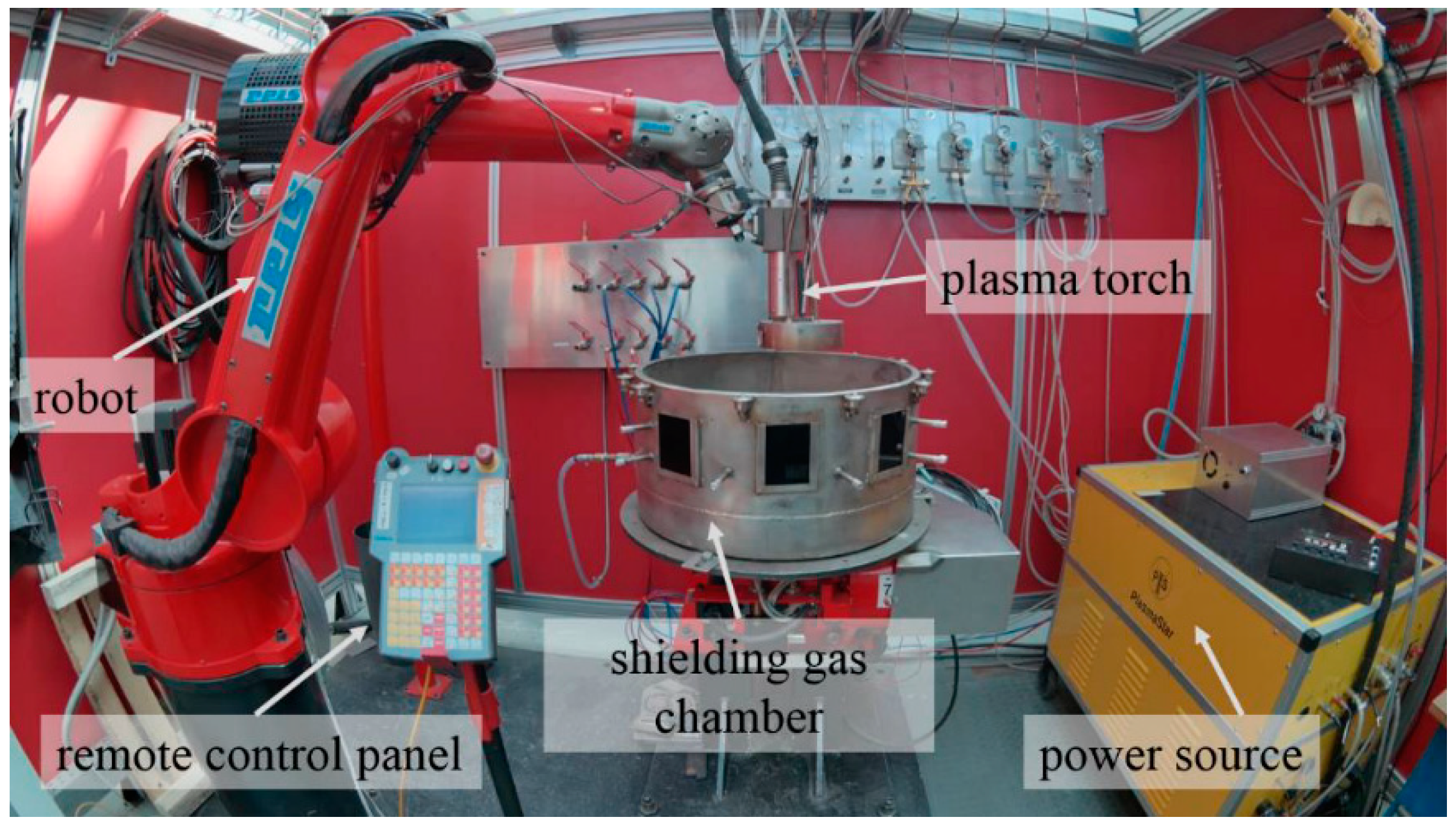

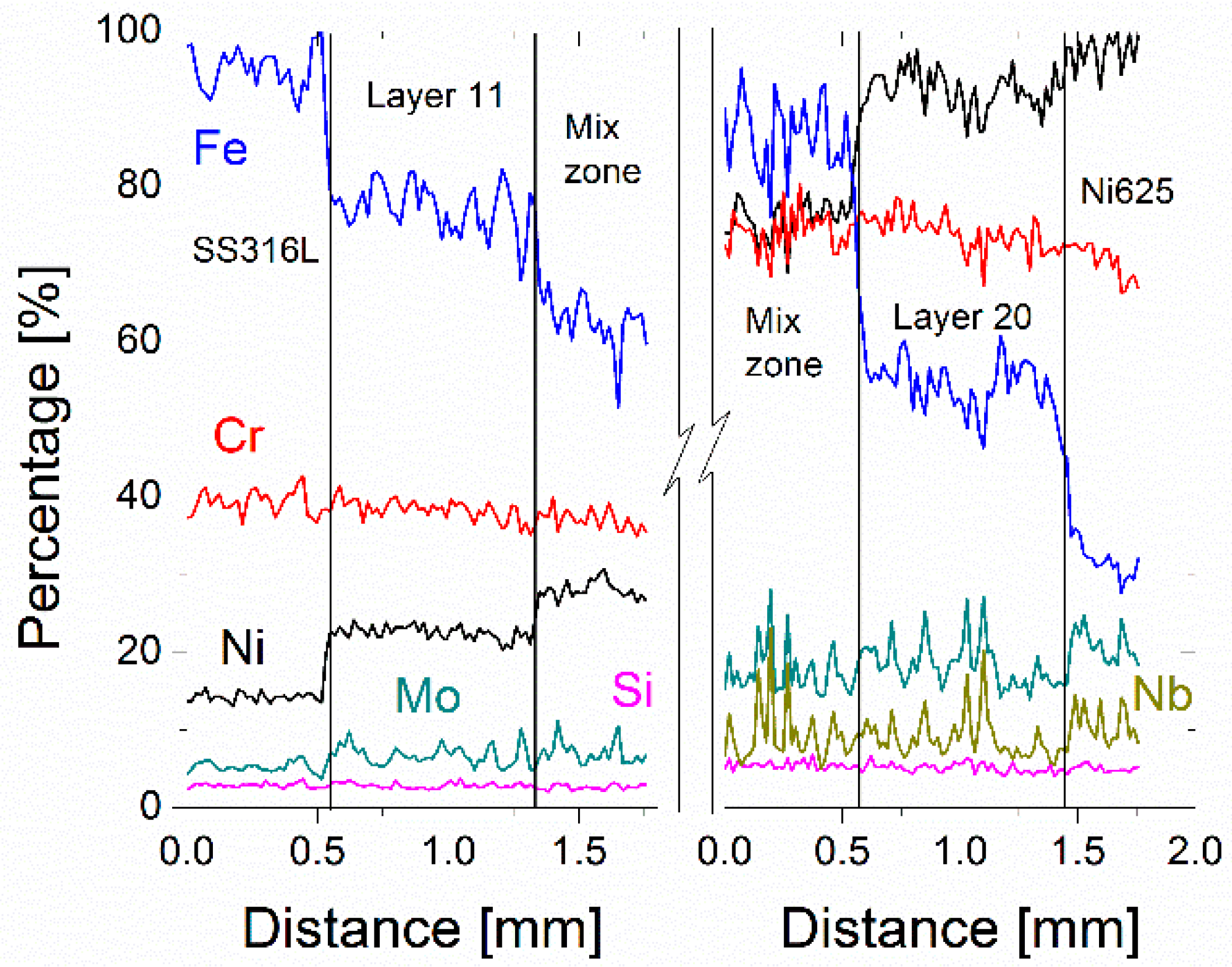

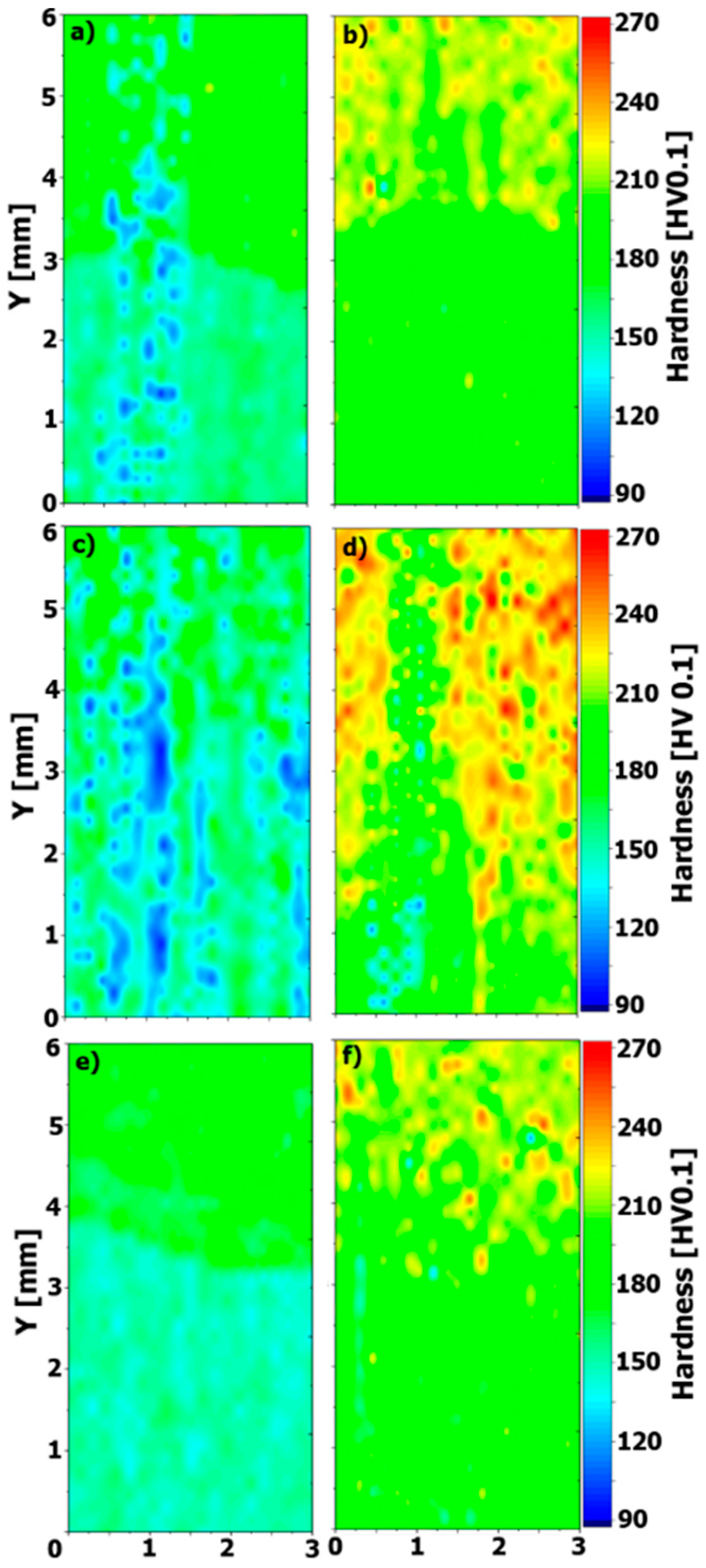

2. Materials and Methods

3. Results and Discussion

3.1. 3DPMD Process

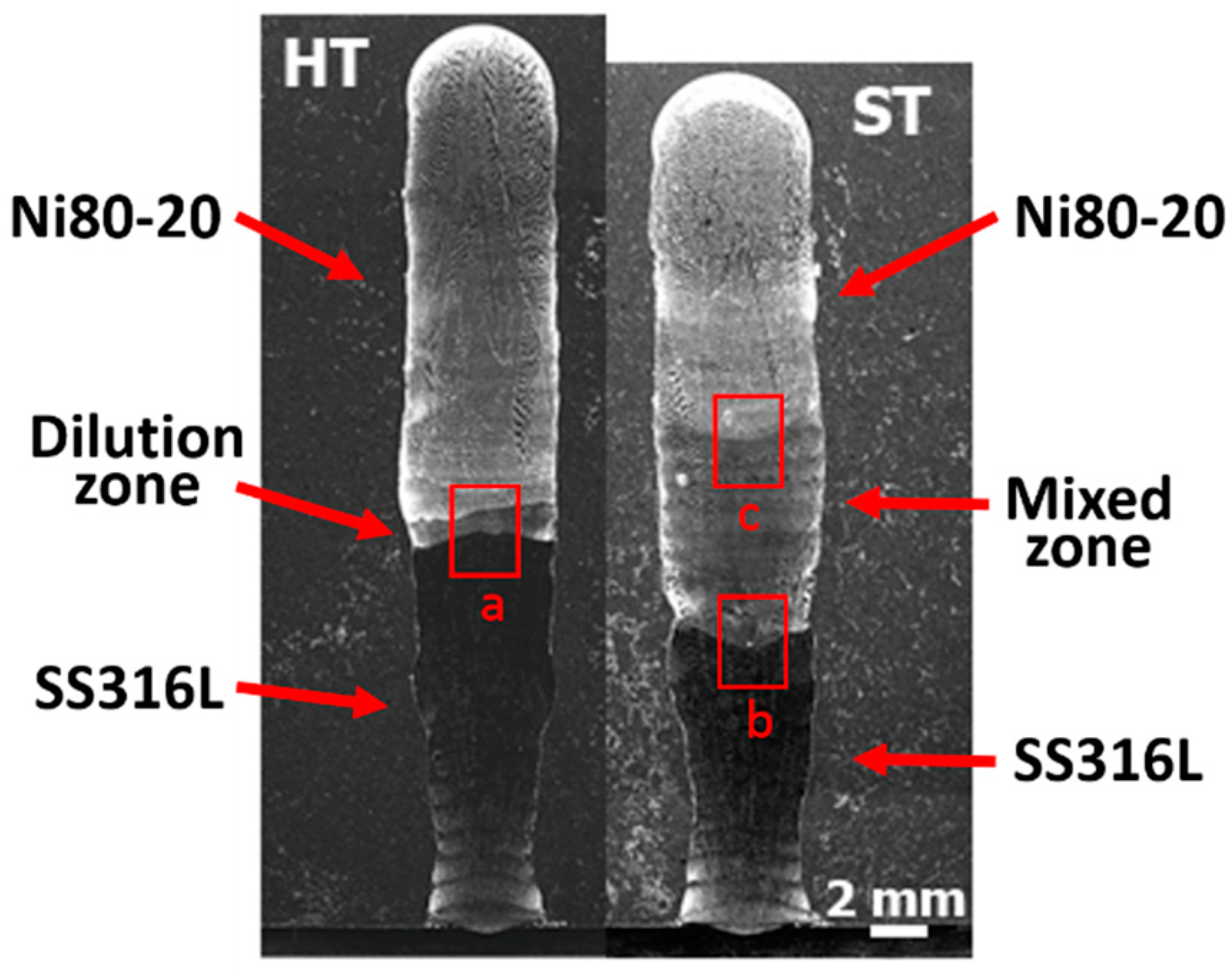

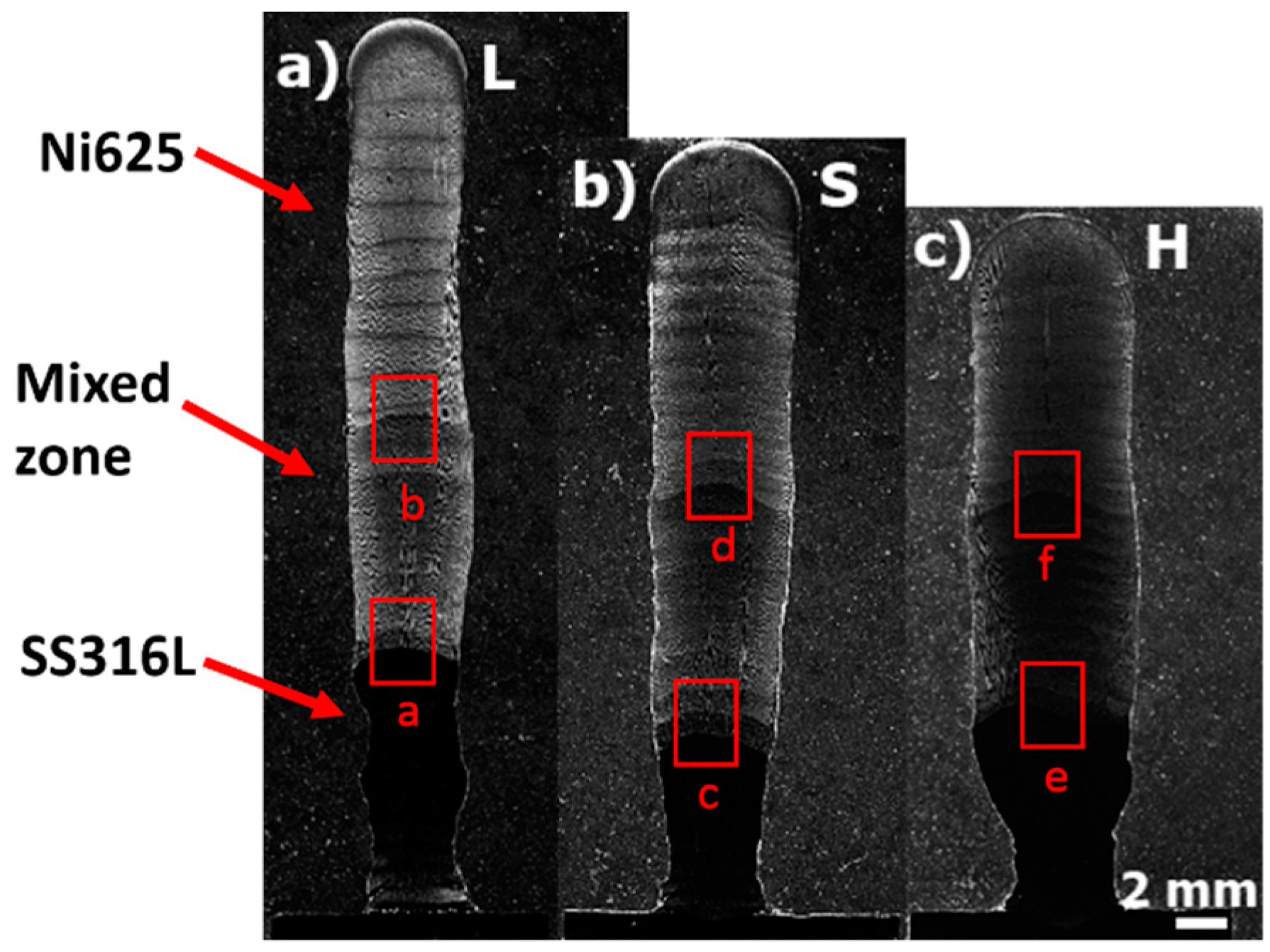

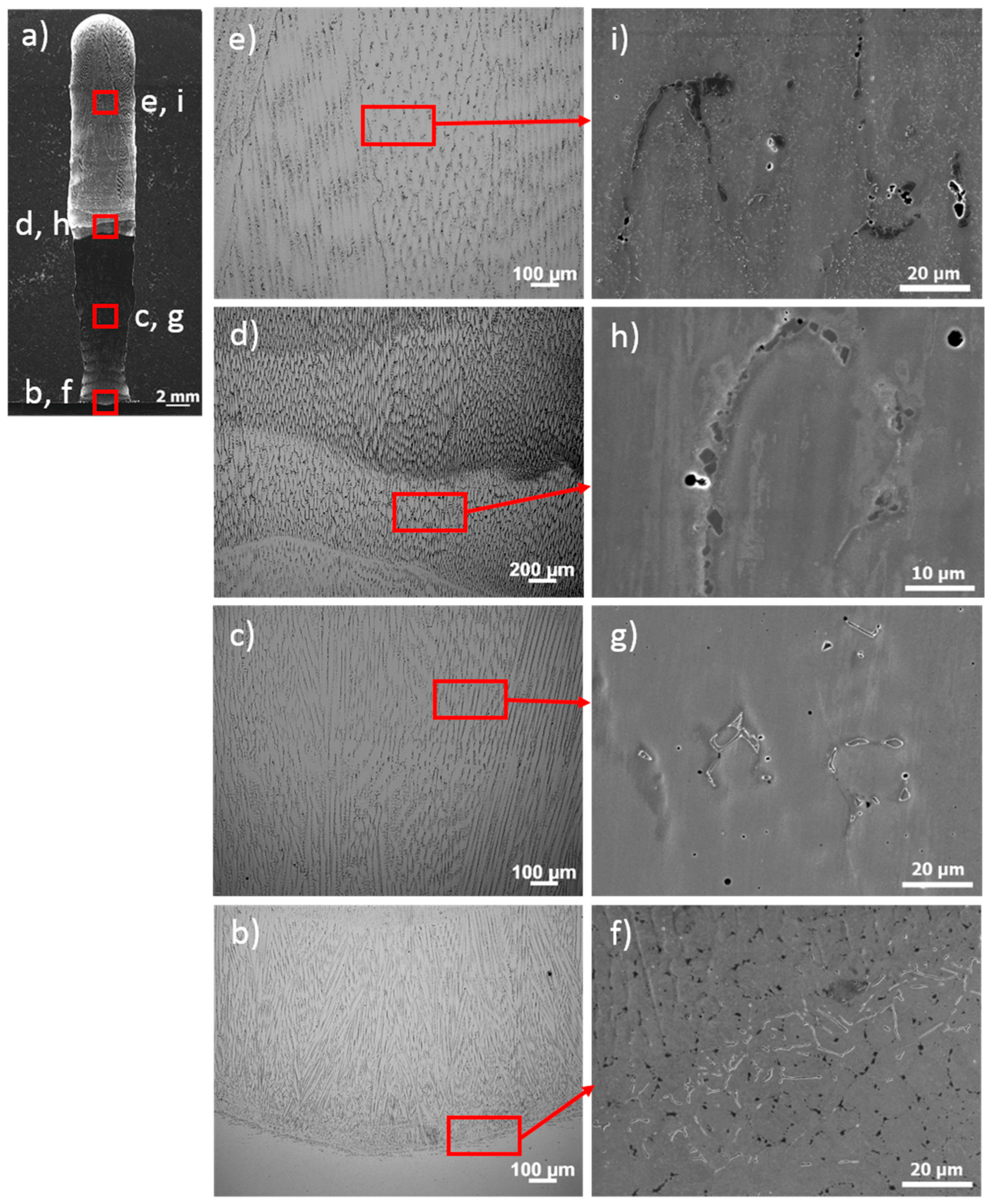

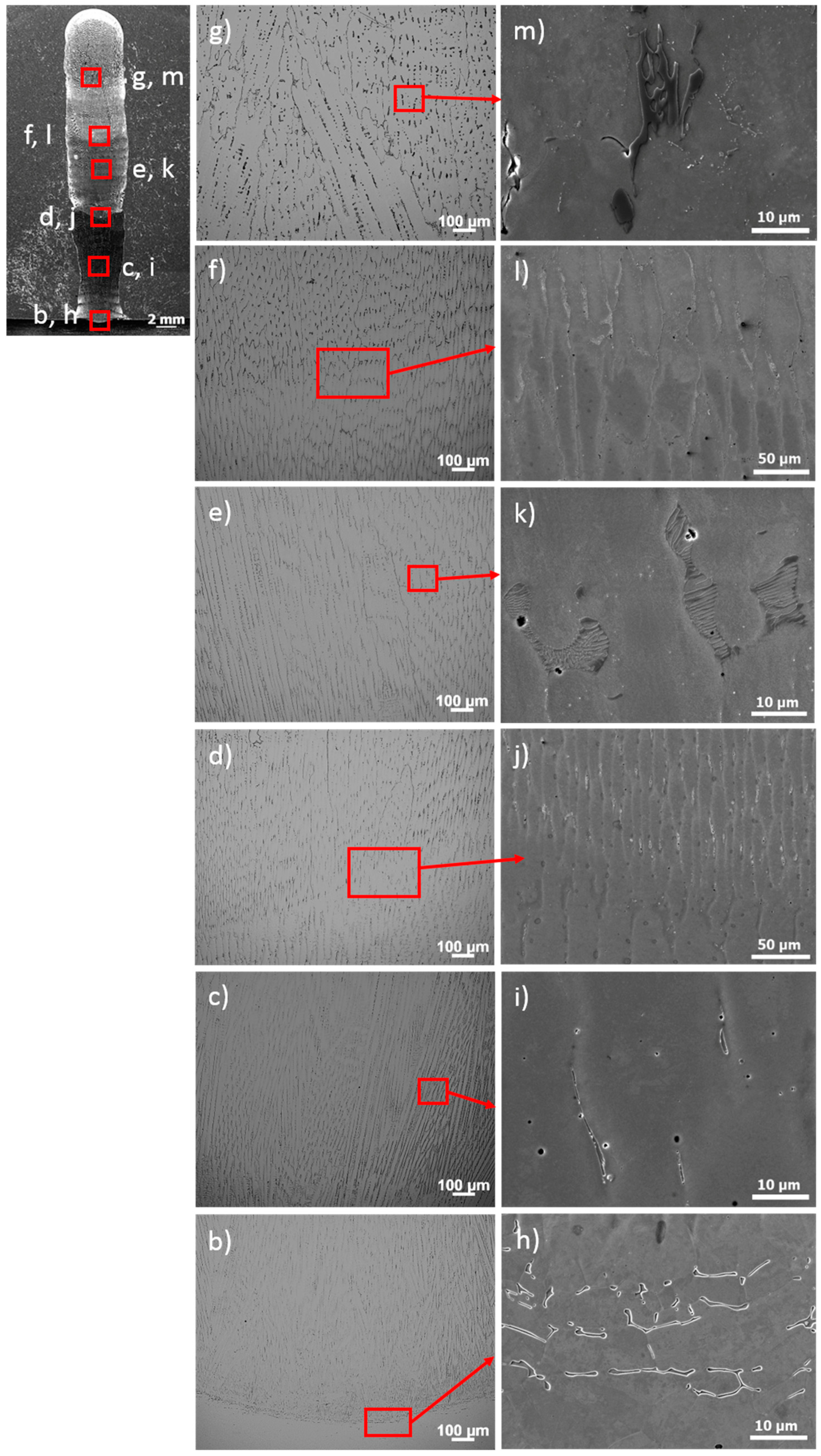

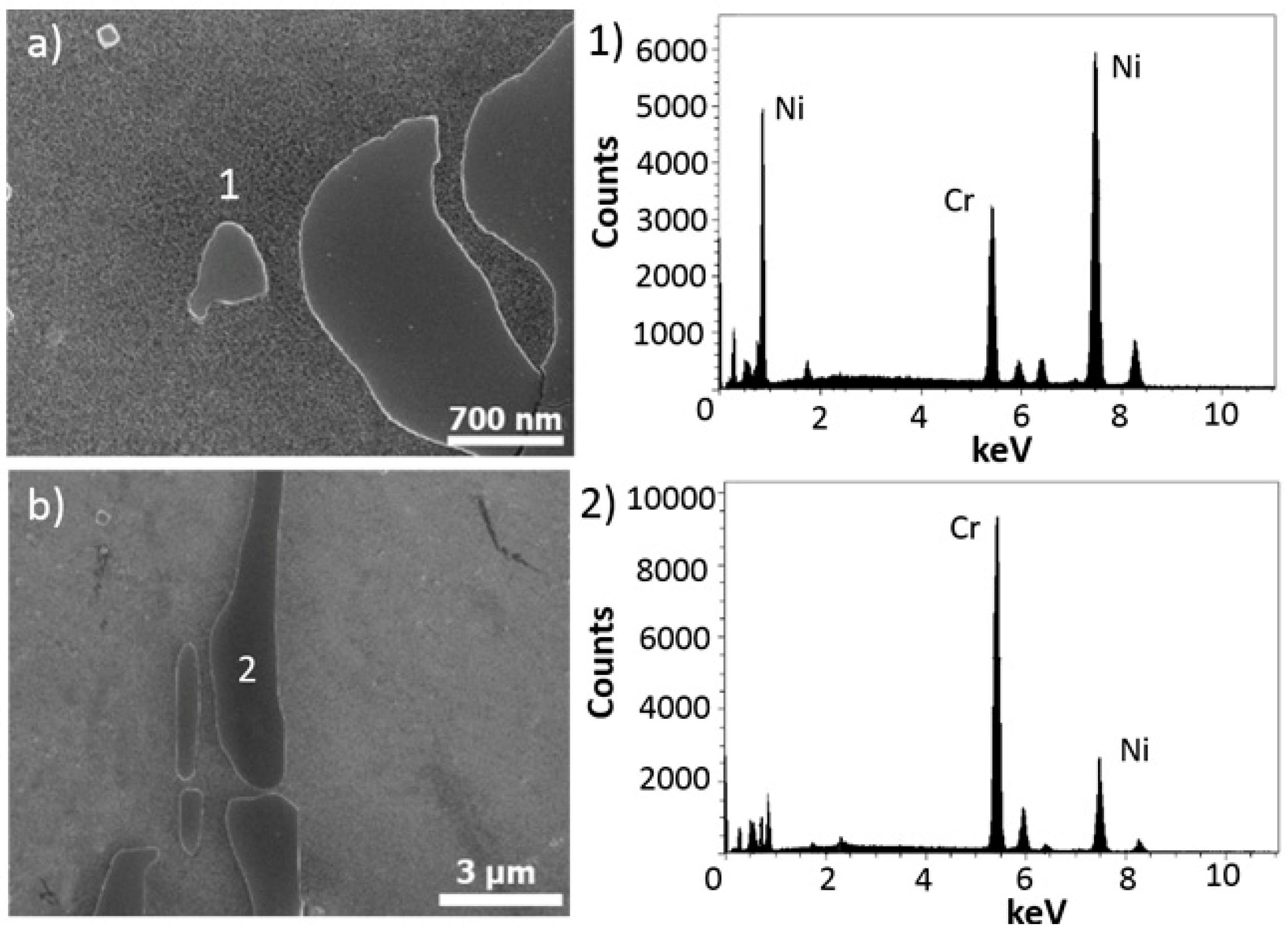

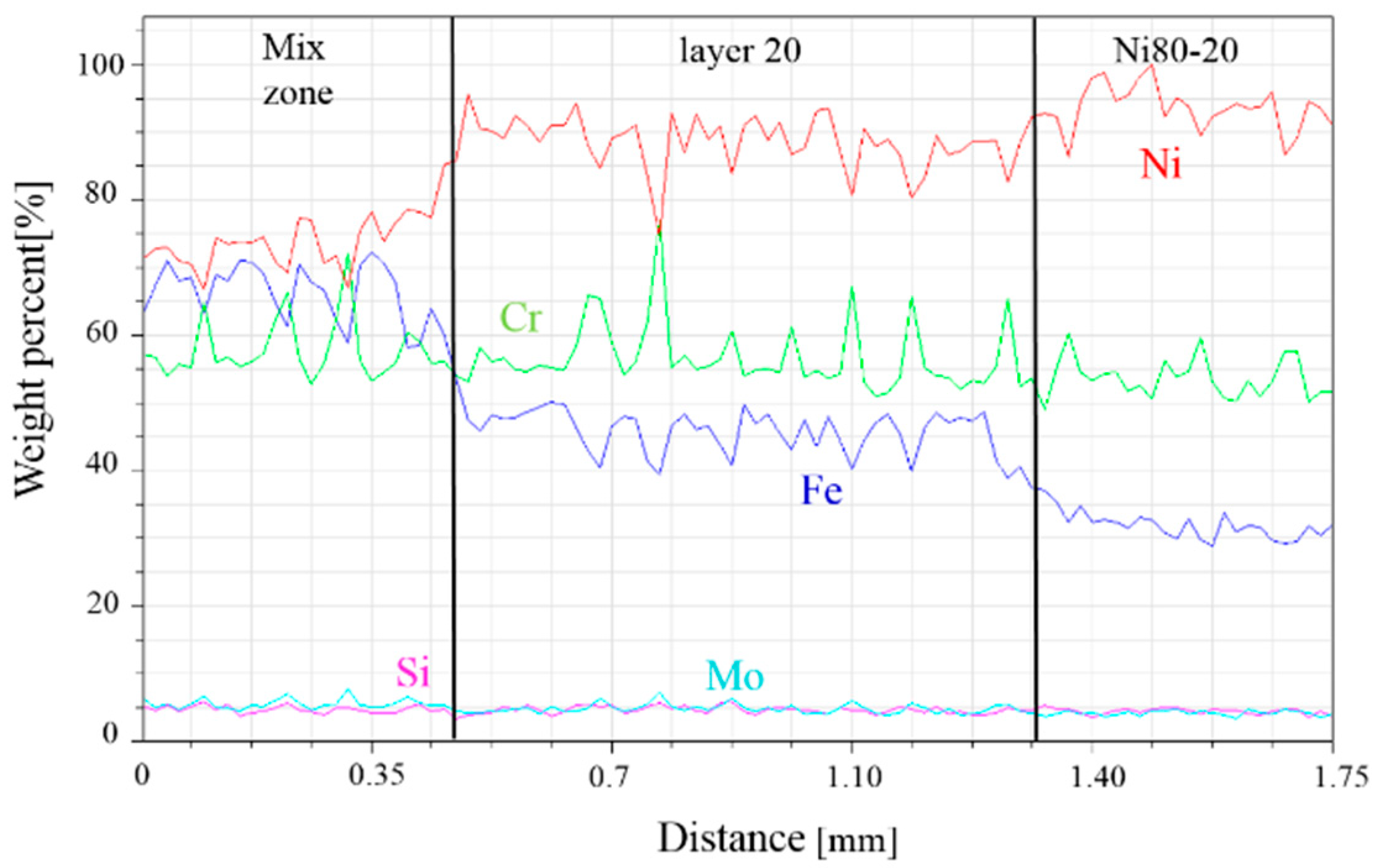

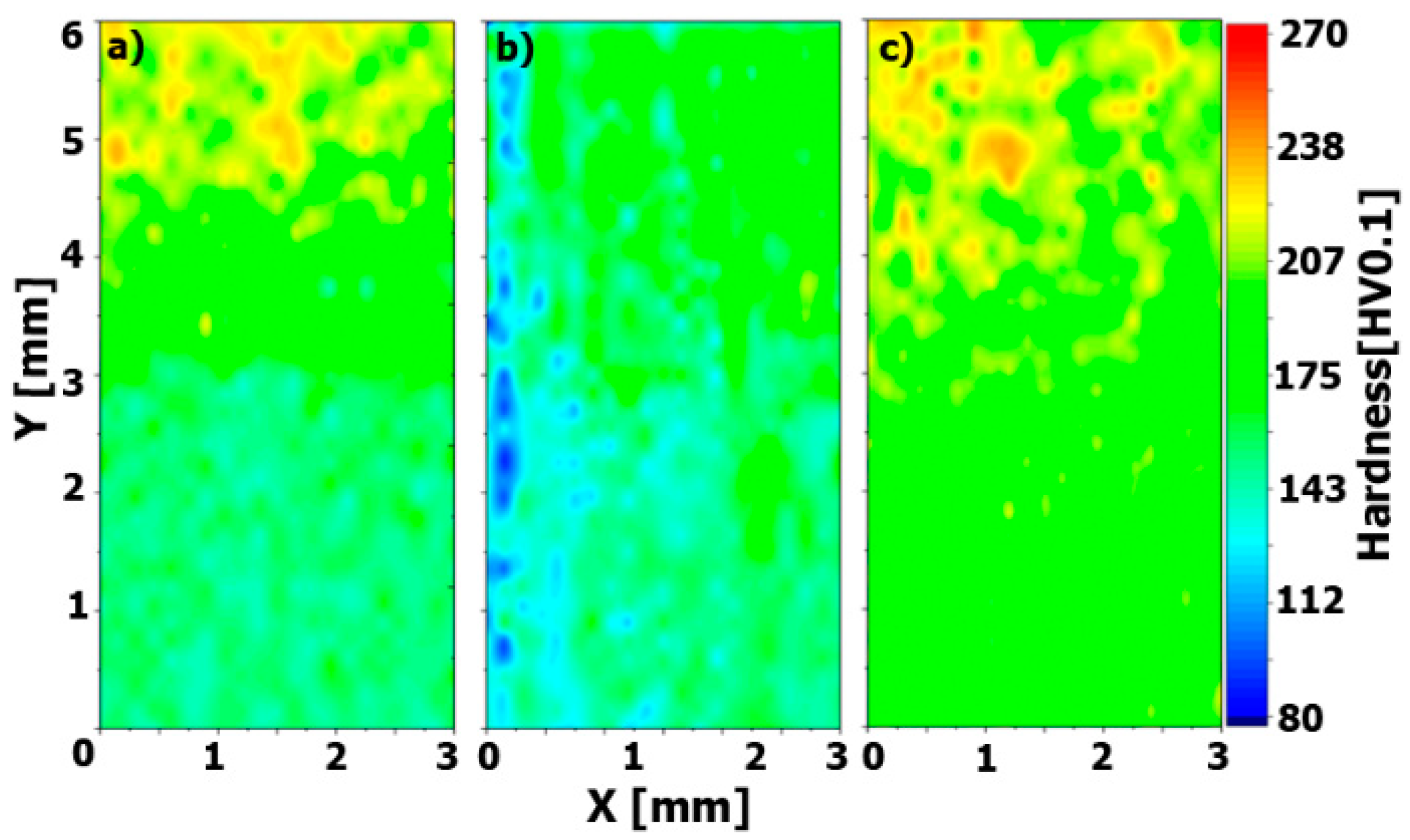

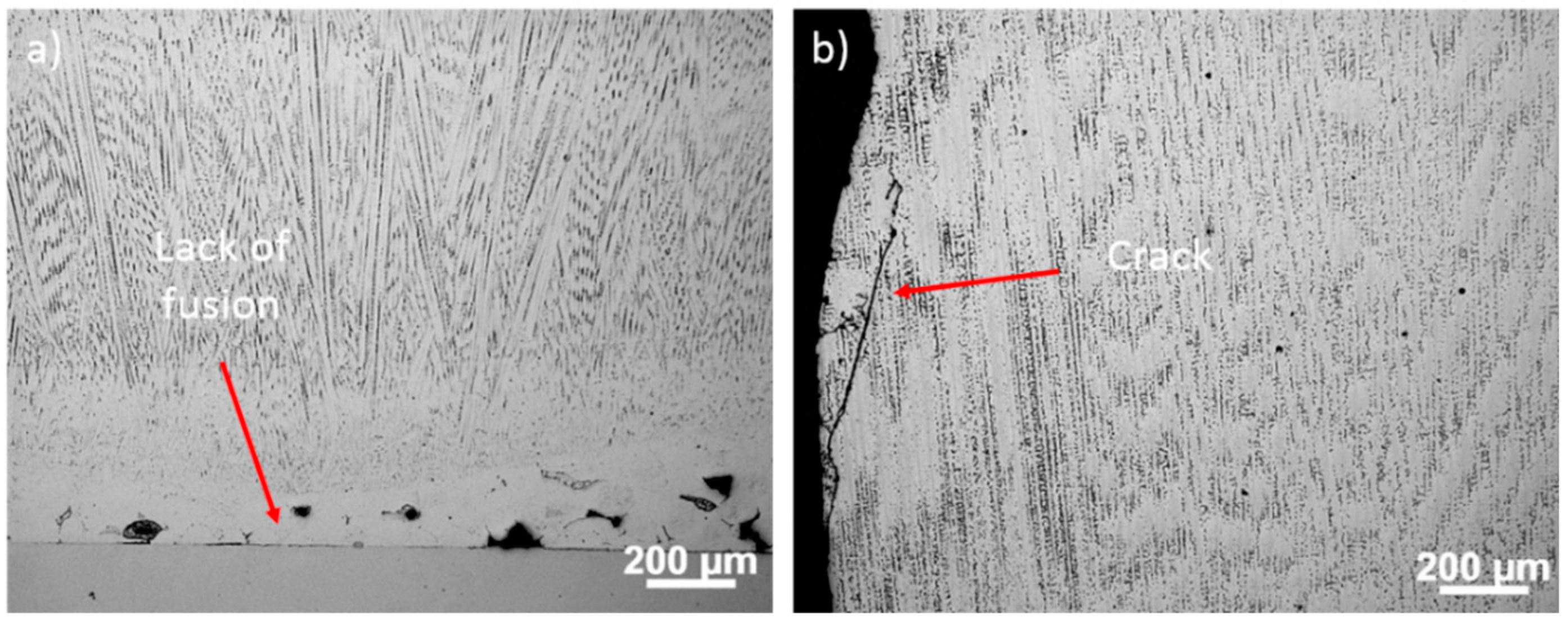

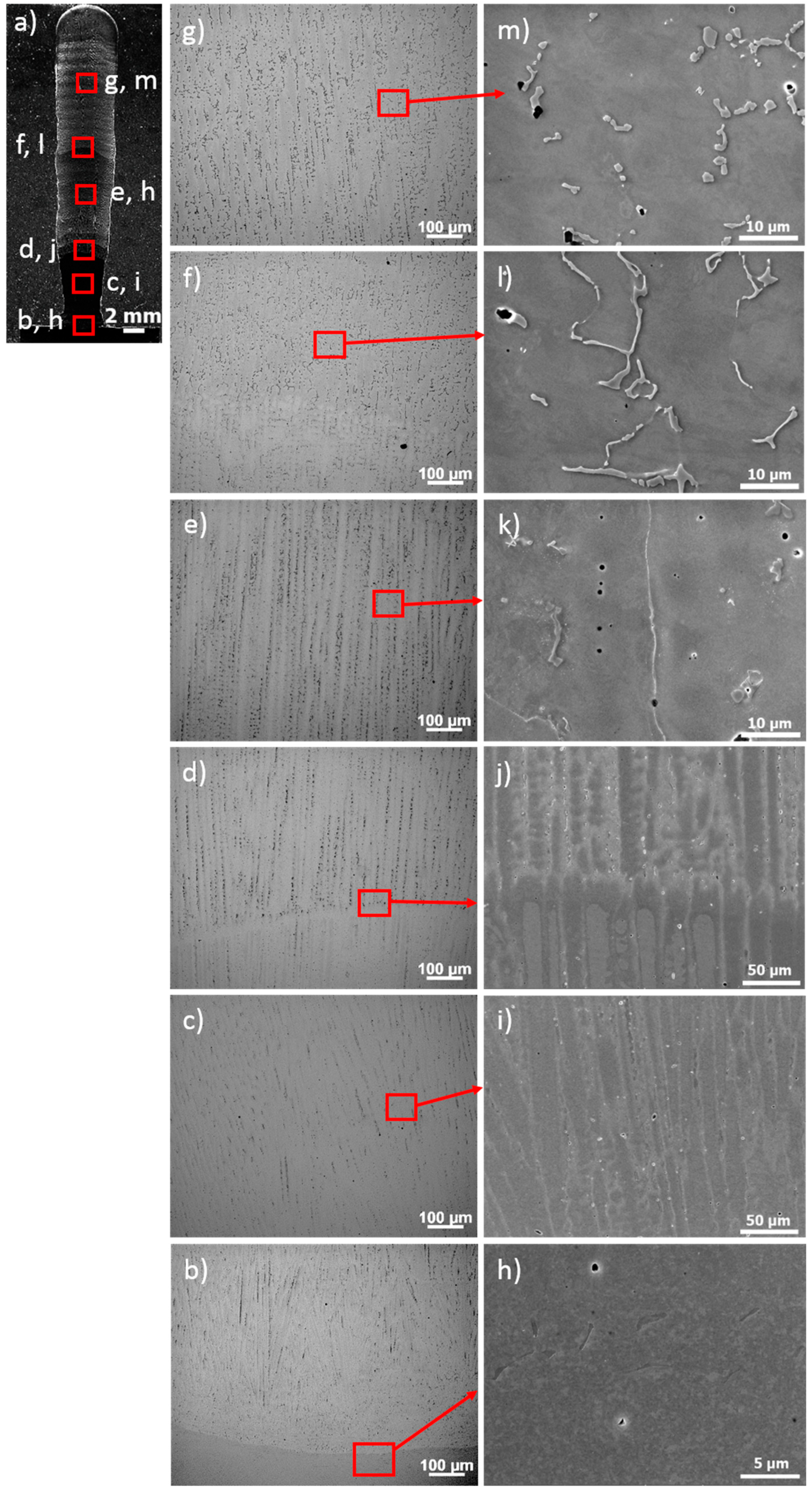

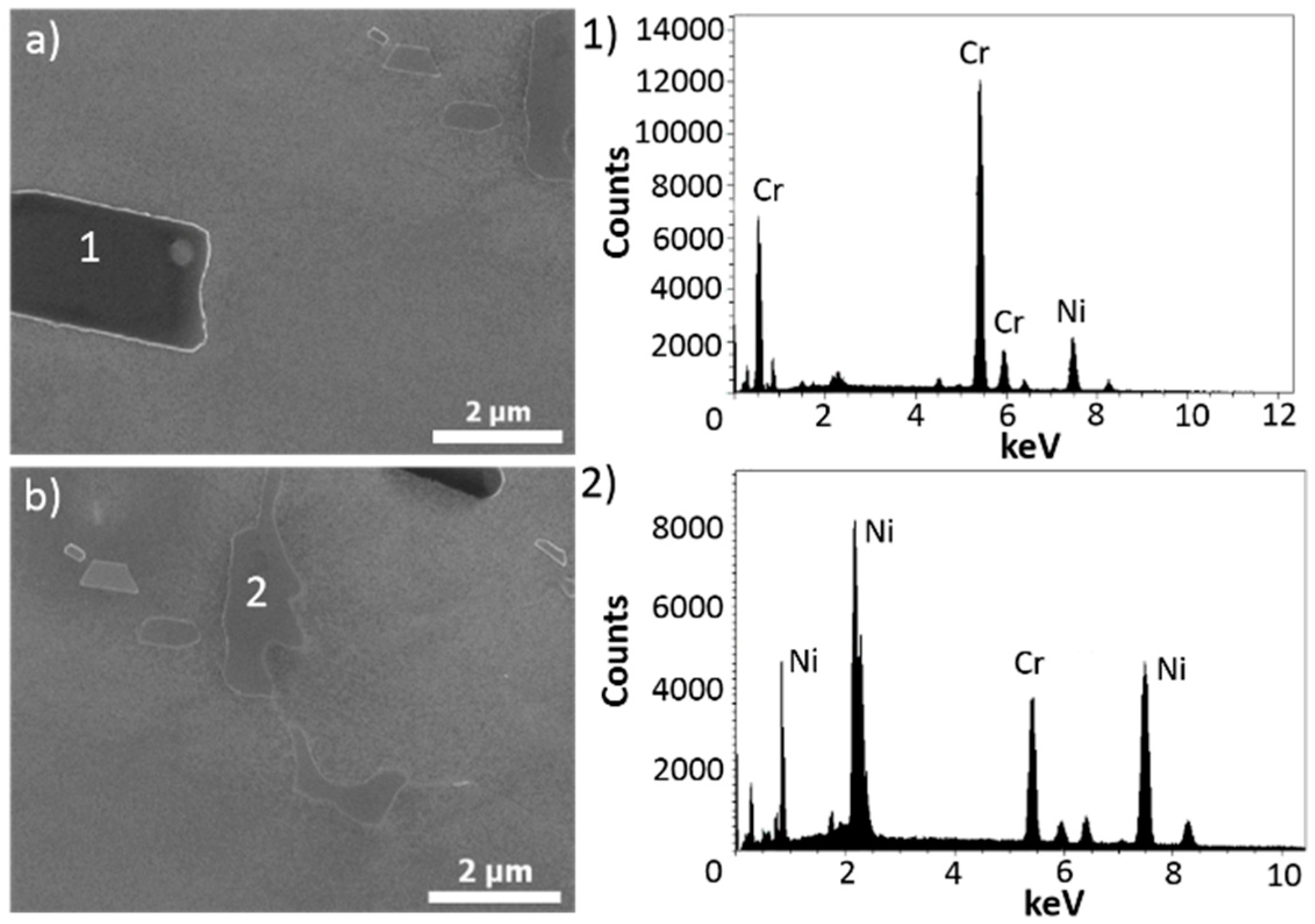

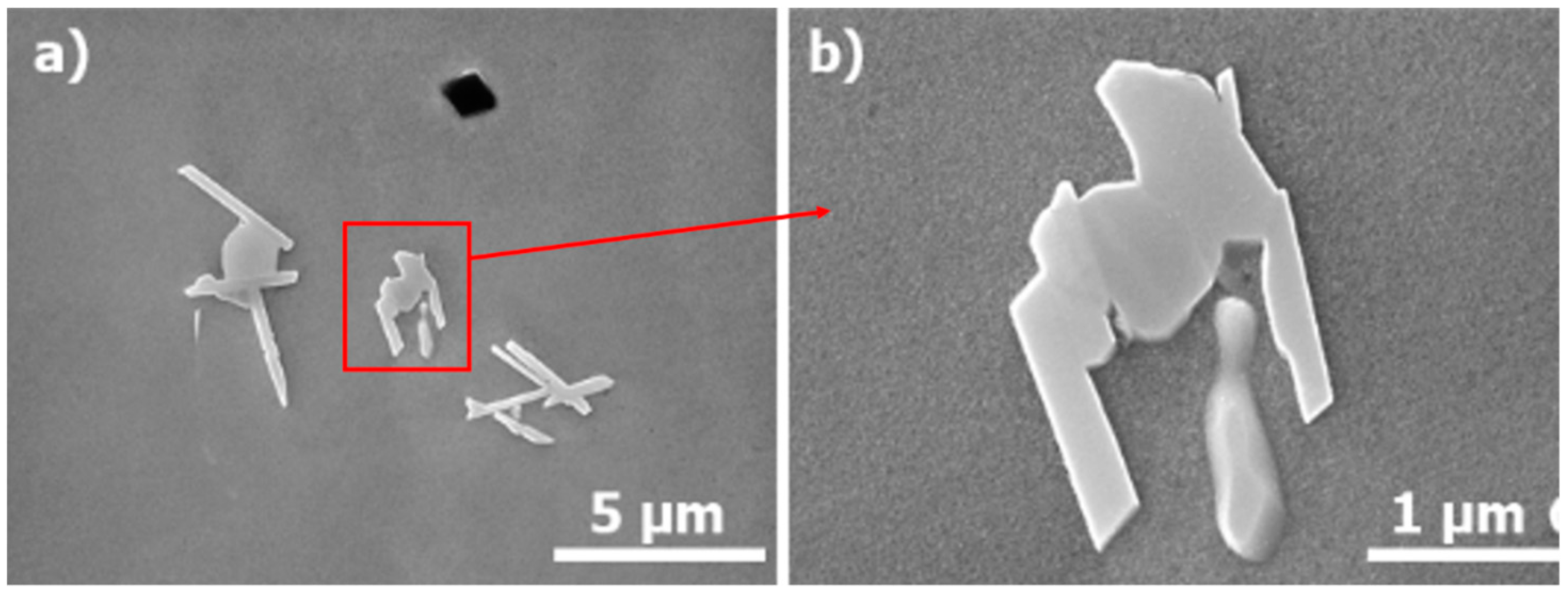

3.2. Microstructural Characterization

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bandyopadhyay, A.; Krishna, B.V.; Xue, W.; Bose, S. Application of laser engineered net shaping (LENS) to manufacture porous and functionally graded structures for load bearing implants. J. Mater. Sci. Mater. Med. 2009, 20, 29–34. [Google Scholar] [CrossRef]

- Parthasarathy, J.; Starly, B.; Raman, S. A design for additive manufacture of functionally graded porous structures with tailored mechanical properties for biomedical applications. J. Manuf. Process. 2011, 13, 160–170. [Google Scholar] [CrossRef]

- Murr, L.E.; Gaytan, S.M.; Martinez, E.; Medina, F.; Wicker, R.B. Metal fabrication by additive manufacturing using laser and electron beam melting technologies. Int. J. Biomater. 2012, 28, 1–14. [Google Scholar] [CrossRef]

- Popovich, V.A.; Borisov, E.V.; Popovich, A.A.; Sufiiarov, V.S.; Masaylo, D.V.; Alzina, L. Functionally graded Inconel 718 processed by additive manufacturing: Crystallographic texture, anisotropy of microstructure and mechanical properties. Mater. Des. 2017, 114, 441–449. [Google Scholar] [CrossRef]

- Hoefer, K.; Nitsche, A.; Abstoss, K.G.; Ertugrul, G.; Haelsig, A.; Mayr, P. Multi-Material additive manufacturing by 3D plasma metal deposition for graded structures of super duplex alloy 1.4410 and the austenitic corrosion resistant alloy 1.4404. JOM 2019. [Google Scholar] [CrossRef]

- Sampath, S.; Herman, H.; Shimoda, N.; Saito, T. Thermal spray processing of FGMs. MRS Bull 1995, 20, 27–31. [Google Scholar] [CrossRef]

- Suresh, S.; Giannakopoulos, A.E.; Alcalá, J. Sherical indentation of compositionally graded materials: Theory and experiments. Acta Mater. 1997, 45, 1307–1321. [Google Scholar]

- Giannakopoulos, A.E.; Suresh, S. Indentation of solids with gradients in elastic properties: Part II axisysmmetric indentors. Int. J. Solids. Struct. 1997, 34, 2393–2428. [Google Scholar] [CrossRef]

- Giannakopoulos, A.E.; Suresh, S.; Finot, M.; Olsson, M. Elastoplastic analysis of thermal cycling: Layered materials with compositional gradients. Acta Metall. Mater. 1995, 43, 1335–1354. [Google Scholar] [CrossRef]

- Williamson, R.L.; Rabin, R.H.; Drake, J.T. Finite elements analysis of thermal residual stresses at graded ceramic-metal interfaces. J. Appl. Phys. 1993, 74, 1310–1320. [Google Scholar] [CrossRef]

- Drake, J.T.; Williamson, R.L.; Rabin, R.H. Finite elemete analysis of thermal residual stresses at graded ceramic-metal interfaces—part II microstructure. J. Appl. Phys. 1993, 74, 1321–1326. [Google Scholar] [CrossRef]

- Erdogan, F. Fracture mechanics of functionally graded materials. Compos. Eng. 1995, 5, 753–770. [Google Scholar] [CrossRef]

- ISO/ASTM 52900:2015 (ASTM F2792). Additive manufacturing—General principles—Terminology. International Organization for Standardization. Available online: https://www.iso.org/standard/69669.html (accessed on 28 April 2019).

- Jhavar, S.; Jain, N.K.; Paul, C.P. Development of micro-plasma transferred arc (µ-PTA) wire deposition process for additive layer manufacturing applications. J. Mater. Process Tech. 2014, 214, 1102–1110. [Google Scholar] [CrossRef]

- Zou, H.; Zhang, H.; Wang, G.; Li, J. Rapid manufacturing of FGM components by using electromagnetic compressed plasma deposition. In Proceedings of the Electromagnetics Research Symposium, Moskva, Russia, 18–21 August 2009. [Google Scholar]

- Hoefer, K.; Hälsig, A.; Mayr, P. Arc-based additive manufacturing of steel components—comparison of wire- and powder-based variants. Weld World 2018, 62, 243–247. [Google Scholar] [CrossRef]

- Hoefer, K.; Mayr, P. 3DPMD – Additive manufacturing of titanium parts using 3D plasma metal deposition. Mater. Sci. Forum 2018, 941, 2137–2141. [Google Scholar] [CrossRef]

- Hoefer, K.; Teichgraeber, C.; Mayr, P.; Berger, M. Arc-based additive Manufacturing—3DPMD (Generative Fertigung mit Lichtbogenprozessen). In Fümotec 2017; Mayr, P., Berger, M., Eds.; Chemnitz University of Technology: Chemnitz, Germany, 2017; pp. 1–14. (In German) [Google Scholar]

- Chen, X.; Li, J.; Cheng, X.; He, B.; Wang, Y.; Huang, Z. Microstructure and mechanical properties of the austenitic stainless steel 316L fabricated by gas metal arc additive manufacturing. Mater. Sci. Eng. 2017, 703, 567–577. [Google Scholar] [CrossRef]

- Feng, Y.; Luo, Z.; Liu, Z.; Li, Y.; Luo, Y.; Huang, Y. Keyhole gas tungsten arc welding of AISI 316L stainless steel. Mater. Des. 2015, 85, 24–31. [Google Scholar] [CrossRef]

- Soltani, H.M.; Tayebi, M. Comparative study of AISI 304L to AISI 316L stainless steels joints by TIG and Nd:YAG laser welding. J. Alloy Compd. 2018, 767, 112–121. [Google Scholar] [CrossRef]

- ElCheikh, H.; Courant, B.; Branchu, S.; Huang, X.; Hasco, J.Y.; Guille, R. Direct laser fabrication process with coaxial powder projection of 316L steel. Opt. Lasers Eng. 2012, 50, 1779–1784. [Google Scholar] [CrossRef]

- Järvinen, J.P.; Matilainen, V.; Li, X.; Piili, H.; Salminen, A.; Mäkelä, I.; Nyrhilä, O. Characterization of effect of support structures in laser additive manufacturing of stainless steel. Phys. Procedia 2014, 56, 72–81. [Google Scholar] [CrossRef]

- Yadollahi, A.; Shamsaei, N.; Thompson, S.M.; Seely, D.W. Effects of process time interval and heat treatment on the mechanical and microstructural properties of direct laser deposited 316L stainless steel. Mater. Sci. Eng. A 2015, 644, 171–183. [Google Scholar] [CrossRef]

- Zhao, J.; Zhang, B.; Li, X.; Li, R. Effects of metal-vapor jet force on the physical behavior of melting wire transfer in electron beam additive manufacturing. J. Mater. Process. Technol. 2015, 220, 243–250. [Google Scholar] [CrossRef]

- Skiba, T.; Baufeld, B.; Biest, O.V.D. Microstructure and mechanical properties of stainless steel component manufactured by shaped metal deposition. ISIJ Int. 2009, 49, 1588–1591. [Google Scholar] [CrossRef]

- Lippold, J.C.; Kotecki, D.J. Welding Metallurgy and Weldability of Stainless Steels; Wiley-Interscience: Hoboken, NJ, USA, 2005. [Google Scholar]

- Kotecki, D.J.; Siewert, T.A. WRC-1992 constitution diagram for stainless steel weld metals: A modification of the WRC-1988 diagram. Weld. J. 1992, 71, 171–178. [Google Scholar]

- Silva, C.C.; de Miranda, H.C.; de Sant’Ana, H.B.; Farias, J.P. Microstructure, hardness and petroleum corrosion evaluation of 316L/AWS E309MoL-16 weld metal. Mater Charact. 2009, 60, 346–352. [Google Scholar] [CrossRef]

- DuPont, J.N.; Lipoold, J.C.; Kiser, S.D. Welding Metallurgy and Weldability of Nickel-Base Alloys; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Donachie, M.J.; Donachie, S.J. Superalloy: A Technical Guide; ASM international: Novelty, OH, USA, 2002. [Google Scholar]

- Ramkumar, K.D.; Mithilesh, P.; Varun, D.; Reddy, A.R.G.; Arivazhagan, N.; Narayanan, S.; Kumar, K.G. Characterization of microstructure and mechanical properties of Inconel 625 and AISI 304 dissimilar weldments. J. Int. Ste. Inst. Jap. 2014, 54, 900–908. [Google Scholar] [CrossRef]

- Subsea Structure Demands. Available online: https://app.aws.org/wj/2002/06/feature2/ (accessed on 23 February 2019).

- Dreshfield, R.L.; Moore, T.J.; Bartolotta, P.A. Post-Test Examination of a Pool Boiler Receiver; DOE/NASA/33408-6; U.S Department of Energy Conservation and Renewable Energy Office of Solar Heat Technologies: Washington, WA, USA, 1992; pp. 1–4.

- Dokme, F.; Kulekci, M.K.; Ugur, U. Microstructural and mechanical characterization of dissimilar metal welding of Inconel 625 and AISI 316L. Metals 2018, 8, 797. [Google Scholar] [CrossRef]

- Mithilesh, P.; Varun, D.; Reddy, A.R.G.; Ramkumar, K.D.; Arivazhagan, N.; Narayanan, S. Investigations on dissimilar weldments of Inconel 625 and AISI 304. Procedia Eng. 2014, 75, 66–70. [Google Scholar] [CrossRef]

- Loh, G.H.; Pei, E.; Harrison, D.; Monzón, M.D. An overview of functionally graded additive manufacturing. Addit. Manuf. 2018, 23, 34–44. [Google Scholar] [CrossRef]

- Banait, S.M.; Jinoop, A.N.; Paul, C.P.; Kumar, H.; Pawade, R.S.; Bindra, K.S. Investigating laser additive manufacturing of functionally graded Ni-Cr-B-Si and SS 316L. In Proceedings of the International Conference on Advances in Thermal Systems, Materials and Design Engineering (ATSMDE2017), Mumbai, India, 21–22 December 2017. [Google Scholar]

- Varghese, P.; Vetrivendan, E.; Dash, M.K.; Ningshen, S.; Kamaraj, M.; Kamachi Mudali, U. Weld overlay coating of Inconel 617M on type 316L stainless steel by cold metal transfer process. Surf. Coat. Tech. 2019, 357, 1004–1013. [Google Scholar] [CrossRef]

- Pulugurtha, S.R.; Newkirk, J.; Liou, F.; Chou, H. Functionally Graded Materials by Laser Metal Deposition (preprint). In Proceedings of the 21st Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 9–11 August 2010; University of Texas Press: Austin, TX, USA. [Google Scholar]

- Abboud, J.H.; Rawlings, R.D.; West, D.R.F. Functionally graded nickel-aluminide and iron-aluminide coatings produced via laser cladding. J. Mater. Sci. 1995, 30, 5931–5938. [Google Scholar] [CrossRef]

- Xu, X.; Lin, X.; Chen, J.; He, F.; Huang, W. Laser Rapid Forming of Ti-Ni Functionally Graded Alloy. Mater. Sci. Forum. 2007, 561, 227–230. [Google Scholar] [CrossRef]

- Khor, K.A.; Dong, Z.L.; Gu, Y.W. Plasma sprayed functionally graded thermal barrier coatings. Mater. Lett. 1999, 38, 437–444. [Google Scholar] [CrossRef]

- Lin, X.; Yue, T.M.; Yang, H.O.; Huang, W.D. Microstructure and phase evolution in laser rapid forming of a functionally graded Ti–Rene88DT alloy. Acta Mater. 2006, 54, 1901–1915. [Google Scholar] [CrossRef]

- Lin, X.; Yue, T.M.; Yang, H.O.; Huang, W.D. Solidification Behavior and the Evolution of Phase in Laser Rapid Forming of Graded Ti6Al4V-Rene88DT Alloy. Metall. Mater. Trans. A 2007, 38A, 127–137. [Google Scholar] [CrossRef]

- Hälsig, A.; Kusch, M.; Mayr, P. New findings on the efficiency of gas shielded arc welding. Weld. World 2012, 56, 98–104. [Google Scholar] [CrossRef]

- ASTM E3-95. Standard Guide for Preparation of Metallographic Specimens; ASTM International: West Conshohocken, PA, USA, 1995; Available online: www.astm.org (accessed on 10 January 2019).

- ASTM E384-99. Standard Test Method for Microindentation Hardness of Materials; ASTM International: West Conshohocken, PA, USA, 1999; Available online: www.astm.org (accessed on 10 January 2018).

- DuPont, J.N. Dilution in Fusion Welding. In ASM handbook Volume 6A. Welding fundamentals and Process; ASM International: Novelty, OH, USA, 2011. [Google Scholar]

- Xu, F.; Lv, Y.; Liu, Y.; Shu, F.; He, P.; Xu, B. Microstructural evolution and mechanical properties of Inconel 625 alloy during pulsed plasma arc deposition process. J. Mater. Sci. Technol. 2013, 29, 480–488. [Google Scholar] [CrossRef]

- ASM International. Heat-Resistant Casting Alloys: Metallographic Techniques and Microstructures. In ASM handbook Volume 9. Metallography and Microstructures; ASM International: Novelty, OH, USA, 1998. [Google Scholar]

- Ram, G.D.J.; Reddy, A.V.; Rao, K.P.; Reddy, G.M.; Sundar, J.K.S. Control of Laves phase in Inconel 718 GTA welds with current pulsing. Sci. Technol. Weld. Join. 2004, 9, 390–398. [Google Scholar]

| Alloy | C | Si | Nb | Mn | Cr | Mo | Ni | Fe |

|---|---|---|---|---|---|---|---|---|

| SS316L | 0.03 | 0.7 | - | 0.5 | 16.5 | 2.1 | 13.0 | Bal. |

| Ni80-20 | - | 1.2 | - | - | 22.0 | - | Bal. | 0.6 |

| Ni625 | 0.03 | 0.5 | 3.2 | 0.4 | 21.1 | 8.5 | Bal. | 4.2 |

| Configuration | Layers | Powder Type | Welding Current (A) | Heat Input (KJ·mm−1) |

|---|---|---|---|---|

| HI | 1–15 | SS316L | 120 | 0.197 |

| 16–30 | Ni80-20 | 105 | 0.173 | |

| ST | 1–10 | SS316L | 120 | 0.197 |

| 11–20 | 50% SS316L 50% Ni80-20 | 110 | 0.181 | |

| 21–30 | Ni80-20 | 105 | 0.173 |

| HI | Layers (#) | Powder Type | Voltage (V) | Welding Current (A) | Heat Input (KJ·mm−1) |

|---|---|---|---|---|---|

| Low (L) | 1–10 | SS316L | 22.73 | 105 | 0.176 |

| 11–20 | 50% SS316L 50% Ni625 | 23.04 | 95 | 0.162 | |

| 21–30 | Ni625 | 22.87 | 90 | 0.151 | |

| Standard (S) | 1–10 | SS316L | 22.82 | 120 | 0.200 |

| 11–20 | 50% SS316L 50% Ni625 | 22.84 | 110 | 0.181 | |

| 21–30 | Ni625 | 22.90 | 105 | 0.177 | |

| High (H) | 1–10 | SS316L | 23.30 | 135 | 0.241 |

| 11–20 | 50% SS316L 50% Ni625 | 23.57 | 125 | 0.214 | |

| 21–30 | Ni625 | 23.73 | 120 | 0.204 |

| HI | Wall Thickness (mm) | Part Height (mm) | Layer Thickness (mm) |

|---|---|---|---|

| Low | 6.5 | 27.5 | 0.92 |

| Standard | 5.8 | 30.5 | 1.02 |

| High | 4.8 | 35.2 | 1.17 |

| Interface | %D |

|---|---|

| Low (L) HI | |

| SS316L to mixed zone | 38.9 |

| mixed zone to Ni625 | 26.3 |

| Standard (S) HI | |

| SS316L to mixed zone | 55.2 |

| mixed zone to Ni625 | 25 |

| High (H) HI | |

| SS316L to mixed zone | 51.1 |

| mixed zone to Ni625 | 23.1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodriguez, J.; Hoefer, K.; Haelsig, A.; Mayr, P. Functionally Graded SS 316L to Ni-Based Structures Produced by 3D Plasma Metal Deposition. Metals 2019, 9, 620. https://doi.org/10.3390/met9060620

Rodriguez J, Hoefer K, Haelsig A, Mayr P. Functionally Graded SS 316L to Ni-Based Structures Produced by 3D Plasma Metal Deposition. Metals. 2019; 9(6):620. https://doi.org/10.3390/met9060620

Chicago/Turabian StyleRodriguez, Johnnatan, Kevin Hoefer, Andre Haelsig, and Peter Mayr. 2019. "Functionally Graded SS 316L to Ni-Based Structures Produced by 3D Plasma Metal Deposition" Metals 9, no. 6: 620. https://doi.org/10.3390/met9060620

APA StyleRodriguez, J., Hoefer, K., Haelsig, A., & Mayr, P. (2019). Functionally Graded SS 316L to Ni-Based Structures Produced by 3D Plasma Metal Deposition. Metals, 9(6), 620. https://doi.org/10.3390/met9060620