Interfacial Reaction and Microstructure Evolution of Sn-9Zn/Ni(Cu) Solder Joints

Abstract

1. Introduction

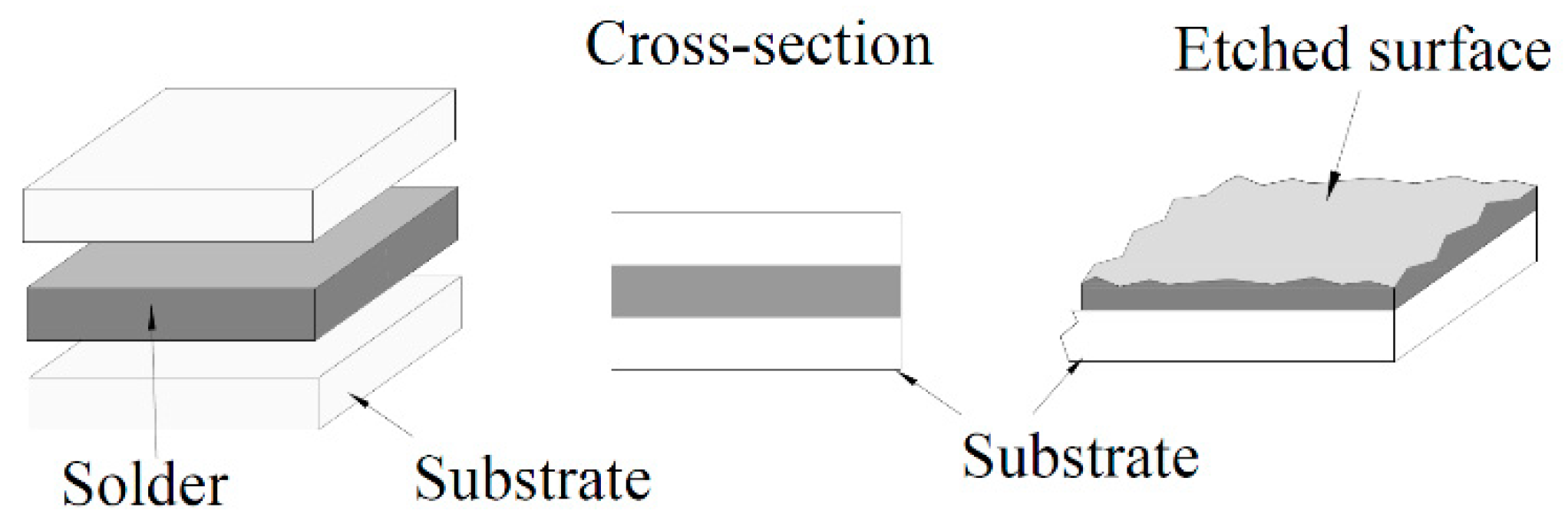

2. Materials and Methods

3. Results and Discussions

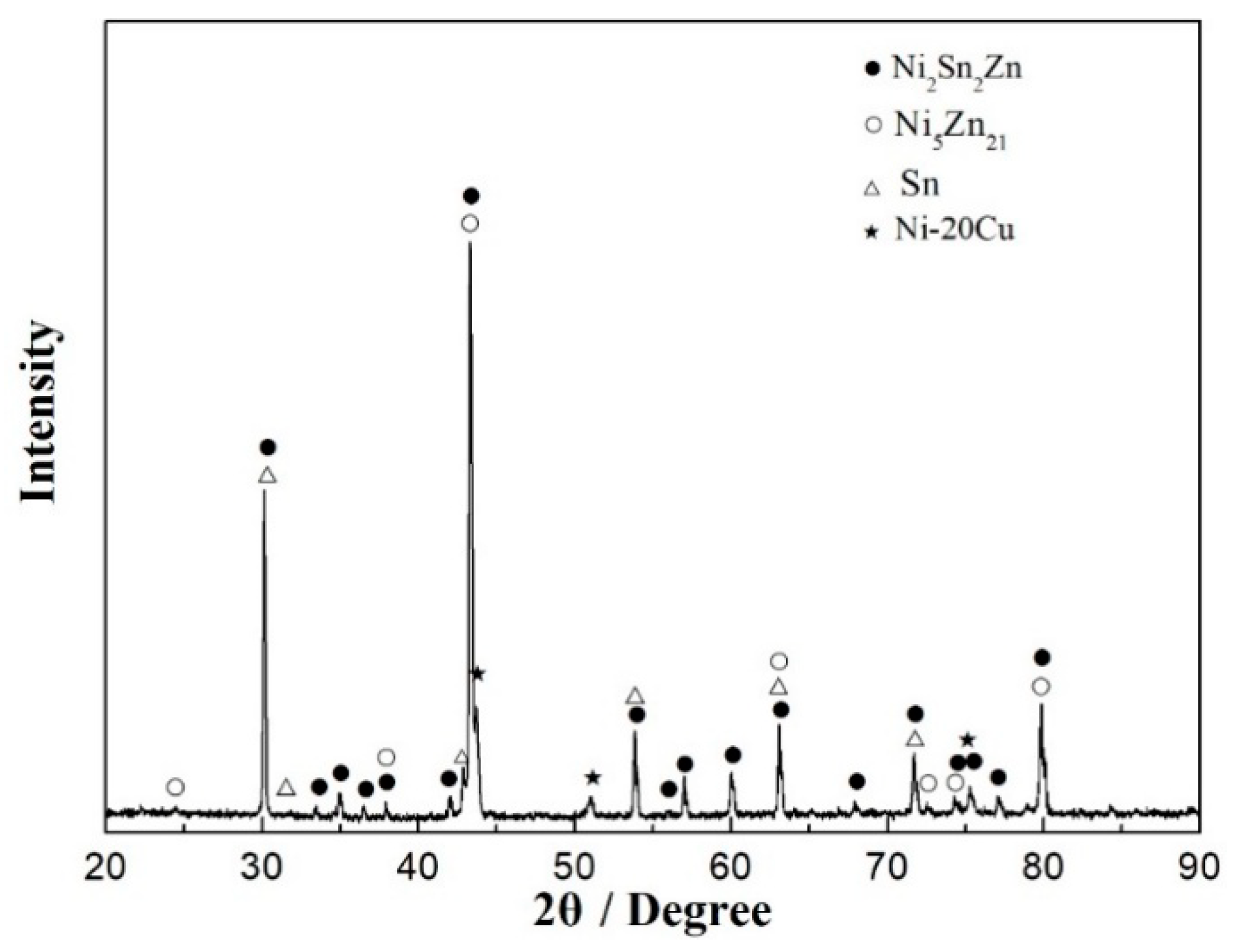

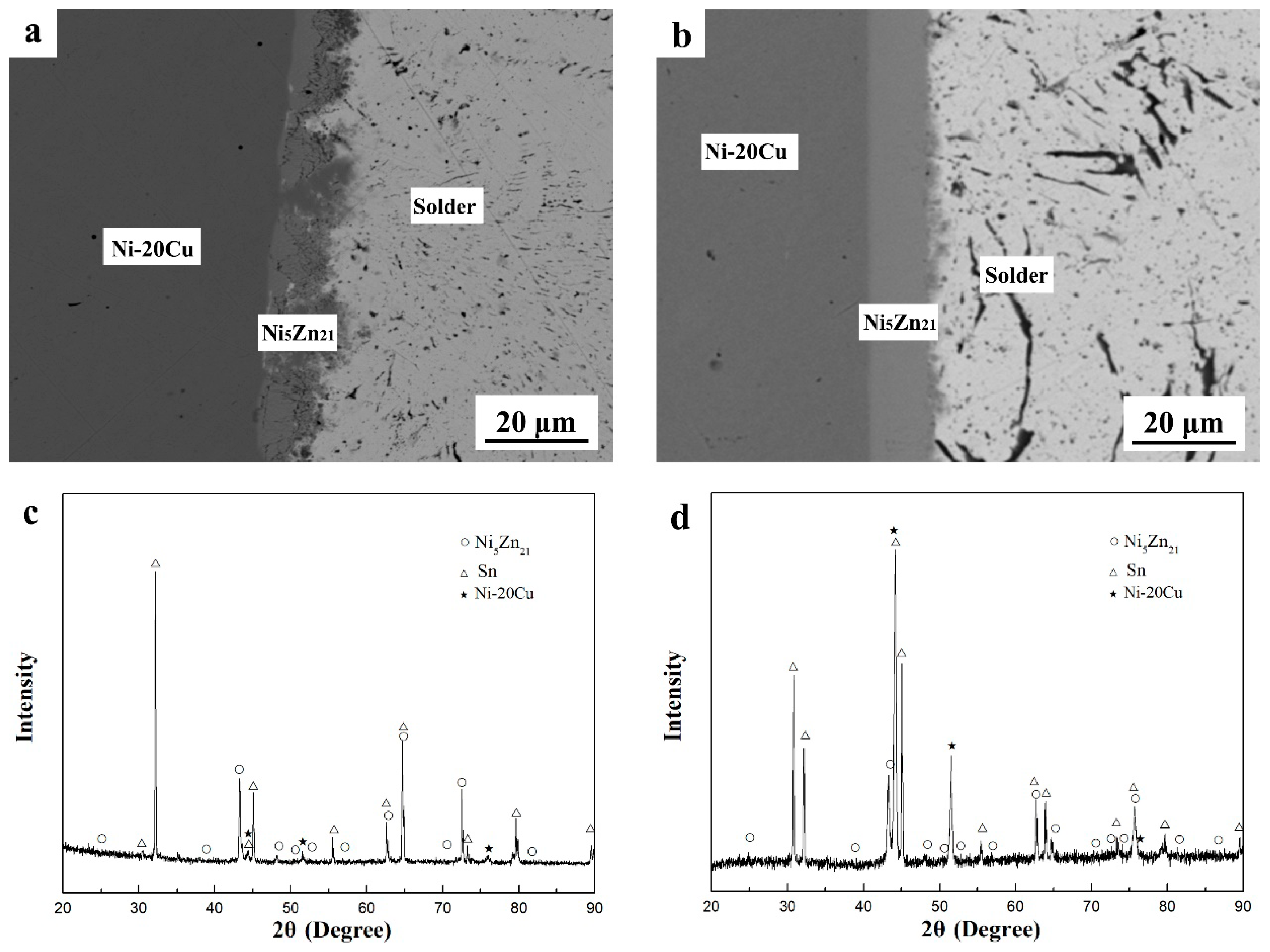

3.1. Reaction Products in Sn-Zn/Ni-20Cu Joint

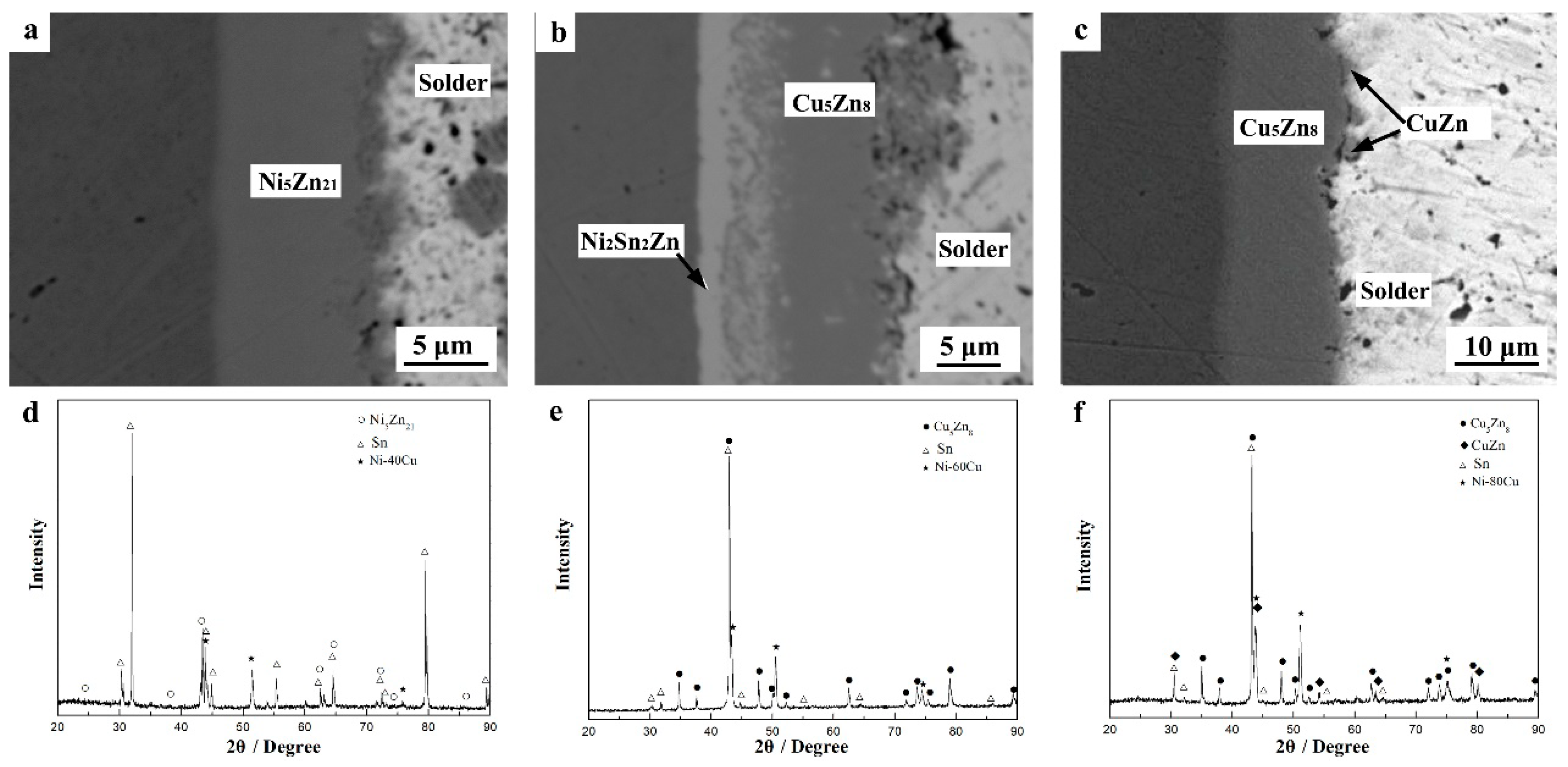

3.2. Effect of Cu Content on Reaction Products

3.3. Effect of Soldering Temperature on Reaction Products

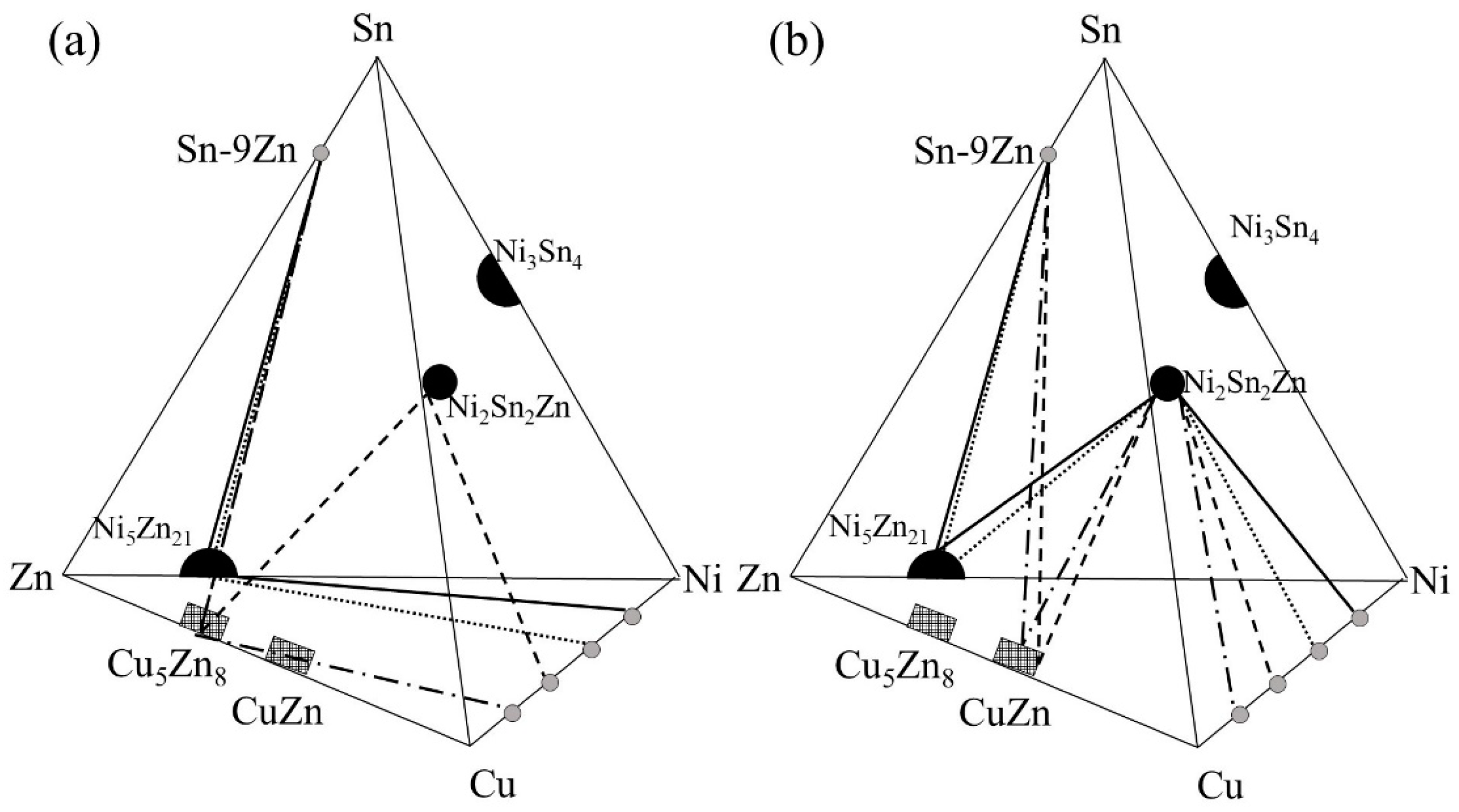

3.4. Discussions

4. Conclusions

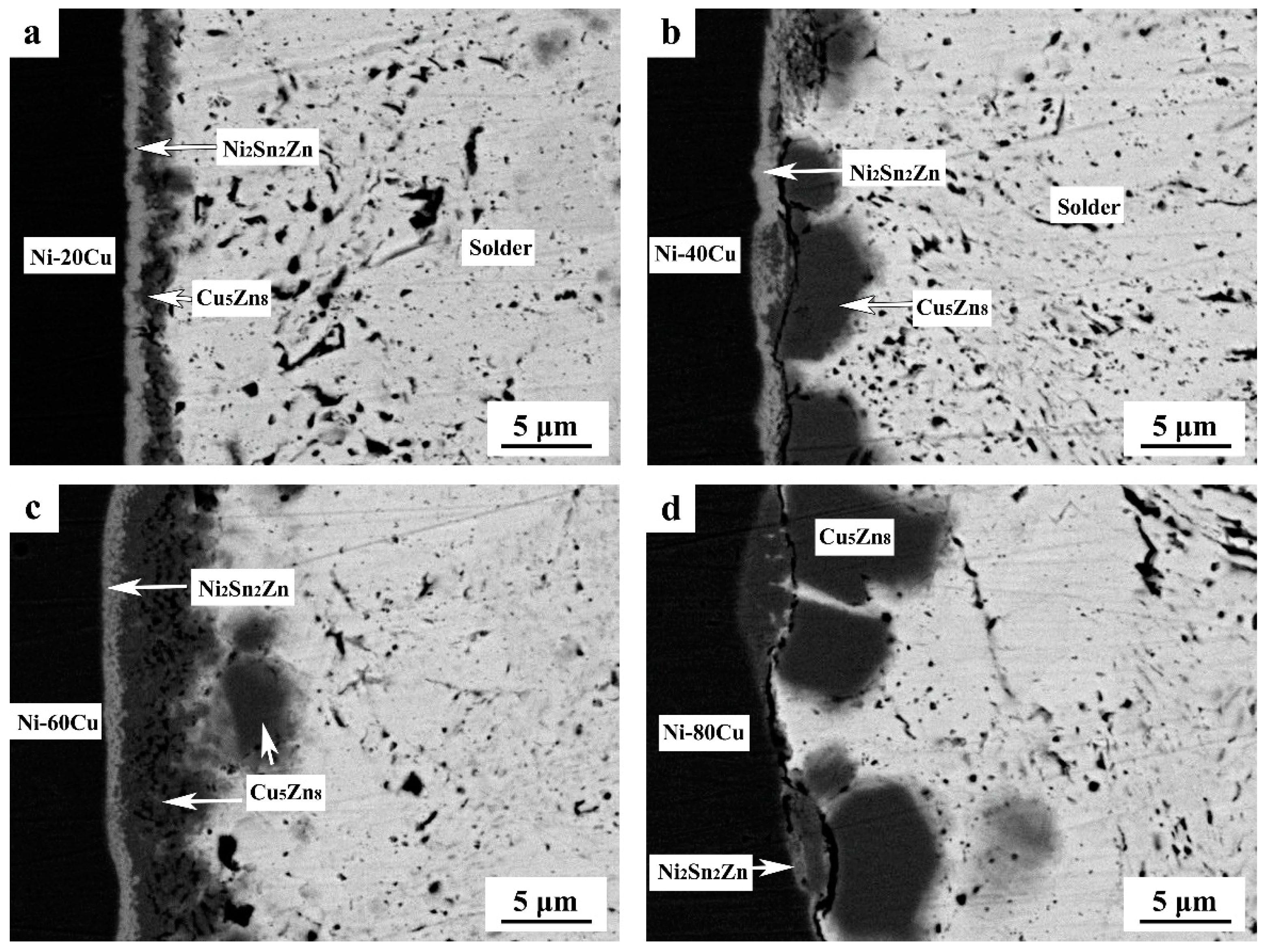

- When soldered at 250 °C, fine-grained Ni5Zn21 was the first formed product in Sn-Zn/Ni-20Cu and Sn-Zn/Ni-40Cu joints, while Ni2Sn2Zn + Cu5Zn8 and fine-grained Cu5Zn8 phases were formed in Sn-Zn/Ni-60Cu and Sn-Zn/Ni-80Cu joints, respectively. Ni5Zn21 layer transferred to Ni2Sn2Zn phase, whereas Cu5Zn8 phase transferred to Ni2Sn2Zn and CuZn phases at prolonged reaction time.

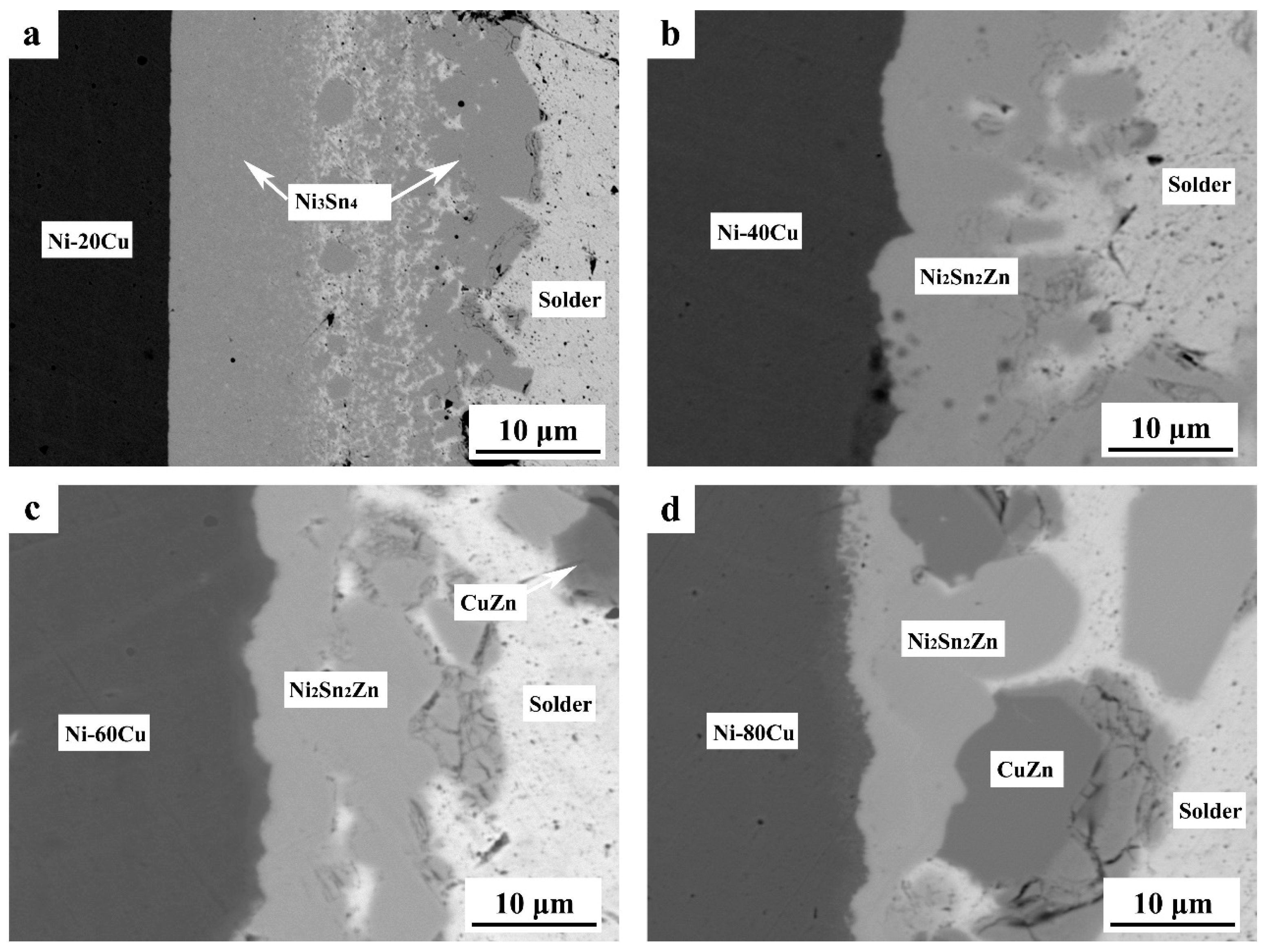

- Ni2Sn2Zn + Cu5Zn8 bi-layered structure was always formed first in Sn-Zn/Ni(Cu) joint at 350 °C regardless of the Cu content in Ni(Cu) substrate (20–80%). However, the bi-layered Ni2Sn2Zn + Cu5Zn8 transferred to a loose Ni3Sn4 layer in the Sn-Zn/Ni-20Cu joint, whereas a Ni2Sn2Zn layer transferred in Sn-Zn/Ni-40Cu joint. Meanwhile, Ni2Sn2Zn and CuZn transferred in Sn-Zn/Ni-60Cu and Sn-Zn/Ni-80Cu joints when the reaction time was prolonged at 350 °C.

- Using Ni(Cu) solid solution substrates, the morphologies of Ni5Zn21 and Cu5Zn8 can be optimized, and various reaction product combinations can be obtained at the interface. These results would provide an effective way to improve the joint reliability of the Sn-Zn soldering system.

Author Contributions

Funding

Conflicts of Interest

References

- Guo, W.; Luan, T.; He, J.; Yan, J. Ultrasonic-assisted soldering of fine-grained 7034 aluminum alloy using Sn-Zn solders below 300 °C. Ultrason. Sonochem. 2018, 40, 815–821. [Google Scholar] [CrossRef] [PubMed]

- Luan, T.; Guo, W.; Yang, S.; Ma, Z.; He, J.; Yan, J. Effect of intermetallic compounds on mechanical properties of copper joints ultrasonic-soldered with Sn-Zn alloy. J. Mater. Process. Technol. 2017, 248, 123–129. [Google Scholar] [CrossRef]

- Zhang, L.; Xue, S.B.; Gao, L.L.; Sheng, Z.; Ye, H.; Xiao, Z.X.; Zeng, G.; Chen, Y.; Yu, S.L. Development of Sn–Zn lead-free solders bearing alloying elements. J. Mater. Sci. -Mater. Electron. 2009, 21, 1–15. [Google Scholar] [CrossRef]

- Liou, W.-k.; Yen, Y.-W.; Jao, C.-C. Interfacial Reactions of Sn-9Zn-xCu (x = 1, 4, 7, 10) Solders with Ni Substrates. J. Electron. Mater. 2009, 38, 2222–2227. [Google Scholar] [CrossRef]

- Zhao, N.; Zhong, Y.; Huang, M.L.; Dong, W.; Ma, H.T.; Wang, Y.P. In situ study on interfacial reactions of Cu/Sn–9Zn/Cu solder joints under temperature gradient. J. Alloys Compd. 2016, 682, 1–6. [Google Scholar] [CrossRef]

- Yoon, J.-W.; Jung, S.-B. Reliability studies of Sn–9Zn/Cu solder joints with aging treatment. J. Alloys Compd. 2006, 407, 141–149. [Google Scholar] [CrossRef]

- Zhu, W.; Liu, H.; Wang, J.; Ma, G.; Jin, Z. Interfacial Reactions Between Sn-Zn Alloys and Ni Substrates. J. Electron. Mater. 2009, 39, 209–214. [Google Scholar] [CrossRef]

- Laurila, T.; Vuorinen, V.; Kivilahti, J.K. Interfacial reactions between lead-free solders and common base materials. Mater. Sci. Eng. R Rep. 2005, 49, 1–60. [Google Scholar] [CrossRef]

- Tu, K.; Liu, Y. Recent advances on kinetic analysis of solder joint reactions in 3D IC packaging technology. Mater. Sci. Eng. R Rep. 2019, 136, 1–12. [Google Scholar] [CrossRef]

- Kao, C.R.; Chang, Y.A. A theoretical analysis for the formation of periodic layered structure in ternary diffusion couples involving a displacement type of reactions. Acta Metall. Mater. 1993, 41, 3463–3472. [Google Scholar] [CrossRef]

- Wang, J.Y.; Lin, C.F.; Chen, C.M. Retarding the Cu5Zn8 phase fracture at the Sn–9wt.% Zn/Cu interface. Scr. Mater. 2011, 64, 633–636. [Google Scholar] [CrossRef]

- Liu, J.-C.; Wang, Z.-H.; Xie, J.-Y.; Ma, J.-S.; Shi, Q.-Y.; Zhang, G.; Suganuma, K. Effects of intermetallic-forming element additions on microstructure and corrosion behavior of Sn–Zn solder alloys. Corros. Sci. 2016, 112, 150–159. [Google Scholar] [CrossRef]

- Liu, J.-C.; Zhang, G.; Ma, J.-S.; Suganuma, K. Ti addition to enhance corrosion resistance of Sn–Zn solder alloy by tailoring microstructure. J. Alloys Compd. 2015, 644, 113–118. [Google Scholar] [CrossRef]

- Hu, Y.-h.; Xue, S.-b.; Wang, H.; Ye, H.; Xiao, Z.-x.; Gao, L.-l. Effects of rare earth element Nd on the solderability and microstructure of Sn–Zn lead-free solder. J. Mater. Sci. -Mater. Electron. 2010, 22, 481–487. [Google Scholar] [CrossRef]

- Li, J.; Peng, J.; Wang, R.; Feng, Y.; Peng, C. Effects of Co addition on shear strength and interfacial microstructure of Sn–Zn–(Co)/Ni joints. J. Mater. Sci. -Mater. Electron. 2018, 29, 19901–19908. [Google Scholar] [CrossRef]

- Ren, G.; Wilding, I.J.; Collins, M.N. Alloying influences on low melt temperature SnZn and SnBi solder alloys for electronic interconnections. J. Alloys Compd. 2016, 665, 251–260. [Google Scholar] [CrossRef]

- Huang, Y.C.; Chen, S.W. Co alloying and size effects on solidification and interfacial reactions in the Sn–Zn–(Co)/Cu couples. J. Mater. Res. 2010, 25, 2430–2438. [Google Scholar] [CrossRef]

- Huang, M.; Hou, X.; Kang, N.; Yang, Y. Microstructure and interfacial reaction of Sn–Zn–X (Al, Ag) near-eutectic solders on Al and Cu substrates. J. Mater. Sci. -Mater. Electron. 2014, 25, 2311–2319. [Google Scholar] [CrossRef]

- Maeshima, T.; Ikehata, H.; Terui, K.; Sakamoto, Y. Effect of Ni to the Cu substrate on the interfacial reaction with Sn-Cu solder. Mater. Des. 2016, 103, 106–113. [Google Scholar] [CrossRef]

- Peng, J.; Wang, R.C.; Wang, M.; Liu, H.S. Interfacial Microstructure Evolution and Shear Behavior of Au-Sn/Ni-xCu Joints at 350 °C. J. Electron. Mater. 2017, 46, 2021–2029. [Google Scholar] [CrossRef]

- Lin, H.-f.; Chang, Y.-c.; Chen, C.-c. Sn-Zn/Ni-Co Interfacial Reactions at 250 °C. J. Electron. Mater. 2014, 43, 3333–3340. [Google Scholar] [CrossRef]

- Huang, K.C.; Shieu, F.S.; Huang, T.S.; Lu, C.T.; Chen, C.W.; Tseng, H.W.; Cheng, S.L.; Liu, C.Y. Study of Interfacial Reactions Between Sn(Cu) Solders and Ni-Co Alloy Layers. J. Electron. Mater. 2010, 39, 2403–2411. [Google Scholar] [CrossRef][Green Version]

- Chen, C.-C.; Chan, Y.-T.; Chen, Y.-T. Interfacial reactions between Sn-Cu solders and Ni-Co alloys at 250 °C. Int. J. Mater. Res. 2011, 25, 1321–1328. [Google Scholar] [CrossRef]

- Chen, C.-c.; Chen, Y.-t. Alternating reaction phases in Sn–Cu/Ni–Co solid-state reactions. J. Alloys Compd. 2012, 545, 28–31. [Google Scholar] [CrossRef]

- Schmetterer, C.; Rajamohan, D.; Ipser, H.; Flandorfer, H. The high-temperature phase equilibria of the Ni–Sn–Zn system: Isothermal sections. Intermetallics 2011, 19, 1489–1501. [Google Scholar] [CrossRef] [PubMed]

- Schmetterer, C.; Rajamohan, D.; Effenberger, H.S.; Flandorfer, H. Ni2Sn2Zn from single-crystal X-ray diffraction. Acta Crystallogr. Sect. C Cryst. Struct. Commun. 2012, 68, i65–i67. [Google Scholar] [CrossRef]

- Gandova, V.; Soares, D.; Lilova, K.; Tedenac, J.C.; Vassilev, G.P. Phase equilibria in the Sn–Zn–Ni system. Int. J. Mater. Res. 2011, 102, 257. [Google Scholar] [CrossRef]

- Gandova, V.; Vassilev, G.P. Thermodynamic optimization and phase equilibria in the ternary system Ni–Sn–Zn. J. Alloys Compd. 2014, 609, 1–6. [Google Scholar] [CrossRef]

- Chang, J.; Seo, S.-K.; Lee, H.M. Phase Equilibria in the Sn-Ni-Zn Ternary System: Isothermal Sections at 200 °C, 500 °C, and 800 °C. J. Electron. Mater. 2010, 39, 2643–2652. [Google Scholar] [CrossRef]

- Liang, J.-L.; Du, Y.; Tang, Y.-Y.; Xie, S.-B.; Xu, H.-H.; Zeng, L.-M.; Liu, Y.; Zhu, Q.-M.; Nong, L.-Q. Phase Equilibria in the Ni-Sn-Zn System at 500 °C. J. Electron. Mater. 2011, 40, 2290–2299. [Google Scholar] [CrossRef]

- Chen, S.-w.; Hsu, C.-m.; Chou, C.-y.; Hsu, C.-w. Isothermal section of ternary Sn-Zn-Ni phase equilibria at 250 °C. Prog. Nat. Sci. Mater. Int. 2011, 21, 386–391. [Google Scholar] [CrossRef]

- Wołczyński, W.; Okane, T.; Senderowski, C.; Zasada, D.; Kania, B.; Janczak-Rusch, J. Thermodynamic justification for the Ni/Al/Ni joint formation by a diffusion brazing. Int. J. Thermodyn. 2011, 14, 97–105. [Google Scholar] [CrossRef]

- Wołczyński, W.; Okane, T.; Senderowski, C.; Kania, B.; Zasada, D.; Janczak-Rusch, J. Meta-stable conditions of diffusion brazing. Arch. Metall. Mater. 2011, 56, 311–323. [Google Scholar] [CrossRef]

- Huang, Y.-c.; Chen, S.-w.; Chou, C.-y.; Gierlotka, W. Liquidus projection and thermodynamic modeling of Sn–Zn–Cu ternary system. J. Alloys Compd. 2009, 477, 283–290. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, H.; Xie, Z.; Jin, Z. Prediction of interfacial reaction products between metals with same lattice structure through thermodynamic modeling. CALPHAD 2016, 52, 180–185. [Google Scholar] [CrossRef]

- Chan, Y.C.; Chiu, M.Y.; Chuang, T.H. Intermetallic Compounds Formed during the Soldering Reactions of Eutectic Sn-9Zn with Cu and Ni Substrates. Zeitschrift Für Metallkunde 2002, 93, 95–98. [Google Scholar] [CrossRef]

- Chen, W.M.; Yang, S.C.; Tsai, M.H.; Kao, C.R. Uncovering the driving force for massive spalling in the Sn–Cu/Ni system. Scr. Mater. 2010, 63, 47–49. [Google Scholar] [CrossRef]

| Nomenclature | Composition Phase Name | Refs. | ||

|---|---|---|---|---|

| Ni | Sn | Zn | ||

| T1 | 36.0 | 38.0 | 26.0 | [27,28] |

| τ2 | 38.5 | 35.7 | 25.8 | [29] |

| δ | 36.8 | 38.8 | 24.4 | [30] |

| τ1 | 49.7 | 36.6 | 13.7 | [30] |

| δ | 31.8 | 44.5 | 23.7 | [31] |

| τ3 | 33.3 | 42.8 | 23.8 | [25] |

| Ni2Sn2Zn | 40.0 | 40.0 | 20.0 | [26] |

| Substrate | Compositions (at.%) | Phase | |||

|---|---|---|---|---|---|

| Ni | Cu | Sn | Zn | ||

| Ni-20Cu | 16.44 | 1.98 | 1.45 | 80.13 | Ni5Zn21 |

| Ni-40Cu | 14.94 | 9.25 | 0.31 | 75.50 | Ni5Zn21 |

| Ni-60Cu | 26.12 | 16.91 | 41.95 | 15.01 | Ni2Sn2Zn |

| 8.87 | 21.74 | 1.75 | 67.64 | Cu5Zn8 | |

| Ni-80Cu | 5.61 | 27.97 | 1.24 | 65.17 | Cu5Zn8 |

| 5.17 | 35.32 | 8.43 | 51.08 | CuZn | |

| Substrates | Soldering Time (h) | |||

|---|---|---|---|---|

| 1 | 4 | 9 | 16 | |

| Ni-20Cu | Ni5Zn21 | Ni5Zn21 | Ni5Zn21 | Ni2Sn2Zn + Ni5Zn21 |

| Ni-40Cu | Ni5Zn21 | Ni5Zn21 | Ni5Zn21 | Ni2Sn2Zn + Ni5Zn21 |

| Ni-60Cu | Ni2Sn2Zn + Cu5Zn8 | Ni2Sn2Zn + Cu5Zn8 | Ni2Sn2Zn + Cu5Zn8 | Ni2Sn2Zn + CuZn |

| Ni-80Cu | Cu5Zn8 | Cu5Zn8 | Cu5Zn8 + CuZn | Ni2Sn2Zn + CuZn |

| Substrates | Soldering Time | ||

|---|---|---|---|

| 2 min | 10 min | 60 min | |

| Ni-20Cu | Ni2Sn2Zn + Cu5Zn8 | Ni2Sn2Zn + Cu5Zn8 | Ni3Sn4 |

| Ni-40Cu | Ni2Sn2Zn + Cu5Zn8 | Ni2Sn2Zn + Cu5Zn8 | Ni2Sn2Zn |

| Ni-60Cu | Ni2Sn2Zn + Cu5Zn8 | Ni2Sn2Zn + Cu5Zn8 | Ni2Sn2Zn + CuZn |

| Ni-80Cu | Ni2Sn2Zn + Cu5Zn8 | Ni2Sn2Zn + Cu5Zn8 | Ni2Sn2Zn + CuZn |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, X.; Peng, J.; Wei, X.; Yan, P.; Wang, F. Interfacial Reaction and Microstructure Evolution of Sn-9Zn/Ni(Cu) Solder Joints. Metals 2019, 9, 604. https://doi.org/10.3390/met9050604

Zhu X, Peng J, Wei X, Yan P, Wang F. Interfacial Reaction and Microstructure Evolution of Sn-9Zn/Ni(Cu) Solder Joints. Metals. 2019; 9(5):604. https://doi.org/10.3390/met9050604

Chicago/Turabian StyleZhu, Xuewei, Jian Peng, Xiaofeng Wei, Pengpeng Yan, and Fu Wang. 2019. "Interfacial Reaction and Microstructure Evolution of Sn-9Zn/Ni(Cu) Solder Joints" Metals 9, no. 5: 604. https://doi.org/10.3390/met9050604

APA StyleZhu, X., Peng, J., Wei, X., Yan, P., & Wang, F. (2019). Interfacial Reaction and Microstructure Evolution of Sn-9Zn/Ni(Cu) Solder Joints. Metals, 9(5), 604. https://doi.org/10.3390/met9050604