Fabrication and Fatigue Behavior of Aluminum Foam Sandwich Panel via Liquid Diffusion Welding Method

Abstract

1. Introduction

2. Materials and Experimental Methods

3. Results and Discussion

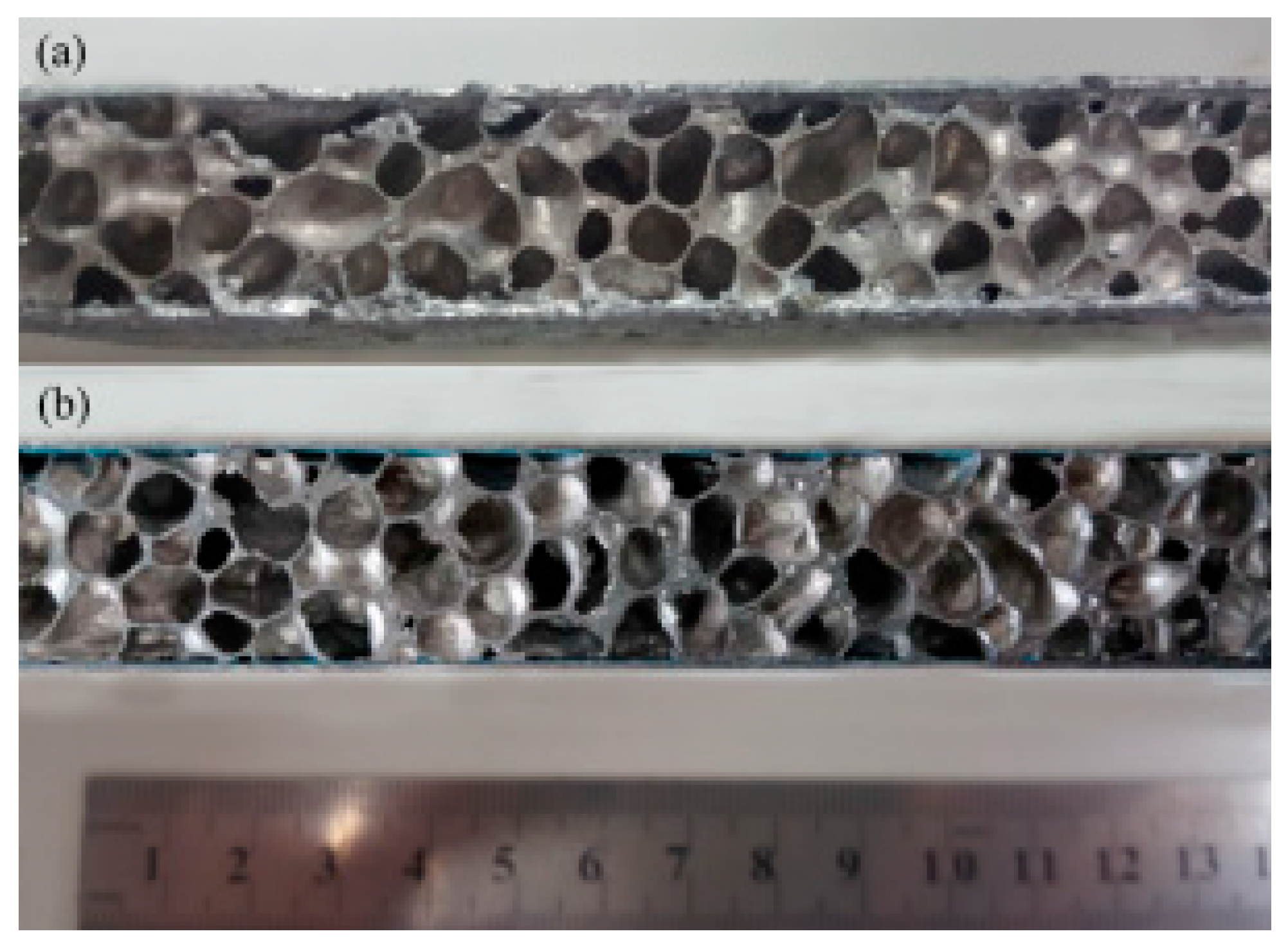

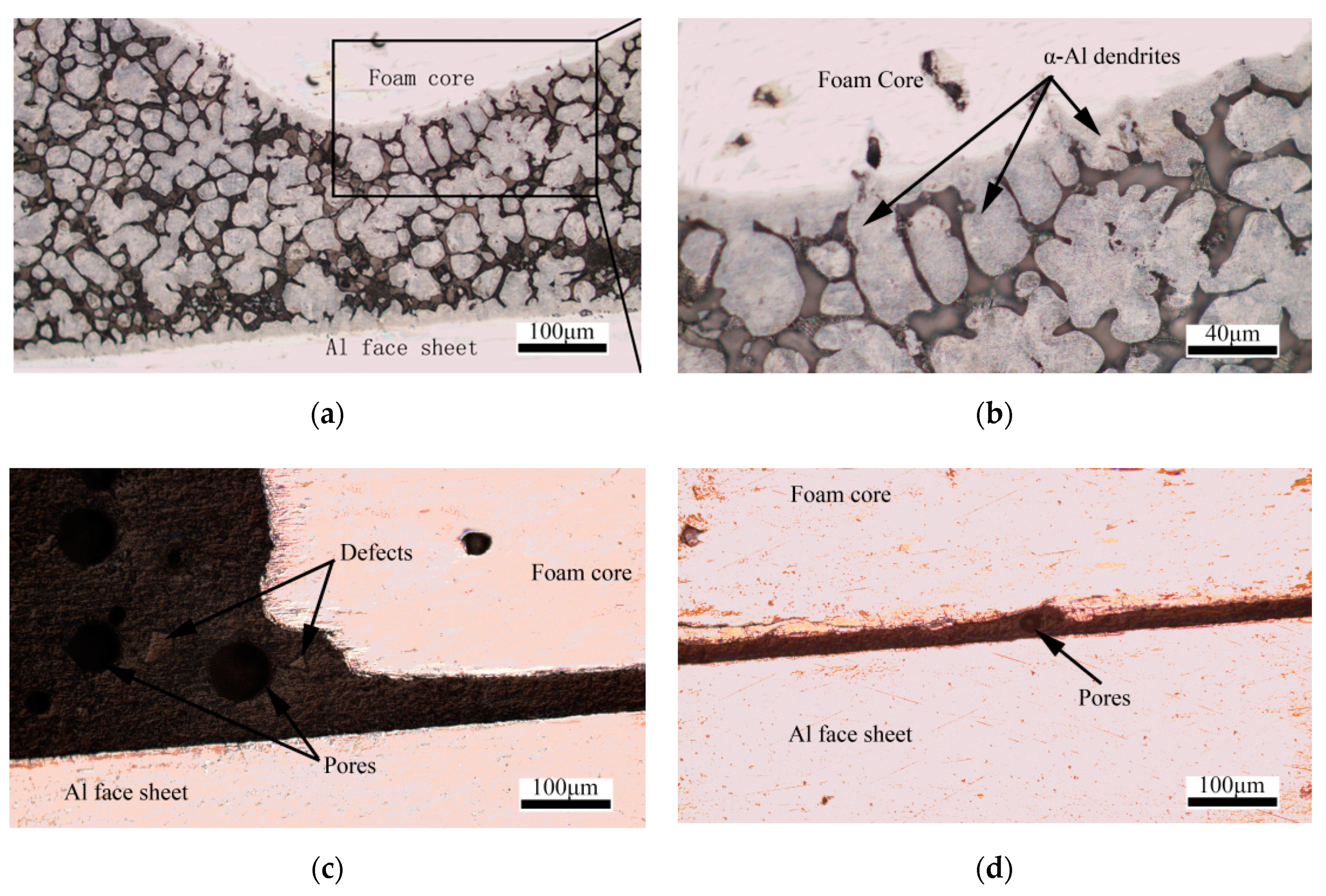

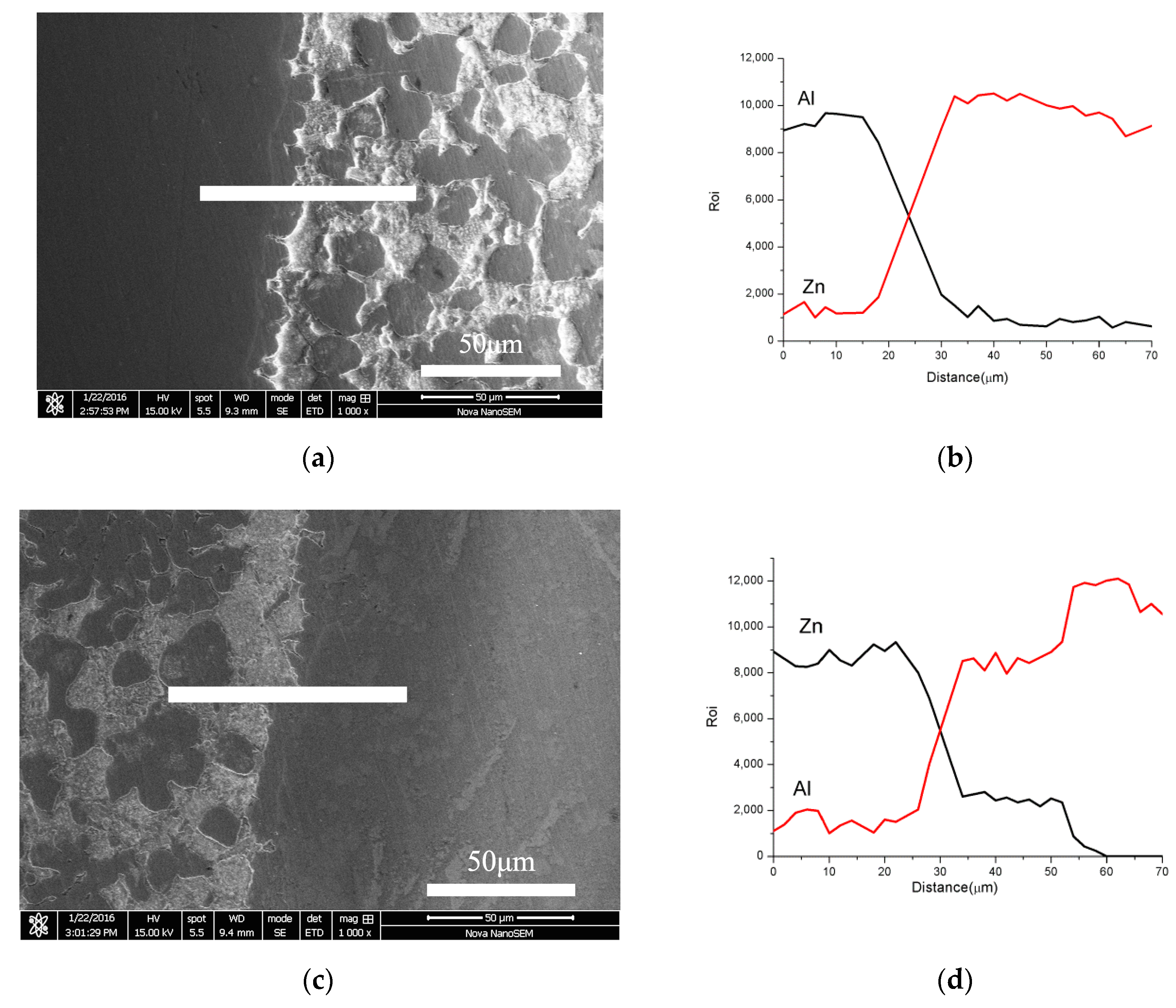

3.1. Microstructure

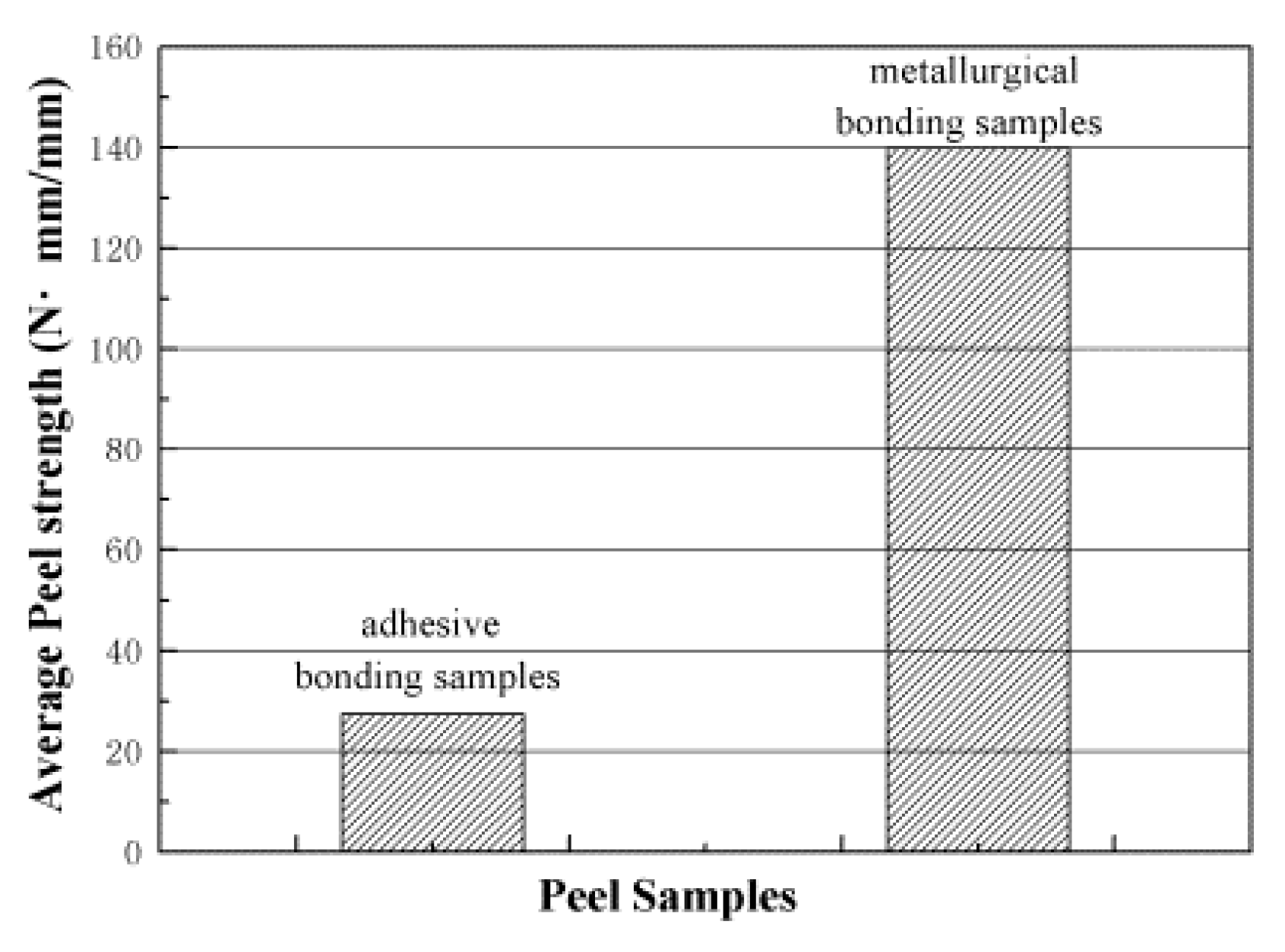

3.2. Peel Strength Test

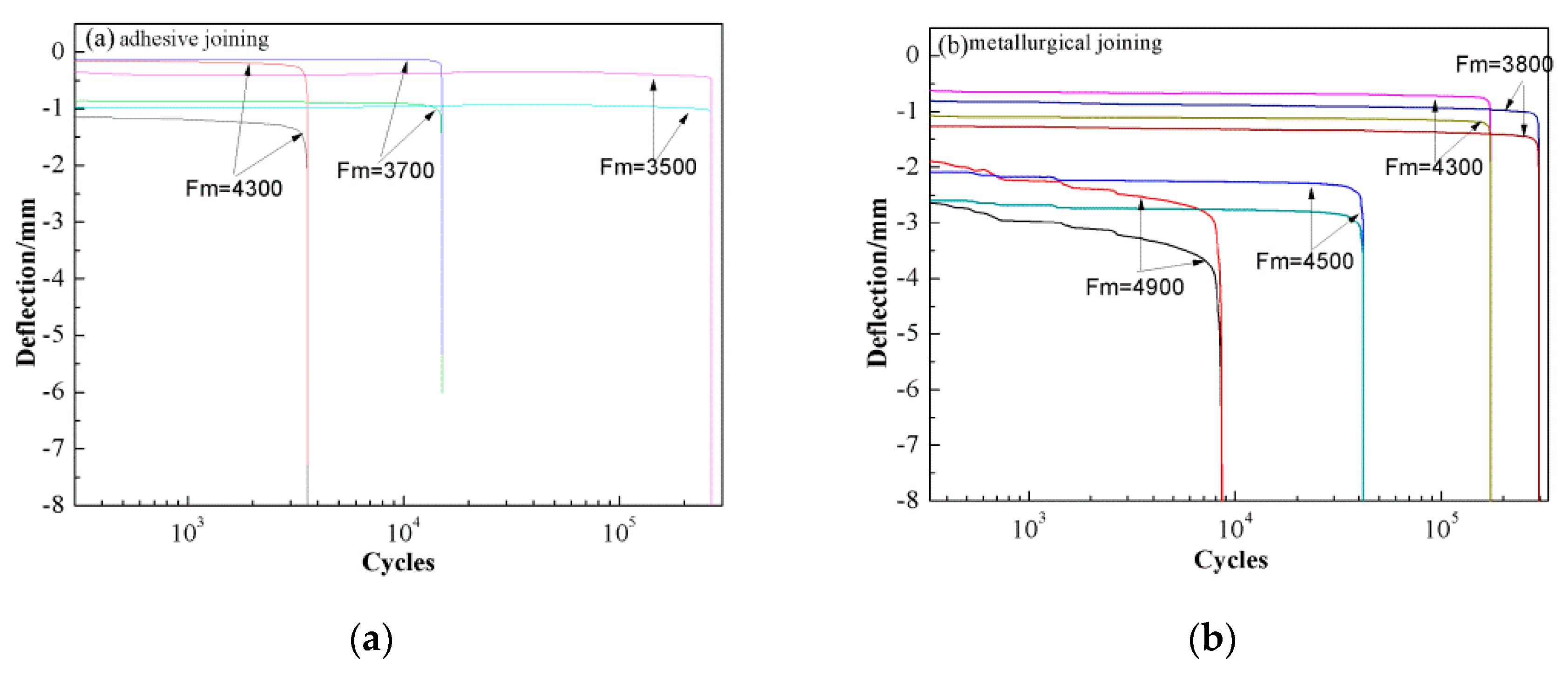

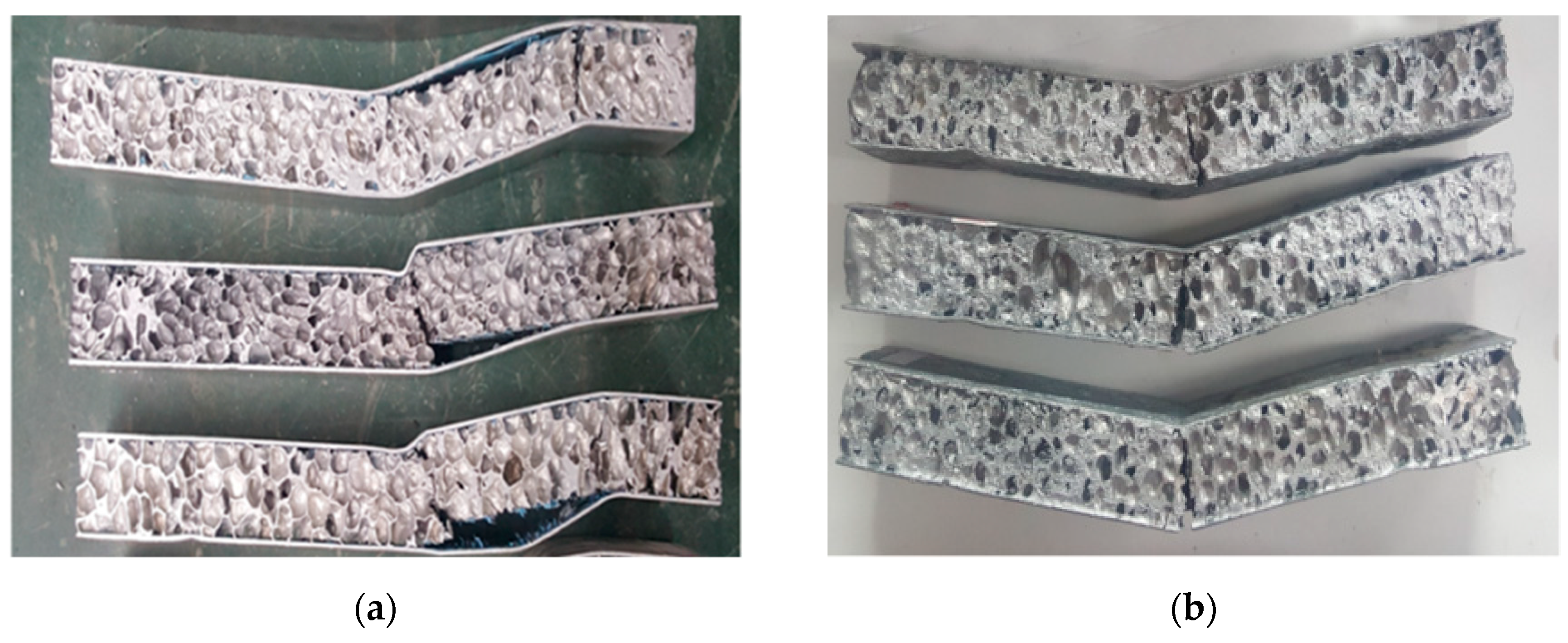

3.3. Three-Point Bending Fatigue

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ashby, M.F.; Lu, T.J. Metals foam: A survey. Sci. China 2003, 46, 521–532. [Google Scholar] [CrossRef]

- Davies, G.J.; Zhen, S. Metallic foams: their production, properties and applications. J. Mater. Sci. 1983, 18, 1899–1911. [Google Scholar] [CrossRef]

- Alvandi-Tabrizi, Y.; Whisler, D.A.; Kim, H.; Rabiei, A. High strain rate behavior of composite metal foams. Mater. Sci. Eng. 2015, A631, 248–257. [Google Scholar] [CrossRef]

- Gui, M.C.; Wang, D.B.; Wu, J.J.; Yuan, G.J.; Li, C.G. Deformation and damping behaviors of foamed Al-Si-SiCp composite. Mater. Sci. Eng. 2000, A286, 282–288. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F. Cellular Solids: Structure & Properties; Cambridge University Press: Cambridge, UK, 1997; p. 510. [Google Scholar]

- Katona, B.; Szebényi, G.; Orbulov, I.N. Fatigue properties of ceramic hollow sphere filled aluminium matrix syntactic foams. Mater. Sci. Eng. 2017, A679, 350–357. [Google Scholar]

- Katona, B.; Szebényi, A.T.; Orbulov, I.N. Compressive characteristics and low frequency damping of aluminium matrix syntactic foams. Mater. Sci. Eng. 2019, A739, 140–148. [Google Scholar]

- Vendra, L.; Nevile, B.; Rabiel, A. Fatigue in aluminium-steel and steel-steel composite foams. Mater. Sci. Eng. 2009, A517, 146–153. [Google Scholar]

- Banhart, J.; Seeliger, H.W. Aluminium Foam Sandwich Panels: Manufacture, Metallurgy and Applications. Adv. Eng. Mater. 2008, 10, 793–802. [Google Scholar] [CrossRef]

- Garcia-Moreno, F. Commercial Applications of Metal Foams: Their Properties and Production. Materials 2018, 9, 85. [Google Scholar] [CrossRef]

- Crupi, V.; Epasto, G.; Guglielmino, E. Comparison of aluminium sandwiches for lightweight ship structures: Honeycomb vs. foam. Mar. Struct. 2013, 30, 74–96. [Google Scholar] [CrossRef]

- Golovin, I.S.; Sinning, H.R. Damping in some cellular metallic materials. J. Alloys Compd. 2003, 355, 2–9. [Google Scholar] [CrossRef]

- Yang, D.H.; Yang, S.R.; Wang, H.; Ma, A.B.; Jiang, J.H.; Chen, J.Q.; Wang, D.L. Compressive properties of cellular Mg foams fabricated by melt-foaming method. Mater. Sci. Eng. 2010, A527, 5405–5409. [Google Scholar] [CrossRef]

- Huang, Z.; Qin, Z.; Chu, F. Damping mechanism of elastic-viscoelastic-elastic sandwich structures. Compos. Struct. 2016, 153, 96–107. [Google Scholar] [CrossRef]

- Yu, G.C.; Feng, L.J.; Wu, L.Z. Thermal and mechanical properties of a multifunctional composite square honeycomb sandwich structure. Mater. Des. 2016, 102, 238–246. [Google Scholar] [CrossRef]

- Harte, A.M.; Fleck, N.A.; Ashby, M.F. Sandwich panel design using Aluminum alloy foam. Adv. Eng. Mater. 2000, 2, 219–222. [Google Scholar] [CrossRef]

- Hangai, Y.; Takahashi, K.; Yamaguchi, R.; Utsunomiya, T.; Kitahara, S.; Kuwazuru, O.; Yoshikawa, N. Nondestructive observation of pore structure deformation behavior of functionally graded Aluminum foam by X-ray computed tomography. Mater. Sci. Eng. 2012, A556, 678–684. [Google Scholar] [CrossRef]

- Chen, N.; Feng, Y.; Chen, J.; Li, B.; Chen, F.; Zhao, J. Vacuum Brazing Processes of Aluminum Foam. Rare Metal Mater. Eng. 2013, 42, 1118–1122. [Google Scholar]

- Matsumoto, R.; Tsuruoka, H.; Otsu, M.; Utsunomiya, H. Fabrication of skin layer on Aluminum foam surface by friction stir incremental forming and its mechanical properties. J. Mater. Process. Technol. 2015, 218, 23–31. [Google Scholar] [CrossRef]

- D’Urso, G.; Maccarini, G. The formability of Aluminum Foam Sandwich panels. Int. J. Mater. Form. 2012, 5, 243–257. [Google Scholar] [CrossRef]

- Olurin, O.B.; Fleck, N.A.; Ashby, M.F. Joining of Aluminum foam with fasteners and adhesives. J. Mater. Sci. 2000, 35, 1079–1085. [Google Scholar] [CrossRef]

- Deshpande, V.S.; Fleck, N.A. High strain rate compressive behaviour of aluminium alloy foams. Int. J. Imapct Eng. 2000, 24, 277–298. [Google Scholar] [CrossRef]

- Jitai, N. Joining of Aluminium Alloy Sheets to Aluminium Alloy Foam Using Metal Glasses. Metals 2018, 8, 614. [Google Scholar]

- Duarte, I.; Krstulović-Opara, L.; Vesenjak, M. Axial crush behaviour of the aluminium alloy in-situ foam filled tubes with very low wall thickness. Compos. Struct. 2018, 192, 184–192. [Google Scholar] [CrossRef]

- Kitazono, K.; Kitajima, A.; Sato, E.; Matsushita, J.; Kuribayashi, K. Solid-state diffusion bonding of closed-cell Aluminum foams. Mater. Sci. Eng. 2002, A237, 128–132. [Google Scholar] [CrossRef]

- Ubertalli, G.; Ferrais, M.; Bangash, M.K. Joining of AL-6016 to Al-foam using Zn-based joining materials. Compsites Part A 2017, 96, 122–128. [Google Scholar] [CrossRef]

- ASTM_C393-C393M-06, Standard Test Method for Core Shear Properties of Sandwich Constructions by Beam Flexu-re; ASTM International: West Conshohocken, PA, America, 2006.

- GB/T 1457-2005, Test Method for Climbing Drum Peel Strength of Sandwich Constructions; Standards Press of China: Beijing, China, 2005.

- Wang, H.; Yang, D.; He, S.; He, D. Fabrication of open-cell Al foam core sandwich by vibration aided liquid phase bonding method and its mechanical properties. J. Mater. Sci. Technol. 2010, 26, 423–428. [Google Scholar] [CrossRef]

- Wan, L.; Huang, Y.; Lv, S.; Feng, J. Fabrication and interfacial characterization of Aluminum Foam Sandwich via fluxless soldering with surface abrasion. Compos. Struct. 2015, 123, 366–373. [Google Scholar] [CrossRef]

- Kotadia, H.R.; Das, A. Modification of solidification microstructure in hypo- and hyper-eutectic Al–Si alloys under high-intensity ultrasonic irradiation. Mater. Chem. Phys. 2011, 125, 853–859. [Google Scholar] [CrossRef]

- Xu, Z.; Yan, J.; Zhang, B.; Kong, X.; Yang, S. Behaviors of Oxide film at the ultrasonic aided interaction interface of Zn-Al alloy and Al2O3p/6061Al composites in air. Mater. Sci. Eng. 2006, A415, 80–86. [Google Scholar] [CrossRef]

- Zhang, S.; Zhao, Y.; Cheng, X.; Chen, G.; Dai, Q. High-energy ultrasonic field effects on the microstructure and mechanical behaviors of A356 alloy. J. Alloys Compd. 2009, 470, 168–172. [Google Scholar] [CrossRef]

- Zheng, D.; Chen, R.; Ma, T.; Ding, H.; Su, Y.; Guo, J.; Fu, H. Microstructure modification and mechanical performances enhancement of Ti44Al6Nb1 Cr alloy by ultrasound treatment. J. Alloys Compd. 2017, 710, 409–417. [Google Scholar] [CrossRef]

- Harte, A.M.; Fleck, N.A.; Ashby, M.F. The fatigue strength of sandwich beams with an aluminium alloy foam core. Int. J. Fatigue 2001, 23, 499–507. [Google Scholar] [CrossRef]

- Burman, M.; Zenkert, D. Fatigue of foam core sandwich beams—1: undamaged specimens. Int. J. Fatigue 1997, 19, 551–561. [Google Scholar] [CrossRef]

- Linul, E.; Serban, D.A.; Marsavina, L.; Kovacik, J. Low-cycle fatigue behaviour of ductile closed-cell aluminium alloy foams. Fatigue Fract. Eng. Mater. Struct. 2017, 40, 597–604. [Google Scholar] [CrossRef]

- Chen, C.; Harte, A.M.; Fleck, N.A. The plastic collapse of sandwich beams with a metallic foam. Int. J. Mech. Sci. 2001, 43, 1483–1506. [Google Scholar] [CrossRef]

- Duart, I.; Teixeir-Dias, F.; Graça, A.; Ferreira, A.J.M. Failure Modes and Influence of the Quasi-static Deformation Rate on the Mechanical Behavior of Sandwich Panels with Aluminum Foam Cores. Mech. Adv. Mater. Struct. 2010, 17, 335–342. [Google Scholar] [CrossRef]

| Samples | Joint | Peel Strength (N·mm/mm) | Average |

|---|---|---|---|

| 1 | adhesive | 25.2 | 27.5 |

| 2 | adhesive | 28.3 | |

| 3 | adhesive | 29.0 | |

| 4 | metallurgical | 147.3 | 140.0 |

| 5 | metallurgical | 135.1 | |

| 6 | metallurgical | 137.6 |

| Samples | Joint | Max Loading (N) | Life Cycles | Average |

|---|---|---|---|---|

| 1 | metallurgical | 5300 | 1438 | 1238 |

| 2 | metallurgical | 5300 | 1092 | |

| 3 | metallurgical | 5300 | 1184 | |

| 4 | metallurgical | 4900 | 8890 | 9639 |

| 5 | metallurgical | 4900 | 10,435 | |

| 6 | metallurgical | 4900 | 9592 | |

| 7 | metallurgical | 4500 | 37,623 | 41,881 |

| 8 | metallurgical | 4500 | 46,071 | |

| 9 | metallurgical | 4500 | 41,949 | |

| 10 | metallurgical | 4000 | 147,892 | 141,186 |

| 11 | metallurgical | 4000 | 152,377 | |

| 12 | metallurgical | 4000 | 123,289 | |

| 13 | metallurgical | 3800 | 325,071 | 296,950 |

| 14 | metallurgical | 3800 | 289,765 | |

| 15 | metallurgical | 3800 | 276,014 | |

| 16 | adhesive | 5300 | 123 | 157 |

| 17 | adhesive | 5300 | 186 | |

| 18 | adhesive | 5300 | 162 | |

| 19 | adhesive | 4300 | 3981 | 3592 |

| 20 | adhesive | 4300 | 3032 | |

| 21 | adhesive | 4300 | 3763 | |

| 22 | adhesive | 3700 | 15,769 | 15,861 |

| 23 | adhesive | 3700 | 14,291 | |

| 24 | adhesive | 3700 | 17,523 | |

| 25 | adhesive | 3500 | 260,817 | 267,345 |

| 26 | adhesive | 3500 | 291,082 | |

| 27 | adhesive | 3500 | 250,136 | |

| 28 | adhesive | 3350 | 883,188 | 958,252 |

| 29 | adhesive | 3350 | 1,078,321 | |

| 30 | adhesive | 3350 | 913,247 | |

| 31 | adhesive | 3150 | 1,213,484 | 1,320,030 |

| 32 | adhesive | 3150 | 1,456,872 | |

| 33 | adhesive | 3150 | 1,289,734 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, C.; Hu, Z.; Mo, F.; Wang, Y. Fabrication and Fatigue Behavior of Aluminum Foam Sandwich Panel via Liquid Diffusion Welding Method. Metals 2019, 9, 582. https://doi.org/10.3390/met9050582

Yao C, Hu Z, Mo F, Wang Y. Fabrication and Fatigue Behavior of Aluminum Foam Sandwich Panel via Liquid Diffusion Welding Method. Metals. 2019; 9(5):582. https://doi.org/10.3390/met9050582

Chicago/Turabian StyleYao, Cheng, Zhengfei Hu, Fan Mo, and Yu Wang. 2019. "Fabrication and Fatigue Behavior of Aluminum Foam Sandwich Panel via Liquid Diffusion Welding Method" Metals 9, no. 5: 582. https://doi.org/10.3390/met9050582

APA StyleYao, C., Hu, Z., Mo, F., & Wang, Y. (2019). Fabrication and Fatigue Behavior of Aluminum Foam Sandwich Panel via Liquid Diffusion Welding Method. Metals, 9(5), 582. https://doi.org/10.3390/met9050582