Influence of Austenite Grain Size on Mechanical Properties after Quench and Partitioning Treatment of a 42SiCr Steel

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

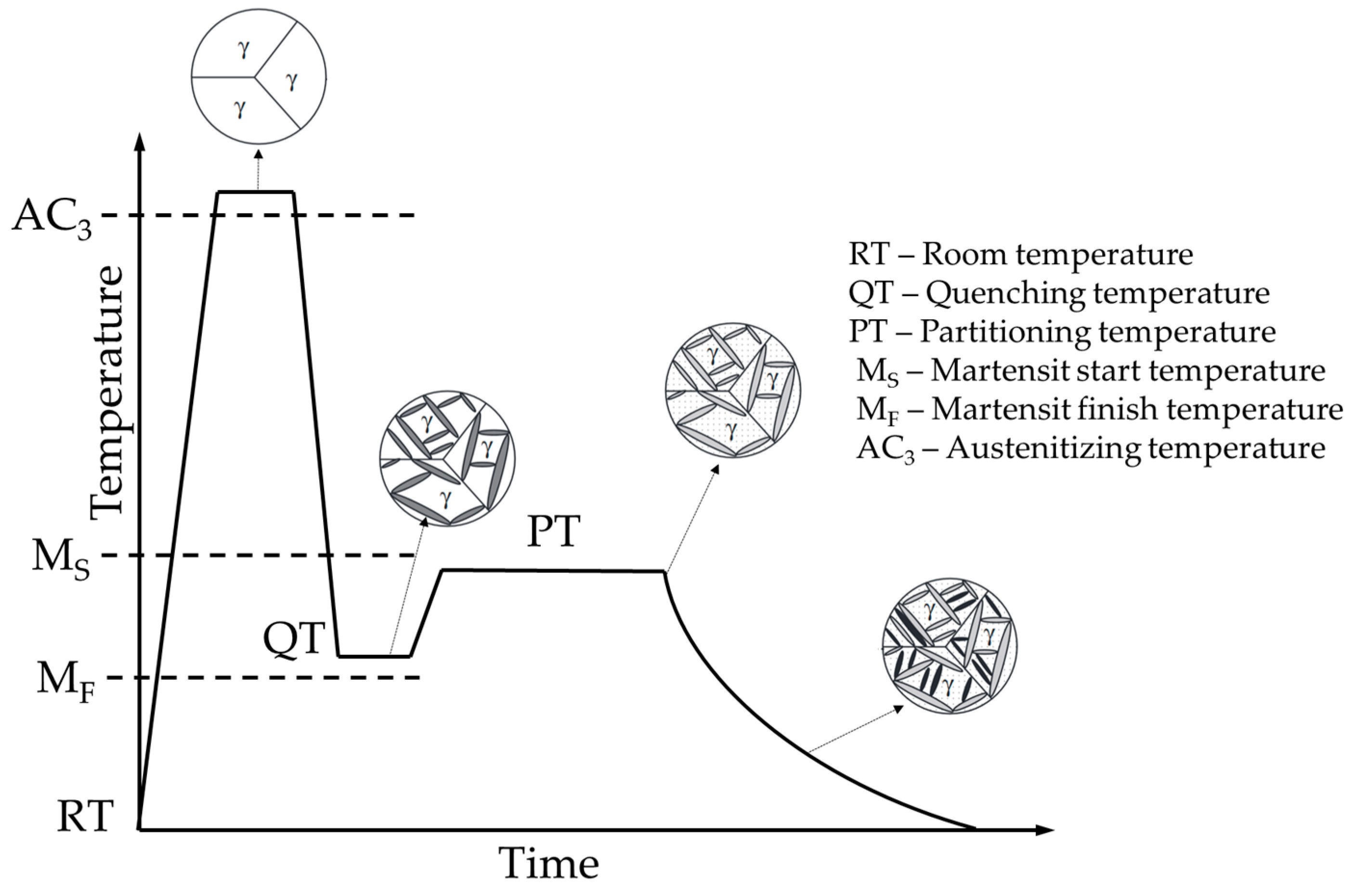

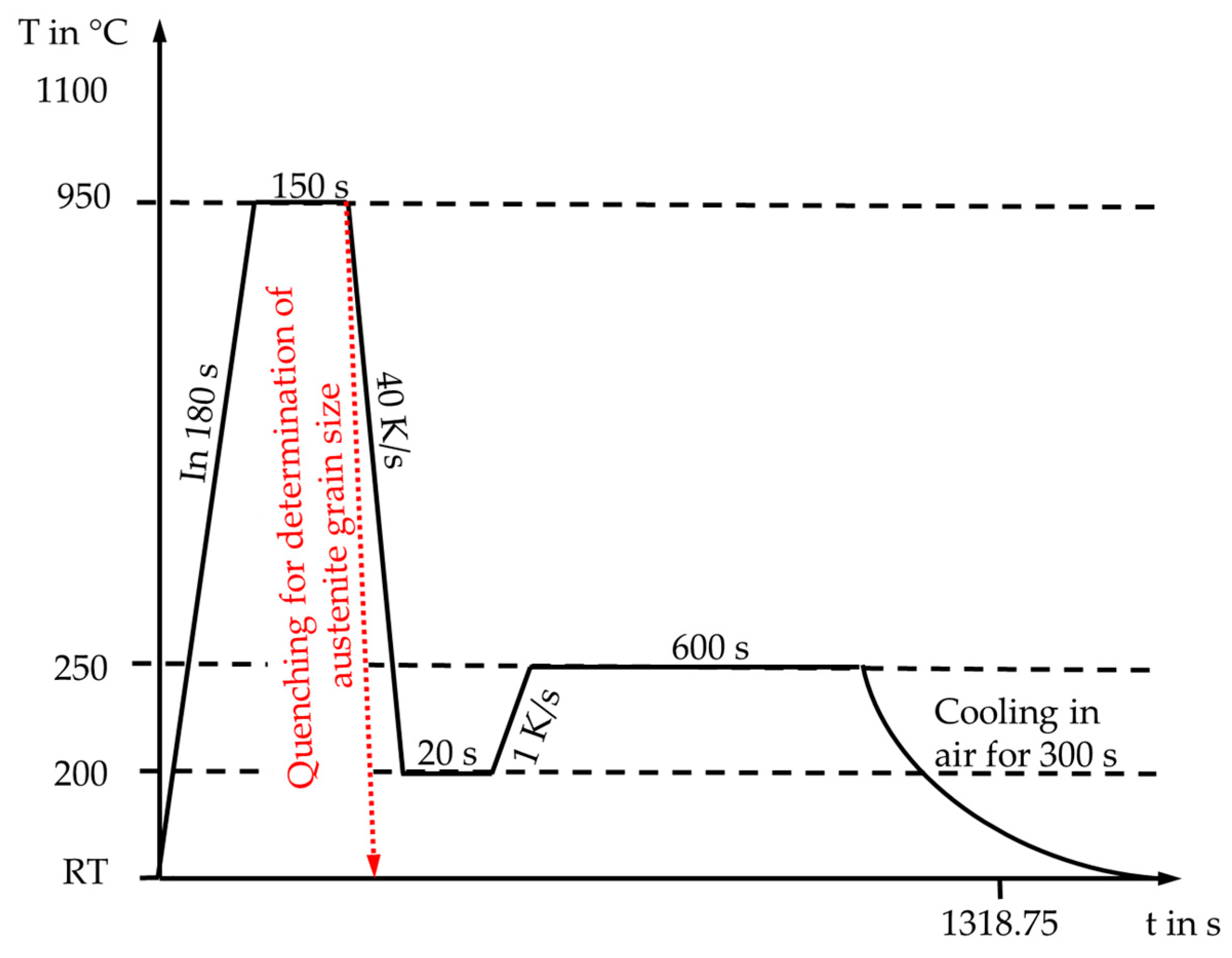

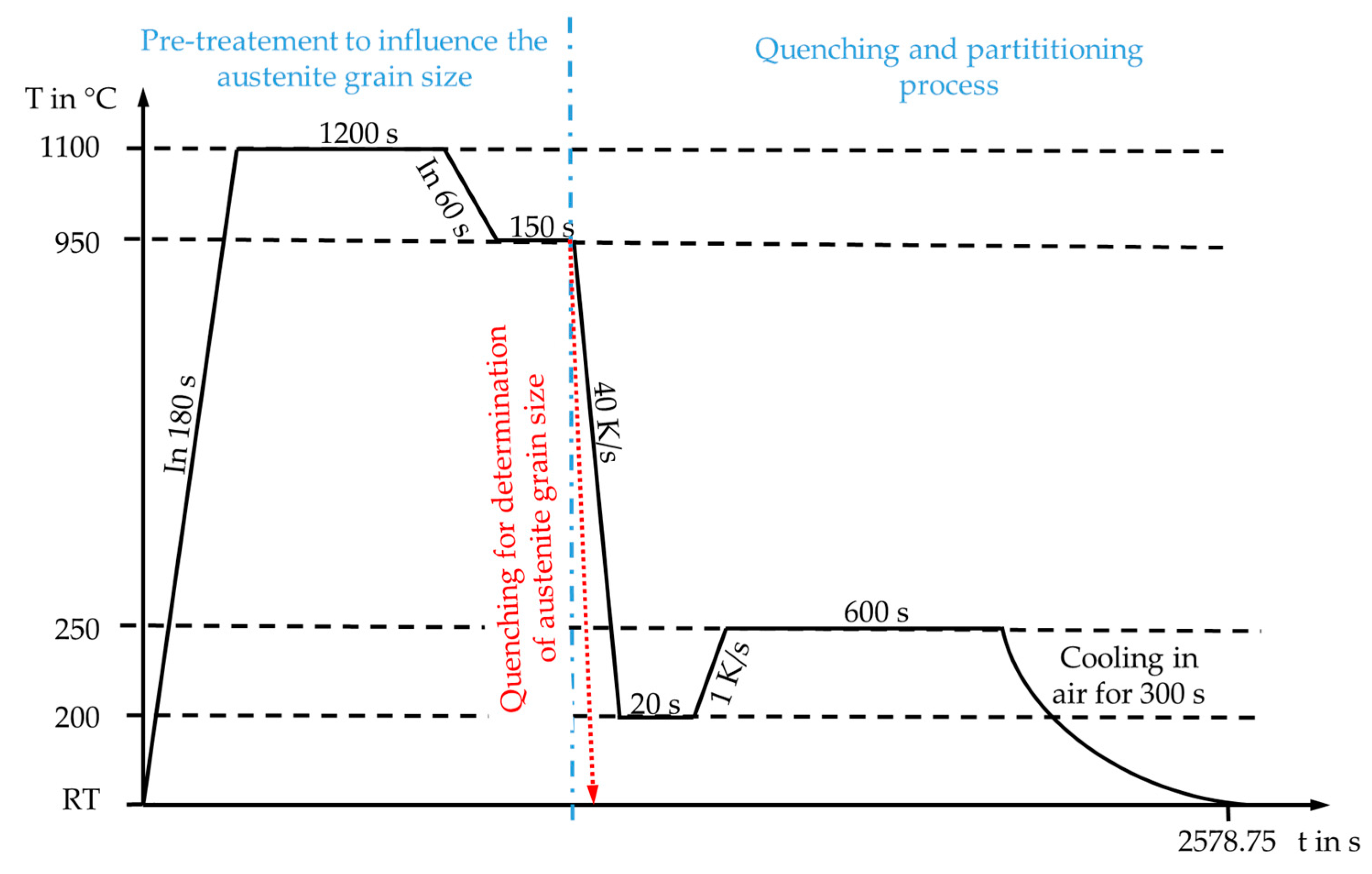

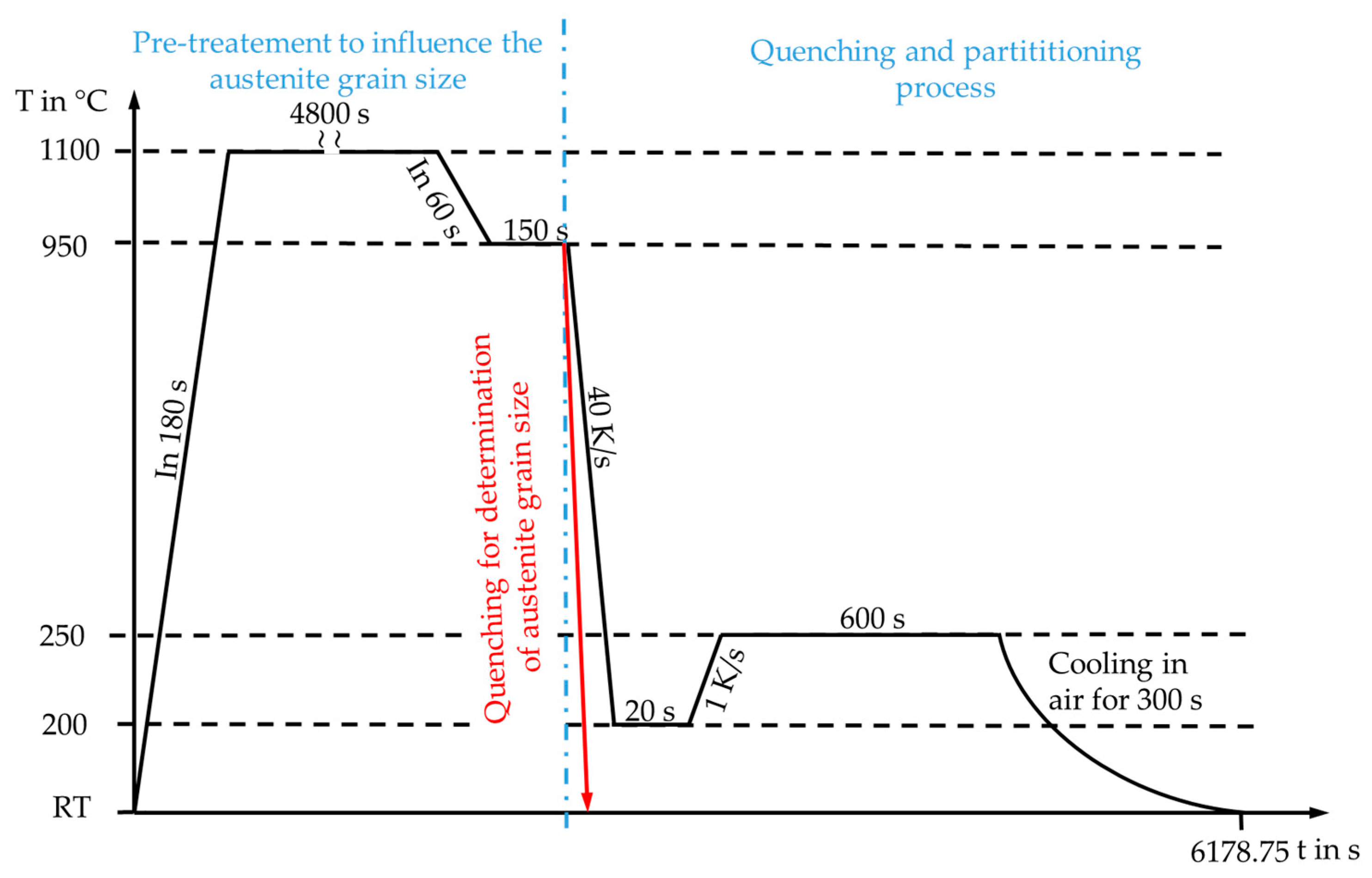

2.2. Method of Heat Treatment

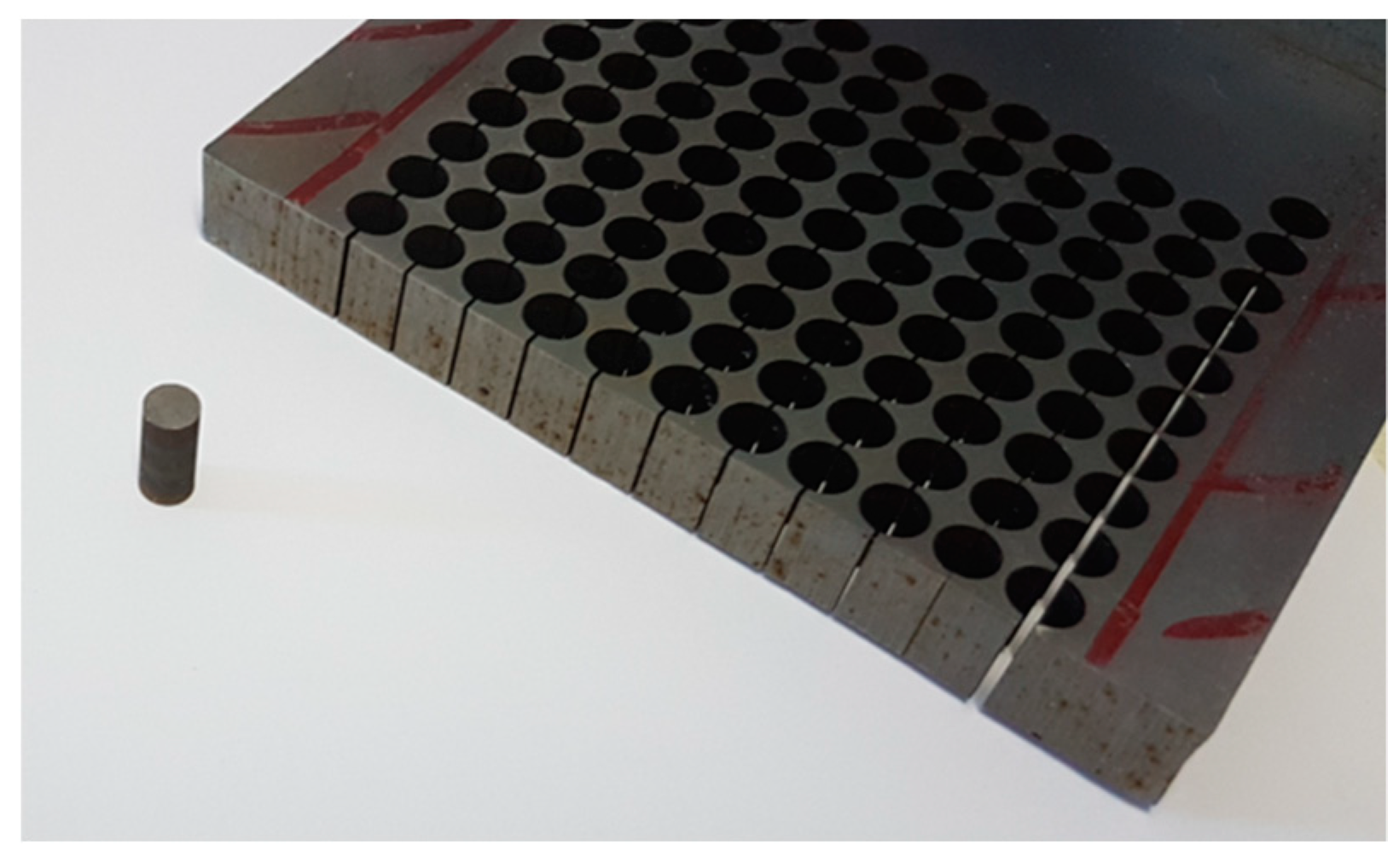

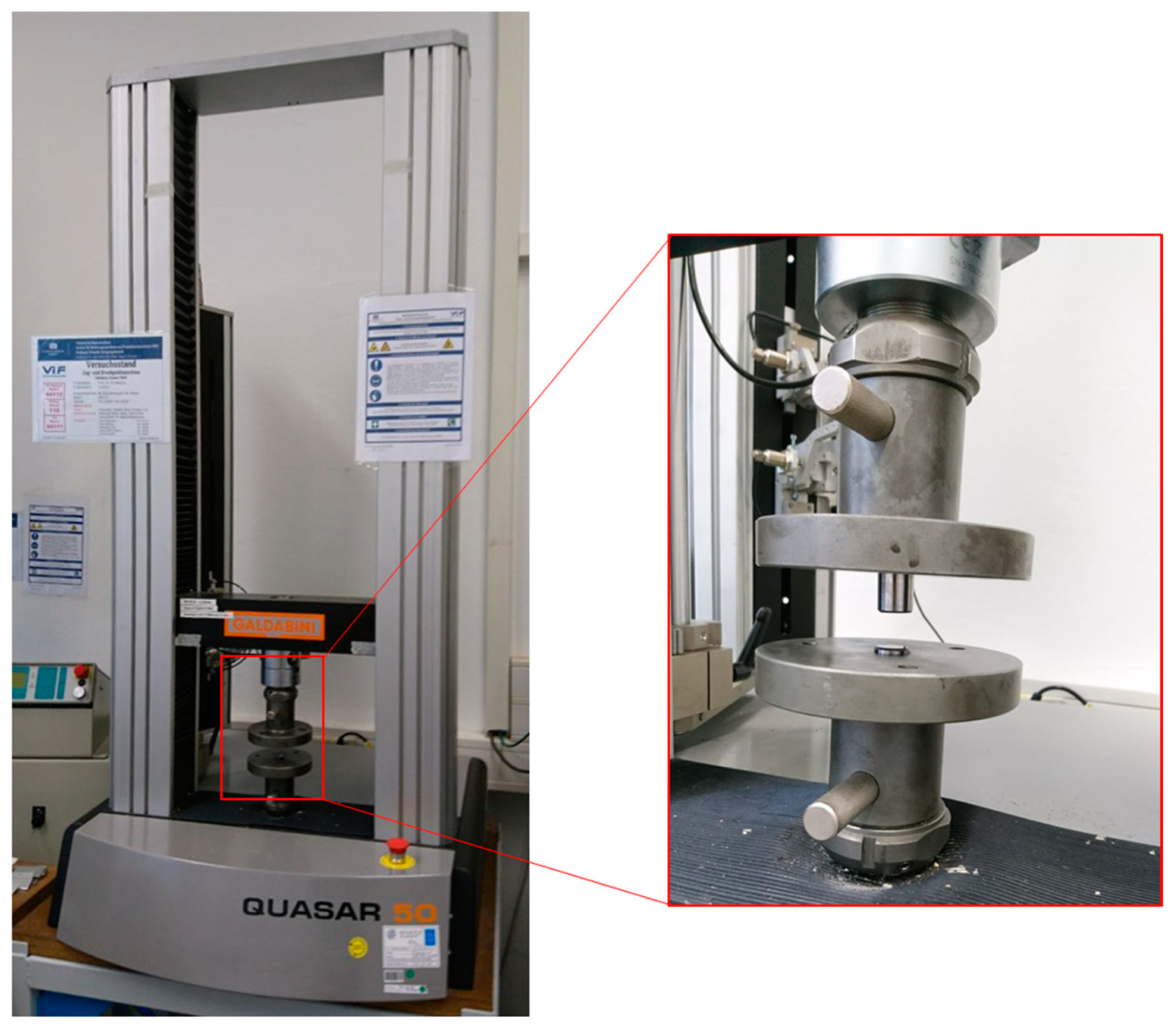

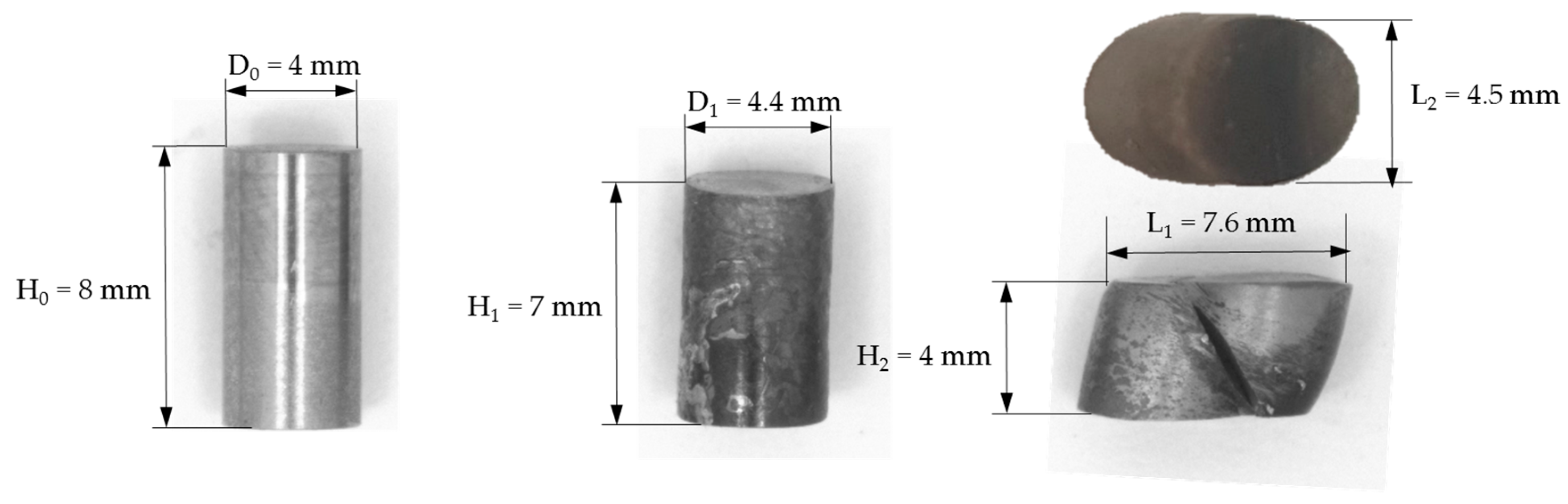

2.3. Determination of Mechanical Properties

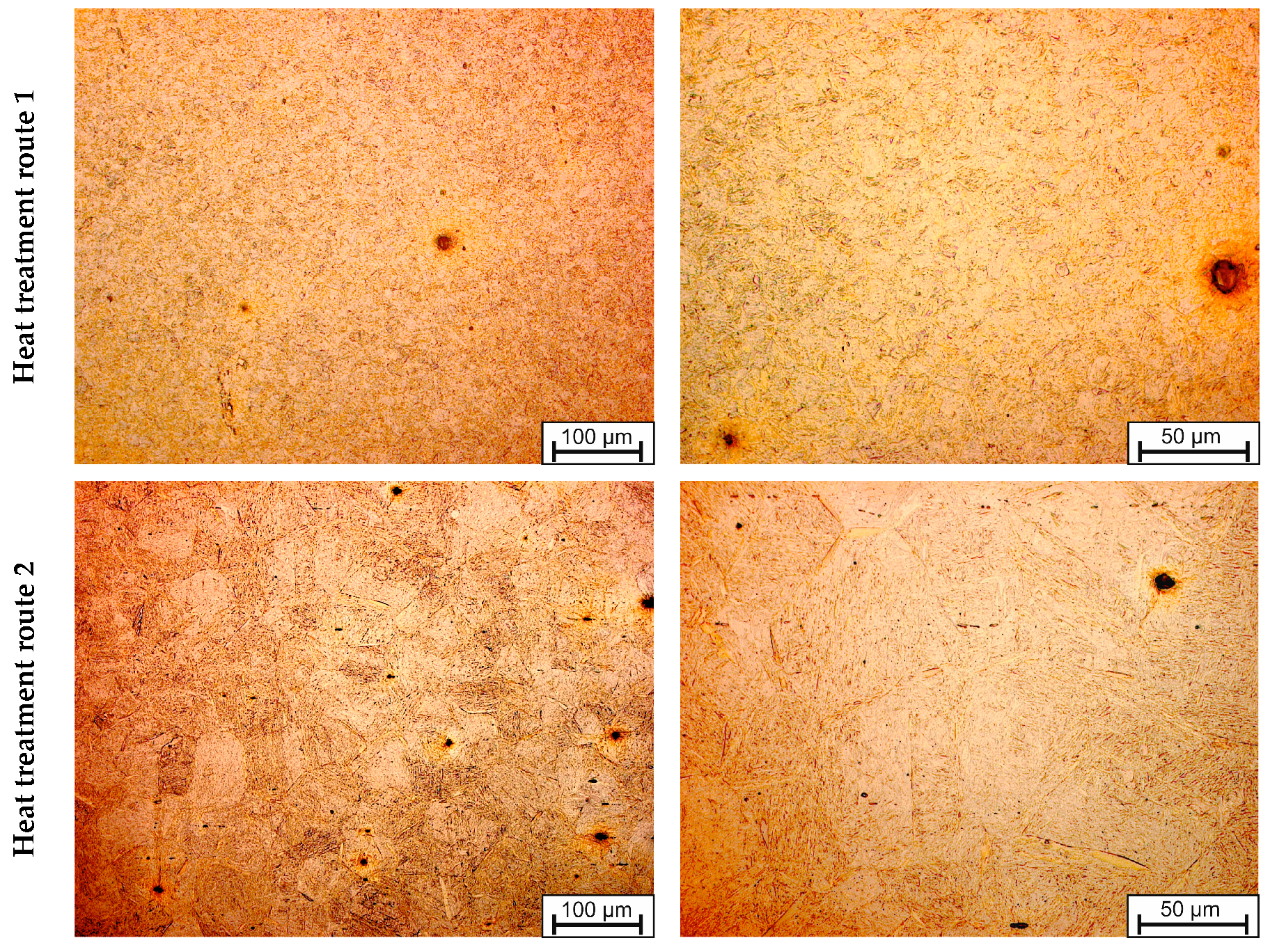

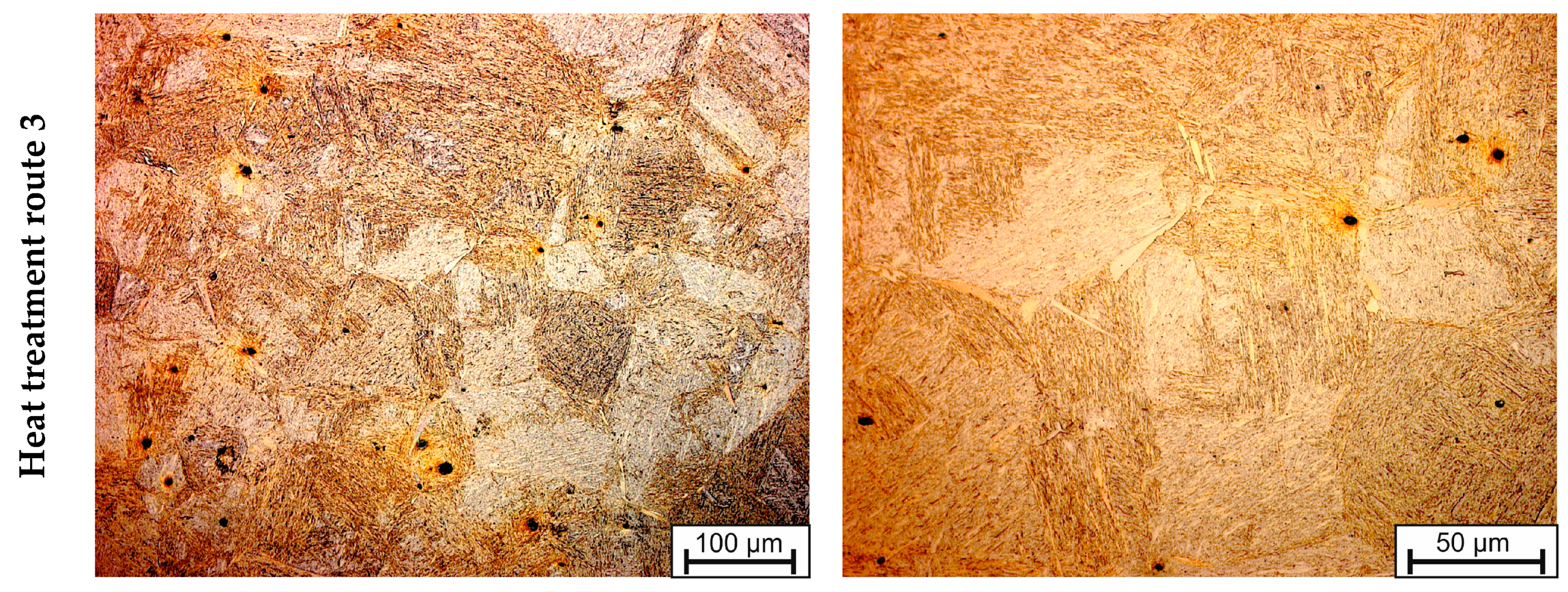

2.4. Microstructure Analysis after Q-P Treatment

2.5. Determination of Fraction of Retained Austenite

3. Results and Discussion

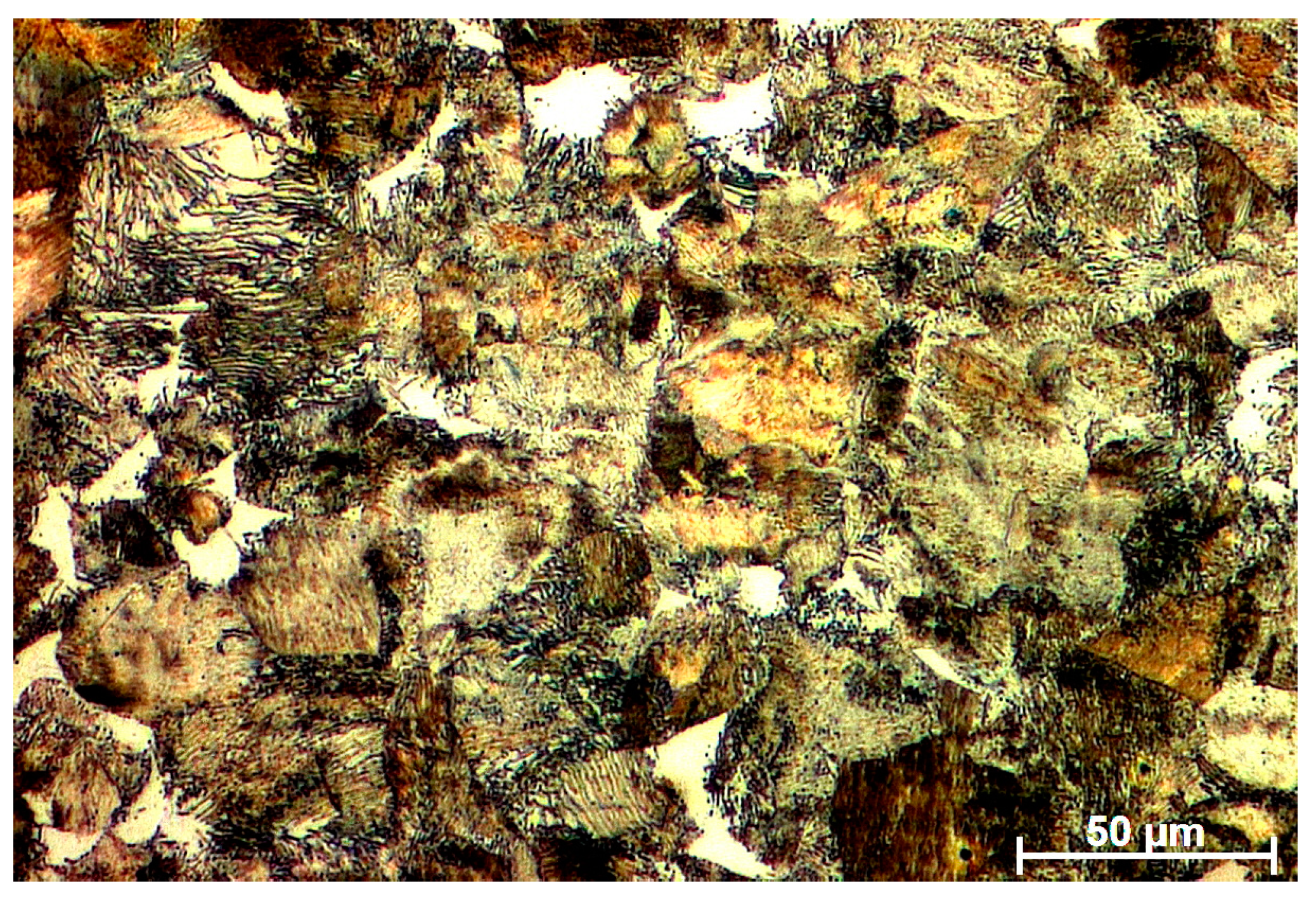

3.1. Analysis of Austenite Grain Size

3.2. Upsetting Tests

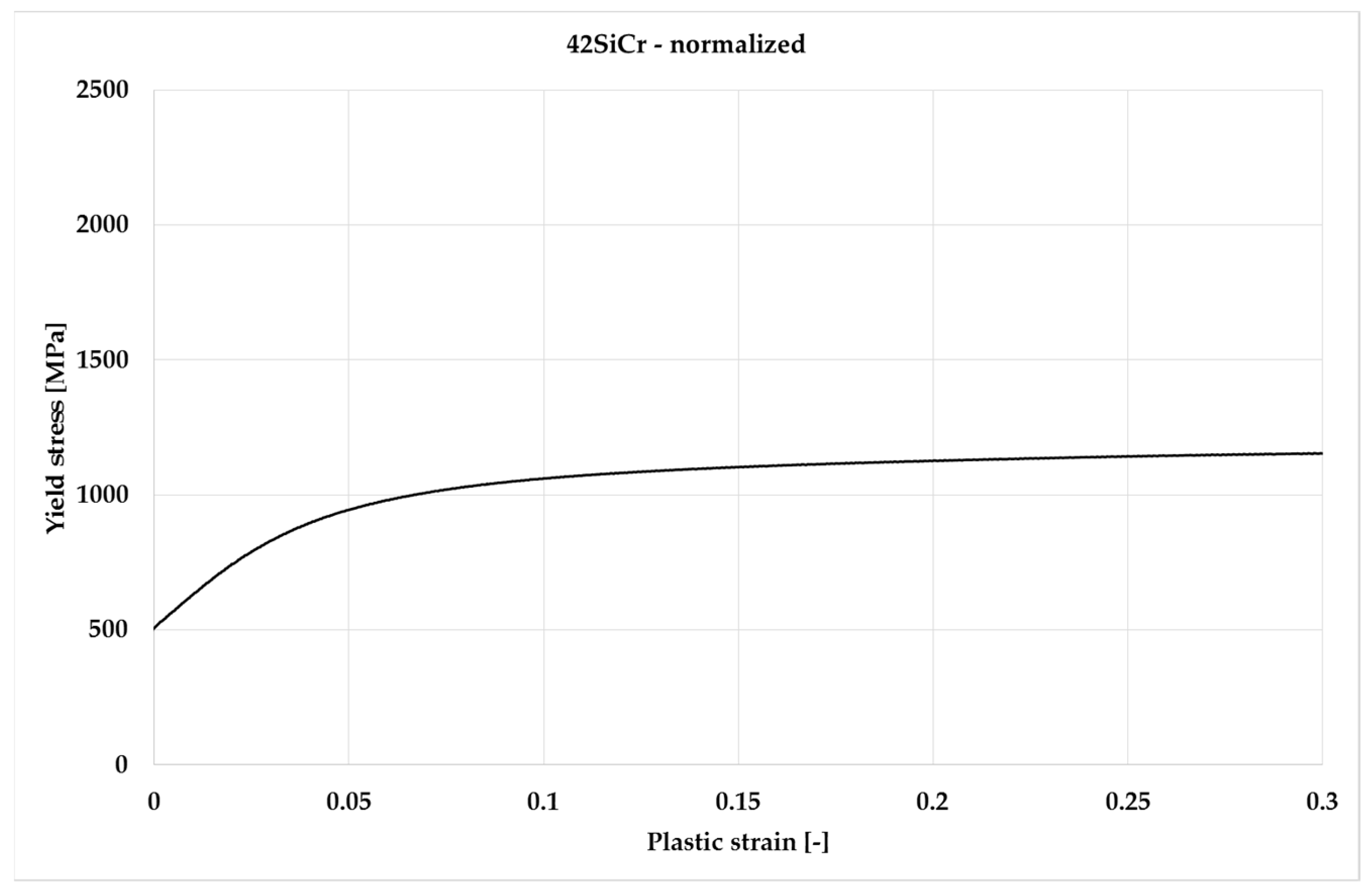

3.3. SEM Analysis

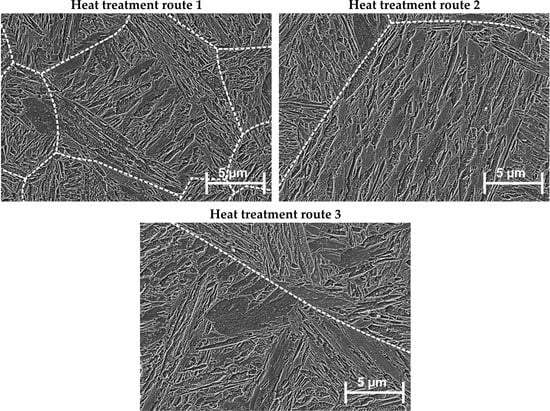

3.4. Fraction of Retained Austenite

4. Summary and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Karbasian, H.; Tekkaya, A.E. A review on hot stamping. J. Mater. Process. Technol. 2010, 210, 2103–2118. [Google Scholar] [CrossRef]

- Speer, J.G.; Rizzo Assunção, F.C.; Matlock, D.K.; Edmonds, D.V. The Quenching and Partitioning Process: Background and Recent Progress. Mater. Res. 2005, 8, 417–423. [Google Scholar] [CrossRef]

- Jirková, H.; Mašek, B.; Wagner, M.F.-X.; Langmajerová, D.; Kučerová, L.; Treml, R.; Kiener, D. Influence of Metastable Retained Austenite on Macro and Micromechanical Properties of Steel Processed by the Q-P Process. J. Alloys Compd. 2014, 615, 163–168. [Google Scholar] [CrossRef]

- Jirková, H.; Kučerová, L.; Mašek, B. Effect of Quenching and Partitioning Temperatures in the Q-P Process on the Properties of AHSS with Various Amounts of Manganese and Silicon. Mater. Sci. Forum 2012, 706–709, 2734–2739. [Google Scholar] [CrossRef]

- Mašek, B.; Jirková, H.; Hauserová, D.; Kučerová, L.; Klaubeová, D. The Effect of Mn and Si on the Properties of Advanced High Strength Steels Processed by Quenching and Partitioning. Mater. Sci. Forum 2010, 654–656, 94–97. [Google Scholar]

- Seo, E.J.; Cho, L.; Estrin, Y.; De Cooman, B.C. Microstructure-mechanical properties relationships for quenching and partitioning processed steel. Acta Mater. 2016, 113, 124–139. [Google Scholar] [CrossRef]

- Yan, S.; Liu, X.; Liu, W.J.; Liang, T.; Zhang, B.; Liu, L.; Zhao, Y. Comparative study on microstructure and mechanical properties of a C-Mn-Si steel treated by quenching and partitioning (Q & P) processes after a full and intercritical austenitization. Mater. Sci. Eng. A 2017, 684, 261–269. [Google Scholar]

- Wendler, M.; Ullrich, C.; Hauser, M.; Krüger, L.; Volkova, O.; Weiß, A.; Mola, J. Quenching and partitioning processing of fully austenitic stainless steels. Acta Mater. 2017, 133, 346–355. [Google Scholar] [CrossRef]

- Mehner, T.; Scharf, I.; Frint, P.; Schubert, F.; Mašek, B.; Wagner, M.F.-X.; Lampke, T. Hydrogen embrittlement of a quenching and partitioning steel during corrosion and zinc electroplating. Mater. Sci. Eng. A 2019, 744, 247–254. [Google Scholar] [CrossRef]

- Pöhlandt, K.; Becker, H.-J.; Becker, N. Werkstoffe und Werkstoffprüfung für die Kaltmassivumformung; Expert Verlag GmbH: Tübingen, Germany, 1994; Volume 427, ISBN 978-3816909187. (In German) [Google Scholar]

- Graf, M.; Ullmann, M.; Korpala, G.; Wester, H.; Awiszus, B.; Kawalla, R.; Behrens, B.-A. Forming and Oxidation Behavior During Forging with Consideration of Carbon Content of Steel. Metals 2018, 8, 996. [Google Scholar] [CrossRef]

| C | Si | Mn | Cr | Mo | Al | Nb | Fe |

|---|---|---|---|---|---|---|---|

| 0.42 | 2.00 | 0.60 | 1.30 | 0.03 | 0.008 | 0.03 | balance |

| Heat Treatment Route | Grain Size in µm | Fraction of Retained Austenite in % |

|---|---|---|

| 1 | 11 | 9.9 |

| 2 | 60 | 9.5 |

| 3 | 80 | 7.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Härtel, S.; Awiszus, B.; Graf, M.; Nitsche, A.; Böhme, M.; Wagner, M.F.-X.; Jirkova, H.; Masek, B. Influence of Austenite Grain Size on Mechanical Properties after Quench and Partitioning Treatment of a 42SiCr Steel. Metals 2019, 9, 577. https://doi.org/10.3390/met9050577

Härtel S, Awiszus B, Graf M, Nitsche A, Böhme M, Wagner MF-X, Jirkova H, Masek B. Influence of Austenite Grain Size on Mechanical Properties after Quench and Partitioning Treatment of a 42SiCr Steel. Metals. 2019; 9(5):577. https://doi.org/10.3390/met9050577

Chicago/Turabian StyleHärtel, Sebastian, Birgit Awiszus, Marcel Graf, Alexander Nitsche, Marcus Böhme, Martin F.-X. Wagner, Hana Jirkova, and Bohuslav Masek. 2019. "Influence of Austenite Grain Size on Mechanical Properties after Quench and Partitioning Treatment of a 42SiCr Steel" Metals 9, no. 5: 577. https://doi.org/10.3390/met9050577

APA StyleHärtel, S., Awiszus, B., Graf, M., Nitsche, A., Böhme, M., Wagner, M. F.-X., Jirkova, H., & Masek, B. (2019). Influence of Austenite Grain Size on Mechanical Properties after Quench and Partitioning Treatment of a 42SiCr Steel. Metals, 9(5), 577. https://doi.org/10.3390/met9050577