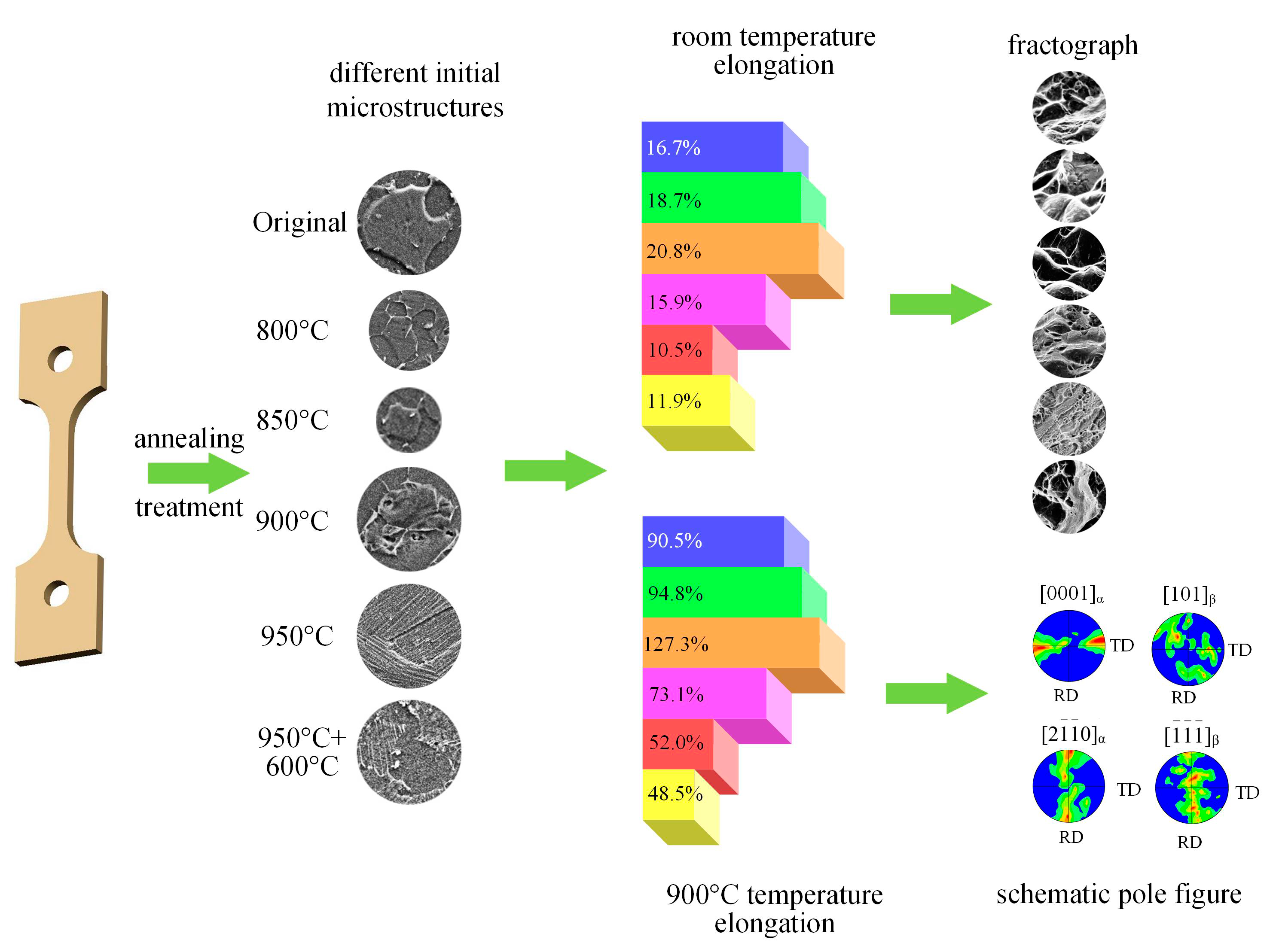

The Effect of Initial Annealing Microstructures on the Forming Characteristics of Ti–4Al–2V Titanium Alloy

Abstract

:1. Introduction

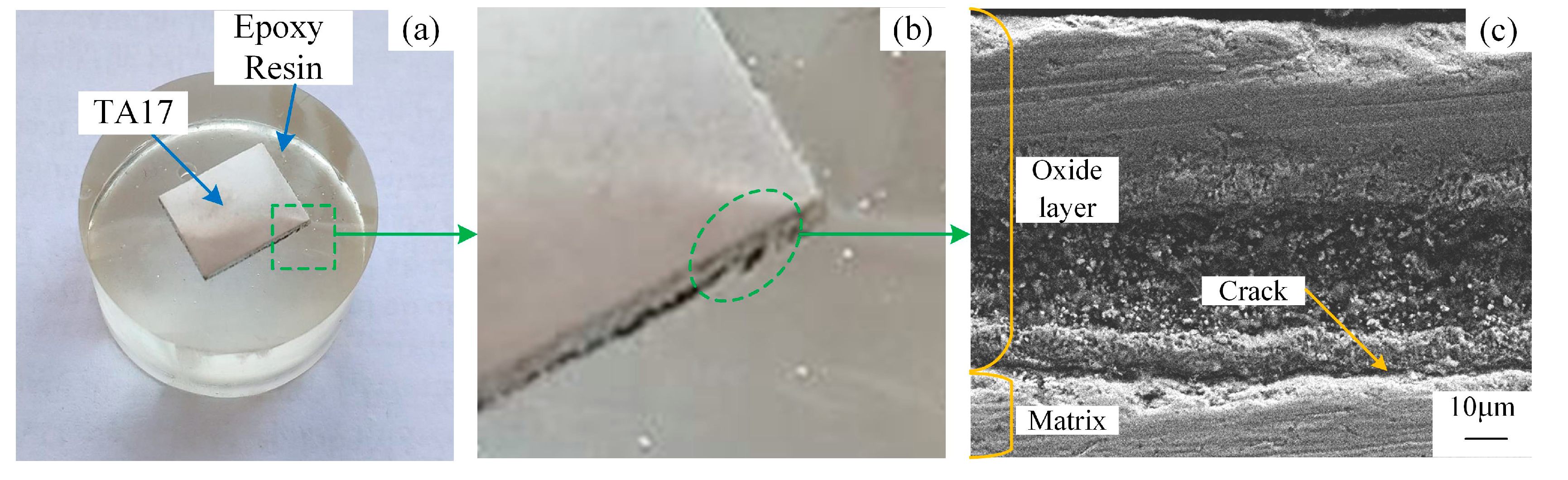

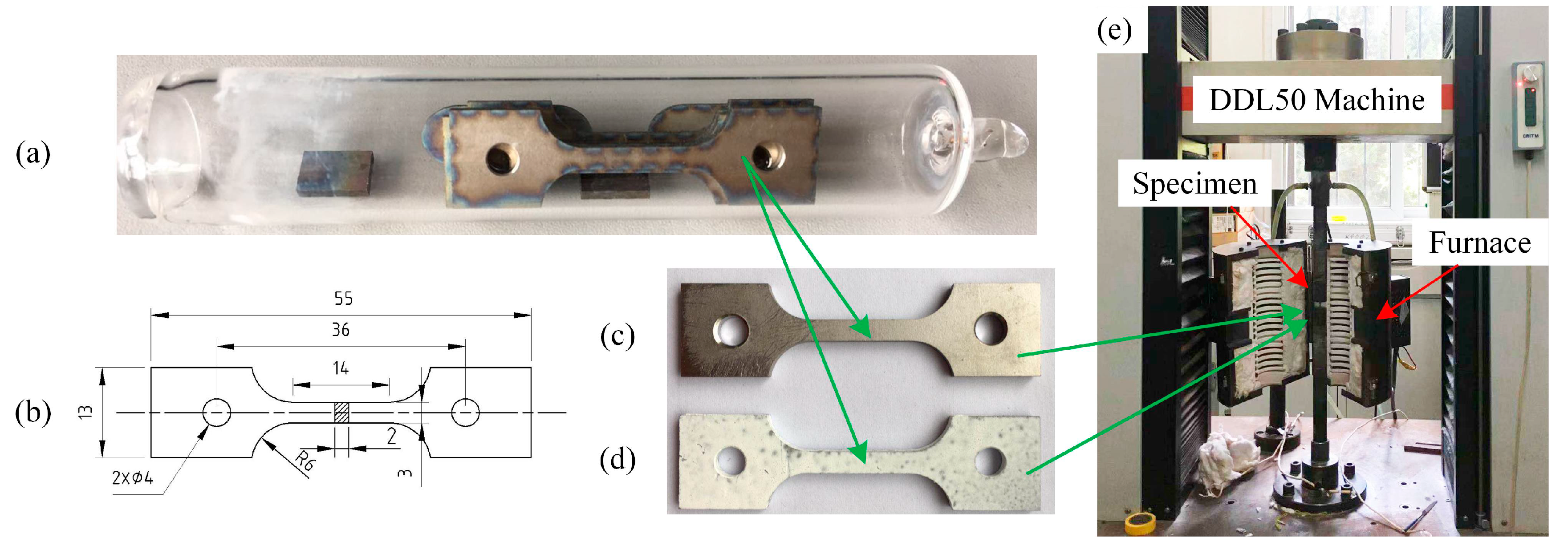

2. Material and Experimental Procedures

2.1. Materials

2.2. Experimental Procedures

3. Results and Discussion

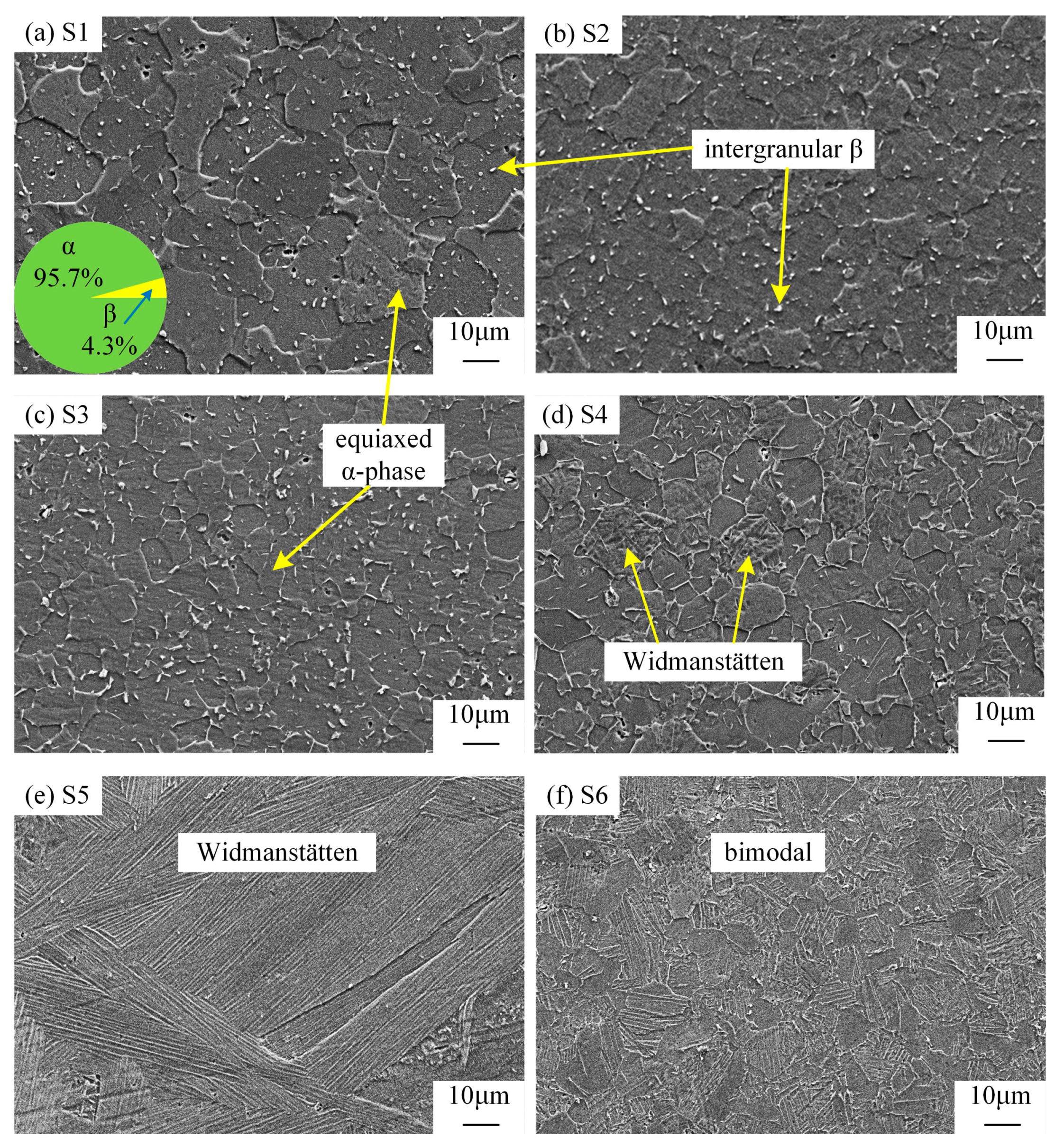

3.1. Different Microstructures

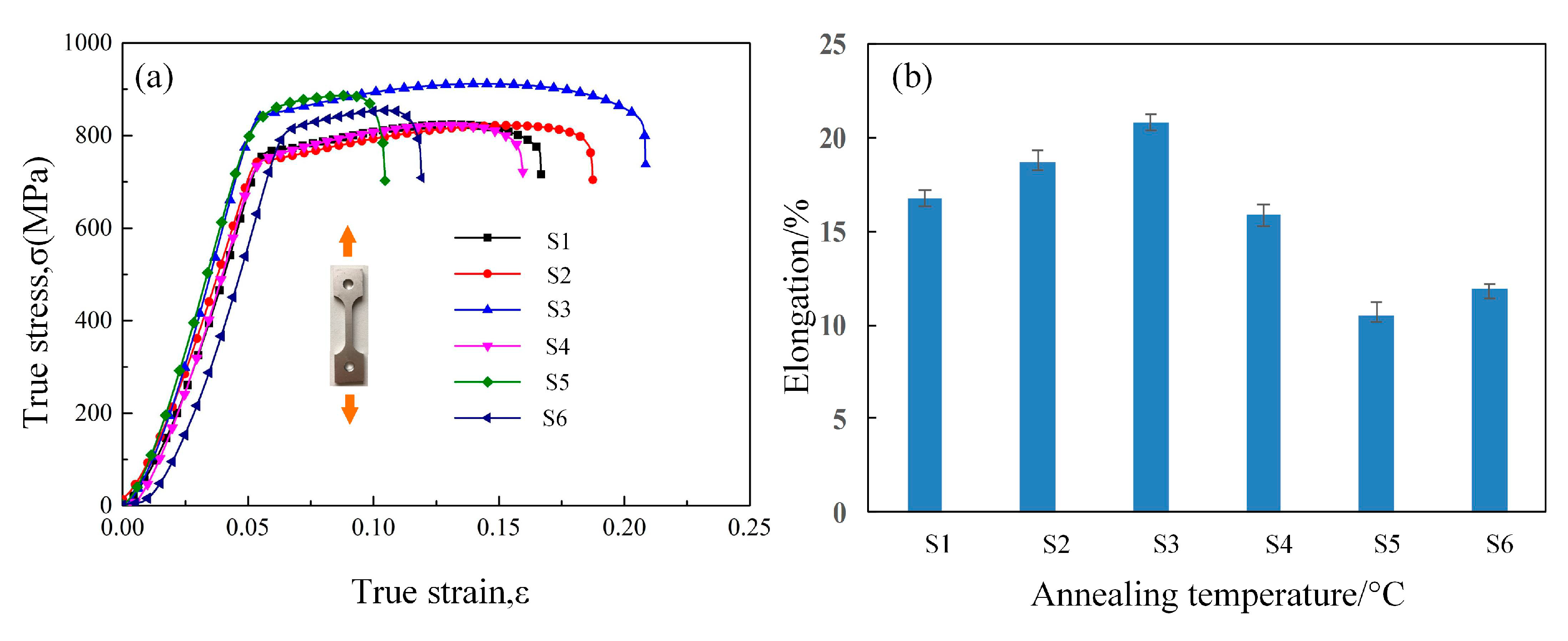

3.2. The Room Temperature Mechanical Properties

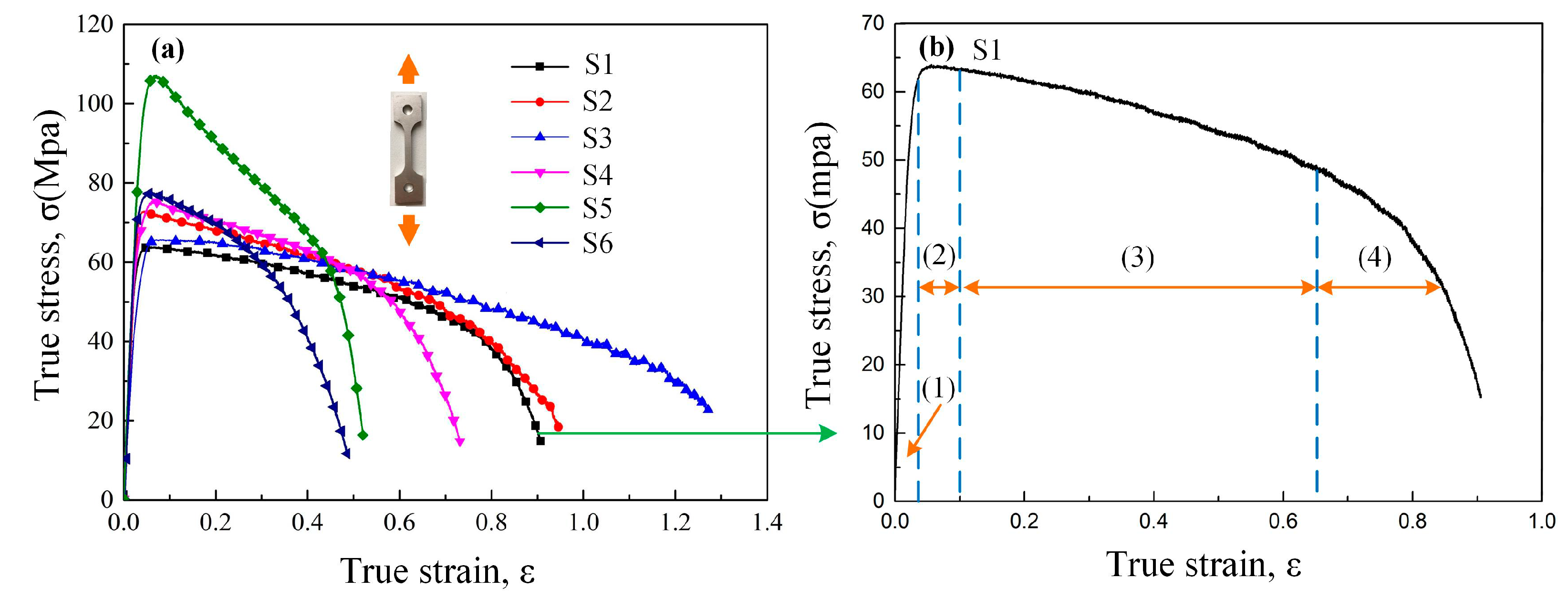

3.2.1. Mechanical Properties

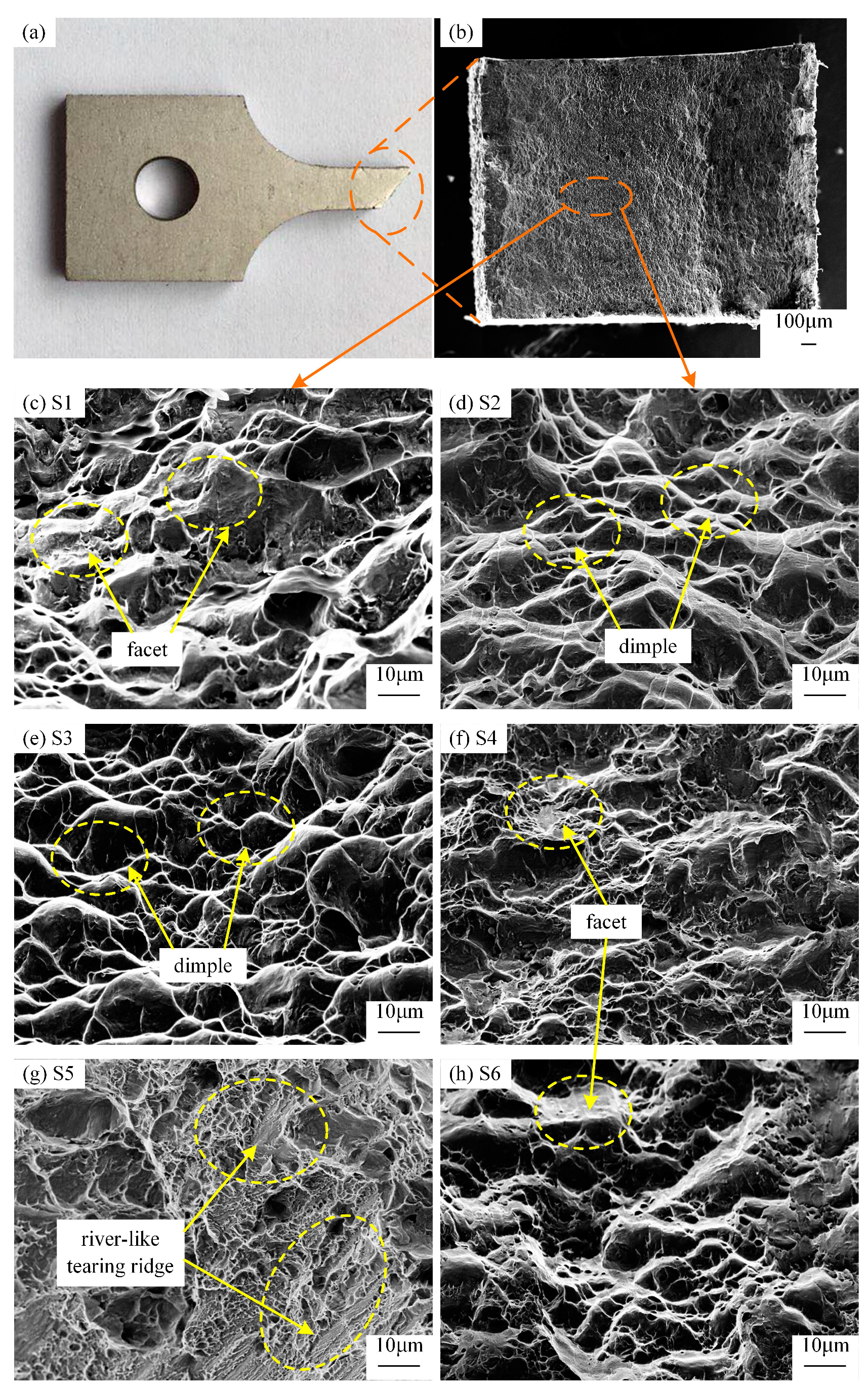

3.2.2. Fractograph Analysis

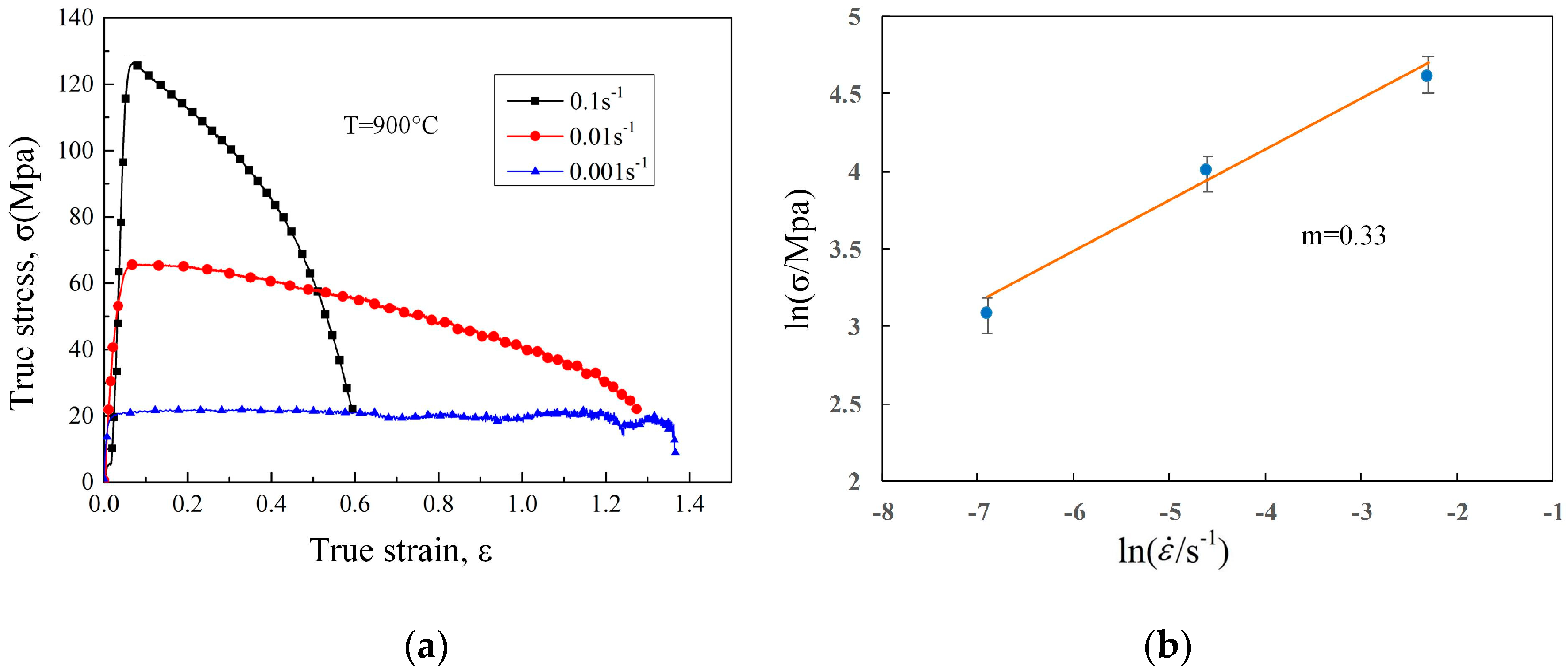

3.3. The Hot-Mechanical Properties of Different Microstructures

3.4. The Superplasticity of TA17

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yang, H.; Li, L.; Wang, Q.; Guo, L. Research on the Development of Advanced Forming for Lightweight Alloy Materials Area. J. Mech. Eng. 2010, 46, 31–32. [Google Scholar] [CrossRef]

- Wu, J.; Lv, Z.D.; Zhang, C.J.; Han, J.C.; Zhang, H.Z.; Zhang, S.Z.; Hayat, M.; Cao, P. Investigation of the Deformation Mechanism of a near β Titanium Alloy through Isothermal Compression. Metals 2017, 7, 498. [Google Scholar] [CrossRef]

- Peters, M.; Kumpfert, J.; Ward, C.H.; Leyens, C. Titanium Alloys for Aerospace Applications. Adv. Eng. Mater. 2003, 5, 419–427. [Google Scholar] [CrossRef]

- Li, J.L.; Wang, B.Y.; Huang, H.; Fang, S.; Chen, P.; Shen, J.X. Unified modelling of the flow behaviour and softening mechanism of a TC6 titanium alloy during hot deformation. J. Alloys Compd. 2018, 748, 1031–1043. [Google Scholar] [CrossRef]

- Xiao, J.; Li, D.S.; Li, X.Q.; Deng, T.S. Constitutive modeling and microstructure change of Ti–6Al–4V during the hot tensile deformation. J. Alloys Compd. 2012, 541, 346–352. [Google Scholar] [CrossRef]

- Huang, D.M.; Yang, X.F.; Wei, Q.F.; Chen, Y.; Guo, H.; Liang, S.L.; Wang, Y. Causes of surface stripe cracks of Ti–4Al–2V alloy cold-rolled sheet. Rare Met. 2014, 33, 522–526. [Google Scholar] [CrossRef]

- Wang, T.; Guo, H.Z.; Wang, Y.W.; Peng, X.N.; Zhao, Y.; Yao, Z.K. The effect of microstructure on tensile properties, deformation mechanisms and fracture models of TG6 high temperature titanium alloy. Mater. Sci. Eng. A 2011, 528, 2370–2379. [Google Scholar] [CrossRef]

- Velay, V.; Matsumoto, H.; Vidal, V.; Chiba, A. Behavior modeling and microstructural evolutions of Ti–6Al–4V alloy under hot forming conditions. Int. J. Mech. Sci. 2016, 108–109, 1–13. [Google Scholar] [CrossRef]

- Fan, X.G.; Yang, H.; Gao, P.F. The mechanism of flow softening in subtransus hot working of two-phase titanium alloy with equiaxed structure. Chin. Sci. Bull. 2014, 59, 2859–2867. [Google Scholar] [CrossRef]

- Guo, P.; Zhao, Y.Q.; Zeng, W.D.; Hong, Q. The effect of microstructure on the mechanical properties of TC4-DT titanium alloys. Mater. Sci. Eng. A 2013, 563, 106–111. [Google Scholar] [CrossRef]

- Zhao, H.J.; Wang, B.Y.; Liu, G.; Yang, L.; Xiao, W.C. Effect of vacuum annealing on microstructure and mechanical properties of TA15 titanium alloy sheets. Trans. Nonferr. Met. Soc. China 2015, 25, 1881–1888. [Google Scholar] [CrossRef]

- Luo, J.; Li, L.; Li, M.Q. Deformation behavior of Ti–5Al–2Sn–2Zr–4Mo–4Cr alloy with two initial microstructures during hot working. Trans. Nonferr. Met. Soc. Chin. 2016, 26, 414–422. [Google Scholar] [CrossRef]

- Peng, X.N.; Guo, H.Z.; Wang, T.; Yao, Z.K. Effects of β treatments on microstructures and mechanical properties of TC4-DT titanium alloy. Mater. Sci. Eng. A 2012, 533, 55–63. [Google Scholar] [CrossRef]

- Cai, J.; Li, F.G.; Liu, T.Y.; Chen, B.; He, M. Constitutive equations for elevated temperature flow stress of Ti–6Al–4V alloy considering the effect of strain. Mater. Des. 2011, 32, 1144–1151. [Google Scholar] [CrossRef]

- Oliveira, D.P.; Prokofiev, E.; Sanches, L.F.R.; Polyakova, V.; Valiev, R.Z.; Botta, W.J.; Junior, A.M.J.; Bolfarini, C. Surface chemical treatment of ultrafine-grained Ti–6Al–7Nb alloy processed by severe plastic deformation. J. Alloys Compd. 2015, 643, S241–S245. [Google Scholar] [CrossRef]

- Yu, H.B.; Zhang, D.L.; Chen, Y.Y.; Cao, P.; Gabbitas, B. Synthesis of an ultrafine grained TiAl based alloy by subzero temperature milling and HIP, its microstructure and mechanical properties. J. Alloys Compd. 2009, 474, 105–112. [Google Scholar] [CrossRef]

- Zhang, Z.X.; Qu, S.J.; Feng, A.H.; Shen, J.; Chen, D.L. Hot deformation behavior of Ti-6Al-4V alloy: Effect of initial microstructure. J. Alloys Compd. 2017, 718, 170–181. [Google Scholar] [CrossRef]

- Ma, B.L.; Wu, X.D.; Li, X.J.; Wan, M.; Cai, Z.Y. Investigation on the hot formability of TA15 titanium alloy sheet. Mater. Des. 2016, 94, 9–16. [Google Scholar] [CrossRef]

- Badr, O.M.; Rolfe, B.; Hodgson, P.; Weiss, M. Forming of high strength titanium sheet at room temperature. Mater. Des. 2015, 66, 618–626. [Google Scholar] [CrossRef]

- Shekhar, S.; Sarkar, R.; Kar, S.K.; Bhattacharjee, A. Effect of solution treatment and aging on microstructure and tensile properties of high strength β titanium alloy, Ti–5Al–5V–5Mo–3Cr. Mater. Des. 2015, 66, 596–610. [Google Scholar] [CrossRef]

- Li, H.M.; Li, M.Q.; Luo, J.; Wang, K. Microstructure and mechanical properties of heat-treated Ti–5Al–2Sn–2Zr–4Mo–4Cr. Trans. Nonferr. Met. Soc. Chin. 2015, 25, 2893–2900. [Google Scholar] [CrossRef]

- Zhou, M.; Lin, Y.C.; Deng, J.; Jiang, Y. Hot tensile deformation behaviors and constitutive model of an Al–Zn–Mg–Cu alloy. Mater. Des. 2014, 59, 141–150. [Google Scholar] [CrossRef]

- Liu, Z.G.; Li, P.J.; Xiong, L.G.; Liu, T.Y.; He, L.J. High-temperature tensile deformation behavior and microstructure evolution of Ti55 titanium alloy. Mater. Sci. Eng. A 2017, 680, 259–269. [Google Scholar] [CrossRef]

- Ning, Y.Q.; Yao, Z.K.; Li, H.; Guo, H.Z.; Tao, Y.; Zhang, Y.W. High temperature deformation behavior of hot isostatically pressed P/M FGH4096 superalloy. Mater. Sci. Eng. A 2010, 527, 961–966. [Google Scholar] [CrossRef]

- Rabeeh, B.M.; Rokhlin, S.I.; Soboyejo, W.O. Microplasticity and fracture in a Ti-15V-3Cr-3Al-3Sn alloy. Scr. Mater. 1996, 35, 1429–1434. [Google Scholar] [CrossRef]

- Da Silva Briguente, N.; Oñoro, J.; Briguente, F.P.; Resende, F.A.; Lidovino dos Reis, J.; Reis, D.A.P.; de Oliveira, A.C. The Influence of Laser Nitriding on Creep Behavior of Ti-4Al-4V Alloy with Widmanstätten Microstructure. Metals 2019, 9, 236. [Google Scholar] [CrossRef]

- Sun, J.Z.; Li, M.Q.; Li, H. Deformation behavior of TC17 titanium alloy with basketweave microstructure during isothermal compression. J. Alloys Compd. 2018, 730, 533–543. [Google Scholar] [CrossRef]

- Li, H.; Zhao, Z.; Ning, Y.; Guo, H.; Yao, Z. Characterization of Microstructural Evolution for a Near-α Titanium Alloy with Different Initial Lamellar Microstructures. Metals 2018, 8, 1045. [Google Scholar] [CrossRef]

- Majorell, A.; Srivatsa, S.; Picu, R.C. Mechanical behavior of Ti–6Al–4V at high and moderate temperatures—Part I: Experimental results. Mater. Sci. Eng. A 2002, 326, 297–305. [Google Scholar] [CrossRef]

- Lee, S.B.; Lee, C.S.; Kim, J.S.; Chang, Y.W. Mechanical and microstructural analysis on the superplastic deformation behavior of Ti–6Al–4V Alloy. Int. J. Mech. Sci. 2000, 42, 1555–1569. [Google Scholar] [CrossRef]

- Mosleh, A.; Mikhaylovskaya, A.; Kotov, A.; AbuShanab, W.; Moustafa, E.; Portnoy, V. Experimental Investigation of the Effect of Temperature and Strain Rate on the Superplastic Deformation Behavior of Ti-Based Alloys in the (α+β) Temperature Field. Metals 2018, 8, 819. [Google Scholar] [CrossRef]

| Al | V | Fe | Si | O | N | H | C | Ti |

|---|---|---|---|---|---|---|---|---|

| 4.3 | 2.1 | 0.25 | 0.15 | 0.15 | 0.05 | 0.015 | 0.08 | Bal |

| Annealing No. | Annealing Processes |

|---|---|

| S1 | as received |

| S2 | 800 °C/2 h/AC (air cooling) |

| S3 | 850 °C/2 h/AC |

| S4 | 900 °C/2 h/AC |

| S5 | 950 °C/2 h/AC |

| S6 | (950 °C/2 h/AC) + (600 °C/2 h/AC) |

| Annealing No. | Yield Strength (MPa) | Peak Strength (MPa) | Elongation (%) |

|---|---|---|---|

| S1 | 745.3 | 821.3 | 16.7 |

| S2 | 734.1 | 824.2 | 18.7 |

| S3 | 814.8 | 911.8 | 20.8 |

| S4 | 739.2 | 822.9 | 15.9 |

| S5 | 812.5 | 886.7 | 10.5 |

| S6 | 793.7 | 854.6 | 11.9 |

| Annealing No. | Yield Strength (MPa) | Peak Strength (MPa) | Elongation (%) |

|---|---|---|---|

| S1 | 59.1 | 63.9 | 90.5 |

| S2 | 68.4 | 72.5 | 94.8 |

| S3 | 60.5 | 65.8 | 127.3 |

| S4 | 72.1 | 76.0 | 73.1 |

| S5 | 103.3 | 107.1 | 52.0 |

| S6 | 72.6 | 77.5 | 48 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, B.; Li, H.; Zhang, J.; Kong, N. The Effect of Initial Annealing Microstructures on the Forming Characteristics of Ti–4Al–2V Titanium Alloy. Metals 2019, 9, 576. https://doi.org/10.3390/met9050576

Yan B, Li H, Zhang J, Kong N. The Effect of Initial Annealing Microstructures on the Forming Characteristics of Ti–4Al–2V Titanium Alloy. Metals. 2019; 9(5):576. https://doi.org/10.3390/met9050576

Chicago/Turabian StyleYan, Bin, Hongbo Li, Jie Zhang, and Ning Kong. 2019. "The Effect of Initial Annealing Microstructures on the Forming Characteristics of Ti–4Al–2V Titanium Alloy" Metals 9, no. 5: 576. https://doi.org/10.3390/met9050576

APA StyleYan, B., Li, H., Zhang, J., & Kong, N. (2019). The Effect of Initial Annealing Microstructures on the Forming Characteristics of Ti–4Al–2V Titanium Alloy. Metals, 9(5), 576. https://doi.org/10.3390/met9050576