Research on AZ80 + 0.4%Ce (wt %) Ultra-Thin-Walled Tubes of Magnesium Alloys: The Forming Process, Microstructure Evolution and Mechanical Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Strengthening Mechanism

2.2. Materials and Molds

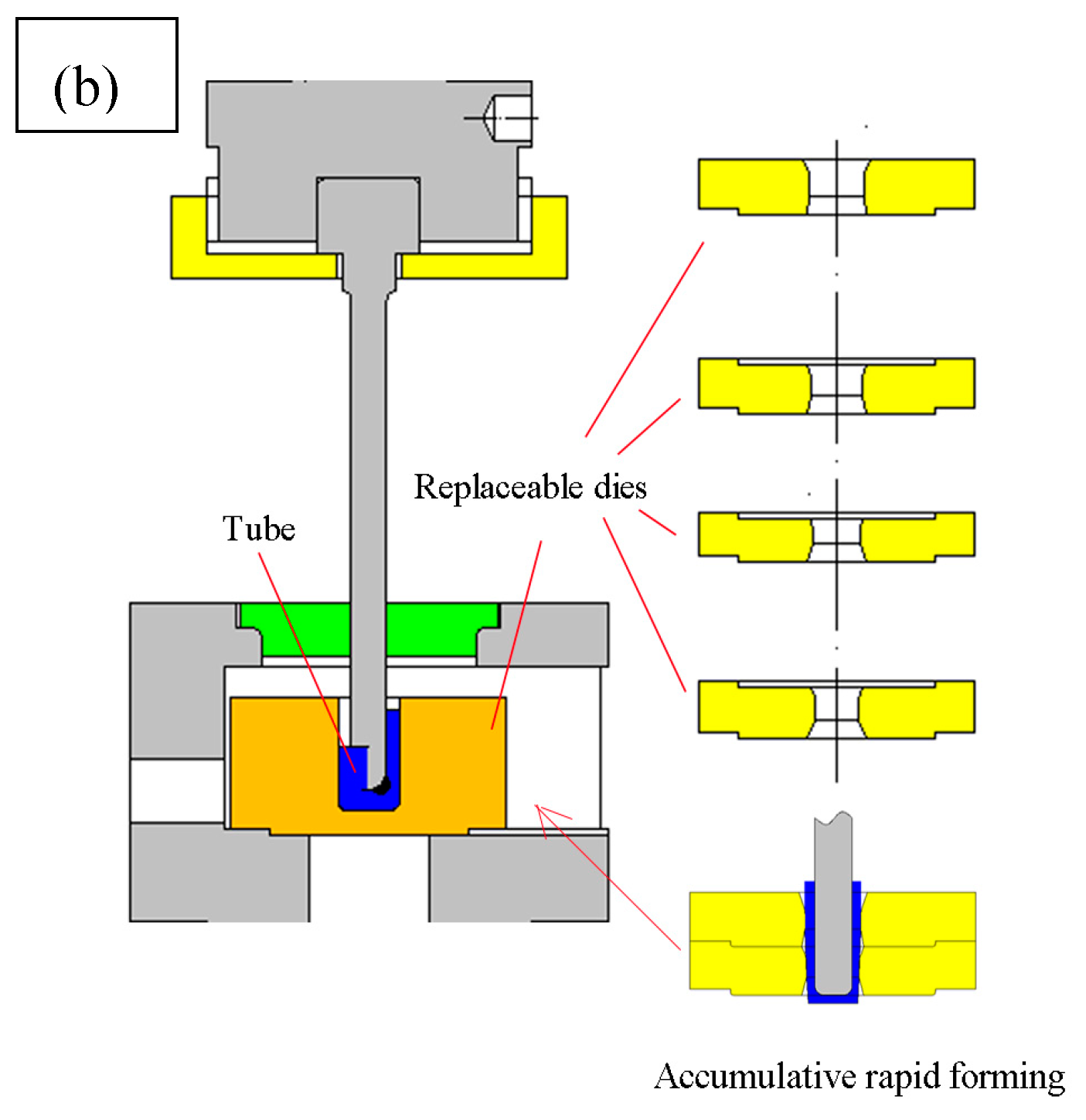

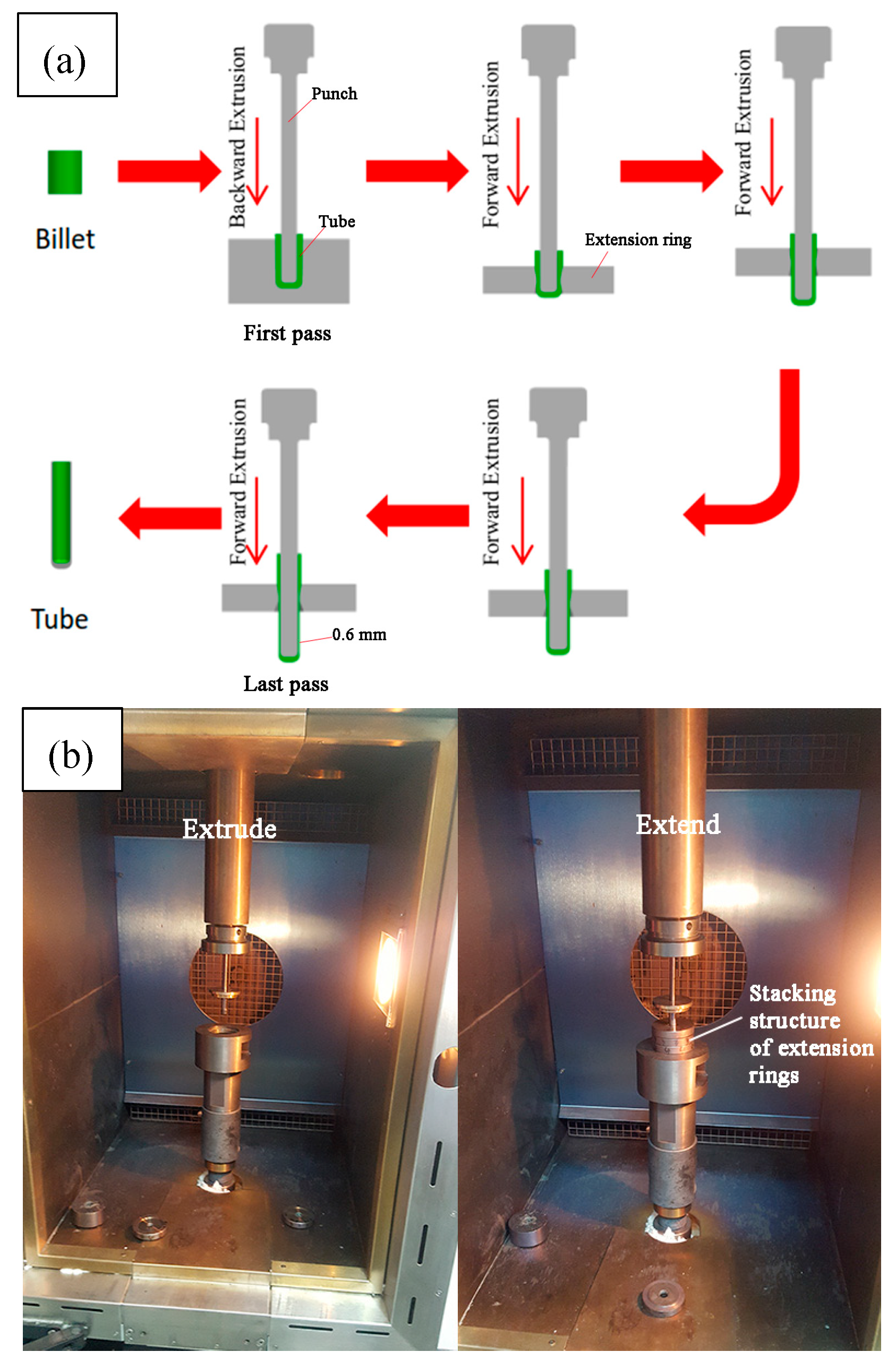

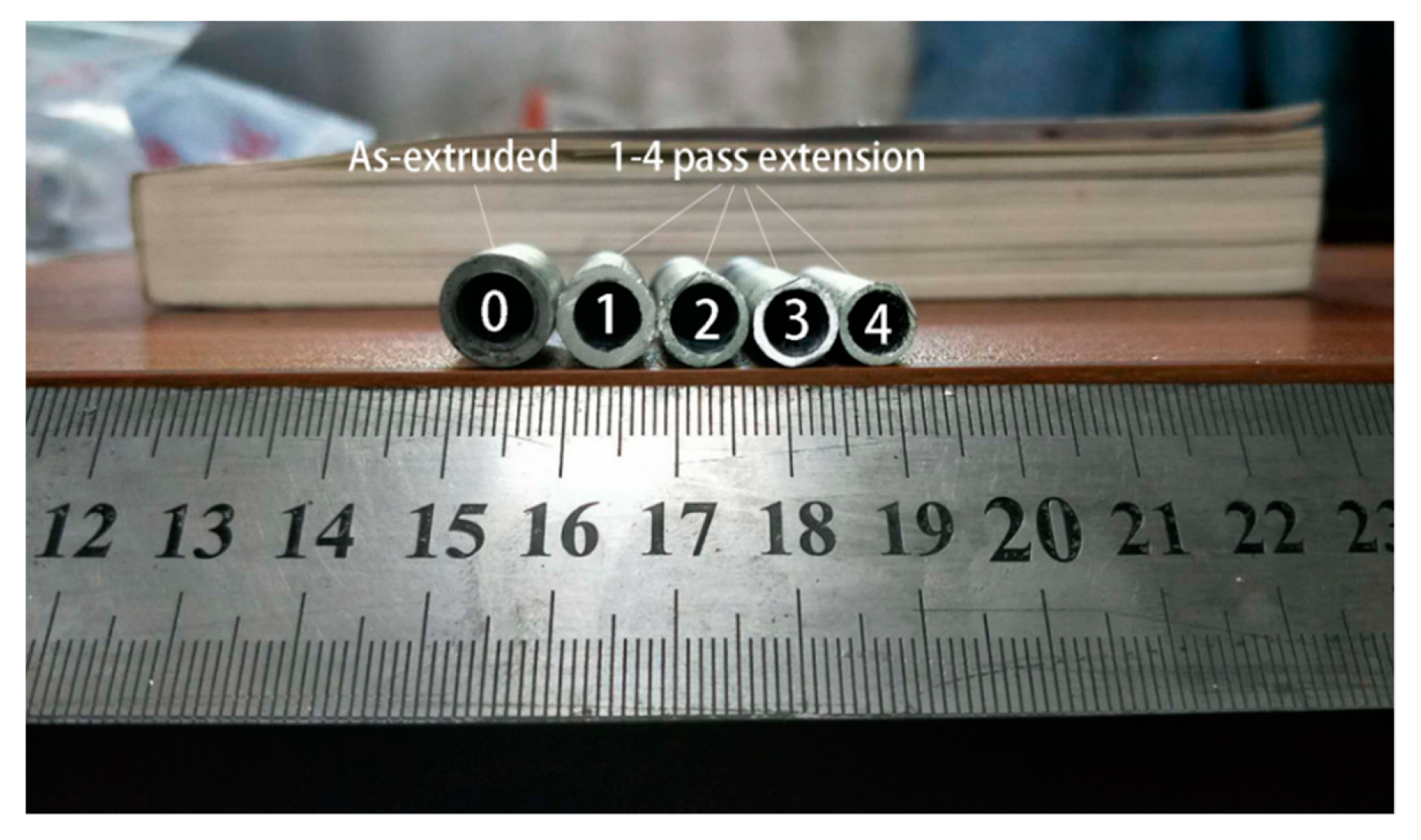

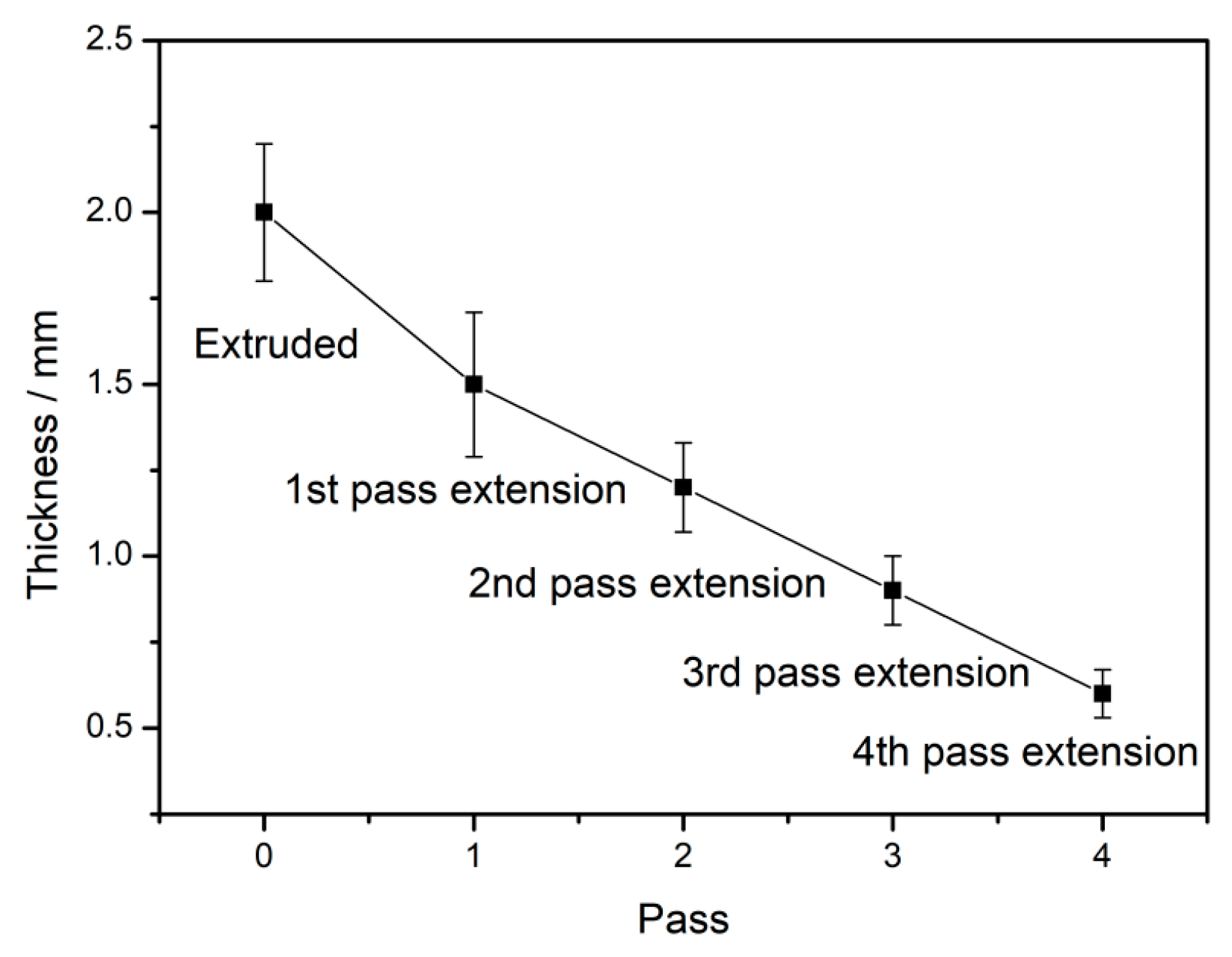

2.3. Experimental Procedures

3. Results and Discussion

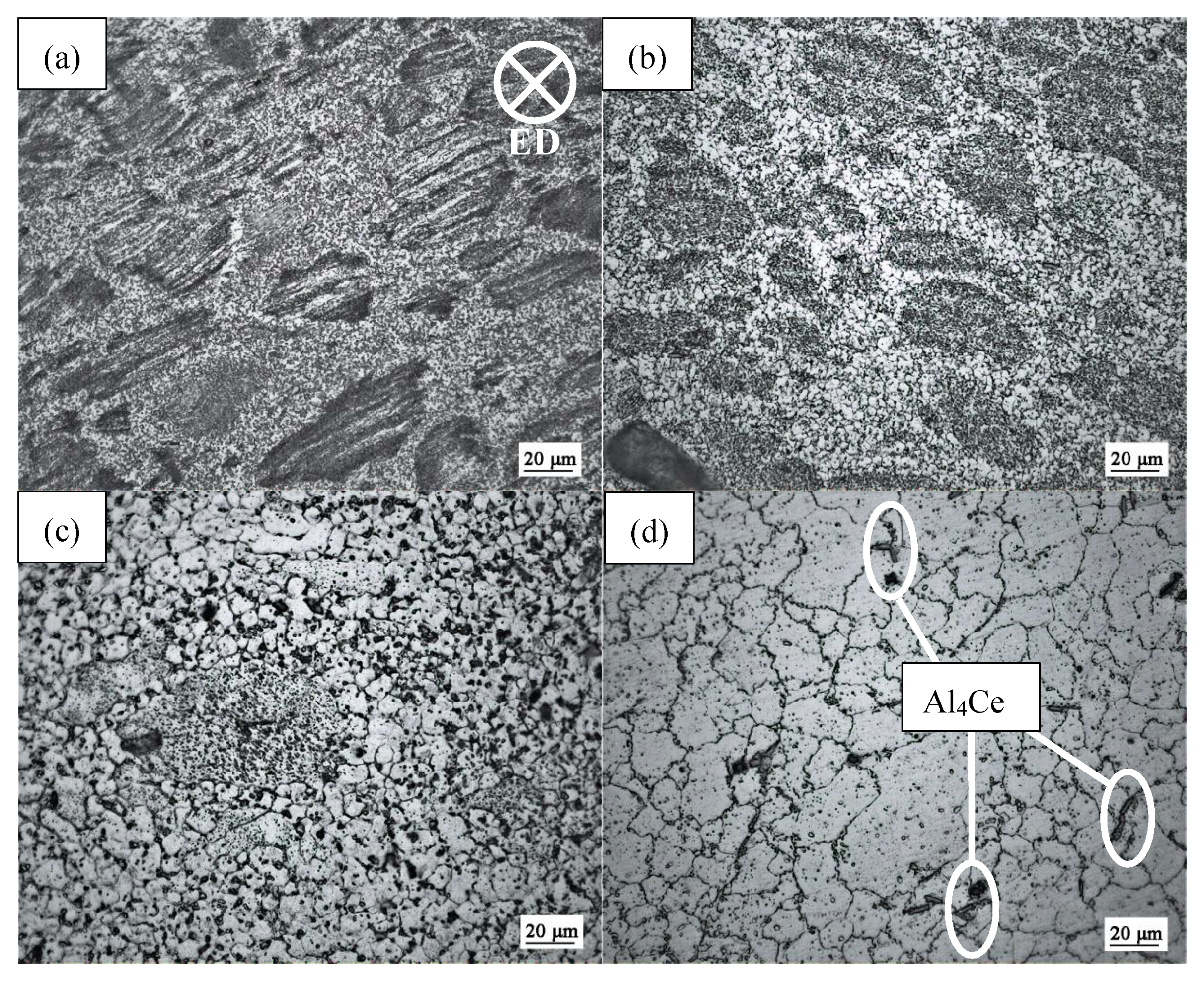

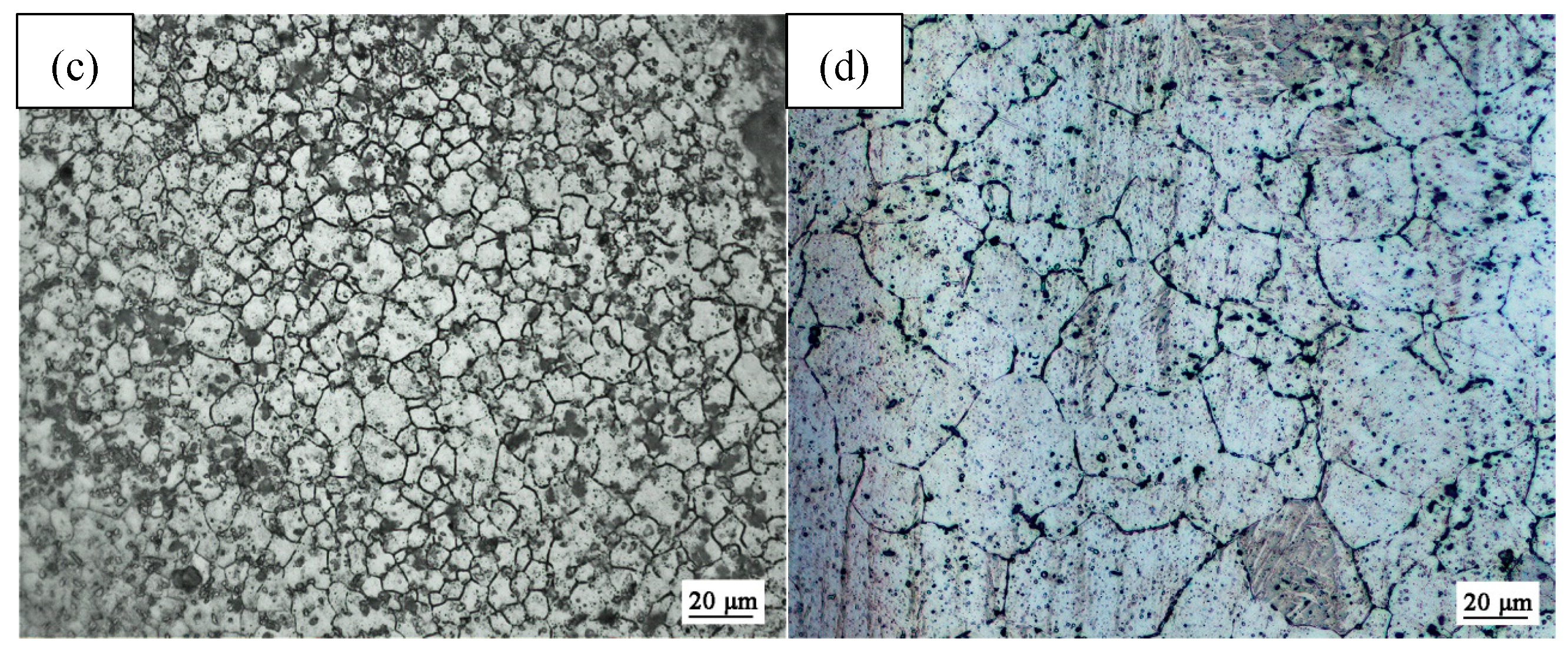

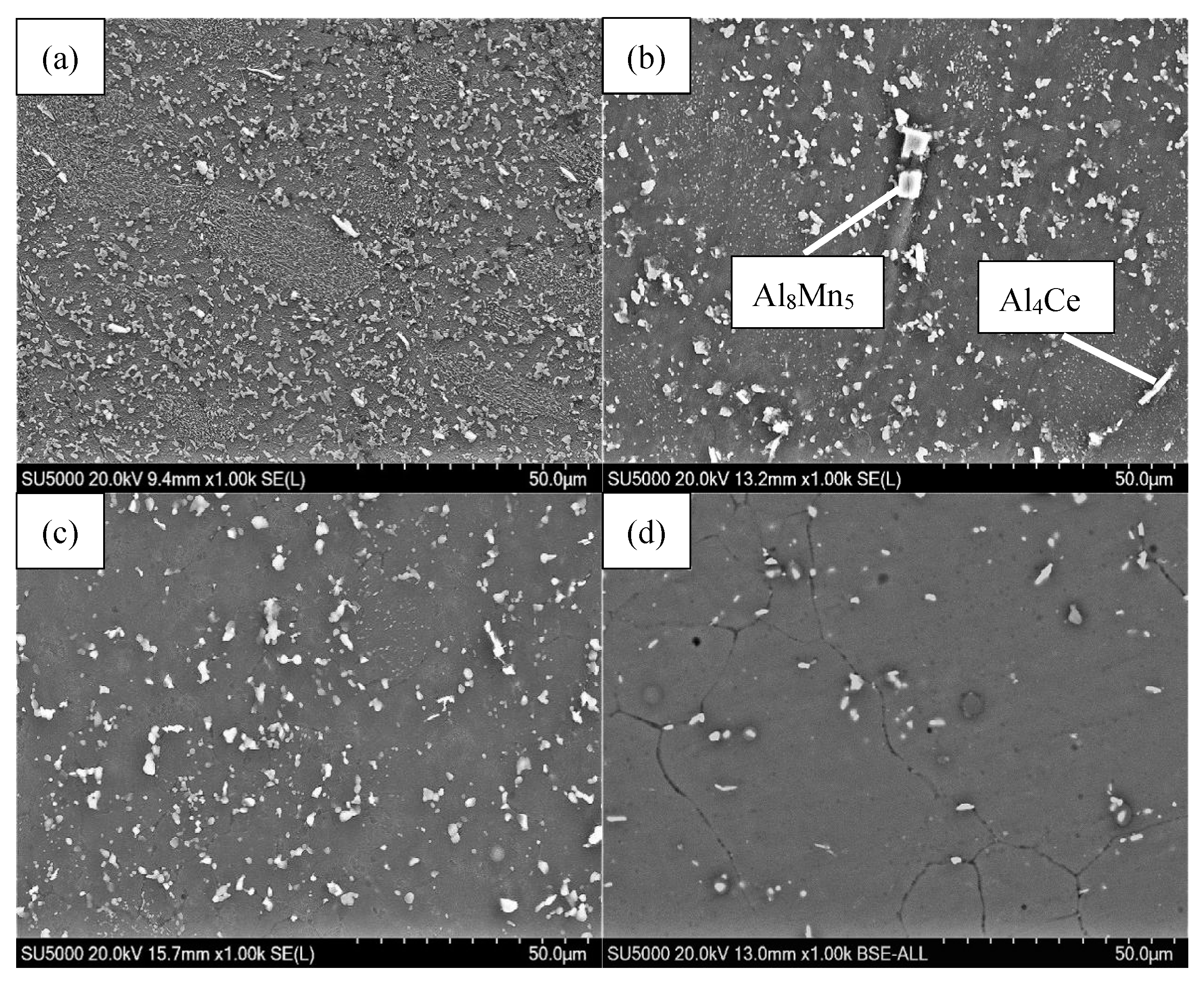

3.1. Microstructure Evolution

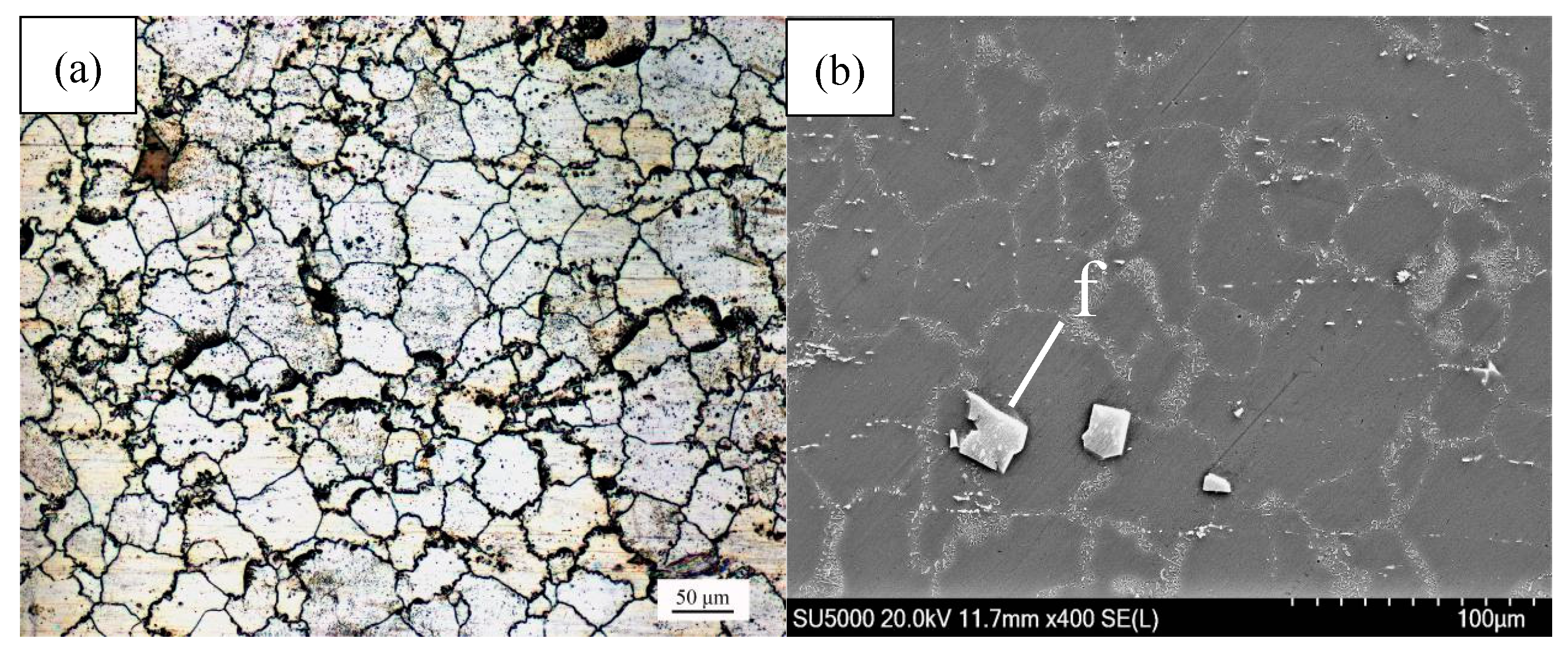

3.1.1. Φ10 mm × 10 mm Original Extruded Bar

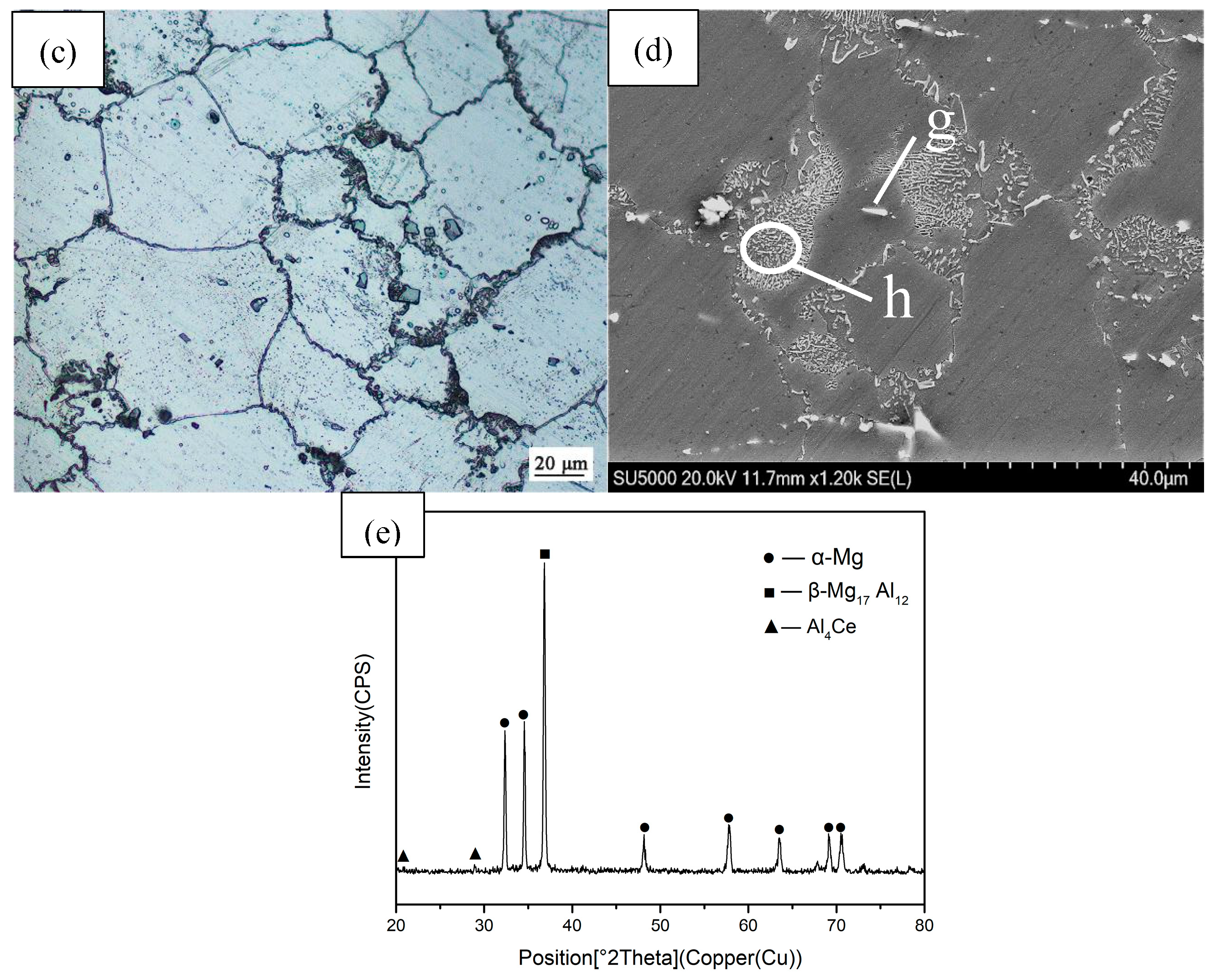

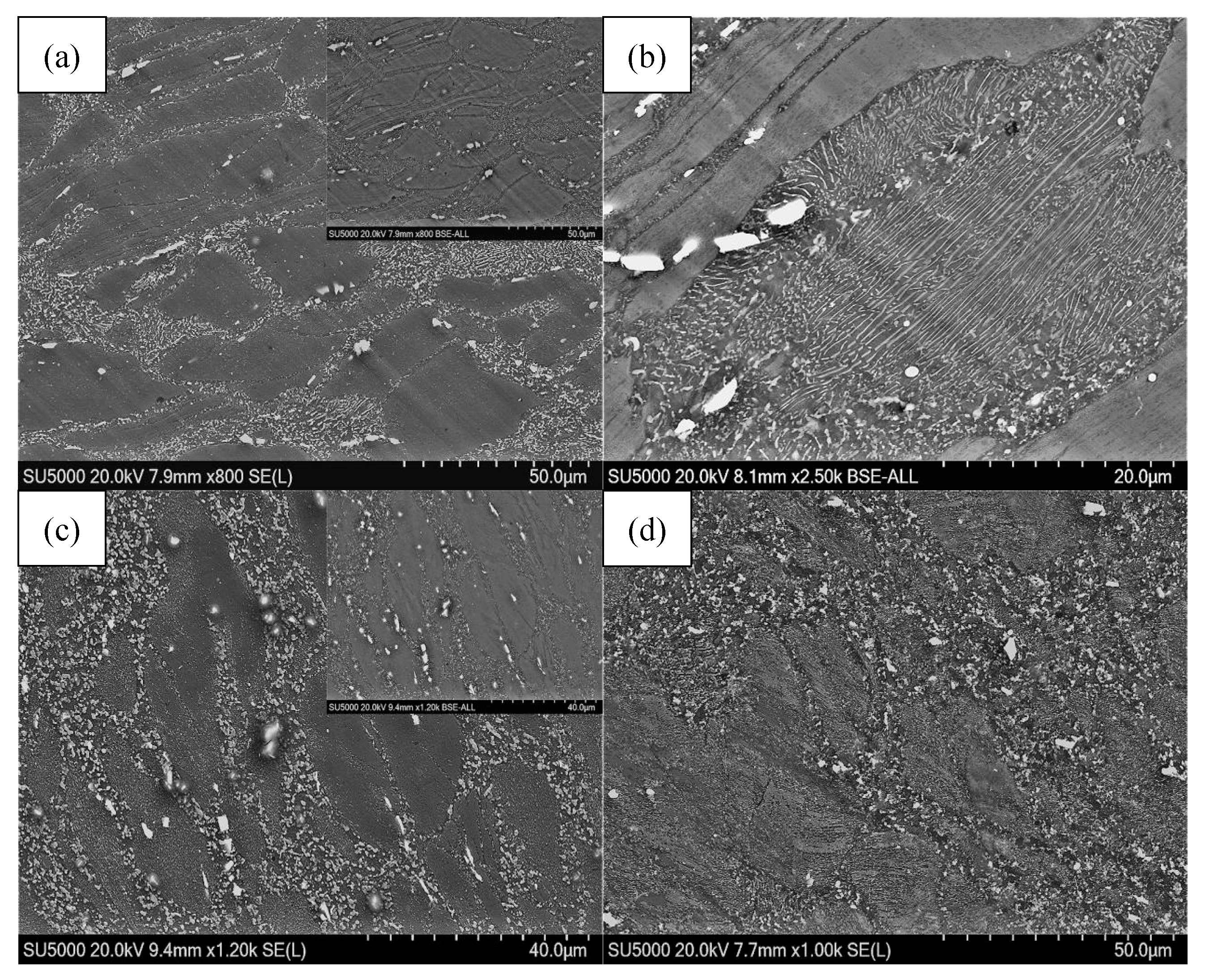

3.1.2. Microstructure Evolution at the Same Temperature with Different Passes

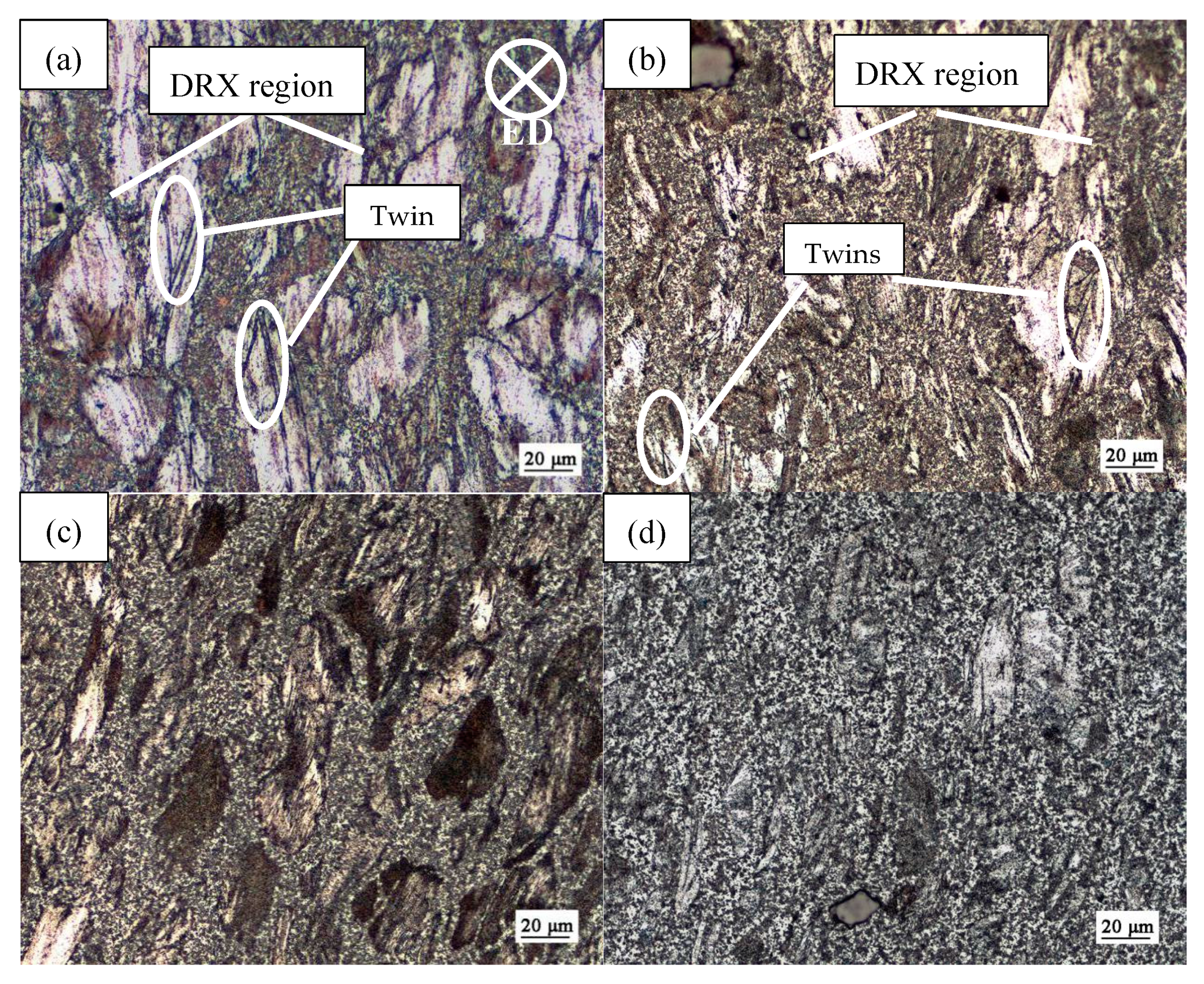

3.1.3. Microstructure Evolution at the Same Pass with Different Temperatures

3.2. Mechanical Properties

4. Conclusions

- (1)

- The molds were designed and thin-walled tubes of AZ80 + 0.4%Ce magnesium alloy with an inside diameter of 6.0 mm and a wall thickness of 0.6 mm were fabricated by hot multi-pass variable wall thickness back extrusion, which can be split into two processes: hot backward extrusion and four-pass hot extension with variable diameters. The success of AZ80 + 0.4%Ce can provide a reference for other magnesium alloys to fabricate ultra-thin walled tubes for electronic components and medical devices.

- (2)

- According to the microstructure analysis, the grain size decreased from 46.3 μm to 8.9 μm with four-pass extension at a deformation temperature of 350 °C and a punch speed of 0.1 mm/s, while there was excessive grain growth at 390 °C and non-uniformity of grain sizes and phases at 310 °C.

- (3)

- Twinning occurred when the deformation temperature was below 310 °C, and disappeared gradually with the increase in accumulated strain. Twinning, precipitation of second phases, twinning dynamic recrystallization (TDRX), and work hardening were combined to change the hardness of tubes at 240 °C and 270 °C. The formation of twins hindered the slip of dislocations and refined grains at the same time. When the temperature reaches 350 °C and higher, the competitive mechanism between work hardening and DRX softening dominates plastic deformation. The hardness reached 93HV after the third extension without annealing at 350 °C and would be higher after heat treatment.

5. Patents

Author Contributions

Funding

Conflicts of Interest

References

- Yuan, S.W.; Chen, L.; Tang, J.W.; Zhao, G.Q.; Zhang, C.S.; Yu, J.Q. Correlation between homogenization treatment and subsequent hot extrusion of Al-Mg-Si alloy. J. Mater. Sci. 2019, 54, 9843–9856. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, J.X.; Zhao, G.Q.; Wang, Z.S.; Zhang, C.S. Microstructure and mechanical properties of Mg-Al-Zn alloy extruded by porthole die with different initial billets. Mater. Sci. Eng. A 2018, 718, 390–397. [Google Scholar] [CrossRef]

- Li, C.J.; Sun, H.F.; Li, X.W.; Zhang, J.L.; Fang, W.B.; Tan, Z.Y. Microstructure, texture and mechanical properties of Mg-3.0Zn-0.2Ca alloys fabricated by extrusion at various temperatures. J. Alloys Compd. 2015, 652, 122–131. [Google Scholar] [CrossRef]

- Liu, F.; Chen, C.X.; Niu, J.L.; Pei, J.; Zhang, H.; Huang, H.; Yuan, G.Y. The processing of Mg alloy micro-tubes for biodegradable vascular stents. Mater. Sci. Eng C 2015, 48, 400–407. [Google Scholar] [CrossRef]

- Chino, Y.; Kimura, K.; Mabuchi, M. Twinning behavior and deformation machanisms of extruded AZ31 Mg alloy. Mater. Sci. Eng. A 2008, 486, 481–488. [Google Scholar] [CrossRef]

- Nakata, T.; Mezaki, T.; Xu, C.; Oh-ishi, K.; Shimizu, K.; Hanaki, S.; Kamado, S. Improving tensile properties of dilute Mg-0.27Al-0.13Ca-0.21Mn (at. %) alloy by low temperature high speed extrusion. J. Alloys Compd. 2015, 648, 428–437. [Google Scholar] [CrossRef]

- Zheng, Y.F.; Gu, X.N.; Witte, F. Biodegradable metals. Mater. Sci. Eng. R. 2014, 77, 1–34. [Google Scholar] [CrossRef]

- Zhang, Z.M.; Yan, Z.M.; DU, Y.; Zhang, G.S.; Zhu, J.X.; Ren, L.Y.; Wang, Y.D. Hot deformation behavior of homogenized Mg-13.5Gd-3.2Y-2.3Zn-0.5Zr alloy via hot compression tests. Materials 2018, 11, 2282. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.S.; Zhang, Z.M.; Li, X.B.; Yan, Z.M.; Che, X.; Yu, J.M.; Meng, Y.Z. Effects of repetitive upsetting-extrusion parameters on microstructure and texture evolution of Mg-Gd-Y-Zn-Zr alloy. J. Alloys Compd. 2019, 790, 48–57. [Google Scholar] [CrossRef]

- Zhang, G.S.; Zhang, Z.M.; Du, Y.; Yan, Z.M.; Che, X. Effect of isothermal repetitive upsetting extrusion on the microstructure of Mg-12.0Gd-4.5Y-2.0Zn-0.4Zr alloy. Materials 2018, 11, 2092. [Google Scholar] [CrossRef]

- Wang, L.X.; Fang, G.; Qian, L.Y.; Leeflang, S.; DUszczyk, J.; Zhou, J. Forming of magnesium alloy microtubes in the fabrication of biodegradable stents. Prog. Nat. Sci.-Mater. 2014, 24, 500–506. [Google Scholar] [CrossRef]

- Hanada, K.; Matsuzaki, K.; Huang, X.S.; Chino, Y. Fabrication of Mg alloy tubes for biodegradable stent application. Mater. Sci. Eng. C 2013, 33, 4746–4750. [Google Scholar] [CrossRef] [PubMed]

- Kustra, P.; Milenin, A.; Plonka, B.; Furushima, T. Production process of biocompatible magnesium alloy tubes using extrusion and dieless drawing process. J. Mater. Eng. Perform. 2016, 25, 2528–2535. [Google Scholar] [CrossRef]

- Chen, W.Z.; Zhang, W.C.; Chao, H.Y.; Zhang, L.X.; Wang, E.D. Influence of large cold strain on the microstructural evolution for a magnesium alloy subjected to multi-pass cold drawing. Mater. Sci. Eng. A 2015, 623, 92–96. [Google Scholar] [CrossRef]

- Ge, Q.; Dellasega, D.; Demir, A.G.; Vedani, M. The processing of ultrafine-grained Mg tubes for biodegradable stents. Acta Biomater. 2013, 9, 8604–8610. [Google Scholar] [CrossRef] [PubMed]

- Faraji, G.; Yavari, P.; Aghdamifar, S.; Mashhadi, M.M. Mechanical and microstructure properties of ultra-fine grained AZ91 magnesium alloy tubes processed via multi pass tubular channel angular pressing (TCAP). J. Mater. Sci. Technol. 2014, 30, 134–138. [Google Scholar] [CrossRef]

- Wang, L.Q.; He, Y.F.; Zhao, H.; Xie, H.B.; Yi, S.; Ren, Y.P.; Qin, G.W. Effect of cumulative strain on the microstructure and mechanical properties of Zn-0.02 wt% Mg alloy wires during room-temperature drawing process. J. Alloys Comp. 2018, 740, 949–957. [Google Scholar] [CrossRef]

- Zheng, X.W.; Luo, P.; Dong, J.; Wang, S.M. Microstructure characteristic and mechanical properties of high-strength Mg-Nd-Zn-Zr alloy seamless tube produced by integrated extrusion. J. Mater. Eng. Perform. 2018, 27, 794–802. [Google Scholar] [CrossRef]

- Amani, S.; Faraji, G.; Kazemi Mehrabadi, H.; Abrinia, K.; Ghanbari, H. A combined method for producing high strength and ductility magnesium microtubes fo biodegradable vascular stents application. J. Alloys Compd. 2017, 723, 467–476. [Google Scholar] [CrossRef]

- Yu, J.M.; Zhang, Z.M.; Xu, P.; Dong, B.B.; Wang, Q.; Meng, M.; Hao, H.Y.; Li, X.B.; Yin, X.Y. Dynamic recrystallization behavior of Gd-containing Mg alloy under torsion deformation. J. Alloys Compd. 2019, 787, 239–253. [Google Scholar] [CrossRef]

- Guo, F.L.; Feng, B.; Fu, S.W.; Xin, Y.C.; Xu, S.W.; Liu, Q. Microstructure and texture in an extruded Mg-Al-Ca-Mn flat-oval tube. J. Magn. Alloy. 2017, 5, 13–19. [Google Scholar] [CrossRef]

- Yu, J.M.; Zhang, Z.M.; Wang, Q.; Yin, X.Y.; Cui, J.Y.; Qi, H.N. Dynamic recrystallization behavior of magnesium alloys with LPSO during hot deformation. J. Alloys Compd. 2017, 704, 382–389. [Google Scholar] [CrossRef]

- Wang, C.P.; Li, F.G.; Li, J.H. Producing thin-walled tube of pure copper by severe plastic deformation of shear extrusion. Rare Met. Mater. Eng. 2015, 44, 2391–2395. [Google Scholar]

- Sadeghi, A.; Martin, E.; Pekguleryuz, M. Texture evolution and twinning during the expansion of hot extruded AZ31+Sr seamless tubes. Metall. Mater. Trans. A 2014, 45, 6304–6316. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, J.G.; Chen, Z.Y.; Zha, M.; Wang, C.; Liu, S.; Yan, R.F. Effect of Ce addition on modifying the microstructure and achieving a high elongation with a relatively high strength of as-extruded AZ80 magnesium alloy. Materials 2019, 12, 76. [Google Scholar] [CrossRef]

- Yin, S.Q.; Zhang, Z.Q.; Yu, J.M.; Zhao, Z.L.; Liu, M.; Bao, L.; Jia, Z.; Cui, J.Z.; Wang, P. Achieving excellent superplasticity of Mg-7Zn-5Gd-0.6Zr alloy at low temperature regime. Sci. Rep. 2019, 9, 4365. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Q.F.; Li, L.; Zhang, Z.Q.; Zhao, Z.H.; Zuo, Y.B.; Cui, J.Z. Microstructure evolution of AZ80 magnesium alloy during multi-directional forging process. Mater. Trans. 2014, 55, 207–274. [Google Scholar] [CrossRef]

- Luo, L.; Xiao, Z.Y.; Huo, Q.H.; Yang, Y.; Huang, W.Y.; Guo, J.C.; Ye, Y.X.; Yang, X.Y. Enhanced mechanical properties of a hot-extruded AZ80 Mg alloy rod by pre-treatments and post-hot compression. J. Alloys Compd. 2018, 740, 180–193. [Google Scholar] [CrossRef]

- Zhang, X.B.; Mao, L.; Yuan, G.Y.; Wang, Z.Z. Performances of biodegradable Mg-Nd-Zn-Zr magnesium alloy for cardiovascular stent. Rare Met. Mater. Eng. 2013, 42, 1300–1305. [Google Scholar]

- He, Z.B.; Yin, Z.M.; Lin, S.; Deng, Y.; Shang, B.C.; Zhou, X. Preparation, microstructure and properties of Al-Zn-Mg-Sc alloy tubes. J. Rare Earths 2010, 28, 641–646. [Google Scholar] [CrossRef]

- Qiu, W.; Liu, Z.Q.; Yu, R.Z.; Chen, J.; Ren, Y.J.; He, J.J.; Li, W.; Li, C. Utilization of VN particles for grain refinement and mechanical properties of AZ31 magnesium alloy. J. Alloys Compd. 2019, 781, 1150–1158. [Google Scholar] [CrossRef]

| Al | Zn | Ce | Mn | Si | Cu | Fe | Ni | Mg |

|---|---|---|---|---|---|---|---|---|

| 8.90 | 0.53 | 0.40 | 0.20 | ≦0.01 | ≦0.01 | ≦0.005 | ≦0.005 | balance |

| Pass | Inner Diameter/mm | Outer Diameter/mm | Wall Thickness Reduction/mm | Cumulative Area Reduction Percentage/% |

|---|---|---|---|---|

| 0 | 6.0 | 10.0 | ||

| 1 | 6.0 | 9.0 | 0.5 | 43.8 |

| 2 | 6.0 | 8.4 | 0.3 | 64.0 |

| 3 | 6.0 | 7.8 | 0.3 | 79.8 |

| 4 | 6.0 | 7.2 | 0.3 | 91.0 |

| Points | Mg | Al | Mn | Ce |

|---|---|---|---|---|

| f | 8.34 | 45.34 | 36.44 | 9.88 |

| g | 47.97 | 40.94 | 9.35 | 0.15 |

| h | 55.24 | 34.99 | 9.69 | 0.08 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, Z.; Fang, M.; Lian, Z.; Zhang, Z.; Zhu, J.; Zhang, G.; Wang, Y. Research on AZ80 + 0.4%Ce (wt %) Ultra-Thin-Walled Tubes of Magnesium Alloys: The Forming Process, Microstructure Evolution and Mechanical Properties. Metals 2019, 9, 563. https://doi.org/10.3390/met9050563

Yan Z, Fang M, Lian Z, Zhang Z, Zhu J, Zhang G, Wang Y. Research on AZ80 + 0.4%Ce (wt %) Ultra-Thin-Walled Tubes of Magnesium Alloys: The Forming Process, Microstructure Evolution and Mechanical Properties. Metals. 2019; 9(5):563. https://doi.org/10.3390/met9050563

Chicago/Turabian StyleYan, Zhaoming, Min Fang, Zhendong Lian, Zhimin Zhang, Jiaxuan Zhu, Guanshi Zhang, and Yiding Wang. 2019. "Research on AZ80 + 0.4%Ce (wt %) Ultra-Thin-Walled Tubes of Magnesium Alloys: The Forming Process, Microstructure Evolution and Mechanical Properties" Metals 9, no. 5: 563. https://doi.org/10.3390/met9050563

APA StyleYan, Z., Fang, M., Lian, Z., Zhang, Z., Zhu, J., Zhang, G., & Wang, Y. (2019). Research on AZ80 + 0.4%Ce (wt %) Ultra-Thin-Walled Tubes of Magnesium Alloys: The Forming Process, Microstructure Evolution and Mechanical Properties. Metals, 9(5), 563. https://doi.org/10.3390/met9050563