Predicting the Tensile Behaviour of Cast Alloys by a Pattern Recognition Analysis on Experimental Data

Abstract

1. Introduction

2. Aims and Scope

- -

- Predict the mechanical properties of metals and, in particular, the tensile properties such as, yield strength, ultimate strength, ultimate strain and Young’s modulus, starting from experimental data. In addition, it would be possible to investigate the relationship between these properties and fundamental aspects of metallurgy, as in the cases of constituent elements, microstructures, process parameters or treatments.

- -

- Use information directly taken from micrographs by a conventional process of image analysis but globally converted into macro-indicators related to the content of graphite, ferrite, perlite, nodularity and vermicularity. In addition, it would be possible to discuss the interrelations existing between all these features—mechanical and metallurgical—with the scope to recognize essential and overabundant information. This investigation will involve two different families of cast alloys, a nodular cast iron (SGI) and a less common compact graphite cast iron (CGI).

- -

- Select and use these essential data inside a Machine Learning (ML) approach, based on pattern recognition, with the scope to perform an ‘intelligent analysis’ of experimental measures. In this task, some of the most common methods of ML will be applied, specifically the Random Forest (RF), the Artificial Neural Network (NN) and the k-nearest neighbours (kNN). These classifiers will be implemented by the use of conventional codes and accessible platforms, comparing them in terms of functionality and accuracy in prediction, especially in association with the consistency and quality of the dataset used for training but also considering the overall variability of the phenomena under investigation.

- -

- Introduce essential concerns regarding the real applicability of these techniques for scopes related to the material design, product/process quality control and so on, including practical suggestions on the way to simplify the procedure towards an industrially-oriented application.

3. Materials and Methods

3.1. Experimental Data

3.1.1. Casting

- 1)

- Spheroidal Graphite Iron (SGI), a material also called nodular or ductile iron with respect to its high ductility, offered by the spheroidal shape of graphite;

- 2)

- Compacted Graphite Iron (CGI), a material with intermediate properties between grey and nodular iron, thanks to a more compact form of graphite that is becoming quite popular, particularly in the automotive sector [48].

3.1.2. Metallurgical and Mechanical Properties

- -

- Quantity of Graphite

- -

- Quantity of Ferrite

- -

- Quantity of Perlite

- -

- Grade of Nodularity

- -

- Grade of Vermicularity

- -

- Ultimate Tensile Strength [UTS],

- -

- Yield Strength [YS],

- -

- Ultimate Strain [ε],

- -

- Young’s modulus [E].

3.2. Machine Learning Algorithms

3.2.1. Random Forest (RF)

3.2.2. Neural Network (NN)

3.2.3. K-Nearest Neighbours (kNN)

3.3. Correlations

- 0 < rxy < 0.3 there is a weak correlation;

- 0.3 < rxy < 0.7 there is a moderate correlation;

- rxy > 0.7 there is a strong correlation.

- -

- experimental measures by way of estimating the influence between different properties;

- -

- experimental and predicted values by way of estimating the accuracy of the ML methods.

4. Results

4.1. Experimental Measures

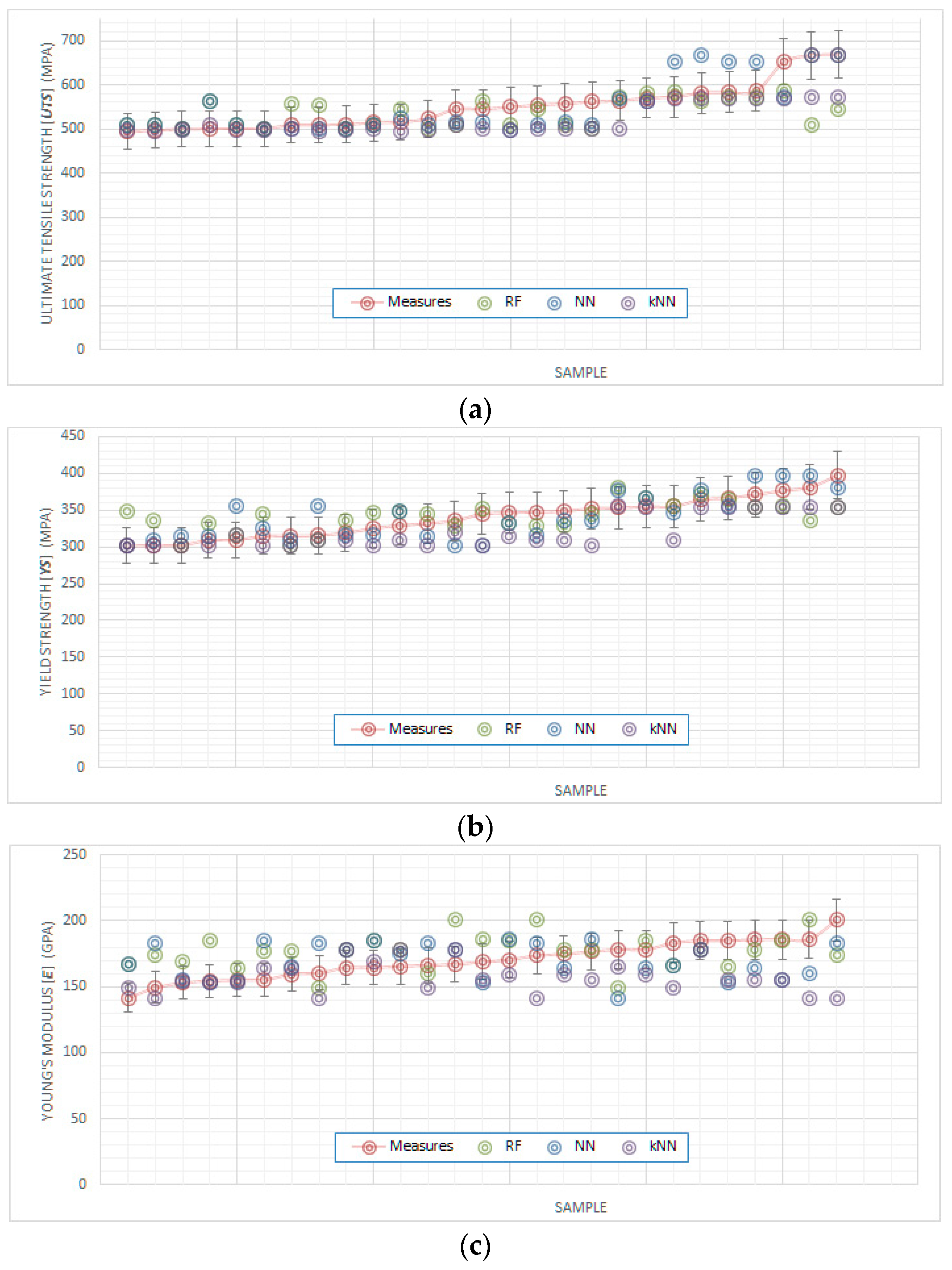

4.2. Spheroidal Graphite Cast Iron

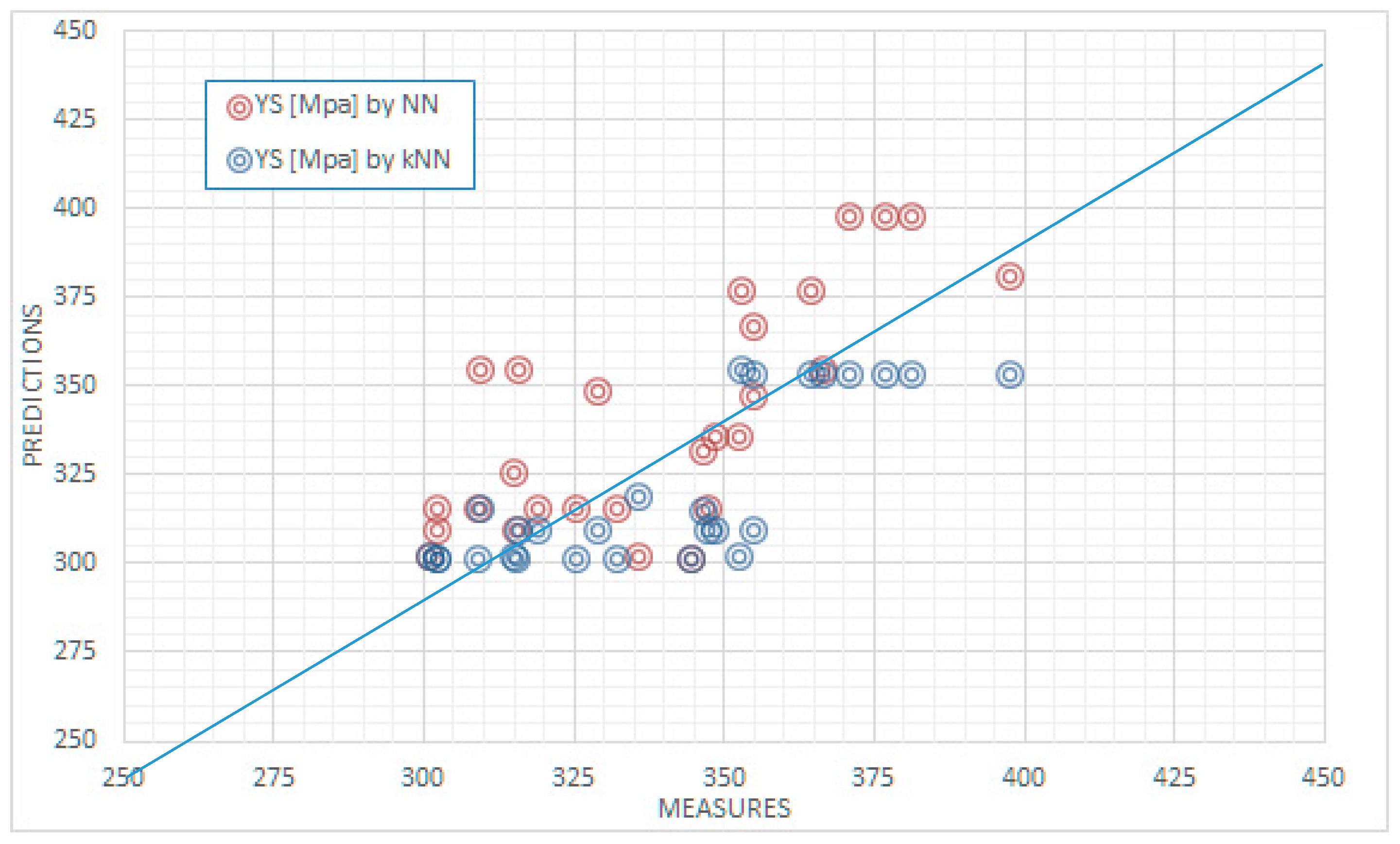

4.3. Compacted Graphite Cast Iron

5. Discussion

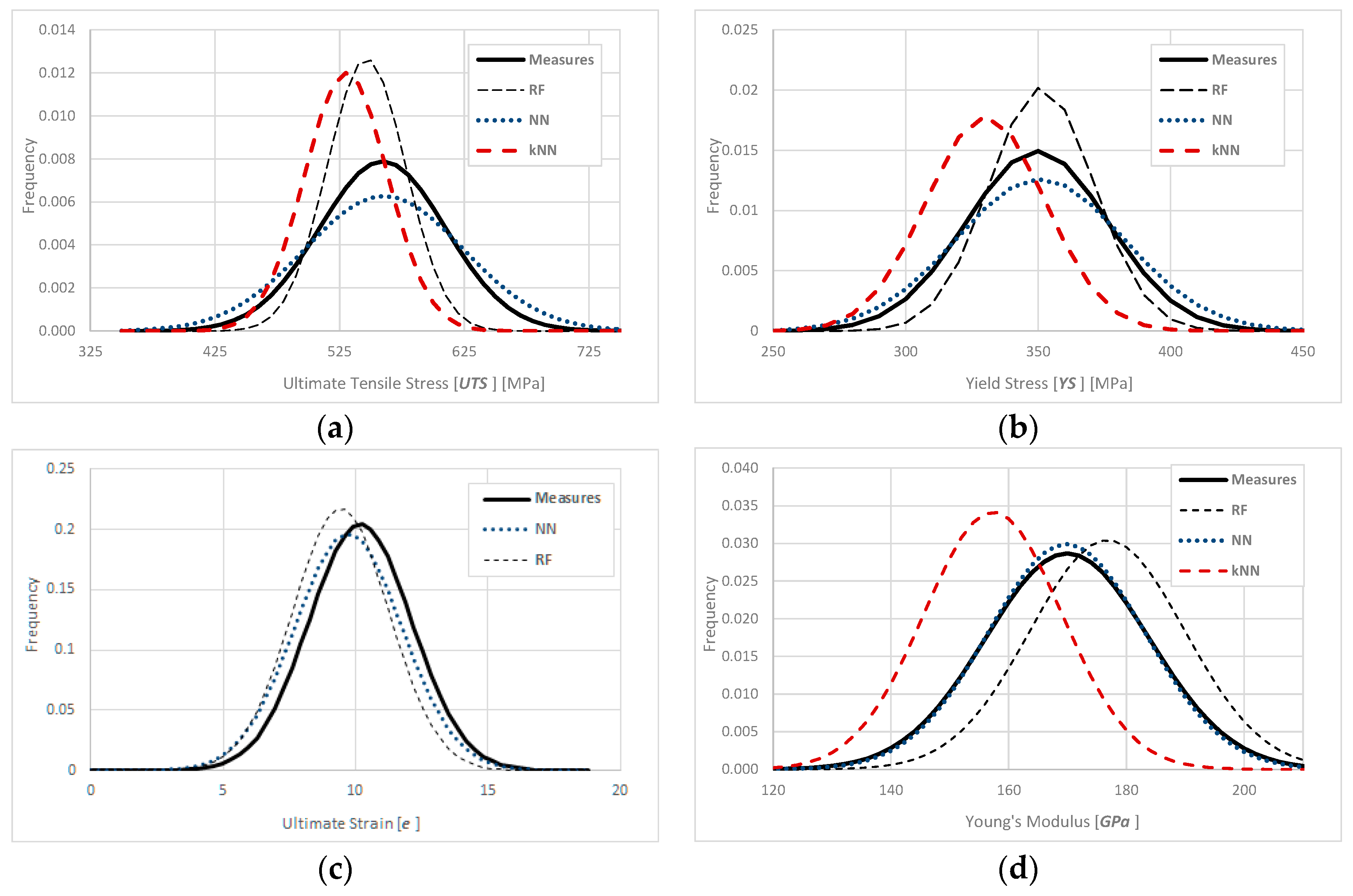

5.1. Prediction Model Validation

5.2. Data Preliminary Analysis

- -

- the SGI is more affected than the CGI with respect to changes in the metallurgical properties;

- -

- the content of graphite is not so relevant for the definition of mechanical properties, especially in the case of SGI, while it has a light negative effect on CGI;

- -

- the contents of ferrite and perlite, more than others, directly influence the material strength, especially in the case of SGI;

- -

- the ductility is directly related to ferrite and perlite content but not to graphite in the case of SGI, while the graphite shows a light negative effect on CGI;

- -

- the Young’s modulus, evaluated as standard, is practically uncorrelated, except for a slight dependency to the nodularity and to the vermicularity, more relevant in the case of CGI.

5.3. Expert Algorithms

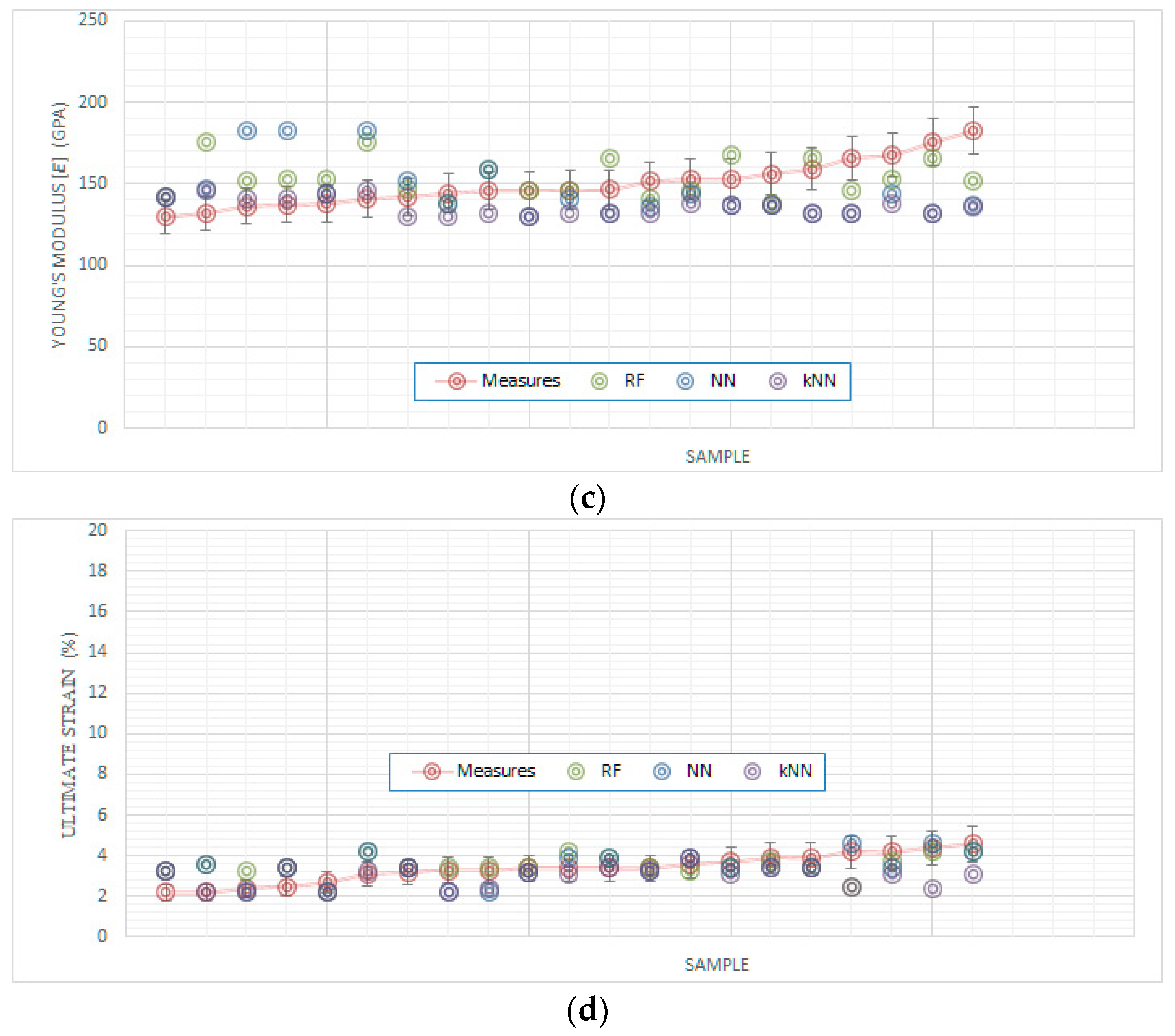

5.4. Mean Values and Variability

5.5. Mean Values and Error Estimation

5.6. Correlations

5.7. Results Summary

- -

- ML methods confirm their general validity in predicting the mechanical properties of metals;

- -

- this seems true, even in the presence of a quite limited dataset to be used for training;

- -

- information can be directly taken from micrographs by a conventional process of image analysis and macro-indicators without the need to go through deeper metallurgical investigations;

- -

- in particular, the NN method seems the most appropriate of those considered;

- -

- the kNN method, although it has good accuracy, also shows a tendency to systematic errors;

- -

- the accuracy in prediction is different for each specific property under investigation, achieving the best results for UTS and YS but also offering acceptable indications in the other cases;

- -

- the average values of experiments and predictions (measured by μ) often coincide in practice;

- -

- the deviation with respect to the average values (measured by σ) shows a variability in prediction in line with the intrinsic variability as revealed by the experimental measurements;

- -

- the Pearson correlation (rxy) can be conveniently adopted for a quick evaluation of data but also for the validation of predictions.

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| SGI | Spheroidal cast iron |

| CGI | Compact graphite cast iron |

| GR | Graphite |

| FE | Ferrite |

| PE | Perlite |

| NO | Grade of Nodularity |

| VE | Grade of Vermicularity |

| HB | Brinell hardness |

| AI | Artificial Intelligence |

| ANN | Artificial Neural Network |

| ML | Machine Learning |

| RF | Random Forest method |

| NN | Neural Network method |

| kNN | k-Nearest Neighbours method |

| μ | Mean Value |

| σ | Standard Deviation |

| σ% | Relative Standard Deviation |

| rxy | Pearson Correlation Coeff. |

| UTS | Ultimate Tensile Strength |

| YS | Yield Strength |

| ε | Ultimate Strain/Ductility |

| E | Young’s/Elasticity Modulus |

Appendix B

| Specimen | GR | FE | PE | NO | VE | UTS | YS | ε | E |

|---|---|---|---|---|---|---|---|---|---|

| % | % | % | % | % | MPa | MPa | % | GPa | |

| 1 | 9.1 | 47.5 | 43.4 | 53.9 | 36.8 | 500.0 | 315.3 | 10.2 | 154.5 |

| 2 | 12.2 | 47.1 | 40.8 | 63.6 | 27.2 | 501.0 | 302.3 | 10.3 | 164.6 |

| 3 | 13.6 | 42.5 | 43.9 | 75.2 | 17.0 | 508.7 | 315.7 | 8.6 | 184.9 |

| 4 | 8.6 | 48.6 | 42.8 | 62.6 | 30.4 | 496.8 | 301.2 | 11.6 | 184.9 |

| 5 | 12.1 | 48.5 | 39.5 | 67.1 | 26.2 | 494.8 | 325.4 | 8.5 | 170.5 |

| 6 | 11.2 | 42.8 | 46.0 | 68.8 | 23.7 | 508.8 | 314.8 | 8.0 | 185.7 |

| 7 | 8.3 | 43.6 | 48.1 | 50.9 | 40.9 | 501.4 | 309.2 | 9.8 | 153.0 |

| 8 | 12.6 | 43.6 | 43.8 | 79.0 | 15.2 | 500.5 | 309.4 | 8.8 | 178.2 |

| 9 | 6.3 | 52.8 | 40.9 | 56.4 | 34.4 | 510.2 | 302.1 | 8.0 | 155.0 |

| 10 | 8.6 | 43.7 | 47.8 | 65.7 | 24.3 | 549.9 | 344.7 | 11.7 | 168.9 |

| 11 | 12.1 | 44.8 | 43.1 | 75.5 | 17.1 | 561.5 | 347.5 | 13.4 | 178.2 |

| 12 | 8.1 | 49.0 | 42.9 | 75.7 | 17.3 | 545.4 | 329.1 | 12.8 | 165.4 |

| 13 | 9.2 | 40.8 | 50.0 | 66.9 | 23.6 | 554.4 | 352.4 | 10.4 | 155.3 |

| 14 | 7.1 | 44.6 | 48.3 | 68.6 | 22.3 | 544.8 | 346.4 | 10.9 | 176.7 |

| 15 | 9.4 | 47.3 | 43.4 | 75.1 | 17.1 | 557.4 | 348.7 | 12.2 | 174.7 |

| 16 | 13.2 | 34.2 | 52.7 | 86.1 | 9.4 | 570.4 | 354.8 | 11.4 | 141.7 |

| 17 | 11.3 | 30.5 | 58.2 | 85.7 | 9.4 | 586.4 | 366.5 | 7.5 | 186.0 |

| 18 | 13.7 | 39.2 | 47.1 | 84.4 | 10.8 | 564.4 | 354.9 | 9.8 | 167.0 |

| 19 | 9.1 | 32.1 | 58.8 | 78.2 | 16.3 | 582.9 | 370.9 | 8.0 | 173.7 |

| 20 | 10.2 | 30.8 | 59.1 | 80.8 | 14.1 | 572.5 | 353.0 | 8.5 | 149.2 |

| 21 | 7.6 | 33.5 | 58.8 | 84.6 | 10.2 | 581.9 | 364.4 | 12.7 | 200.6 |

| 22 | 9.3 | 24.6 | 66.1 | 89.6 | 5.9 | 651.7 | 376.8 | 9.9 | 160.4 |

| 23 | 7.0 | 22.7 | 70.3 | 81.6 | 11.9 | 668.7 | 397.5 | 9.0 | 183.3 |

| 24 | 6.5 | 24.8 | 68.7 | 74.2 | 17.7 | 666.6 | 381.2 | 8.8 | 166.4 |

| 25 | 10.2 | 55.7 | 34.1 | 77.7 | 16.6 | 514.2 | 319.0 | 15.2 | 164.6 |

| 26 | 7.0 | 51.6 | 41.4 | 72.5 | 19.7 | 515.7 | 335.7 | 8.1 | 159.6 |

| 27 | 7.1 | 45.2 | 47.7 | 61.9 | 27.6 | 523.9 | 332.0 | 10.7 | 185.9 |

| Mean (μ) | 9.7 | 41.2 | 49.2 | 72.7 | 20.1 | 549.4 | 339.7 | 10.2 | 170.0 |

| St. Dev. (σ) | 2.3 | 9.0 | 9.4 | 10.2 | 8.8 | 50.6 | 26.7 | 1.9 | 13.9 |

| R. St. Dev. (σ%) | 24% | 22% | 19% | 14% | 44% | 9% | 8% | 19% | 8% |

| Specimen | GR | FE | PE | NO | VE | UTS | YS | ε | E |

|---|---|---|---|---|---|---|---|---|---|

| % | % | % | % | % | MPa | MPa | % | GPa | |

| 1 | 21.0 | 60.2 | 18.8 | 16.1 | 81.2 | 318.8 | 253.1 | 3.3 | 136.1 |

| 2 | 17.3 | 62.3 | 20.4 | 12.1 | 85.1 | 350.1 | 274.3 | 2.2 | 182.5 |

| 3 | 13.9 | 62.9 | 23.2 | 15.4 | 82.2 | 307.5 | 237.8 | 3.3 | 146.3 |

| 4 | 14.5 | 61.6 | 23.9 | 9.4 | 88.5 | 314.1 | 252.4 | 2.2 | 137.1 |

| 5 | 14.5 | 62.6 | 22.9 | 23.4 | 74.3 | 316.2 | 259.1 | 2.5 | 142.1 |

| 6 | 13.2 | 64.8 | 22.0 | 13.0 | 84.4 | 308.4 | 252.3 | 2.4 | 140.8 |

| 7 | 15.7 | 64.3 | 20.0 | 17.5 | 79.7 | 321.7 | 258.5 | 3.4 | 151.4 |

| 8 | 12.6 | 61.9 | 25.6 | 11.7 | 86.4 | 315.0 | 249.7 | 2.7 | 152.9 |

| 9 | 16.7 | 53.5 | 29.8 | 9.0 | 88.9 | 312.4 | 249.5 | 3.6 | 156.3 |

| 11 | 11.4 | 64.9 | 23.7 | 15.1 | 82.7 | 338.3 | 273.0 | 4.4 | 175.6 |

| 12 | 9.2 | 67.6 | 23.3 | 21.6 | 74.6 | 338.8 | 257.3 | 4.2 | 146.4 |

| 14 | 11.2 | 65.8 | 22.9 | 17.9 | 80.0 | 336.8 | 274.0 | 4.6 | 132.1 |

| 15 | 10.3 | 63.0 | 26.8 | 16.7 | 81.4 | 339.2 | 270.9 | 4.2 | 145.7 |

| 16 | 14.6 | 56.6 | 28.9 | 19.5 | 78.5 | 345.8 | 263.9 | 3.4 | 145.8 |

| 17 | 10.1 | 62.9 | 27.0 | 16.7 | 81.7 | 346.4 | 278.4 | 3.7 | 159.2 |

| 18 | 11.1 | 63.5 | 25.5 | 16.2 | 81.8 | 354.6 | 288.3 | 3.1 | 165.6 |

| 19 | 9.8 | 59.9 | 30.3 | 17.8 | 80.5 | 345.0 | 274.9 | 3.4 | 152.6 |

| 20 | 12.8 | 58.3 | 28.9 | 24.0 | 74.0 | 345.7 | 284.1 | 3.2 | 129.8 |

| 22 | 12.9 | 52.9 | 34.2 | 18.5 | 79.5 | 370.7 | 281.0 | 3.9 | 144.3 |

| 23 | 12.6 | 53.4 | 34.0 | 16.3 | 81.9 | 374.0 | 295.8 | 3.4 | 137.9 |

| 24 | 9.7 | 55.2 | 35.2 | 13.3 | 85.4 | 380.8 | 296.7 | 3.9 | 167.9 |

| Mean (μ) | 13.0 | 61.2 | 25.8 | 16.6 | 81.2 | 337.2 | 267.9 | 3.4 | 149.9 |

| St. Dev. (σ) | 3.0 | 4.3 | 4.7 | 4.0 | 4.2 | 21.8 | 16.3 | 0.7 | 14.0 |

| R. St. Dev. (σ%) | 23% | 7% | 18% | 24% | 5% | 6% | 6% | 21% | 9% |

Appendix C

| UTS | YS | ε | E | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MPa | RF | NN | kNN | MPa | RF | NN | kNN | % | RF | NN | kNN | GPa | RF | NN | kNN |

| 495 | 510 | 509 | 497 | 325 | 348 | 316 | 301 | 8.5 | 8.0 | 8.0 | 8.0 | 171 | 185 | 186 | 160 |

| 497 | 510 | 510 | 495 | 301 | 349 | 302 | 302 | 11.6 | 10.7 | 10.2 | 8.0 | 185 | 165 | 153 | 155 |

| 500 | 501 | 501 | 497 | 315 | 302 | 309 | 301 | 10.2 | 8.0 | 8.0 | 8.0 | 155 | 185 | 153 | 153 |

| 501 | 510 | 509 | 497 | 302 | 301 | 315 | 301 | 10.3 | 8.0 | 8.0 | 8.0 | 165 | 185 | 185 | 169 |

| 501 | 562 | 564 | 509 | 309 | 316 | 355 | 316 | 8.8 | 9.0 | 9.0 | 7.5 | 178 | 149 | 142 | 165 |

| 501 | 500 | 500 | 497 | 309 | 332 | 315 | 301 | 9.8 | 11.4 | 8.6 | 8.6 | 153 | 169 | 155 | 155 |

| 509 | 557 | 501 | 501 | 316 | 309 | 355 | 309 | 8.6 | 8.8 | 8.5 | 8.8 | 185 | 178 | 178 | 178 |

| 509 | 554 | 501 | 495 | 315 | 345 | 325 | 302 | 8.0 | 10.2 | 10.7 | 9.8 | 186 | 178 | 165 | 155 |

| 510 | 500 | 500 | 497 | 302 | 336 | 309 | 301 | 8.0 | 10.9 | 9.8 | 8.5 | 155 | 165 | 155 | 153 |

| 514 | 510 | 509 | 501 | 319 | 336 | 316 | 309 | 15.2 | 8.1 | 12.8 | 8.1 | 165 | 178 | 178 | 178 |

| 516 | 545 | 524 | 495 | 336 | 329 | 302 | 319 | 8.1 | 12.8 | 15.2 | 8.5 | 160 | 177 | 165 | 165 |

| 524 | 501 | 510 | 497 | 332 | 345 | 315 | 301 | 10.7 | 10.9 | 10.2 | 10.3 | 186 | 185 | 155 | 155 |

| 545 | 562 | 516 | 501 | 329 | 349 | 349 | 309 | 12.8 | 13.4 | 15.2 | 8.1 | 165 | 178 | 175 | 178 |

| 545 | 509 | 516 | 509 | 346 | 332 | 332 | 315 | 10.9 | 10.7 | 10.7 | 8.0 | 177 | 178 | 186 | 155 |

| 550 | 509 | 497 | 497 | 345 | 352 | 301 | 301 | 11.7 | 10.4 | 10.7 | 8.0 | 169 | 186 | 153 | 155 |

| 554 | 545 | 510 | 501 | 352 | 345 | 336 | 302 | 10.4 | 8.0 | 8.0 | 8.0 | 155 | 177 | 185 | 165 |

| 557 | 509 | 514 | 501 | 349 | 329 | 336 | 309 | 12.2 | 8.0 | 8.0 | 8.1 | 175 | 178 | 165 | 160 |

| 562 | 501 | 509 | 501 | 348 | 329 | 316 | 309 | 13.4 | 8.0 | 8.0 | 8.0 | 178 | 185 | 165 | 160 |

| 564 | 573 | 570 | 501 | 355 | 355 | 348 | 309 | 9.8 | 10.2 | 8.0 | 8.0 | 167 | 201 | 178 | 178 |

| 570 | 582 | 564 | 564 | 355 | 367 | 367 | 353 | 11.4 | 7.5 | 8.5 | 7.5 | 142 | 167 | 167 | 149 |

| 573 | 583 | 652 | 570 | 353 | 381 | 377 | 355 | 8.5 | 8.0 | 9.9 | 7.5 | 149 | 174 | 183 | 142 |

| 582 | 564 | 669 | 570 | 364 | 371 | 377 | 353 | 12.7 | 7.5 | 9.9 | 7.5 | 201 | 174 | 183 | 142 |

| 583 | 573 | 652 | 570 | 371 | 353 | 398 | 353 | 8.0 | 8.5 | 9.0 | 7.5 | 174 | 201 | 183 | 142 |

| 586 | 573 | 652 | 570 | 367 | 364 | 355 | 353 | 7.5 | 8.0 | 8.8 | 8.0 | 186 | 201 | 160 | 142 |

| 652 | 586 | 573 | 570 | 377 | 355 | 398 | 353 | 9.9 | 7.5 | 7.5 | 7.5 | 160 | 149 | 183 | 142 |

| 667 | 510 | 669 | 573 | 381 | 336 | 398 | 353 | 8.8 | 13.4 | 11.4 | 8.6 | 166 | 160 | 183 | 149 |

| 669 | 545 | 667 | 573 | 398 | 353 | 381 | 353 | 9.0 | 8.8 | 9.9 | 7.5 | 183 | 166 | 166 | 149 |

| UTS | YS | ε | E | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MPa | RF | NN | kNN | MPa | RF | NN | kNN | % | RF | NN | kNN | GPa | RF | NN | kNN |

| 308 | 316 | 350 | 308 | 238 | 288 | 252 | 252 | 3.3 | 3.4 | 2.2 | 2.4 | 146 | 146 | 141 | 132 |

| 308 | 355 | 314 | 308 | 252 | 238 | 274 | 238 | 2.4 | 3.3 | 2.2 | 2.2 | 141 | 176 | 183 | 146 |

| 312 | 371 | 315 | 312 | 250 | 252 | 281 | 250 | 3.6 | 3.3 | 3.9 | 3.9 | 156 | 138 | 137 | 137 |

| 314 | 312 | 312 | 314 | 252 | 250 | 250 | 238 | 2.2 | 3.6 | 3.6 | 2.2 | 137 | 153 | 183 | 141 |

| 315 | 308 | 314 | 315 | 250 | 252 | 252 | 238 | 2.7 | 2.2 | 2.2 | 2.2 | 153 | 168 | 137 | 137 |

| 316 | 322 | 346 | 316 | 259 | 284 | 284 | 257 | 2.5 | 3.4 | 3.4 | 3.4 | 142 | 146 | 151 | 130 |

| 319 | 350 | 322 | 319 | 253 | 259 | 274 | 238 | 3.3 | 3.4 | 2.2 | 2.2 | 136 | 151 | 183 | 141 |

| 322 | 319 | 319 | 322 | 259 | 252 | 259 | 238 | 3.4 | 3.4 | 3.2 | 3.2 | 151 | 141 | 136 | 132 |

| 337 | 355 | 339 | 337 | 274 | 257 | 257 | 238 | 4.6 | 4.2 | 4.2 | 3.1 | 132 | 176 | 146 | 146 |

| 338 | 339 | 337 | 338 | 273 | 288 | 250 | 252 | 4.4 | 4.2 | 4.6 | 2.4 | 176 | 166 | 132 | 132 |

| 339 | 346 | 337 | 339 | 271 | 278 | 238 | 273 | 4.2 | 2.5 | 4.6 | 2.5 | 146 | 159 | 159 | 132 |

| 339 | 337 | 308 | 339 | 257 | 271 | 259 | 259 | 4.2 | 3.7 | 3.4 | 3.1 | 146 | 166 | 132 | 132 |

| 345 | 346 | 346 | 345 | 275 | 278 | 281 | 271 | 3.4 | 3.4 | 3.3 | 3.3 | 153 | 146 | 144 | 138 |

| 346 | 316 | 346 | 346 | 264 | 281 | 296 | 271 | 3.4 | 4.2 | 3.9 | 3.1 | 146 | 146 | 130 | 130 |

| 346 | 339 | 339 | 346 | 278 | 271 | 271 | 271 | 3.7 | 3.4 | 3.4 | 3.1 | 159 | 166 | 132 | 132 |

| 346 | 316 | 316 | 346 | 284 | 259 | 259 | 257 | 3.2 | 3.4 | 3.4 | 3.4 | 130 | 142 | 142 | 142 |

| 350 | 308 | 319 | 350 | 274 | 252 | 253 | 238 | 2.2 | 3.3 | 3.3 | 3.3 | 183 | 151 | 137 | 136 |

| 355 | 338 | 339 | 355 | 288 | 273 | 275 | 238 | 3.1 | 4.2 | 4.2 | 3.3 | 166 | 146 | 132 | 132 |

| 371 | 381 | 374 | 371 | 281 | 296 | 296 | 264 | 3.9 | 3.4 | 3.4 | 3.4 | 144 | 138 | 138 | 130 |

| 374 | 381 | 371 | 374 | 296 | 281 | 281 | 250 | 3.4 | 3.9 | 3.9 | 3.4 | 138 | 153 | 144 | 144 |

| 381 | 374 | 312 | 381 | 297 | 274 | 296 | 250 | 3.9 | 3.7 | 3.4 | 3.4 | 168 | 153 | 144 | 138 |

References

- Ashby, M.F.; Jones, D.R.H. Engineering Materials 1: An Introduction to Properties, Applications and Design, 4th ed.; Elsevier: Oxford, UK, 2012. [Google Scholar]

- Hans, E.; Koski, J.; Osyczka, A. Multicriteria Design Optimization: Procedures and Applications; Springer Science & Business Media: Berlin, Germany, 2012. [Google Scholar]

- Boyles, A. The Structure of Cast Iron: A Series of Three Educational Lectures on the Structure of Cast Iron; American Society for Metals: Russell Township, OH, USA, 1947. [Google Scholar]

- Fragassa, C. Material selection in machine design: The change of cast iron for improving the high-quality in woodworking. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2016, 231, 18–30. [Google Scholar] [CrossRef]

- Campbell, F.C. Elements of Metallurgy and Engineering Alloys; ASM International: Materials Park, OH, USA, 2008; p. 453. [Google Scholar]

- Elliott, R. Cast Iron Technology; Butterworth-Heinemann: London, UK, 1988. [Google Scholar]

- Sinha, A.K. Physical Metallurgy Handbook; McGraw-Hill Professional Publishing: New York, NY, USA, 2003. [Google Scholar]

- Damir, A.N.; Elkhatib, A.; Nassef, G. Prediction of fatigue life using modal analysis for grey and ductile cast iron. Int. J. Fatigue 2007, 29, 499–507. [Google Scholar] [CrossRef]

- Elkholy, A. Prediction of abrasion wear for slurry pump materials. Wear 1983, 84, 39–49. [Google Scholar] [CrossRef]

- Berdin, C.; Dong, M.J.; Prioul, C. Local approach of damage and fracture toughness for nodular cast iron. Eng. Fract. Mech. 2001, 68, 1107–1117. [Google Scholar] [CrossRef]

- Kim, J.; Bae, C.; Woo, H.; Kim, J.; Hong, S. Assessment of residual tensile strength on cast iron pipes. In Pipelines 2007: Advances and Experiences with Trenchless Pipeline Projects; Mohammad Najafi, P.E., Lynn Osborn, P.E., Eds.; ASCE: Reston, VA, USA, 2007; pp. 1–7. [Google Scholar]

- Atkinson, K.; Whiter, J.T.; Smith, P.A.; Mulheron, M. Failure of small diameter cast iron pipes. Urban Water 2002, 4, 263–271. [Google Scholar] [CrossRef]

- Fragassa, C.; Zigulic, R.; Pavlovic, A. Push-pull fatigue test on ductile and vermicular cast irons. Eng. Rev. 2016, 36, 269–280. [Google Scholar]

- Álvarez, L.; Luis, C.J.; Puertas, I. Analysis of the influence of chemical composition on the mechanical and metallurgical properties of engine cylinder blocks in grey cast iron. J. Mater. Process. Technol. 2004, 153, 1039–1044. [Google Scholar] [CrossRef]

- Fragassa, C.; Minak, G.; Pavlovic, A. Tribological aspects of cast iron investigated via fracture toughness. Tribol. Ind. 2016, 38, 1–10. [Google Scholar]

- Li, Y.; Chen, W.; Huang, D.; Luo, J.; Liu, J.; Chen, Y.; Liu, Q.; Su, S. Energy conservation and emissions reduction strategies in foundry industry. China Foundry 2010, 7, 392–399. [Google Scholar]

- Gonzaga, R.A.; Carrasquilla, J.F. Influence of an appropriate balance of the alloying elements on microstructure and on mechanical properties of nodular cast iron. J. Mater. Process. Technol. 2005, 162, 293–297. [Google Scholar] [CrossRef]

- McNeil, I. An Encyclopedia of the History of Technology; Routledge: London, UK, 2002. [Google Scholar]

- Angus, H.T. Cast Iron: Physical and Engineering Properties; Elsevier: London, UK, 2013. [Google Scholar]

- Collini, L.; Nicoletto, G.; Konečná, R. Microstructure and mechanical properties of pearlitic gray cast iron. Mater. Sci. Eng. A 2008, 488, 529–539. [Google Scholar] [CrossRef]

- Radovic, N.; Morri, A.; Fragassa, C. A study on the tensile behaviour of spheroidal and compacted graphite cast irons based on microstructural analysis. In Proceedings of the 11th IMEKO TC15 Youth Symposium on Experimental Solid Mechanics, Brasov, Romania, 30 May–02 June 2012; pp. 185–190. [Google Scholar]

- Fragassa, C.; Pavlovic, A. Compacted and spheroidal graphite irons: Experimental evaluation of Poisson’s ratio. FME Trans. 2016, 44, 327–332. [Google Scholar] [CrossRef]

- Fragassa, C.; Radovic, N.; Pavlovic, A.; Minak, G. Comparison of mechanical properties in compacted and spheroidal graphite irons. Tribol. Ind. 2016, 38, 49–59. [Google Scholar]

- Tiedje, N. Solidification, processing and properties of ductile cast iron. Mater. Sci. Technol. 2010, 26, 505–514. [Google Scholar] [CrossRef]

- Costa, N.; Machado, N.; Silva, F.S. A new method for prediction of nodular cast iron fatigue limit. Int. J. Fatigue 2010, 32, 988–995. [Google Scholar] [CrossRef]

- Shiraki, N.; Usui, Y.; Kanno, T. Effects of number of graphite nodules on fatigue limit and fracture origins in heavy section spheroidal graphite cast iron. Mater. Trans. 2016, 57, 379–384. [Google Scholar] [CrossRef]

- Santos, C.A.; Spim, J.A., Jr.; Ierardi, M.C.; Garcia, A. The use of artificial intelligence technique for the optimisation of process parameters used in the continuous casting of steel. Appl. Math. Modell. 2002, 26, 1077–1092. [Google Scholar] [CrossRef]

- Calcaterra, S.; Campana, G.; Tomesani, L. Prediction of mechanical properties in spheroidal cast iron by neural networks. J. Mater. Process. Technol. 2000, 104, 74–80. [Google Scholar] [CrossRef]

- Roshan, H.D.; Sudesh, K. Expert system for analysis of casting defects: Cause module. Trans. Am. Foundrymen’s Soc. 1989, 97, 601–606. [Google Scholar]

- Artificial Intelligence. Available online: https://en.wikipedia.org/wiki/Artificial_intelligence (accessed on 15 March 2019).

- Fukunaga, K. Introduction to Statistical Pattern Recognition; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Dong, M.J.; Hu, G.K.; Diboine, A.; Moulin, D.; Prioul, C. Damage modelling in nodular cast iron. J. Phys. IV 1993, 3, 643–648. [Google Scholar] [CrossRef][Green Version]

- Gonzaga, R.A. Influence of ferrite and pearlite content on mechanical properties of ductile cast irons. Mater. Sci. Eng. A 2013, 567, 1–8. [Google Scholar] [CrossRef]

- Radisa, R.; Ducic, N.; Manasijevic, S.; Markovic, N.; Cojbasic, Z. Casting improvement based on metaheuristic optimization and numerical simulation. Facta Univ. Ser. Mech. Eng. 2017, 15, 397–411. [Google Scholar] [CrossRef]

- Voracek, J. Prediction of mechanical properties of cast irons. Appl. Soft Comput. 2001, 1, 119–125. [Google Scholar] [CrossRef]

- Kohavi, R.; Provost, F. Glossary of terms. Mach. Learn. 1998, 30, 271–274. [Google Scholar]

- Weiss, S.M.; Kulikowski, C.A. Computer Systems That Learn: Classification and Prediction Methods from Statistics, Neural Nets, Machine Learning and Expert Systems; Morgan Kaufmann: San Mateo, CA, USA, 1991; Volume 123. [Google Scholar]

- Bishop, C.M. Pattern Recognition and Machine Learning; Springer: New York, NY, USA, 2006. [Google Scholar]

- Anzai, Y. Pattern Recognition and Machine Learning; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Maulik, U.; Sanghamitra, B. Genetic algorithm-based clustering technique. Pattern Recognit. 2000, 33, 1455–1465. [Google Scholar] [CrossRef]

- Samuel, A.L. Some studies in machine learning using the game of checkers. IBM J. Res. Dev. 2000, 44, 206–226. [Google Scholar] [CrossRef]

- Schmidhuber, J. Deep learning in neural networks: An overview. Neural Netw. 2015, 61, 85–117. [Google Scholar] [CrossRef]

- Hughes, I.C.H.; Powell, J.; de Albuquerque, V.H.C.; Cortez, P.C.; de Alexandria, A.R.; Tavares, J.M.R. A new solution for automatic microstructures analysis from images based on a backpropagation artificial neural network. Nondestr. Test. Eval. 2008, 23, 273–283. [Google Scholar]

- Perzyk, M.; Kochański, A.W. Prediction of ductile cast iron quality by artificial neural networks. J. Mater. Process. Technol. 2001, 109, 305–307. [Google Scholar] [CrossRef]

- Ward, L.; Agrawal, A.; Choudhary, A.; Wolverton, A. A general-purpose machine learning framework for predicting properties of inorganic materials. Comput. Mater. 2016, 2, 16028. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, T.; Ju, W.; Shi, S. Materials discovery and design using machine learning. J. Materiomics 2017, 3, 159–177. [Google Scholar] [CrossRef]

- SCM Foundry. Available online: http://www.scmfonderie.it/?l=en&p=azienda (accessed on 15 November 2015).

- Altstetter, J.D.; Nowicki, R.M. Compacted Graphite Iron—Its properties and automotive applications. AFS Trans. 1982, 82, 959–970. [Google Scholar]

- BS EN ISO 1563. Founding. Spheroidal Graphite Cast Iron; BSI: London, UK, 2012. [Google Scholar]

- EN ISO 6892-1. Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature; ISO: Geneva, Switzerland, 2016. [Google Scholar]

- Orange Platform. Available online: https://orange.biolab.si/ (accessed on 10 April 2019).

- Wolpert, D.H.; Macready, W.G. No free lunch theorems for optimization. IEEE Trans. Evol. Comput. 1997, 1, 67. [Google Scholar] [CrossRef]

- Wolpert, D. The lack of a priori distinctions between learning algorithms. Neural Comput. 1996, 8, 1341–1390. [Google Scholar] [CrossRef]

- Babic, M.; Calì, M.; Nazarenko, I.; Fragassa, C.; Ekinovic, S.; Mihaliková, M.; Janjić, M.; Belič, I. Surface roughness evaluation in hardened materials by pattern recognition using network theory. Int. J. Interact. Des. Manuf. 2018, 13, 211–219. [Google Scholar] [CrossRef]

- Lin, Y.; Yongho, J. Random forests and adaptive nearest neighbours. J. Am. Stat. Assoc. 2006, 101, 578–590. [Google Scholar] [CrossRef]

- Gurney, K. An Introduction to Neural Networks; CRC Press: London, UK, 2014. [Google Scholar]

- Garcia, S.; Derrac, J.; Cano, J.; Herrera, F. Prototype selection for nearest neighbour classification: Taxonomy and empirical study. IEEE Trans. Pattern Anal. Mach. Intell. 2012, 34, 417–435. [Google Scholar] [CrossRef] [PubMed]

- Wagner, N.; Rondinelli, J.M. Theory-guided machine learning in materials science. Front. Mater. 2016, 3, 28. [Google Scholar] [CrossRef]

- Pilania, G.; Wang, C.; Jiang, X.; Rajasekaran, S.; Ramprasad, R. Accelerating materials property predictions using machine learning. Sci. Rep. 2013, 3, 2810. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Ling, C. A strategy to apply machine learning to small datasets in materials science. Npj Comput. Mater. 2018, 4, 25. [Google Scholar] [CrossRef]

- Sata, A. Mechanical property prediction of investment castings using artificial neural network and multivariate regression analysis. In Proceeding of the 63rd Indian Foundry Congress, Greater Noida, India, 27 February–1 March 2015. [Google Scholar]

- Lucisano, G.; Stefanovic, M.; Fragassa, C. Advanced design solutions for high-precision woodworking machines. Inter. J. Qual. Res. 2016, 10, 143–158. [Google Scholar]

- Dawson, S.; Schroeder, T. Practical applications for compacted graphite iron. AFS Trans. 2004, 47, 1–9. [Google Scholar]

| Number of trees | 15 |

| Fixed seed for random generator | 32 |

| Do not split subset smaller than | 5 |

| Learning speed | 0.6 |

| Inertial coefficient | 0.5 |

| Test mass tolerance | 0.02 |

| Tolerance of the learning set | 0.03 |

| Number of layers | 5 |

| Metric | Chebyshev |

| Number of Neighbours | 2 |

| Weight | Uniform |

| SGI | Graphite | Ferrite | Perlite | Nodularity | Vermicularity |

| Graphite | 1.00 | 0.04 | −0.29 | 0.34 | −0.30 |

| Ferrite | 0.04 | 1.00 | −0.79 | 0.13 | −0.19 |

| Perlite | −0.29 | −0.79 | 1.00 | 0.03 | 0.05 |

| Nodularity | 0.34 | 0.13 | 0.03 | 1.00 | −0.99 |

| Vermicularity | −0.30 | −0.19 | 0.05 | −0.99 | 1.00 |

| CGI | Graphite | Ferrite | Perlite | Nodularity | Vermicularity |

| Graphite | 1.00 | −0.20 | −0.45 | −0.24 | 0.20 |

| Ferrite | −0.20 | 1.00 | −0.79 | 0.13 | −0.19 |

| Perlite | −0.45 | −0.79 | 1.00 | 0.03 | 0.05 |

| Nodularity | −0.24 | 0.13 | 0.03 | 1.00 | −0.99 |

| Vermicularity | 0.20 | −0.19 | 0.05 | −0.99 | 1.00 |

| SGI | Graphite | Ferrite | Perlite | Nodularity | Vermicularity |

| Ultimate Tensile Strength (UTS) | −0.25 | −0.87 | 0.90 | 0.63 | −0.65 |

| Yield Strength (YS) | −0.19 | −0.83 | 0.84 | 0.67 | −0.69 |

| Ultimate Strain (ε) | −0.03 | 0.34 | −0.32 | 0.05 | −0.06 |

| Young’s Modulus (E) | −0.03 | −0.09 | 0.09 | 0.18 | −0.21 |

| CGI | Graphite | Ferrite | Perlite | Nodularity | Vermicularity |

| Ultimate Tensile Strength (UTS) | −0.44 | −0.46 | 0.69 | 0.23 | −0.17 |

| Yield Strength (YS) | −0.46 | −0.35 | 0.61 | 0.25 | −0.17 |

| Ultimate Strain (ε) | −0.47 | 0.00 | 0.29 | 0.28 | −0.26 |

| Young’s Modulus (E) | −0.11 | 0.08 | 0.00 | −0.39 | 0.38 |

| SGI | Unit | Data | RF | NN | kNN |

| Ultimate Tensile Strength (UTS) | MPa | 549 ± 51 (9%) | 536 ± 31 (6%) | 550 ± 64 (12%) | 520 ± 33 (6%) |

| Yield Strength (YS) | MPa | 340 ± 27 (8%) | 341 ± 20 (6%) | 341 ± 31 (9%) | 320 ± 22 (7%) |

| Ultimate Strain (ε) | % | 10.2 ± 1.9 (19%) | 9.4 ± 1.8 (19%) | 9.7 ± 2.0 (21%) | 8.1 ± 0.1 (8%) |

| Young’s Modulus (E) | GPa | 170 ± 14 (8%) | 177 ± 13 (7%) | 170 ± 13 (8%) | 157 ± 12 (7%) |

| CGI | Unit | Data | RF | NN | kNN |

| Ultimate Tensile Strength (UTS) | MPa | 337 ± 22 (6%) | 340 ± 24 (7%) | 332 ± 19 (6%) | 317 ± 5 (4%) |

| Yield Strength (YS) | MPa | 268 ± 16 (6%) | 268 ± 16 (6%) | 268 ± 17 (6%) | 251 ± 13 (5%) |

| Ultimate Strain (ε) | % | 3.4 ± 0.7 (21%) | 3.5 ± 0.5 (14%) | 3.4 ± 0.7 (21%) | 3.0 ± 0.5 (18%) |

| Young’s Modulus (E) | GPa | 150 ± 14 (9%) | 154 ± 12 (8%) | 146 ± 17 (12%) | 136 ± 20 (4%) |

| Property | SGI | CGI | ||||

|---|---|---|---|---|---|---|

| RF | NN | kNN | RF | NN | kNN | |

| Ultimate Tensile Strength (UTS) | −2.4% | 0.2% | −5.3% | 0.9% | −1.5% | −5.9% |

| Yield Strength (YS) | 0.3% | 0.3% | −5.9% | 0.0% | 0.0% | −6.3% |

| Ultimate Strain (ε) | −7.8% | −4.9% | −20.6% | 2.9% | −11.8% | −11.8% |

| Young’s modulus (E) | 4.1% | 0.0% | −7.6% | 2.7% | −2.7% | −9.3% |

| Pearson Correlation Coefficient (rxy) | SGI | CGI | ||||

|---|---|---|---|---|---|---|

| RF | NN | k-NN | RF | NN | kNN | |

| Ultimate Tensile Strength (UTS) | 0.39 | 0.76 | 0.81 | 0.48 | 0.41 | 0.37 |

| Yield Strength (YS) | 0.56 | 0.74 | 0.79 | 0.33 | 0.33 | 0.22 |

| Ultimate Strain (ε) | −0.12 | 0.17 | −0.14 | 0.29 | 0.50 | 0.19 |

| Young’s modulus (E) | 0.17 | −0.07 | −0.05 | −0.02 | −0.48 | −0.41 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fragassa, C.; Babic, M.; Bergmann, C.P.; Minak, G. Predicting the Tensile Behaviour of Cast Alloys by a Pattern Recognition Analysis on Experimental Data. Metals 2019, 9, 557. https://doi.org/10.3390/met9050557

Fragassa C, Babic M, Bergmann CP, Minak G. Predicting the Tensile Behaviour of Cast Alloys by a Pattern Recognition Analysis on Experimental Data. Metals. 2019; 9(5):557. https://doi.org/10.3390/met9050557

Chicago/Turabian StyleFragassa, Cristiano, Matej Babic, Carlos Perez Bergmann, and Giangiacomo Minak. 2019. "Predicting the Tensile Behaviour of Cast Alloys by a Pattern Recognition Analysis on Experimental Data" Metals 9, no. 5: 557. https://doi.org/10.3390/met9050557

APA StyleFragassa, C., Babic, M., Bergmann, C. P., & Minak, G. (2019). Predicting the Tensile Behaviour of Cast Alloys by a Pattern Recognition Analysis on Experimental Data. Metals, 9(5), 557. https://doi.org/10.3390/met9050557