The Role of Acoustic Pressure during Solidification of AlSi7Mg Alloy in Sand Mold Casting

Abstract

1. Introduction

2. Methodology

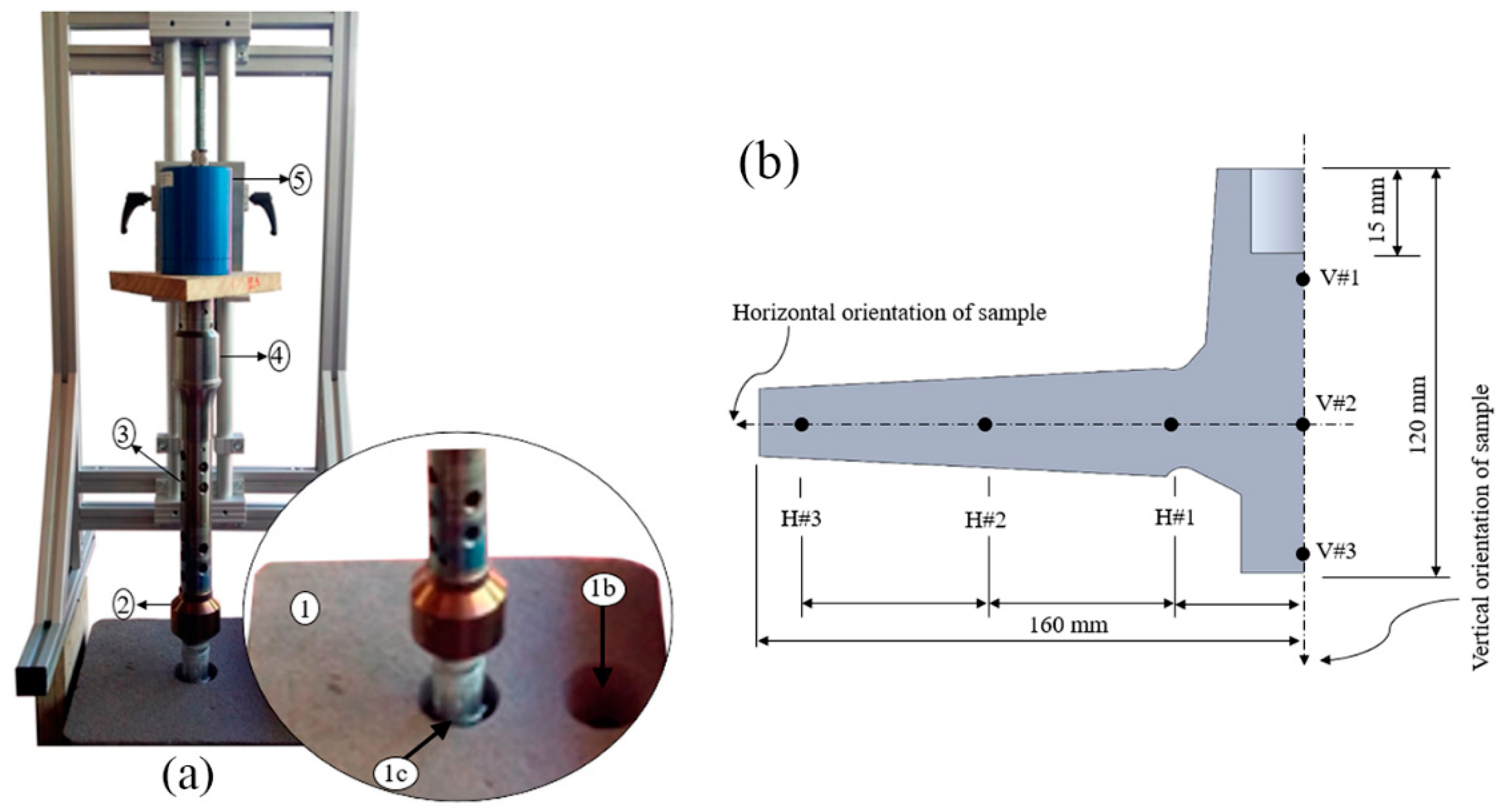

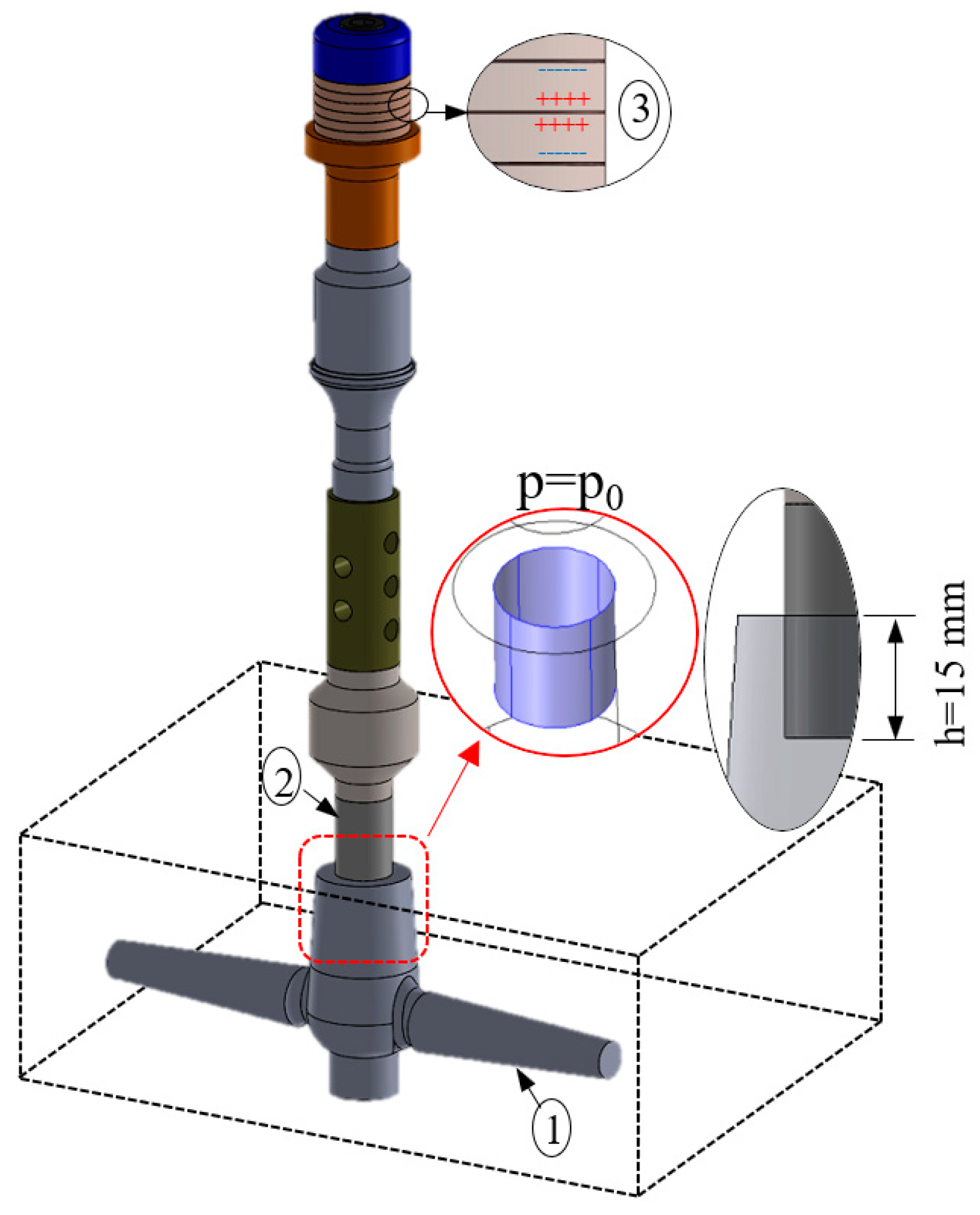

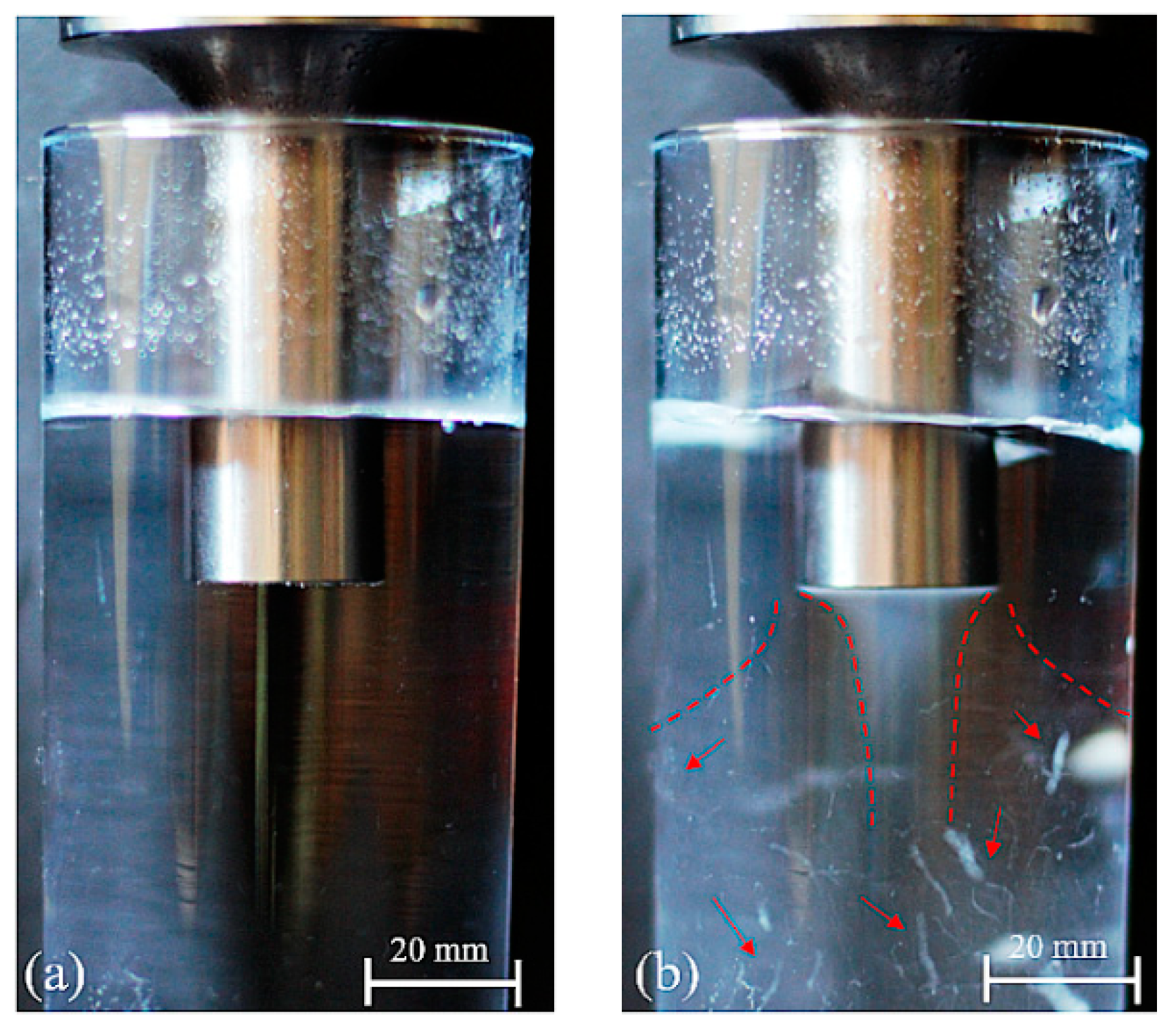

2.1. Experimental Setup and Procedure

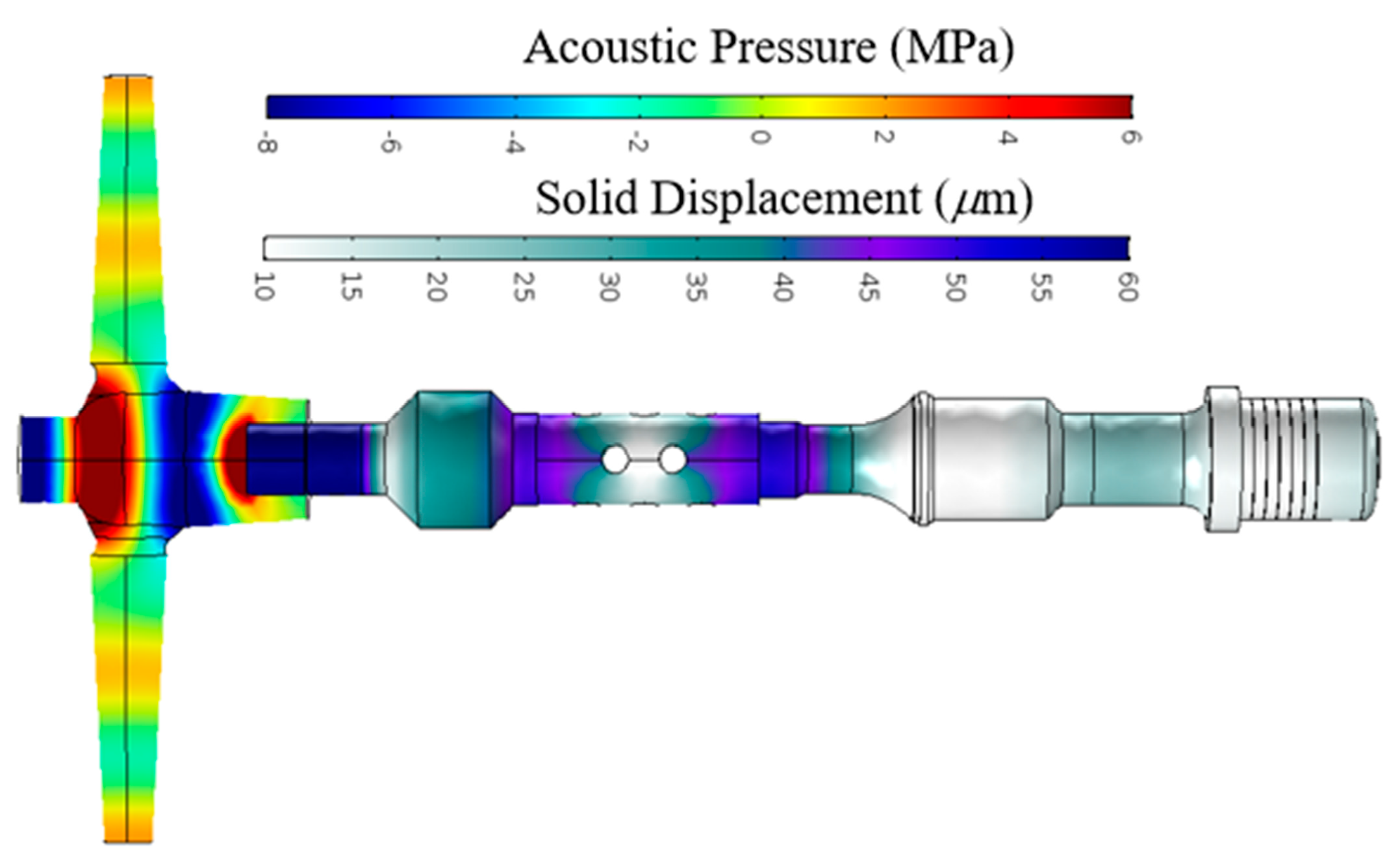

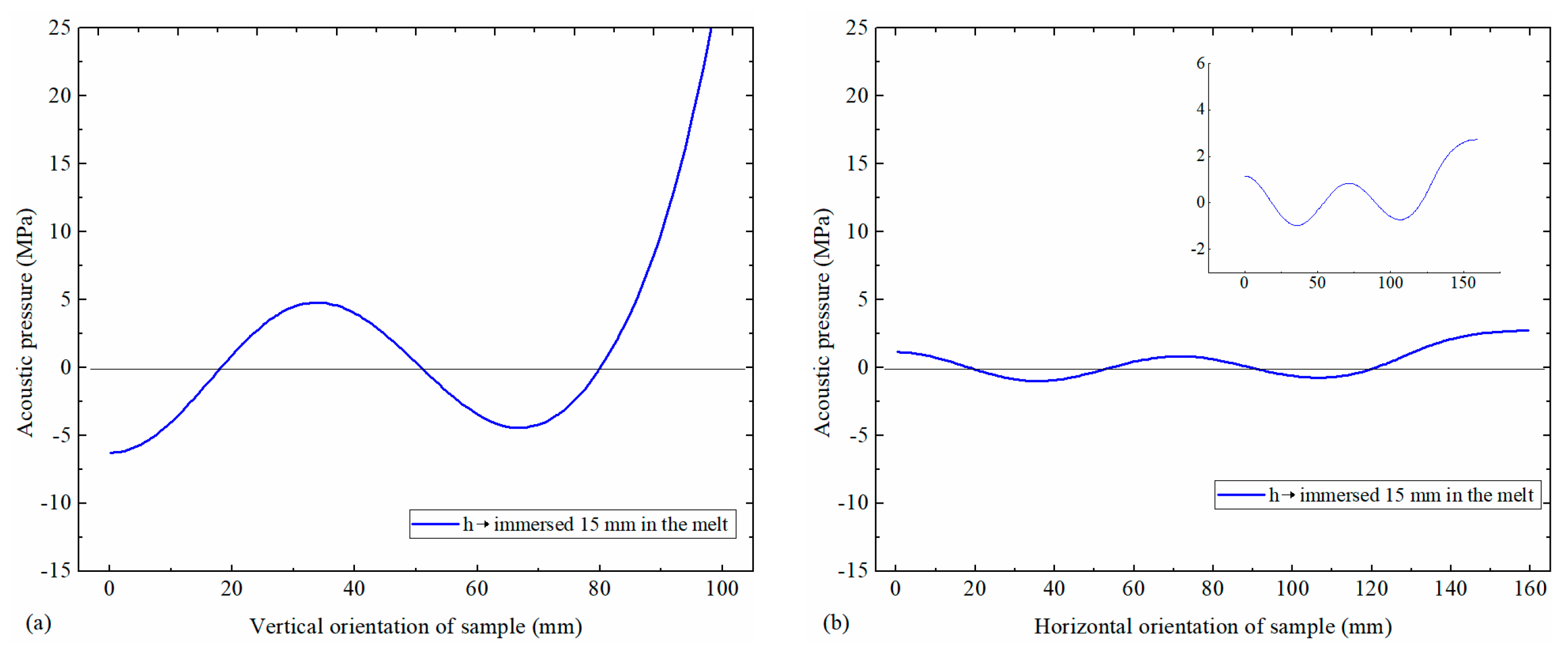

2.2. Computational Modeling

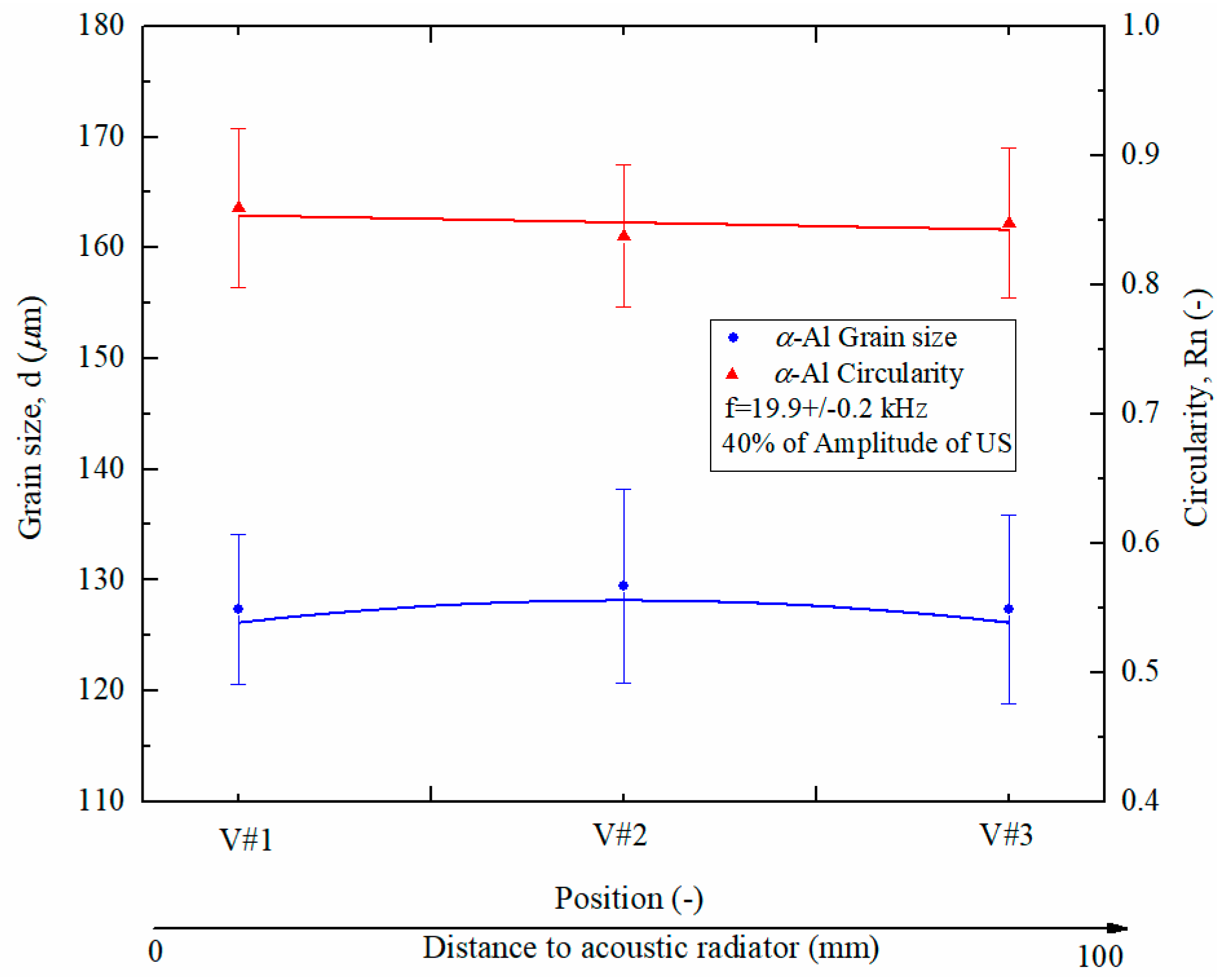

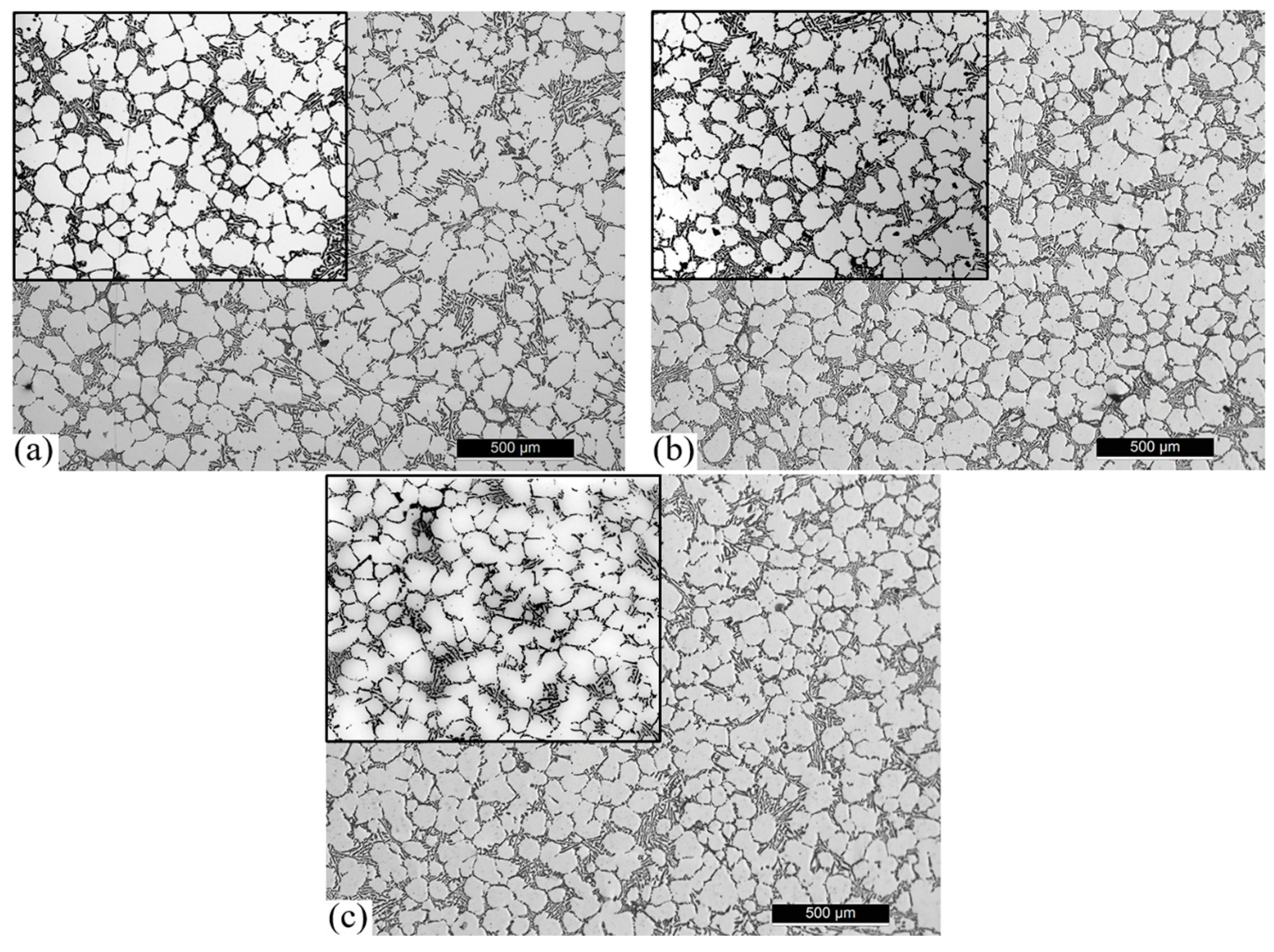

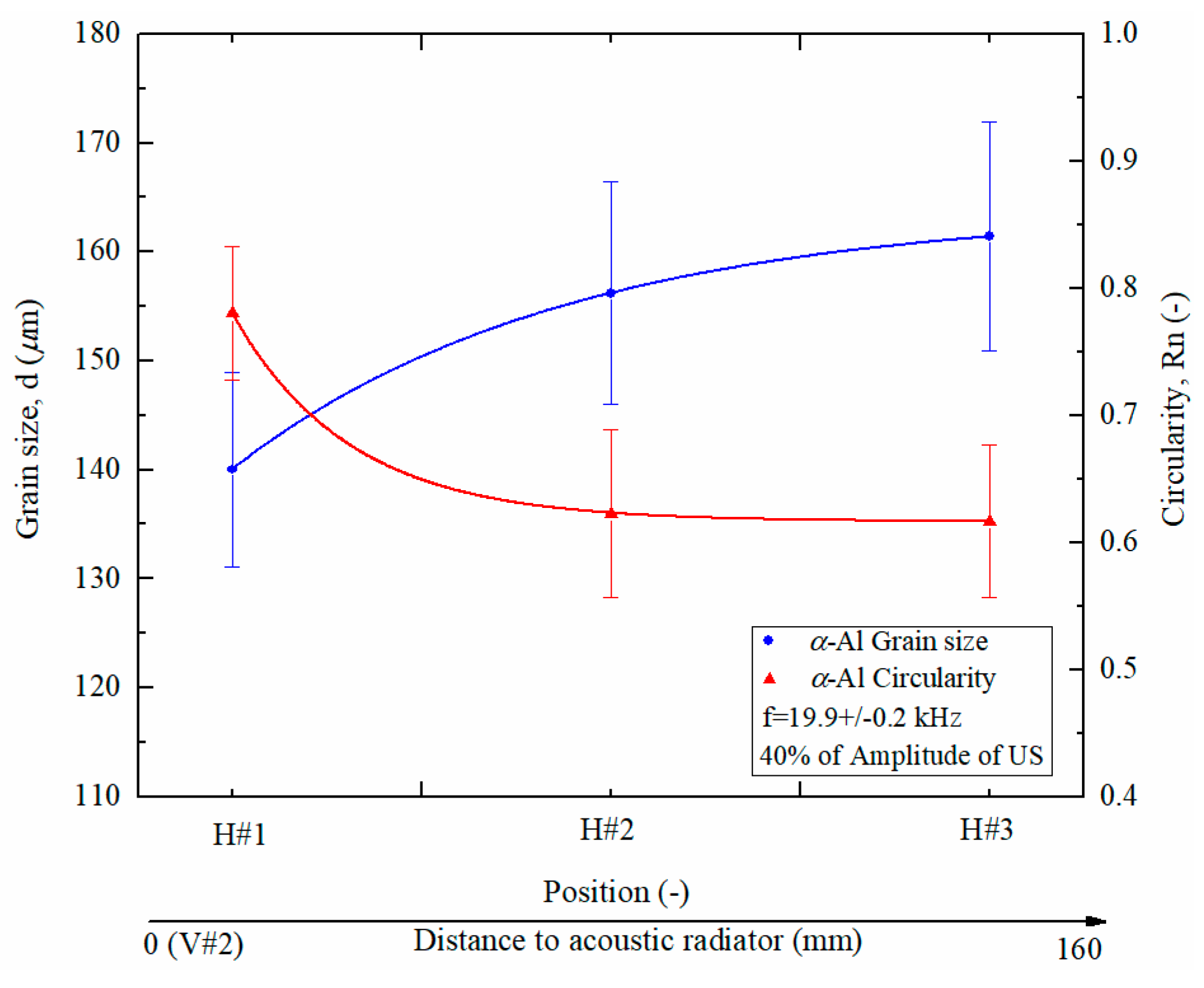

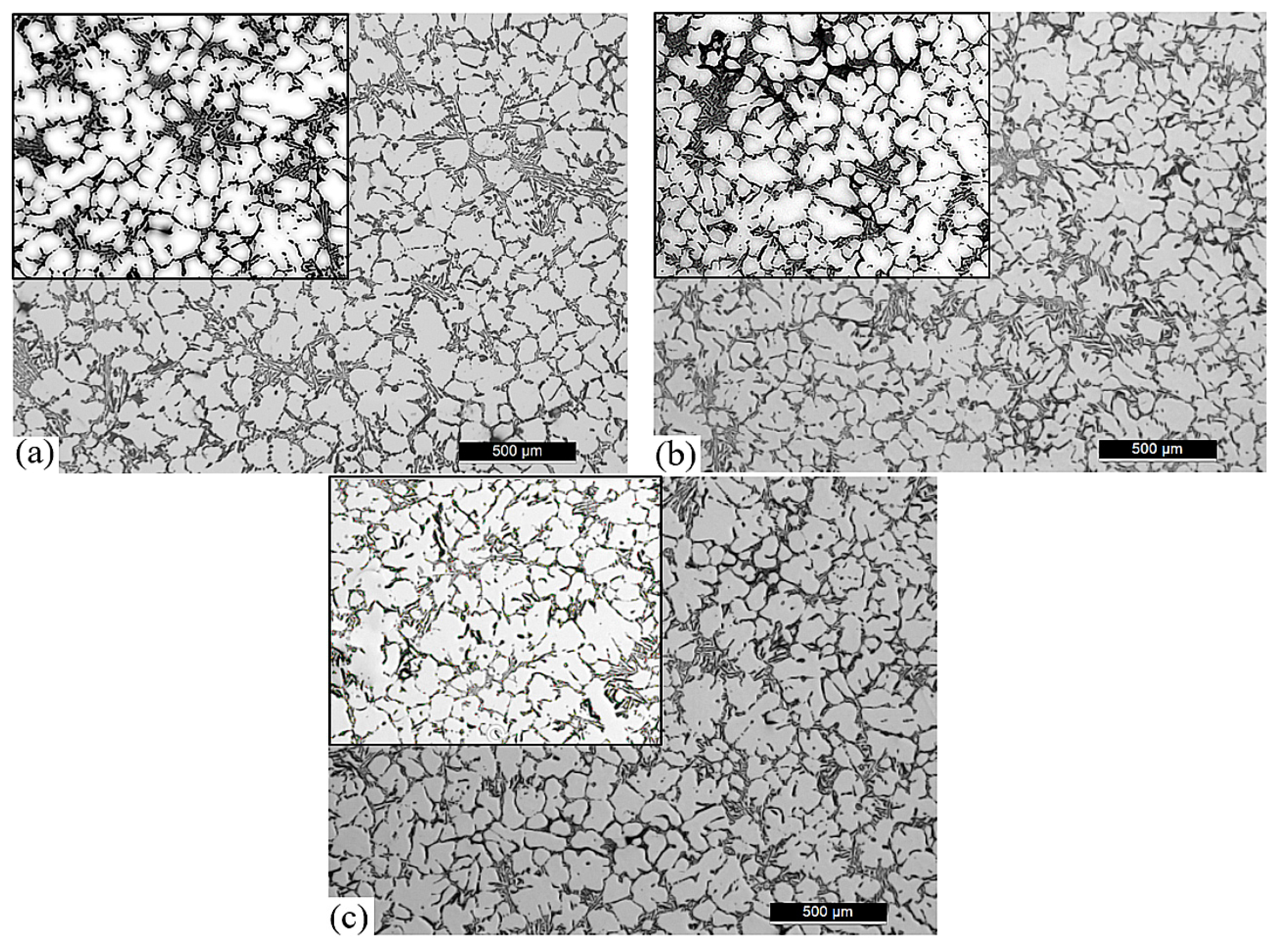

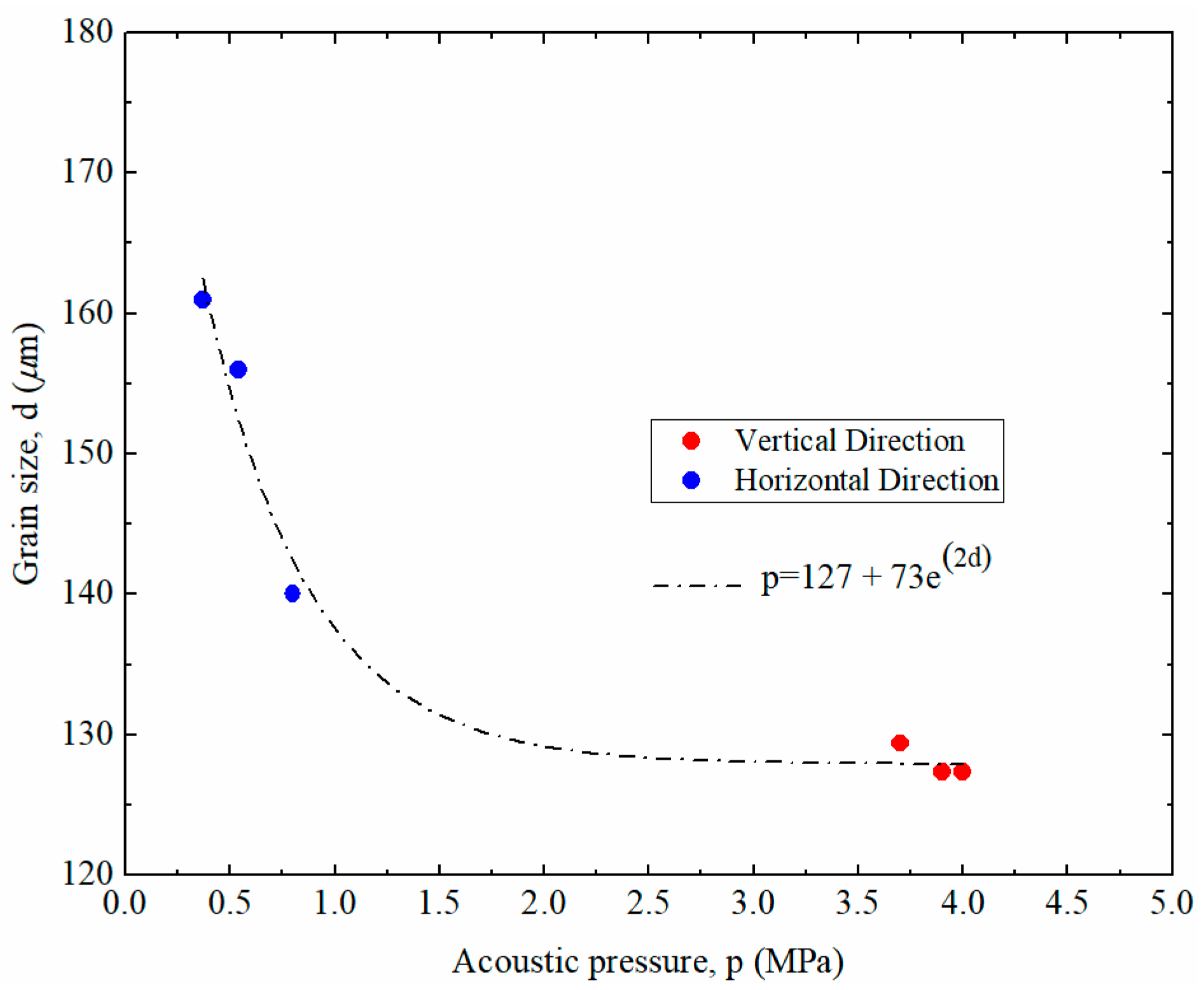

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nguyen, R.T.; Imholte, D.D.; Rios, O.R.; Weiss, D.; Sims, Z.; Stromme, E.; McCall, S.K. Anticipating impacts of introducing aluminum-cerium alloys into the United States automotive market. Resour. Conserv. Recycl. 2019, 144, 340–349. [Google Scholar] [CrossRef]

- Jarry, P.; Rappaz, M. Recent advances in the metallurgy of aluminium alloys. Part I: Solidification and casting. C. R. Phys. 2018, 19, 672–687. [Google Scholar] [CrossRef]

- Liang, G.; Ali, Y.; You, G.; Zhang, M.-X. Effect of cooling rate on grain refinement of cast aluminium alloys. Materialia 2018, 3, 113–121. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, T.; Yao, Z.; Zhu, M. Modeling of hydrogen porosity formation during solidification of dendrites and irregular eutectics in Al–Si alloys. Materialia 2018, 4, 211–220. [Google Scholar] [CrossRef]

- Brůna, M.; Bolibruchová, D.; Pastirčák, R. Numerical Simulation of Porosity for Al Based Alloys. Procedia Eng. 2017, 177, 488–495. [Google Scholar] [CrossRef]

- Su, H.; Toda, H.; Masunaga, R.; Shimizu, K.; Gao, H.; Sasaki, K.; Bhuiyan, M.S.; Uesugi, K.; Takeuchi, A.; Watanabe, Y. Influence of hydrogen on strain localization and fracture behavior in AlZnMgCu aluminum alloys. Acta Mater. 2018, 159, 332–343. [Google Scholar] [CrossRef]

- Jung, J.-G.; Cho, Y.-H.; Lee, J.-M.; Kim, H.-W.; Euh, K. Designing the composition and processing route of aluminum alloys using CALPHAD: Case studies. Calphad 2019, 64, 236–247. [Google Scholar] [CrossRef]

- Rotella, A.; Nadot, Y.; Piellard, M.; Augustin, R.; Fleuriot, M. Fatigue limit of a cast Al-Si-Mg alloy (A357-T6) with natural casting shrinkages using ASTM standard X-ray inspection. Int. J. Fatigue 2018, 114, 177–188. [Google Scholar] [CrossRef]

- Mancilla, E.; Cruz-Méndez, W.; Garduño, I.E.; González-Rivera, C.; Ramírez-Argáez, M.A.; Ascanio, G. Comparison of the hydrodynamic performance of rotor-injector devices in a water physical model of an aluminum degassing ladle. Chem. Eng. Res. Des. 2017, 118, 158–169. [Google Scholar] [CrossRef]

- Haghayeghi, R.; Bahai, H.; Kapranos, P. Effect of ultrasonic argon degassing on dissolved hydrogen in aluminium alloy. Mater. Lett. 2012, 82, 230–232. [Google Scholar] [CrossRef]

- Li, J.; Huang, M.; Ma, M.; Ye, W.; Liu, D.; Sone, D.; Bai, B.; Fang, H. Performance comparison of AlTiC and AlTiB master alloys in grain refinement of commercial and high purity aluminum. Trans. Nonferrous Met. Soc. China 2006, 16, 242–253. [Google Scholar] [CrossRef]

- Lu, L.; Dahle, A.K. Effects of combined additions of Sr and AlTiB grain refiners in hypoeutectic Al–Si foundry alloys. Mater. Sci. Eng. A 2006, 435–436, 288–296. [Google Scholar] [CrossRef]

- Ding, W.; Xu, C.; Hou, X.; Zhao, X.; Chen, T.; Zhao, W.; Xia, T.; Qiao, J. Preparation and synthesis thermokinetics of novel Al-Ti-C-La composite master alloys. J. Alloys Compd. 2019, 776, 904–911. [Google Scholar] [CrossRef]

- Öztürk, İ.; Hapçı Ağaoğlu, G.; Erzi, E.; Dispinar, D.; Orhan, G. Effects of strontium addition on the microstructure and corrosion behavior of A356 aluminum alloy. J. Alloys Compd. 2018, 763, 384–391. [Google Scholar] [CrossRef]

- Barbosa, J.; Puga, H. Ultrasonic Melt Treatment of Light Alloys. Int. J. Met. 2019, 13, 180–189. [Google Scholar] [CrossRef]

- Eskin, D.G.; Tzanakis, I.; Wang, F.; Lebon, G.S.B.; Subroto, T.; Pericleous, K.; Mi, J. Fundamental studies of ultrasonic melt processing. Ultrason. Sonochem. 2019, 52, 455–467. [Google Scholar] [CrossRef] [PubMed]

- Tzanakis, I.; Lebon, G.S.B.; Eskin, D.G.; Pericleous, K.A. Characterisation of the ultrasonic acoustic spectrum and pressure field in aluminium melt with an advanced cavitometer. J. Mater. Process. Technol. 2016, 229, 582–586. [Google Scholar] [CrossRef]

- Barbosa, J.; Puga, H. Ultrasonic melt processing in the low pressure investment casting of Al alloys. J. Mater. Process. Technol. 2017, 244, 150–156. [Google Scholar] [CrossRef]

- Tuan, N.Q.; Puga, H.; Barbosa, J.; Pinto, A.M.P. Grain refinement of Al-Mg-Sc alloy by ultrasonic treatment. Met. Mater. Int. 2015, 21, 72–78. [Google Scholar] [CrossRef]

- Kotadia, H.R.; Qian, M.; Das, A. Solidification of aluminium alloys under ultrasonication: An overview. Trans. Indian Inst. Met. 2018, 71, 2681–2686. [Google Scholar] [CrossRef]

- Wang, G.; Wang, Q.; Easton, M.A.; Dargusch, M.S.; Qian, M.; Eskin, D.G.; StJohn, D.H. Role of ultrasonic treatment, inoculation and solute in the grain refinement of commercial purity aluminium. Sci. Rep. 2017, 7, 9729. [Google Scholar] [CrossRef] [PubMed]

- Puga, H.; Barbosa, J.; Costa, S.; Ribeiro, S.; Pinto, A.M.P.; Prokic, M. Influence of indirect ultrasonic vibration on the microstructure and mechanical behavior of Al–Si–Cu alloy. Mater. Sci. Eng. A 2013, 560, 589–595. [Google Scholar] [CrossRef]

- Puga, H.; Carneiro, V.; Barbosa, J.; Vieira, V. Effect of ultrasonic treatment in the static and dynamic mechanical behavior of AZ91D Mg alloy. Metals 2015, 5, 2210–2221. [Google Scholar] [CrossRef]

- Weiss, D. Chapter 5—Advances in the Sand Casting of Aluminium Alloys. In Fundamentals of Aluminium Metallurgy; Lumley, R.N., Ed.; Woodhead Publishing: Sawston, UK, 2018; pp. 159–171. ISBN 978-0-08-102063-0. [Google Scholar]

- Shangguan, H.; Kang, J.; Deng, C.; Hu, Y.; Huang, T. 3D-printed shell-truss sand mold for aluminum castings. J. Mater. Process. Technol. 2017, 250, 247–253. [Google Scholar] [CrossRef]

- Carneiro, V.H.; Puga, H. Solution treatment enhances both static and damping properties of Al–Si–Mg alloys. Metall. Mater. Trans. A 2018, 49, 5942–5945. [Google Scholar] [CrossRef]

- Carneiro, V.H.; Puga, H.; Meireles, J. Heat treatment as a route to tailor the yield-damping properties in A356 alloys. Mater. Sci. Eng. A 2018, 729, 1–8. [Google Scholar] [CrossRef]

- Puga, H.; Barbosa, J.; Seabra, E.; Ribeiro, S.; Prokic, M. The influence of processing parameters on the ultrasonic degassing of molten AlSi9Cu3 aluminium alloy. Mater. Lett. 2009, 63, 806–808. [Google Scholar] [CrossRef]

- Eskin, G.I. Ultrasonic Treatment of Light Alloy Melts; CRC Press: Boca Raton, FL, USA, 1998; ISBN 1-4987-0179-5. [Google Scholar]

- Mozammil, S.; Karloopia, J.; Jha, P.K. Investigation of porosity in Al casting. Mater. Today Proc. 2018, 5, 17270–17276. [Google Scholar] [CrossRef]

- Dispinar, D.; Akhtar, S.; Nordmark, A.; Di Sabatino, M.; Arnberg, L. Degassing, hydrogen and porosity phenomena in A356. Mater. Sci. Eng. A 2010, 527, 3719–3725. [Google Scholar] [CrossRef]

- Puga, H.; Costa, S.; Barbosa, J.; Ribeiro, S.; Prokic, M. Influence of ultrasonic melt treatment on microstructure and mechanical properties of AlSi9Cu3 alloy. J. Mater. Process. Technol. 2011, 211, 1729–1735. [Google Scholar] [CrossRef]

| Alloy | Chemical Composition (wt%) | Source | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Si | Fe | Mg | Cu | Mn | Zn | Ti | Al | Res. | ||

| Std AlSi7Mg0.3 | 6.5–7.5 | 0.6 | 0.20–0.45 | 0.25 | 0.35 | 0.35 | 0.25 | Bal. | 0.15 | (1) |

| Used alloy | 7.44 | 0.0 | 0.32 | 0.07 | 0.07 | 0.05 | 0.11 | 91.53 | 0.21 | (2) |

| (1) According to Aluminum Association, Inc. | ||||||||||

| (2) Composition of the alloy used in the experimental work. | ||||||||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Puga, H.; Barbosa, J.; Carneiro, V.H. The Role of Acoustic Pressure during Solidification of AlSi7Mg Alloy in Sand Mold Casting. Metals 2019, 9, 490. https://doi.org/10.3390/met9050490

Puga H, Barbosa J, Carneiro VH. The Role of Acoustic Pressure during Solidification of AlSi7Mg Alloy in Sand Mold Casting. Metals. 2019; 9(5):490. https://doi.org/10.3390/met9050490

Chicago/Turabian StylePuga, H., J. Barbosa, and V. H. Carneiro. 2019. "The Role of Acoustic Pressure during Solidification of AlSi7Mg Alloy in Sand Mold Casting" Metals 9, no. 5: 490. https://doi.org/10.3390/met9050490

APA StylePuga, H., Barbosa, J., & Carneiro, V. H. (2019). The Role of Acoustic Pressure during Solidification of AlSi7Mg Alloy in Sand Mold Casting. Metals, 9(5), 490. https://doi.org/10.3390/met9050490