Effects of Prebending Radii on Microstructure and Fatigue Performance of Al-Zn-Mg-Cu Aluminum Alloy after Creep Age Forming

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

2.2. Creep Age Forming Experiments

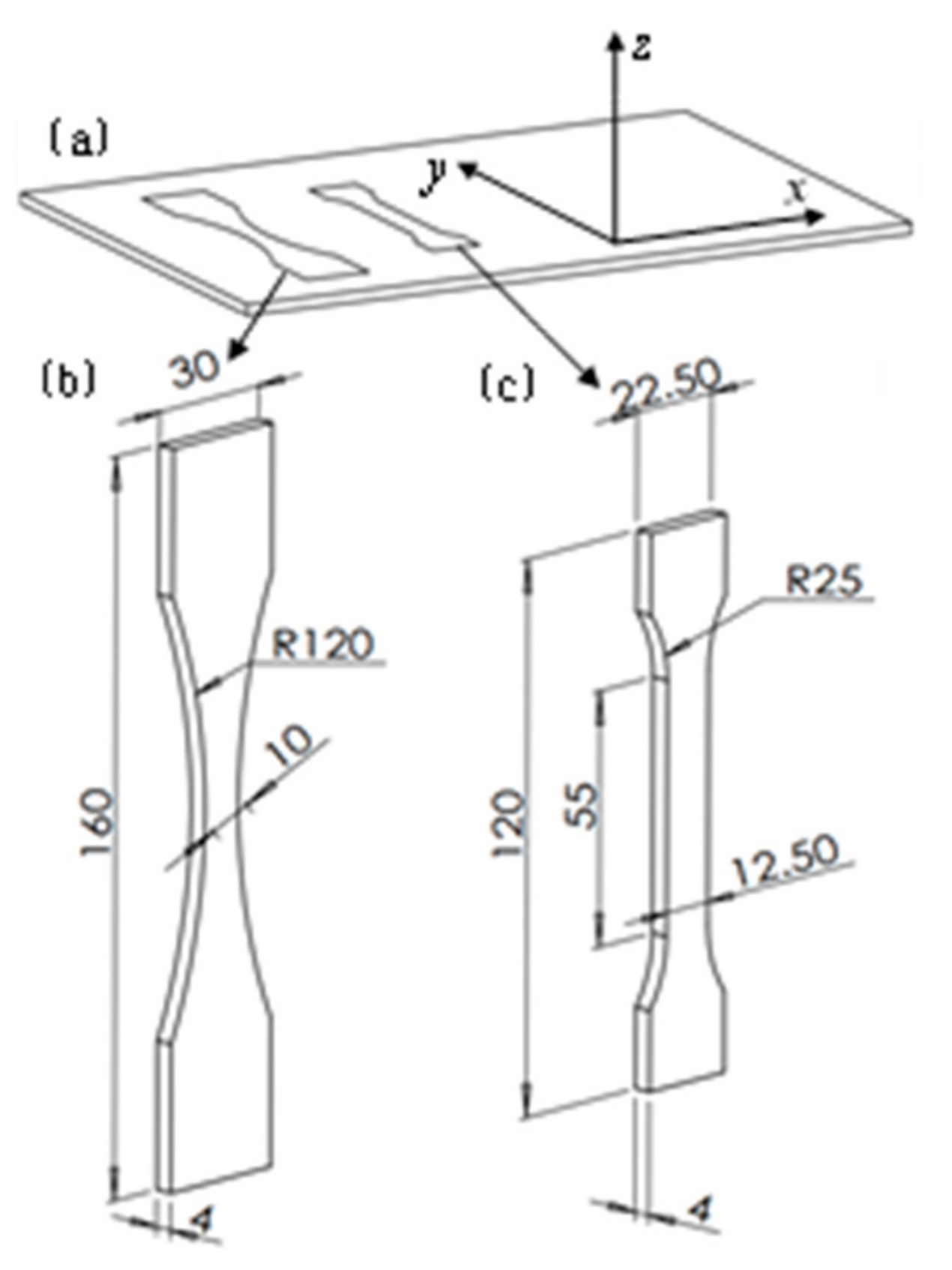

2.3. Specimen Preparation

2.4. Testing

2.5. Microstructure Observation

3. Results and Discussion

3.1. Effects of Prebending Radii on Mechanical Properties

3.2. Effects of Prebending Radii on HCF

3.3. Effects of Prebending Radii on Microstructure

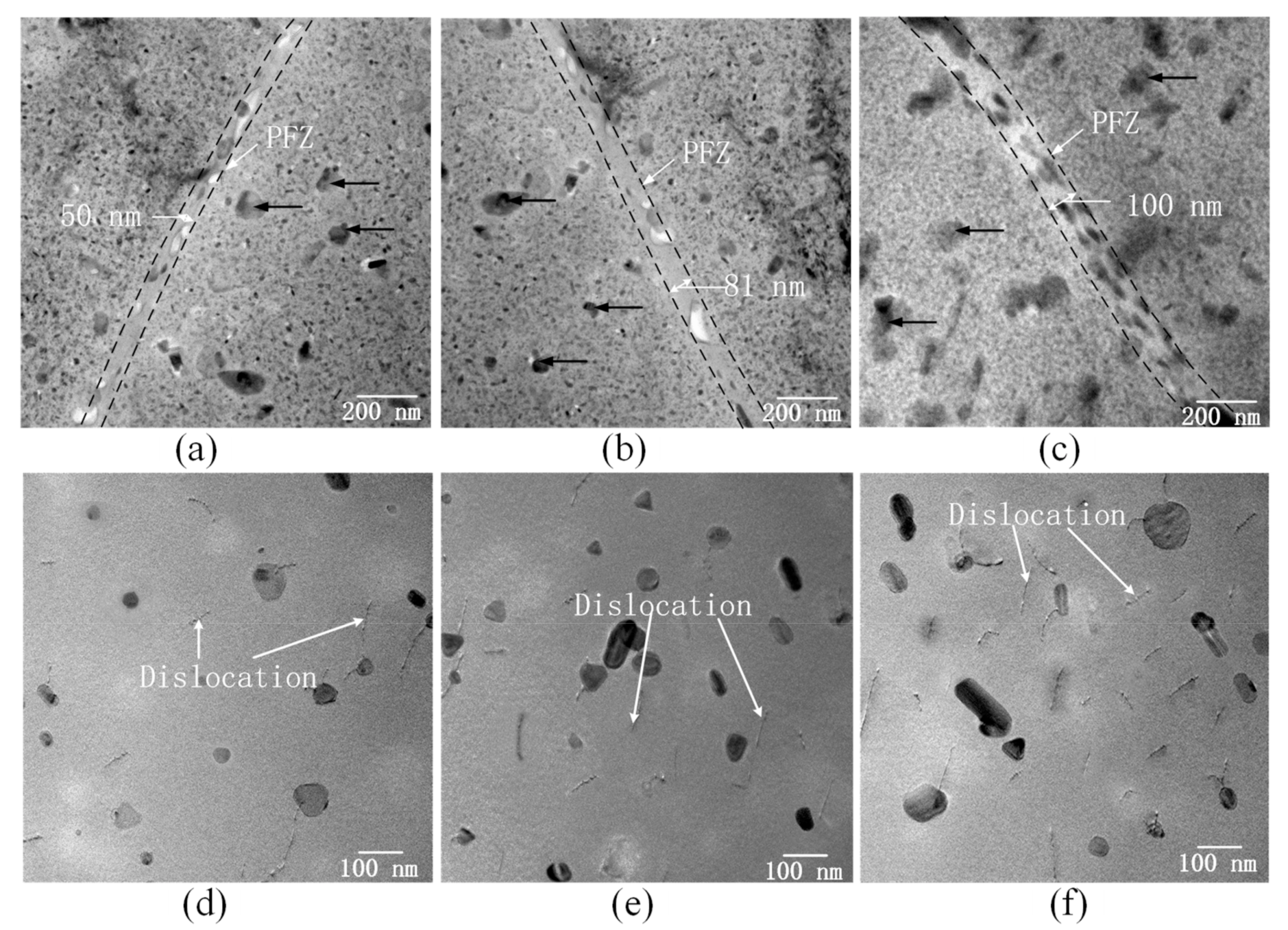

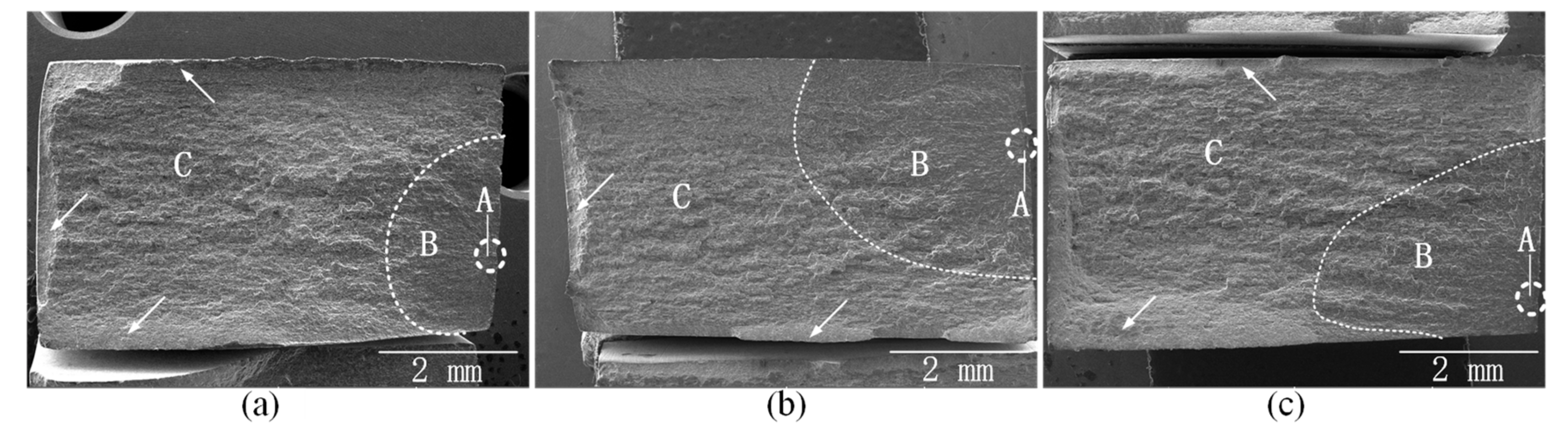

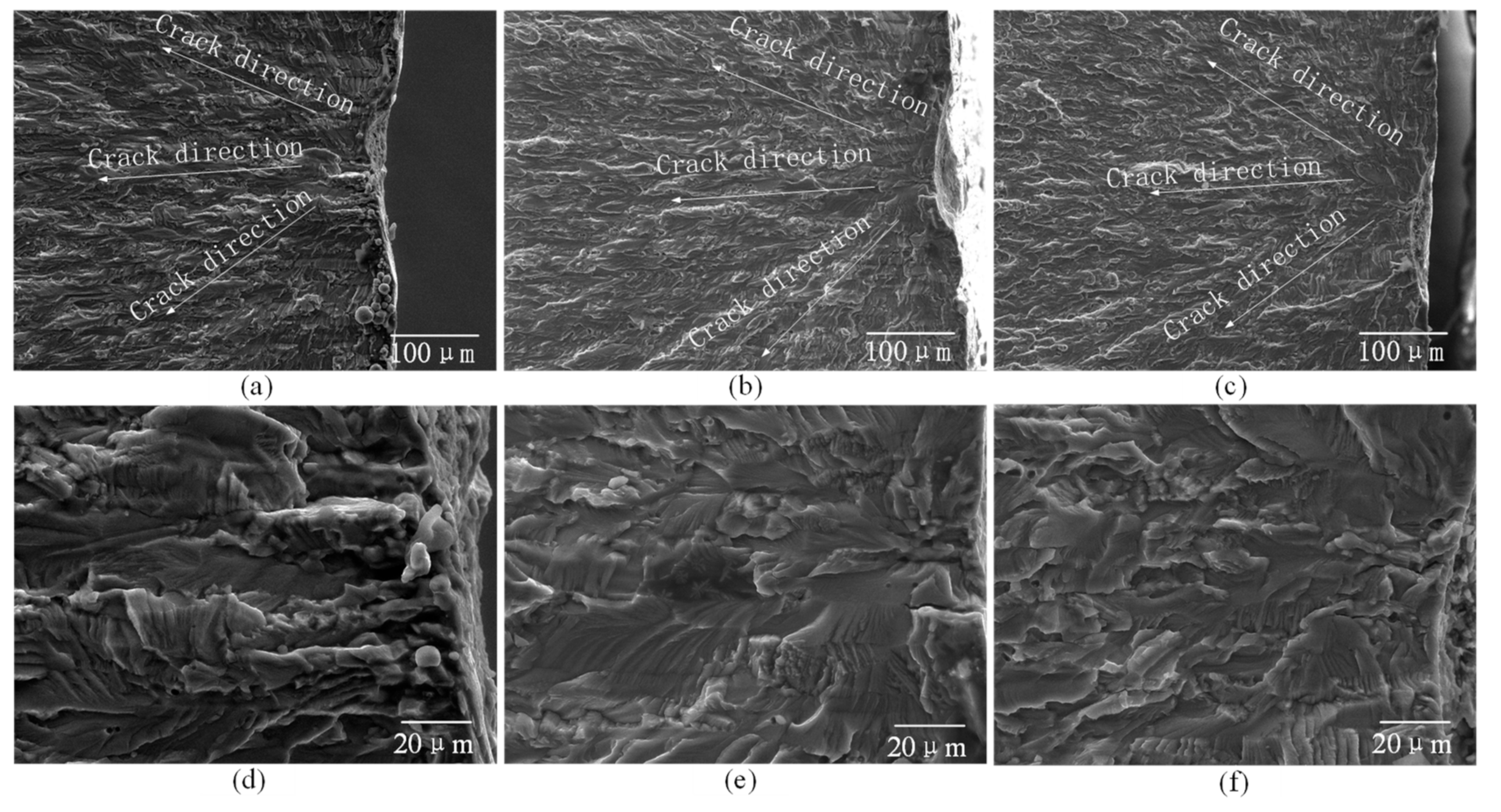

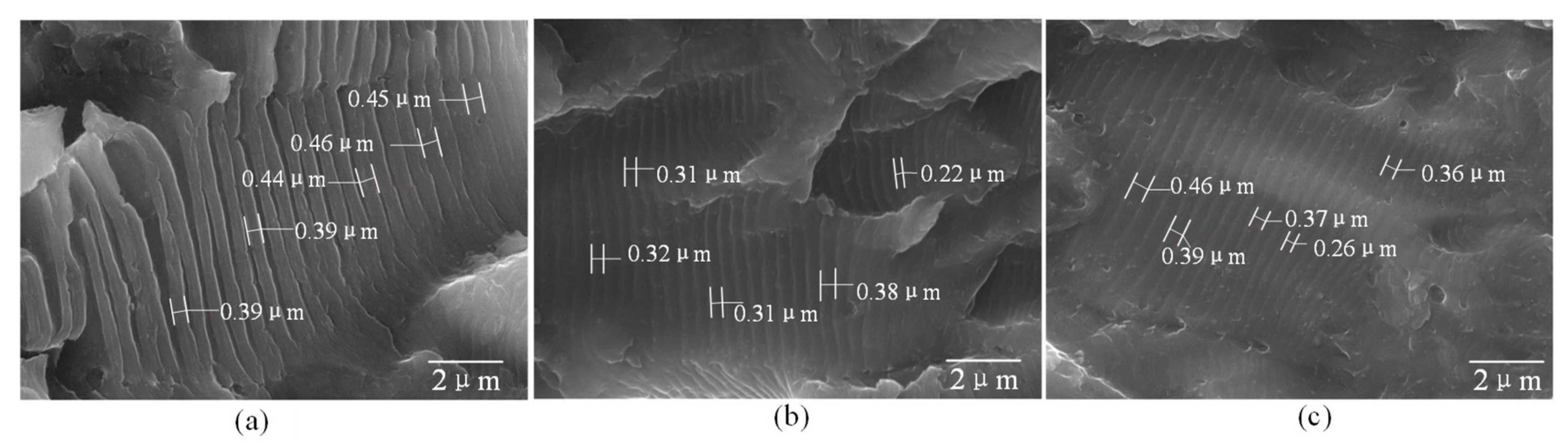

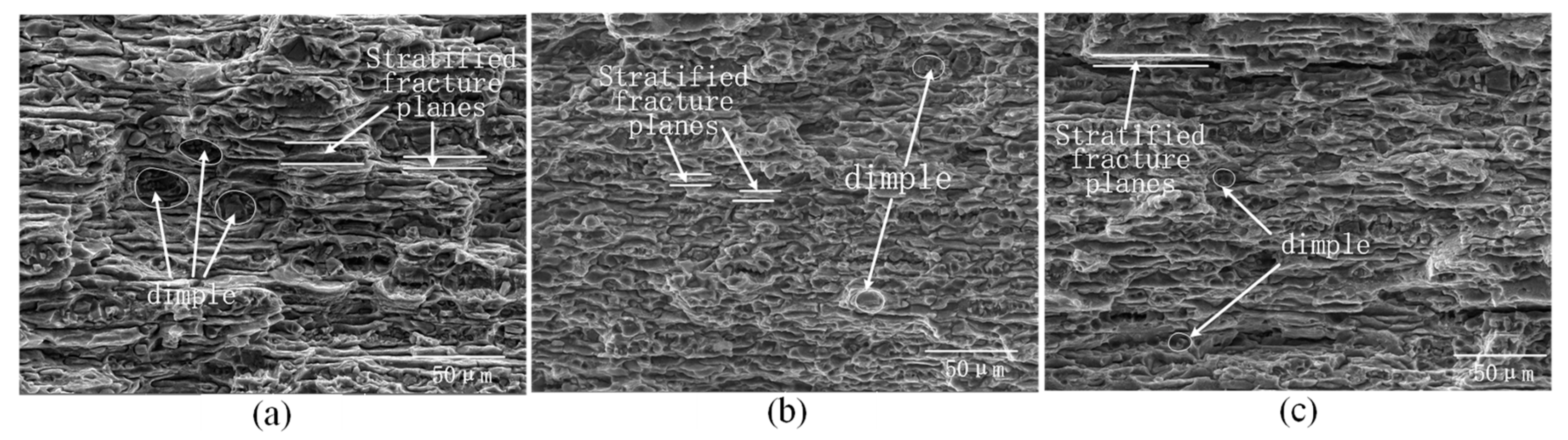

3.4. Effects of Prebending Radii on Fracture Morphology

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhu, A.W.; Starke, E.A. Materials aspects of age-forming of Al-xCu Alloys. J. Mater. Process. Technol. 2001, 117, 354–358. [Google Scholar] [CrossRef]

- Inforzato, D.J.; Costa, J.P.R.; Fernandez, F.F.; Travessa, D.N. Creep-age forming of AA7475 aluminum panels for aircraft lower wing skin application. Mater. Res. 2012, 15, 596–602. [Google Scholar] [CrossRef]

- Liu, C.; Liu, Y.; Li, S.B.; Ma, L.Y.; Zhao, X.Q.; Wang, Q. Effect of creep aging forming on the fatigue crack growth of an AA2524 alloy. Mater. Sci. Eng. A 2018, 725, 375–381. [Google Scholar] [CrossRef]

- Brewer, H. Age forming integrally stiffened, aluminum aerospace structures in an autoclave. In Proceedings of the Aircraft Design & Operations Meeting, Seattle, WA, USA, 31 July–2 August 1989. [Google Scholar]

- Pitch, E.P.D.; Styles, C.M. Creep age forming of 2024, 8090 and 7449 alloys. Mater. Sci. Forum 2000, 331–337, 455–460. [Google Scholar] [CrossRef]

- Huang, X.; Zeng, Y.S. Study on spring back during creep age forming of aluminum alloy 7075. J. Plast. Eng. 2012, 19, 79–82. [Google Scholar] [CrossRef]

- Jin, X.; Wan, M.; Li, C. Effect of creep age forming on fatigue for 7B04 aluminum alloy. Forg. Stamp. Technol. 2011, 26, 124–127. [Google Scholar] [CrossRef]

- Adachi, T.; Kimura, S.; Nagayama, T. Age forming technology for aircraft wing skin. Mater. Forum 2004, 28, 202–207. [Google Scholar]

- Eberl, F.; Gardineer, S.; Campanile, G. Age formable panels for commercial aircraft. Proc. Inst. Mech. Eng. Part G Aerosp. Eng. 2008, 222, 872–886. [Google Scholar] [CrossRef]

- Peddieson, J.; Buchanan, G.R. Mathematical modeling of an age-forming process. Math. Comput. Model. 1990, 14, 1057–1060. [Google Scholar] [CrossRef]

- Sallah, M.H.; Peddieson, J.; Foroudastan, S. A mathematical model of autoclave age forming. J. Mater. Process. Technol. 1991, 28, 211–219. [Google Scholar] [CrossRef]

- Ho, K.C.; Lin, J.; Dean, T.A. Constitutive modeling of primary creep for age forming an aluminum alloy. J. Mater. Process. Technol. 2004, 153, 122–127. [Google Scholar] [CrossRef]

- Sarioglu, F.; Orhaner, F.O. Effect of prolonged heating at 130 °C on fatigue crack propagation of 2024 Al alloy in three orientations. Mater. Sci. Eng. A 1998, 248, 115–119. [Google Scholar] [CrossRef]

- Bray, G.H.; Glazov, M.; Rioja, R.J.; Li, D.; Gangloff, R.P. Effect of artificial aging on the fatigue crack propagation resistance of 2000 series aluminum alloys. Int. J. Fatigue 2001, 23, S265–S276. [Google Scholar] [CrossRef]

- Lumley, R.N.; O’Donnell, R.G.; Polmear, I.J. Enhanced fatigue resistance by under aging an Al-Cu-Mg-Ag alloy. Mater. Forum 2005, 29, 256–261. [Google Scholar]

- Chen, G.-Q.; Fu, X.-S.; Zhao, F.; Zhou, W.-L. Microstructures and mechanical properties of 2A12 aluminum alloy after age forming. Trans. Nonferrous Met. Soc. China 2012, 22, 1975–1980. [Google Scholar] [CrossRef]

- Yang, D.L.; Liu, Y.L.; Li, S.B.; Ma, L.Y.; Liu, C.; Yi, J.H. Effects of aging temperature on microstructure and high cycle fatigue performance of 7075 aluminum alloy. J. Wuhan Univ. Technol. (Mater. Sci.) 2017, 32, 677–684. [Google Scholar] [CrossRef]

- Zhan, L.H.; Li, Y.G.; Huang, M.H. Microstructures and properties of 2124 alloy creep ageing under stress. J. Cent. South Univ. (Sci. Technol.) 2012, 43, 926–931. [Google Scholar]

- Zhu, A.W.; Starke, E.A. Stress ageing of Al-xCu alloys: Experiments. Acta Mater. 2001, 49, 2285–2295. [Google Scholar] [CrossRef]

- Liu, J.H.; Li, D.; Liu, P.Y.; Guo, B.L.; Zhu, G.W. Effect of ageing and retrogression treatments on mechanical and corrosion properties of 7075 aluminum alloy. Trans. Met. Heat Treat. 2002, 23, 50–53. [Google Scholar] [CrossRef]

- Liu, D.H.; Xie, Y.X.; Li, J.C. Influence of process parameters on creep age forming formability of 7075 aluminum alloy sheets. Mater. Sci. Technol. 2015, 23, 50–56. [Google Scholar] [CrossRef]

- Yang, D.L.; Liu, Y.L.; Li, S.B.; Yi, J.H.; Tao, J. Investigation of uniaxial asymmetric high-cycle fatigue failure behavior of 7075-T651 Aluminum Alloy Sheet. In Proceedings of the International Conference on Material Science and Applications (ICMSA 2015), Suzhou, China, 13–14 June 2015; Atlantis Press: Paris, France. [Google Scholar] [CrossRef]

- Li, C.; Dai, S.L.; Zhang, K.; Ru, J.G. Effect of stress on microstructure and mechanical properties during age forming process of 7050 aluminum alloy. Hangkong Cailiao Xuebao J. Aeronaut. Mater. 2013, 33, 19–23. [Google Scholar] [CrossRef]

- Wang, C.H.; Zhang, T.; Yin, H.X.; Lv, Z.F. Effect of aging treatment on microstructure and properties of 7075 aluminum alloy. Heat Treat. Met. 2017, 42, 87–90. [Google Scholar] [CrossRef]

- Suresh, S. Fatigue of Materials; Cambridge University Press: Cambridge, UK, 1998; pp. 238–248. [Google Scholar] [CrossRef]

| Group No. | Temperature/K | Time/h | ρ/mm |

|---|---|---|---|

| CT1 | 443 | 10 | 1500 |

| CT2 | 443 | 10 | 1000 |

| CT3 | 443 | 10 | 500 |

| Group No. | Prebending Radii ρ/mm | Average Hardness/HV | Average UTS σb/MPa | Average YS σ0.2/MPa | Average δ/% |

|---|---|---|---|---|---|

| CT1 | 1500 | 187 | 569.6 | 505 | 12.6 |

| CT2 | 1000 | 183 | 552.47 | 468.64 | 12.51 |

| CT3 | 500 | 172 | 538.36 | 466.51 | 6.12 |

| The standard deviation | - | 7.77 | 15.64 | 21.63 | 3.72 |

| Group No. | Prebending Radii/mm | Conditional Fatigue Limits/MPa |

|---|---|---|

| CT1 | 1500 | 188.91 |

| CT2 | 1000 | 178.27 |

| CT3 | 500 | 169.44 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, D.; Miao, J.; Zhang, F.; Fu, Z.; Liu, Y. Effects of Prebending Radii on Microstructure and Fatigue Performance of Al-Zn-Mg-Cu Aluminum Alloy after Creep Age Forming. Metals 2019, 9, 630. https://doi.org/10.3390/met9060630

Yang D, Miao J, Zhang F, Fu Z, Liu Y. Effects of Prebending Radii on Microstructure and Fatigue Performance of Al-Zn-Mg-Cu Aluminum Alloy after Creep Age Forming. Metals. 2019; 9(6):630. https://doi.org/10.3390/met9060630

Chicago/Turabian StyleYang, Dalian, Jingjing Miao, Fanyu Zhang, Zhuo Fu, and Yilun Liu. 2019. "Effects of Prebending Radii on Microstructure and Fatigue Performance of Al-Zn-Mg-Cu Aluminum Alloy after Creep Age Forming" Metals 9, no. 6: 630. https://doi.org/10.3390/met9060630

APA StyleYang, D., Miao, J., Zhang, F., Fu, Z., & Liu, Y. (2019). Effects of Prebending Radii on Microstructure and Fatigue Performance of Al-Zn-Mg-Cu Aluminum Alloy after Creep Age Forming. Metals, 9(6), 630. https://doi.org/10.3390/met9060630