Microstructure and Magnetic Properties of Mn55Bi45 Powders Obtained by Different Ball Milling Processes

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

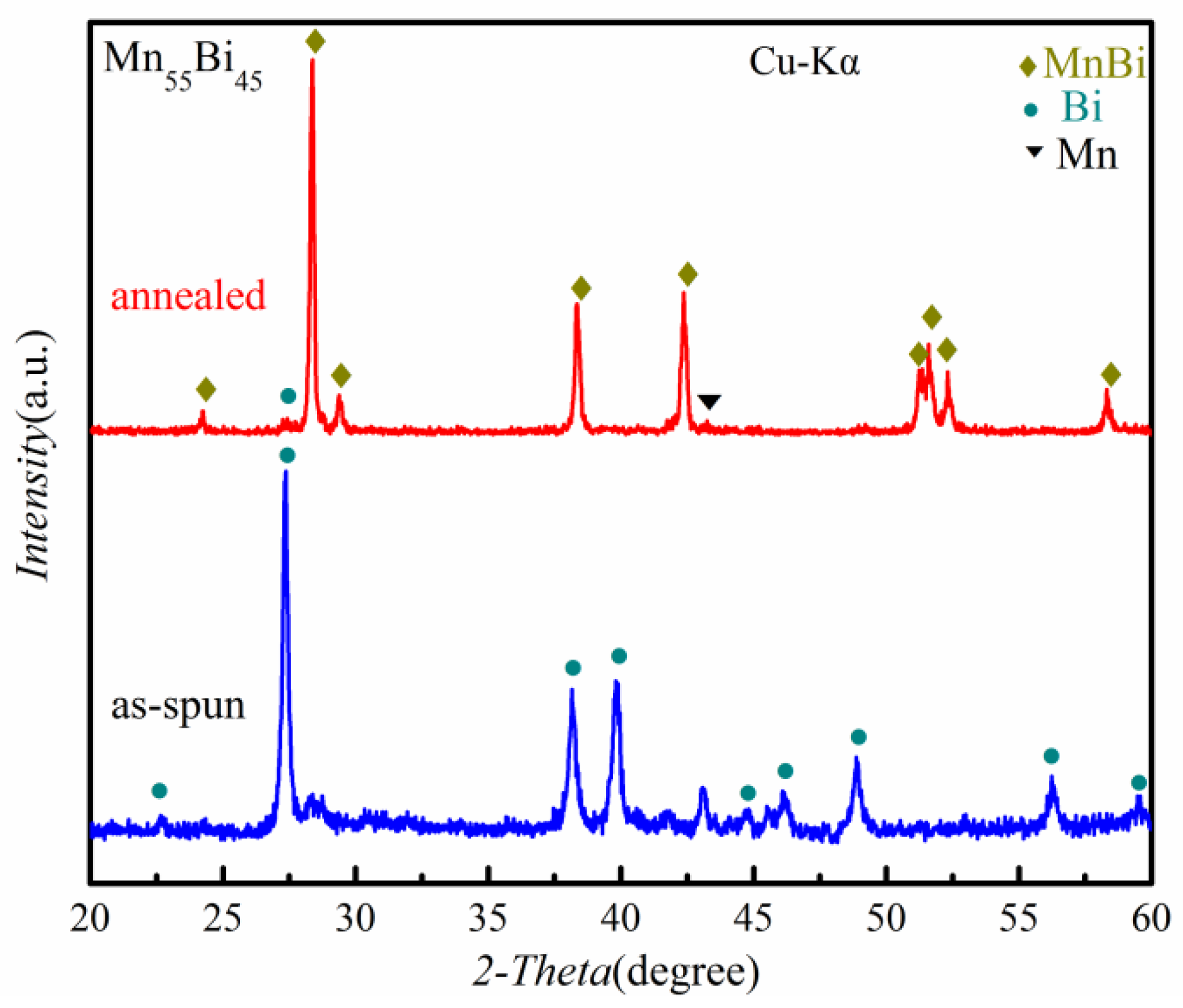

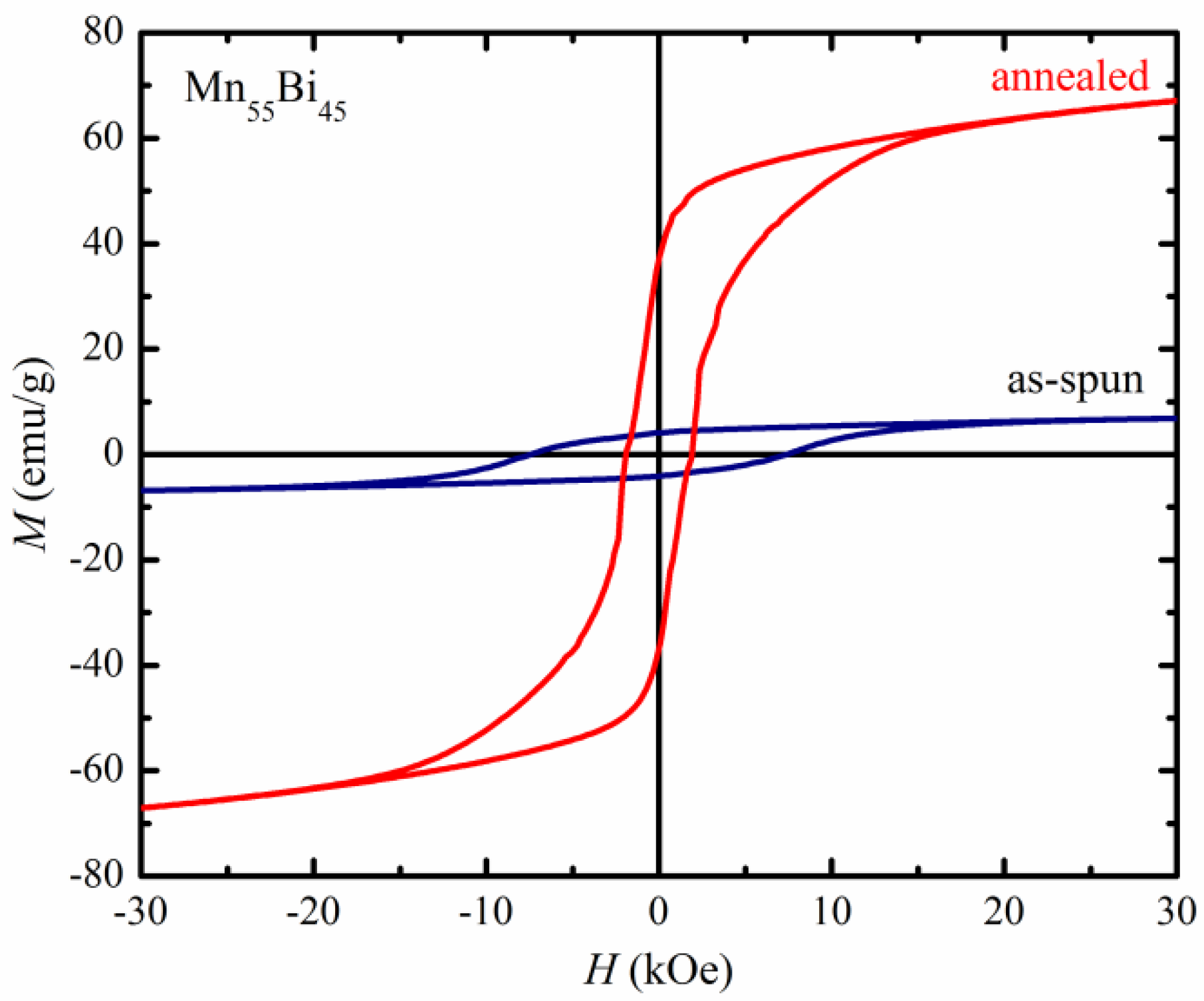

3.1. High Purity of LTP MnBi Ribbons

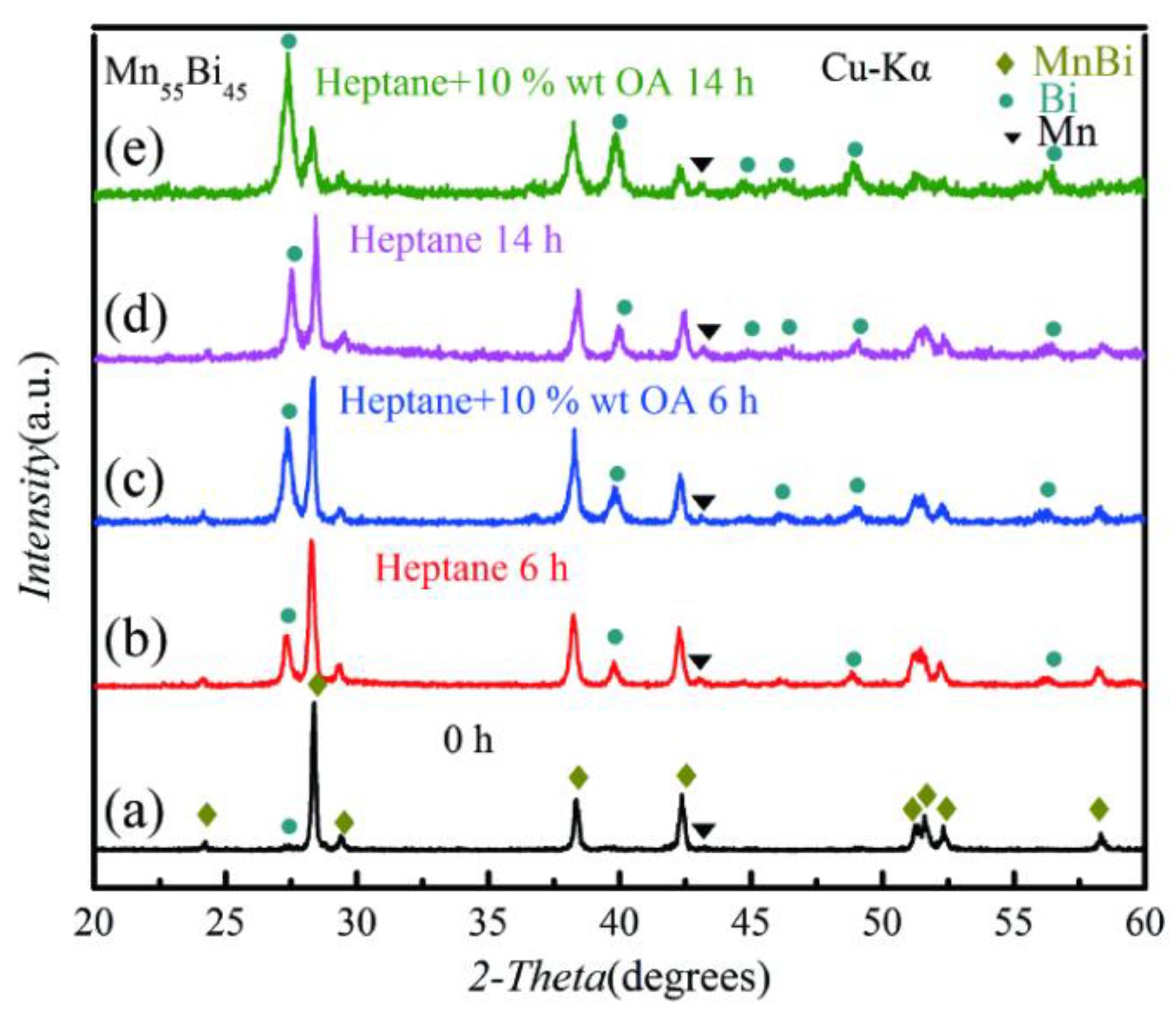

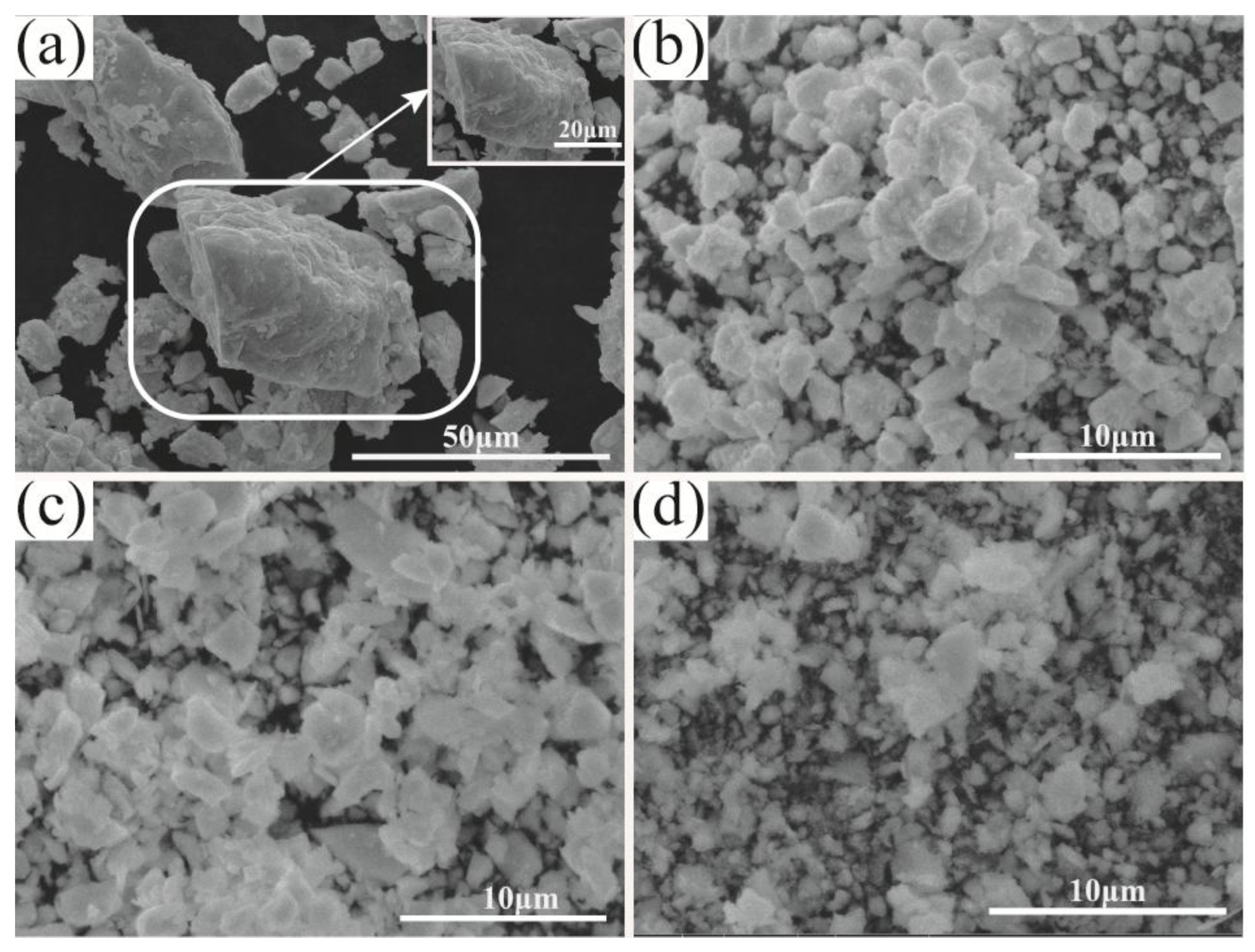

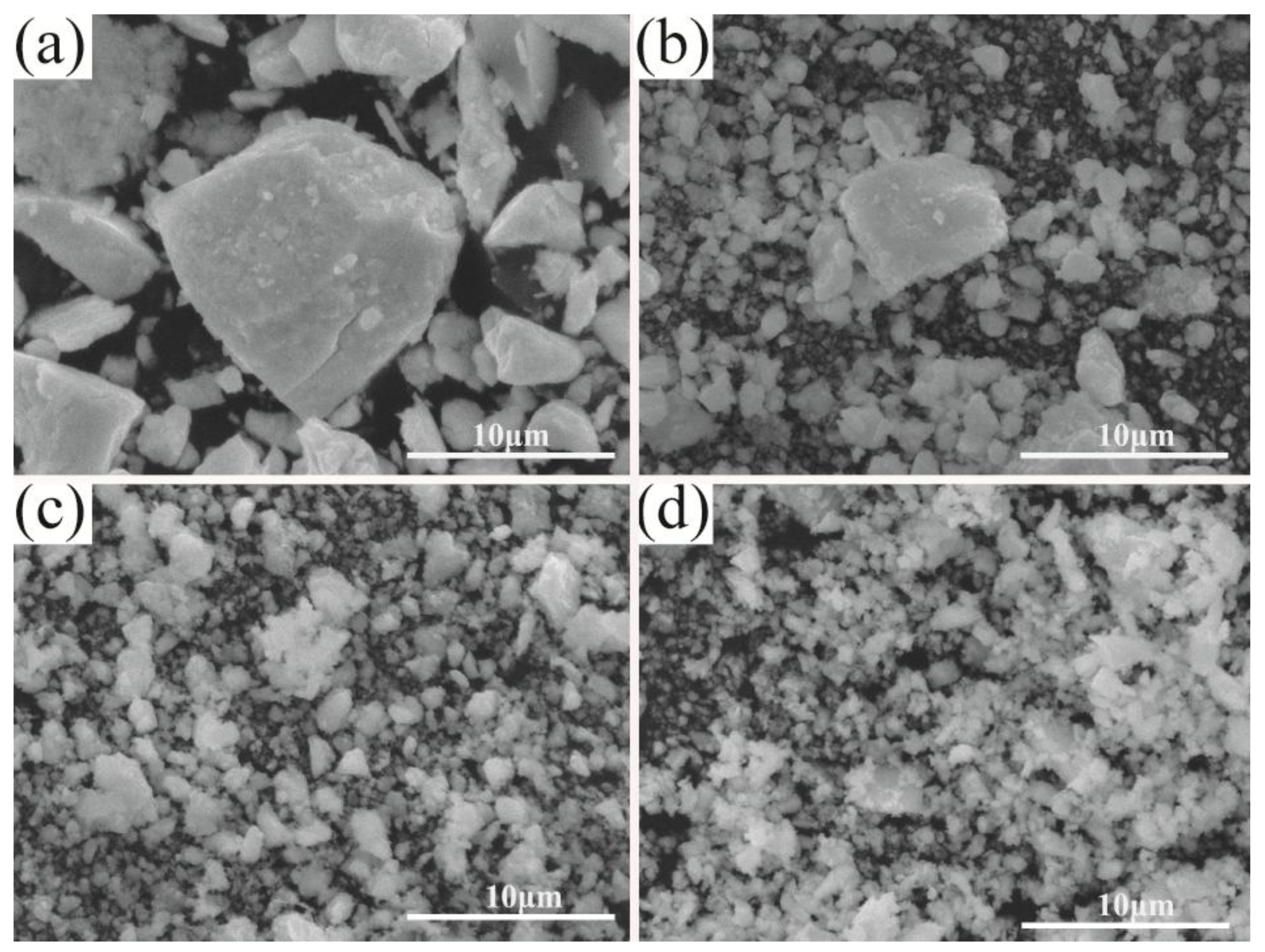

3.2. Microstructure of Mn55Bi45 Powders Obtained by Different Ball Milling Processes

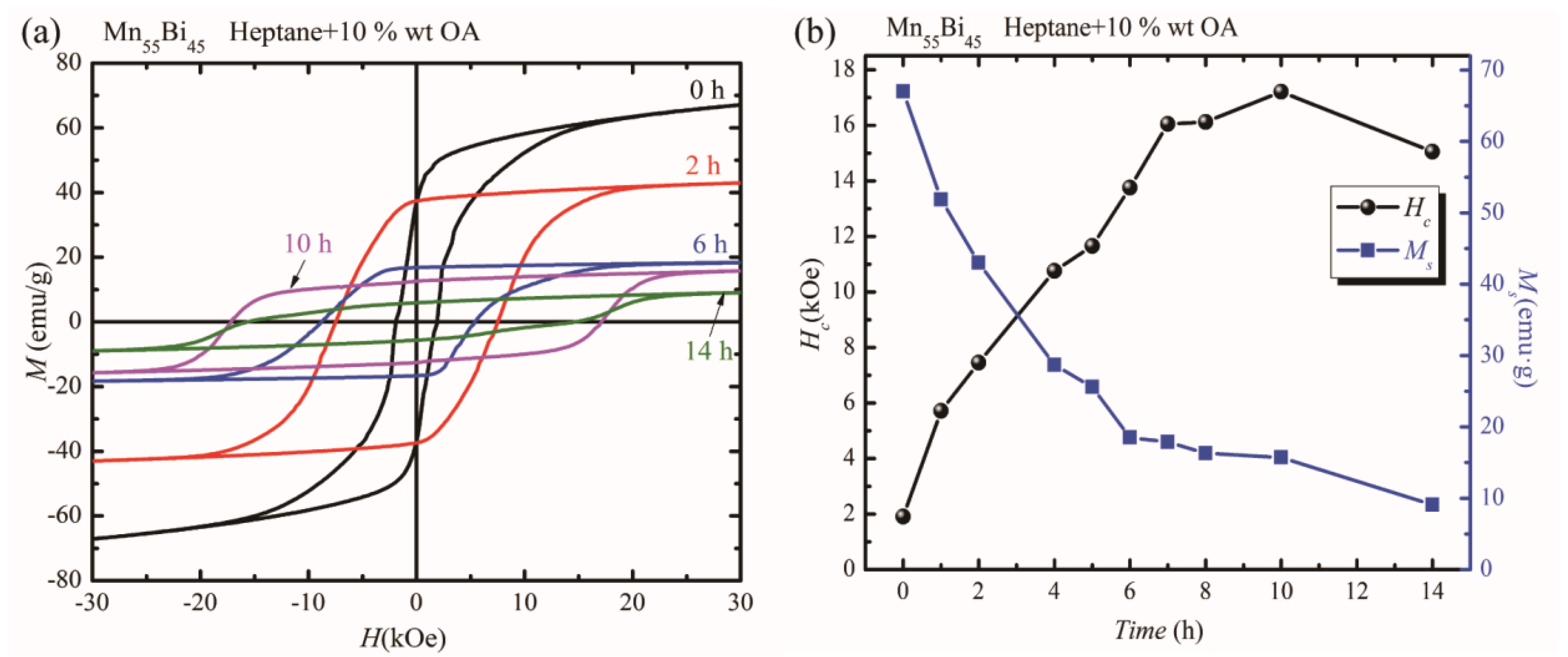

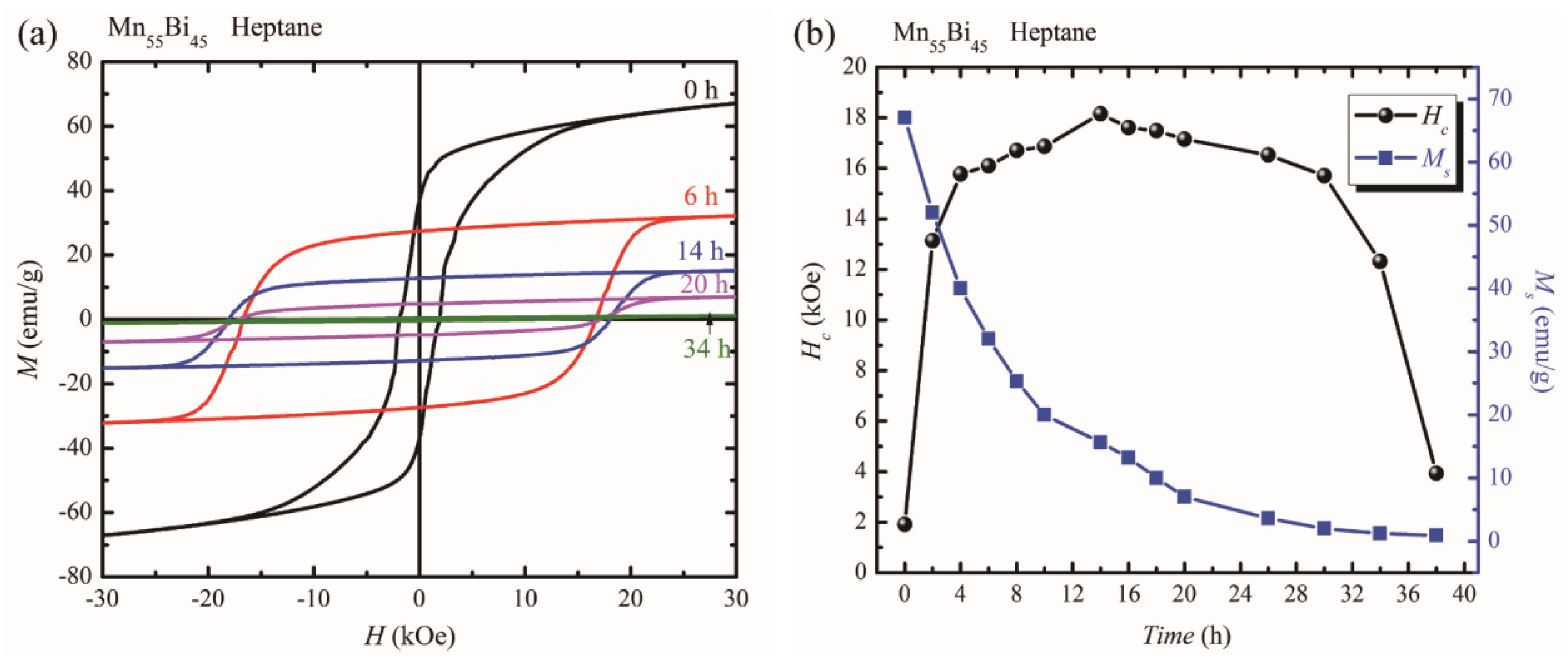

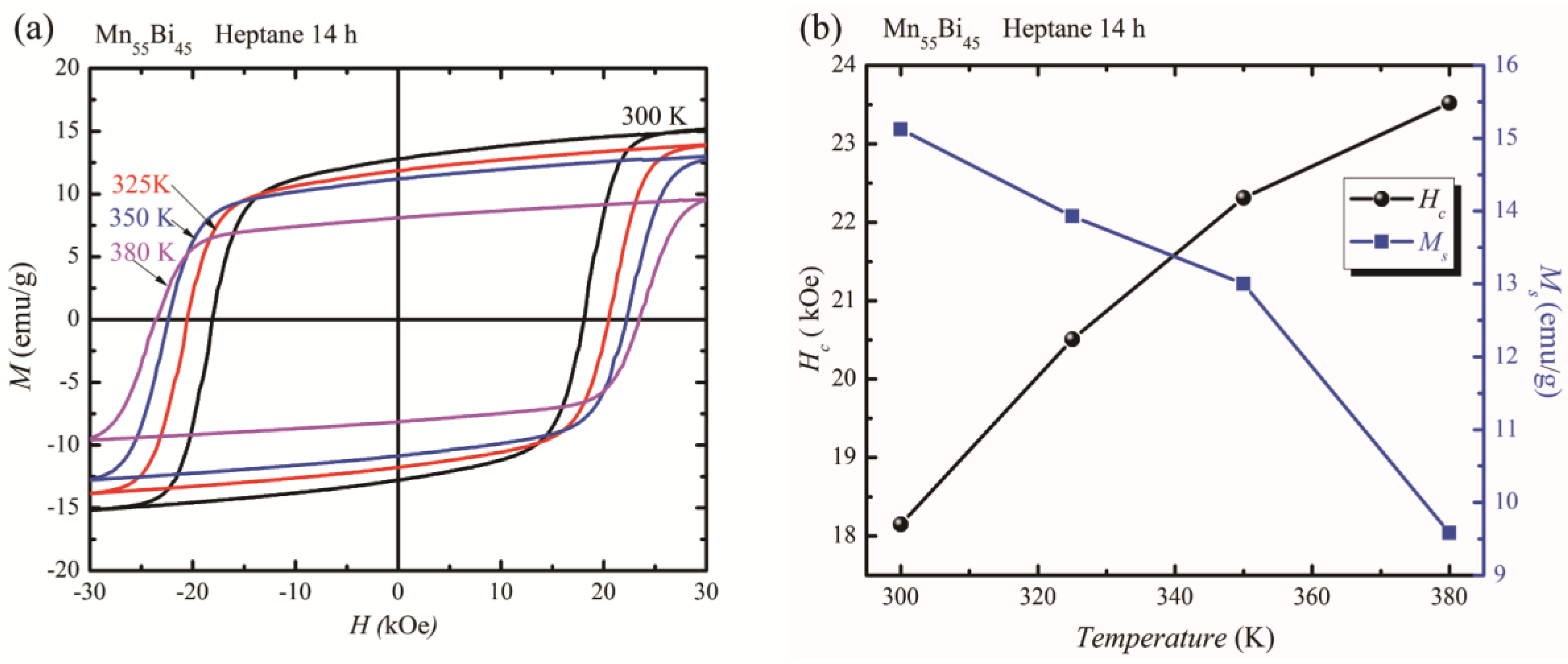

3.3. Magnetic Properties of Mn55Bi45 Powders Obtained by Different Ball Milling Processes

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Poudyal, N.; Liu, J.P. Advances in nanostructured permanent magnets research. J. Phys. D Appl. Phys. 2013, 46, 043001. [Google Scholar] [CrossRef]

- Bailey, G.; Mancheri, N.; Van Acker, K. Sustainability of Permanent Rare Earth Magnet Motors in (H)EV Industry. J. Sustain. Metall. 2017, 3, 611–626. [Google Scholar] [CrossRef]

- Cao, S.; Yue, M.; Yang, Y.X.; Zhang, D.T.; Liu, W.Q.; Zhang, J.X.; Guo, Z.H.; Li, W. Magnetic properties and thermal stability of MnBi/NdFeB hybrid bonded magnets. J. Appl. Phys. 2011, 109, 07A740. [Google Scholar] [CrossRef]

- McCallum, R.W.; Lewis, L.; Skomski, R.; Kramer, M.J.; Anderson, I.E. Practical aspects of modern and future permanent magnets. Annu. Rev. Mater. Res. 2014, 44, 451–477. [Google Scholar] [CrossRef]

- Kuz’min, M.D.; Skokov, K.P.; Jian, H.; Radulov, I.; Gutfleisch, O. Towards high performance permanent magnets without rare earths. J. Phys. Condens. Matter 2014, 26, 064205. [Google Scholar] [CrossRef]

- Song, Y.M.; Xiang, Z.; Wang, T.L.; Niu, J.C.; Xia, K.D.; Lu, W.; Zhang, H.; Cao, Y.Z.; Yoshimura, S.; Saito, H. High temperature exchange bias effect in melt-spun Mn55Bi45 alloys. Appl. Phys. Lett. 2016, 109, 112402. [Google Scholar] [CrossRef]

- Yang, J.B.; Yang, Y.B.; Chen, X.G.; Ma, X.B.; Han, J.Z.; Yang, Y.C.; Guo, S.; Yan, A.R.; Huang, Q.Z.; Wu, M.M.; et al. Anisotropic nanocrystalline MnBi with high coercivity at high temperature. Appl. Phys. Lett. 2011, 99, 082505. [Google Scholar] [CrossRef]

- Saito, T.; Nishimura, R.; Nishio-Hamane, D. Magnetic properties of Mn-Bi melt-spun ribbons. J. Magn. Magn. Mater. 2014, 349, 9–14. [Google Scholar] [CrossRef]

- Yang, Y.B.; Chen, X.G.; Guo, S.; Yan, A.R.; Huang, Q.Z.; Wu, M.M.; Chen, D.F.; Yang, Y.C.; Yang, J.B. Temperature dependences of structure and coercivity for melt-spun MnBi compound. J. Magn. Magn. Mater. 2013, 330, 106–110. [Google Scholar] [CrossRef]

- Xiang, Z.; Song, Y.M.; Pan, D.; Shen, Y.L.; Qian, L.W.; Luo, Z.Y.; Liu, Y.S.; Yang, H.W.; Yan, H.; Lu, W. Coercivity enhancement and magnetization process in Mn55Bi45 alloys with refined particle size. J. Alloys Compd. 2018, 744, 432–437. [Google Scholar] [CrossRef]

- Cui, J.; Choi, J.P.; Li, G.; Polikarpov, E.; Darsell, J.; Overman, N.; Olszta, M.; Schreiber, D.; Bowden, M.; Droubay, T.; et al. Thermal stability of MnBi magnetic materials. J. Phys. Condens. Matter 2014, 26, 064212. [Google Scholar] [CrossRef] [PubMed]

- Oikawa, K.; Mitsui, Y.; Koyama, K.; Anzai, K. Thermodynamic Assessment of the Bi-Mn System. Mater. Trans. 2011, 52, 2032–2039. [Google Scholar] [CrossRef]

- Lu, W.; Luo, Z.Y.; Xiang, Z.; Wang, X.; Pan, F.; Tian, W.; Yan, Y. Synthesis and magnetic properties of LTP-Mn55Bi45/Fe7Co3 and LTP-Mn55Bi45/Co magnetic nanocomposites with enhanced energy product. Mater. Lett. 2019, 236, 514–516. [Google Scholar] [CrossRef]

- Dai, Q.L.; Warsi, M.A.; Xiao, J.Q.; Ren, S.Q. Solution processed MnBi-FeCo magnetic nanocomposites. Nano Res. 2016, 9, 3222–3228. [Google Scholar] [CrossRef]

- Nguyen, P.K.; Jin, S.; Berkowitz, A.E. Unexpected magnetic domain behavior in LTP-MnBi. IEEE Trans. Magn. 2013, 49, 3387–3390. [Google Scholar] [CrossRef]

- Xie, W.; Polikarpov, E.; Choi, J.P.; Bowden, M.E.; Sun, K.W.; Cui, J. Effect of ball milling and heat treatment process on MnBi powders magnetic properties. J. Alloys Compd. 2016, 680, 1–5. [Google Scholar] [CrossRef]

- Yousefi, M.; Sharafi, S.; Mehrolhosseiny, A. Correlation between structural parameters and magnetic properties of ball milled nanocrystalline Fe-Co-Si powders. Adv. Powder Technol. 2014, 25, 752–760. [Google Scholar] [CrossRef]

- Mondal, B.N.; Sardar, G.; Nath, D.N.; Chattopadhyay, P.P. Ferromagnetic behavior of nanocrystalline Cu–Mn alloy prepared by ball milling. J. Magn. Magn. Mater. 2014, 371, 139–143. [Google Scholar] [CrossRef]

- Li, B.B.; Ma, Y.L.; Shao, B.; Li, C.H.; Chen, D.M.; Sun, J.C.; Zheng, Q.; Yin, X. Preparation and magnetic properties of anisotropic MnBi powders. Phys. B Condens. Matter 2018, 530, 322–326. [Google Scholar] [CrossRef]

- Kanari, K.; Sarafidis, C.; Gjoka, M.; Niarchos, D.; Kalogirou, O. Processing of magnetically anisotropic MnBi particles by surfactant assisted ball milling. J. Magn. Magn. Mater. 2017, 426, 691–697. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Han, J.Z.; Liu, S.Q.; Tian, H.D.; Zhao, H.; Du, H.L.; Yang, Y.C.; Fang, Y.K.; Li, W.; Yang, J.B. Structural modification and ultra-high coercivity of nanostructural anisotropic MnBi/Bi films. Acta Mater. 2017, 128, 96–102. [Google Scholar] [CrossRef]

- Yang, Y.B.; Chen, X.G.; Wu, R.; Wei, J.Z.; Ma, X.B.; Han, J.Z.; Du, H.L.; Liu, S.Q.; Wang, C.S.; Yang, Y.C.; et al. Preparation and magnetic properties of MnBi. J. Appl. Phys. 2012, 111, 07E312. [Google Scholar] [CrossRef]

- Rao, N.V.R.; Gabay, A.M.; Hu, X.; Hadjipanayis, G.C. Fabrication of anisotropic MnBi nanoparticles by mechanochemical process. J. Alloys Compd. 2014, 586, 349–352. [Google Scholar] [CrossRef]

- Li, C.H.; Guo, D.L.; Shao, B.; Li, K.J.; Li, B.B.; Chen, D.M. Effect of heat treatment and ball milling on MnBi magnetic materials. Mater. Res. Express 2018, 5, 016104. [Google Scholar] [CrossRef]

- Guo, X.; Chen, X.; Altounian, Z.; Ström-Olsen, J.O. Magnetic properties of MnBi prepared by rapid solidification. Phys. Rev. B 1992, 46, 14578–14582. [Google Scholar] [CrossRef]

| Sample | Ms (emu/g) | Hc (kOe) | Mr/Ms (%) | (BH)max (MGOe) |

|---|---|---|---|---|

| Heptane + 10 wt% OA (2h) | 43 | 7.5 | 86.9 | 4.2 |

| Heptane (2h) | 52 | 13.1 | 89.9 | 7.1 |

| Heptane + 10 wt% OA (4h) | 27 | 10.8 | 88.3 | 2.0 |

| Heptane (4h) | 40 | 15.8 | 90.0 | 4.1 |

| Heptane + 10 wt% OA (6h) | 19 | 13.8 | 91.1 | 0.9 |

| Heptane (6h) | 32 | 16.1 | 85.3 | 2.3 |

| Heptane + 10 wt% OA (10h) | 16 | 17.2 | 79.4 | 0.5 |

| Heptane (10h) | 20 | 16.9 | 84.6 | 1.0 |

| Heptane + 10 wt% OA (14h) | 9 | 15.1 | 65.1 | 0.1 |

| Heptane (14h) | 16 | 18.2 | 84.5 | 0.3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Pan, D.; Xiang, Z.; Lu, W.; Batalu, D. Microstructure and Magnetic Properties of Mn55Bi45 Powders Obtained by Different Ball Milling Processes. Metals 2019, 9, 441. https://doi.org/10.3390/met9040441

Li X, Pan D, Xiang Z, Lu W, Batalu D. Microstructure and Magnetic Properties of Mn55Bi45 Powders Obtained by Different Ball Milling Processes. Metals. 2019; 9(4):441. https://doi.org/10.3390/met9040441

Chicago/Turabian StyleLi, Xiang, Dong Pan, Zhen Xiang, Wei Lu, and Dan Batalu. 2019. "Microstructure and Magnetic Properties of Mn55Bi45 Powders Obtained by Different Ball Milling Processes" Metals 9, no. 4: 441. https://doi.org/10.3390/met9040441

APA StyleLi, X., Pan, D., Xiang, Z., Lu, W., & Batalu, D. (2019). Microstructure and Magnetic Properties of Mn55Bi45 Powders Obtained by Different Ball Milling Processes. Metals, 9(4), 441. https://doi.org/10.3390/met9040441