Blunt Notch Strength of AA2024 3-3/2-0.4 Fibre Metal Laminate Under Biaxial Tensile Loading

Abstract

:1. Introduction

- (1)

- Failure mode: ultimate tensile strength (no notch in laminate) in fibre direction. At similar thickness, the yield strength of AA2024-FML is reached earlier than in the monolithic alloy, owing to residual stresses provoked by the polymer curing process and the effective Young’s modulus that results from the combination of the aluminium alloy foils and the prepregs. Above the yield strength of the FML, the fibres start to bare a significant part of the load and a second linear stress/strain behaviour develops. Failure of the laminate occurs when the maximum strength of the fibres is reached. The ultimate tensile strength of Standard-GLARE3-3/2-0.4 is about 680 MPa in the fibre direction [1].

- (2)

- Blunt notch failure mode. Drilling holes in GLARE leads to the sectioning of glass fibres, i.e., the main load carrying component of the laminate is damaged. Stress concentrations appear in the vicinity of the holes, e.g., in riveted joints, and high shear stresses form between undamaged fibres. This phenomenon is called “fibre splitting” [1]. Following fibre splitting, the fibres adjacent to the drilled hole (undamaged) must bear additional loads from the sectioned fibres. However, delamination between aluminium alloy foils and prepreg goes along with the previously explained process, influencing the local load distribution and hence the failure load. The complex sequence of failure modes relates to the local strains and stresses, and, therefore, blunt notch failure must be related to net section stresses (see Equation (1)):where W is the width of the specimen and D is the sum of the diameter of the holes. This leads to a situation where the blunt notch strength depends on the size of the specimen. This means that the wider the specimen, the more the blunt notch strength decreases [7]. Finally, the blunt notch strength always provides a design value. The demand to relate blunt notch failure stresses under off-axis conditions to the net section is one of the challenges during the sizing of FML panes. The typical blunt notch stress (net stress) of Standard-GLARE3-3/2-4 is about 480 MPa in the L-direction (fibre orientation 0°) [1].

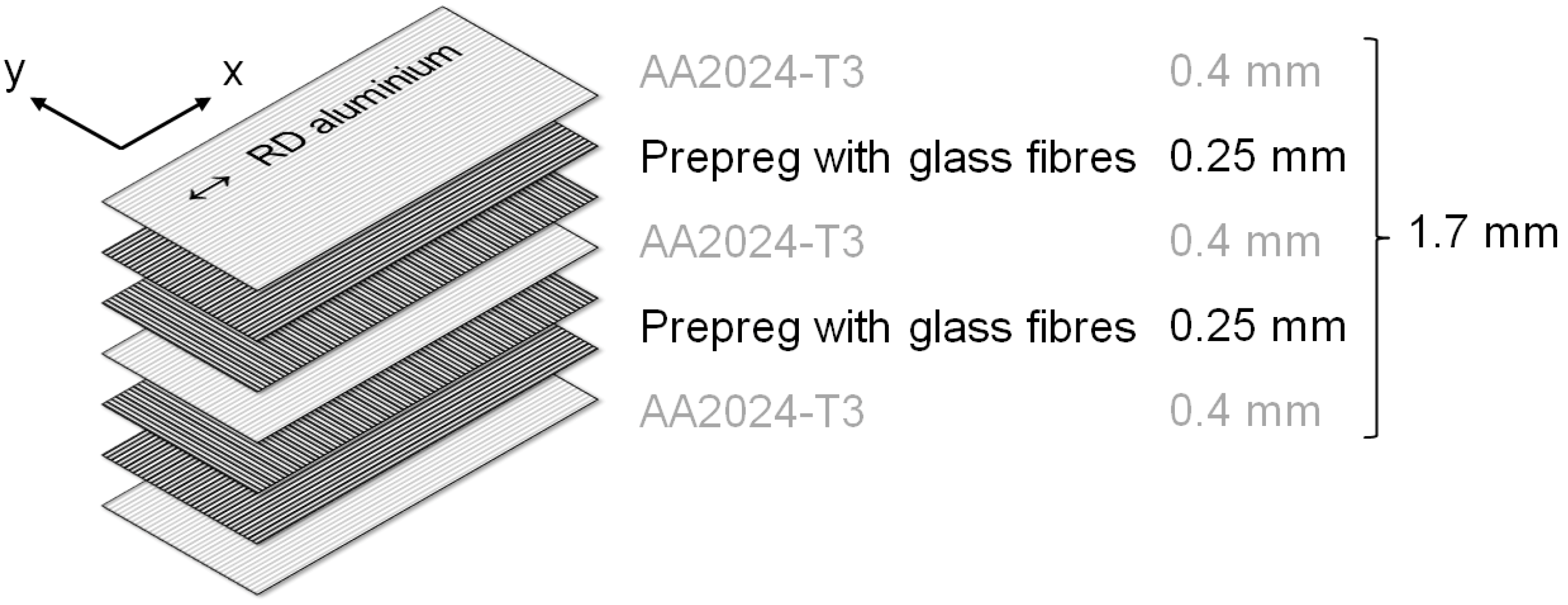

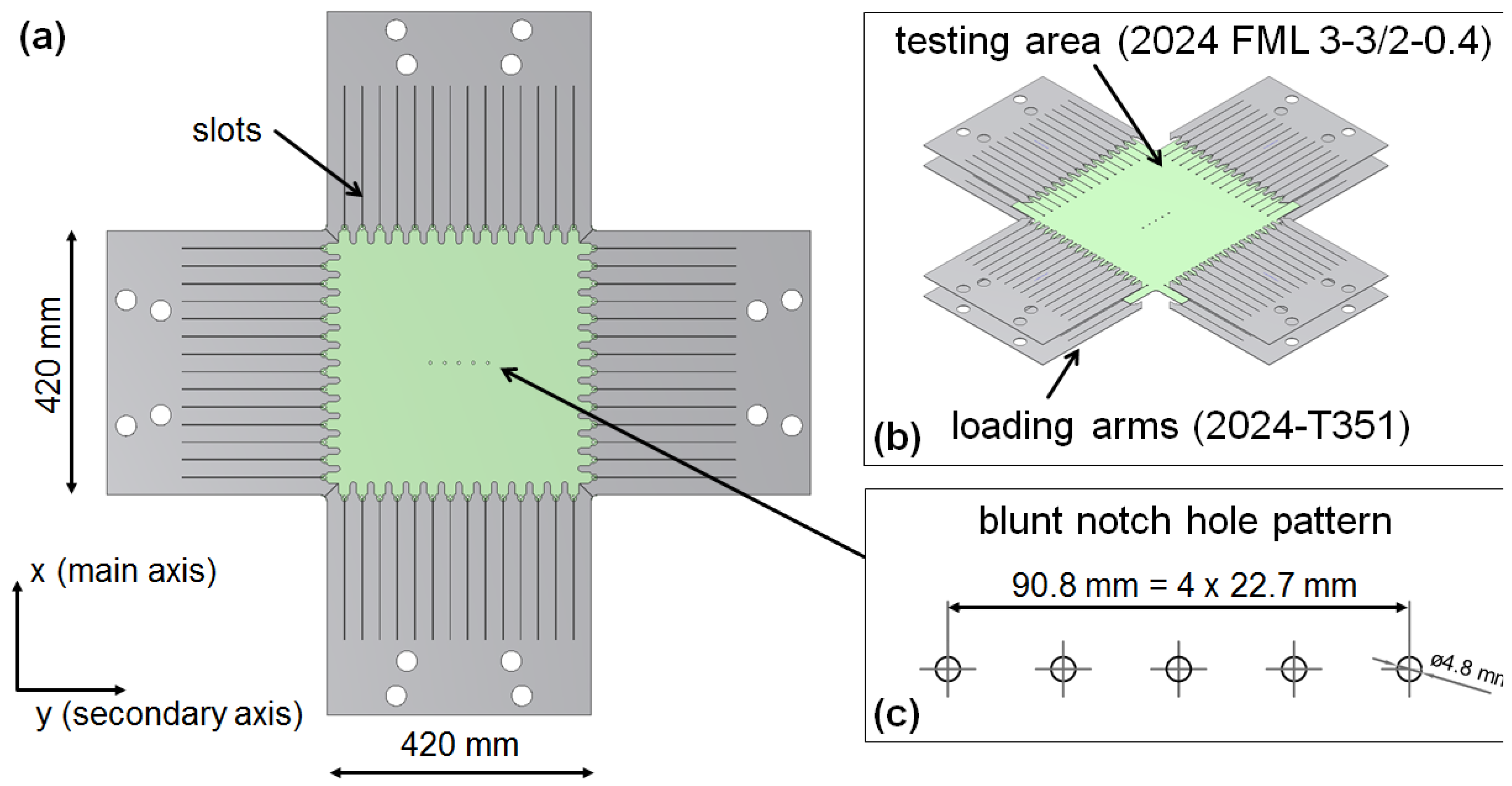

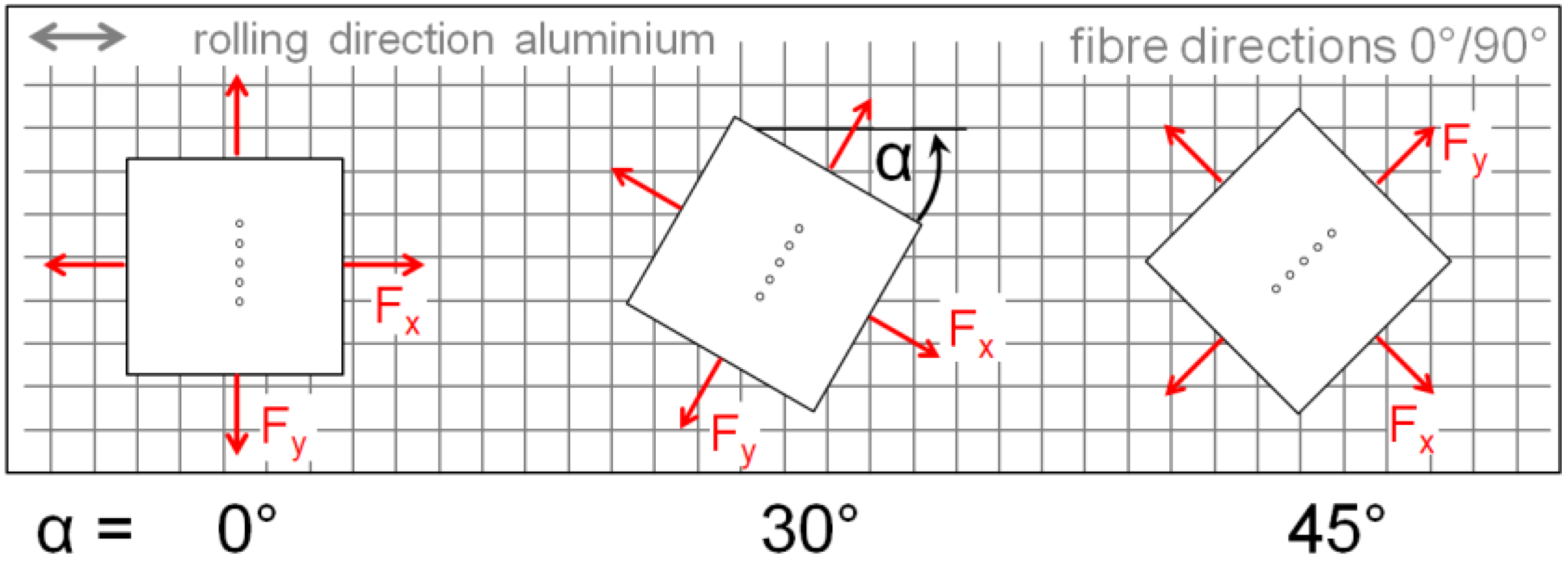

2. Material and Specimen Design

2.1. Material

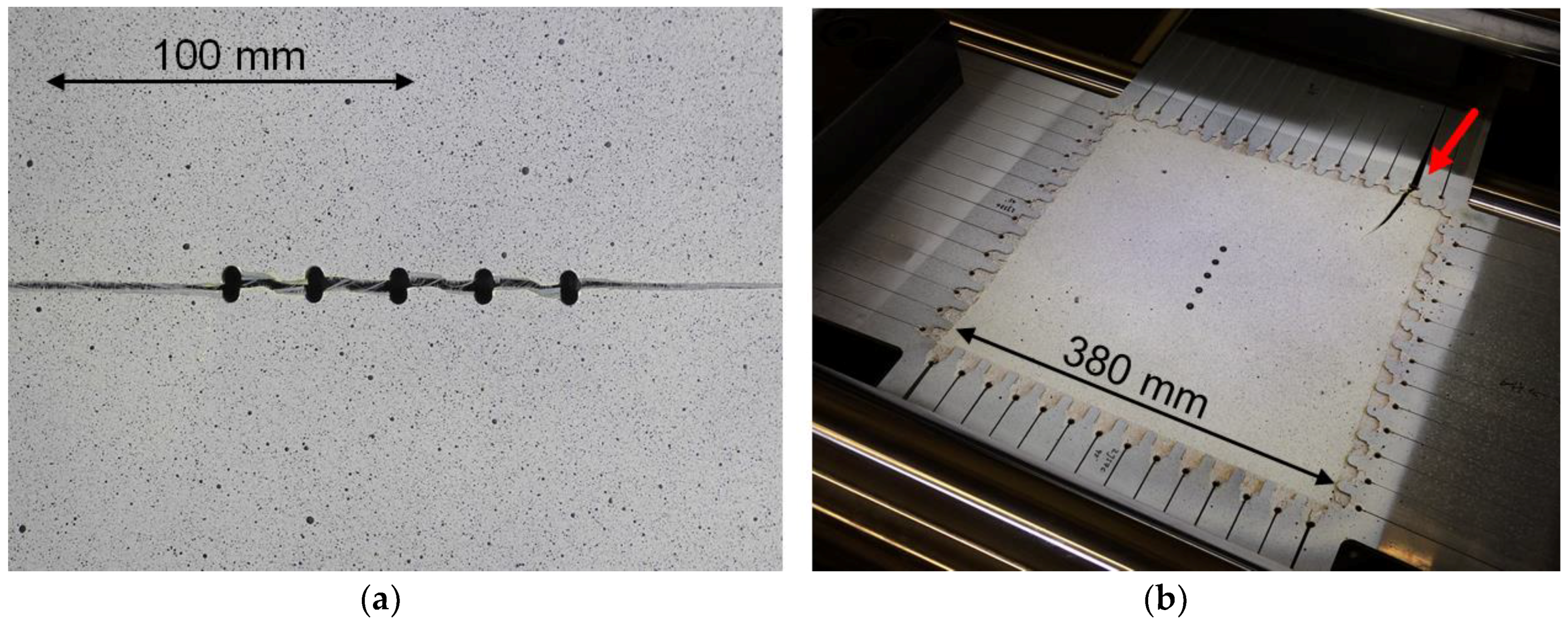

2.2. Design of Specimen for Biaxial Tests

3. Biaxial Tensile Tests

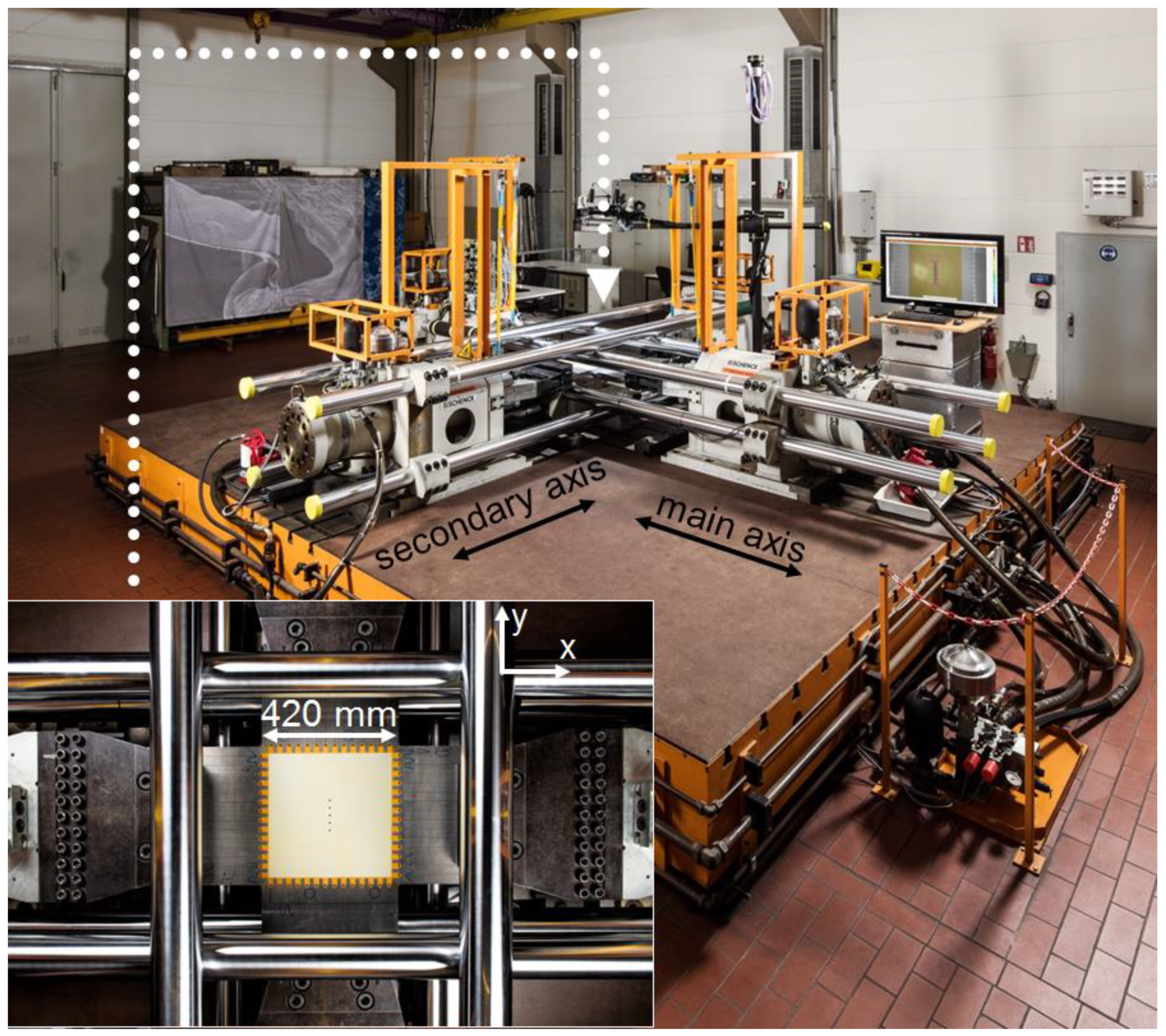

3.1. Experimental Setup

3.2. Results

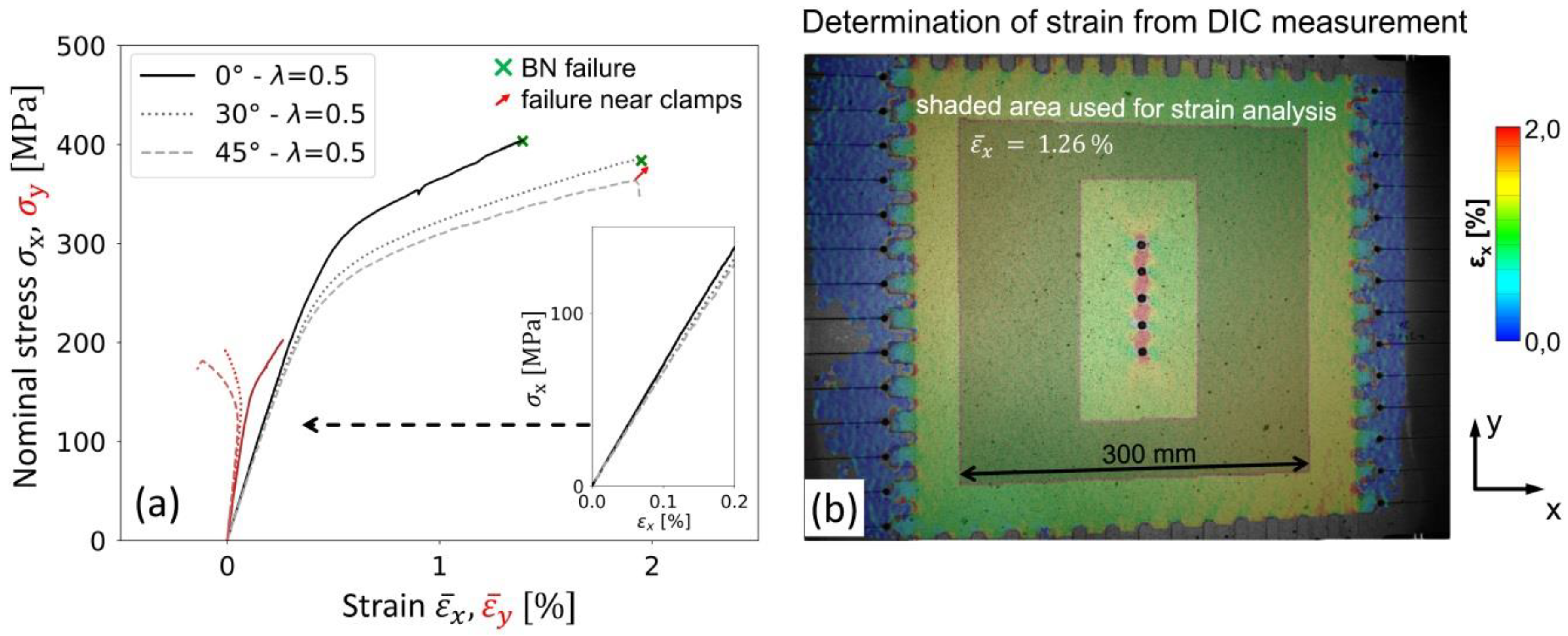

- For α = 0°, the linear-to-nonlinear transition takes places at the highest stress level compared to 30° and 45°.

- The slope of the linear range decreases with off-axis angle (insert in Figure 6a).

- The tangent modulus, i.e., the slope of the stress-strain curve in the inelastic regime, for α = 0° is higher compared to α = 30° and 45°.

- The strain for α = 0° (red solid line in Figure 6a) shows positive values with a continuous positive slope throughout the test, while for α = 30° and 45° (dashed and dotted red lines in Figure 6a) the slope is positive until the inelastic range is reached. Subsequently, the slope becomes negative, and even negative strains are reached. This behaviour can be explained by a change of the Poisson’s ratio ν from the elastic to plastic regime, due to shearing between the polymeric matrix and the fibers. While the Poisson’s ratio of the FML remains almost constant at about 0.3 for α = 0°, ν increases from ν = 0.35 (α = 30°) and ν = 0.37 (α = 45°) to above 0.5 in the linear-to-nonlinear transition. This effect has also been reported by other authors [16]. A Poisson’s ratio ν > 0.5 induces negative strains for λ = 0.5 and results in the unusual trend of the stress-strain curve -.

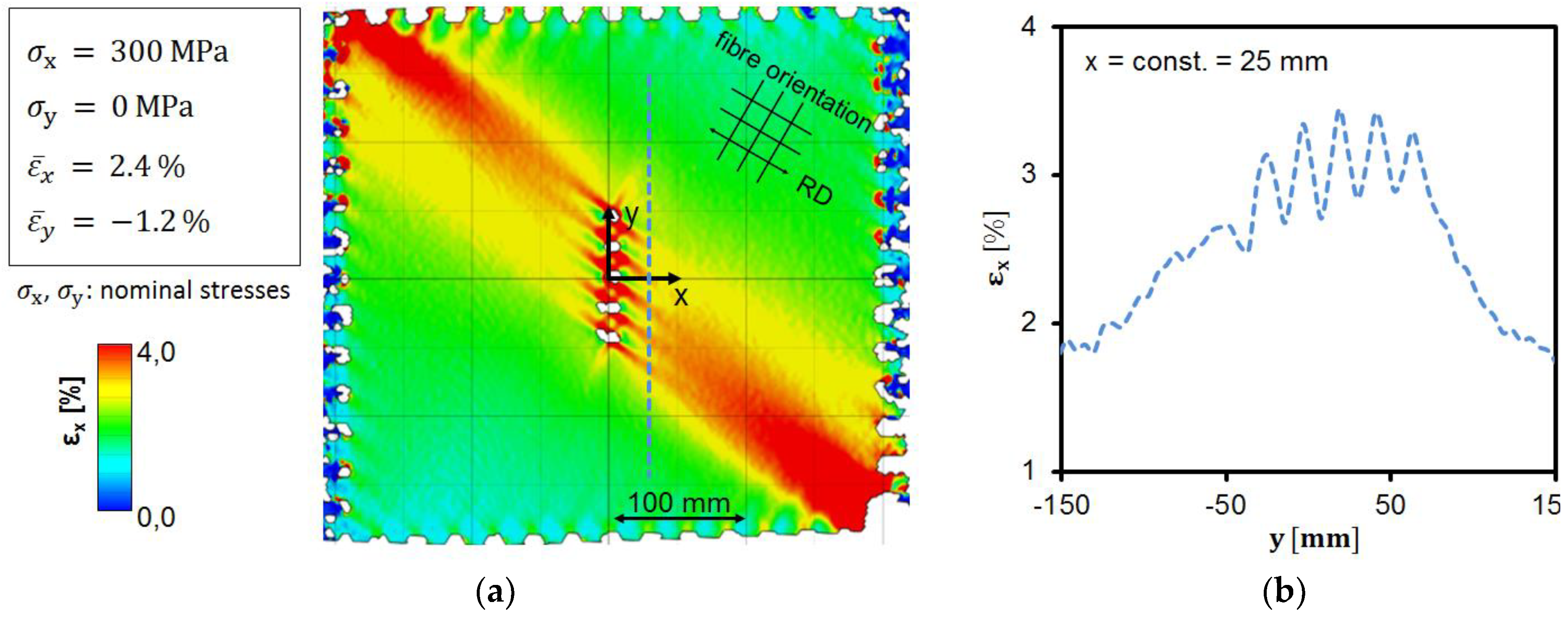

- The corners of the specimen undergo increased strain concentrations (see left upper edge and right lower edge in Figure 8a), which raises the probability of failure outside the BN pattern.

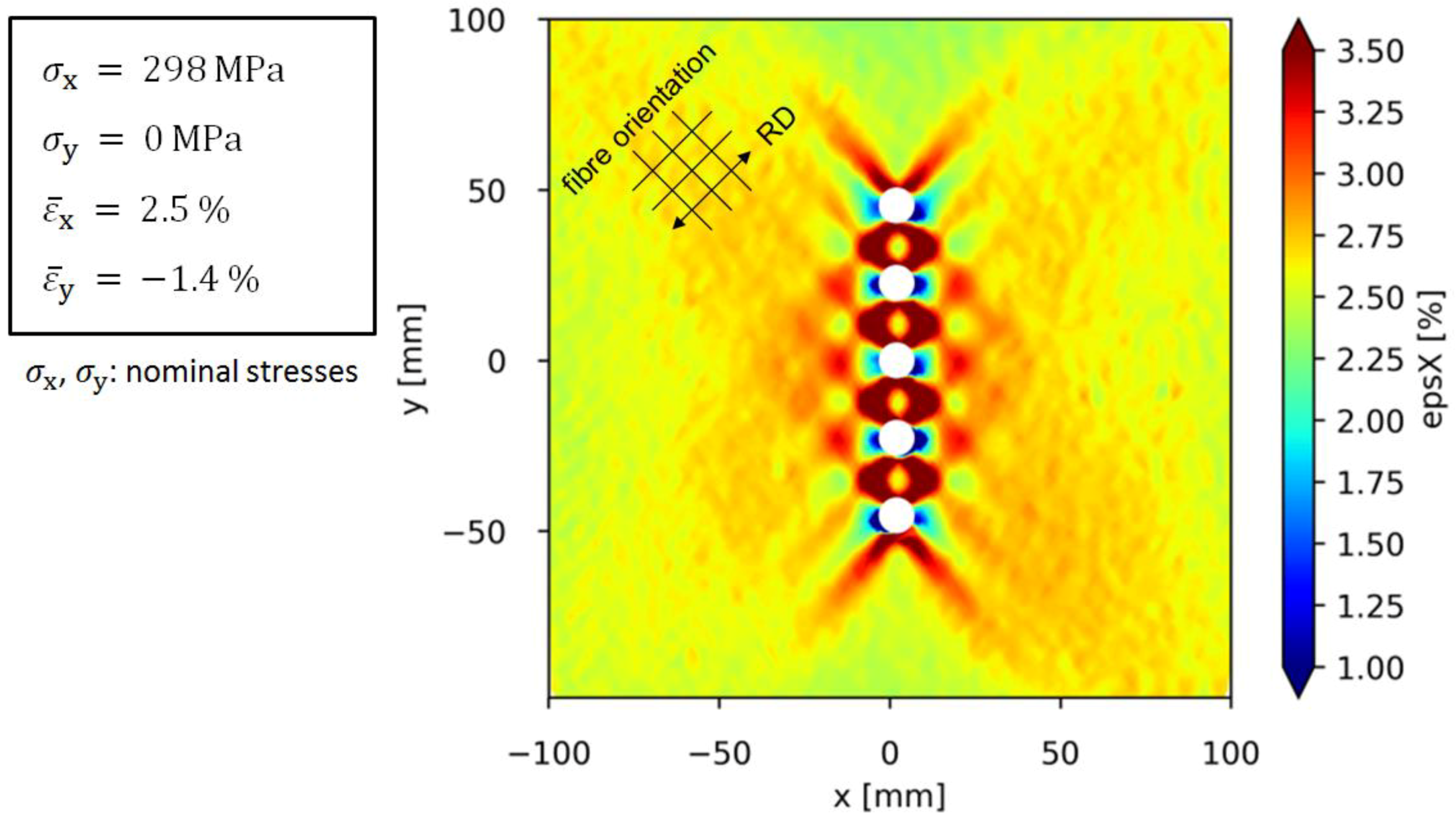

- The holes are not loaded equally, as it can be seen in Figure 8b. Thus, the strain profile close to the BN pattern shows a distinct asymmetry.

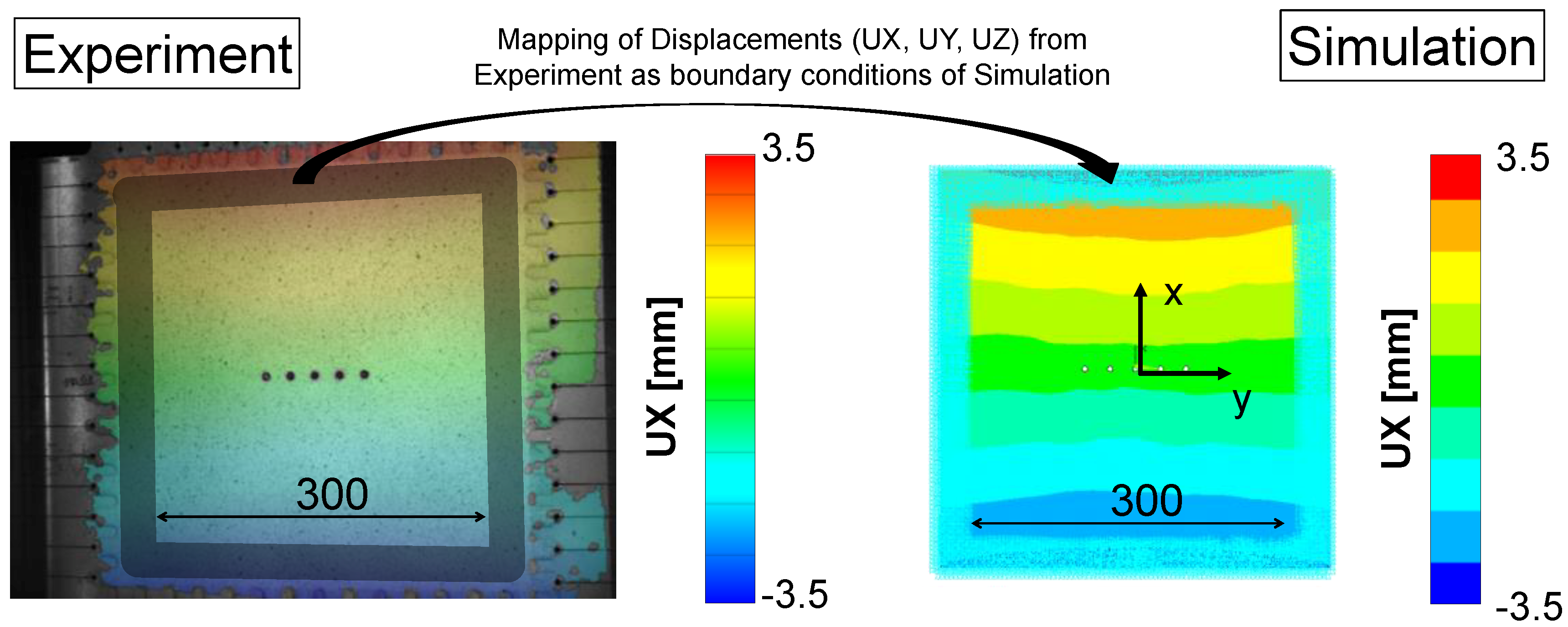

4. Finite-Element-Simulation

4.1. Description of Model

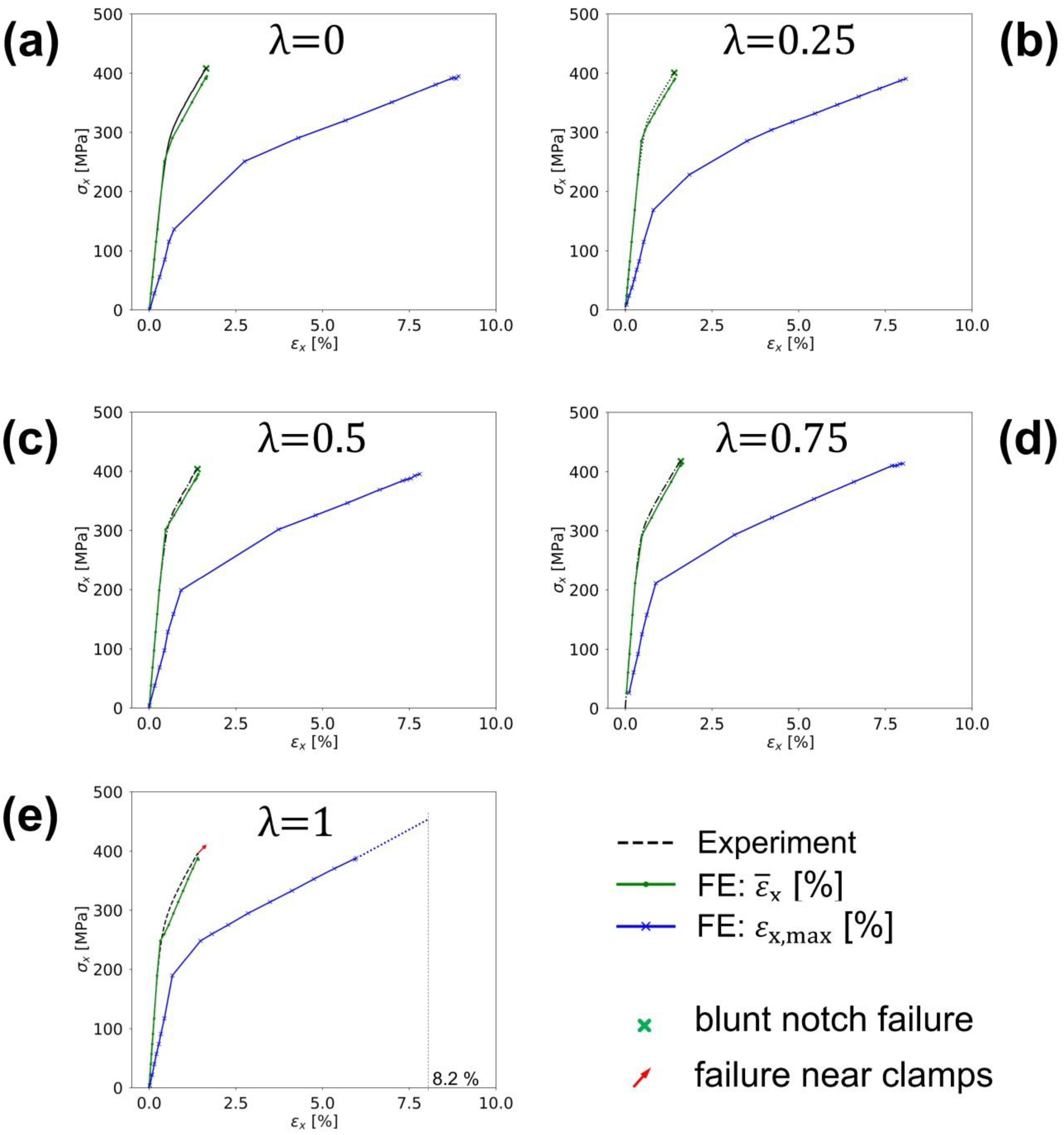

4.2. FE Simulation Results

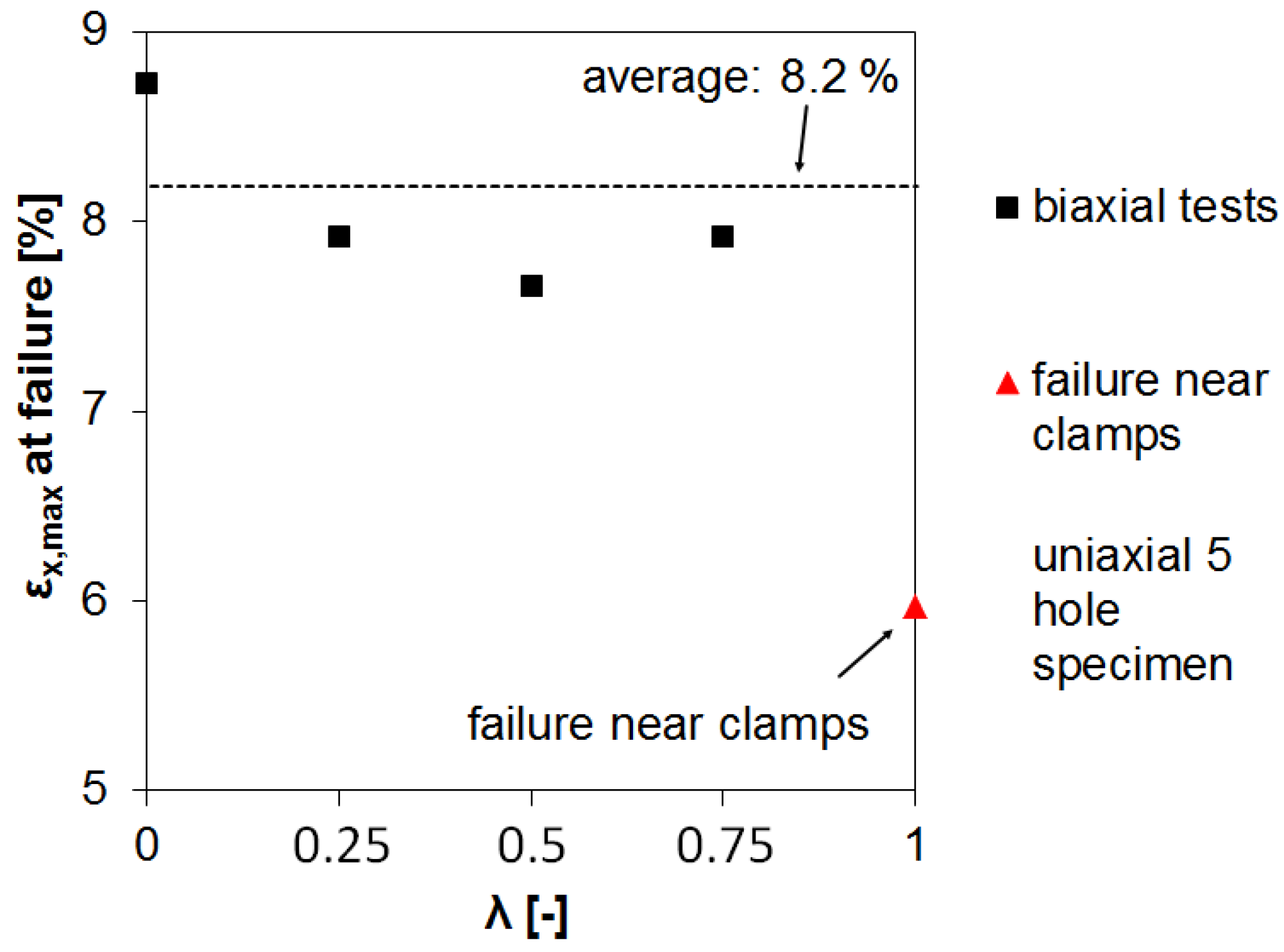

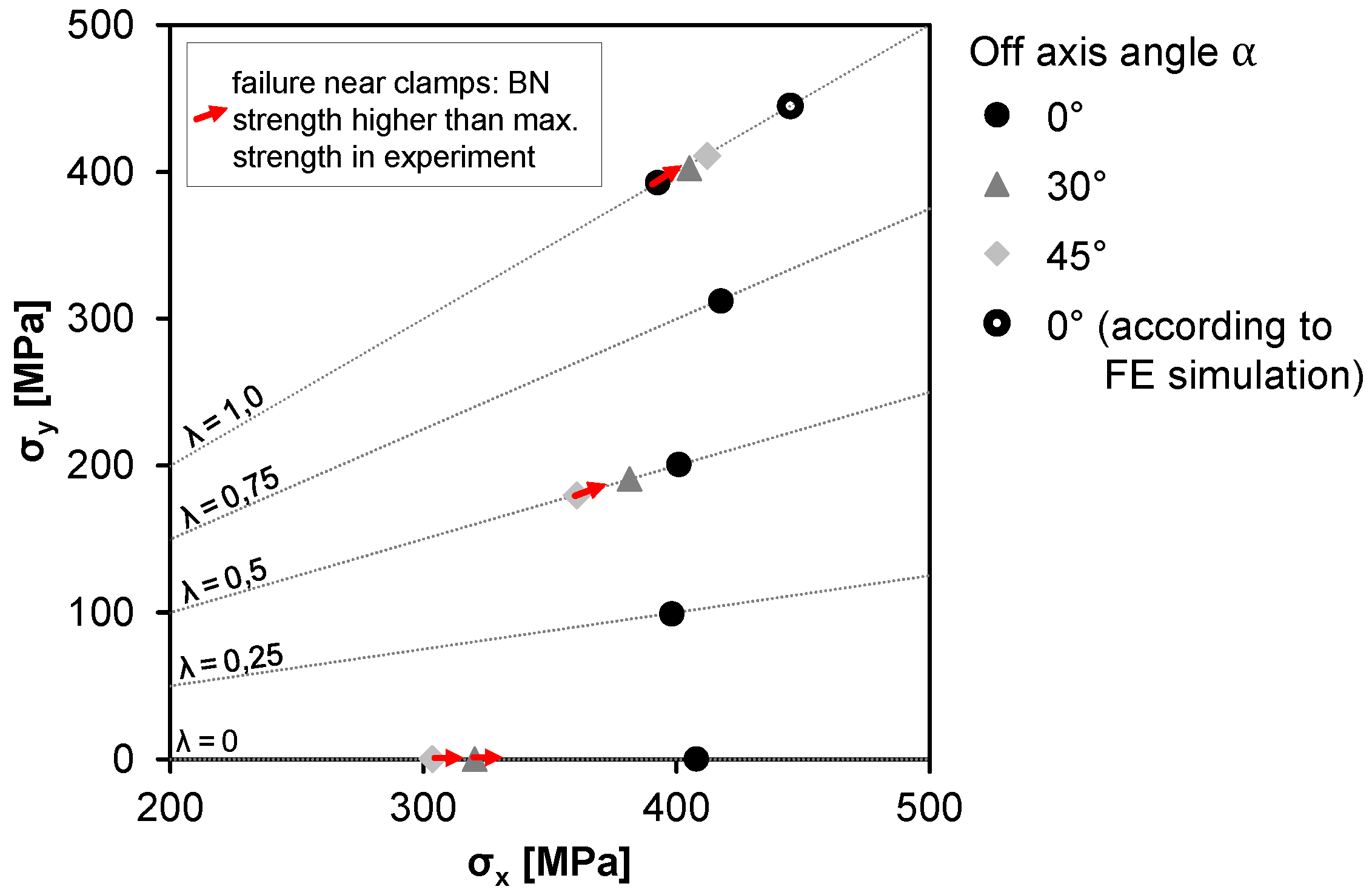

- α = 0°:The BN strength for λ = 1 was adjusted by means of the FE simulation, considering that the maximum strain at the holes prior to failure was about 8.2%. Biaxial loading can be marked as slightly beneficial for the BN strength, as there was an increase of strength from λ = 0.25 (σx,BN = 398 MPa) to λ = 1 (σx,BN = 445 MPa). The BN strength for λ = 0 reached about 408 MPa.

- α = 30°:Two experiments with failure in the BN pattern could be conducted successfully. Again, the BN strength seems to increase with an increasing biaxiality ratio from λ = 0.5 (σx,BN = 382 MPa) to λ = 1 (σx,BN = 405 MPa). As described in Section 3.2, the specimens, and hence the BN pattern, underwent severe strain asymmetry during testing.

- α = 45°:Only one experiment (for λ = 1, σx,BN = 412 MPa) could be tested with the failure of the BN pattern. This BN strength is only 7% lower than the corresponding estimated value for α = 0°.

5. Summary and Conclusions

- The blunt notch strength is not significantly affected by multiaxial stresses. In the conducted biaxial experiments, the specimens failed at nominal stresses σx of about 400 MPa independent of the biaxiality ratios λ.

- Digital image correlation is able to capture the strain field in the gauge area and locally in the vicinity of the blunt notches to compute the average strain and to observe local effects caused by damage in the laminate.

- Asymmetric off-axis angles of 30° relative to the loading direction also cause asymmetric strain fields. Consequently, stress concentrations occur in the corners of the gauge area, and some experiments failed early.

- An FE model for α = 0° with orthotropic linear-elastic material properties for the unidirectional prepreg layers and ideal plastic isotropic hardening for the Al alloy layers was utilized. Mapping of displacements, as measured with the DIC system during the experiments, served as boundary conditions for the simulation. Good agreement of the experimental and simulated stress-strain-curves indicates the general applicability of the used FE model.

- With the help of the FE model, maximum strains at the holes prior to failure were determined to be in the order of 8.2% (averaged) for the experiments with α = 0°. Based on this finding, the BN strength of the experiment with λ = 0 that failed outside the blunt notch pattern could be estimated.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Alderliesten, R.C. Fatigue and Fracture of Fibre Metal Laminates; Springer International Publishing: Delft, The Netherlands, 2017. [Google Scholar]

- Wu, G.; Yang, J.M. The mechanical behavior of GLARE laminates for aircraft structures. JOM 2005, 57, 72–79. [Google Scholar] [CrossRef]

- Sinmazcelik, T.; Avcu, E.; Bora, M.Ö.; Çoban, O. A review: Fibre metal laminates, background, bonding types and applied test methods. Mater. Des. 2011, 32, 3671–3685. [Google Scholar] [CrossRef]

- Ritchie, R.O.; Yu, W.; Bucci, R.J. Fatigue crack propagation in ARALL® LAMINATES: Measurement of the effect of crack-tip shielding from crack bridging. Eng. Fract. Mech. 1989, 32, 361–377. [Google Scholar] [CrossRef]

- Vries, D.; Johan, T. Blunt and Sharp Notch Behaviour of Glare Laminates. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2001. [Google Scholar]

- Vermeeren, C.A.J.R. An Historic Overview of the Development of Fibre Metal Laminates. Appl. Compos. Mater. 2003, 10, 189–205. [Google Scholar] [CrossRef]

- Vermeeren, C.A.J.R. The Blunt Notch Behaviour of Metal Laminates: ARALL and GLARE; Delft University of Technology: Delft, The Netherlands, 1990. [Google Scholar]

- Mönch, E.; Galster, D. A method for producing a defined uniform biaxial tensile stress field. Br. J. Appl. Phys. 1963, 14, 810–812. [Google Scholar] [CrossRef]

- Demmerle, S.; Boehler, J.P. Optimal design of biaxial tensile cruciform specimens. J. Mech. Phys. Solids 1993, 41, 143–181. [Google Scholar] [CrossRef]

- Dalle Donne, C.; Trautmann, K.H.; Amstutz, H. Cruciform specimens for in-plane biaxial fracture, deformation, and fatigue testing. In Multiaxial Fatigue and Deformation: Testing and Prediction; ASTM STP: West Conshohocken, PA, USA, 2000; Volume 1387, pp. 405–422. [Google Scholar]

- Breitbarth, E.; Besel, M.; Reh, S. Biaxial testing of cruciform specimens representing characteristics of a metallic airplane fuselage section. Int. J. Fatigue 2018, 108, 116–126. [Google Scholar] [CrossRef]

- Breitbarth, E.; Besel, M. Fatigue crack deflection in cruciform specimens subjected to biaxial loading conditions. Int. J. Fatigue 2018, 113, 345–350. [Google Scholar] [CrossRef]

- Pilkey, W.D.; Pilkey, D.F. Petersonś Stress Concentration Factors; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Kawai, M.; Arai, Y. Off-axis notched strength of fiber–metal laminates and a formula for predicting anisotropic size effect. Compos. Part A: Appl. Sci. Manuf. 2009, 40, 1900–1910. [Google Scholar] [CrossRef]

- Beumler, T. Flying GLARE-A Contribution to Aircraft Certification Issues on Strength Properties in Non-Damaged and Fatiguedamaged GLARE Structures; TU Delft: Delft, The Netherlands, 2004. [Google Scholar]

- Kawai, M.; Morishita, M.; Tomura, S.; Takumida, K. Inelastic Behavior and Strength of Fiber-Metal Hybrid Composite: GLARE. Int. J. Mech. Sci. 1998, 40, 183–198. [Google Scholar] [CrossRef]

- Soltani, P.; Keikhosravy, M.; Oskouei, R.H.; Soutis, C. Studying the Tensile Behaviour of GLARE Laminates: A Finite Element Modelling Approach. Appl. Compos. Mater. 2011, 18, 271–282. [Google Scholar] [CrossRef]

- Yeh, P.-C.; Chang, P.Y.; Yang, J.M.; Wu, P.H.; Liu, M.C. Blunt notch strength of hybrid boron/glass/aluminum fiber metal laminates. Mater. Sci. Eng. A 2011, 528, 2164–2173. [Google Scholar] [CrossRef]

- Pagano, N.; Halpin, J. Influence of end constraint in the testing of anisotropic bodies. J. Compos. Mater. 1968, 2, 18–31. [Google Scholar] [CrossRef]

- Bosker, O.J. Finite Element Calculations to Predict the Uni-Axial on-Axis and off-Axis Blunt Notch Strength of Glare and Comparison with Test Results; Report; TU Delft: Delft, The Netherlands, 1999. [Google Scholar]

| Biaxial testing machine |

|

| 3D DIC system |

|

| Off-Axis Angle α | No. | Biaxiality Ratio λ | Max Nominal Stress σx [MPa] σy [MPa] | Location of Failure | |

|---|---|---|---|---|---|

| 0° | 1 | 0 | 408 | 0 | Blunt notch failure |

| 2 | 0.25 | 398 | 90 | Blunt notch failure | |

| 3 | 0.5 | 401 | 201 | Blunt notch failure | |

| 4 | 0.75 | 418 | 312 | Blunt notch failure | |

| 5 | 1.0 | 393 | 393 | crack in loading arms | |

| 30° | 6 | 0 | 313 | 0 | crack in loading arms followed by blunt notch failure |

| 7 | 0.5 | 382 | 191 | Blunt notch failure | |

| 8 | 1.0 | 291 | 289 | Blunt notch failure | |

| 45° | 9 | 0 | 304 | 0 | crack in loading arms |

| 10 | 0.5 | 361 | 180 | crack in loading arms | |

| 11 | 1.0 | 412 | 411 | Blunt notch failure | |

| Elastic Constants | Aluminium Layer 2024-T3 | Unidirectional (UD) Prepreg |

|---|---|---|

| Ex | 72,400 MPa | 54,000 MPa |

| Ey | 1 MPa | |

| Ez | 1 MPa | |

| νxy | 0.33 | 0.33 |

| νyz | 0.0575 | |

| νxz | 0.33 | |

| Gxy | calculated automatically by FE software | 5,55 MPa |

| Gyz | 0.47 MPa | |

| Gxz | 5548 MPa |

| Strain [%] | Stress [MPa] |

|---|---|

| 0.0 | 0.0 |

| 0.465 | 330 |

| 2.85 | 400 |

| 16.5 | 400 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schwinn, J.; Breitbarth, E.; Beumler, T.; Requena, G. Blunt Notch Strength of AA2024 3-3/2-0.4 Fibre Metal Laminate Under Biaxial Tensile Loading. Metals 2019, 9, 413. https://doi.org/10.3390/met9040413

Schwinn J, Breitbarth E, Beumler T, Requena G. Blunt Notch Strength of AA2024 3-3/2-0.4 Fibre Metal Laminate Under Biaxial Tensile Loading. Metals. 2019; 9(4):413. https://doi.org/10.3390/met9040413

Chicago/Turabian StyleSchwinn, Julian, Eric Breitbarth, Thomas Beumler, and Guillermo Requena. 2019. "Blunt Notch Strength of AA2024 3-3/2-0.4 Fibre Metal Laminate Under Biaxial Tensile Loading" Metals 9, no. 4: 413. https://doi.org/10.3390/met9040413

APA StyleSchwinn, J., Breitbarth, E., Beumler, T., & Requena, G. (2019). Blunt Notch Strength of AA2024 3-3/2-0.4 Fibre Metal Laminate Under Biaxial Tensile Loading. Metals, 9(4), 413. https://doi.org/10.3390/met9040413