Fluid Flow Control in a Billet Tundish during Steel Filling Operations

Abstract

:1. Introduction

2. Mathematical Model for the Two-Phase Flow

2.1. The Volume of Fluid Model

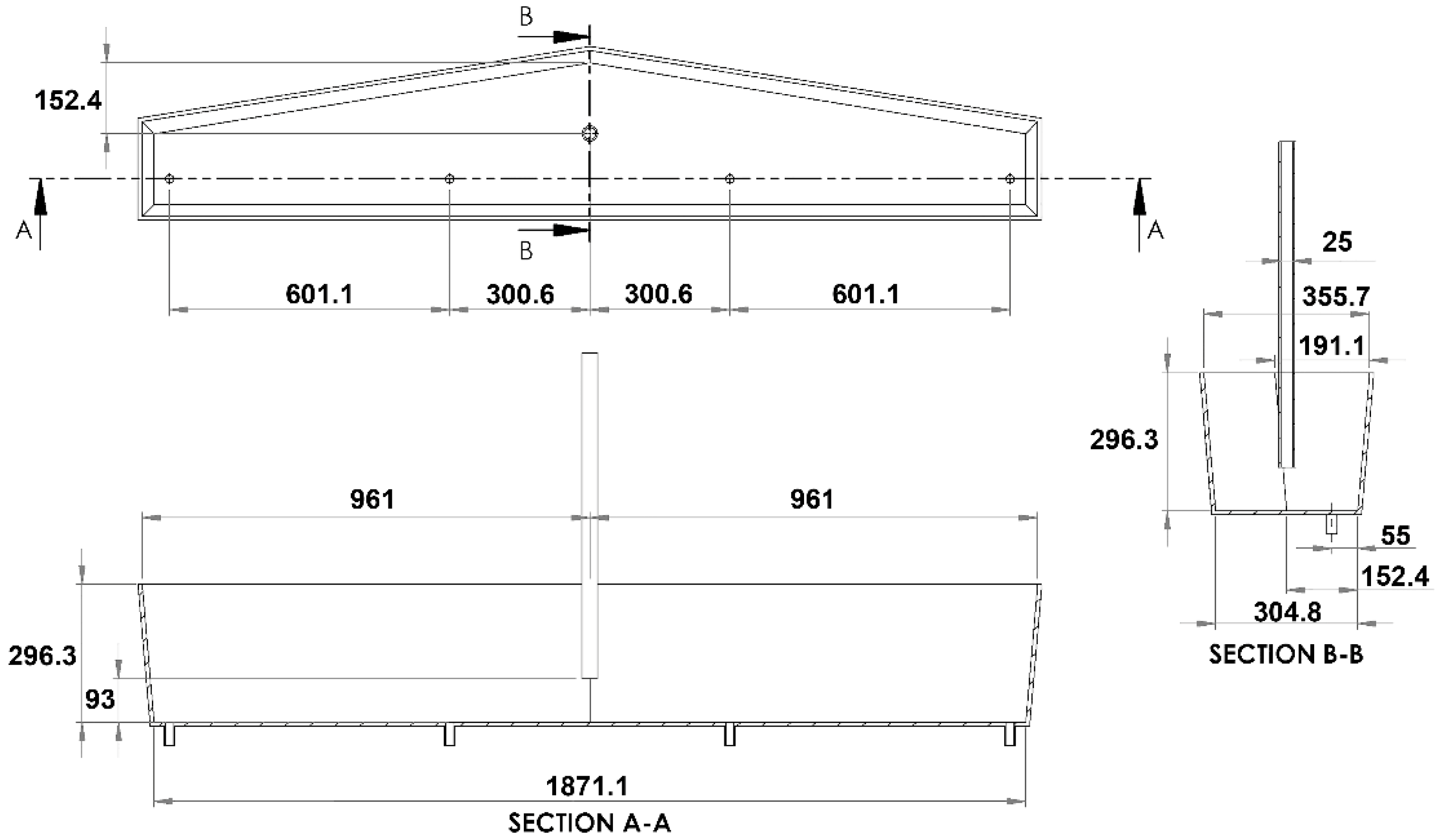

2.2. Boundary Conditions and Algorithm of Solution

3. Results and Discussion

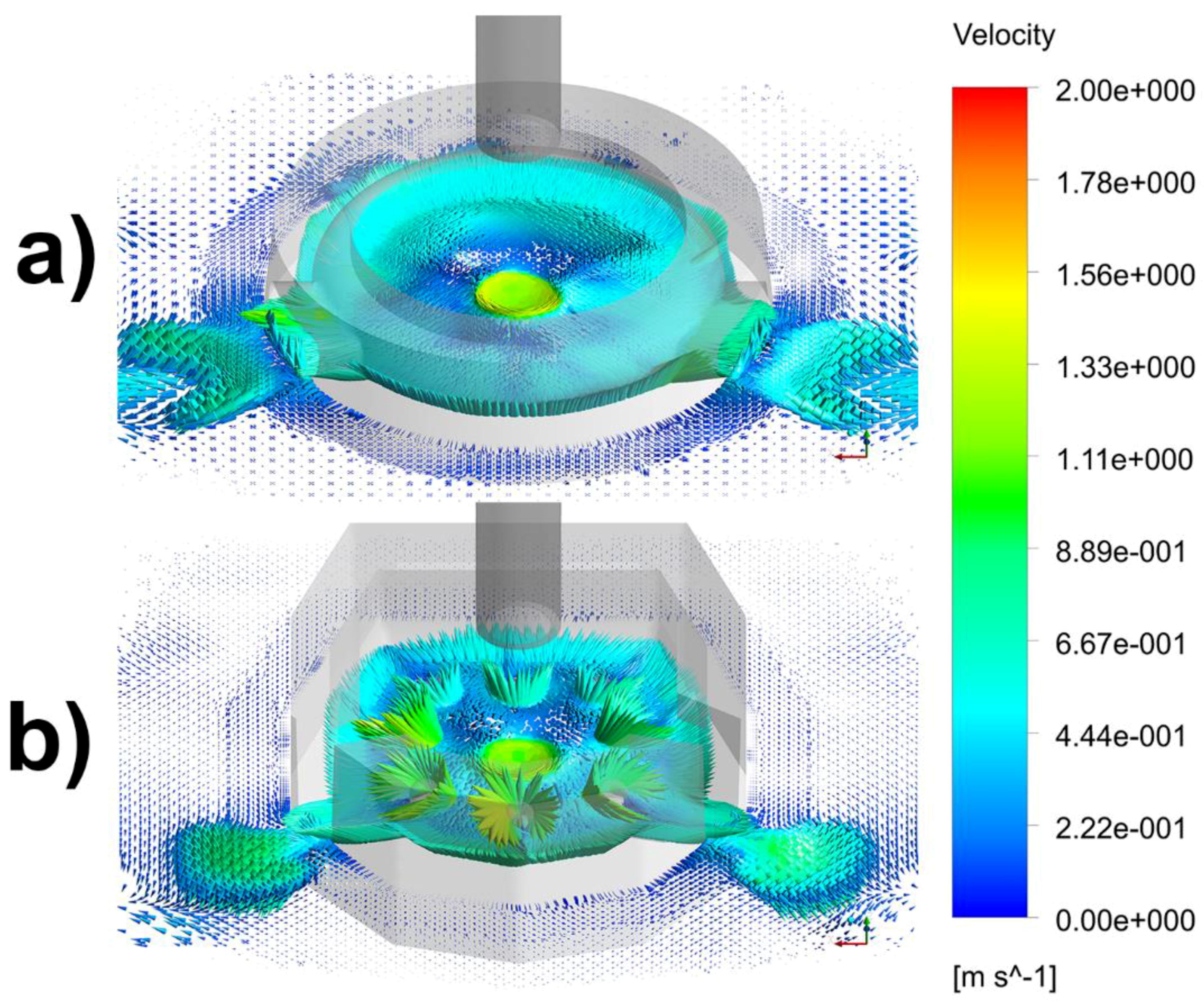

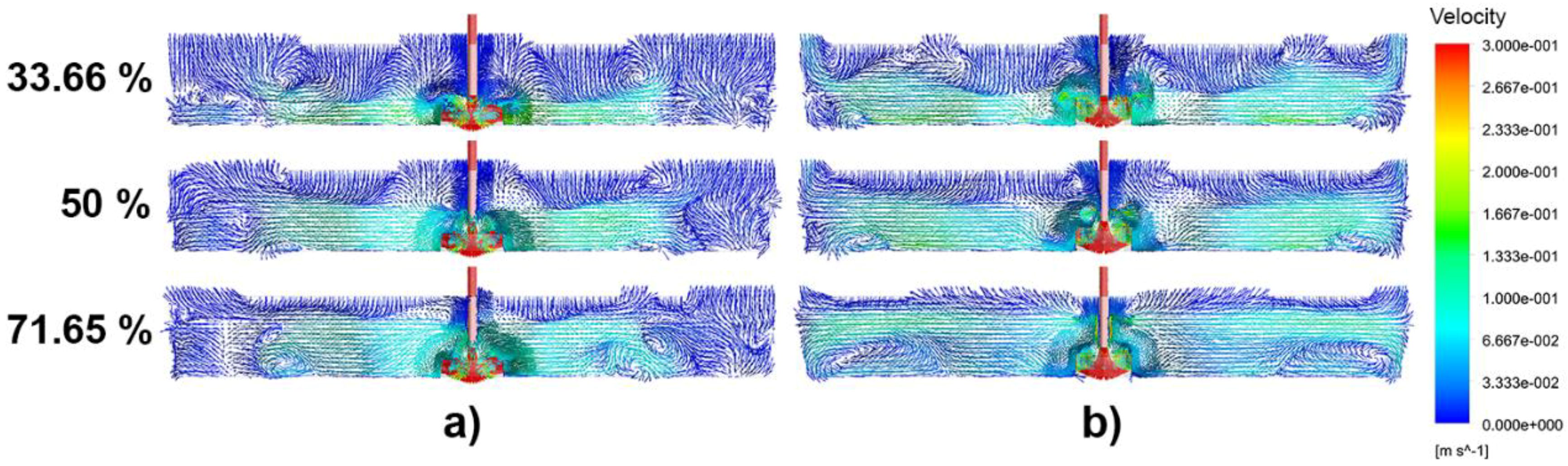

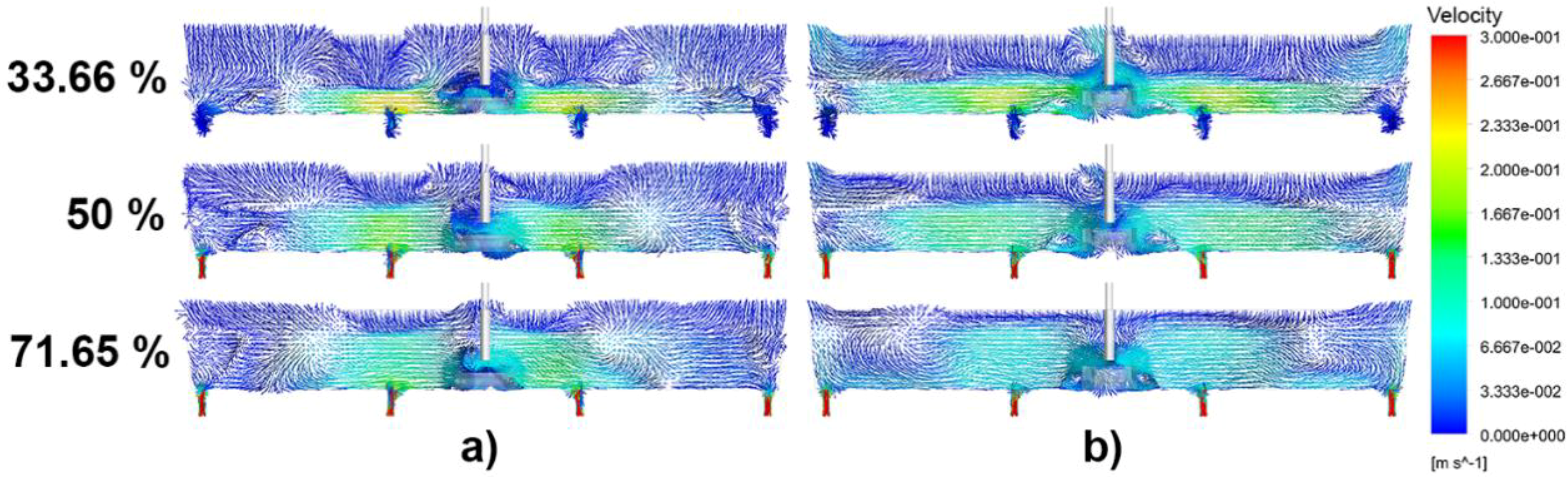

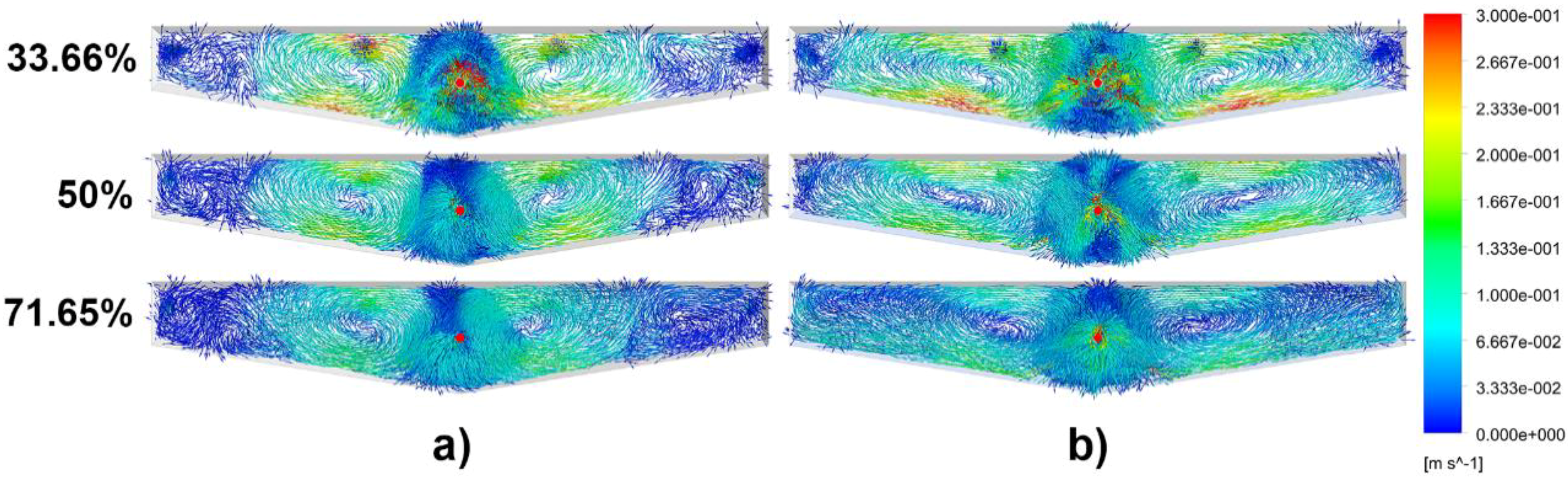

3.1. Control of Steel Freezing in Outer Strands

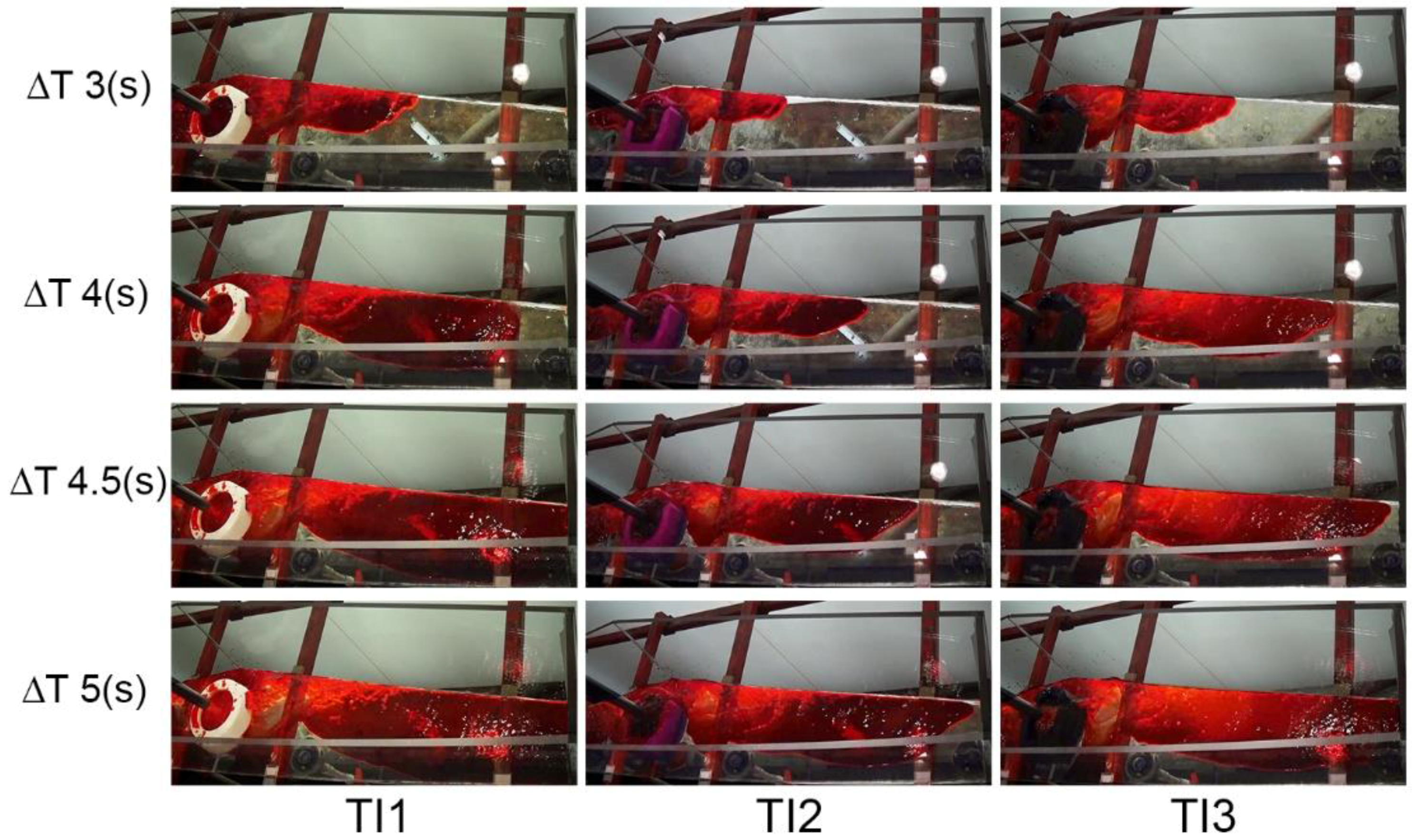

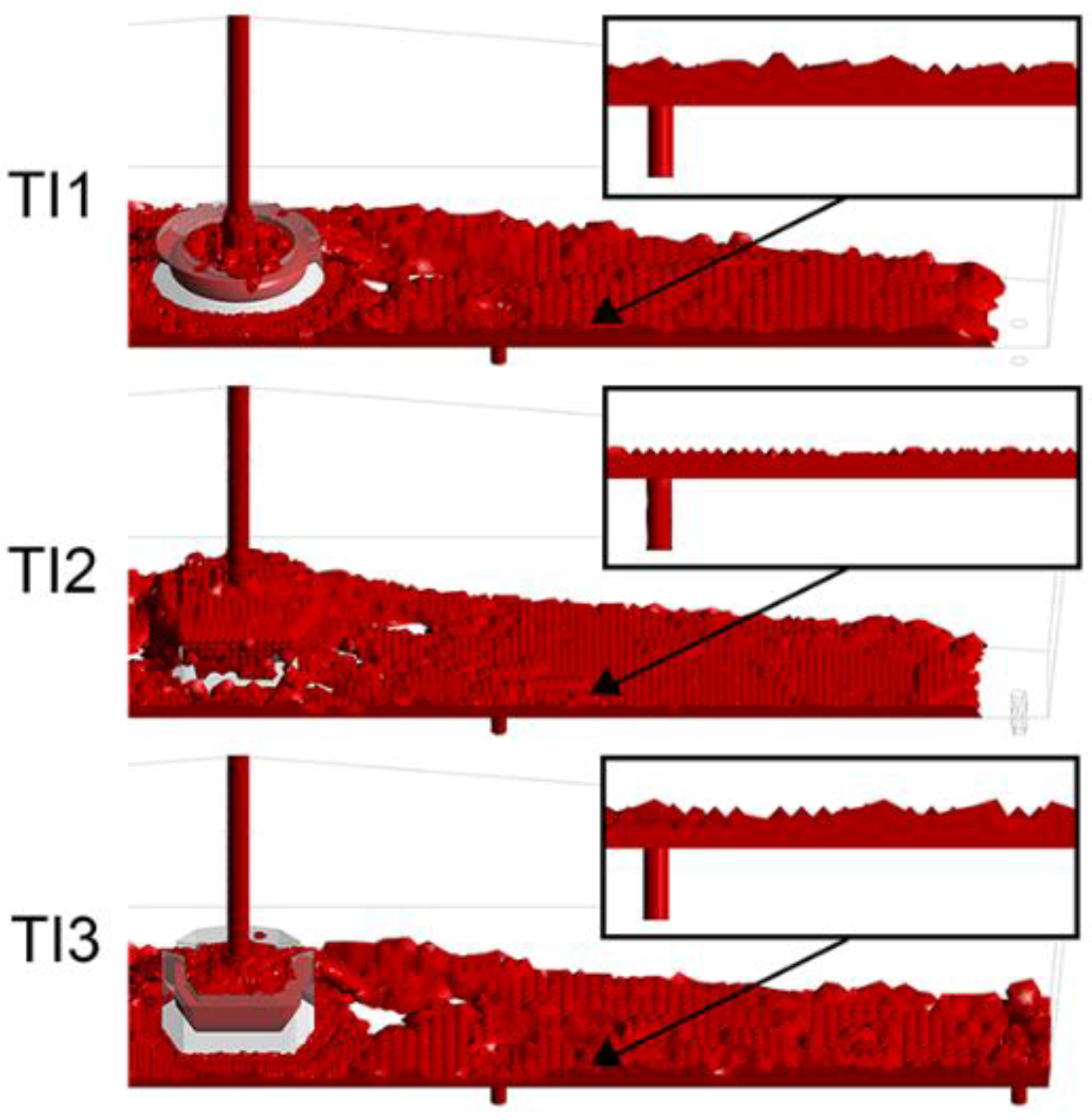

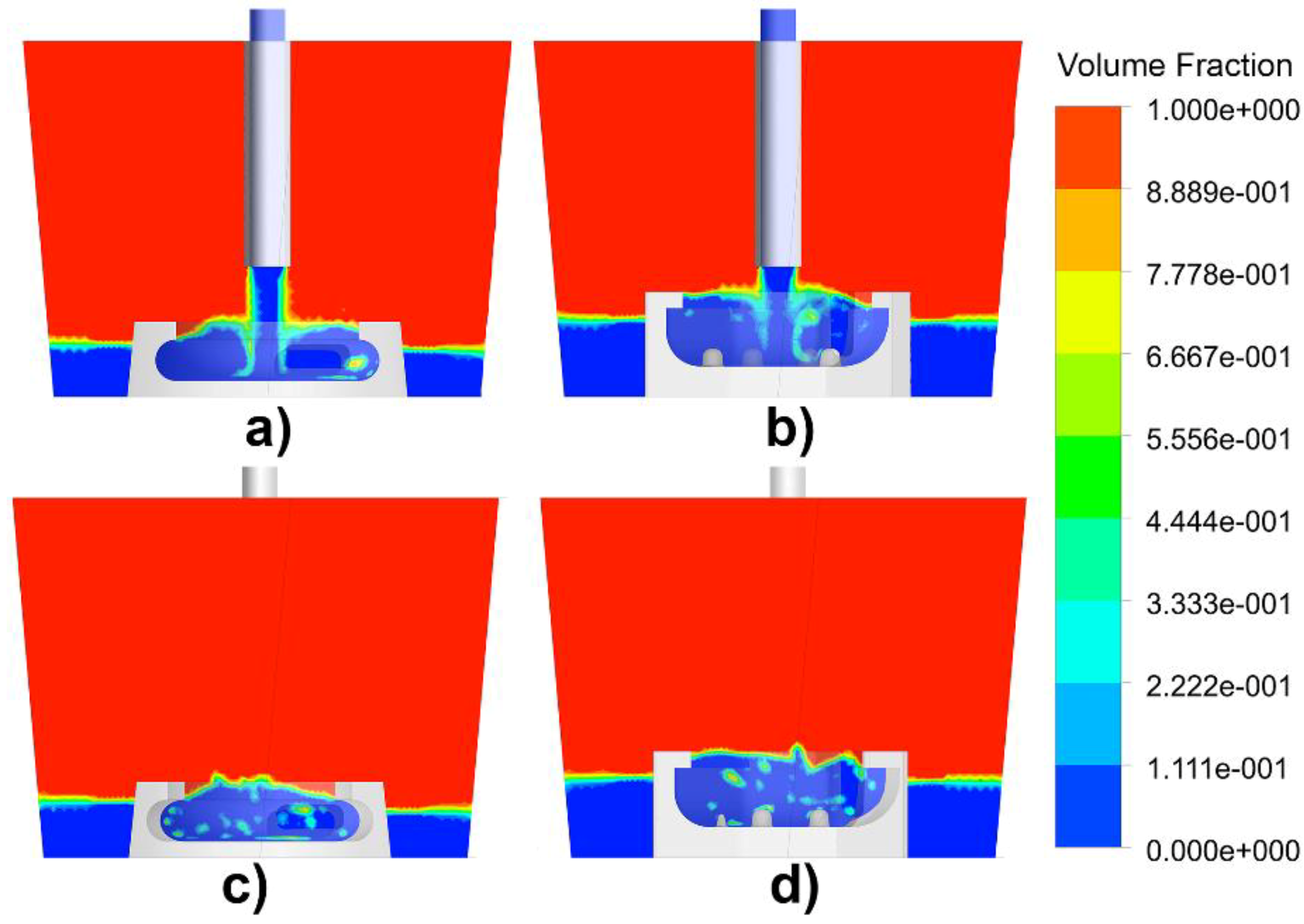

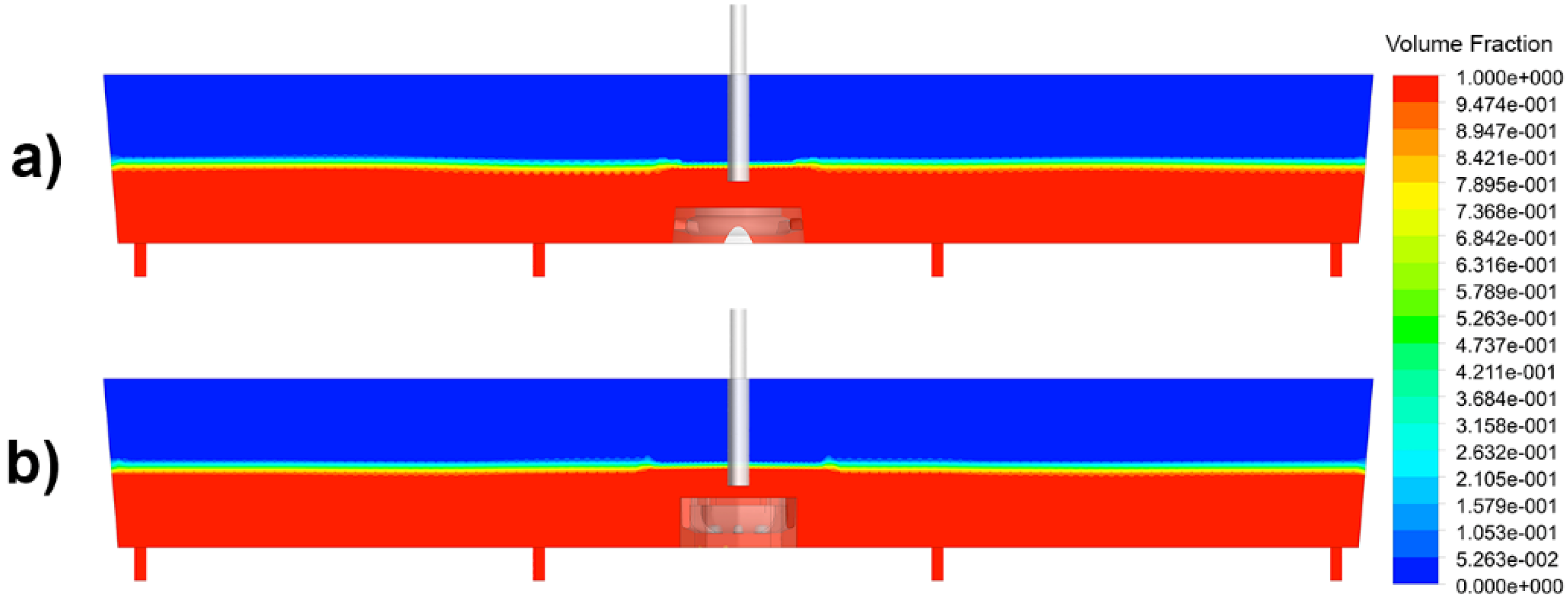

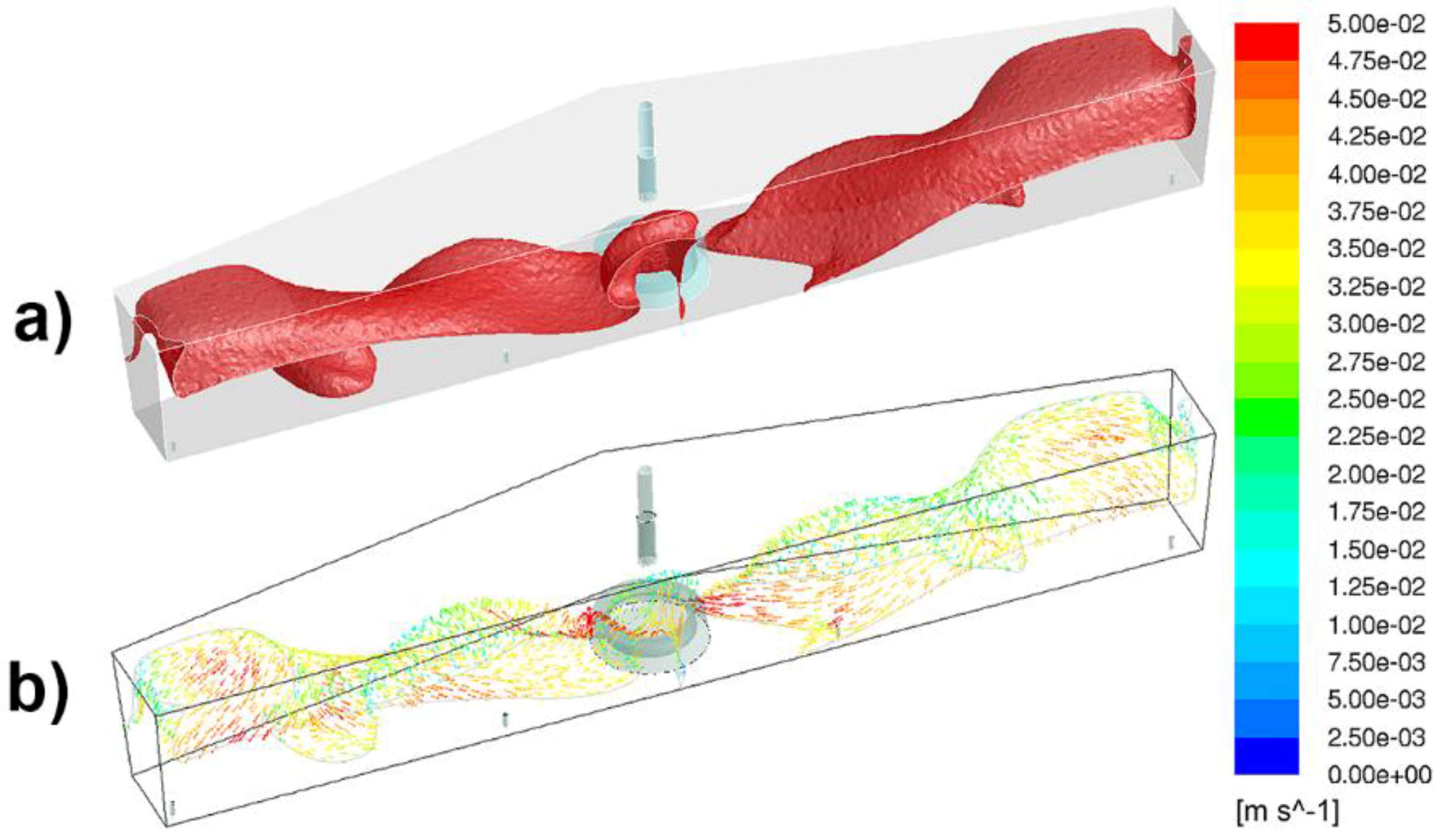

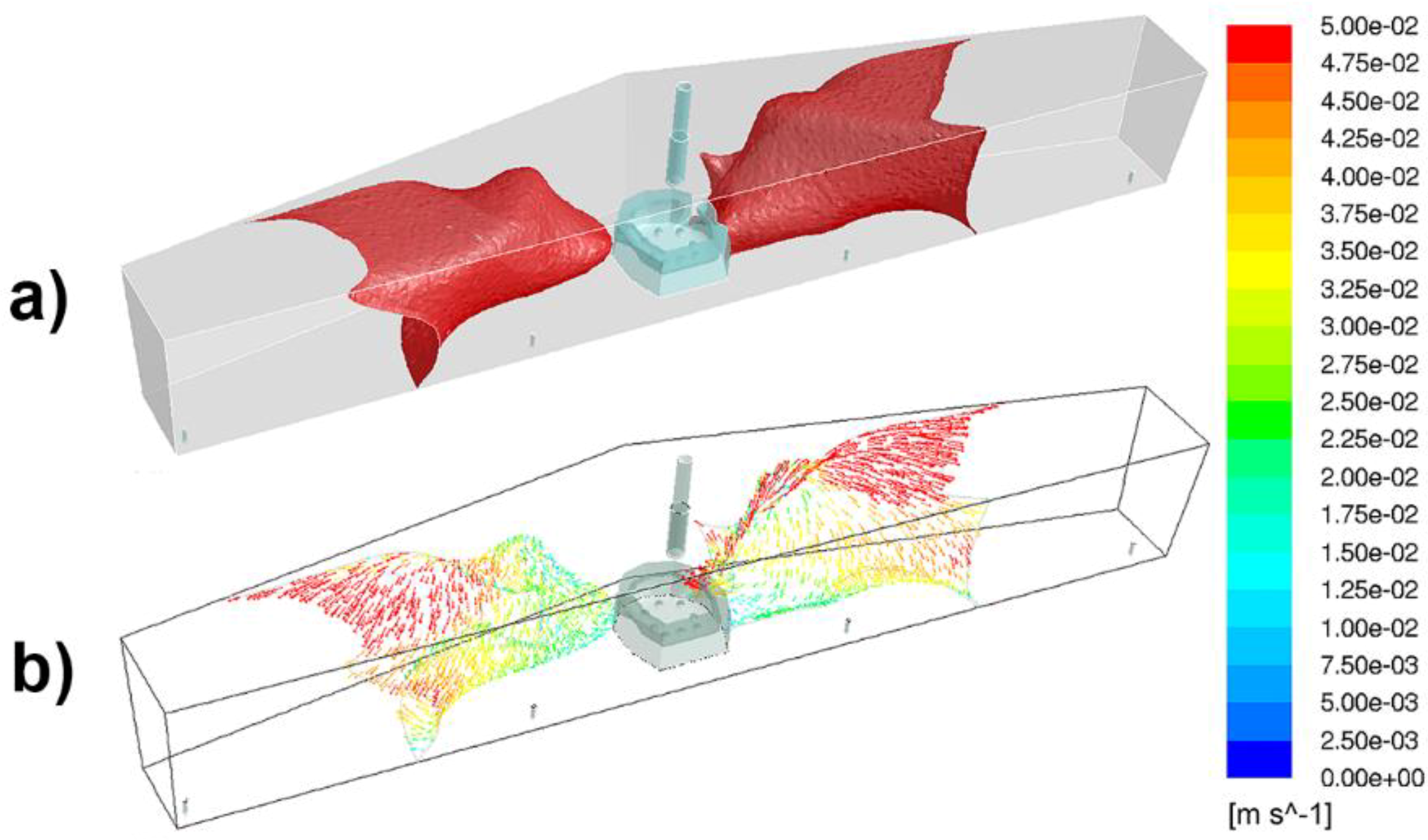

3.2. Control of Tundish Filling Operations

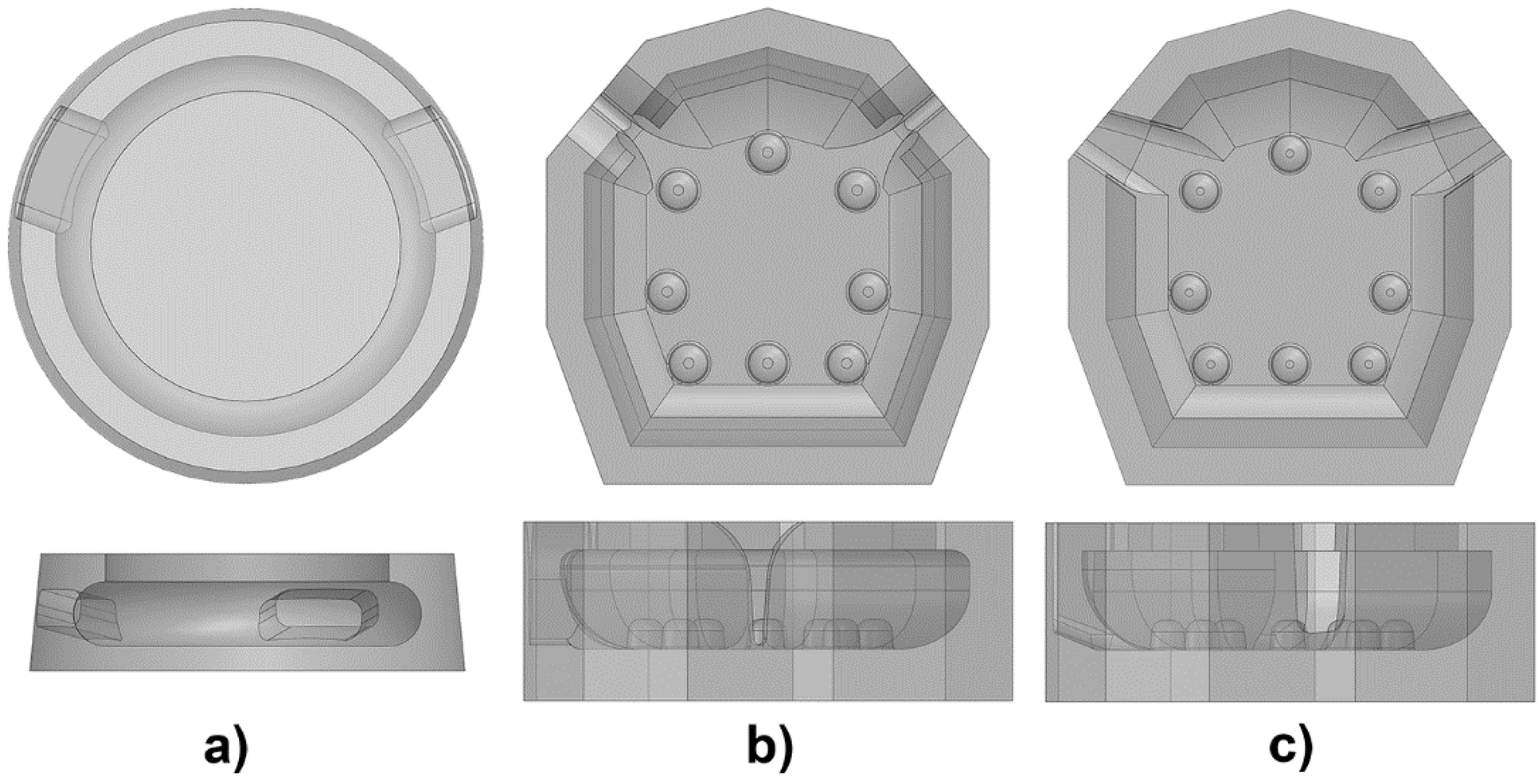

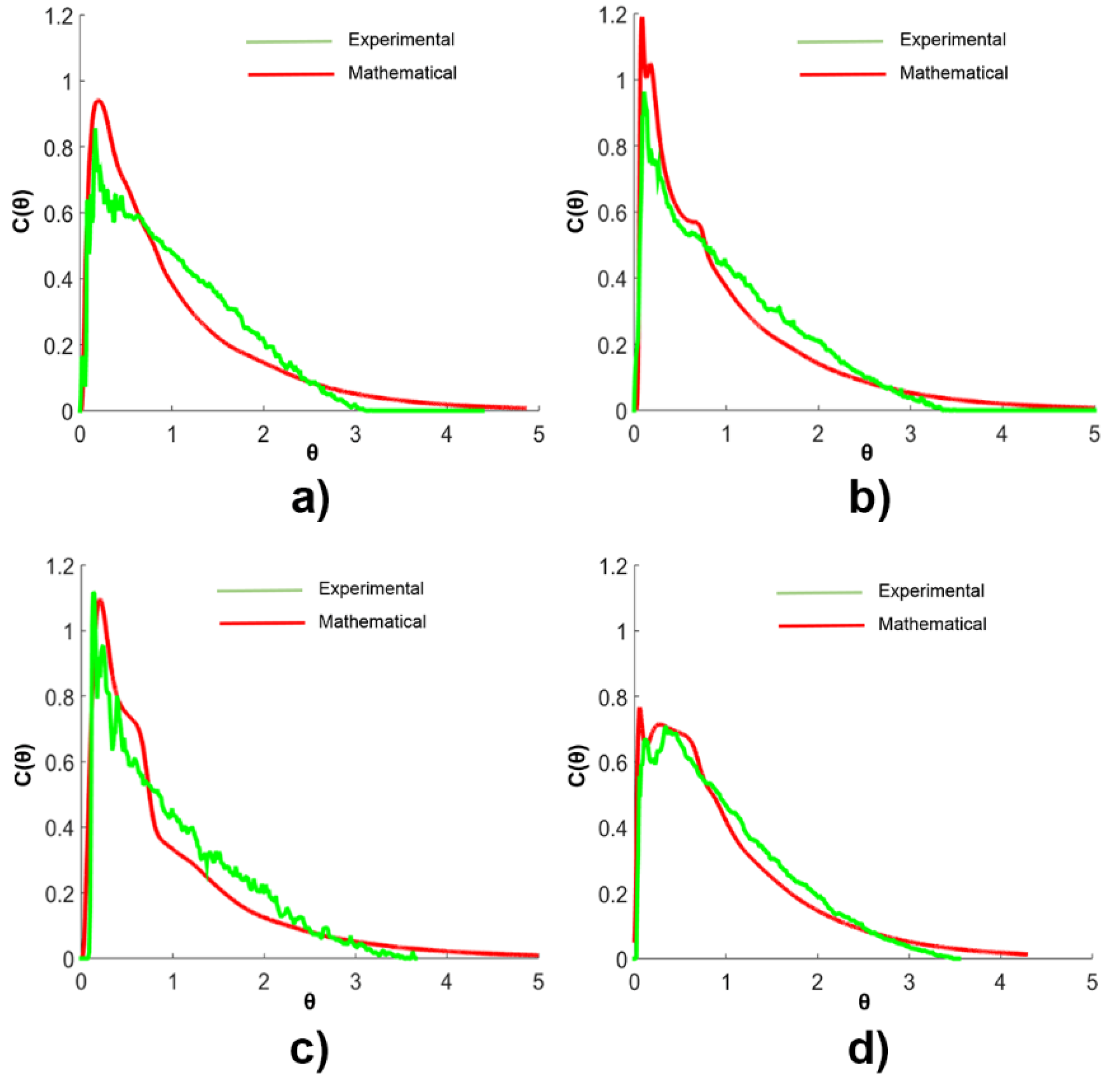

3.3. Experimental and Numerical RTD Curves

- TI2 yielded the highest plug volume fraction (which favors floatation of inclusions), but as mentioned above, delayed the steel stream toward the extreme strands leading to steel freezing problems during startup.

- TI3 yielded a slightly larger plug flow fraction than TI1, with smaller mixed flow fraction.

- The concentration peak of TI3 was the tallest among the three inhibitors.

4. Conclusions

- The coupling of physical and mathematical multiphase simulations provides a powerful modern approach to solve practical industrial problems.

- The VOF model predicts the speed at which the experimental stream of liquid in the tundish flows along the floor very well.

- The current requirements for the optimum design of turbulence inhibitors should include the maximization of plug flow patterns in combination with a good performance during unsteady operations of the tundish.

- The TI3 provides the highest plug flow using a flow pattern that sends the liquid toward the bath surface driving the inclusions toward the metal–slag interface.

Author Contributions

Acknowledgments

Conflicts of Interest

Nomenclature

| C | Concentration of a tracer |

| D0 and Deff | Molecular and turbulent diffusivities |

| F | Additional term force in the Navier–Stokes equations |

| Q | Liquid flow rate through the tundish |

| t | Time |

| tmin | Minimum residence time of the tracer inside the tundish |

| Mean residence time distribution | |

| TI1, TI2, TI3 | Turbulence inhibitors 1, 2, and 3 |

| u, v | Velocities |

| Sc | Schmidt number |

| V | Liquid volume in the tundish |

| Vd, Vdead | Dead volume |

| Vp, VPlug | Plug volume |

| Vm, Vmix. | Mixing volume |

| p | Pressure |

| α | Volume fraction |

| ρ | Density |

| μ | Viscosity |

| λ | Scale factor |

| Phase indicator | |

| θmean | As defined in Table 2. |

| Sub-Indexes | |

| p, q | Phases p and q |

| t | Turbulent |

References

- Morales, R.D.; López-Ramírez, S.; Palafox-Ramos, J.; de Jesus Barreto Sandoval, J.; Zacharias, D. Melt flow control in a multistrand tundish using a turbulence inhibitor. Metall. Mater. Trans. B 2000, 31, 1505–1515. [Google Scholar] [CrossRef]

- Fogler, H.S. Elements of Chemical Reaction Engineering; Prentice Hall Inc.: London, UK, 1992; pp. 708–710. [Google Scholar]

- López-Ramírez, S.; de Jesus Barreto-Sandoval, J.; Morales, R.D.; Zacharias, D. Physical and mathematical determination of the influence of input temperature changes on the molten steel flow characteristics in slab Tundishes. Metall. Mater. Trans. B 2001, 35, 957–966. [Google Scholar] [CrossRef]

- Espino-Zarate, A.; Morales, R.D.; Nájera-Bastida, A.; Macías-Hernández, M.; Sandoval-Ramos, A. Fluid flow and mechanisms of momentum transfer in a six-strand tundish. Metall. Mater. Trans. B 2010, 41, 962–975. [Google Scholar] [CrossRef]

- García-Hernández, S.; Morales, R.D.; de Jesus Barreto Sandoval, J.; Calderón-Ramos, I.; Gutiérrez, E. Modeling study of slag emulsification during ladle change-over using a dissipative ladle shroud. Steel Res. Int. 2016, 87, 1154–1167. [Google Scholar] [CrossRef]

- Morales, R.D.; García-Hernández, S.; de Jesus Barreto Sandoval, J.; Ceballos-Huerta, A.; Ramos, I.C.; Gutiérrez, E. Multiphase flow Modeling of slag entrainment during ladle change-over operation. Metall. Mater. Trans. B 2016, 47, 2595–2606. [Google Scholar] [CrossRef]

- Morales, R.D.; Guarneros, J.; Nájera-Bastida, A.; Rodrñiguez, J. Control of two-phase flows during startup operations of casting sequences in a billet tundish. JOM 2018, 70, 2103–2108. [Google Scholar] [CrossRef]

- Frank, M. White, Fluid Mechanics, 4th ed.; McGraw-Hill: New York, NY, USA, 1999; pp. 294–296. [Google Scholar]

- Hirth, C.W.; Nichols, B.D. Volume of Fluid (VOF) Method for the Dynamics of Free Boundaries. J. Comput. Phys. 1981, 39, 201. [Google Scholar] [CrossRef]

- Yeoh, G.H.; Tu, J. Computational Techniques for Multiphase Flows; Butterworth-Heinemann: Oxford, UK, 2010; pp. 133–170. [Google Scholar]

- Manual of ANSYS-FLUENT. Available online: http://www.ansys.com/Products/Fluids/ANSYS-Fluent (accessed on 5 March 2018).

- Ferziger, H.; Peric, M. Computational Methods for Fluid Dynamics; Springer: New York, NY, USA; Berlin, Germany, 2002; pp. 72–75. [Google Scholar]

- Bird, R.B.; Stewart, W.E.; Lightfoot, E.N. Transport. Phenomena, 2nd ed.; John Wiley & Sons: New York, NY, USA, 2007; pp. 166–168. [Google Scholar]

- Brackbill, J.U.; Kothe, D.B.; Zemack, C. A continuum method for modeling surface tension. J. Comput. Phys. 1992, 100, 335–354. [Google Scholar] [CrossRef]

- Manual of Solid Works. Available online: www.solidworks.com (accessed on 5 March 2018).

- Levenspiel, O. Chemical Reaction Engineering; John Wiley and Sons: New York, NY, USA, 1999; pp. 257–312. [Google Scholar]

| Operating Conditions | Value |

|---|---|

| Normal operating level | 254 mm |

| Ladle shroud diameter | 25 mm |

| Ladle shroud submergence | 161 |

| Typical liquid flow rate at inlet | 19.92 L/min |

| Flow rate for tundish filling | 40 L/min |

| Inside diameter of the strand | 18 mm |

| Flow Parameters | TI1 | TI2 | TI3 |

|---|---|---|---|

| Average time (s) | 358.43 | 358.43 | 358.43 |

| Plug (%) | 8.16 | 16.95 | 11.0 |

| Mixture (%) | 44.0 | 35.0 | 40.1 |

| Dead Volume (%) | 47.84 | 48.05 | 48.9 |

| Cpeak (g/cm3) | 26.37 × 10−6 | 27.13 × 10−6 | 32.5 × 10−6 |

| RTD Curves | |||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morales, R.D.; Guarneros, J.; Chattopadhyay, K.; Nájera-Bastida, A.; Rodríguez, J. Fluid Flow Control in a Billet Tundish during Steel Filling Operations. Metals 2019, 9, 394. https://doi.org/10.3390/met9040394

Morales RD, Guarneros J, Chattopadhyay K, Nájera-Bastida A, Rodríguez J. Fluid Flow Control in a Billet Tundish during Steel Filling Operations. Metals. 2019; 9(4):394. https://doi.org/10.3390/met9040394

Chicago/Turabian StyleMorales, Rodolfo D., Javier Guarneros, Kinnor Chattopadhyay, Alfonso Nájera-Bastida, and Jafeth Rodríguez. 2019. "Fluid Flow Control in a Billet Tundish during Steel Filling Operations" Metals 9, no. 4: 394. https://doi.org/10.3390/met9040394

APA StyleMorales, R. D., Guarneros, J., Chattopadhyay, K., Nájera-Bastida, A., & Rodríguez, J. (2019). Fluid Flow Control in a Billet Tundish during Steel Filling Operations. Metals, 9(4), 394. https://doi.org/10.3390/met9040394