Butt Joining of Bi-Layered Aluminum Sheets through Friction Stir Welding: Tensile Stresses, Bending Stresses, Residual Stresses, and Fractrography

Abstract

1. Introduction

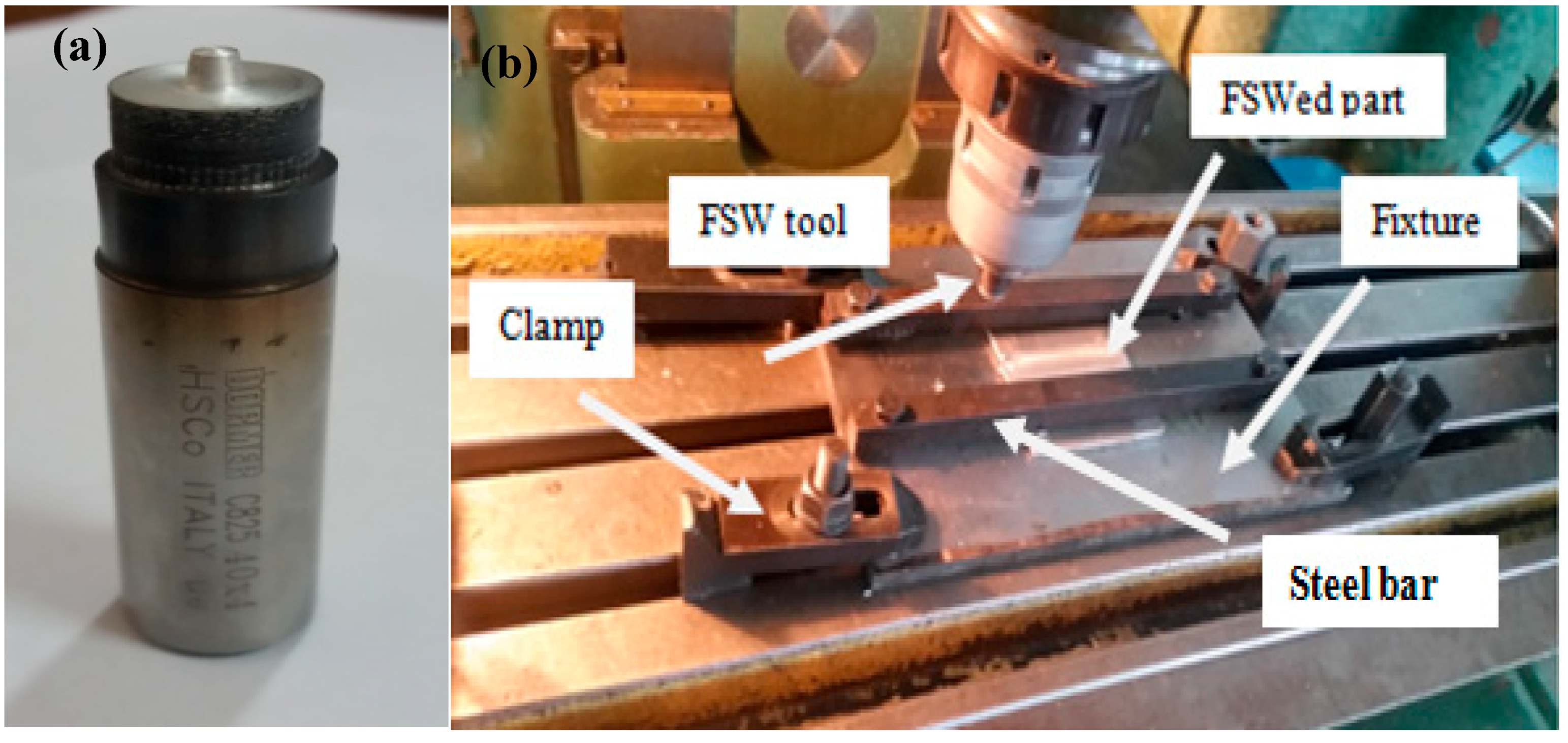

2. Materials and Methods

3. Results and Discussion

3.1. Microscopic Observations

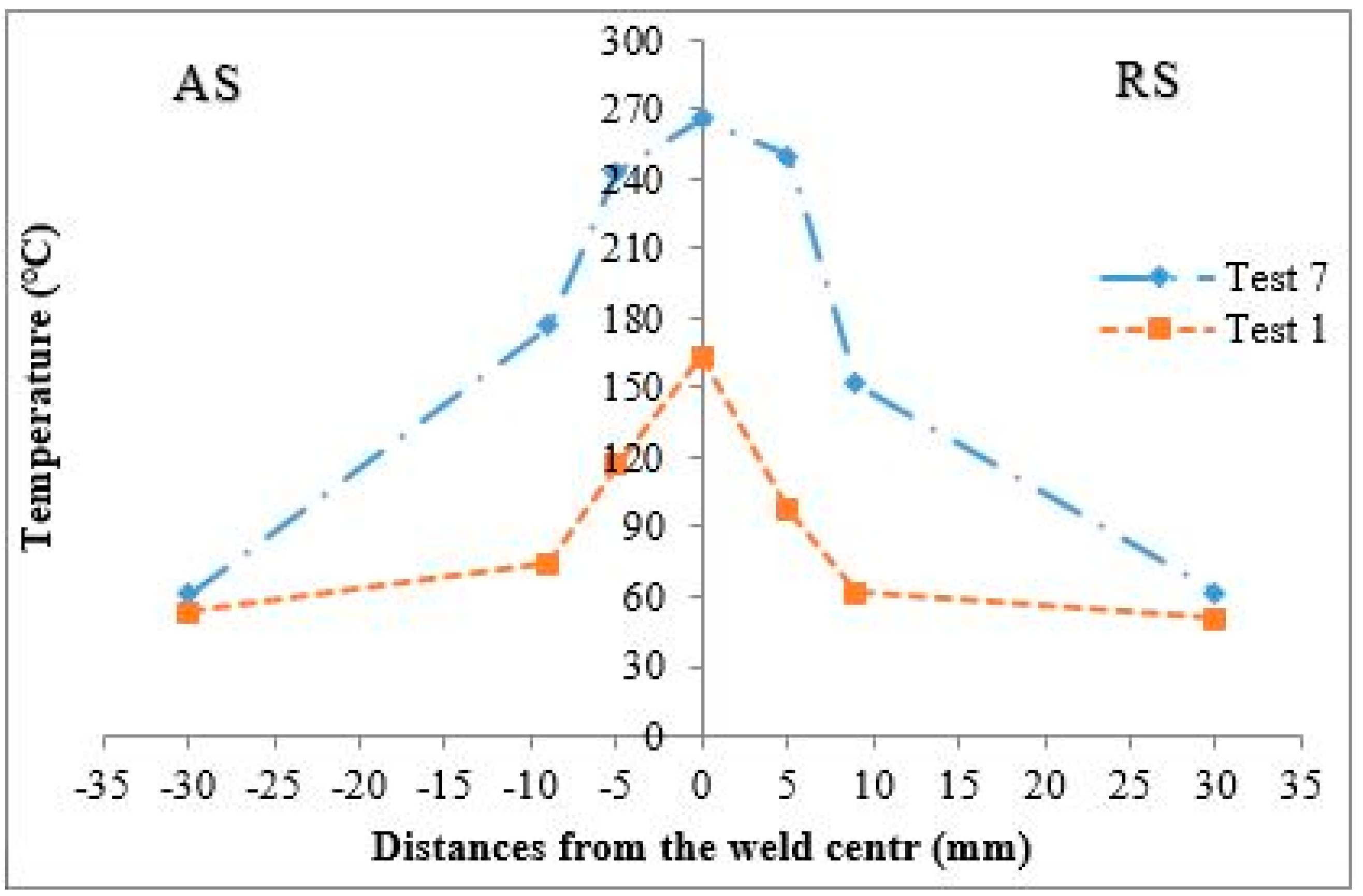

3.2. Temperature Evolution

3.3. Tensile Properties

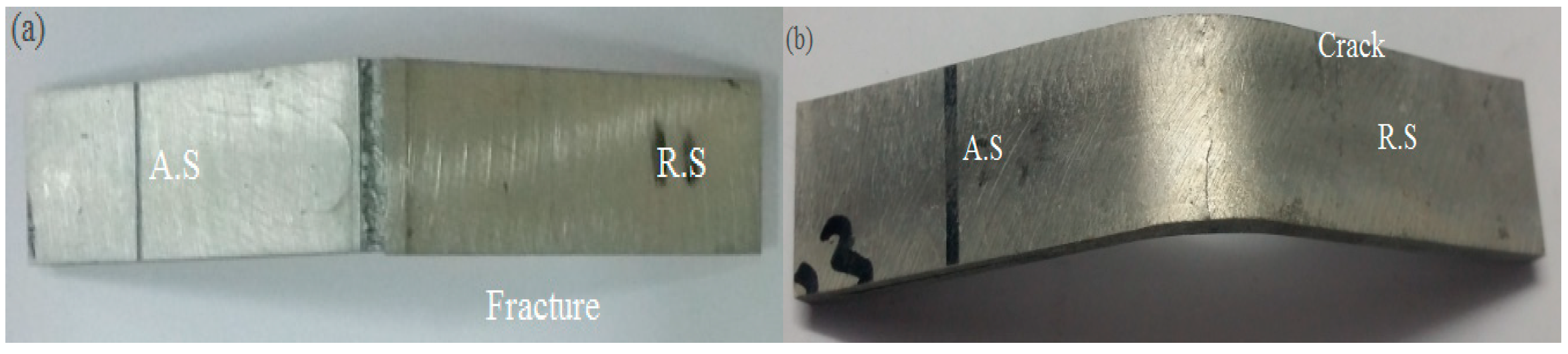

3.4. Guided Bend Test for Ductility of Welds

3.5. Residual Stress Distribution in Welded Zones

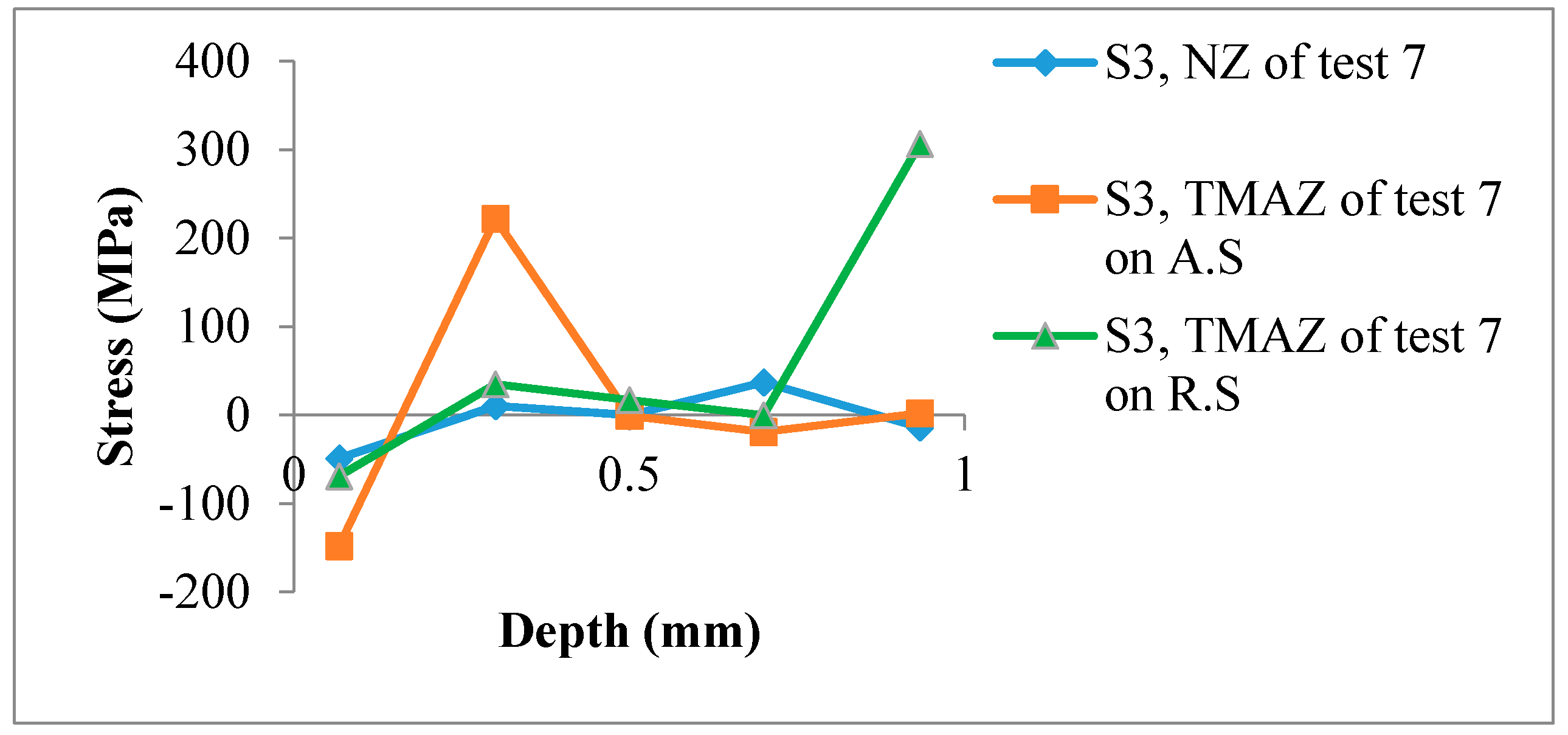

3.6. Comparison of Residual Stress Distribution

3.7. Fracture Mechanism

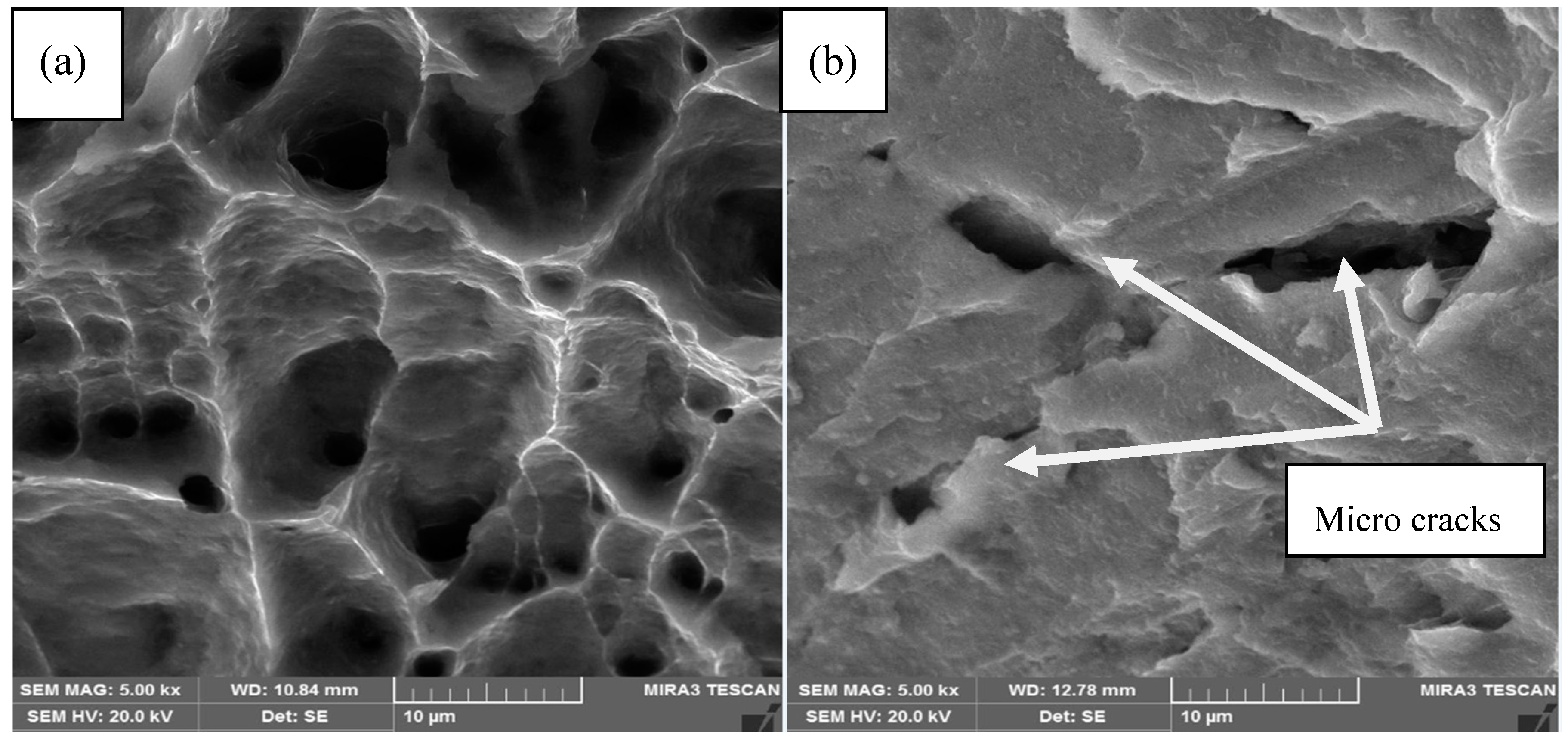

3.7.1. Fracture under Tensile Loadings

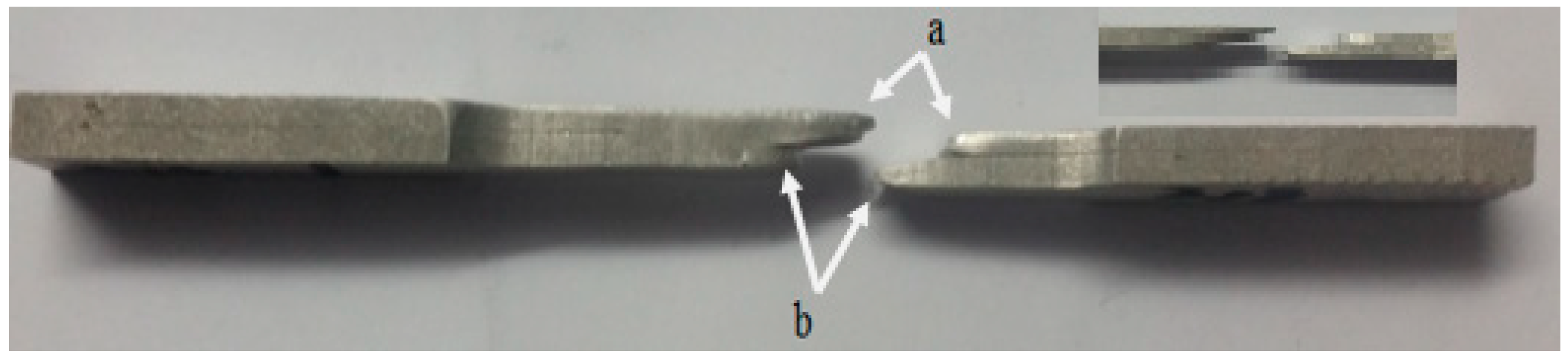

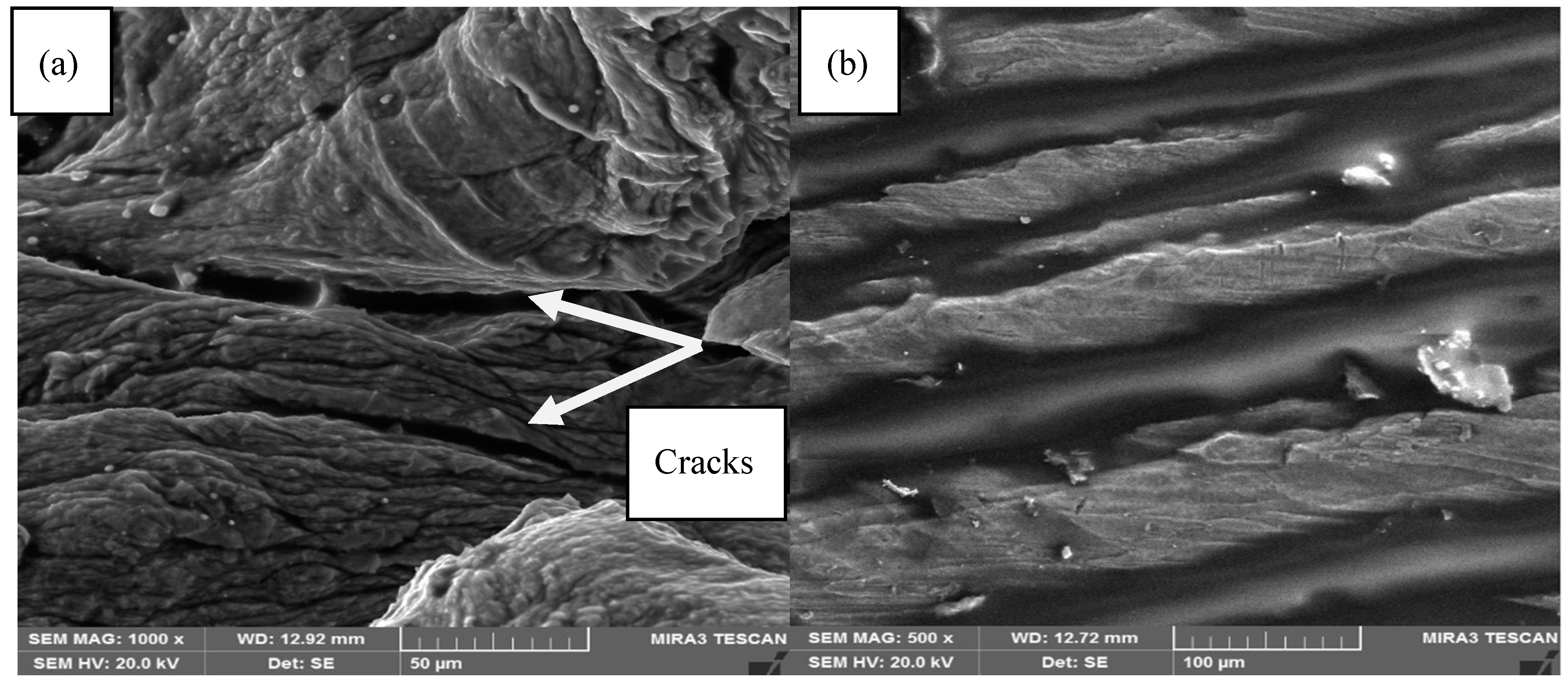

3.7.2. Fracture under Bending Loads

3.8. Comparison between FSW of Layered and Monolithic Sheet Metals

3.9. Proposed Welding Conditions for Laminated Aluminum Sheets

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kelkar, A.; Roth, R.; Clark, J. Automobile bodies: Can aluminum be an economical alternative to steel? JOM 2001, 53, 28–32. [Google Scholar]

- Blawert, C.; Hort, N.; Kainer, K.U. Automotive applications of magnesium and its alloys. Trans. Indian Inst. Met. 2004, 57, 397–408. [Google Scholar]

- Jo, Y.M.; Lee, K.S.; Lee, Y.S.; Kang, N. Influence of annealing on the interface-correlated mechanical properties of a Ti/STS clad sheet. J. Korean Inst. Met. Mater. 2014, 52, 881–891. [Google Scholar]

- Mishra, R.S.; Ma, Z.Y. Frictions stir welding and processing. Mater. Sci. Eng. R Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Stephan, A.; Airbus Deutschland GmbH. Laminate Sheet, in Particular for Fuselage Skin Sheets for Aircrafts. U.S. Patent 7,875,333, 25 January 2011. [Google Scholar]

- Shigematsu, I.; Kwon, Y.J.; Suzuki, K.; Imai, T.; Saito, N. Joining of 5083 and 6061 aluminum alloys by friction stir welding. J. Mater. Sci. Lett. 2003, 22, 353–356. [Google Scholar] [CrossRef]

- Cao, X.; Jahazi, M. Effect of tool rotational speed and probe length on lap joint quality of a friction stir welded magnesium alloy. Mater. Des. 2011, 32, 1–11. [Google Scholar] [CrossRef]

- Xu, N.; Ueji, R.; Fujii, H. Dynamic and static change of grain size and texture of copper during friction stir welding. J. Mater. Process.Technol. 2016, 232, 90–99. [Google Scholar] [CrossRef]

- Buffa, G.; Fratini, L.; Micari, F. Mechanical and microstructural properties prediction by artificial neural networks in FSW processes of dual phase titanium alloys. J. Manuf. Process. 2012, 14, 289–296. [Google Scholar] [CrossRef]

- Thomas, W.M.; Nicholas, E.D. Friction stir welding for the transportation industries. Mater. Des. 1997, 18, 269–273. [Google Scholar] [CrossRef]

- Perrett, J.G.; Martin, J.; Threadgill, P.L.; Ahmed, M.M.Z. Recent developments in friction stir welding of thick section aluminium alloys. In Proceedings of the 6th World Congress, Aluminium Two Thousand, Florence, Italy, 15 March 2007; pp. 13–17. [Google Scholar]

- Threadgill, P. Friction stir welds in aluminium alloys–preliminary microstructural assessment. TWI Bull. 1997, 38, 30–33. [Google Scholar]

- Biallas, G.; Braun, R.; Donne, C.D.; Staniek, G.; Kaysser, W.A. Mechanical properties and corrosion behaviour of friction stir welded 2024-T3. In Proceedings of the First International Symposium on Friction Stir Welding, Thousand Oaks, CA, USA, 14–16 June 1999. [Google Scholar]

- Mishra, R.S.; Sharma, S.R.; Mara, N.A.; Mahoney, M.W. Mechanical properties of friction stir welded aluminum alloys. In Joining of Advanced and Specialty Materials; ASM International: Materials Park, OH, USA, 2000; pp. 157–159. [Google Scholar]

- Von Strombeck, A.; dos Santos, J.F.; Torster, F.; Laureano, P.; Koc, M. Fracture Toughness Behavior of FSW Joints on Aluminum Alloys. In Proceedings of the 1st International Symposium on Friction Stir Welding, Thousand Oaks, CA, USA, 14–16 June 1999. [Google Scholar]

- Bisadi, H.; Tour, M.; Tavakoli, A. The influence of process parameters on microstructure and mechanical properties of friction stir welded Al 5083 alloy lap joint. Am. J. Mater. Sci. 2011, 1, 93–97. [Google Scholar] [CrossRef]

- Peel, M.; Steuwer, A.; Preuss, M.; Withers, P.J. Microstructure, mechanical properties and residual stresses as a function of welding speed in aluminium AA5083 friction stir welds. Acta Mater. 2003, 51, 4791–4801. [Google Scholar] [CrossRef]

- Donne, C.D.; Lima, E.; Wegener, J.; Pyzalla, A.; Buslaps, T. Investigations on residual stresses in friction stir welds. In Proceedings of the Third International Symposium on Friction Stir Welding, Kobe, Japan, 27–28 September 2001. [Google Scholar]

- James, M.; Mahoney, M.; Waldron, D. Residual Stress Measurements in Friction Stir Welded Aluminum Alloys. In Proceedings of the 1st International Symposium on Friction StirWelding, Thousand Oaks, CA, USA, 14–16 June 1999. [Google Scholar]

- Beygi, R.; Kazeminezhad, M.; Kokabi, A.H. Butt joining of Al–Cu bilayer sheet through friction stir welding. Trans. Nonferrous Met. Soc. China 2012, 22, 2925–2929. [Google Scholar] [CrossRef]

- Lee, T.H.; Lee, Y.J.; Park, K.T.; Jeong, H.G.; Lee, J.H. Mechanical and asymmetrical thermal properties of Al/Cu composite fabricated by repeated hydrostatic extrusion process. Met. Mater. Int. 2015, 21, 402–407. [Google Scholar] [CrossRef]

- Khan, I.; Hussain, G.; Tariq, M.; Ilyas, M. Fabrication of UHMW polyethylene/nano-hydroxyapatite biocomposite via heat-assisted friction stir processing. Int. J. Adv. Manuf. Technol. 2018, 96, 3651–3663. [Google Scholar] [CrossRef]

- Mahoney, M.W.; Rhodes, C.G.; Flintoff, J.G.; Bingel, W.H.; Spurling, R.A. Properties of friction-stir-welded 7075 T651 aluminum. Metall. Mater. Trans. A 1998, 29, 1955–1964. [Google Scholar] [CrossRef]

- Dialami, N.; Cervera, M.; Chiumenti, M.; de Saracibar, C.A. Local–global strategy for the prediction of residual stresses in FSW processes. Int. J. Adv. Manuf. Technol. 2017, 88, 3099–3111. [Google Scholar] [CrossRef]

- Buglioni, L.; Tufaro, L.N.; Svoboda, H.G. Thermal cycles and residual stresses in FSW of aluminum alloys: Experimental measurements and numerical models. Procedia Mater. Sci. 2015, 9, 87–96. [Google Scholar] [CrossRef]

- Arbegast, W.J.; Hartley, P.J. Friction Stir Welding. In Proceedings of the 5th International Conference on Trends in Welding Research, Pine Mountain, GA, USA, 1–5 June 1998; p. 541. [Google Scholar]

- Khodir, A.; Shibayanagi, T. Microstructure and mechanical properties of friction stir welded AA2024-T3 aluminum alloy. Mater. Trans. 2007, 48, 1928–1937. [Google Scholar] [CrossRef]

- CAVALIERE, P.; Cerri, E.; Marzoli, L.; Dos Santos, J. Friction stir welding of ceramic particle reinforced aluminium based metal matrix composites. Appl. Compos. Mater. 2004, 11, 247–258. [Google Scholar] [CrossRef]

- Chen, X.G.; da Silva, M.; Gougeon, P.; St-Georges, L. Microstructure and mechanical properties of friction stir welded A A60 63–B4C metal matrix composites. Mater. Sci. Eng. A 2009, 518, 174–184. [Google Scholar] [CrossRef]

- Khodir, S.A.; Shibayanagi, T. Friction stir welding of dissimilar AA2024 and AA7075 aluminum alloys. Mater. Sci. Eng. B 2008, 148, 82–87. [Google Scholar] [CrossRef]

| Material | Al | Fe | Si | Cr | Cu | Zn | Mn | Others |

|---|---|---|---|---|---|---|---|---|

| 1350 | 99.5 Min | 0.40 Max | 0.10 Max | 0.10 Max | 0.05 Max | 0.05 Max | 0.01 Max | 0.03 each 0.1 total |

| Density (kg/m3) | Poisson’s Ratio | Elastic Modulus (GPa) | Tensile Strength (MPa) | Yield Strength (MPa) | % Elongation (for Gauge Length of 25 mm) |

|---|---|---|---|---|---|

| 2600–2800 | 0.33 | 69–80 | 96.9 | 81 | 28.4 |

| Test No. | Tool Rotation Rate (ω, rpm) | Tool Traverse Rate (v, mm/min) |

|---|---|---|

| 1 | 750 | 47.5 |

| 2 | 75 | |

| 3 | 118 | |

| 4 | 1180 | 47.5 |

| 5 | 75 | |

| 6 | 118 | |

| 7 | 1500 | 47.5 |

| 8 | 75 | |

| 9 | 118 |

| Sample | % Elongation | Ultimate Tensile Strength (MPa) | Deviation from the Mean Value (%) | Defects |

|---|---|---|---|---|

| Test 1 | 4.93 | 33.72 | 2.2 to 3.4 | Voids |

| Test 2 | 17.75 | 75.39 | 1 to 2.5 | - |

| Test 3 | 19.72 | 74.39 | 2.5 to 3.3 | - |

| Test 4 | 5.32 | 34.32 | 2.1 to 3.1 | Voids |

| Test 5 | 11.16 | 66.09 | 0.6 to 2.5 | - |

| Test 6 | 15.14 | 66.06 | 1.2 to 2.1 | - |

| Test 7 | 24.72 | 79.10 | 2.6 to 2.9 | - |

| Test 8 | 18.20 | 78.98 | 1 to 1.5 | Voids |

| Test 9 | 19.96 | 76.98 | 0.8 to 2.1 | Cracks |

| BM | 28.40 | 96.92 | 0.2 to 1 | - |

| Sample | Average Flexural Strength (MPa) | Deviation from the Mean Value (%) | Fracture | Defects |

|---|---|---|---|---|

| Test 1 | 0.45 | 1 | YES | Voids |

| Test 2 | 2.52 | 3 | NO | - |

| Test 3 | 3.15 | 1.2 | YES | - |

| Test 4 | 0.87 | 0.5 | YES | Voids |

| Test 5 | 2.1 | 0.6 | YES | - |

| Test 6 | 2.49 | 2.1 | SMALL | - |

| Test 7 | 2.53 | 1.3 | NO | - |

| Test 8 | 2.94 | 2.8 | SMALL | Voids |

| Test 9 | 2.93 | 3.3 | NO | Cracks |

| BM | 2.5 | 0.2 to 1 | NO | - |

| Material | Monolithic/Laminated | Work Piece Thickness (mm) | Rotational Speed (ω, rpm) | Feed Rate (ν, mm/min) | UTS (MPa) | % Elongation |

|---|---|---|---|---|---|---|

| 2024-T3/7075-T6 [27] | M | 3 | “↑” | “→” | “↑” | “↑” |

| 400–800 | 100 | 399–407 | 14–14.3 | |||

| 2024-T3/7075-T6 [27] | M | 3 | “↑” | “→” | “↓” | “↓” |

| 1200–2000 | 100 | 423–363 | 14.9–7.5 | |||

| AA7005/Al2O3/10p [28] | M | 7 | “↑” | “→” | “↑” | 58 |

| 800 | 56 | 260 | ● | |||

| AA6063/ B4C [29] | M | 4.5 | “↑” | “→” | “↓” | 2.5 |

| 1200–1500 | 600 | 176 | ● | |||

| 2024-T3/7075-T6 [30] | M | 3 | “→” | “↑” | “↓” | “↓” |

| 1200 | 102-198 | 423–398 | 14.9–11.4 | |||

| 2024Al-T3 [13] | M | 4 | “↑” | “↑” | “↑” | “↑” |

| 800–1250 | 80–125 | 408–432 | 6.6–7.6 | |||

| 2024-T3/7075-T6 [30] | M | 3 | “→” | “↑” | “↑” | “↑” |

| 1200 | 42–72 | 395–404 | 13.6–14.5 | |||

| Al-1350 [Current Study] | L | 4 | “↑” | “→” | “↑” | “↑” |

| 750–1500 | 47.5 | 33.7–77.5 | 4.9–24.7 | |||

| Al-1350 [Current Study] | L | 4 | “→” | “↑” | “↑” | “↑” |

| 1180 | 47.5–118 | 34.3–66 | 5.3–15.1 | |||

| Al-1350 [Current Study] | L | 4 | “→” | “↑” | “↓” | “↓” |

| 1500 | 47.5–118 | 77.5–77 | 24.7–20 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, H.; Tariq, M.; Hussain, G.; Khan, I.; Imran Khan, M.; Khan, W.A. Butt Joining of Bi-Layered Aluminum Sheets through Friction Stir Welding: Tensile Stresses, Bending Stresses, Residual Stresses, and Fractrography. Metals 2019, 9, 384. https://doi.org/10.3390/met9040384

Wei H, Tariq M, Hussain G, Khan I, Imran Khan M, Khan WA. Butt Joining of Bi-Layered Aluminum Sheets through Friction Stir Welding: Tensile Stresses, Bending Stresses, Residual Stresses, and Fractrography. Metals. 2019; 9(4):384. https://doi.org/10.3390/met9040384

Chicago/Turabian StyleWei, Hongyu, Muhammad Tariq, Ghulam Hussain, Imran Khan, Muhammad Imran Khan, and Wasim A. Khan. 2019. "Butt Joining of Bi-Layered Aluminum Sheets through Friction Stir Welding: Tensile Stresses, Bending Stresses, Residual Stresses, and Fractrography" Metals 9, no. 4: 384. https://doi.org/10.3390/met9040384

APA StyleWei, H., Tariq, M., Hussain, G., Khan, I., Imran Khan, M., & Khan, W. A. (2019). Butt Joining of Bi-Layered Aluminum Sheets through Friction Stir Welding: Tensile Stresses, Bending Stresses, Residual Stresses, and Fractrography. Metals, 9(4), 384. https://doi.org/10.3390/met9040384