The Effect of Different Annealing Temperatures on Recrystallization Microstructure and Texture of Clock-Rolled Tantalum Plates with Strong Texture Gradient

Abstract

1. Introduction

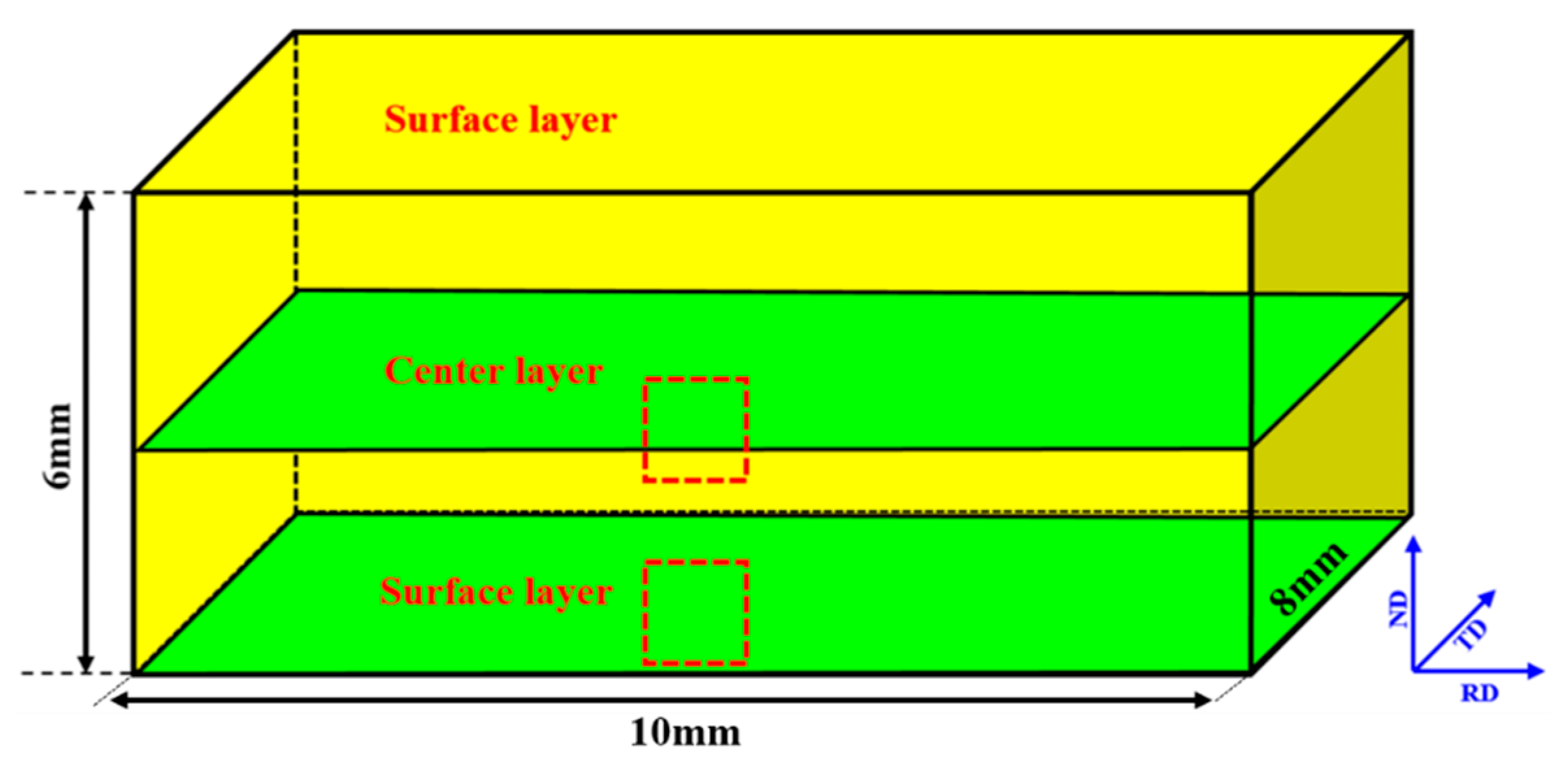

2. Experimental Method

3. Results

3.1. Deformation Behavior

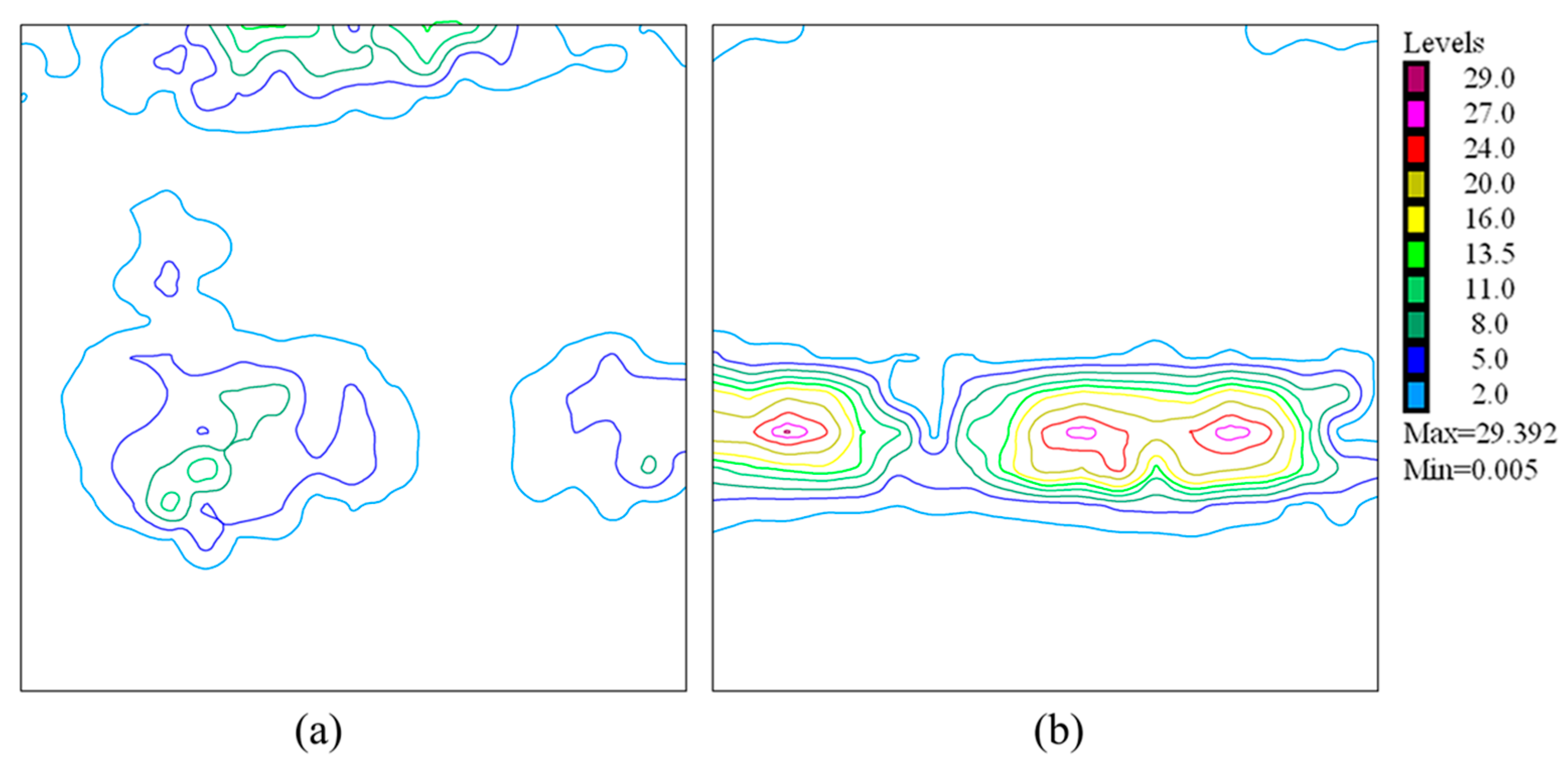

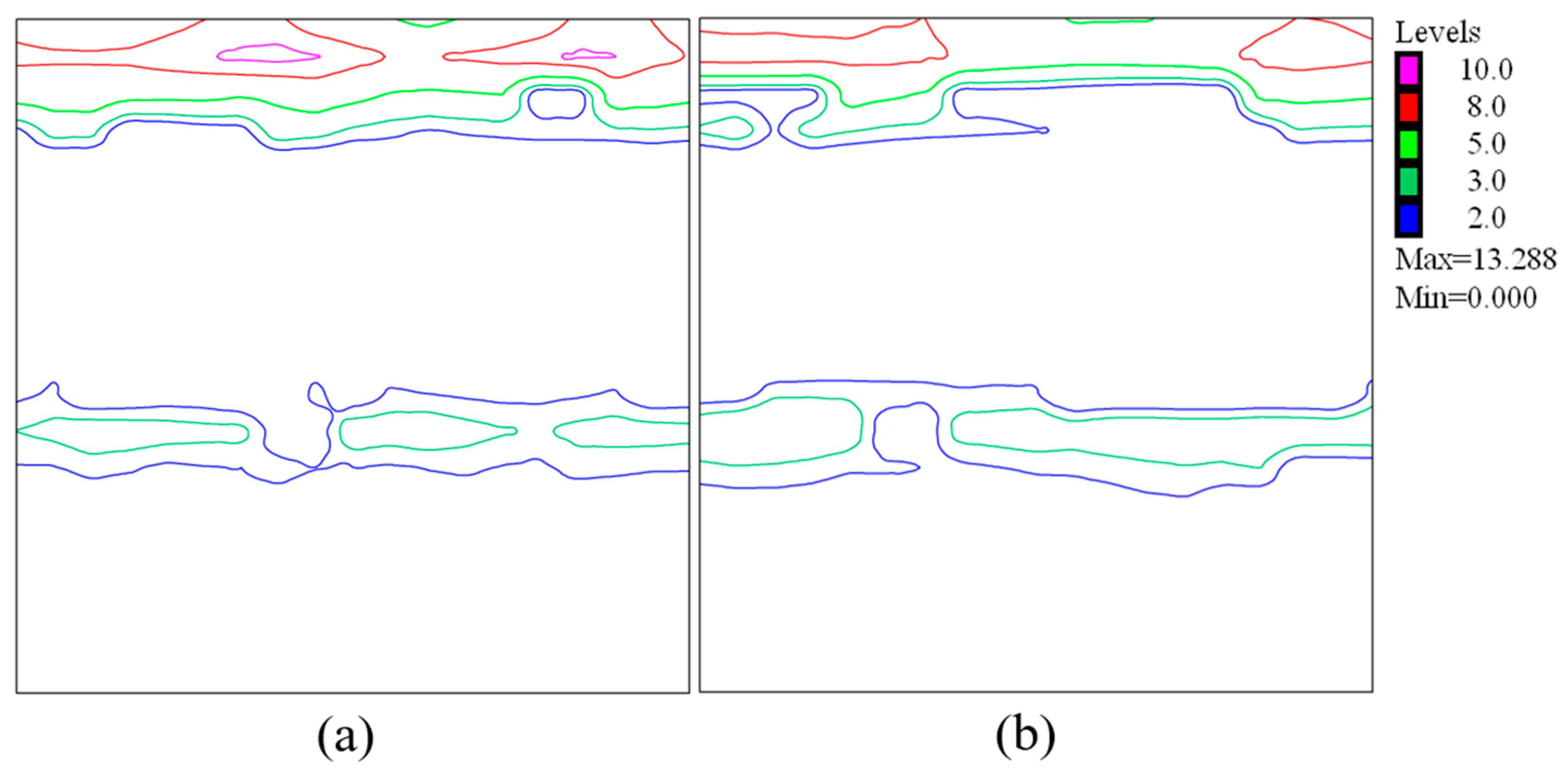

3.1.1. Texture Distribution

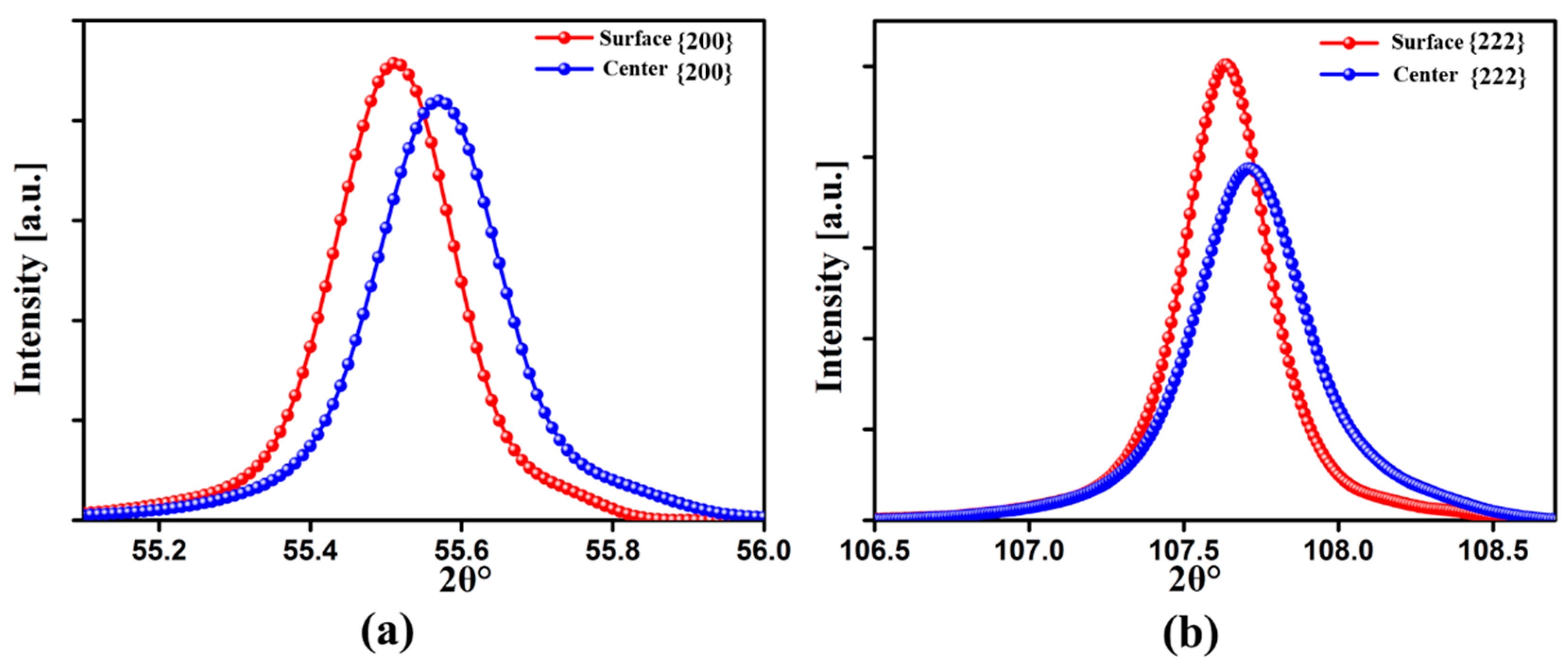

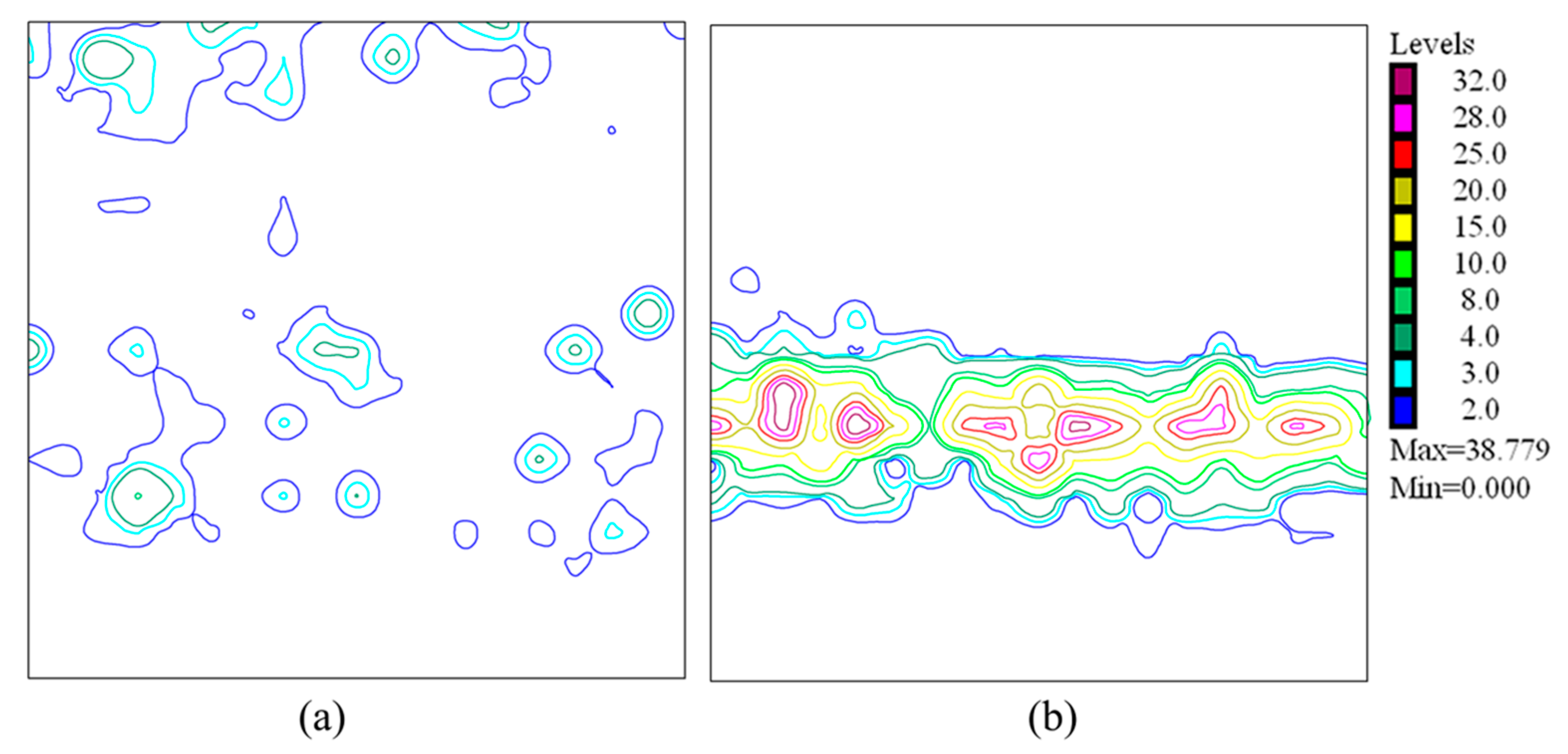

3.1.2. Stored Energy Distribution

3.2. Recrystallization Behavior

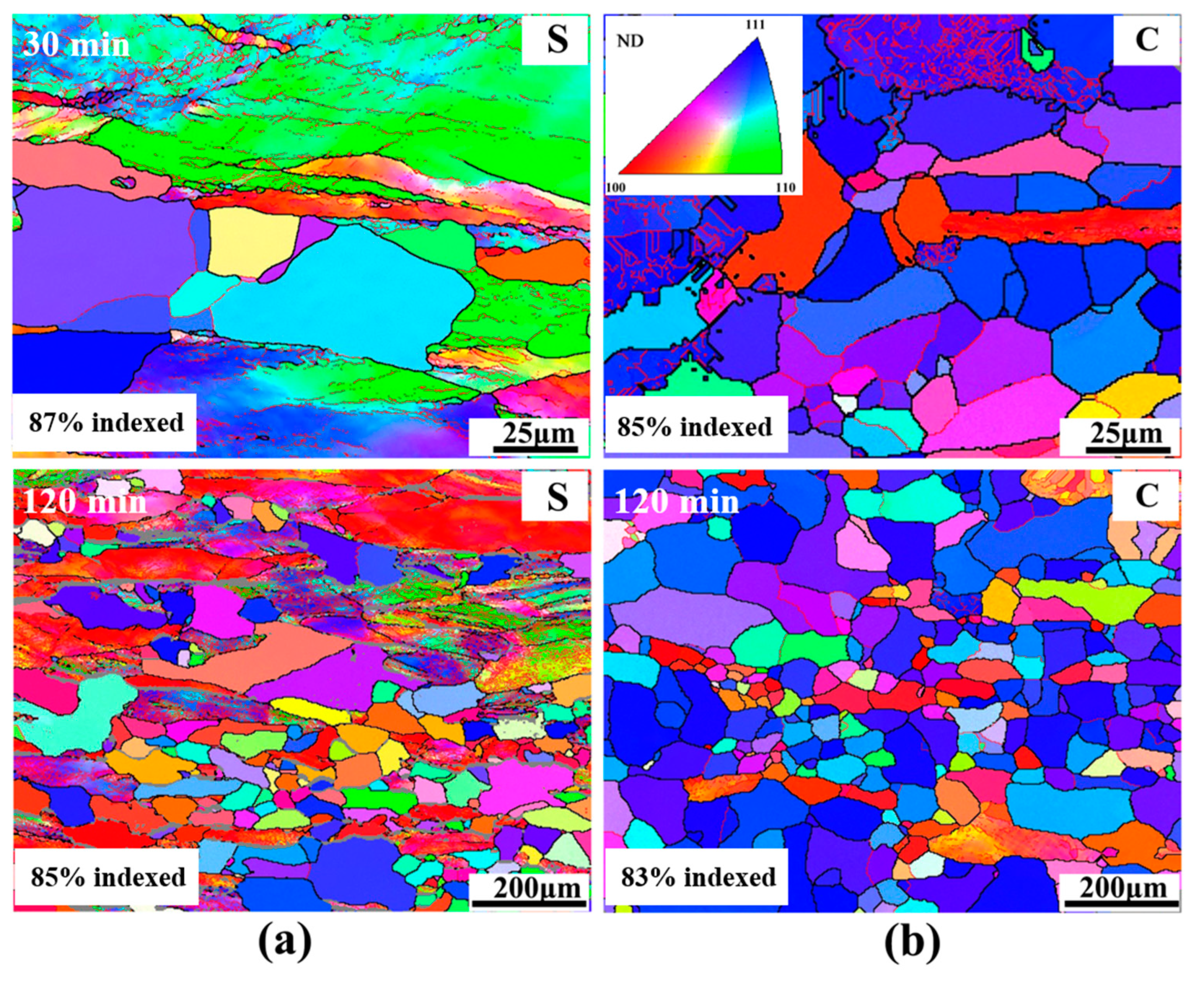

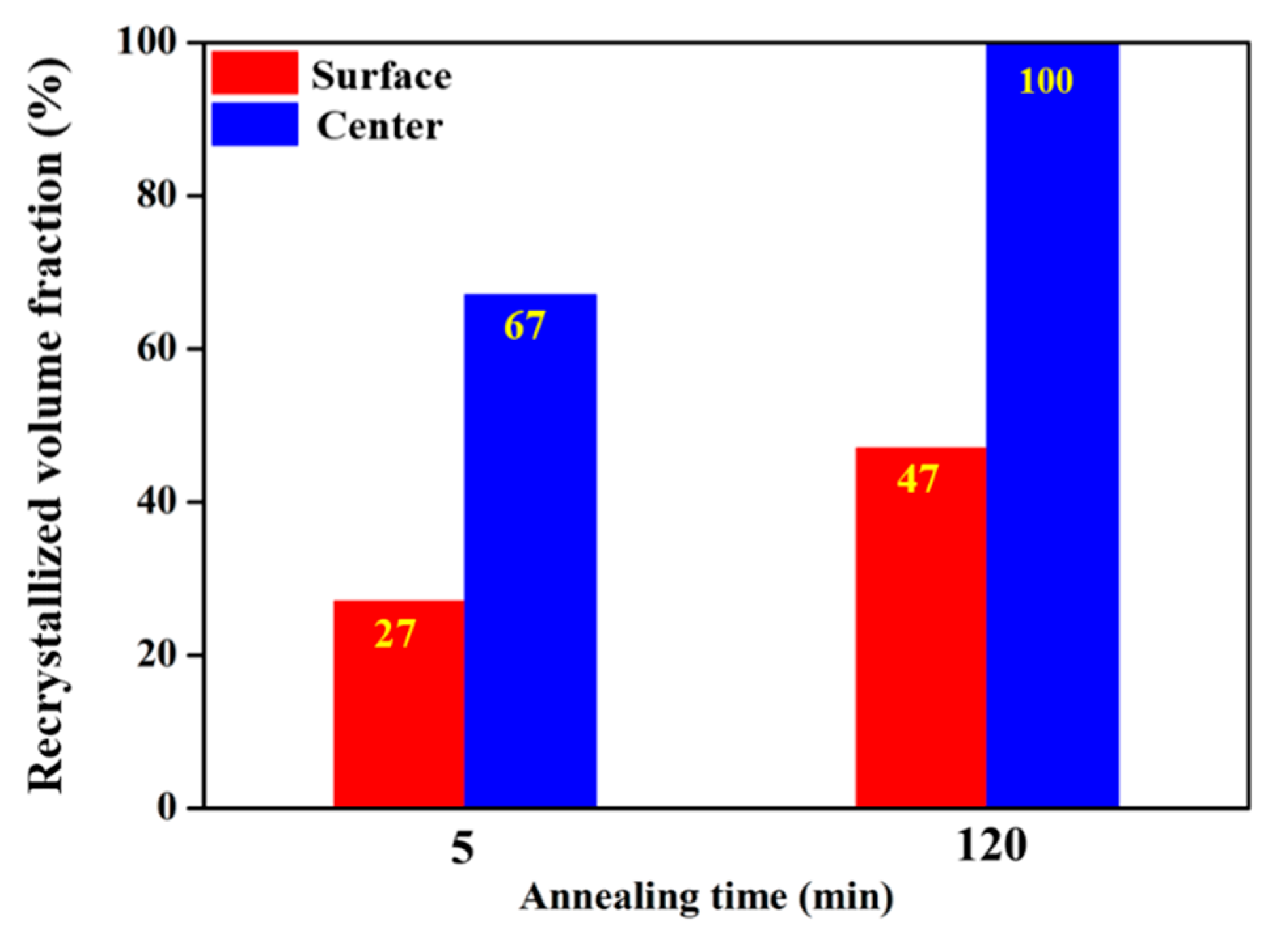

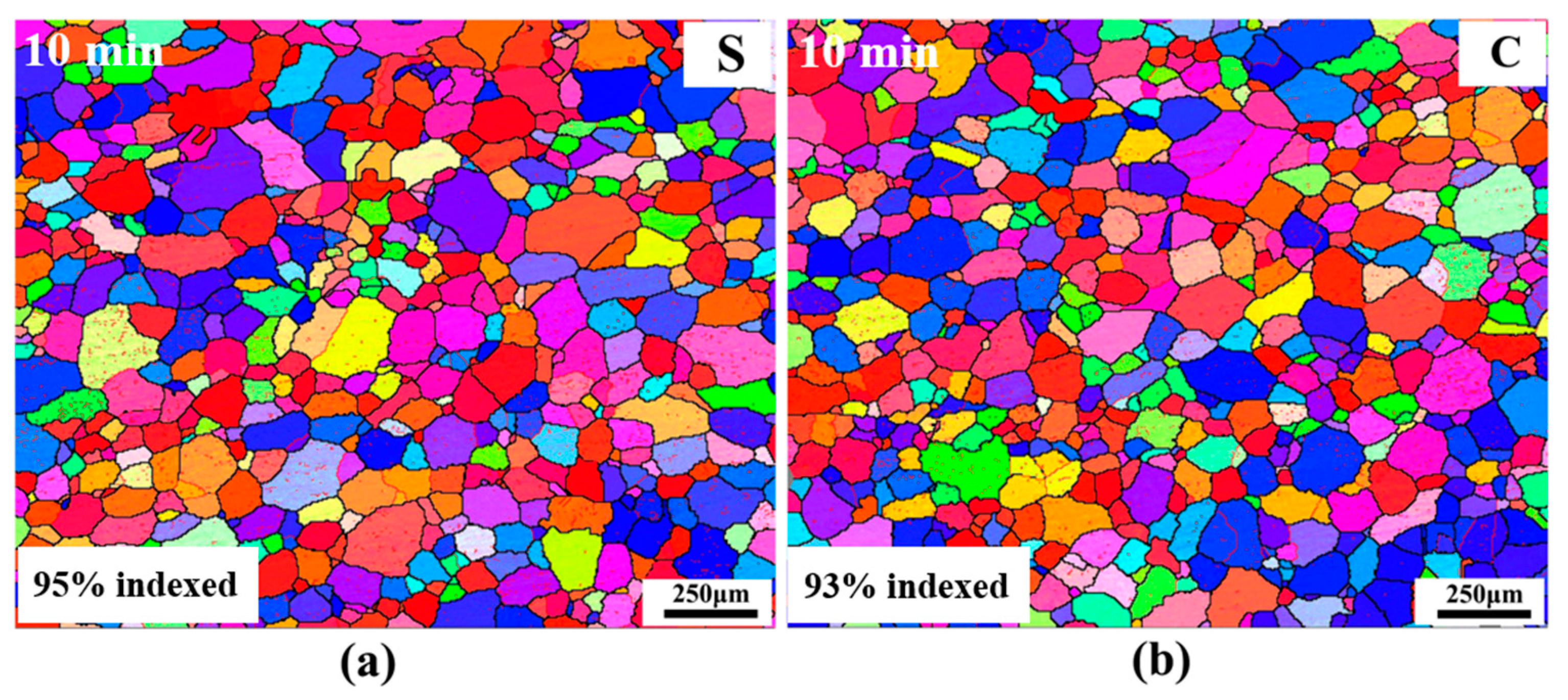

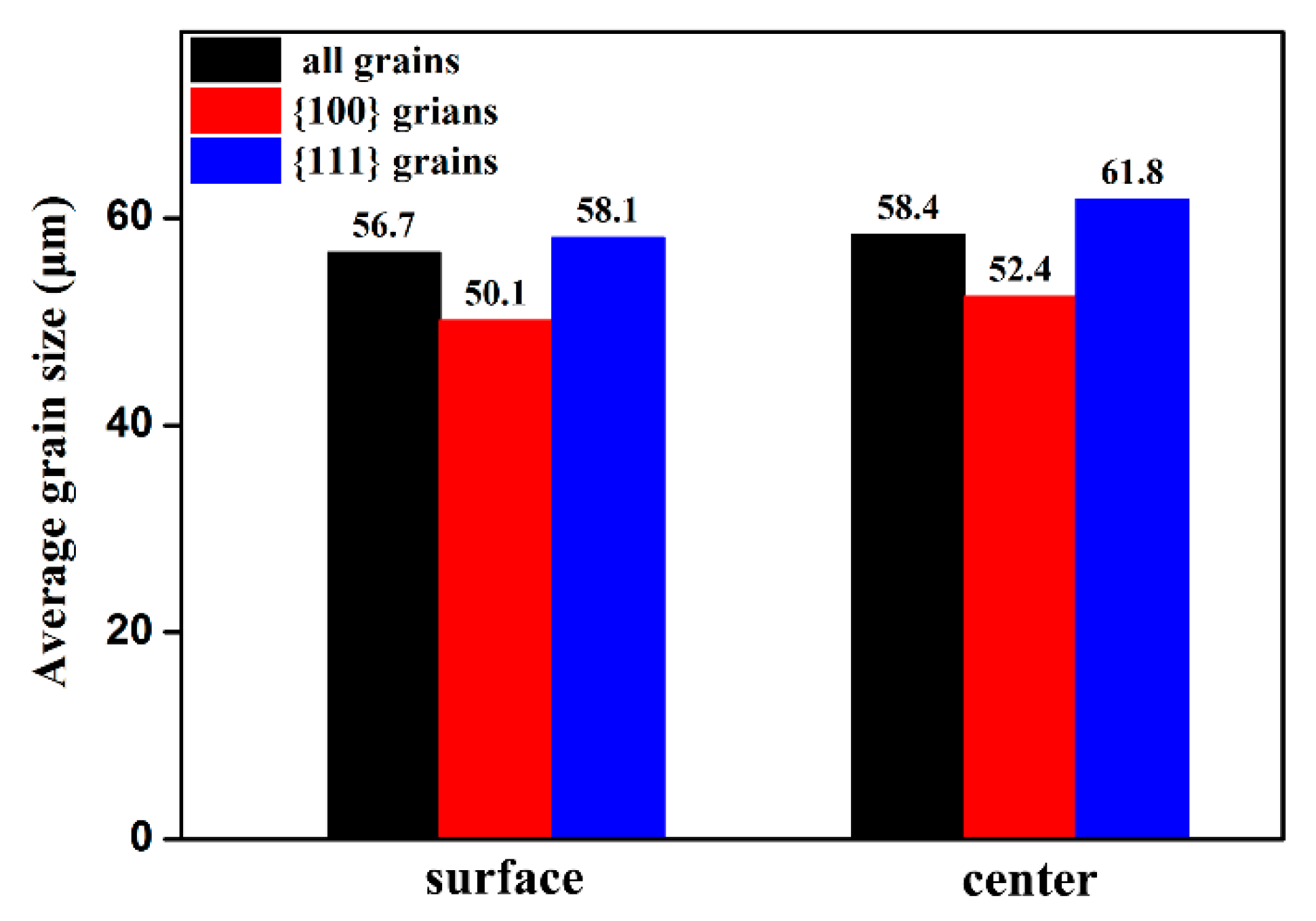

3.2.1. Microstructure Distribution when Annealed at 950 °C

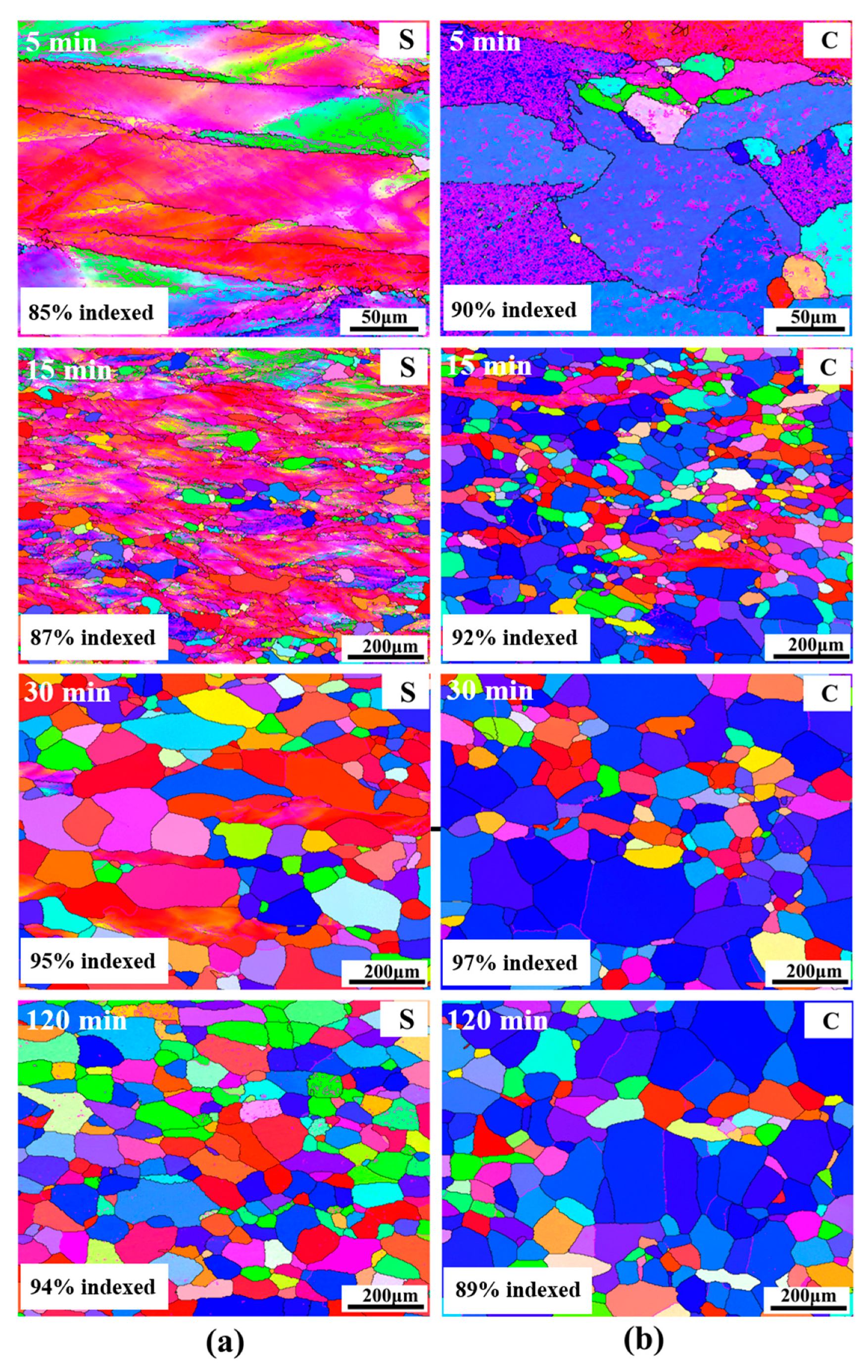

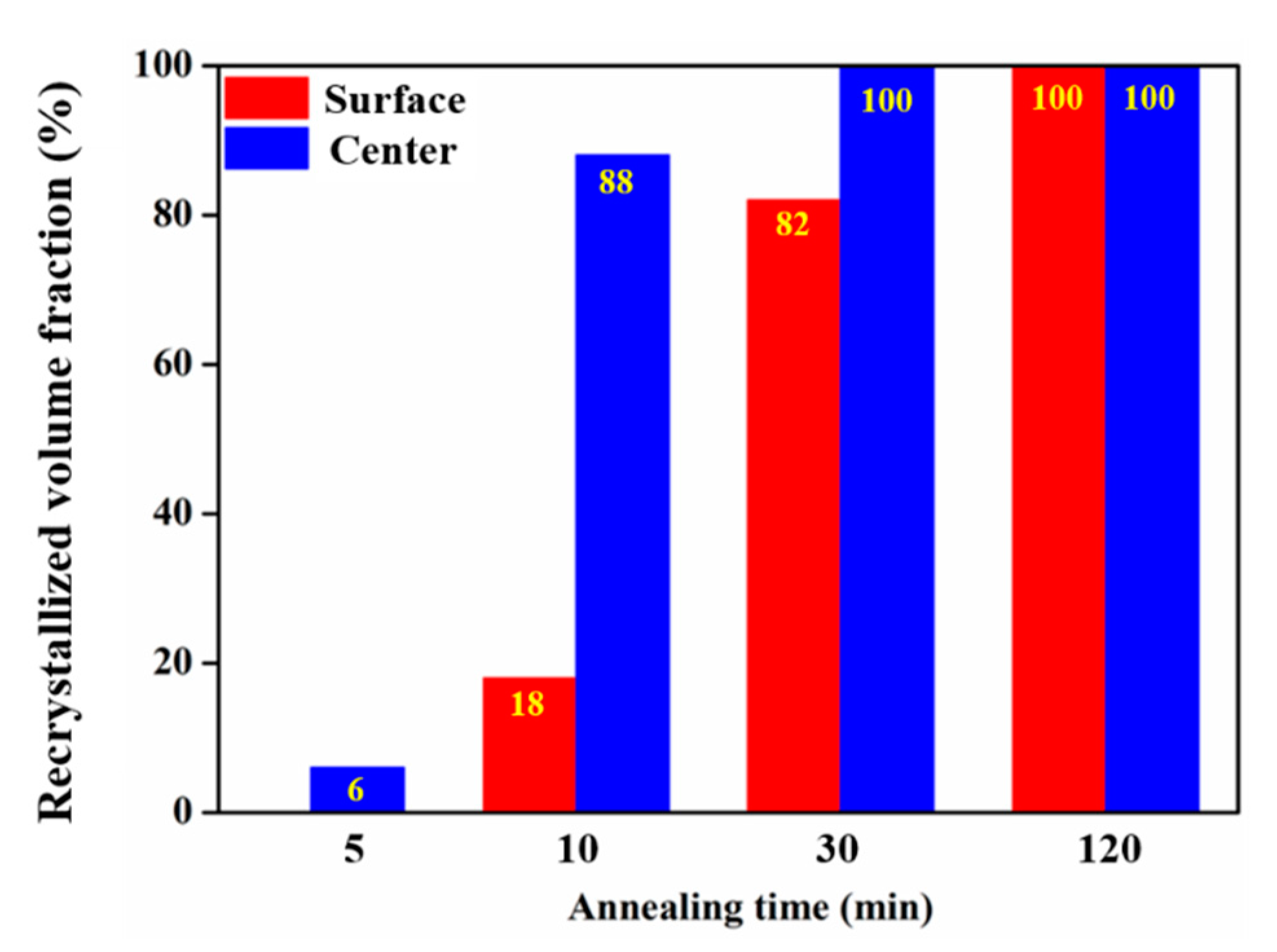

3.2.2. Microstructure and Texture Distribution when Annealed at 1050 °C

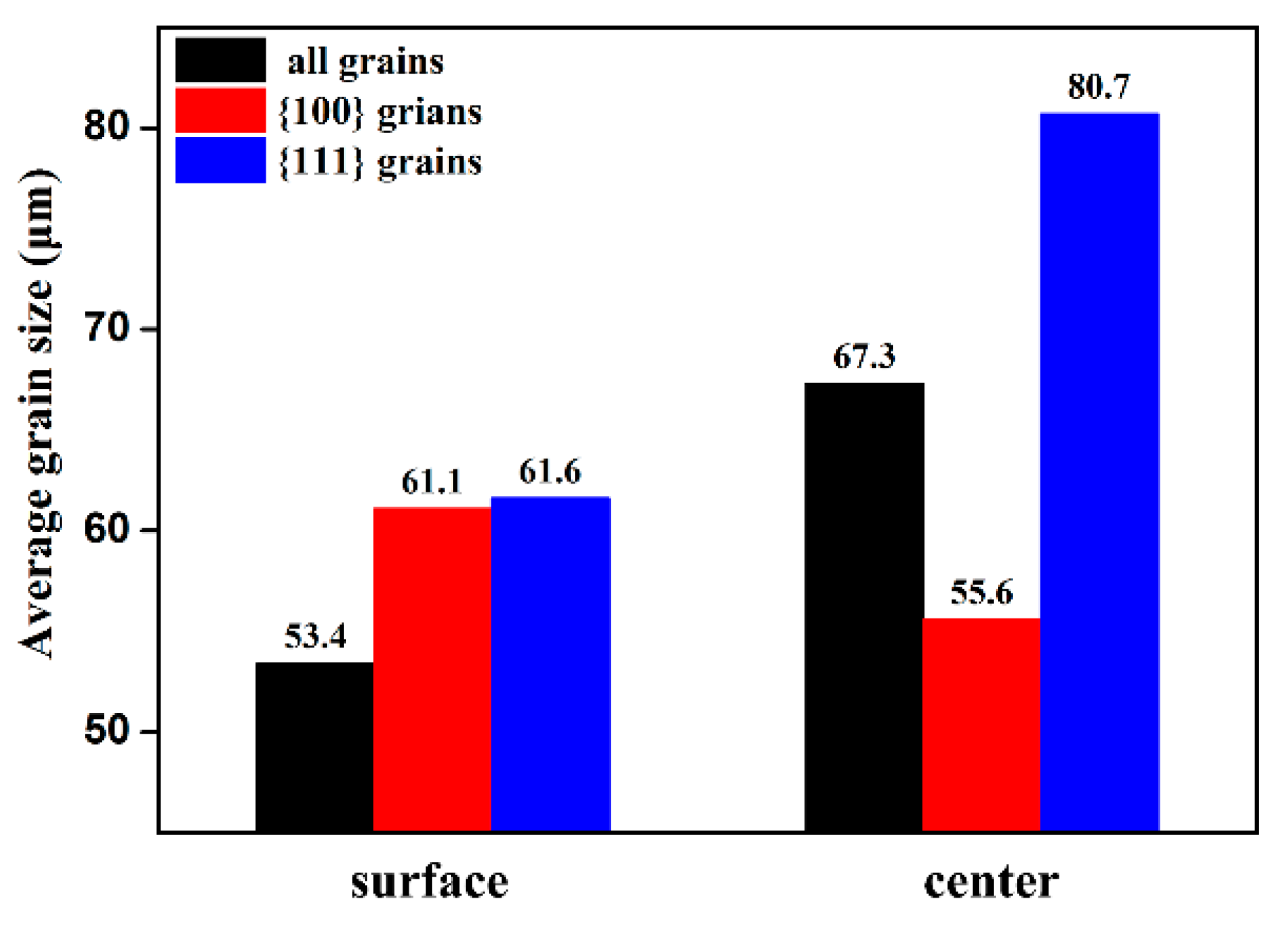

3.2.3. Microstructure and Texture Distribution when Annealed at 1250 °C

4. Discussion

4.1. Initial Texture and Stored Energy Gradient

4.2. The Effect of Annealing Temperature on Recrystallization Microstructure

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Cardonne, S.; Kumar, P.; Michaluk, C.; Schwartz, H. Tantalum and its alloys. Int. J. Refract. Met. Hard Mater. 1995, 13, 187–194. [Google Scholar] [CrossRef]

- Michaluk, C.A. Correlating discrete orientation and grain size to the sputter deposition properties of tantalum. J. electron. Mater. 2002, 31, 2–9. [Google Scholar] [CrossRef]

- Zhu, J.L.; Deng, C.; Liu, Y.H.; Lin, N.; Liu, S.F. Effects of Annealing Temperature on Recrystallization Texture and Microstructure Uniformity of High Purity Tantalum. Metals 2019, 9, 75. [Google Scholar] [CrossRef]

- Zhang, Z.; Kho, L.; Wickersham, C.E. Effect of grain orientation on tantalum magnetron sputtering yield. J. Vac. Sci. Technol. A 2006, 24, 1107. [Google Scholar] [CrossRef]

- Choi, G.S.; Lim, J.W.; Munirathnam, N.R.; Kim, I.H.; Kim, J.S. Preparation of 5N grade tantalum by electron beam melting. J. Alloys Compd. 2009, 469, 298–303. [Google Scholar] [CrossRef]

- Liu, S.F.; Fan, H.Y.; Deng, C.; Hao, X.B.; Guo, Y.; Liu, Q. Through-thickness texture in clock-rolled tantalum plate. Int. J. Refract. Met. Hard Mater. 2015, 48, 194–200. [Google Scholar] [CrossRef]

- Fan, H.Y.; Liu, S.F.; Li, L.J.; Deng, C.; Liu, Q. Largely alleviating the orientation dependence by sequentially changing strain paths. Mater. Design 2016, 97, 464–472. [Google Scholar] [CrossRef]

- Deng, C.; Liu, S.F.; Ji, J.L.; Hao, X.B.; Zhang, Z.Q.; Liu, Q. Texture evolution of high purity tantalum under different rolling paths. J. Mater. Process. Tech. 2014, 214, 462–469. [Google Scholar] [CrossRef]

- Huang, X.; Huang, G.J.; Xiao, D.P.; Liu, Q. Effect of Clock Rolling on Microstructures and Properties of AZ31 Magnesium Alloy Sheets. Mater. Sci. Forum. 2011, 686, 40–45. [Google Scholar] [CrossRef]

- Mccabe, R.J.; Proust, G.; Cerreta, E.K.; Misra, A. Quantitative analysis of deformation twinning in zirconium. Int. J. Plasticity. 2009, 25, 454–472. [Google Scholar] [CrossRef]

- Pawlik, K. Determination of the orientation distribution function from pole figures in arbitrarily defined cells. Phys. Stat. Sol. B. 1986, 134, 477–483. [Google Scholar] [CrossRef]

- Raabe, D. Simulation of rolling textures of b.c.c. metals considering grain interactions and crystallographic slip on {110}, {112} and {123} planes. Mater. Sci. Eng. A 1995, 197, 31–37. [Google Scholar] [CrossRef]

- Borbély, A.; Driver, J.H.; Ungár, T. An X-ray method for the determination of stored energies in texture components of deformed metals; application to cold worked ultra high purity iron. Acta Mater. 2000, 48, 2005–2016. [Google Scholar] [CrossRef]

- Rajmohan, N.; Hayakawa, Y.; Szpunar, J.A.; Root, J.H. Neutron diffraction method for stored energy measurement in interstitial free steel. Acta Mater. 1997, 45, 2485–2494. [Google Scholar] [CrossRef]

- Dey, S.; Gayathri, N.; Bhattacharya, M.; Mukherjee, P. In Situ XRD Studies of the Process Dynamics During Annealing in Cold-Rolled Copper. Metall. Mater. Trans. 2016, 47, 1–11. [Google Scholar] [CrossRef]

- Ruestes, C.J.; Stukowski, A.; Tang, Y.; Tramontina, D.R.; Erhart, P.; Remington, B.A.; Urbassek, H.M.; Meyers, M.A.; Bringa, E.M. Atomistic simulation of tantalum nanoindentation: Effects of indenter diameter, penetration velocity, and interatomic potentials on defect mechanisms and evolution. Mater. Sci. Eng. A 2014, 613, 390–403. [Google Scholar] [CrossRef]

- Ikehata, H.; Nagasako, N.; Kuramoto, S.; Saito, T. Designing New Structural Materials Using Density Functional Theory: The Example of Gum MetalTM. MRS Bulletin 2011, 31, 688–692. [Google Scholar] [CrossRef]

- Park, Y.B.; Lee, D.N.; Gottstein, G. The evolution of recrystallization textures in body centred cubic metals. Acta Mater. 1998, 46, 3371–3379. [Google Scholar] [CrossRef]

- Mishin, O.V.; Bay, B.; Jensen, D.J. Through-thickness texture gradients in cold-rolled aluminum. Metall. Mater. Trans. 2000, 31, 1653–1662. [Google Scholar] [CrossRef]

- Chen, J.Z.; Zhen, L.; Shao, W.Z.; Dai, S.L.; Cui, Y.X. Through-thickness texture gradient in AA 7055 aluminum alloy. Mater. Lett. 2008, 62, 88–90. [Google Scholar] [CrossRef]

- Engler, O.; Tomé, C.N.; Huh, M.Y. A study of through-thickness texture gradients in rolled sheets. Metall. Mater. Trans. 2000, 31, 2299–2315. [Google Scholar] [CrossRef]

- Choi, C.H.; Kwon, J.W.; Oh, K.H.; Lee, D.N. Analysis of deformation texture inhomogeneity and stability condition of shear components in f.c.c. metals. Acta Mater. 1997, 45, 5119–5128. [Google Scholar] [CrossRef]

- Deng, C.; Liu, S.F.; Hao, X.B.; Ji, J.L.; Liu, Q.; Fan, H.Y. Through-thickness texture gradient of tantalum sputtering target. Rare Metals 2017, 36, 523–526. [Google Scholar] [CrossRef]

- Deng, C.; Liu, S.F.; Hao, X.B.; Ji, J.L.; Zhang, Z.Q.; Liu, Q. Orientation dependence of stored energy release and microstructure evolution in cold rolled tantalum. Int. J. Refract. Met. Hard Mater. 2014, 46, 24–29. [Google Scholar] [CrossRef]

- Liu, Y.H.; Liu, S.F.; Zhu, J.L.; Deng, C.; Fan, H.Y.; Cao, L.F.; Liu, Q. Strain path dependence of microstructure and annealing behavior in high purity tantalum. Mater. Sci. Eng. A 2017, 707, 518–530. [Google Scholar] [CrossRef]

- Vandermeer, R.A.; Snyder, W.B. Recovery and recrystallization in rolled tantalum single crystals. Metall. Trans. A 1979, 10, 1031–1044. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Y.; Mishin, O.V.; Tao, N.; Pantleon, W.; Juul Jensen, D. Microstructural Analysis of Orientation-Dependent Recovery and Recrystallization in a Modified 9Cr-1Mo Steel Deformed by Compression at a High Strain Rate. Metall. Mater. Trans. A 2016, 47, 4682–4693. [Google Scholar] [CrossRef]

| Annealing Temperature | Annealing Times |

|---|---|

| 950 °C | 30 min, 120 min |

| 1050 °C | 5 min, 10 min, 30 min, 120 min |

| 1250 °C | 10 min |

| Position | hkl | Yhkl/GPa | νhkl | Br | Ba | SEhkl/(J.mol−1) |

|---|---|---|---|---|---|---|

| Surface layer | (200) | 145.6 | 0.32 | 0.170 | 0.120 | 2.248 |

| (222) | 284.4 | 0.36 | 0.304 | 0.116 | 4.113 | |

| Center layer | (200) | 145.6 | 0.32 | 0.201 | 0.120 | 4.024 |

| (222) | 284.4 | 0.36 | 0.448 | 0.116 | 9.727 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, J.; Liu, S.; Yang, S.; Zhang, Y.; Zhang, J.; Zhang, C.; Deng, C. The Effect of Different Annealing Temperatures on Recrystallization Microstructure and Texture of Clock-Rolled Tantalum Plates with Strong Texture Gradient. Metals 2019, 9, 358. https://doi.org/10.3390/met9030358

Zhu J, Liu S, Yang S, Zhang Y, Zhang J, Zhang C, Deng C. The Effect of Different Annealing Temperatures on Recrystallization Microstructure and Texture of Clock-Rolled Tantalum Plates with Strong Texture Gradient. Metals. 2019; 9(3):358. https://doi.org/10.3390/met9030358

Chicago/Turabian StyleZhu, Jialin, Shifeng Liu, Shuai Yang, Yu Zhang, Jing Zhang, Chenghang Zhang, and Chao Deng. 2019. "The Effect of Different Annealing Temperatures on Recrystallization Microstructure and Texture of Clock-Rolled Tantalum Plates with Strong Texture Gradient" Metals 9, no. 3: 358. https://doi.org/10.3390/met9030358

APA StyleZhu, J., Liu, S., Yang, S., Zhang, Y., Zhang, J., Zhang, C., & Deng, C. (2019). The Effect of Different Annealing Temperatures on Recrystallization Microstructure and Texture of Clock-Rolled Tantalum Plates with Strong Texture Gradient. Metals, 9(3), 358. https://doi.org/10.3390/met9030358