Abstract

NiCr/hBN self-lubricating composites with hBN solid-lubricant contents of 8%, 9%, 10%, 11%, and 12% (mass fractions) were prepared by powder-metallurgy method. Their tribological properties at room temperature and 600, 700, and 800 °C were studied. SEM and XRD were performed to analyze their wear-surface morphology and abrasive-dust composition. Results indicate that the NiCr/hBN self-lubricating composites have favorable tribological properties at room temperature and 600 °C. The optimum comprehensive friction and wear performance are achieved at 10% hBN, and the main wear mechanism is abrasive wear. At 700 and 800 °C, the friction and wear properties of NiCr/hBN self-lubricating composites obviously decline. The wear surface experiences oxidation and the spinel oxides Cr2O3, NiCr2O4, and CrBO3 are formed. The main wear mechanism becomes combined scratching and glue form of adhesive wear, leading to greatly increased wear rate for the NiCr/hBN sel-lubricating composites.

1. Introduction

In aero-engines, the high-temperature alloy NiCr is used as the base material of the sealing material between the blade and cartridge receiver because of the alloy’s high-temperature wear resistance, oxidation resistance, and high-temperature mechanical behaviors [1,2,3]. For aero-engine operation, the sealing material should be usable for a long time at high temperatures and should exert a certain self-lubrication antifriction effect. Thus, self-lubricating composite preparation by adding solid lubricant to the NiCr-based alloy has become an important research subject and is thus extensively studied [4,5].

Solid lubricants commonly used in self-lubricating composites generally include graphite, MoS2, CaF2, BF2, and hexagonal boron nitride (hBN), where graphite and MoS2 can be used only at <500 °C as restricted by their own physical properties [6,7]. CaF2 and BaF2 have favorable lubricating properties at high temperatures, but they are generally used under dry-friction conditions [8]. Conversely, hBN has favorable lubricating properties under dry and wet conditions [9]. It has a planar hexagonal net layer crystal structure similar to the hexagonal crystal system structure of graphite. This feature corresponds to a large atomic spacing along the direction of the axis c, a small binding force, and easy interlayer sliding, which lead to the excellent lubricating property of hBN. Thus, hBN is a preferable solid lubricant in metal-matrix composites for high-temperature applications in the aviation industry [10,11].

The lubrication and mechanical properties of NiCr/hBN composites are negatively correlated, so preparing NiCr/hBN composites with good comprehensive properties is challenging. Thus, the sintering process and composition optimization of NiCr/hBN composites, as well as their influence on the composites’ room-temperature friction and wear mechanism, have been extensively studied [12,13,14,15]. With increased hBN content from 5% to 10%, the physical and mechanical properties of hBN composites gradually decline, although their tribological properties can be improved. When the hBN content exceeds 10%, the wear rate of the self-lubricating composite increases due to the low strength of the matrix material [12]. Bingyu [13,14] indicated that NiCr/hBN composites achieve the optimum properties at 8–12% hBN content. Currently, studies on the tribological properties of NiCr/hBN self-lubricating composites are restricted to the normal-temperature stage. According to the working features of an engine, the working temperature of NiCr/hBN material generally exceeds 400 °C. Changchuan [15] studied the oxidation behaviors of the NiCr/hBN composites at >600 ℃. They found that the material has favorable high-temperature stability at 600 °C and undergoes oxidation at >700 °C. However, no study has reported on the friction and wear properties of NiCr/hBN composites at high temperatures.

In the present work, Ni-20Cr alloy was used as the matrix, and then 8%, 9%, 10%, 11%, and 12% hBN solid lubricants were added to study the friction and wear behaviors of NiCr/hBN self-lubricating composites at room temperature (25 °C) and 600, 700, and 800 °C. Our results can provide a theoretical basis for the application of NiCr/hBN composites in the aero-engine industry.

2. Experiment

2.1. Preparation of NiCr/hBN Composites

Metals taken as Ni-20Cr alloy ingot were prepared by vacuum melting with high-purity raw metal materials (Cr and Ni), and Ni-20Cr powders were prepared by atomization technology in argon atmosphere. The powders used to prepare samples were sieved until their average particle size was <48 μm. Hexagonal crystal hBN powders (produced by Dandong Rijin Technology Co., Ltd., Dandong, China; average particle size <5 μm) were selected to metalize Ni by chemical precipitation [12]. The metalized hBN solid lubricant was blended with Ni-20Cr alloy powders by pressing into long blocks with dimensions of 38 mm × 6 mm × 6 mm and wafers with dimensions of Φ 43 mm × 3 mm under 300 MPa pressure at room temperature. The hBN contents in the samples were 8%, 9%, 10%, 11%, and 12%, and the pressed pressure was maintained for 8 s. After sample preforming, they were sintered for 120 min at 1150 °C and vacuum degree of 1 × 10−3 Pa to 3 × 10−3 Pa. To improve the compactness and mechanical properties of the composites, the pre-sintered specimens were re-pressed under 600 MPa pressure and then annealed at 850 °C in a vacuum furnace for 60 min to obtain the NiCr/hBN composites.

2.2. Friction and Wear Property Tests

Friction and wear property tests of the composites were implemented on an MMU-10G high-temperature friction and wear tester (Ji’nan Lanbo Test Equipment Co. Ltd., Ji’nan, China). The friction pair used in the test was a 1Cr18Ni9Ti annular pad with 40 N load and 250 r/min revolving speed. The experimental ambient temperature was room temperature (about 25 °C) and ambient humidity was about 40%. The test specimens were prepared in a Φ 43 mm × 3 mm wafer in advance, polished into 1200# abrasive paper, and rinsed using ethyl alcohol. During the test process, the machine automatically read the friction coefficient and then calculated the wear extent through the weighing method. An analytical balance was used to weigh the specimens before and after the friction at 0.001 g precision. The average wear rate K was calculated as follows:

where m1 and m2 are the specimen masses before and after friction (g), respectively, ρ is the real density of the specimen, and t is the friction time (min). The reported results were averaged from at least five measurements.

2.3. Analytical Test

The density of the NiCr/hBN self-lubricating composite was detected through the wax immersion-drainage method, and the porosity ηV of the composite was calculated through Equation (2).

where D0 is the theoretical density of the specimen and DV is the measured density of the specimen (unit g/cm3).

The three-point flexural-strength detection of the specimen was carried out on a CCS-44100 universal electronic testing machine (Ji’nan Ruima Machinery Equipment Co., Ltd., Ji’nan, China). A RigakuD-MAX 2000 X-ray diffractometer (Rigaku Corporation, Tokyo, Janpan) was used for the phase analysis of abrasive dusts, and the detection angle was within 10°–80°. The fracture appearance and wear-surface morphology of the specimens were observed with a Sirion200 field-emission scanning electron microscope (FEI Corporation, Hillsboro, OR, USA).

3. Results and Discussion

3.1. Physical and Mechanical Properties of NiCr/hBN Composites

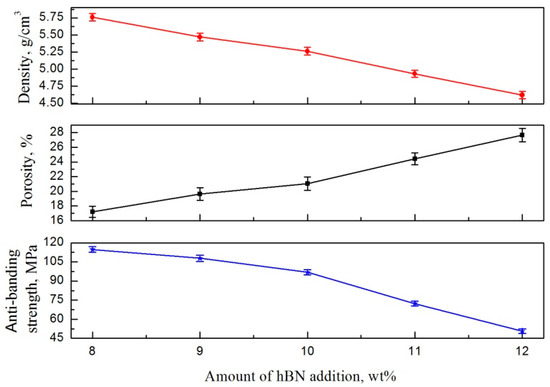

The effects of hBN contents on the density, porosity, and flexural strength of the NiCr/hBN self-lubricating composites are shown in Figure 1. The density of the NiCr/hBN composites showed an approximately linear decline with increased hBN content. The material porosity gradually increased with increased hBN content, and an inflection point appeared at 10% hBN. Thus, at this point, the rising amplitude of material porosity increased. Material flexural strength also gradually declined with increased hBN content, and an inflection point appeared at 10% hBN as well. This finding means that increased hBN content from 8% to 10% led to slowly decreased flexural strength of NiCr/hBN composites; conversely, increased content from 10% to 12% led to abruptly decreased flexural strength of the material.

Figure 1.

Influence of hBN content on the density, porosity, and flexural strength of NiCr/hBN composites.

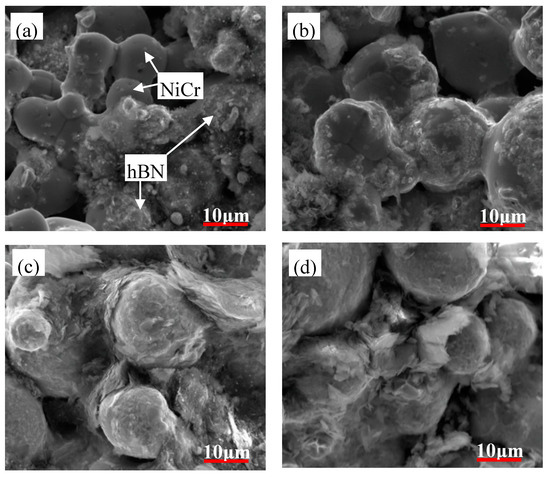

Figure 2 shows three-point flexural fracture appearance of NiCr/hBN composites with hBN contents of 8%, 9%, 10%, and 12%. Spherical NiCr alloy particles and pinnate hBN powders are observed. When the hBN content was 8%, an obvious sintering well formed between NiCr particles due to the diffusion and bonding during sintering, as shown in Figure 2a. However, when the hBN content was increased to 9% and 10%, the hBN powders dispersed among NiCr particles hindered the diffusion and bonding, as shown in Figure 2b,c. Considering the large difference between the densities of hBN (2.28 g/cm3) and NiCr alloy (8.47 g/cm3), the volume fraction of hBN increased by about 2.5% when its mass fraction increased by 1%, which resulted in increased quantity of hBN powders dispersed among NiCr particles. During preparation, hBN was dispersed between NiCr particles with favorable thermal stability and low sintering activity. It hindered the mutual diffusion among NiCr particles, and a greater hBN content corresponded to more obvious hindering effect, so the flexural strength of the composite gradually declined with increased hBN content. When the hBN content was 12%, its volume fraction exceeded 30%, so the sintering of NiCr particles was seriously hindered and no obvious sintering well formed on the material fracture, as shown in Figure 2d. Thus, the flexural strength of the material dropped sharply.

Figure 2.

Fracture appearances of NiCr/hBN composites with different hBN contents: (a) 8%, (b) 9%, (c) 10%; and (d) 12%.

Pores are known to become the areas of stress concentration under external loads, leading to the generation of microcracks and the decline of a material’s mechanical properties. With increased porosity, the influence of porosity on material properties is strengthened, and the material strength declines more obviously. According to the fracture appearance in Figure 2, pores obviously increased as hBN content increased; the sintering necks of NiCr particles and the bonding force among particles were reduced. Increased porosity can further decrease the compactness degree of the material and reduces strength of the sintering body.

The relationship between porosity θ and flexural strength σb is [16]

where σ0 is the flexural strength of the material with porosity approaching zero and is approximately equal to the flexural strength of the compact material; and β is a constant related to the pore shape. According to Equation (3), the flexural strength of the composite significantly declines with increased porosity θ, which is identical with the experimental result as shown in Figure 1.

3.2. High-Temperature Friction and Wear Properties of NiCr/hBN Composites

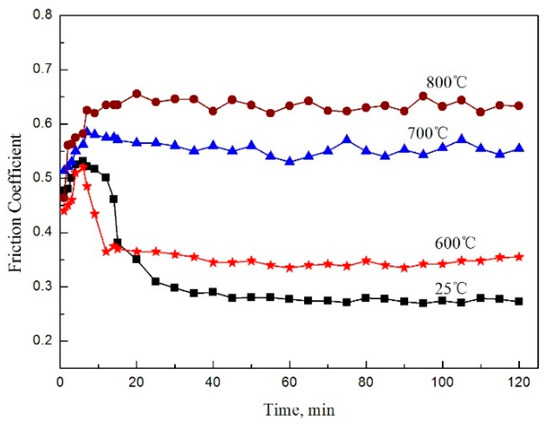

The change in friction coefficient of the NiCr/hBN composites containing 10% hBN with friction time at different temperatures is shown in Figure 3. At 25 and 600 °C, the material friction coefficient was high in the initial friction phase and declined to a steady level after about 20 min. The stable friction coefficient at room temperature w lower than that at 600 °C. At 700 and 800 °C, the material friction coefficient was low in the initial friction phase, taking about 10 min to reach the stable friction phase in the test; after the stable phase, the friction coefficient of the composite increased and became less stable than that at 25 and 600 °C. The stable friction coefficients of NiCr/10% hBN composites were about 0.28, 0.35, 0.56, and 0.63 at 25, 600, 700, and 800 °C, respectively.

Figure 3.

Friction coefficient vs. time curves of friction pairs.

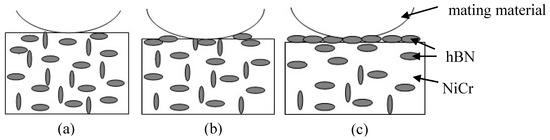

The schematic of the formation of NiCr/hBN self-lubricating composite films during sliding friction is shown in Figure 4. The NiCr/hBN composite is regarded as a whole, whereas the solid lubricant hBN is uniformly distributed throughout the material. Before the friction phase starts, the contact surface of friction pairs was the contact surface between the metal matrix and mating material, as shown in Figure 4a. At the same time, it was in a nonsolid lubrication state, so friction coefficients in the initial friction phase at all temperatures were large (Figure 3). When the initial friction phase was started, the surface of the composite experienced deformation due to extrusion, and a large quantity of friction heat was generated. The hBN solid lubricant that was uniformly distributed throughout the material gradually flowed toward the friction surface after extrusion, and the friction surface transformed into a mixed surface of solid lubricant and metal matrix, as shown in Figure 4b. Thus, the friction coefficient between friction pairs gradually declined. As the extrusion-induced deformation continued, the hBN content on the friction surface continuously increased. Given the small shear strength of hBN, it was sheared and spread out on the external surface under the effect of frictional force, and a lubricating film with complete coverage formed, as shown in Figure 4c. This time, the friction coefficient between friction pairs reached a stable state.

Figure 4.

Schematic of the formation of solid lubricating film for NiCr/hBN composite: (a) pre-friction stage, (b) initial friction stage; and (c) stable friction stage.

According to the formation mechanism of the solid lubricating film, Blau et al. [17] proposed that when the solid lubricating film consists of metal matrix and solid lubricating film, the friction coefficient between friction pairs can be expressed as follows:

where μm is the friction coefficient between the metal matrix and mating material, and μe is the friction coefficient between the solid lubricating film and mating material. When n = 1, the friction surface reaches a complete solid-lubrication state and μ = μe; thus, the friction coefficient is equal to that of pure hBN (about 0.25) [10]. When n = 0, the friction surface is in a nonsolid lubrication state and μ = μm; thus, the friction coefficient is equal to the friction coefficient of pure NiCr matrix (about 0.46) [18]. Accordingly, if the Ni-Cr/hBN composite does not undergo oxidation, then the lubricating film consists of solid lubricant and metal matrix and its friction coefficient is between 0.25 and 0.46 (Figure 3) at room temperature and 600 °C. However, with increased friction temperature to 700 and 800 °C, the friction coefficient is much higher than that of NiCr matrix, indicating the presence of components with a high friction coefficient in the lubricating film.

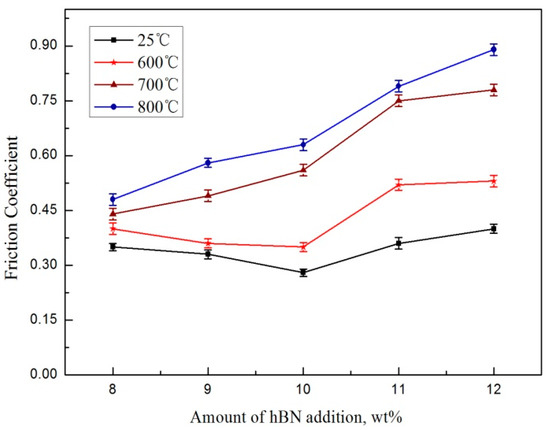

To investigate the friction and wear behavior of NiCr/hBN composite at high temperature, the friction coefficients and wear rates of the materials with different hBN contents at various friction temperatures were tested in this study. Figure 5 shows the change curves of the friction coefficient of NiCr/hBN composites with different hBN contents at different friction temperatures. When the friction temperature was room temperature and 600 °C, the friction coefficient initially decreased and then increased with increased hBN content and reached the minimum value at 10% hBN content. When the friction temperature was 700 and 800 °C, the friction coefficient increased with increased hBN content. When the hBN content was constant, the friction coefficients of the NiCr/hBN composites increased with increased friction temperature.

Figure 5.

Influence of hBN content on the friction coefficient of NiCr/hBN composite at different friction temperatures.

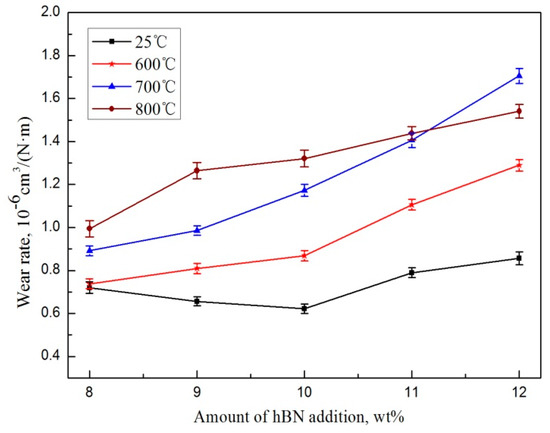

Figure 6 shows the change curves of NiCr/hBN composite with different hBN contents at different friction temperatures. At room temperature, the wear rate of NiCr/hBN composite initially decreased and then increased with increased hBN content, reaching the minimum value when the hBN content was 10%. At 600 °C, the wear rate of the NiCr/hBN composite initially increased gradually and then increased abruptly when the hBN content exceeded 10%, which indicates that the wear mechanism of the material changes when the hBN content exceeds 10%. At 700 °C, the wear rate of the NiCr/hBN composite linearly increased, but at 800 °C, the wear rate of the material abruptly increased with increased hBN content from 8% to 9%. When hBN content exceeded 9%, the wear rate increased slowly and remained unchanged.

Figure 6.

Influence of hBN content on the wear rate of NiCr/hBN composite at different friction temperatures.

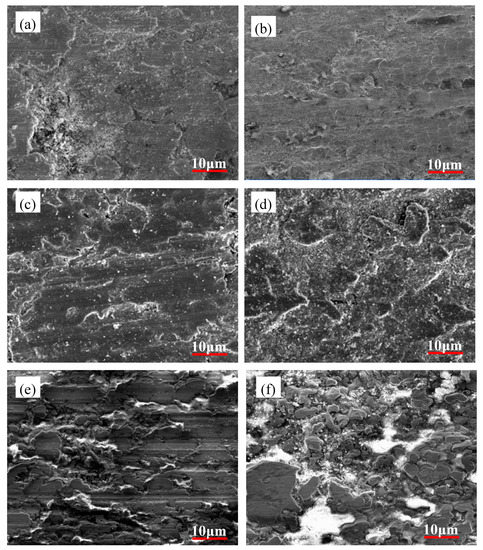

The wear-surface morphologies of NiCr/hBN self-lubricating composite under different frictional conditions are shown in Figure 7. At room temperature, the lubricating-film coverage on the wear surface of NiCr/hBN composite containing 8% hBN was incomplete, and the boundary of NiCr particles was vague, as shown in Figure 7a; the friction coefficient was the maximum. When the hBN content was 10%, the lubricating-film coverage was complete and the friction coefficient reached the minimum value. With increased temperature to 600 °C, the lubricating film basically covered the entire wear surface of NiCr/hBN composite containing 10% hBN, as shown in Figure 7c, so the friction coefficient remained low. However, the wear surface loosened with peeling pits forming in local parts, and then the wear rate slightly increased. When the hBN content was increased to 12%, the lubricating film fell off and its coverage on the specimen surface was incomplete, as shown in Figure 7d, so both friction coefficient and wear rate obviously increased. At 800 °C, obvious furrows appeared on the wear surface of NiCr/hBN material containing 10% hBN with peeling pits forming in local parts, as shown in Figure 7e. A large area on the wear surface of 12% hBN material fell off and almost no lubricating film existed, as shown in Figure 7f, so its wear rate was large at 800 °C.

Figure 7.

Wear-surface morphologies of the NiCr/hBN self-lubricating composites under different friction conditions: (a) 8% hBN, 25 °C; (b) 10% hBN, 25 °C; (c) 10% hBN, 600 °C; (d) 12% hBN, 600 °C; (e) 10% hBN, 800 °C; and (f) 12% hBN, 800 °C.

3.3. Analysis of the High-Temperature Friction and Wear Mechanism of NiCr/hBN Composites

According to the formation mechanism of the lubricating film, it forms on the friction surface of NiCr/hBN composite accompanied by processes such as material deformation and hBN flow, so the formation of the lubricating film is related to factors such as the strength of the composite material, magnitude of load, and hBN content. In other words, decreased material strength, increased magnitude of load, or increased hBN content can all promote the formation of the lubricating film and reduce the friction coefficient, thereby improving the lubrication properties. However, according to Figure 5, the friction coefficient of NiCr/hBN composite does not gradually decrease with increased hBN content and decreased material strength because the favorable tribological properties of the material depends on the formation capacity of the lubricating film and on the wear rate of the lubricating film.

The wear rate of the lubricating film is influenced by the strength of the composite and the repair ability and wear resistance of the solid lubricating film. First, if the strength of the composite is too low, then the shear force during the friction process goes deeply into the material such that the matrix is torn and peeled off. Thus, the lubricating film difficultly retains its integrity because it loses the support from the matrix; consequently, the lubrication properties of the composite decline. Second, after the solid lubricating film is peeled off, the solid lubricant in the matrix continues to be extruded outside. At this time, the solid lubricant must guarantee sufficient content and favorable mobility to form a new lubricating film and fill the void caused by wear and, thus, guarantee good lubrication properties. Furthermore, the matching between solid lubricant and matrix, the matrix-surface conditions, and the composition and thickness of the solid lubricating film directly affect the wear resistance of the lubricating film.

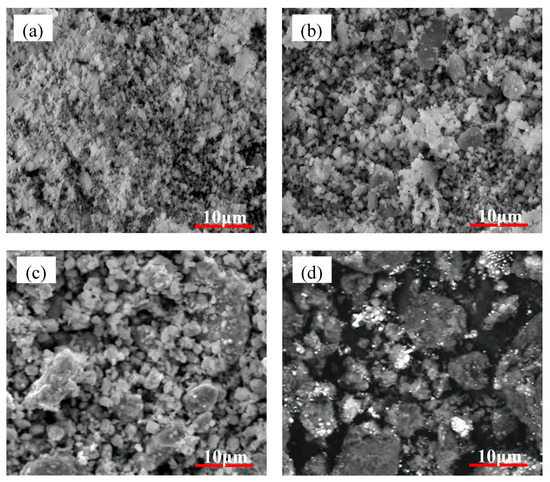

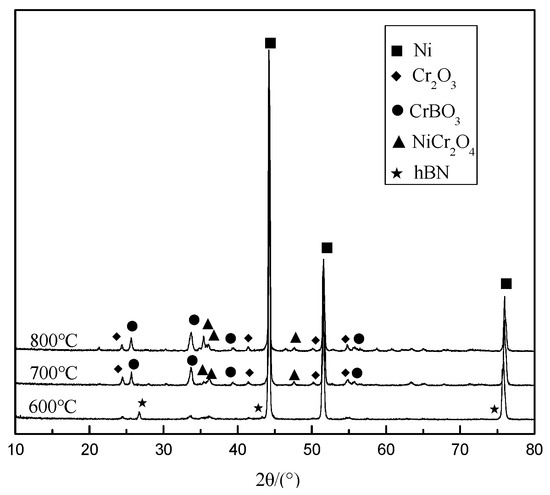

At room temperature and 600 °C, the strength of the NiCr/hBN composite increases with increased hBN content from 8% to 10%. The main wear mechanism of the composite is abrasive wear, and its abrasive dusts mainly present a flocculent shape with fine and uniform particle sizes, or a small quantity of massive abrasive dusts appear as shown in Figure 8a,b. To identify the physical phases of abrasive dusts, XRD analysis was carried out, and results are shown in Figure 9. As the physical phase at 25 °C is basically identical with that at 600 °C, the analytic curve of abrasive dusts at room temperature is neglected in the figure. As shown in Figure 9, abrasive dusts are mainly hBN and Ni (Cr) alloy at 600 °C. Combined with the wear-surface morphologies shown in Figure 7a–c, plastic deformation on the material surface is found to be slight at room temperature and 600 °C. Bulges on the material surface fall off and are separated under the effect of shear force, and abrasive particles are formed. This wear form usually occurs at the surface layer of the solid lubricating film and can be repaired through the material self-consumption effect with flat wear surface, so the wear process is relatively stable. When the hBN content reaches 12%, the sintering degree of the composite is lowered, and the strength abruptly declines. As the supporting effect of the matrix declines, the wear resistance of the lubricating film decreases, and adhesive wear occurs locally, as shown in Figure 7d.

Figure 8.

Abrasive dusts morphologies of NiCr/10% hBN composite at (a) 25 °C, (b) 600 °C, (c) 700 °C; and (d) 800 °C.

Figure 9.

XRD patterns of abrasive at 600, 700, and 800 °C.

At 700 and 800 °C, the strength of the NiCr alloy matrix significantly declines at high temperature, leading to phenomena such as increased plastic deformation of the material, enlarged frictional contact area, and crushing of the lubricating film. Thus, the tribological properties of NiCr/hBN composite decline, as shown in Figure 5 and Figure 6. At 700 and 800 °C, increased hBN content gradually increases the friction coefficient and wear rate of NiCr/hBN composite. At 700 °C, abrasive dusts become granular and their particle sizes enlarge. At 800 °C, these abrasive dusts are mainly large particles, as shown in Figure 8c,d. Figure 9 shows that at 700 and 800 °C, three spinel-type oxides (Cr2O3, CrBO3, and NiCr2O4) appear as abrasive dusts in addition to hBN and Ni (Cr). This finding indicates that oxidation occurs on the wear surface and that oxides with high hardness are generated, so the sliding friction on the friction interface is aggravated. Hence, the friction coefficient of NiCr/hBN composite is larger than that of the matrix metal at 700 and 800 °C, as shown in Figure 3 and Figure 5. According to the analysis of wear-surface morphologies shown in Figure 7e,f, after oxides appear on the material surface at high temperature, the main wear mechanism of the composite transforms into scratching and gluing forms, which are the main wear forms of adhesive wear. During the wear process, shear failure occurs at the lubricating film layer with soft material texture and further develop toward the deep hard-metal layer accompanied by a large quantity of furrows, as shown in Figure 7e. This furrow effect continues to degrade the friction and wear properties of the composites. When plastic deformation at the contact peak point is large and the surface temperature is high, the stress of the adhesive bonding point enlarges. If the stress exceeds the shear strength of the composite itself, shear failure occurs at the deep metal part and gluing phenomenon occurs, as concretely manifested by the overall peeling off and large-scale peeling pits shown in Figure 7f.

4. Conclusions

- (1)

- With increased friction temperature, the friction coefficient and wear rate of NiCr/hBN self-lubricating composite gradually increase. i.e., friction and wear properties decline. However, friction and wear properties are favorable at 600 °C, indicating that NiCr/hBN self-lubricating composite has a wide operating temperature range of 25–600 °C, which meets the working temperature requirement (400–600 °C) of the material.

- (2)

- The main wear mechanism of NiCr/hBN self-lubricating composite is abrasive wear at <600 °C. At 10% hBN content, NiCr/hBN composite has the optimum tribological properties.

- (3)

- At 700 and 800 °C, the friction and wear properties of NiCr/hBN self-lubricating composite obviously decline, oxidation occurs on the wear surface, the spinel oxides Cr2O3, NiCr2O4, and CrBO3 are generated, the wear mechanism becomes combined scratching and gluing forms of adhesive wear, and the wear rate of the composite substantially increases.

Author Contributions

X.Z. performed the property tests, analyzed the data, and wrote the paper. X.W. conceived/designed the experiments. Y.H. provided guidance and assistance in the experiments. F.W. and P.Y. prepared the composites.

Funding

This research was funded by the Shaanxi Province Science and Technology Key Project (No. 2016NY-137) and the Fundamental Research Funds for the Central Universities (Nos. 2452017132 and 2452016075), respectively.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Hong, K.H.; Kim, J.H.; Chang, K.; Kwon, J.Y. The role of Cr on oxide formation in Ni-Cr alloys: A theoretical study. Comput. Mater. Sci. 2018, 142, 185–191. [Google Scholar] [CrossRef]

- Sushko, M.L.; Schreiber, D.K.; Rosso, K.M.; Bruemmer, S.M. Role of Cr-rich carbide precipitates in the intergranular oxidation of Ni-Cr alloys. Scr. Mater. 2018, 156, 51–54. [Google Scholar] [CrossRef]

- Vialas, N.; Monceau, D. Effect of Cr content on interdiffusion and Kirkendall pore formation during homogenization of pack-aluminized Ni and Ni-Cr wires. Intermetallics 2018, 101, 108–115. [Google Scholar]

- Huang, X.Y.; Wang, J.H.; Zhang, H.Q.; Ren, J.; Zan, Q.F.; Gong, Q.M.; Wu, B. WC-Ni-Cr-based self-lubricating composites fabricated by pulsed electric current sintering with addition of WS2 solid lubricant. Int. J. Refract. Met. Hard Mater. 2017, 66, 158–162. [Google Scholar] [CrossRef]

- Wang, Y.; Lei, K.; Ruan, Y.; Dong, W. Microstructure and wear resistance of c-BN/Ni–Cr–Ti composites prepared by spark plasma sintering. Int. J. Refract. Met. Hard Mater. 2016, 54, 98–103. [Google Scholar] [CrossRef]

- Du, L.Z.; Zhang, W.G.; Liu, W.; Zhang, J.M. Preparation and characterization of plasma sprayed Ni3Al–hBN composite coating. Surf. Coat. Technol. 2010, 205, 2419–2424. [Google Scholar] [CrossRef]

- Li, C.L.; Duan, L.C.; Tan, S.C.; Zhang, W.J.; Pan, B.S. Effect of CaF2 and hBN on the mechanical and tribological properties of Fe-based impregnated diamond bit matrix. Int. J. Refract. Met. Hard Mater. 2018, 75, 118–125. [Google Scholar] [CrossRef]

- Chen, J.M.; Hou, G.L.; Chen, J.; An, Y.L.; Zhou, H.D.; Zhao, X.Q.; Yang, J. Composition versus friction and wear behavior of plasma sprayed WC–(W,Cr)2C–Ni/Ag/BaF2–CaF2 self-lubricating composite coatings for use up to 600 °C. Appl. Surf. Sci. 2012, 261, 584–592. [Google Scholar] [CrossRef]

- Chen, W.E.I.; Zhang, D.; Lv, Z.L.; Li, H.Q. Self-lubricating mechanisms via the in situ formed tribo-film of sintered ceramics with hBN addition in a high humidity environment. Int. J. Refract. Met. Hard Mater. 2017, 66, 163–173. [Google Scholar] [CrossRef]

- Tyagia, R.; Xiong, D.S.; Li, J.L.; Dai, J.H. Elevated temperature tribological behavior of Ni based composites containing nano-silver and hBN. Wear 2010, 269, 884–890. [Google Scholar] [CrossRef]

- Pandaa, J.N.; Bijwea, J.; Pandeyb, R.K. Role of micro and nano-particles of hBN as a secondary solid lubricant for improving tribo-potential of PAEK composite. Tribol. Int. 2019, 130, 400–412. [Google Scholar] [CrossRef]

- Wei, X.F.; Wang, R.C.; Peng, C.Q. Effect of BN surface plated nickel on sintering properties of Ni-Cr/BN antifriction sealing material. J. Cent. South Univ. 2010, 41, 150–155. [Google Scholar]

- Jiang, B.Y.; Liu, S.M.; Wang, R.C. Effect of BN on mechanical and tribological properties of BN/Ni(Cr) self-lubricating composites. Mater. Sci. Eng. Powder Metall. 2009, 14, 57–62. [Google Scholar]

- Jiang, B.Y.; Wang, R.C.; Peng, C.Q. Influence of sintering temperature on structure and properties of BN/Ni(Cr) self-lubricating composites. J. Cent. South Univ. 2012, 43, 93–99. [Google Scholar]

- Wang, C.C.; Wang, R.C.; Peng, C.Q. High temperature oxidation behaviours of Ni-20Cr/hBN self-lubricating composites. Chin. J. Nonferrous Met. 2013, 23, 356–361. [Google Scholar]

- Ding, H.D.; Li, Y.W.; Hao, H.Q. Grey Equat ion between Bending Strength and Porosity of Copper Graphite Material. Chin. J. Nonferrous Met. 1996, 6, 123–126. [Google Scholar]

- Blau, F.P.; Yust, C.S. Micro-friction studies of model self-lubricating surfaces. Surf. Technol. 1993, 62, 380–387. [Google Scholar] [CrossRef]

- Xiong, D.S. Lubrication behavior of Ni-Cr-based alloys containing MoS2 at high temperature. Wear 2001, 251, 1094–1099. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).