Investigation of the Temperature-Related Wear Performance of Hard Nanostructured Coatings Deposited on a S600 High Speed Steel

Abstract

1. Introduction

2. Materials and Methods

3. Results

4. Discussion

5. Conclusions

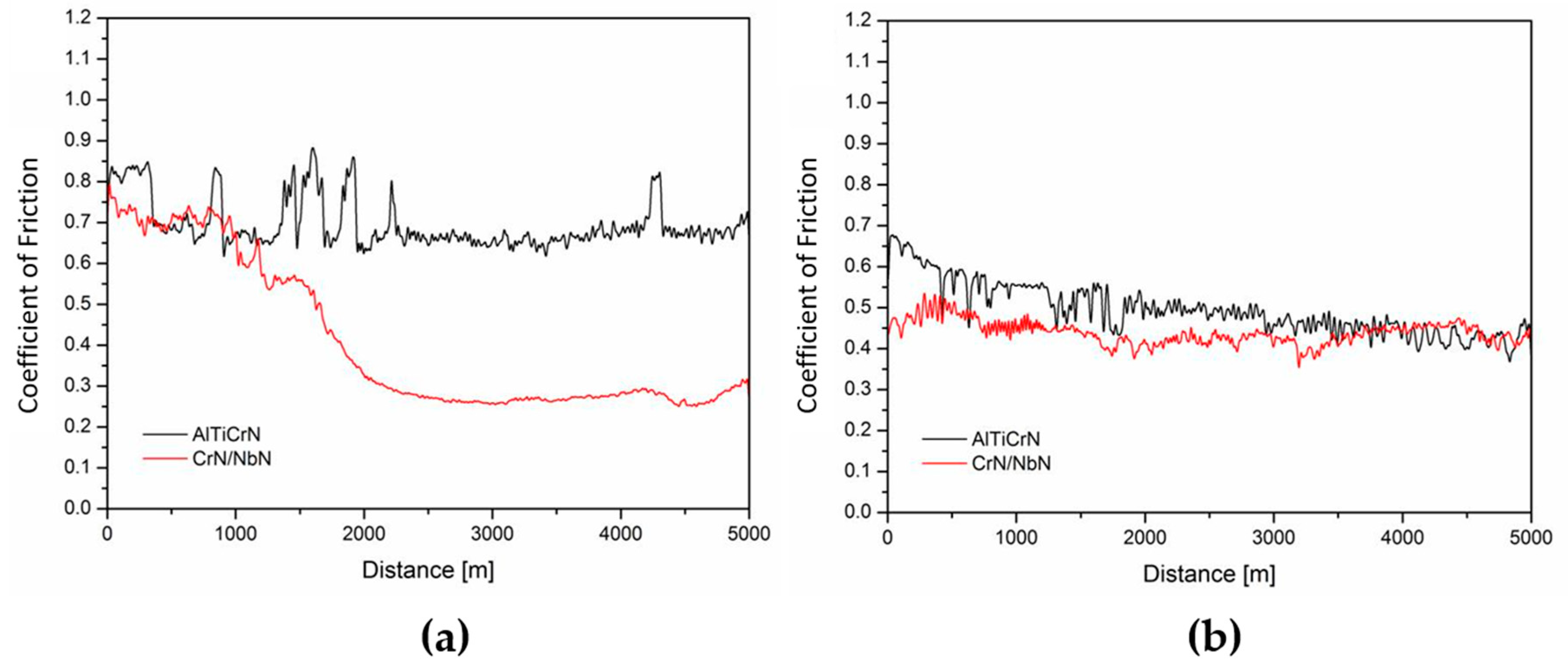

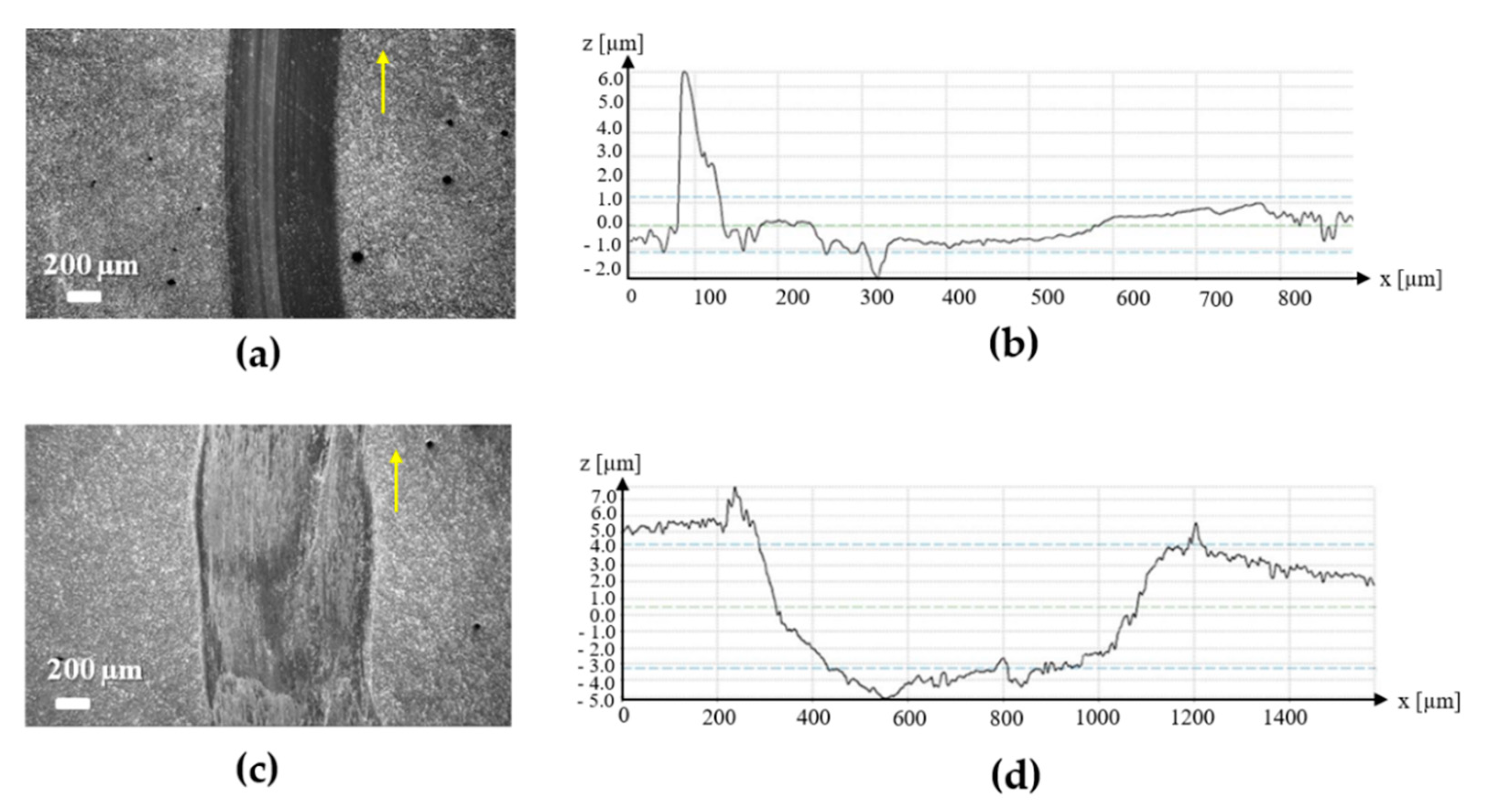

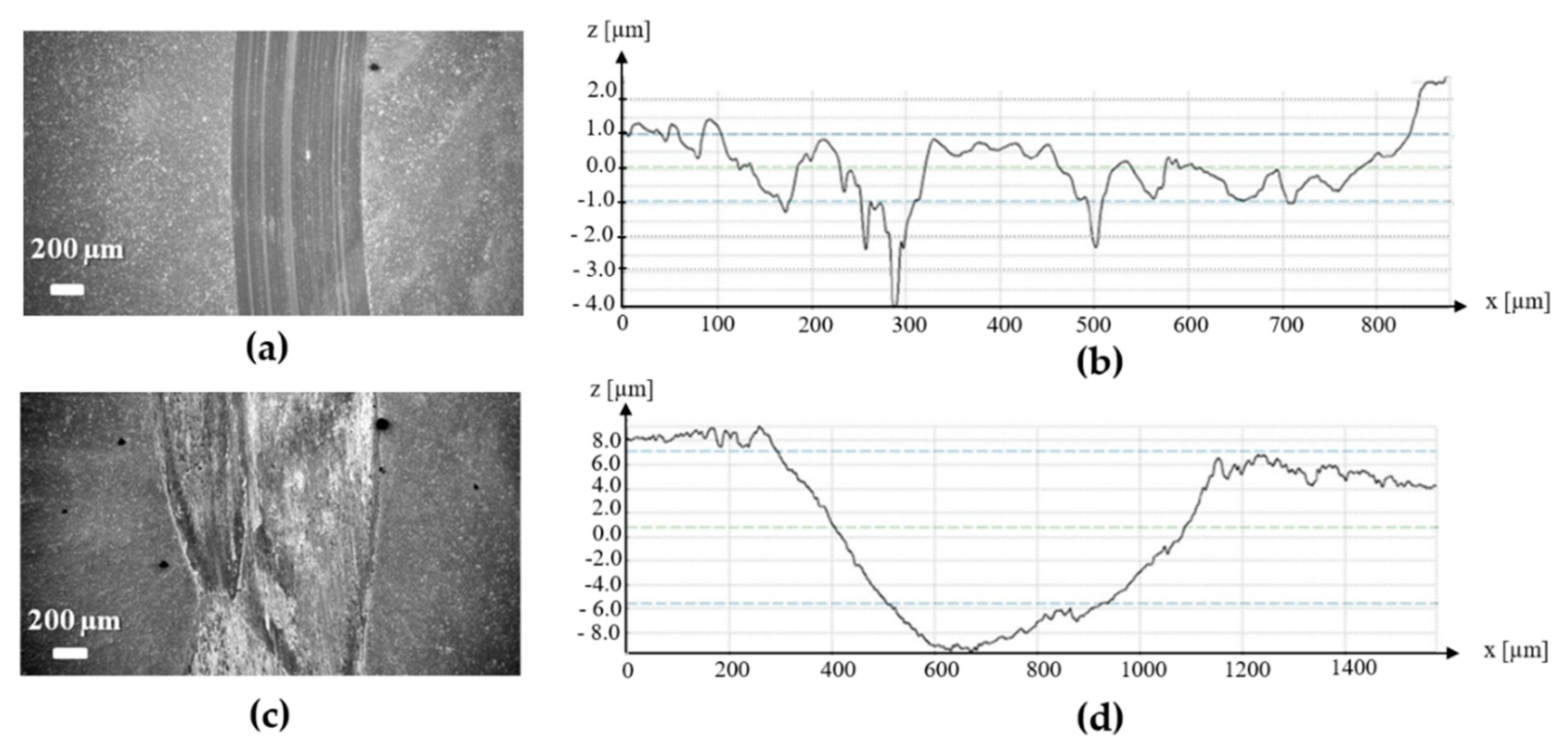

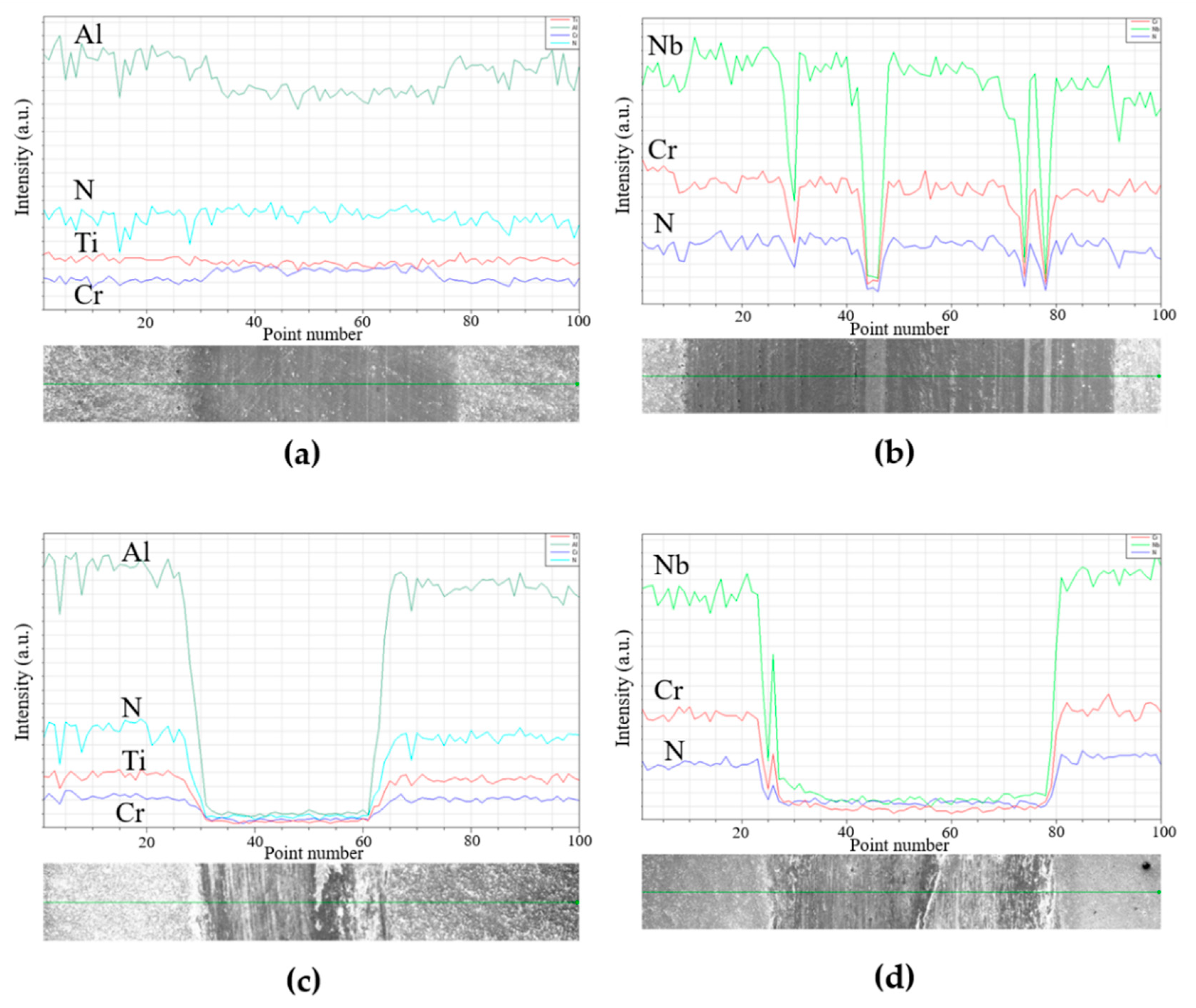

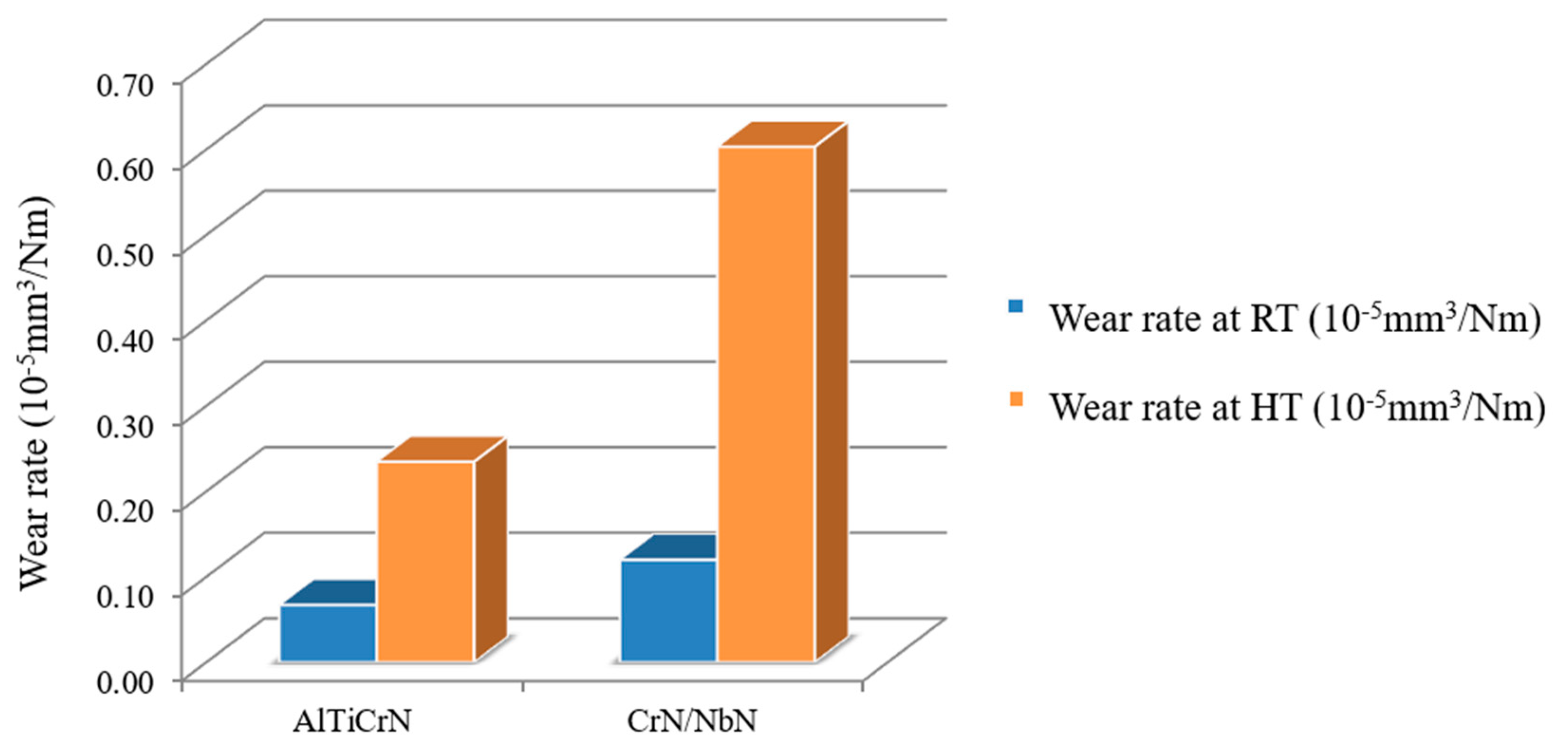

- The multilayered AlTiCrN coating exhibited the best response under the RT tribotest; on the other hand, the coating stability and friction properties were strongly affected by the HT regime, resulting in the complete removal of the coating from the S600 HSS substrate.

- The nanolayered superlattice CrN/NbN coating showed the worst overall performance under the HT tribotest, being quickly and completely removed from the substrate. Moreover, this sample showed a partial removal of the coating in the wear tracks during the RT wear test due to the applied conditions.

- Both the multilayered and the nanolayered coatings showed remarkable material removal during the HT tribotests, as well as a spallation phenomenon on the edges of the wear tracks.

- The tribotests performed at HT showed a dramatic lack of adhesion for both samples.

Author Contributions

Funding

Conflicts of Interest

References

- Bay, N.; Olsson, D.D.; Andreasen, J. Lubricant test methods for sheet metal forming. Tribol. Int. 2008, 41, 844–853. [Google Scholar] [CrossRef]

- Benedicto, E.; Carouc, D.; Rubio, E.M. Technical, Economic and Environmental Review of the Lubrication/Cooling Systems Used in Machining Processes. Procedia Eng. 2017, 184, 99–116. [Google Scholar] [CrossRef]

- Kataoka, S.; Murakawa, M.; Aizawa, T.; Ike, H. Tribology of dry deep-drawing of various metal sheets with use of ceramics tools. Surf. Coat. Technol. 2004, 177–178, 582–590. [Google Scholar] [CrossRef]

- Inspektor, A.; Salvador, P.A. Architecture of PVD coatings for metalcutting applications: A review. Surf. Coat. Technol. 2014, 257, 138–153. [Google Scholar] [CrossRef]

- Zega, B. Hard decorative coatings by reactive physical vapor deposition: 12 Years of development. Surf. Coat. Technol. 1989, 39–40, 507–520. [Google Scholar] [CrossRef]

- Panjan, M.; Klanjšek Gunde, M.; Panjan, P.; Čekada, M. Designing the color of AlTiN hard coating through interference effect. Surf. Coat. Technol. 2014, 254, 65–72. [Google Scholar] [CrossRef]

- Podgornik, B.; Zajec, B.; Bay, N.; Vižintin, J. Application of hard coatings for blanking and piercing tools. Wear 2011, 270, 850–856. [Google Scholar] [CrossRef]

- Voevodin, A.A.; O’Neill, J.P.; Zabinski, J.S. Nanocomposite tribological coatings for aerospace applications. Surf. Coat. Technol. 1999, 116–119, 36–45. [Google Scholar] [CrossRef]

- Aizawa, T.; Iwamura, E.; Itoh, K. Development of nano-columnar carbon coating for dry micro-stamping. Surf. Coat. Technol. 2007, 202, 1177–1181. [Google Scholar] [CrossRef]

- Schmauder, T.; Nauenburg, K.-D.; Kruse, K.; Ickes, G. Hard coatings by plasma CVD on polycarbonate for automotive and optical applications. Thin Solid Films 2006, 502, 270–274. [Google Scholar] [CrossRef]

- Abadias, G.; Djemia, P.H.; Belliard, L. Alloying effects on the structure and elastic properties of hard coatings based on ternary transition metal (M = Ti, Zr or Ta) nitrides. Surf. Coat. Technol. 2014, 257, 129–137. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behavior. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

- Ni, W.; Cheng, Y.-T.; Lukitsch, M.J.; Weiner, A.M.; Lev, L.C.; Grummon, D.S. Effects of the ratio of hardness to Young’s modulus on the friction and wear behavior of bilayer coatings. Appl. Phys. Lett. 2004, 85, 4028–4030. [Google Scholar] [CrossRef]

- Musil, J. Hard nanocomposite coatings: Thermal stability, oxidation resistance and toughness. Surf. Coat. Technol. 2012, 207, 50–65. [Google Scholar] [CrossRef]

- Guo, J.; Wang, H.; Meng, F.; Liu, X.; Huang, F. Tuning the H/E* ratio and E* of AlN coatings by copper addition. Surf. Coat. Technol. 2013, 228, 68–75. [Google Scholar] [CrossRef]

- Voevodin, A.A.; Zabinski, J.S.; Muratore, C. Recent Advances in Hard, Tough, and Low Friction Nanocomposite Coatings. Tsinghua Sci. Technol. 2005, 10, 665–679. [Google Scholar] [CrossRef]

- Wang, C.; Shi, K.; Gross, C.; Pureza, J.M.; de Mesquita Lacerda, M.; Chung, Y.W. Toughness enhancement of nanostructured hard coatings: Design strategies and toughness measurement techniques. Surf. Coat. Technol. 2014, 257, 206–212. [Google Scholar] [CrossRef]

- Kindlund, H.; Sangiovanni, D.G.; Martìnez-de-Olcoz, L.; Lu, J.; Jensen, J.; Birch, J.; Petrov, I.; Greene, J.E.; Chirita, V.; Hultman, L. Toughness enhancement in hard ceramic thin films by alloy design. APL Mater. 2013, 1, 042104. [Google Scholar] [CrossRef]

- Sargade, V.G.; Gangopadhyay, S.; Paul, S.; Chattopadhyay, A.K. Effect of coating thickness and dry performance of tin film deposited on cemented carbide inserts using CFUBMS. Mater. Manuf. Process. 2011, 26, 1028–1033. [Google Scholar] [CrossRef]

- Jawaid, A.; Olajire, K.A. Cuttability investigation of coated carbides. Mater. Manuf. Process. 1999, 14, 559–580. [Google Scholar] [CrossRef]

- Kulkarni, A.P.; Sargade, V.G. Characterization and performance of AlTiN, AlTiCrN, TiN/TiAlN PVD coated carbide tools while turning SS 304. Mater. Manuf. Process. 2015, 30, 748–755. [Google Scholar] [CrossRef]

- Singh, K.; Limaye, P.-K.; Soni, N.L.; Grover, A.K.; Agrawal, R.G.; Suri, A.K. Wear studies of (Ti–Al)N coatings deposited by reactive magnetron sputtering. Wear 2005, 258, 1813–1824. [Google Scholar] [CrossRef]

- Deng, J.X.; Liu, J.H.; Zhao, J.L.; Song, W.L. Wear mechanisms of PVD ZrN coated tools in machining. Int. J. Refract. Met. Hard Mater. 2008, 26, 164–172. [Google Scholar] [CrossRef]

- Wolfe, G.; Petrosky, C.; Quinto, D.T. The role of hard coatings in carbide milling tools. J. Vac. Sci. Technol. A Vac. Surf. Films 1986, 4, 2747–2754. [Google Scholar] [CrossRef]

- Su, Y.L.; Kao, W.H. Optimum multilayer TiN–TiCN coatings for wear resistance and actual application. Wear 1998, 223, 119–130. [Google Scholar] [CrossRef]

- Su, Y.L.; Kao, W.H. Tribological Behavior and Wear Mechanisms of TiN/TiCN/TiN Multilayer Coatings. J. Mater. Eng. Perform. 1998, 7, 601–612. [Google Scholar] [CrossRef]

- Jindal, P.C.; Santhanam, A.T.; Schleinkofer, U.; Shuster, A.F. Performance of PVD TiN, TiCN, and TiAlN coated cemented carbide tools in turning. Int. J. Refract. Met. Hard Mater. 1999, 17, 163–170. [Google Scholar] [CrossRef]

- Zhang, S.; Weiguang, Z. TiN coating of tool steels: A review. J. Mater. Process. Technol. 1993, 39, 165–177. [Google Scholar] [CrossRef]

- Münz, W.D. Titanium aluminum nitride films: A new alternative to TiN coatings. J. Vac. Sci. Technol. A Vac. Surf. Films 1986, 4, 2717–2725. [Google Scholar] [CrossRef]

- Seidl, W.M.; Bartosik, M.; Kolozsvári, S.; Bolvardi, H.; Mayrhofer, P.H. Influence of coating thickness and substrate on stresses and mechanical properties of (Ti,Al,Ta)N/(Al,Cr)N multilayers. Surf. Coat. Technol. 2018, 347, 92–98. [Google Scholar] [CrossRef]

- Ikeda, T.; Sato, H. Phase formation and characterization of hard coatings in the Ti-Al-N system prepared by the cathodic arc ion plating method. Thin Solid Films 1991, 195, 99–110. [Google Scholar] [CrossRef]

- Knotek, O.; Münz, W.D.; Leyendecker, T. Industrial deposition of binary, ternary, and quaternary nitrides of titanium, zirconium, and aluminum. J. Vac. Sci. Technol. A Vac. Surf. Films 1987, 5, 2173–2179. [Google Scholar] [CrossRef]

- Kalss, W.; Reiter, A.; Derflinger, V.; Gey, C.; Endrino, J.L. Modern coatings in high performance cutting applications. Int. J. Refract. Met. Hard Mater. 2006, 24, 399–404. [Google Scholar] [CrossRef]

- Yamamoto, K.; Sato, T.; Takahara, K.; Hanaguri, K. Properties of (Ti,Cr,Al)N coatings with high Al content deposited by new plasma enhanced arc-cathode. Surf. Coat. Technol. 2003, 174, 620–626. [Google Scholar] [CrossRef]

- Deng, J.; Wu, F.; Lian, Y.; Xing, Y.; Li, S. Erosion wear of CrN, TiN, CrAlN, and TiAlN PVD nitride coatings. Int. J. Refract. Met. Hard Mater. 2012, 35, 10–16. [Google Scholar] [CrossRef]

- Panjan, P.; Navinsek, B.; Cekada, M.; Zalar, A. Oxidation behaviour of TiAlN coatings sputtered at low temperature. Vacuum 1999, 53, 127–133. [Google Scholar] [CrossRef]

- Kawate, M.; Hashimoto, A.K.; Suzuki, T. Oxidation resistance of Cr1−xAlxN and Ti1−xAlxN films. Surf. Coat. Technol. 2003, 165, 163–167. [Google Scholar] [CrossRef]

- Hörling, A.; Hultman, L.; Odén, M.; Sjölén, J.; Karlsson, L. Mechanical properties and machining performance of Ti1−xAlxN-coated cutting tools. Surf. Coat. Technol. 2005, 191, 384–392. [Google Scholar] [CrossRef]

- Kulkarni, A.P.; Joshi, G.; Sargade, V.G. Performance of PVD AlTiCrN coating during machining of austenitic stainless steel. Surf. Eng. 2013, 29, 402–405. [Google Scholar] [CrossRef]

- Mayrhofer, P.H.; Hörling, A.; Karlsson, L.; Sjölén, J.; Larsson, T.; Mitterer, C.; Hultman, L. Self-organized nanostructures in the Ti–Al–N system. Appl. Phys. Lett. 2003, 83, 2049–2051. [Google Scholar] [CrossRef]

- Mayrhofer, P.H.; Mitterer, C.; Hultman, L.; Clemens, H. Microstructural design of hard coatings. Prog. Mater. Sci. 2006, 51, 1032–1114. [Google Scholar] [CrossRef]

- Koehler, J. Attempt to Design a Strong Solid. Phys. Rev. B 1970, 2, 547–551. [Google Scholar] [CrossRef]

- Helmersson, U.; Todorova, S.; Barnett, S.A.; Sundgren, J.-E.; Markert, L.C.; Greene, J.E. Growth of single-crystal TiN/VN strained-layer superlattices with extremely high mechanical hardness. J. Appl. Phys. 1987, 62, 481–484. [Google Scholar] [CrossRef]

- Münz, W.D. Large-scale manufacturing of nanoscale multilayered hard coatings deposited by cathodic arc/unbalanced magnetron sputtering. MRS Bull. 2003, 28, 173–179. [Google Scholar] [CrossRef]

- Hovsepian, P.E.; Lewis, D.B.; Münz, W.D. Recent progress in large scale manufacturing of multilayer/superlattice hard coatings. Surf. Coat. Technol. 2000, 133–134, 166–175. [Google Scholar] [CrossRef]

- Hovsepian, P.E.; Münz, W.D. Recent progress in large-scale production of nanoscale multilayer/superlattice hard coatings. Vacuum 2003, 69, 27–36. [Google Scholar] [CrossRef]

- Lewis, D.B.; Hovsepian, P.E.; Schönjahn, C.; Ehiasarian, A.; Smith, I.J. Industrial scale manufactured superlattice hard PVD coatings. Surf. Eng. 2001, 17, 15–27. [Google Scholar]

- Luo, Q.; Lewis, D.B.; Hovsepian, P.E.; Münz, W.D. Transmission Electron Microscopy and X-ray Diffraction Investigation of the Microstructure of Nanoscale Multilayer TiAlN/VN Grown by Unbalanced Magnetron Deposition. J. Mater. Res. 2004, 19, 1093–1104. [Google Scholar] [CrossRef]

- Luo, Q.; Hovsepian, P.E.; Lewis, D.B.; Münz, W.D.; Kok, Y.N.; Cockrem, J.; Bolton, M.; Farinotti, A. Tribological properties of unbalanced magnetron sputtered nano-scale multilayer coatings TiAlN/VN and TiAlCrYN deposited on plasma nitrided steels. Surf. Coat. Technol. 2005, 193, 39–45. [Google Scholar] [CrossRef]

- Luo, Q.; Zhou, Z.; Rainforth, W.M.; Hovsepian, P.E. TEM-EELS study of low-friction superlattice TiAlN/VN coating: The wear mechanisms. Tribol. Lett. 2006, 24, 171–178. [Google Scholar] [CrossRef]

- Barshilia, H.C.; Deepthi, B.; Rajam, K.S. Growth and characterization of TiAlN/CrAlN superlattices prepared by reactive direct current magnetron sputtering. J. Vac. Sci. Technol. A Vac. Surf. Films 2009, 27, 29–36. [Google Scholar] [CrossRef]

- Barshilia, H.C.; Rajam, K.S.; Jain, A.; Gopinadhan, K.; Chaudhary, S. A comparative study on the structure and properties of nanolayered TiN/NbN and TiAlN/TiN multilayer coatings prepared by reactive direct current magnetron sputtering. Thin Solid Films 2006, 503, 158–166. [Google Scholar] [CrossRef]

- Yana, S.; Fua, T.; Wang, R.; Tian, C.; Wang, Z.; Huang, Z.; Yang, B.; Fu, D. Deposition of CrSiN/AlTiSiN nano-multilayer coatings by multi-arc ion plating using gas source silicon. Nucl. Instrum. Methods Phys. Res. Sect. B 2013, 307, 143–146. [Google Scholar] [CrossRef]

- Münz, W.D.; Donohue, L.A.; Hovsepian, P.E. Properties of various large-scale fabricated TiAlN- and CrN-based superlattice coatings grown by combined cathodic arc–unbalanced magnetron sputter deposition. Surf. Coat. Technol. 2000, 125, 269–277. [Google Scholar] [CrossRef]

- Patel, N.; Wang, S.; Inspektor, A.; Salvador, P.A. Secondary hardness enhancement in large period TiN/TaN superlattices. Surf. Coat. Technol. 2014, 254, 21–27. [Google Scholar] [CrossRef]

- An, J.; Zhang, Q.Y. Structure, hardness and tribological properties of nanolayered TiN/TaN multilayer coatings. Mater. Charact. 2007, 58, 439–446. [Google Scholar] [CrossRef]

- Shugurov, A.R.; Kazachenok, M.S. Mechanical properties and tribological behavior of magnetron sputtered TiAlN/TiAl multilayer coatings. Surf. Coat. Technol. 2018, 353, 254–262. [Google Scholar] [CrossRef]

- Ramadoss, R.; Kumar, N.; Dash, S.; Arivuoli, D.; Tyagi, A.K. Wear mechanism of CrN/NbN superlattice coating sliding against various counterbodies. Int. J. Refract. Met. Hard Mater. 2013, 41, 547–552. [Google Scholar] [CrossRef]

- Santecchia, E.; Hamouda, A.M.S.; Musharavati, F.; Zalnezhad, E.; Cabibbo, M.; Spigarelli, S. Wear resistance investigation of titanium nitride-based coatings. Ceram. Int. 2015, 41, 10349–10379. [Google Scholar] [CrossRef]

- Zhou, H.; Zheng, J.; Gui, B.; Geng, D.; Wang, Q. AlTiCrN coatings deposited by hybrid HIPIMS/DC magnetron co-sputtering. Vacuum 2017, 136, 129–136. [Google Scholar] [CrossRef]

- Holmberg, K.; Matthews, A. Coatings Tribology, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Haubner, R.; Lessiak, M.; Pitonak, R.; Köpf, A.; Weissenbacher, R. Evolution of conventional hard coatings for its use on cutting tools. Int. J. Refract. Met. Hard Mater. 2017, 62, 210–218. [Google Scholar] [CrossRef]

- Bobzin, K. High-performance coatings for cutting tools. CIRP J. Manuf. Sci. Technol. 2017, 18, 1–9. [Google Scholar] [CrossRef]

- Cabibbo, M.; El Mehtedi, M.; Clemente, N.; Spigarelli, S.; Hamouda, A.M.S.; Musharavati, F.; Daurù, M. High temperature thermal stability of innovative nanostructured thin coatings for advanced tooling. Key Eng. Mater. 2014, 622–623, 45–52. [Google Scholar] [CrossRef]

- Lafer Company Website. Available online: http://www.lafer.eu/en/technical-notes/ (accessed on 30 January 2019).

- Bhushan, B. Modern Tribology Handbook, 1st ed.; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Aihua, L.; Jianxin, D.; Haibing, C.; Yangyang, C.; Jun, Z. Friction and wear properties of TiN, TiAlN, AlTiN and CrAlN PVD nitride coatings. Int. J. Refract. Met. Hard Mater. 2012, 31, 82–88. [Google Scholar] [CrossRef]

- Yang, S.; Wiemann, E.; Teer, D.G. The properties and performance of Cr-based multilayer nitride hard coatings using unbalanced magnetron sputtering and elemental metal targets. Surf. Coat. Technol. 2004, 188–189, 662–668. [Google Scholar] [CrossRef]

- Yang, S.; Teer, D.G. Properties and performance CrTiAlN of multilayer hard coatings deposited using magnetron sputter ion plating. Surf. Eng. 2002, 18, 391–396. [Google Scholar] [CrossRef]

- Eh Hovsepian, P.; Ehiasarian, A.P.; Purandare, Y.P.; Mayr, P.; Abstoss, K.G.; Mosquera Feijoo, M.; Schulz, W.; Kranzmann, A.; Lasanta, M.I.; Trujillo, J.P. Novel HIPIMS deposited nanostructured CrN/NbN coatings for environmental protection of steam turbine components. J. Alloy. Compd. 2018, 746, 583–593. [Google Scholar] [CrossRef]

- Hovsepian, P.E.; Ehiasarian, A.P.; Purandare, Y.P.; Biswas, B.; Pérez, F.J.; Lasanta, M.I.; de Miguel, M.T.; Illana, A.; Juez-Lorenzo, M.; Muelas, R.; et al. Performance of HIPIMS deposited CrN/NbN nanostructured coatings exposed to 650 °C in pure steam environment. Mater. Chem. Phys. 2016, 179, 110–119. [Google Scholar] [CrossRef]

- Agüero, A.; Juez-Lorenzo, M.; Hovsepian, P.E.; Ehiasarian, A.P.; Purandare, Y.P.; Muelas, R. Long-term behaviour of Nb and Cr nitrides nanostructured coatings under steam at 650 °C. Mechanistic considerations. J. Alloy. Compd. 2018, 739, 549–558. [Google Scholar] [CrossRef]

- Strahin, B.L.; Doll, G.L. Tribological coatings for improving cutting tool performance. Surf. Coat. Technol. 2018, 336, 117–122. [Google Scholar] [CrossRef]

- Kalin, M.; Jerina, J. The effect of temperature and sliding distance on coated (CrN, TiAlN) and uncoated nitrided hot-work tool steels against an aluminium alloy. Wear 2015, 330–331, 371–379. [Google Scholar] [CrossRef]

- Dejun, K.; Guizhong, F. Friction and wear behaviors of AlTiCrN coatings by cathodic arc ion plating at high temperatures. J. Mater. Res. 2015, 30, 503–511. [Google Scholar] [CrossRef]

- Jakubéczyová, D.; Hvizdos, P.; Selecká, M. Investigation of thin layers deposited by two PVD techniques on high speed steel produced by powder metallurgy. Appl. Surf. Sci. 2012, 258, 5105–5110. [Google Scholar] [CrossRef]

- Ma, D.; Ma, S.; Dong, H.; Xu, K.; Bell, T. Microstructure and tribological behaviour of super-hard Ti–Si–C–N nanocomposite coatings deposited by plasma enhanced chemical vapour deposition. Thin Solid Films 2006, 496, 438–444. [Google Scholar] [CrossRef]

- Cabibbo, M.; Clemente, N.; El Mehtedi, M.; Spigarelli, S.; Daurù, M.; Hammuda, A.S.; Musharavati, F. Mechanical and microstructure characterization of hard nanostructured N-bearing thin coating. Metall. Ital. 2015, 5, 5–9. [Google Scholar]

- Tsui, T.Y.; Pharr, G.M.; Oliver, W.C.; Bhatia, C.S.; White, R.L.; Anders, S.; Anders, A.; Brown, I.G. Nanoindentation and nanoscratching of hard carbon coatings for magnetic discs. MRS Online Proc. 1995, 383, 447–452. [Google Scholar] [CrossRef]

- Huang, W.; Zalnezhad, E.; Musharavati, F.; Jahanshahi, P. Investigation of the tribological and biomechanical properties of CrAlTiN and CrN/NbN coatings on SST 304. Ceram. Int. 2017, 43, 7992–8003. [Google Scholar] [CrossRef]

- Bemporad, E.; Pecchio, C.; De Rossi, S.; Carassiti, F. Characterisation and wear properties of industrially produced nanoscaled CrN/NbN multilayer coating. Surf. Coat. Technol. 2004, 188–189, 319–330. [Google Scholar] [CrossRef]

- Savisalo, T.; Lewis, D.B.; Luo, Q.; Bolton, M.; Hovsepian, P.E. Structure of duplex CrN/NbN coatings and their performance against corrosion and wear. Surf. Coat. Technol. 2008, 202, 1661–1667. [Google Scholar] [CrossRef]

- Bai, L.; Zhu, X.; Xiao, J.; He, J. Study on thermal stability of CrTiAlN coating for dry drilling. Surf. Coat. Technol. 2007, 201, 5257–5260. [Google Scholar] [CrossRef]

- Zhou, Z.F.; Tam, P.L.; Shum, P.W.; Li, K.Y. High temperature oxidation of CrTiAlN hard coatings prepared by unbalanced magnetron sputtering. Thin Solid Films 2009, 517, 5243–5247. [Google Scholar] [CrossRef]

- Tam, P.L.; Zhou, Z.F.; Shum, P.W.; Li, K.Y. Structural, mechanical, and tribological studies of Cr–Ti–Al–N coating with different chemical compositions. Thin Solid Films 2008, 516, 5725–5731. [Google Scholar] [CrossRef]

| Coating | Chemical Composition | Structure | Deposition Temperature (K) | Thickness (μm) | Hardness (HV 0.025) | Max Operating Temperature (K) |

|---|---|---|---|---|---|---|

| AlTiCrN | AlTiCrxN1−x | multilayer | 693 | 2.92 | 3300 | 1123 |

| CrN/NbN | Cr0.336Nb0.182N0.482 | nanolayer | 553 | 2.61 | 3000 | 1373 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santecchia, E.; Cabibbo, M.; Hamouda, A.M.S.; Musharavati, F.; Popelka, A.; Spigarelli, S. Investigation of the Temperature-Related Wear Performance of Hard Nanostructured Coatings Deposited on a S600 High Speed Steel. Metals 2019, 9, 332. https://doi.org/10.3390/met9030332

Santecchia E, Cabibbo M, Hamouda AMS, Musharavati F, Popelka A, Spigarelli S. Investigation of the Temperature-Related Wear Performance of Hard Nanostructured Coatings Deposited on a S600 High Speed Steel. Metals. 2019; 9(3):332. https://doi.org/10.3390/met9030332

Chicago/Turabian StyleSantecchia, Eleonora, Marcello Cabibbo, Abdel Magid Salem Hamouda, Farayi Musharavati, Anton Popelka, and Stefano Spigarelli. 2019. "Investigation of the Temperature-Related Wear Performance of Hard Nanostructured Coatings Deposited on a S600 High Speed Steel" Metals 9, no. 3: 332. https://doi.org/10.3390/met9030332

APA StyleSantecchia, E., Cabibbo, M., Hamouda, A. M. S., Musharavati, F., Popelka, A., & Spigarelli, S. (2019). Investigation of the Temperature-Related Wear Performance of Hard Nanostructured Coatings Deposited on a S600 High Speed Steel. Metals, 9(3), 332. https://doi.org/10.3390/met9030332