Transformation-Induced Plasticity in Super Duplex Stainless Steel F55-UNS S32760

Abstract

:1. Introduction

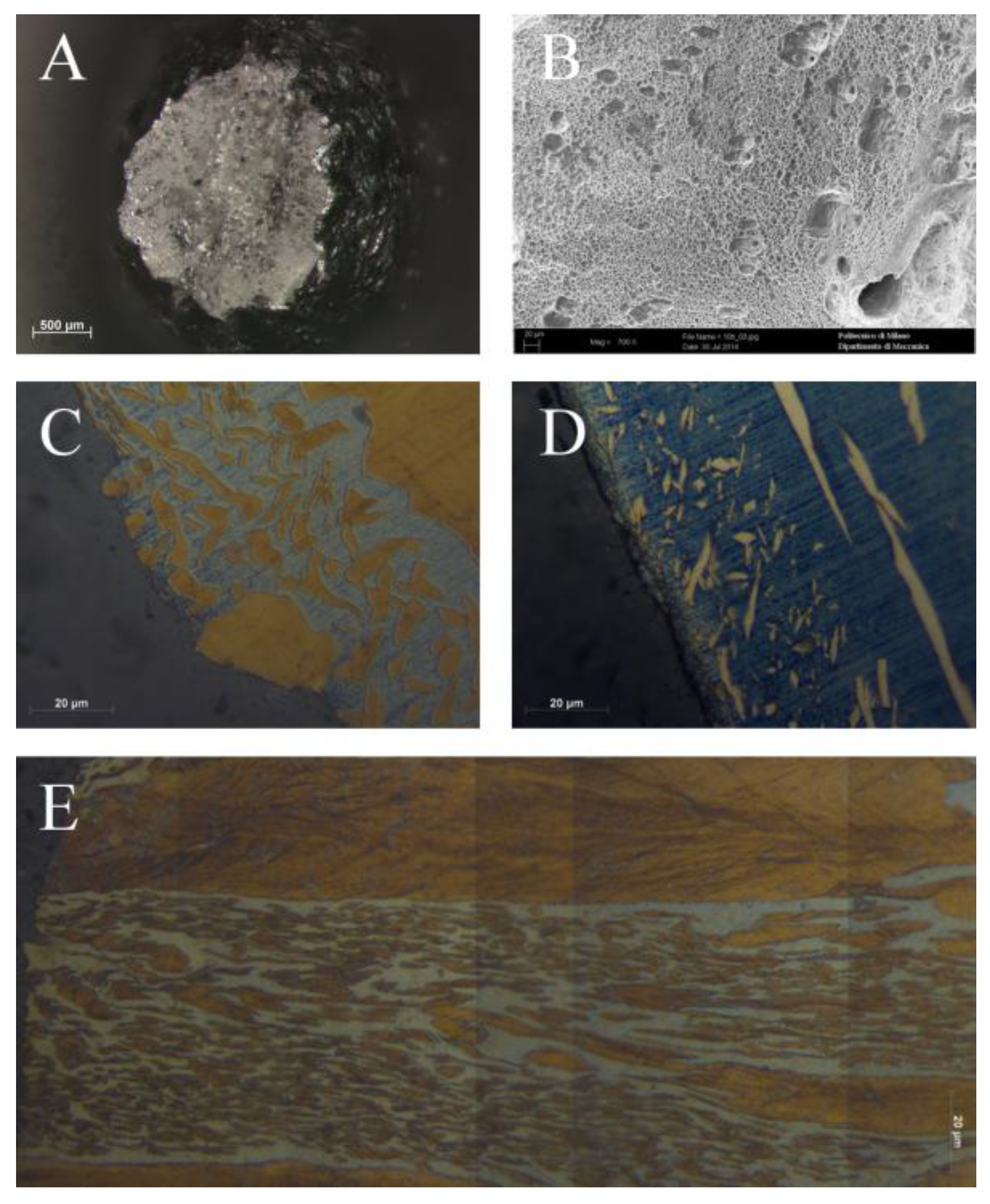

2. Materials and Methods

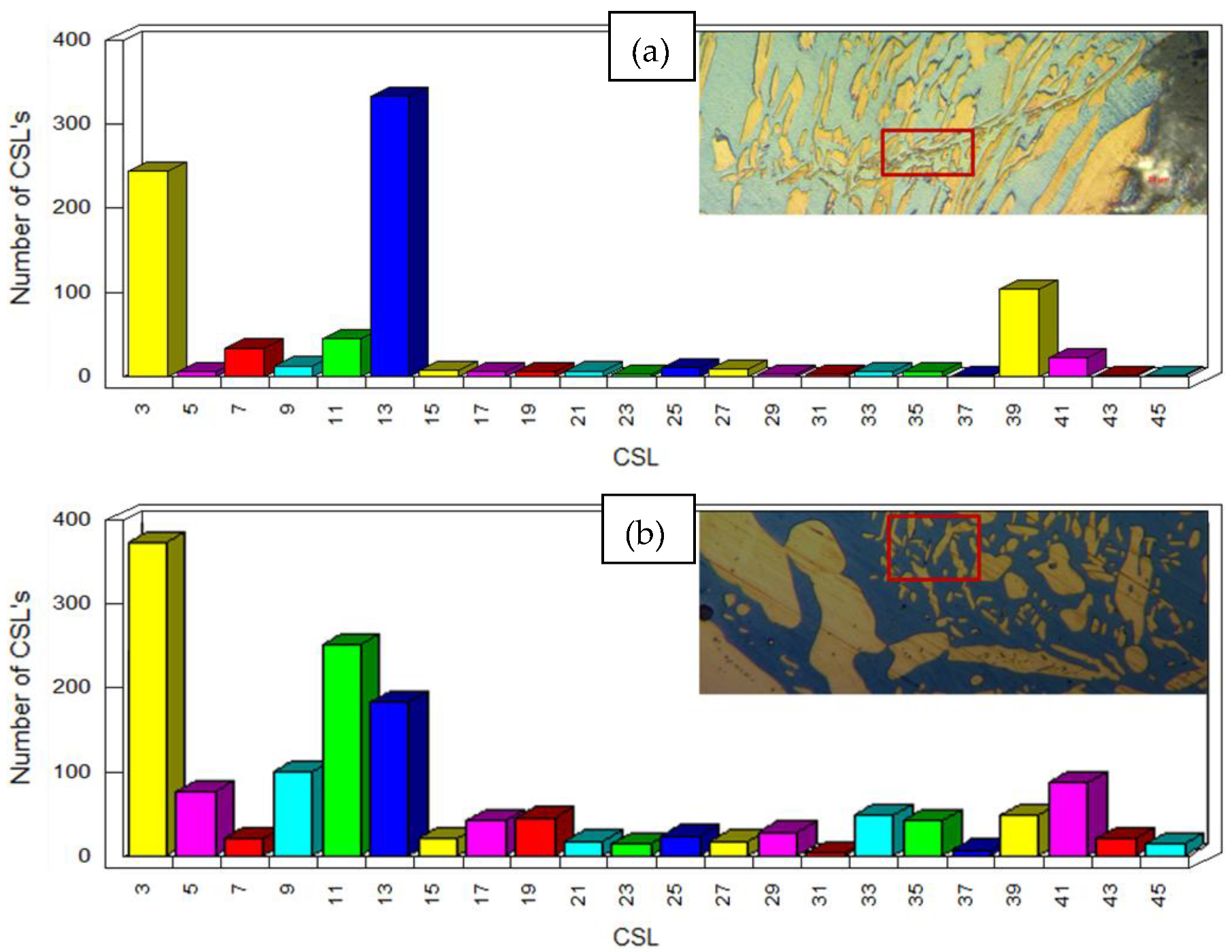

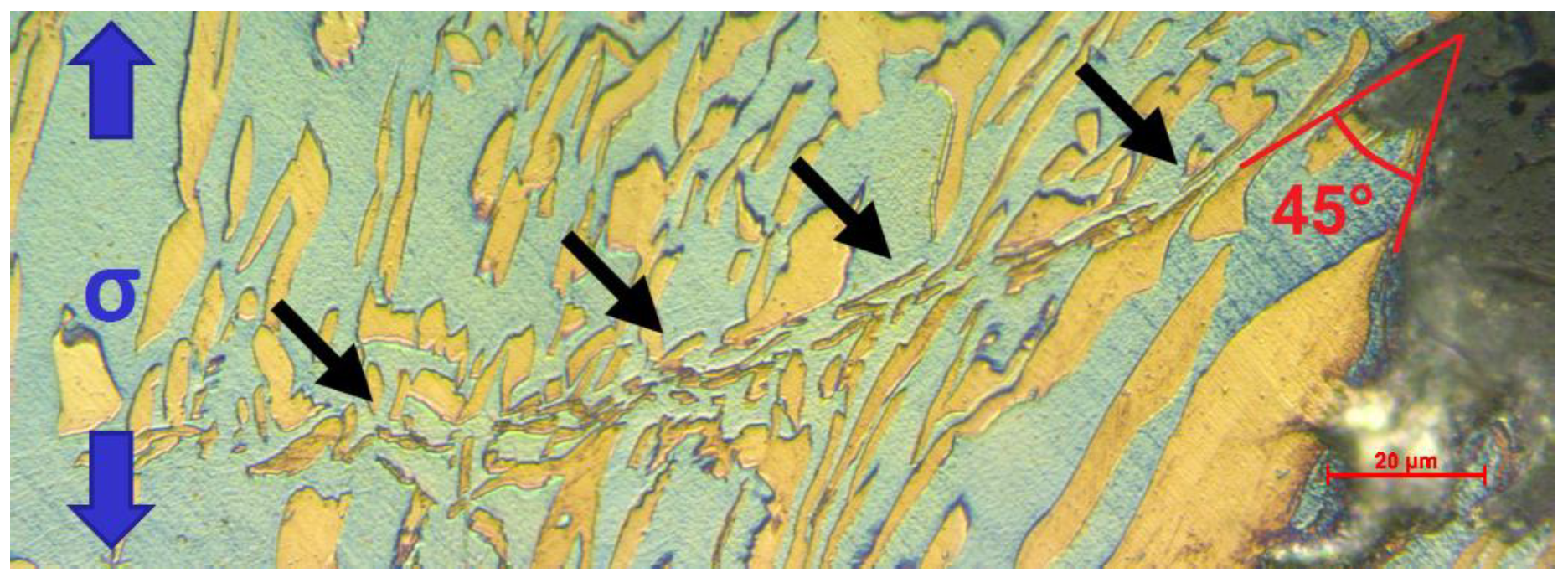

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Corradi, M.; Di Schino, A.; Borri, A.; Rufini, R. A review of the use of stainless steel for masonry repair and reinforcement. Constr. Build. Mater. 2018, 18, 335–346. [Google Scholar] [CrossRef]

- Rufini, R.; Di Pietro, O.; Di Schino, A. Predictive simulation of plastic processing of welded stainless steel pipes. Metals 2018, 8, 519. [Google Scholar] [CrossRef]

- Di Schino, A.; Longobardo, M.; Porcu, G.; Turconi, G.L.; Scoppio, L. Metallurgical design and development of C125 grade for mild sour application. In Proceedings of the NACE-International CORROSION 2006, San Diego, CA, USA, 12–16 March 2006; NACE-06125. pp. 1–14. [Google Scholar]

- Gunn, R.N. Duplex Stainless Steels, Microstructure, Properties and Applications; Woodhead Publishing: Cambridge, UK, 1994. [Google Scholar]

- Alvarez-armas, I. Duplex Stainless Steels: Brief History and Some Recent Alloys. Recent Patents Mech. Eng. 2008, 1, 51–57. [Google Scholar] [CrossRef]

- Nilsson, J.O. Super duplex stainless steels. Mater. Sci. Technol. 1992, 8, 685–700. [Google Scholar] [CrossRef]

- Ciuffini, A.F.; Barella, S.; Di Cecca, C.; Gruttadauria, A.; Mapelli, C.; Mombelli, D. Isothermal Austenite–Ferrite Phase Transformations and Microstructural Evolution during Annealing in Super Duplex Stainless Steels. Metals 2017, 7, 368. [Google Scholar] [CrossRef]

- Knyazeva, M.; Pohl, M. Duplex Steels: Part I: Genesis, Formation, Structure. Metallogr. Microstruct. Anal. 2013, 2, 113–121. [Google Scholar] [CrossRef]

- Charles, J.; Chemelle, P.M. The history of duplex developments, nowadays DSS properties and duplex market future trends. In Proceedings of the 3rd Duplex World Conference, Beaune, France, 13–15 October 2010. [Google Scholar]

- Southwick, P.D.; Honeycombe, R.W.K. Decomposition of ferrite to austenite in 26%Cr-5%Ni stainless steel. Metal Sci. 1980, 14, 253–261. [Google Scholar] [CrossRef]

- Ohmori, Y.; Nakai, K.; Ohtsubo, H.; Isshiki, Y. Mechanism of Widmanstatten austenite formation in a d/y duplex phase stainless steel. ISIJ Int. 1995, 35, 969–975. [Google Scholar] [CrossRef]

- Tomida, T.; Maehara, Y.; Ohmori, Y. Martensitic transformation from δ-ferrite during the Melt-Quenching process of δ-γ duplex stainless steel. Mater. Trans. JIM 1989, 5, 326–336. [Google Scholar] [CrossRef]

- Safdel, A.; Zarei-Hanzaki, A.; Shamsolhodaei, A.; Krooß, P.; Niendorf, T. Room temperature superelastic responses of NiTi alloy treated by two distinct thermomechanical processing schemes. Mater. Sci. Eng. A 2016, 684, 303–311. [Google Scholar] [CrossRef]

- Sato, A.; Chishima, E.; Soma, K.; Mori, T. Shape memory effect in γ↔ϵ transformation in Fe-30Mn-1Si alloy single crystals. Acta Metal. 1982, 32, 1177–1183. [Google Scholar] [CrossRef]

- Otsuka, K.; Ren, X.; Murakami, Y.; Kawano, K.; Ishii, T.; Ohba, T. Composition dependence of the rubber-like behavior in ζ2′-martensite of AuCd alloys. Mater. Sci. Eng. A 1999, 273–275, 558–563. [Google Scholar] [CrossRef]

- Dan, W.J.; Li, S.H.; Zhang, W.G.; Lin, Z.Q. The effect of strain-induced martensitic transformation on mechanical properties of TRIP steel. Mater. Des. 2008, 29, 604–612. [Google Scholar] [CrossRef]

- Sohn, S.S.; Choi, K.; Kwak, J.H.; Kim, N.J.; Lee, S. Novel ferrite-austenite duplex lightweight steel with 77% ductility by transformation induced plasticity and twinning induced plasticity mechanisms. Acta Mater. 2014, 78, 181–189. [Google Scholar] [CrossRef]

- Patra, S.; Ghosh, A.; Kumar, V.; Chakrabarti, D.; Singhal, L.K. Deformation induced austenite formation in as-cast 2101 duplex stainless steel and its effect on hot-ductility. Mater. Sci. Eng. A 2016, 660, 61–70. [Google Scholar] [CrossRef]

- Choi, J.Y.; Ji, J.H.; Hwang, S.W.; Park, K.T. TRIP aided deformation of a near-Ni-free, Mn-N bearing duplex stainless steel. Mater. Sci. Eng. A 2012, 535, 32–39. [Google Scholar] [CrossRef]

- Knyazeva, M.; Pohl, M. Duplex Steels. Part II: Carbides and Nitrides. Metallogr. Microstruct. Anal. 2013, 2, 343–351. [Google Scholar] [CrossRef]

- Pareige, C.; Novy, S.; Saillet, S.; Pareige, P. Study of phase transformation and mechanical properties evolution of duplex stainless steels after long term thermal ageing (>20 years). J. Nucl. Mater. 2011, 411, 90–96. [Google Scholar] [CrossRef]

- Herrera, C.; Ponge, D.; Raabe, D. Design of a novel Mn-based 1 GPa duplex stainless TRIP steel with 60% ductility by a reduction of austenite stability. Acta Mater. 2011, 59, 4653–4664. [Google Scholar] [CrossRef]

- Kocks, U.F.; Mecking, H. Physics and phenomenology of strain hardening: The FCC case. Prog. Mater. Sci. 2003, 48, 171–273. [Google Scholar] [CrossRef]

- Caleyo, F.; Cruz, F.; Baudin, T.; Penelle, R. Texture and grain size dependence of grain boundary character distribution in recrystallized Fe-50% Ni. Scr. Mater. 1999, 41, 847–853. [Google Scholar] [CrossRef]

- Huang, J.C.; Hsiao, I.C.; Wang, T.D.; Lou, B.Y. EBSD study on grain boundary characteristics in fine-grained Al alloys. Scr. Mater. 2000, 43, 213–220. [Google Scholar] [CrossRef]

- Beck, P.A. Annealing of cold worked metals. Adv. Phys. 1954, 3, 245–324. [Google Scholar] [CrossRef]

- Kobayashi, S.; Nakai, K.; Ohmori, Y. Isothermal decomposition of δ-ferrite in a 25Cr-7Ni-0.14N stainless steel. Acta Mater. 2001, 49, 1891–1902. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, F.; Lin, Z. Progress of nanocrystalline growth kinetics based on oriented attachment. Nanoscale 2010, 2, 18–34. [Google Scholar] [CrossRef] [PubMed]

- Balluffi, R.W.; Allen, S.; Carter, W.C. Kinetics of Materials; John Wiley & Sons: Hoboken, NJ, USA, 2005. [Google Scholar]

- Daróczi, L.; Palánki, Z.; Beke, D.L. Determination of the non-chemical free energy terms in martensitic transformations. Mater. Sci. Eng. A 2006, 438–440, 80–84. [Google Scholar]

- Wan, J.; Ruan, H.; Shi, S. Excellent combination of strength and ductility in 15Cr-2Ni duplex stainless steel based on ultrafine-grained austenite phase. Mater. Sci. Eng. A 2017, 690, 96–103. [Google Scholar] [CrossRef]

- Videau, J.-C.; Cailletaud, G.; Pineau, A. Experimental Study of the Transformation-Induced Plasticity in a Cr-Ni-Mo-Al-Ti Steel. J. Phys. IV 1996, 6, 465–474. [Google Scholar] [CrossRef]

- Voronenko, B.I. Austenitic-ferritic stainless steels: A state-of-the-art review. Met. Sci. Heat Treat. 1998, 39, 428–437. [Google Scholar] [CrossRef]

- Horvath, W.; Prantl, W.; Stroißnigg, H.; Werner, E. Micro hardness and microstructure of austenite and ferrite in nitrogen alloyed duplex steels between 20 and 500 °C. Mater. Sci. En. A 1998, 256, 227–236. [Google Scholar] [CrossRef]

- Fréchard, S.; Martin, F.; Clément, C.; Cousty, J. AFM and EBSD combined studies of plastic deformation in a duplex stainless steel. Mater. Sci. Eng. A 2006, 418, 312–319. [Google Scholar] [CrossRef]

- Taleb, L.; Petit, S. New investigations on transformation induced plasticity and its interaction with classical plasticity. Int. J. Plast. 2006, 22, 110–130. [Google Scholar] [CrossRef]

- Huang, B.X.; Wang, X.D.; Rong, Y.H. A method of discrimination between stress-assisted and strain-induced martensitic transformation using atomic force microscopy. Scr. Mater. 2007, 57, 501–504. [Google Scholar] [CrossRef]

- Chatterjee, S.; Bhadeshia, H.K.D.H. Transformation induced plasticity assisted steels: Stress or strain affected martensitic transformation? Mater. Sci. Technol. 2007, 23, 1101–1104. [Google Scholar] [CrossRef]

- Rutter, J.W.; Aust, K.T. Migration of ‹100› tilt grain boundaries in high purity lead Wanderung von ‹100›-neidungskorngrenzen in hochreinem blei. Acta. Metall. 1965, 13, 181–186. [Google Scholar] [CrossRef]

| F55-UNS S32766 | Wt. % | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | Mn | Si | Cr | Ni | Mo | N | Cu | W | Fe | |

| Designation | <0.03 | <1.00 | <1.00 | 24.0–26.0 | 6.0–8.0 | 3.0–4.0 | 0.2–0.3 | 0.5–1.0 | 0.5–1.0 | Bal. |

| OES measure | 0.027 | 0.63 | 0.51 | 24.37 | 6.69 | 5.45 | 0.22 | 0.72 | 0.85 | Bal. |

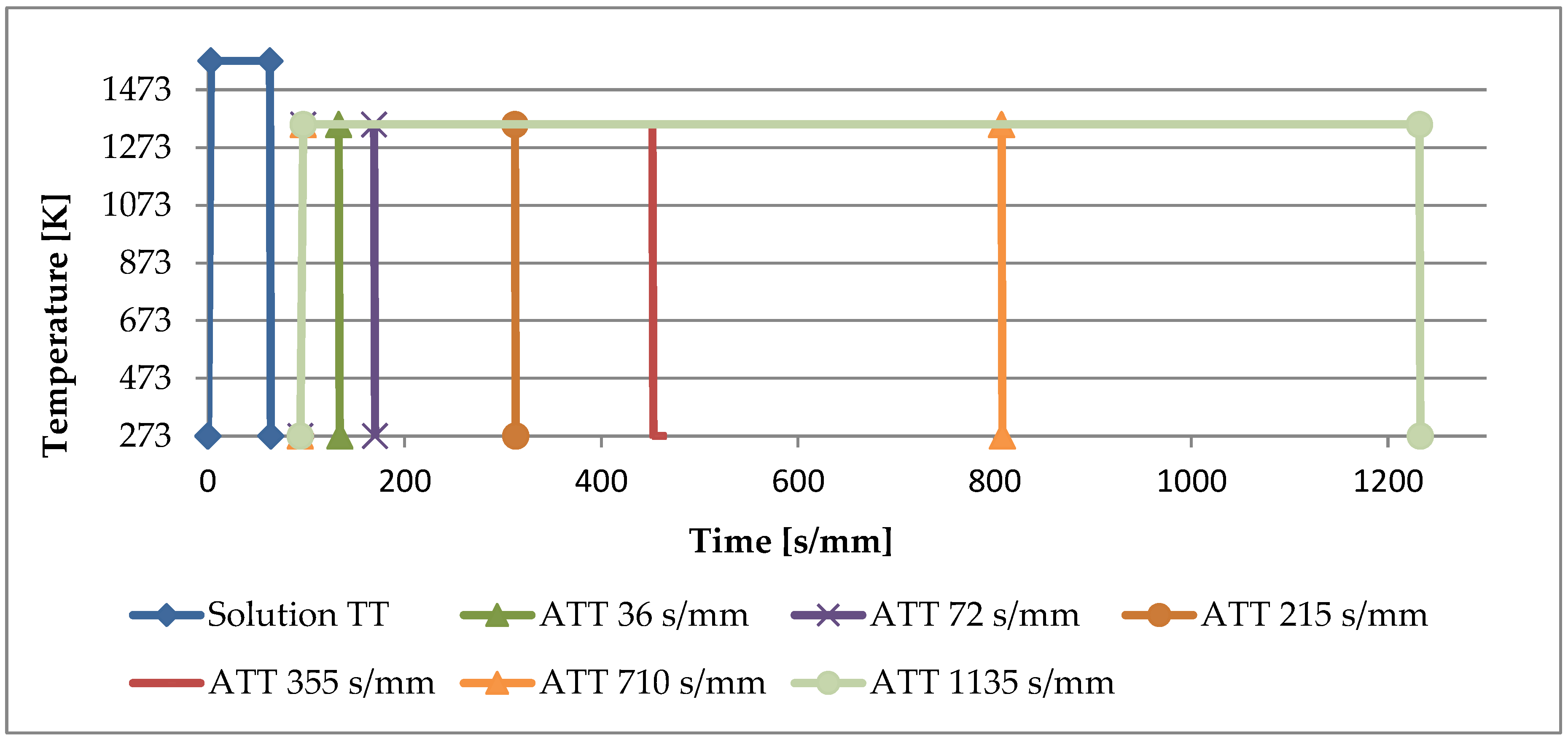

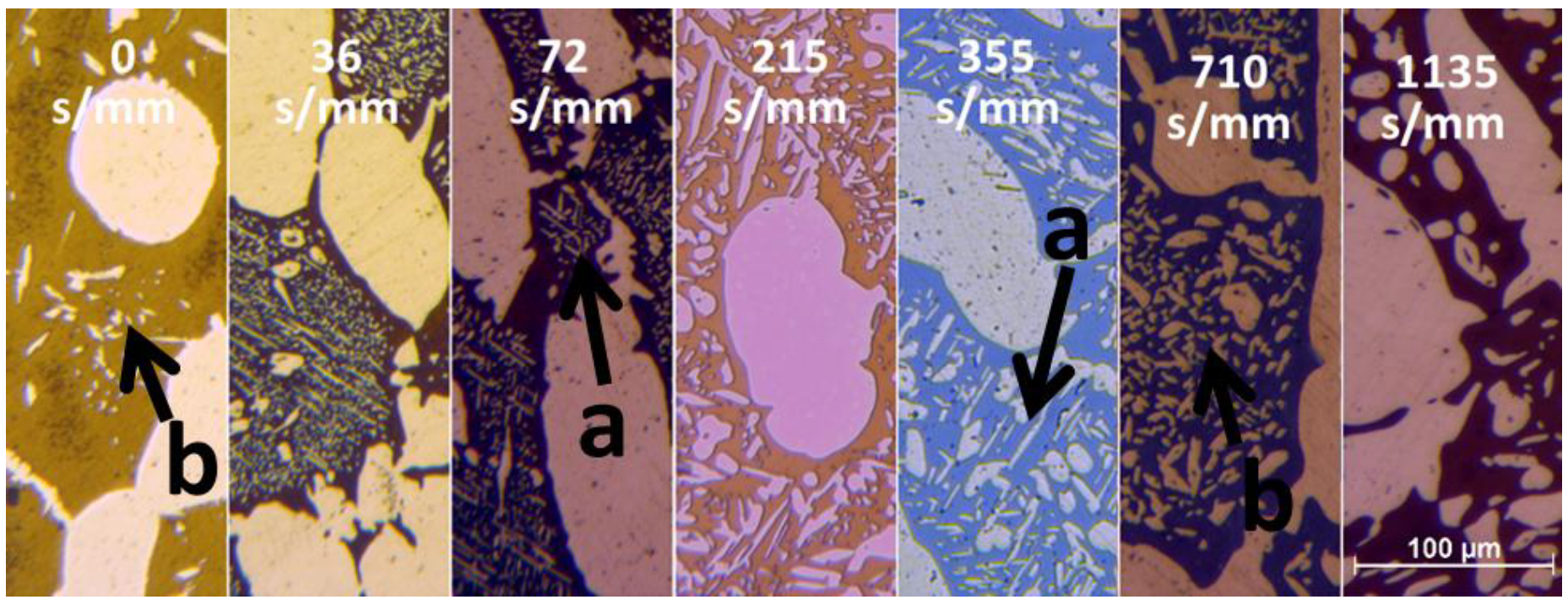

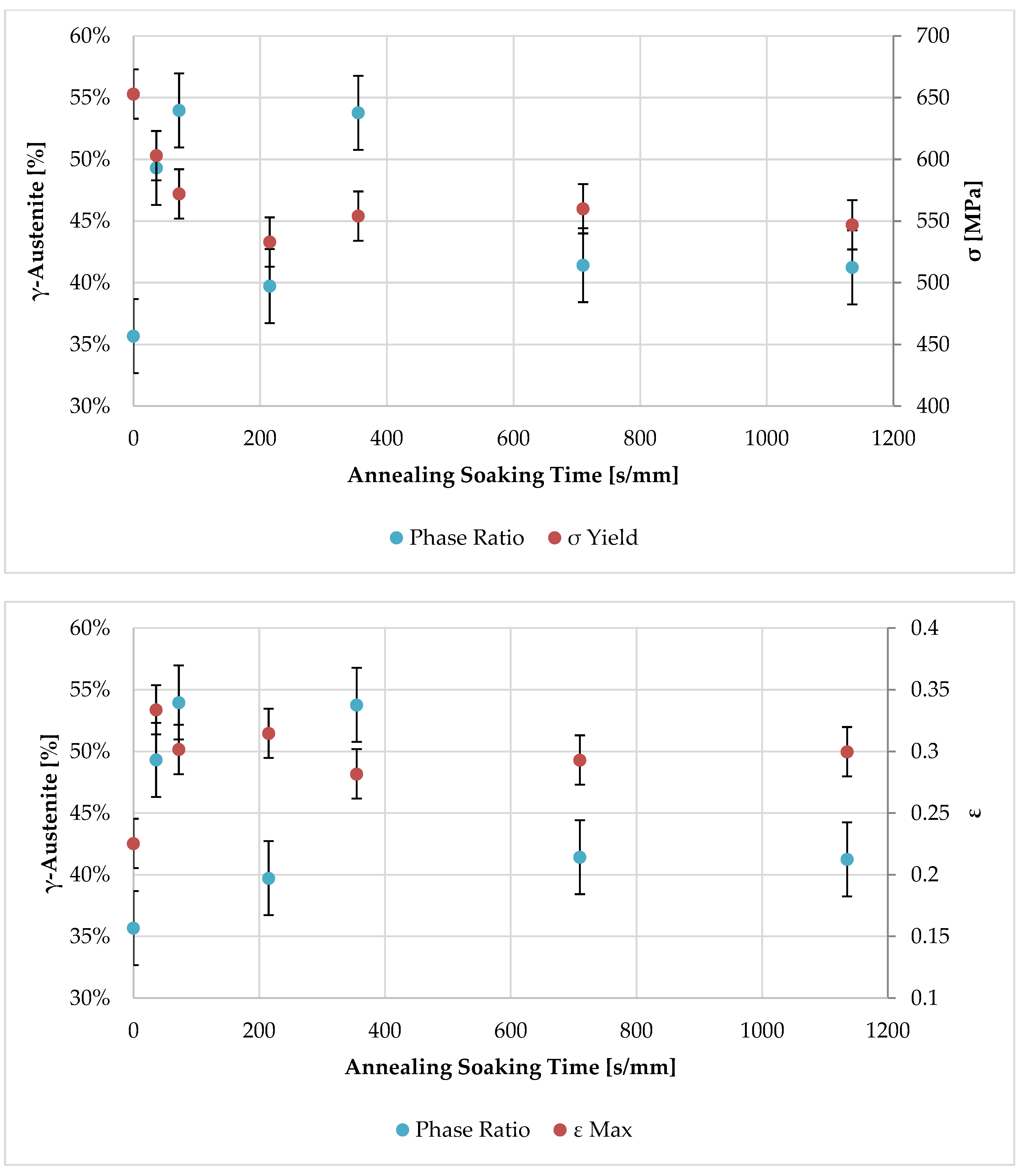

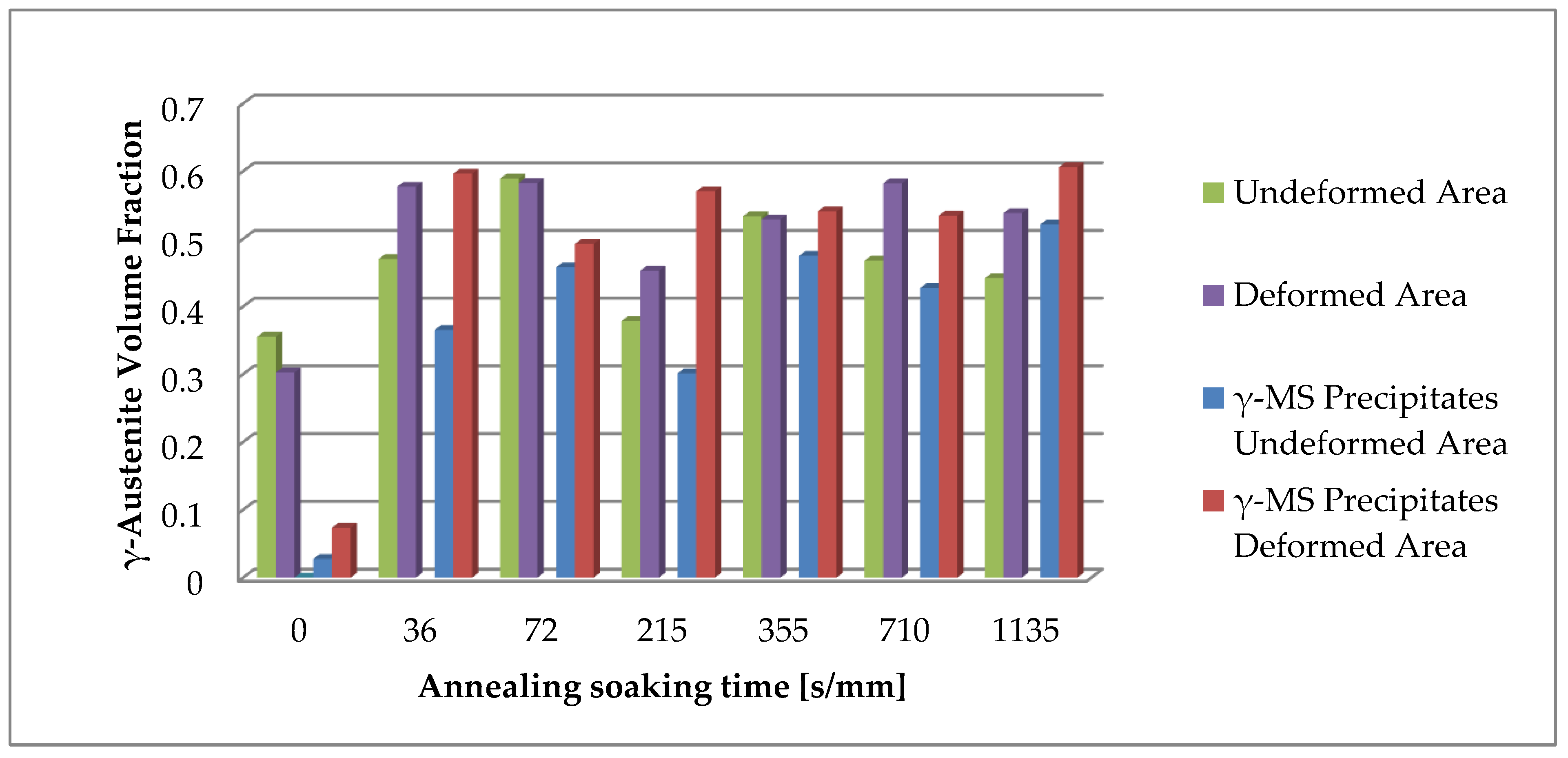

| Annealing Soaking Times [s/mm] | 0 | 36 | 72 | 215 | 355 | 710 | 1135 |

| γ Volume Fraction | 0.36 | 0.49 | 0.54 | 0.40 | 0.54 | 0.41 | 0.41 |

| Error | 0.03 | 0.02 | 0.05 | 0.01 | 0.01 | 0.04 | 0.02 |

| Specimen | Area | Wt.% | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Fe | Cr | Ni | Mo | W | Cu | Mn | Si | ||

| STT 1300 °C | α-ferrite | 60.85 ± 0.31 | 24.92 ± 0.46 | 6.23 ± 0.28 | 5.11 ± 0.33 | 0.80 ± 0.11 | 0.90 ± 0.07 | 0.67 ± 0.32 | 0.52 ± 0.19 |

| ATT 36 s/mm | α-ferrite | 61.68 ± 0.42 | 23.45 ± 0.34 | 4.98 ± 0.32 | 7.02 ± 0.28 | 0.80 ± 0.12 | 0.88 ± 0.9 | 0.61 ± 0.19 | 0.58 ± 0.17 |

| ATT 1135 s/mm | α-ferrite | 63.37 ± 0.35 | 23.24 ± 0.41 | 4.37 ± 0.27 | 6.49 ± 0.22 | 1.08 ± 0.8 | 0.54 ± 0.15 | 0.51 ± 0.14 | 0.40 ± 0.10 |

| Annealing Time [s/mm] | γ% | σy [MPa] | σMax [MPa] | εR | E [GPa] | Adsorbed Energy [J/mm3] |

|---|---|---|---|---|---|---|

| 0 | 35.7 | 653 | 828 | 0.225 | 255 | 176 |

| 36 | 49.3 | 603 | 849 | 0.334 | 211 | 260 |

| 72 | 54.0 | 572 | 839 | 0.302 | 211 | 230 |

| 215 | 39.7 | 533 | 826 | 0.315 | 112 | 237 |

| 355 | 53.8 | 554 | 827 | 0.282 | 181 | 212 |

| 710 | 41.4 | 560 | 803 | 0.293 | 190 | 215 |

| 1135 | 41.3 | 547 | 824 | 0.300 | 245 | 226 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ciuffini, A.F.; Barella, S.; Di Cecca, C.; Di Schino, A.; Gruttadauria, A.; Napoli, G.; Mapelli, C. Transformation-Induced Plasticity in Super Duplex Stainless Steel F55-UNS S32760. Metals 2019, 9, 191. https://doi.org/10.3390/met9020191

Ciuffini AF, Barella S, Di Cecca C, Di Schino A, Gruttadauria A, Napoli G, Mapelli C. Transformation-Induced Plasticity in Super Duplex Stainless Steel F55-UNS S32760. Metals. 2019; 9(2):191. https://doi.org/10.3390/met9020191

Chicago/Turabian StyleCiuffini, Andrea Francesco, Silvia Barella, Cosmo Di Cecca, Andrea Di Schino, Andrea Gruttadauria, Giuseppe Napoli, and Carlo Mapelli. 2019. "Transformation-Induced Plasticity in Super Duplex Stainless Steel F55-UNS S32760" Metals 9, no. 2: 191. https://doi.org/10.3390/met9020191

APA StyleCiuffini, A. F., Barella, S., Di Cecca, C., Di Schino, A., Gruttadauria, A., Napoli, G., & Mapelli, C. (2019). Transformation-Induced Plasticity in Super Duplex Stainless Steel F55-UNS S32760. Metals, 9(2), 191. https://doi.org/10.3390/met9020191