Investigation of Microstructure, Nanohardness and Corrosion Resistance for Oxi-Nitrocarburized Low Carbon Steel

Abstract

:1. Introduction

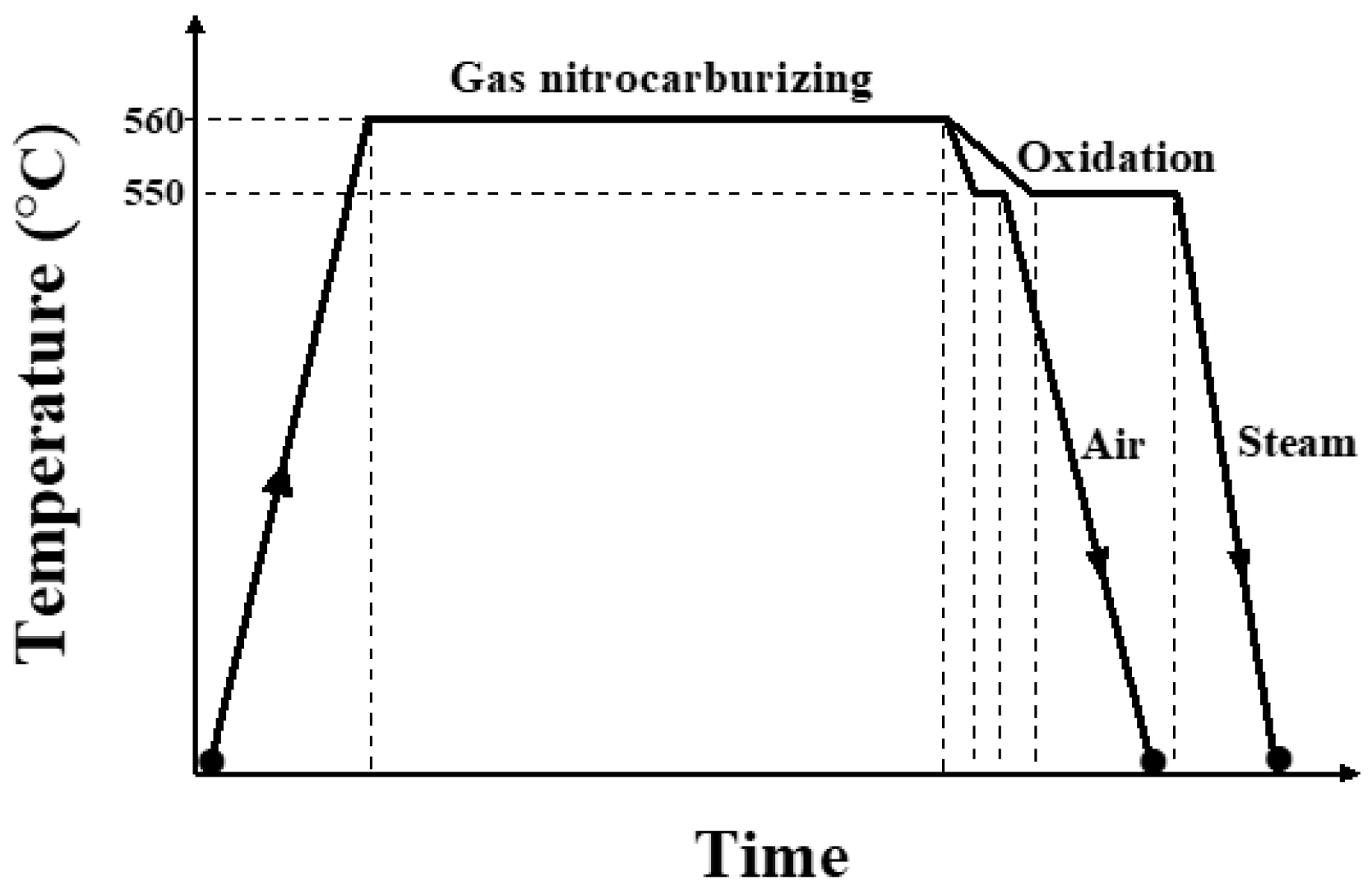

2. Materials and Methods

3. Results and Discussion

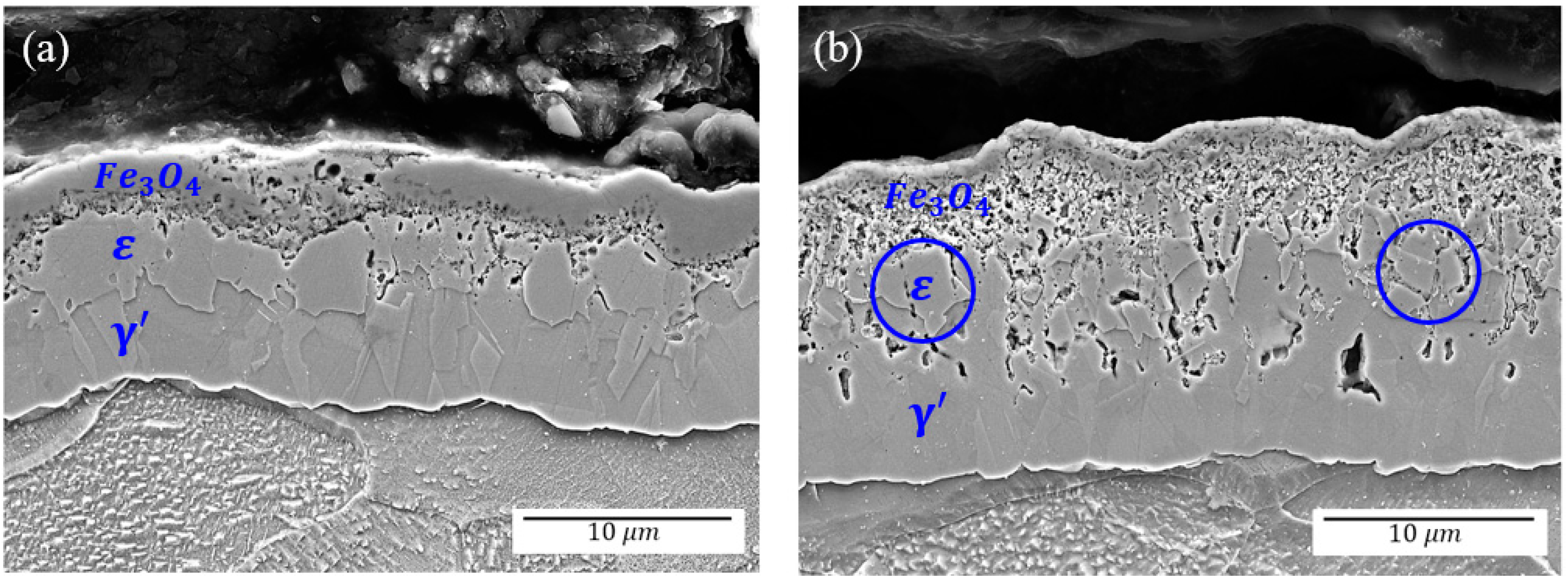

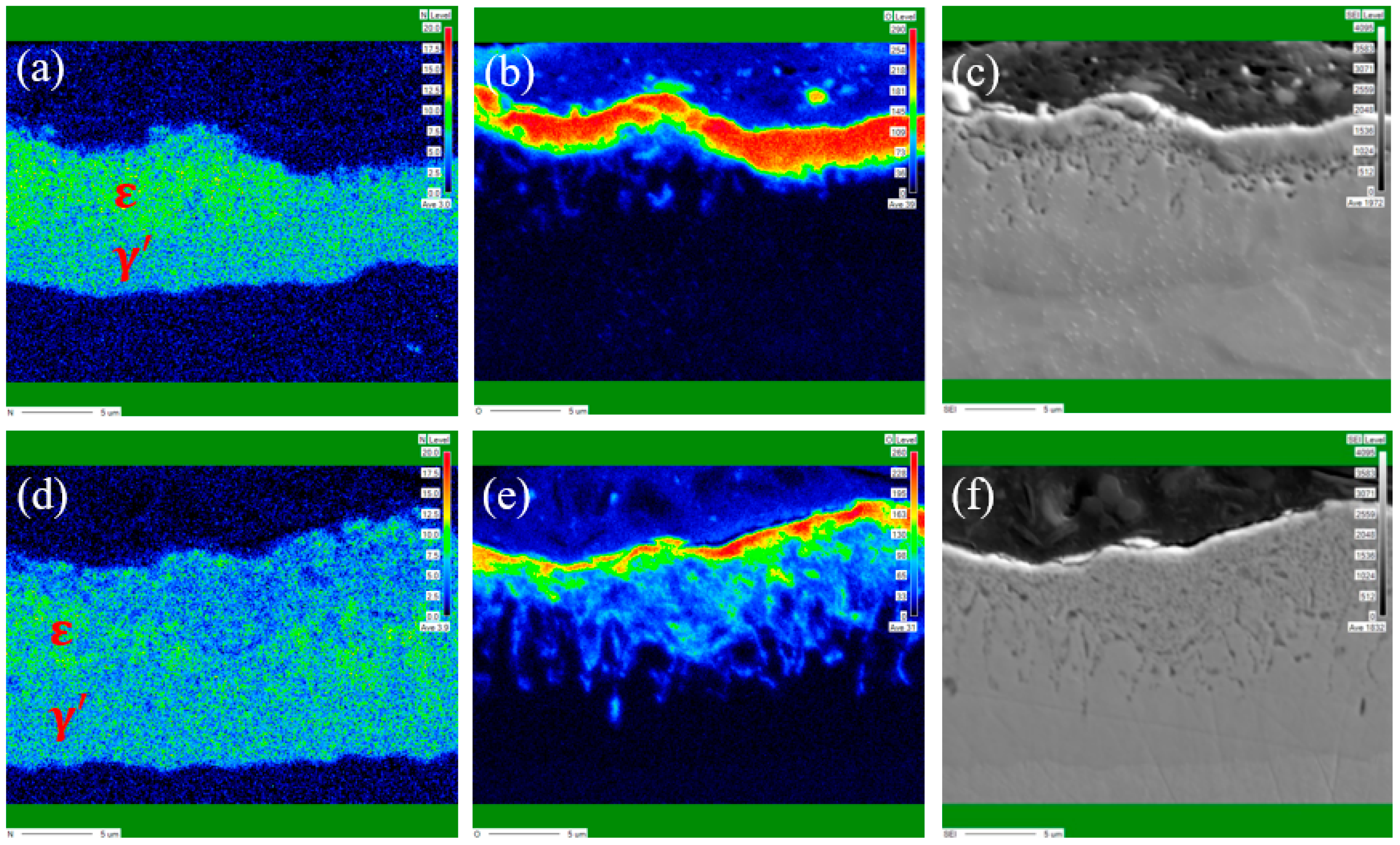

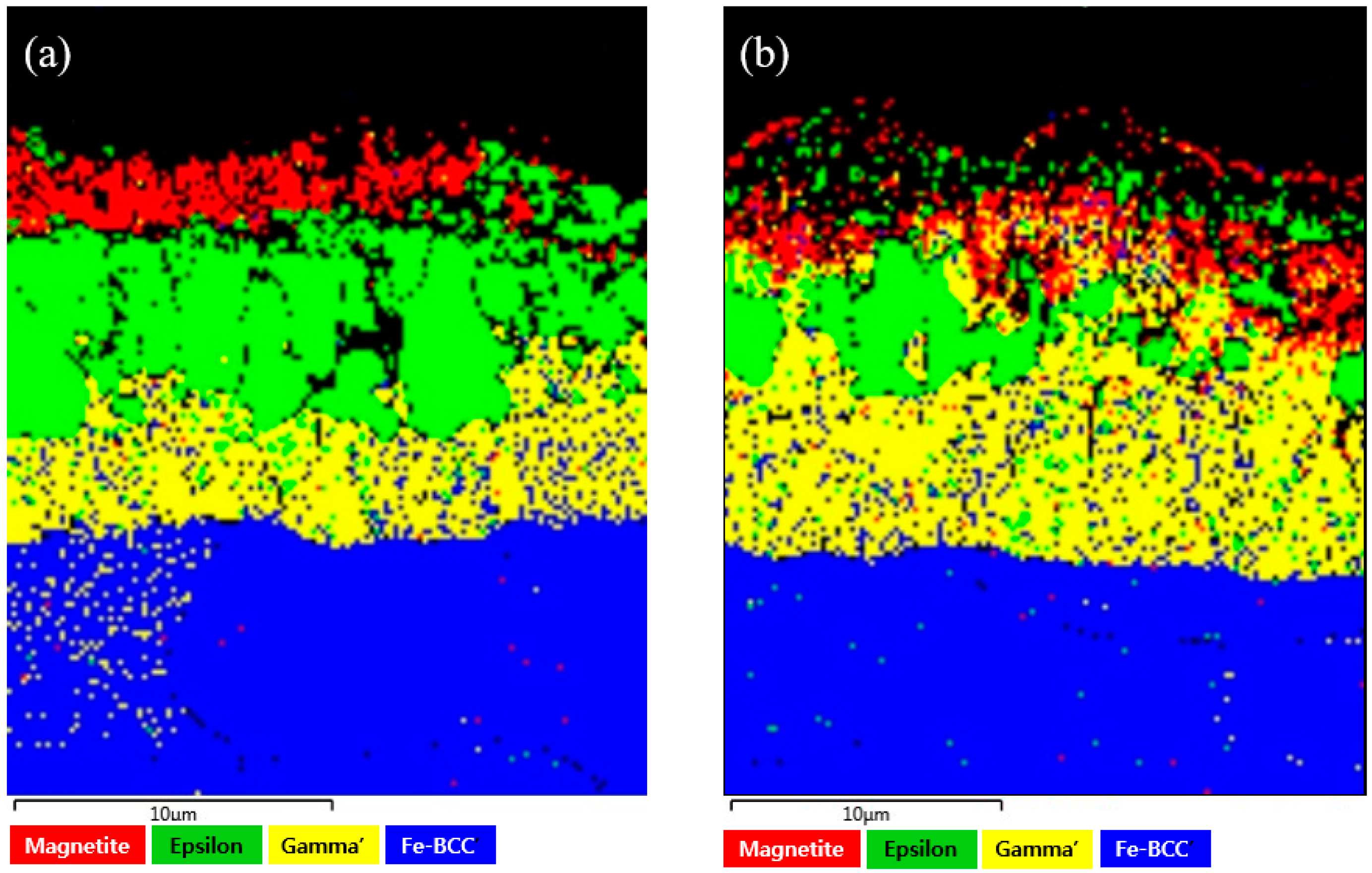

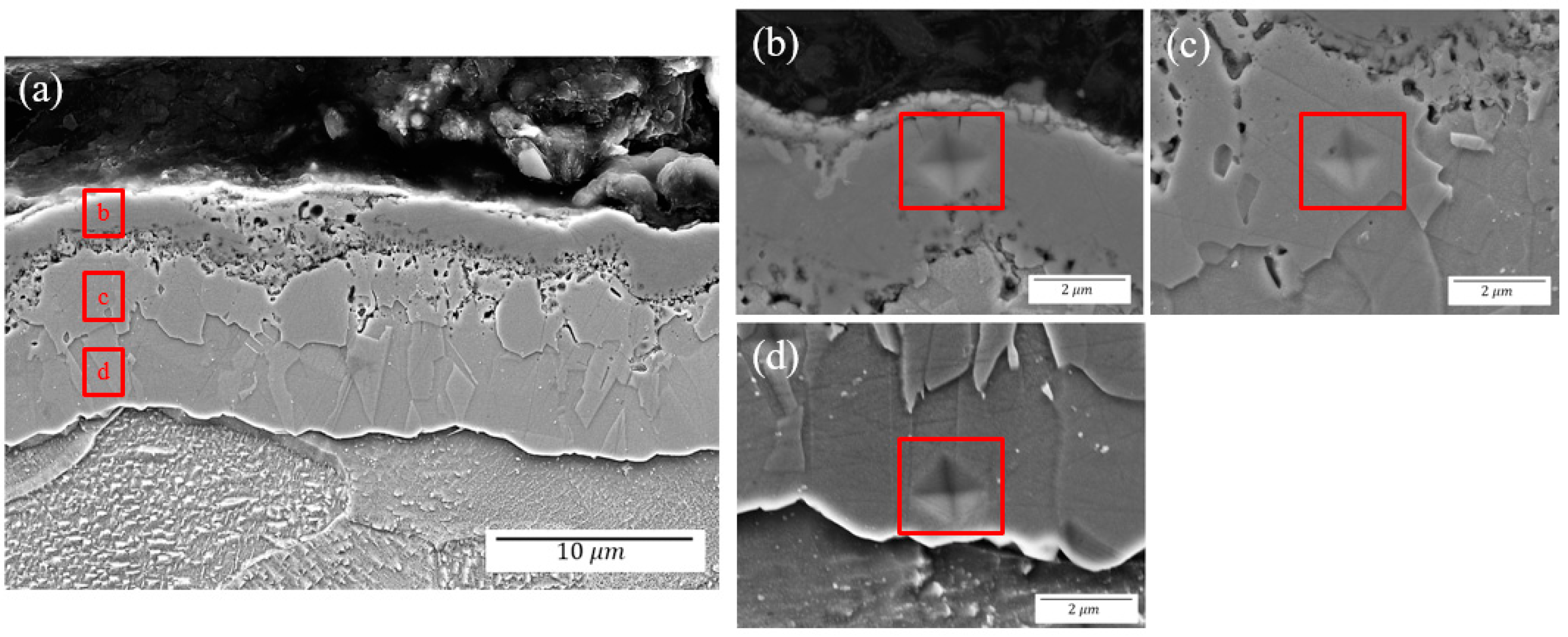

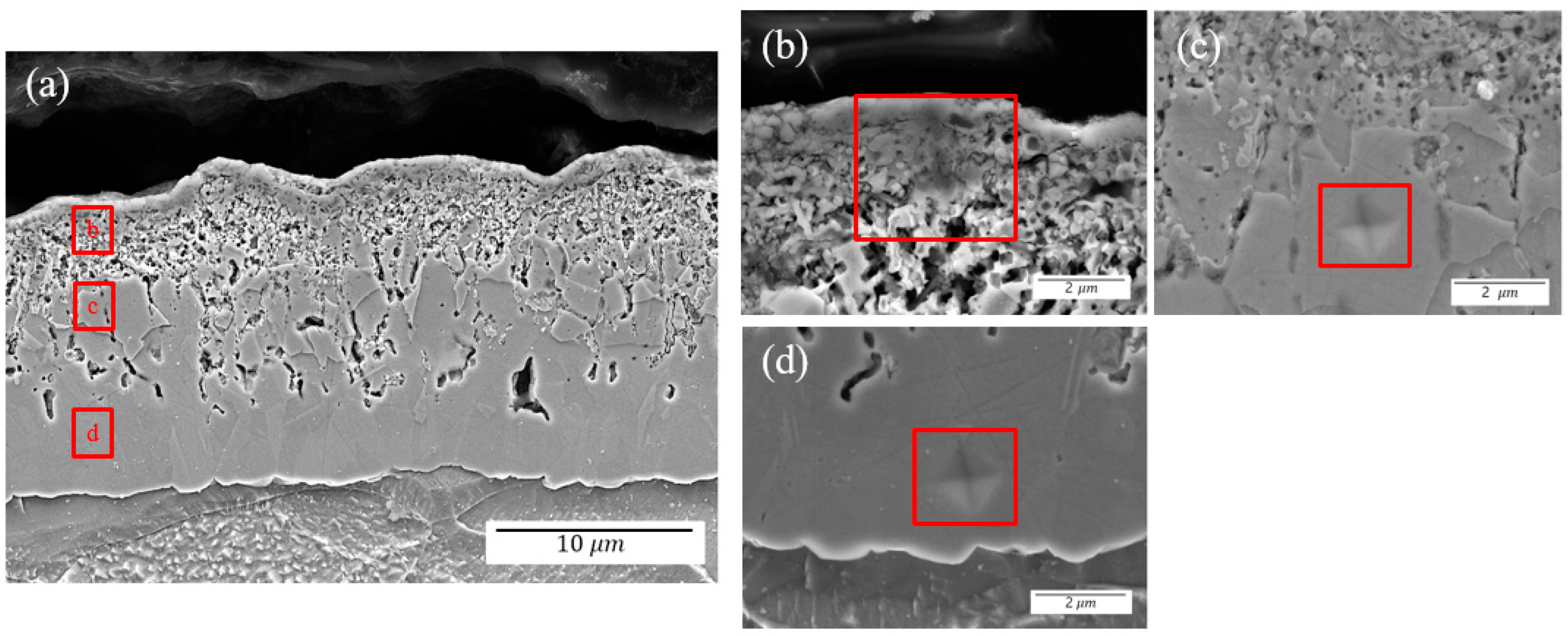

3.1. Microstructure and Phase Analysis

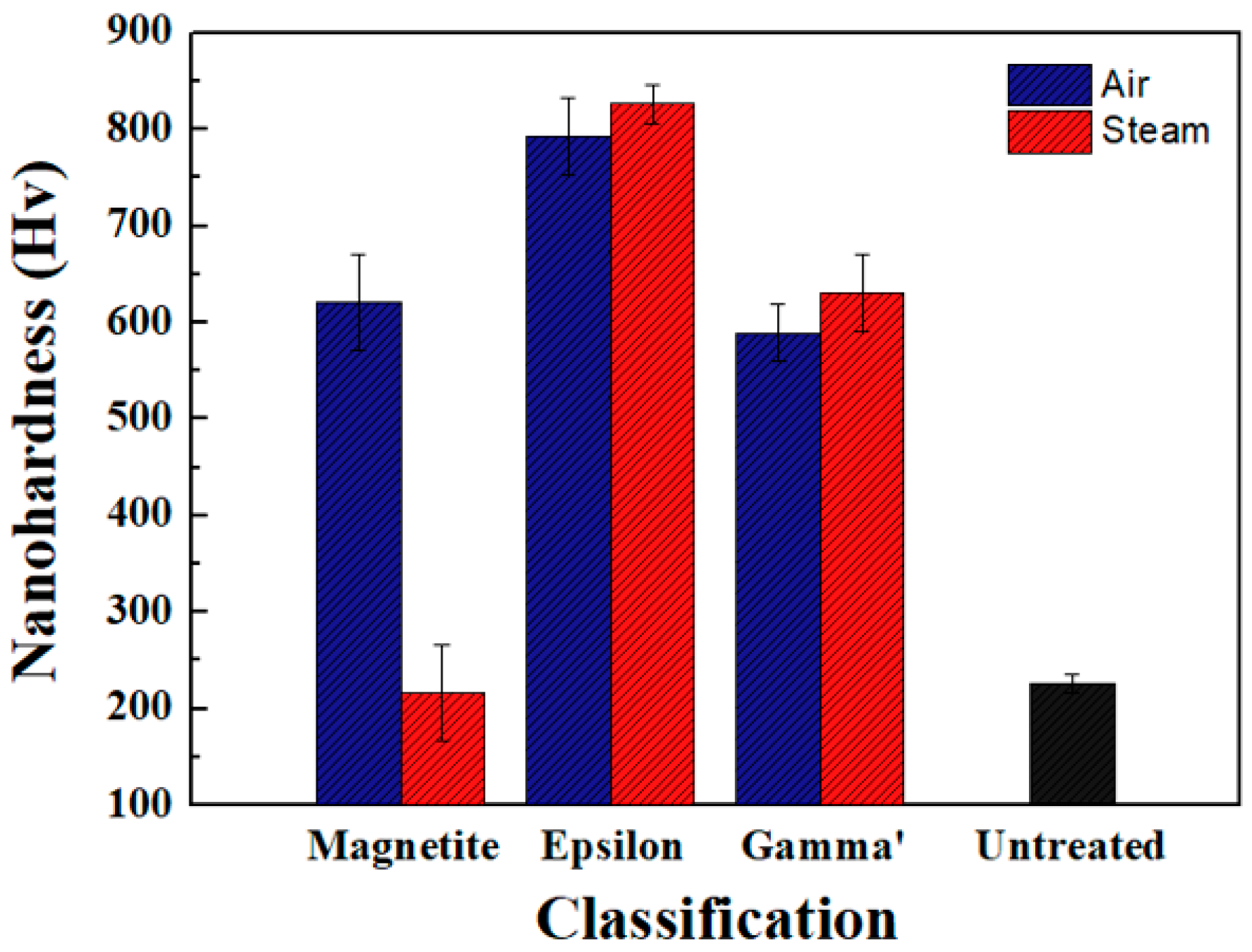

3.2. Nanohardness of the Surface Hardened Layer

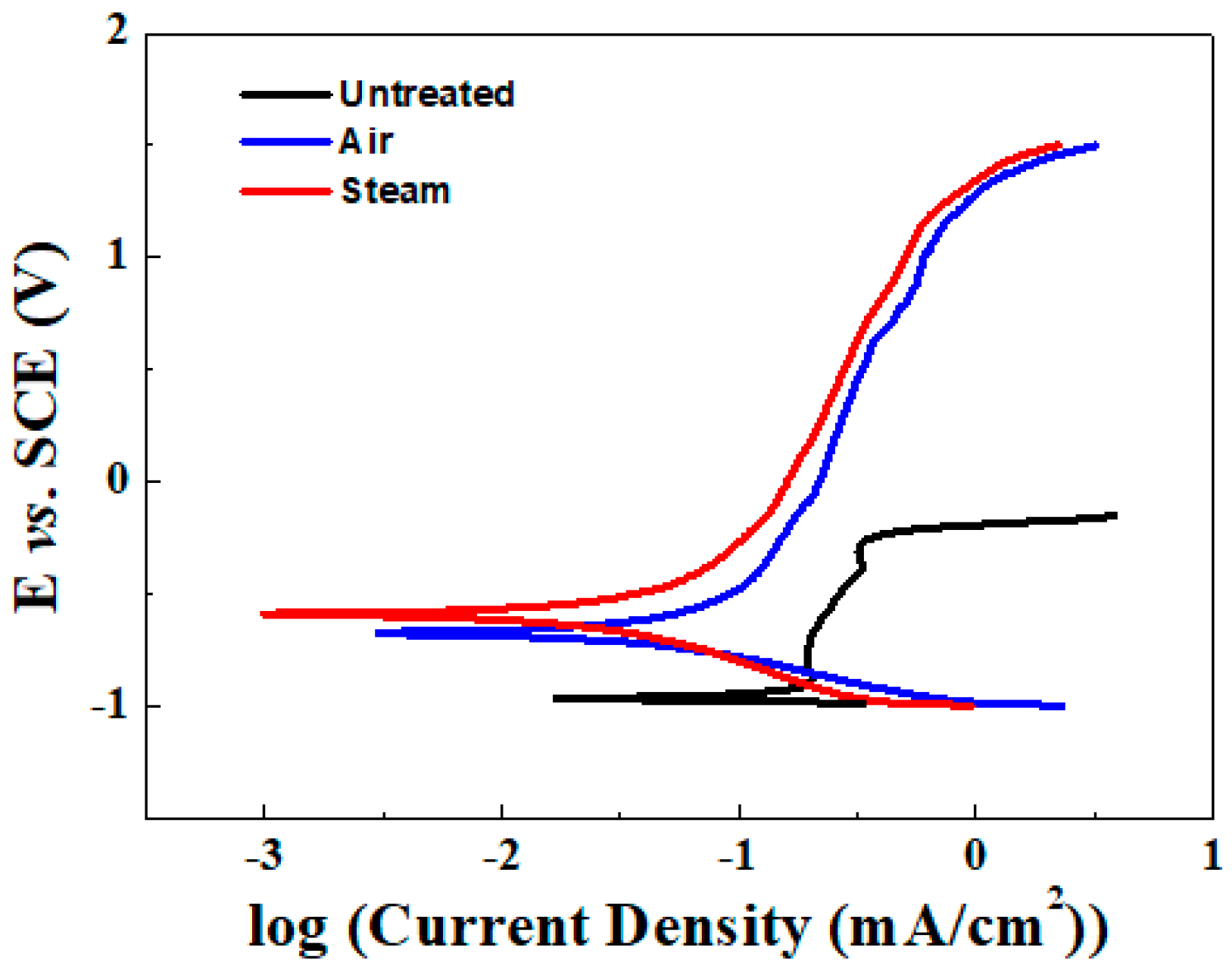

3.3. Corrosion Resistance

4. Conclusions

- EPMA and EBSD methods are useful techniques for analysis of microstructure including the oxide layer of magnetite and compound layer of ε-phase and γ′-phase for oxi-nitrocarburized low-carbon steel.

- Though the nanohardness measured by nanoindentation method is not precise enough, it is worth measuring the nanohardness to understand the cross-sectional microstructure for the surface hardened layer.

- Regardless of the oxidation conditions, the corrosion resistance of the oxi-nitrocarburized specimens showed superior performance when compared to the untreated-specimens. This means that oxi-nitrocarburizing is a potential method for improving the corrosion resistance because of the formation of a thicker magnetite oxide layer.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Hoppe, S. Fundamentals and applications of the combination of plasma nitrocarburizing and oxidizing. Surf. Coat. Technol. 1998, 98, 1194–1204. [Google Scholar] [CrossRef]

- Lee, I. Plasma Nitrocarburizing Technique with Quenching and Tempering for Manufacture of Vehicle Parts. Korean J. Met. Mater. 2015, 53, 398–405. [Google Scholar] [CrossRef]

- Lee, W.B.; Yu, K.C.; Kim, Y.M.; Wi, J.L. Microstructural Evolution of Compound Layers During Gaseous Nitriding of AISI1045 Carbon Steels. Korean J. Met. Mater. 2016, 54, 457–482. [Google Scholar] [CrossRef]

- Jeong, E.K.; Park, I.M.; Lee, I. Plasma post-oxidation of nitrocarburized SUM 24L steel. Mater. Sci. Eng. A 2007, 449–451, 868–871. [Google Scholar] [CrossRef]

- Lee, I. Post-oxidizing treatments of the compound layer on the AISI 4135 steel produced by plasma nitrocarburizing. Surf. Coat. Technol. 2004, 188–189, 669–674. [Google Scholar] [CrossRef]

- Kim, H.K.; Kim, Y.H. Effects of Heat Treatment on Corrosion Resistance Properties of Gas Nitrided Stainless Steels. J. Korean Soc. Heat Treat. 2009, 22, 298–306. [Google Scholar]

- Moon, K.I.; Kim, S.K.; Kim, S.W. A Study on the Corrosion Resistance of Free Cutting Steels after Oxy-Nitriding. J. Korean Soc. Heat Treat. 2006, 19, 90–95. [Google Scholar]

- Jacquet, P.; Coudert, J.B.; Lourdin, P. How different steel grades react to a salt bath nitrocarburizing and post-oxidation process: Influence of alloying elements. Surf. Coat. Technol. 2011, 205, 4064–4067. [Google Scholar] [CrossRef]

- Cho, Y.R.; Fromm, E. The New Measuring Technology for Adhesion Strength of TiN or Al coatings on HSS Substrates. Korean J. Met. Mater. 1995, 5, 310–315. [Google Scholar]

- Kim, Y.C.; Gwak, E.J.; Ahn, S.M.; Han, H.N.; Kim, J.Y. Indentation size effect in nanoporous gold. Acta Mater. 2017, 138, 52–60. [Google Scholar] [CrossRef]

- Somers, M.A.J.; Mittemeijer, E.J. Formation and Growth of Compound Layer on Nitrocarburizing Iron: Kinetics and Microstructural Evolution. Surf. Eng. 1987, 3, 123–137. [Google Scholar] [CrossRef]

- Jutte, R.H.; Kooi, B.J.; Somers, M.A.J.; Mittemeijer, E.J. On the oxidation of α-Fe and ε-Fe2N1−z: I. Oxidation kinetics and microstructural evolution of the oxide and nitride layers. Oxid. Met. 1997, 48, 87–109. [Google Scholar] [CrossRef]

- Fares, M.L.; Chaoui, K.; Le coze, J. Post-oxidizing effects on surface characteristics of salt bath nitrocarburized AISI 02 tool steel type. Surf. Interface Anal. 2009, 41, 549–559. [Google Scholar] [CrossRef]

- Leineweber, A.; Jacobs, H. Theoretical analysis of occupational ordering in hexagonal interstitial compounds: Carbides, nitrides and oxides with “ε-type” superstructures. J. Alloys Compd. 2000, 308, 178–188. [Google Scholar] [CrossRef]

- Zlatanović, M.; Popović, N.; Bogdanov, Ž.; Zlatanvic, S. Plasma post oxidation of nitrocarburized hot work steel samples. Surf. Coat. Technol. 2004, 177–178, 277–283. [Google Scholar] [CrossRef]

- Luo, J.; Stevens, R. Porosity-dependence of elastic moduli and hardness of 3Y-TZP ceramics. Ceram. Int. 1999, 25, 281–286. [Google Scholar] [CrossRef]

- Tang, Q.; Gong, J. Effect of porosity on the microhardness testing of brittle ceramics: A case study on the system of NiO–ZrO2. Ceram. Int. 2013, 39, 8751–8759. [Google Scholar] [CrossRef]

- Abedi, H.R.; Salehi, M.; Yazadkhasti, M.; Hemmasian-E, A. Effect of high temperature post-oxidizing on tribological and corrosion behavior of plasma nitrided AISI 316 austenitic stainless steel. Vacuum 2010, 85, 443–447. [Google Scholar] [CrossRef]

- Sohi, M.H.; Ebrahimi, M.; Raouf, A.H.; Mahboubi, F. Comparative study of the corrosion behaviour of plasma nitrocarburised AISI 4140 steel before and after post-oxidation. Mater. Des. 2010, 31, 4432–4437. [Google Scholar] [CrossRef]

- Cho, Y.W.; Won, J.H.; Woo, J.H.; Yu, S.H.; Cho, Y.R. Effect of Oxi-Nitrocarburizing on the Microstructure, Nanohardness and Corrosion Properties for Low Carbon Steel. Korean J. Met. Mater. 2018, 56, 289–295. [Google Scholar] [CrossRef]

| Fe | C | Mn | P | S | Cu |

|---|---|---|---|---|---|

| Bal. | 0.0018 | 0.206 | 0.092 | 0.004 | 0.051 |

| Notation | Gas Nitrocarburizing | Oxidation | ||||

|---|---|---|---|---|---|---|

| Temp. (°C) | Input Gas Ratio (NH3:N2:CO2) | Time (min) | Temp. (°C) | Input Gas | Time (min) | |

| Untreated-specimen | - | - | - | - | - | - |

| Air-specimen | 560 | 5:4:1 | 100 | 550 | Air | 5 |

| Steam-specimen | 550 | Steam (H2O) | 30 | |||

| Classification | Air-Specimen | Steam-Specimen |

|---|---|---|

| Thickness of Hardened Layer | Thin [8–12 μm] | Thick [14–16 μm] |

| Thickness of Oxide Layer | Thin [1.5–2.5 μm] | Thick [4–6 μm] |

| Microstructure of Oxide Layer | Dense | Porous |

| Thickness of Compound Layer | Thin [6.5–9.5 μm] | Thick [10–12 μm] |

| Microstructure of ε-Phase | Massive, continuous | Small and isolated in the γ′-phase |

| Specimen | Corrosion Potential (V) | Current Density (mA/cm2) |

|---|---|---|

| Untreated | −0.97 | 0.184 |

| Air | −0.77 | 0.087 |

| Steam | −0.75 | 0.071 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cho, Y.-W.; Kang, Y.-J.; Baek, J.-H.; Woo, J.-H.; Cho, Y.-R. Investigation of Microstructure, Nanohardness and Corrosion Resistance for Oxi-Nitrocarburized Low Carbon Steel. Metals 2019, 9, 190. https://doi.org/10.3390/met9020190

Cho Y-W, Kang Y-J, Baek J-H, Woo J-H, Cho Y-R. Investigation of Microstructure, Nanohardness and Corrosion Resistance for Oxi-Nitrocarburized Low Carbon Steel. Metals. 2019; 9(2):190. https://doi.org/10.3390/met9020190

Chicago/Turabian StyleCho, Young-Wook, Young-Joon Kang, Ju-Hwan Baek, Jeong-Ho Woo, and Young-Rae Cho. 2019. "Investigation of Microstructure, Nanohardness and Corrosion Resistance for Oxi-Nitrocarburized Low Carbon Steel" Metals 9, no. 2: 190. https://doi.org/10.3390/met9020190

APA StyleCho, Y.-W., Kang, Y.-J., Baek, J.-H., Woo, J.-H., & Cho, Y.-R. (2019). Investigation of Microstructure, Nanohardness and Corrosion Resistance for Oxi-Nitrocarburized Low Carbon Steel. Metals, 9(2), 190. https://doi.org/10.3390/met9020190