Abstract

The present work investigates the microstructure and tensile properties of a hot rolled 6061 alloy quenched by cold rolls (RQ) at different preheating temperatures. The preheating temperature strongly affects microstructure evolution and mechanical properties. Low preheating temperature (490 °C) resulted in both low strength and low elongation. The RQ alloy preheated at 540 °C exhibited improved ductility compared to those subjected to T6 and T8 temper, and comparable strength to that after T8 temper. The dynamic recovery during hot rolling contributed to the improved tensile elongation and retained work hardening. High preheating temperature also led to pronounced ageing hardening during short-term ageing.

1. Introduction

6xxx aluminum alloys are widely used in the automotive, aerospace and construction industries, due to their good mechanical and chemical properties [1,2,3,4,5,6]. However, their poor formability and high rebound at room temperature are disadvantages of this material [7]. The ductility of aluminum alloys is generally significantly improved at elevated temperatures. Therefore, hot/warm forming techniques are applied to improve the formability. At elevated temperatures, dynamic precipitation may occur during hot deformation, increasing the strength, but the strengthening effect of subsequent ageing was also strongly affected by deformation temperature [6,8,9,10]. It is reported that the additional 20% warm rolling at the ageing temperature increased the mechanical strength of 70% cryorolled 6061 alloy, and did not decrease the elongation, which was attributed to the dynamic precipitation during warm rolling. However, warm rolling weakened the precipitation hardening effect of peak ageing and reduced the elongation after peak ageing [11]. The deformation temperature also influences the grain structure evolution. Dynamic recovery and dynamic recrystallization are competitive softening mechanisms during hot/warm deformation. Dynamic recovery is pronounced during the hot/warm deformation of Al alloys, because of the high stacking fault energy of Al alloys. The study on the effect of temperature on the microstructural evolution of 7075-T7351 aluminum alloy reports that the predominant restoration process during rolling at 250 and 350 °C was dynamic recovery, the recrystallized grains were clearly evident in the specimens rolled at 450 °C [12].

In order to obtain materials with high plasticity and strength, it is necessary to develop new processes. Fan et al. developed a hot forming-quenching integration process using hot-cold dies. Rapid quenching is finished to avoid the formation of coarse precipitates and to restrict the thermal distortion during quenching. They studied the effect of mold temperature on microstructure evolution and mechanical properties [13,14,15,16,17]. The study on the effects of forging speed during die-quench forging process on deformation and aging behavior of Al 6xxx reports that die-quench forging at slow speed led to lower deformation temperature, larger temperature gradient and weaker ageing hardening [18]. Wang et al. and Mohamed et al. reported the formability and failure features in die quenching of AA6082 and AA2024 alloys [19,20]. In these methods the alloys were deformed and quenched simultaneously and the alloys were subjected to natural ageing or artificial ageing for precipitation strengthening [15]. The hot forming-quenching process is an efficient way to produce metal parts with high strength and plasticity. On one hand, dynamic recovery was observed and resulted in improved plasticity [21]. On the other hand, precipitation strengthening during hot forming and artificial ageing improved strength [15]. The deformation temperature is essential to control the microstructure and mechanical properties. However, the effect of preheating temperature on the deformation structure and the subsequent ageing hardening is rarely reported.

In the present work, we studied the microstructure evolution and mechanical properties of a 6061 alloy processed by hot rolling-quenching with cold rolls (RQ) for the principle of hot deformation-die quenching. The effect of preheating temperature on the ageing hardening of RQ processed AA6061 was compared with the traditional T6 and T8 temper. This RQ process can produce products with higher surface quality and mechanical performance through a shortened process.

2. Materials and Methods

6061 plates (3 mm thick, 35 mm in length and 25 mm wide) was cut from a cast ingot, which was homogenization treated at 570 °C for 7 h (air cooled). Table 1 shows the nominal chemical composition of this alloy.

Table 1.

Chemical composition of AA 6061 alloy (in wt.%).

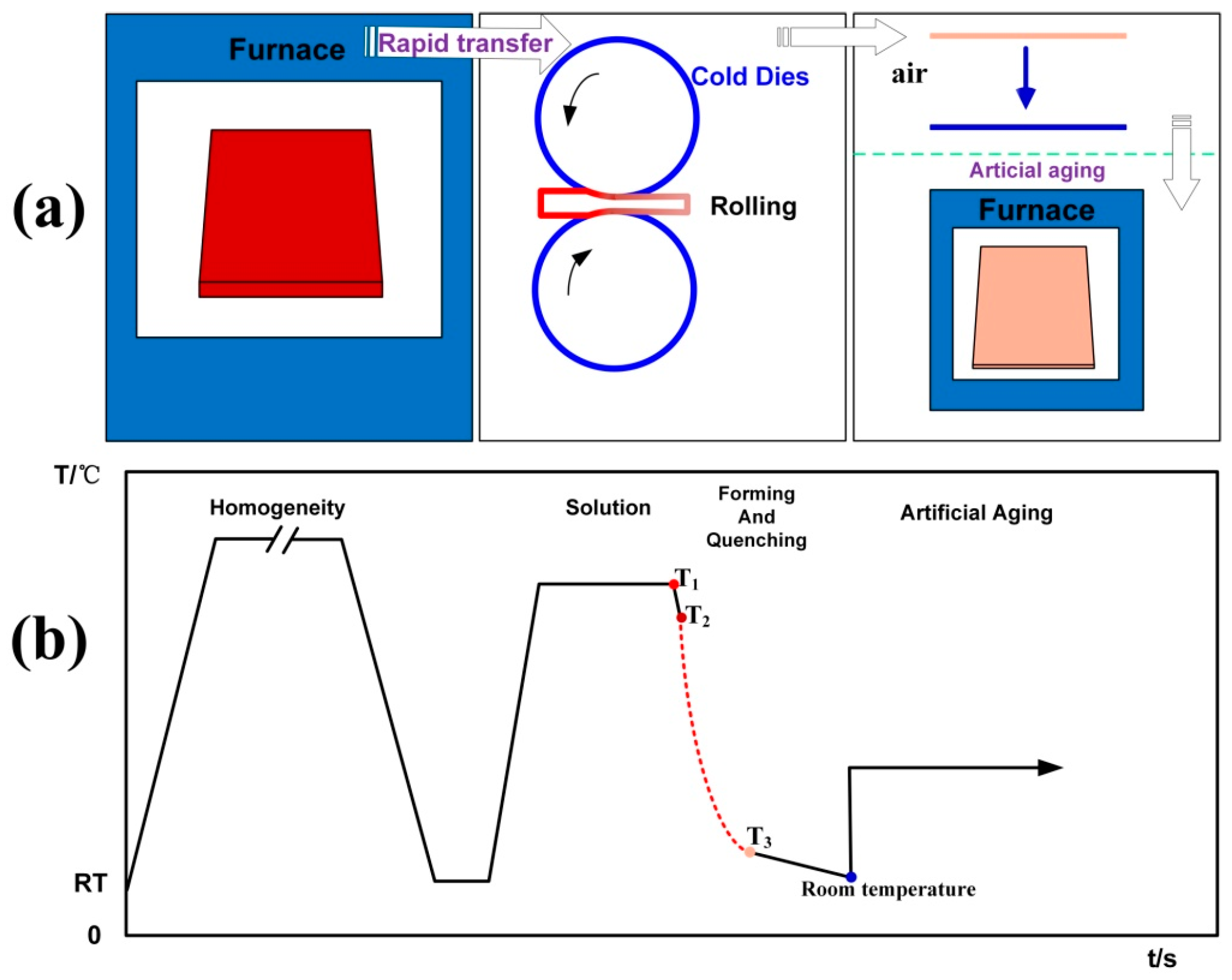

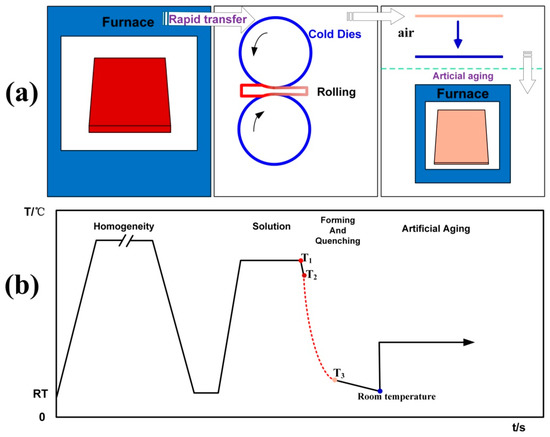

The integrated process procedure is schematically shown in Figure 1. The samples for hot rolling were preheated at a temperature T1 for 0.5 h, and then directly transferred from the furnace to the rolling mill. The transfer took approximately 4 s and the temperature decreased to temperature T2 (measured by an infrared thermometer), due to air cooling. The preheated samples were rolled from 3 mm to 1.2 mm at the rolling speed of 10 m/min to achieve a thickness reduction of 60%. The corresponding logarithmic strain was 0.4, and the strain rate was ~2 × 104 s−1. The sheet temperature dropped to temperature T3 after rolling, due to cold rolls during rolling, and the sample temperature was measured by an infrared thermometer immediately after rolling. Thereafter, the rolled samples at T3 were cooled in air (cooled to room temperature in ~70 s). The temperatures T1, T2 and T3 were measured by the Raytek 3i infrared pyrometer (Raytek, Santa Cruz, CA, USA) and listed in Table 2.

Figure 1.

(a) Schematic diagram; (b) temperature change of hot rolling-quenching integrated process with cold rolls.

Table 2.

The temperature during rolling-quenching integrated process (°C).

The temperature evolution during the processing is shown in Figure 1b, which can be divided into three stages. Firstly, the sheet preheated at T1 was transferred to the rolls. The air cooling dominates at this stage. Next, the sheet was rolled by cold rolls. At this stage, the heat transfer between the hot sheet and the cold rolls was dominant. Finally, the rolled sheet was cooled to room temperature in the air. In this work, the hot rolling-quenching integrated process was referred to as "RQ". We selected two conventional processes for comparison with the process RQ, namely (1) T6 temper: Solution treatment at T1 + water quenching (WQ) + artificial ageing (AA); (2) T8 temper: Solution treatment at T1 + water quenching + cold rolling (CR) with the same thickness reduction followed by artificial ageing. The solution treatment was 0.5 h at 490 °C/540 °C.

Considering the possibility of different temperature history along the rolling direction, all testing samples were taken from the first 30% part of the rolled sheets. Ageing hardening was characterized by Vickers hardness test with a load of 0.5 kg and dwell time of 30 s. The hardness tests were carried out with a HVS-1000A hardness tester (Huayin, Laizhou, China). 20 indentations were measured for each sample. The standard deviation of measured hardness values was within ±3. The first half part was tested. A tensile test was carried out with an MTS 810 material testing system (MTS system, Minneapolis, MN, USA) at room temperature under a strain rate of ~3.0 × 10−4 s−1, and the gauge of the tensile samples was 10 mm in length and 3.8 mm wide.

Samples for electron backscatter diffraction (EBSD) were prepared by mechanical grinding and further by electro polishing in a 10% perchloric acid ethanol solution) at ~−20 °C and 20 V for 60 s. EBSD was performed on a VEGA3 XMU equipped with an Oxford EBSD detector (Tescan, Brno, Czech Republic). The EBSD data were analyzed by the Channel5 software (Oxford Instruments, High Wycombe, UK). Transmission electron microscopy (TEM) characterization was performed on a JEM-2100F (JEOL, Tokyo, Japan). The samples were mechanically polished until the thickness was reduced to 60 μm. Twin-jet electro-polishing was further carried out in the 10% perchloric acid ethanol solution electrolyte at −20 °C and 20 V.

3. Results and Discussion

3.1. Ageing Hardening and Mechanical Properties

Figure 2 shows the rolled sheets after different rolling processes (CR and RQ), which were all preheated at 540 °C. The edge of the sample subjected to CR processing obviously cracked, while the edge did not crack in the RQ sample. It indicates good formability and surface quality after RQ processing.

Figure 2.

6061 sheets after solution treatment + water quenching+ 60% cold rolling (CR) and the 60% hot rolling-quenching integrated process (RQ).

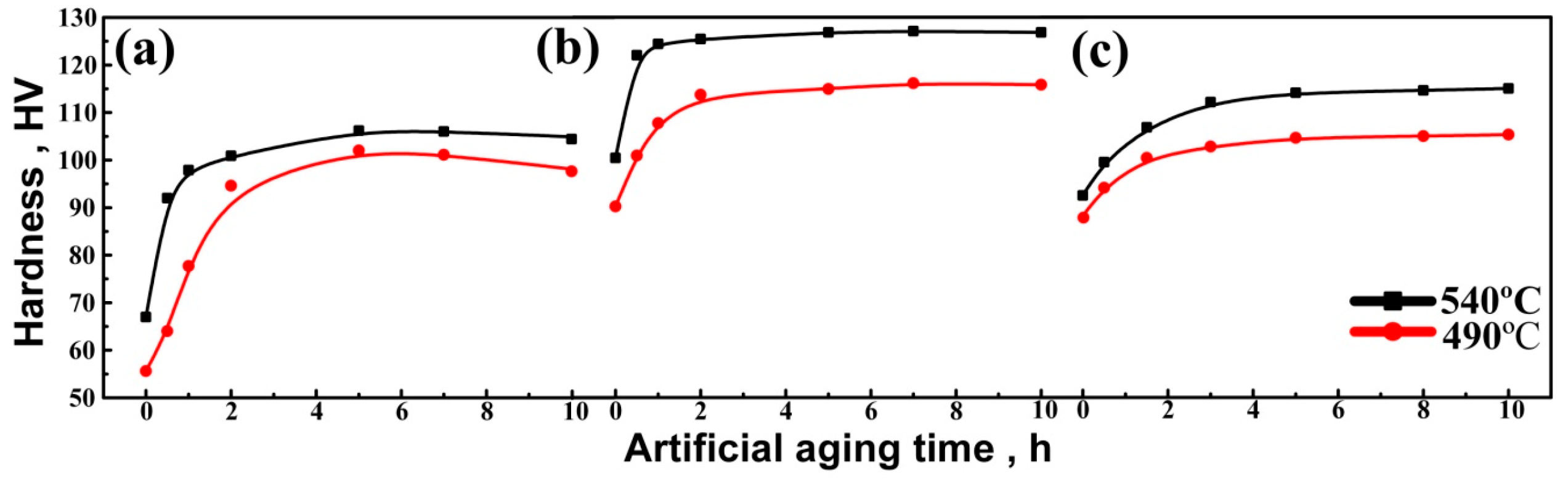

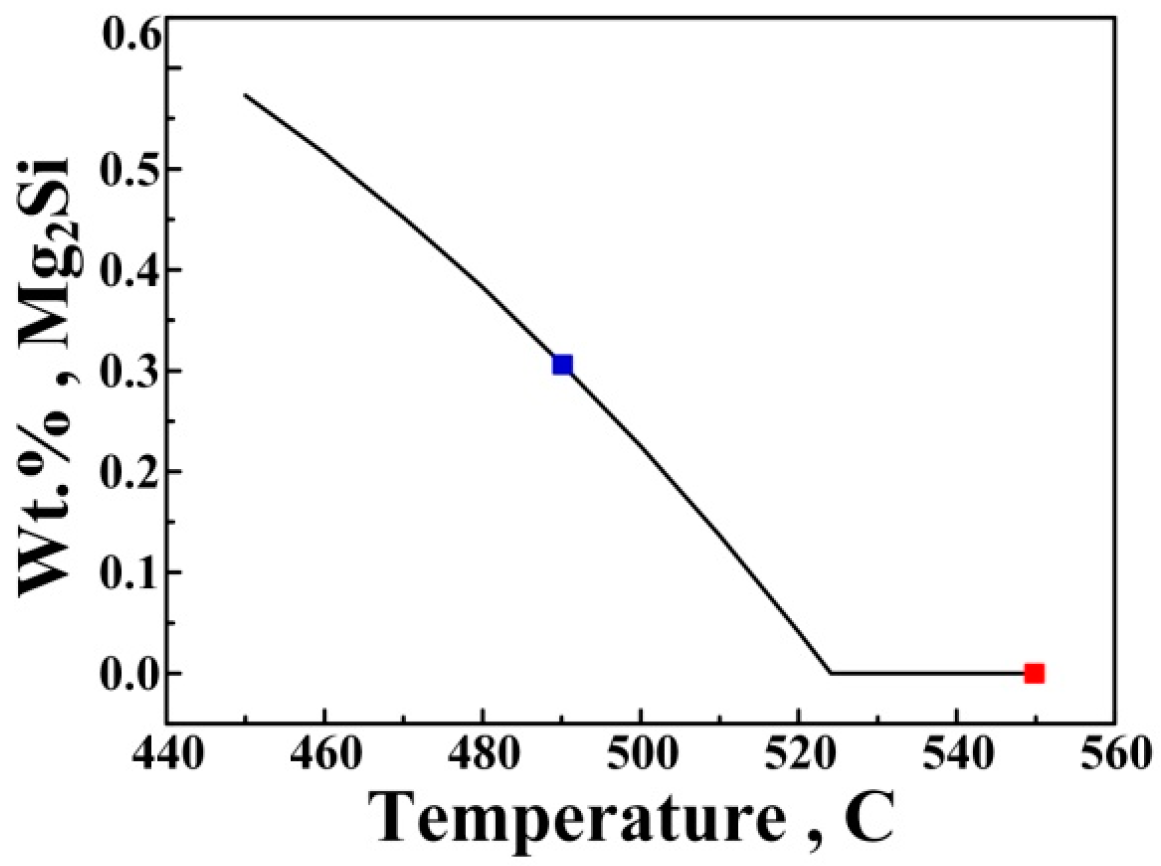

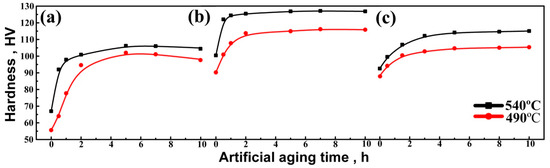

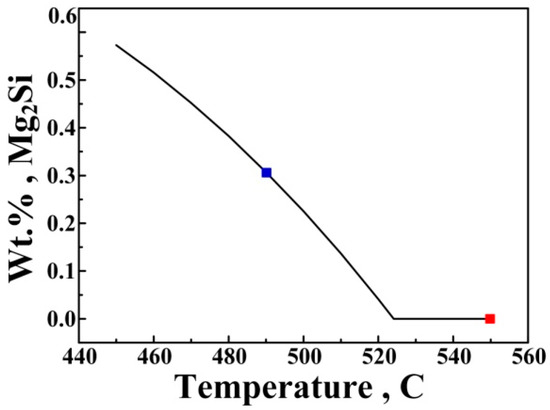

Figure 3 shows the Vickers hardness values of T6, T8 and RQ samples. The hardness values of samples preheated at 540 °C were generally higher than those of samples preheated at 490 °C, due to the higher solubility of Mg and Si in samples preheated at 540 °C (Figure 4). The hardness value for the T6 and T8 samples preheated at 540 °C increased rapidly within one hour of ageing, due to their high cooling rates. The initial hardness of the T8 sample is the largest, due to work hardening of cold deformation.

Figure 3.

Vickers Hardness of (a) water quenching (WQ); (b) CR; (c) RQ of Al 6061 alloy aged at 180 °C as a function of ageing time.

Figure 4.

Equilibrium content of Mg2Si at different solution temperatures (calculated by JMatPro v10.2, Sente Software, Guildford, UK).

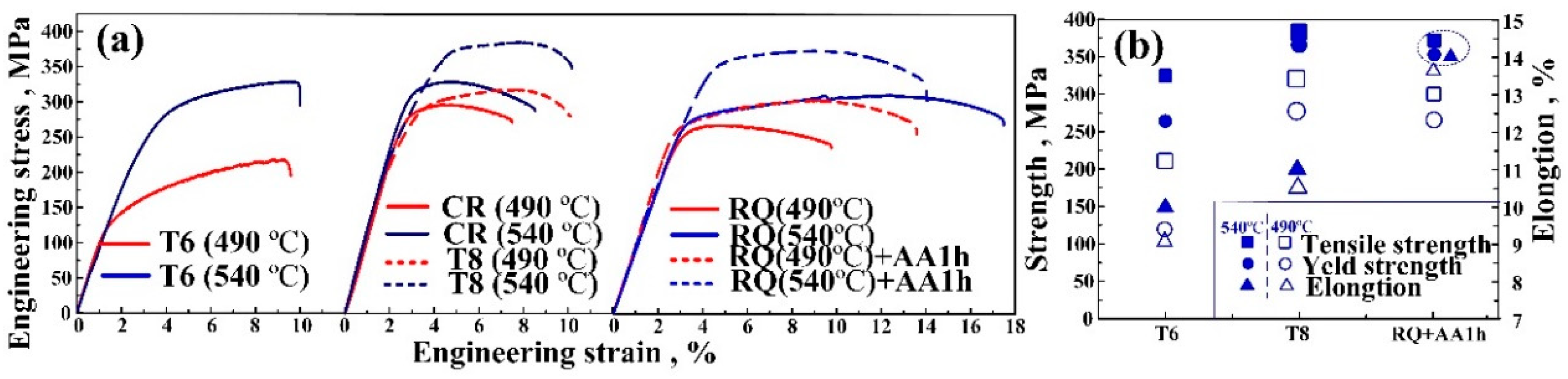

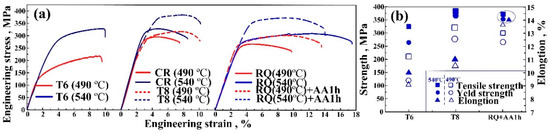

The samples after ageing at 180 °C for 1 h were tension tested at room temperature. The short-term ageing is in principle similar to bake hardening treatment. Engineering tensile stress-strain curves are displayed in Figure 5a. The elongation of RQ samples was increased, compared to CR samples, which should be attributed to the dynamic recovery during hot rolling, and the microstructure is discussed in Section 3.2. The mechanical strength of the samples preheated at 540 °C is higher than those at 490 °C, regardless of whether the samples were in deformed or in aged states. The tensile curves of the CR samples and RQ samples preheated at 490 °C were comparable prior to ageing, showing no work hardening and low elongation. However, the RQ sample preheated at 540 °C showed considerable work hardening and the high elongation, although the yield strength was similar to the RQ sample preheated at 490 °C. After one hour of ageing, the work hardening rates of the CR samples and RQ samples preheated at 490 °C were obviously improved. The yield strength of samples preheated at 540 °C was increased evidently, while short-term ageing did not evidently increase the yield strength of CR and RQ samples preheated at 490 °C. The age hardening is usually characterized by hardness tests. However, both increased yield strength and improved work hardening can result in increased hardness values. The tensile curves can give definite information about yield strength and work hardening. The 1 h ageing of samples preheated at 490 °C did not affect the yield strength, but increased work hardening rate. Thus, the increase in hardness of samples preheated at 490 °C in Figure 3 was attributed to the improved work hardening. The 1 h ageing of samples preheated at 540 °C increased both the yield strength and work hardening rate, resulting in a more pronounced increase in hardness. The improved work hardening also contributed to the increase uniform elongation, and hence the RQ sample preheated at 540 °C showed the highest total elongation.

Figure 5.

(a) The engineering stress-strain curves of samples subjected to T6, T8, RQ and (b) Ultimate tensile strength (UTS), yield strength and total elongation values of T6, T8 and RQ + AA 1 h samples.

Figure 5b shows the mechanical properties after 1 h of artificial ageing. RQ samples showed good mechanical performance. The yield strength of RQ sample preheated at 540 °C increased from 264 MPa to 358 MPa after 1 h of artificial ageing, suggesting that RQ sample preheated at 540 °C had good age hardenability.

3.2. Microstructure and Strengthening Effect

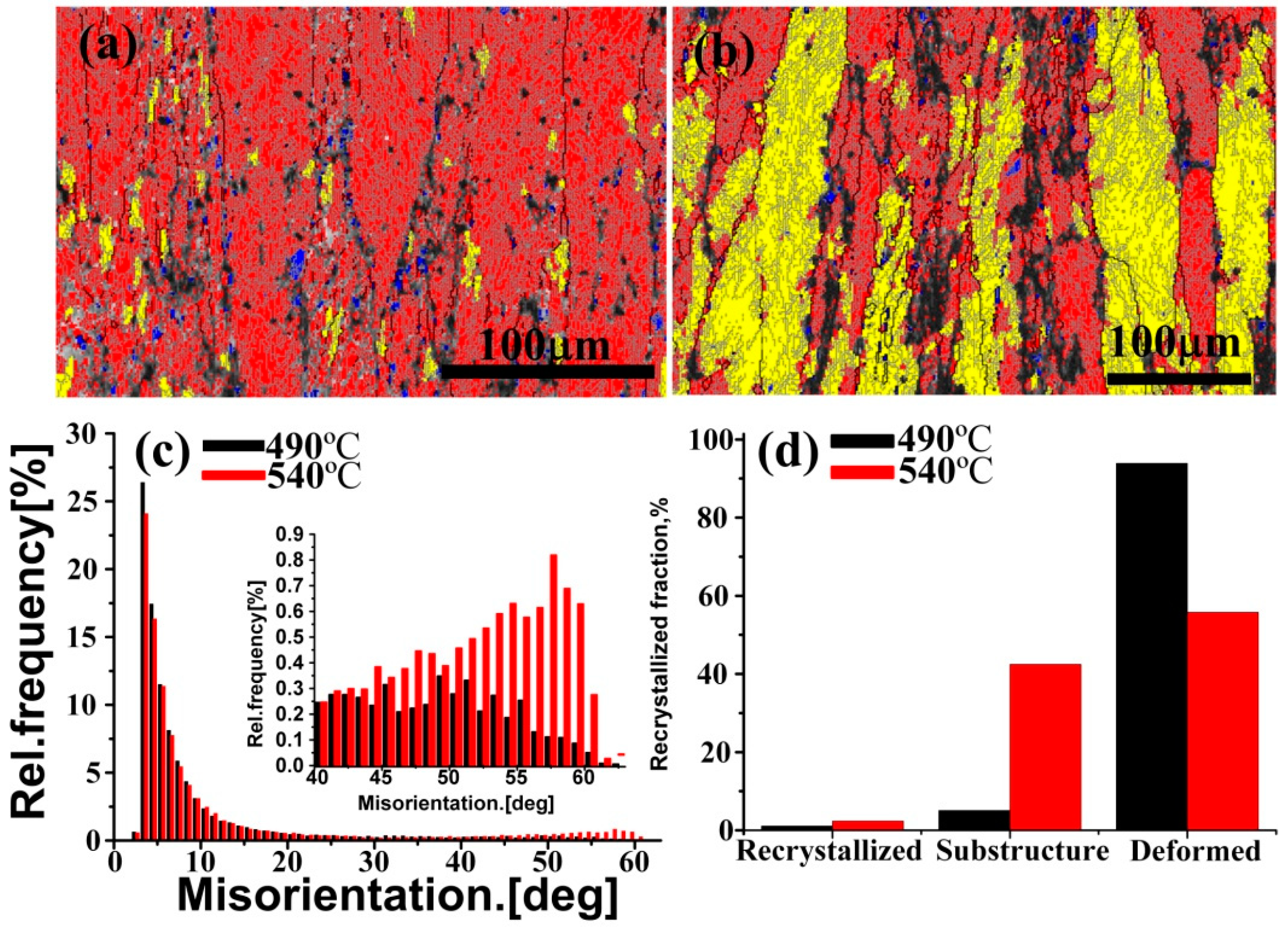

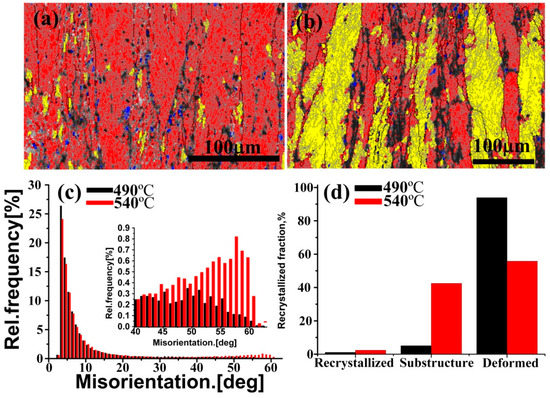

Figure 6 shows the grain structure of as-rolled RQ sample. Few small recrystallized grains were found in both samples. Recovery occurred in the RQ sample preheated at 540 °C, as shown by the grains in yellow in Figure 6b, which is also suggested by the decreased fraction of low angle boundaries in the RQ sample preheated at 540 °C. Compared with the sample preheated at 490 °C, the fraction of recovered substructure increased, consuming the deformed structure (Figure 6d), which contributes to the improved elongation of the material (Figure 5a).

Figure 6.

Electron backscatter diffraction (EBSD) map of RQ samples preheated at (a) 490 °C; (b) 540 °C (recrystallization in blue; substructure in yellow; retained deformation structure in red); (c) grain boundary misorientation distribution; (d) corresponding area fractions of recrystallized, deformed structure and substructure according to internal misorientation.

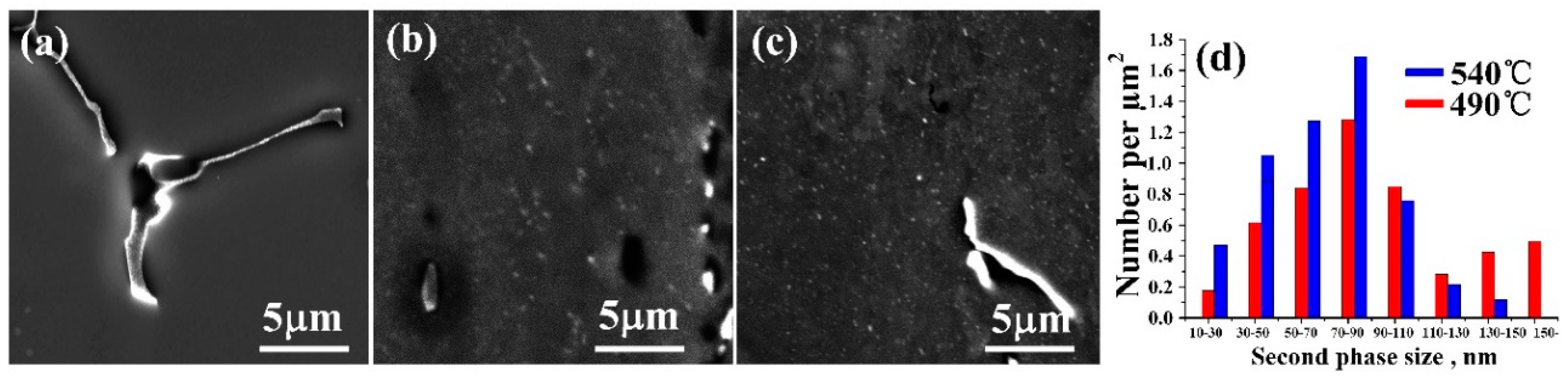

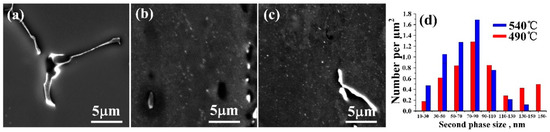

The relatively weak ageing hardening in the RQ sample is caused by the lower cooling rate, which might result in precipitation during hot rolling. Figure 7b,c show a distribution of nanosized precipitates in the as-rolled RQ specimens. The precipitates in the 540-RQ sample is finer than those in the 490-RQ sample, as is shown in Figure 7d. The sizes of precipitates were measured manually in approximately 200–300 particles. However, there was no precipitate in the WQ sample. It demonstrates that precipitation occurred during RQ.

Figure 7.

Images of second phases in the WQ (a) and RQ (b,c) samples prior to ageing; (a,c) preheated at 540 °C, (b) at 490 °C; (d) The size distribution of precipitates in RQ processed alloy preheated at 540 °C and 490 °C.

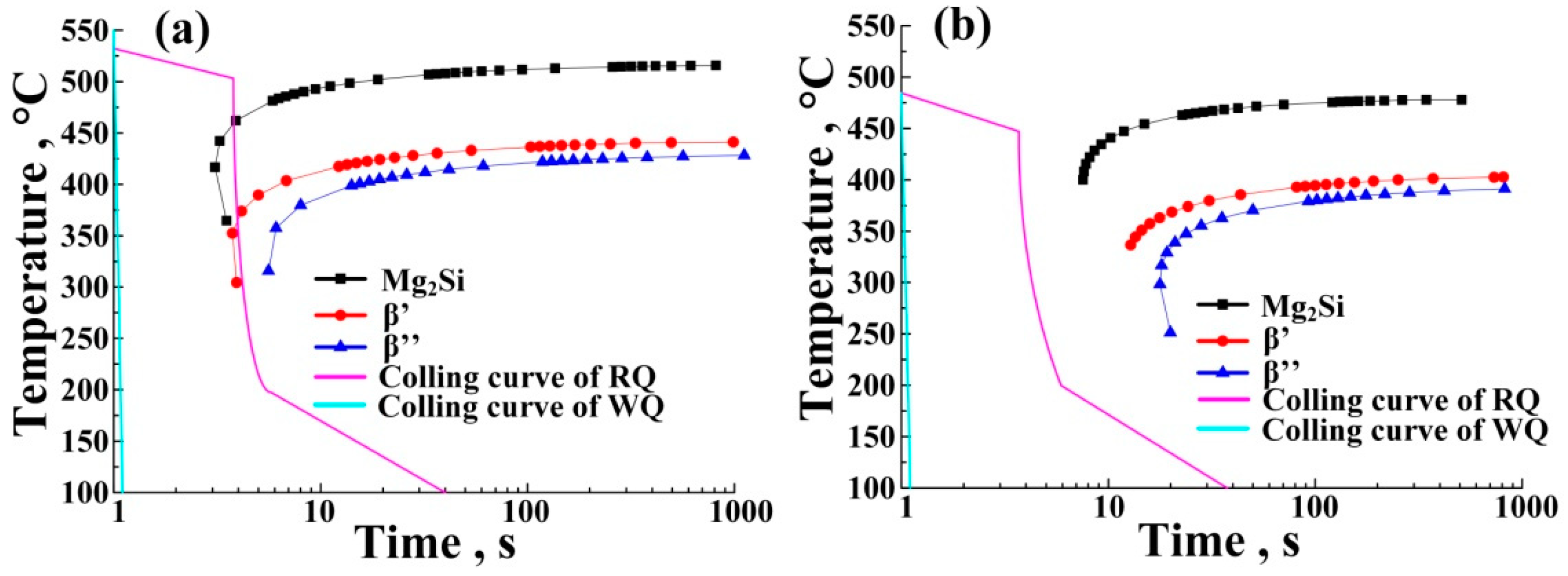

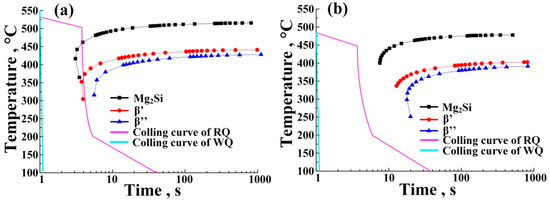

The precipitation tendency during cooling could be indicated by continuous cooling transformation (CCT) curves, which was calculated by JMatPro-v10.2, as shown in Figure 8. The purple line is the cooling curve during the hot rolling-quenching process. The cooling curve intercepts the CCT curves of Mg2Si and β’ (B’) phases after heating at 540 °C, while the cooling curve does not intercept the CCT curves after heating at 490 °C. However, Figure 7b,c verify the presence of precipitates in both cases. The precipitation was probably promoted by the deformation-induced dislocations, which was not considered in the software calculation.

Figure 8.

Continuous cooling transformation (CCT) curve of 6061 aluminum alloy at different solution temperature: (a) 540 °C; (b) 490 °C.

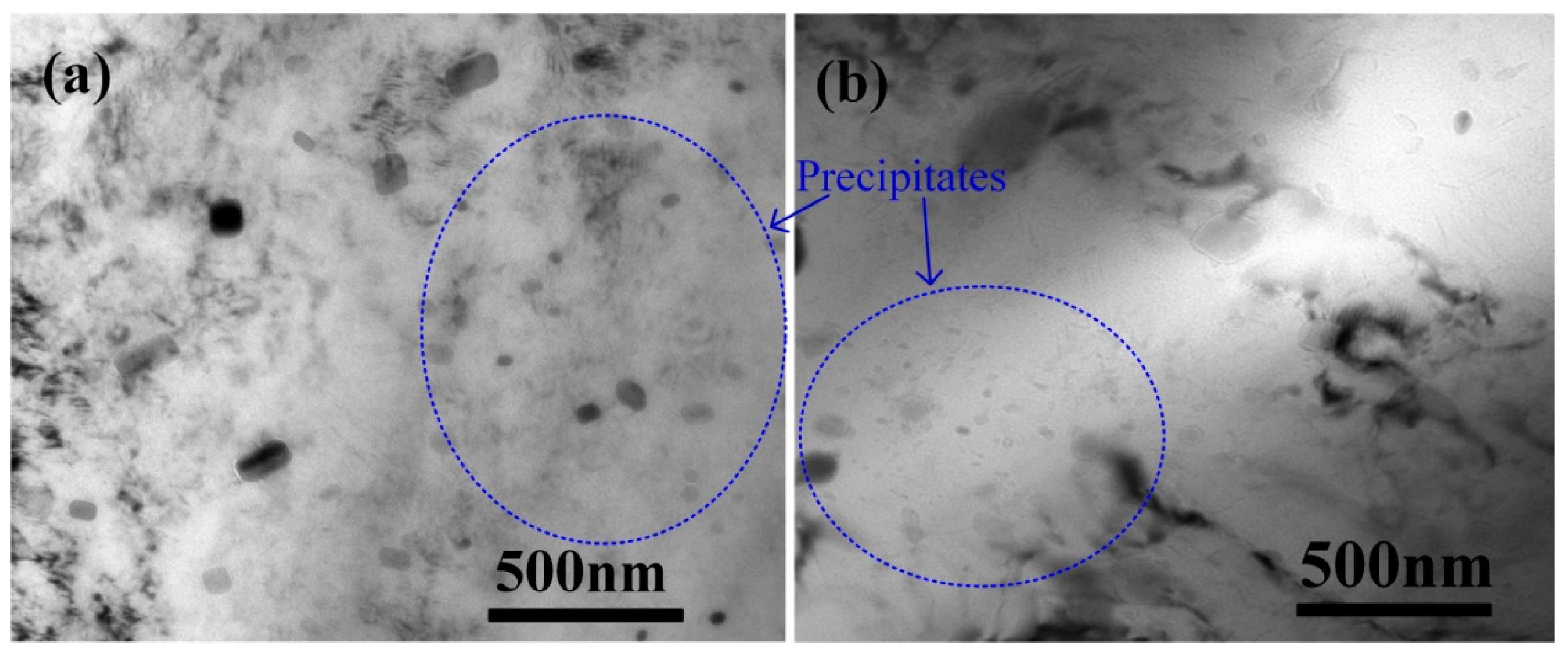

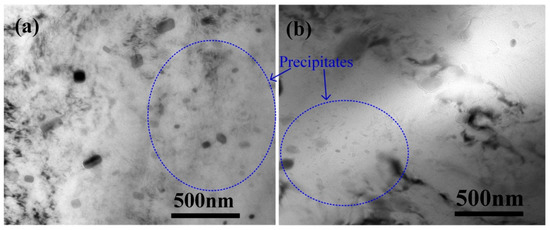

The lower cooling rate of RQ suppressed the ageing kinetics, so the age hardening of the RQ sample was lower than that in the T6 and T8 samples (Figure 3). Figure 9 shows the precipitate distribution of T8 and RQ samples preheated at 540 °C after 1-hour artificial aging. There were fine rod-like precipitates in the T8 and RQ samples which contributed to the ageing hardening. The literature report that the shapes of β’’, B’, and β’ phases are needle, lath and rod. According to the observed morphology, the precipitates are expected to be mainly β’ phase. Tensile strength of RQ sample preheated at 540 °C was significantly improved after 1-hour artificial ageing, due to the precipitation.

Figure 9.

Transmission electron microscopy (TEM) micrograph of (a) WQ + CR; (b) RQ after 1-hour artificial aging preheated at 540 °C.

4. Conclusions

The mechanical properties and microstructure of a 6061 alloy processed by integrated hot rolling-quenching (RQ) were studied by comparing with T6 and T8 tempered alloys. The RQ alloy exhibited high elongation and similar tensile strength, compared to the cold rolled sheet. The improvement in the ductility of RQ sheet was attributed to the pronounced dynamic recovery during hot rolling. The cooling rate of the RQ process was lower than water quenching, resulting in dynamic precipitation during RQ, but the quenching sensitivity of RQ samples depends on the preheating temperature. The sample preheated at a high temperature (540 °C) showed pronounced ageing hardening response to short-term ageing. The RQ alloy aged for 1 h exhibited high tensile strength (370 MPa), improved ductility and surface quality compared to T6 and T8 tempered 6061 alloys.

Author Contributions

Conceptualization, Q.-L.Z.; methodology, Q.-L.Z., T.-T.S., Q.-C.J.; simulation, T.-T.S., Q.-L.Z.; data analysis, T.-T.S., Q.-L.Z., Y.-Y.Z., F.Q.; investigation, T.-T.S., R.G., H.-Y.H.; writing—original draft preparation, T.-T.S., Q.-L.Z.; writing—revised draft, Q.-L.Z.; visualization, T.-T.S.; supervision, Q.-L.Z., F.Q.; project administration, Q.-L.Z., Q.-C.J.

Funding

This work was funded by the National Natural Science Foundation of China (Grant Nos. 51601066 and 51790483), the Science and Technology Development Program of Jilin Province, China (Grant No. 20170101215JC), and the “13th Five-year” Science and Technology Research Program of Education Bureau of Jilin Province, China (Grant No. JJKH20190133KJ).

Acknowledgments

FEM simulation by undergraduate student Tong Zheng is acknowledged.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Rajabi, F.; Zarei-Hanzaki, A.; Eskandari, M.; Khoddam, S. The effects of rolling parameters on the mechanical behavior of 6061 aluminum alloy. Mater. Sci. Eng. A 2013, 578, 90–95. [Google Scholar] [CrossRef]

- Rao, P.N.; Viswanadh, B.; Jayaganthan, R. Effect of cryorolling and warm rolling on precipitation evolution in Al 6061 alloy. Mater. Sci. Eng. A 2014, 606, 1–10. [Google Scholar] [CrossRef]

- Akhtar, F. Microstructure evolution and wear properties of in situ synthesized TiB2 and TiC reinforced steel matrix composites. J. Alloys Compd. 2008, 459, 491–497. [Google Scholar] [CrossRef]

- Huang, C.Q.; Diao, J.P.; Deng, H.; Li, B.J.; Hu, X.H. Microstructure evolution of 6016 aluminum alloy during compression at elevated tomperatures by hot rolling emulation. Trans. Nonferrous Met. Soc. China Engl. Ed. 2013, 23, 1576–1582. [Google Scholar] [CrossRef]

- Odoh, D.; Mahmoodkhani, Y.; Wells, M. Effect of alloy composition on hot deformation behavior of some Al-Mg-Si alloys. Vacuum 2014, 149, 248–255. [Google Scholar] [CrossRef]

- Berndt, N.; Frint, P.; Wagner, F.X. Influence of Extrusion Temperature on the Aging Behavior and Mechanical Properties of an AA6060 Aluminum Alloy. Metals 2018, 8, 51. [Google Scholar] [CrossRef]

- Fan, X.B.; He, Z.B.; Yuan, S.J.; Lin, P. Investigation on strengthening of 6A02 aluminum alloy sheet in hot forming-quenching integrated process with warm forming-dies. Mater. Sci. Eng. A 2013, 578, 221–227. [Google Scholar] [CrossRef]

- Sha, G.; Wang, Y.B.; Liao, X.Z.; Duan, Z.C.; Ringer, S.P. Influence of equal-channel angular pressing on precipitation in an Al–Zn–Mg–Cu alloy. Acta Mater. 2009, 57, 3123–3132. [Google Scholar] [CrossRef]

- Roven, H.J.; Liu, M.; Werenskiold, J.C. Dynamic precipitation during severe plastic deformation of an Al–Mg–Si aluminium alloy. Mater. Sci. Eng. A 2008, 483–484, 54–58. [Google Scholar] [CrossRef]

- Cai, M.; Field, D.P.; Lorimer, G.W. A systematic comparison of static and dynamic ageing of two Al–Mg–Si alloys. Mater. Sci. Eng. A 2004, 373, 65–71. [Google Scholar] [CrossRef]

- Rao, P.N.; Jayaganthan, R. Effects of warm rolling and ageing after cryogenic rolling on mechanical properties and microstructure of Al 6061 alloy. Mater. Des. 2012, 39, 226–233. [Google Scholar]

- Abolhasani, A.; Zarei-Hanzaki, A.; Abedi, H.R.; Rokni, M.R. The room temperature mechanical properties of hot rolled 7075 aluminum alloy. Mater. Des. 2012, 34, 631–636. [Google Scholar] [CrossRef]

- Fan, X.B.; He, Z.B.; Yuan, S.J. Deformation behavior of 5A06 aluminum alloy sheet for rapid gas forming at elevated temperature. Trans. Nonferrous Met. Soc. China Engl. Ed. 2012, 22, s389–s394. [Google Scholar] [CrossRef]

- Fan, X.B.; He, Z.B.; Zhou, W.X.; Yuan, S.J. Formability and strengthening mechanism of solution treated Al-Mg-Si alloy sheet under hot stamping conditions. J. Mater. Process. Technol. 2016, 228, 179–185. [Google Scholar] [CrossRef]

- Fan, X.B.; He, Z.B.; Zheng, K.; Yuan, S.J. Strengthening behavior of Al-Cu-Mg alloy sheet in hot forming-quenching integrated process with cold-hot dies. Mater. Des. 2015, 83, 557–565. [Google Scholar] [CrossRef]

- Yuan, S.J.; Fan, X.B.; He, Z.B. Hot forming-quenching integrated process with cold-hot dies for 2A12 aluminum alloy sheet. Procedia Eng. 2014, 81, 1780–1785. [Google Scholar] [CrossRef]

- Fan, X.B.; Shao, F.; Zheng, K.L.; Wang, Z.B.; Yuan, S.J. Formability and microstructure of AA6061 Al alloy tube for hot metal gas forming at elevated temperature. Trans. Nonferrous Met. Soc. China Engl. Ed. 2012, 22, s364–s369. [Google Scholar]

- Utsunomiya, H.; Tada, K.; Matsumoto, R. Die motion control for die-quench forging process of AA6061 aluminum alloys. CIPR Ann. 2016, 65, 297–300. [Google Scholar] [CrossRef]

- Wang, L.; Strangwood, M.; Balint, D.; Lin, J.; Dean, T.A. Formability and failure mechanisms of AA2024 under hot forming conditions. Mater. Sci. Eng. A 2011, 528, 2648–2656. [Google Scholar] [CrossRef]

- Mohamed, M.S.; Foster, A.D.; Lin, J.; Balint, D.S.; Dean, T.A. Investigation of deformation and failure feature in hot stamping of AA6082: Experimentation and modeling. Int. J. Mach. Tools Manuf. 2012, 53, 27–38. [Google Scholar] [CrossRef]

- Wang, T.; Zhou, X.; Li, Y.F.; Zhang, Z.Q.; Le, Q.C. Effect of Rolling Temperature on the Microstructure and Mechanical Properties of Mg-2Zn-0.4Y Alloy Subjected to Large Strain Rolling. Metals 2018, 8, 937. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).