Strengthening Al-Zn-Mg Alloys via Ultra-Fine Lamella Structures Containing a High Density of Dislocations and Clusters

Abstract

1. Introduction

2. Experimental Materials and Procedures

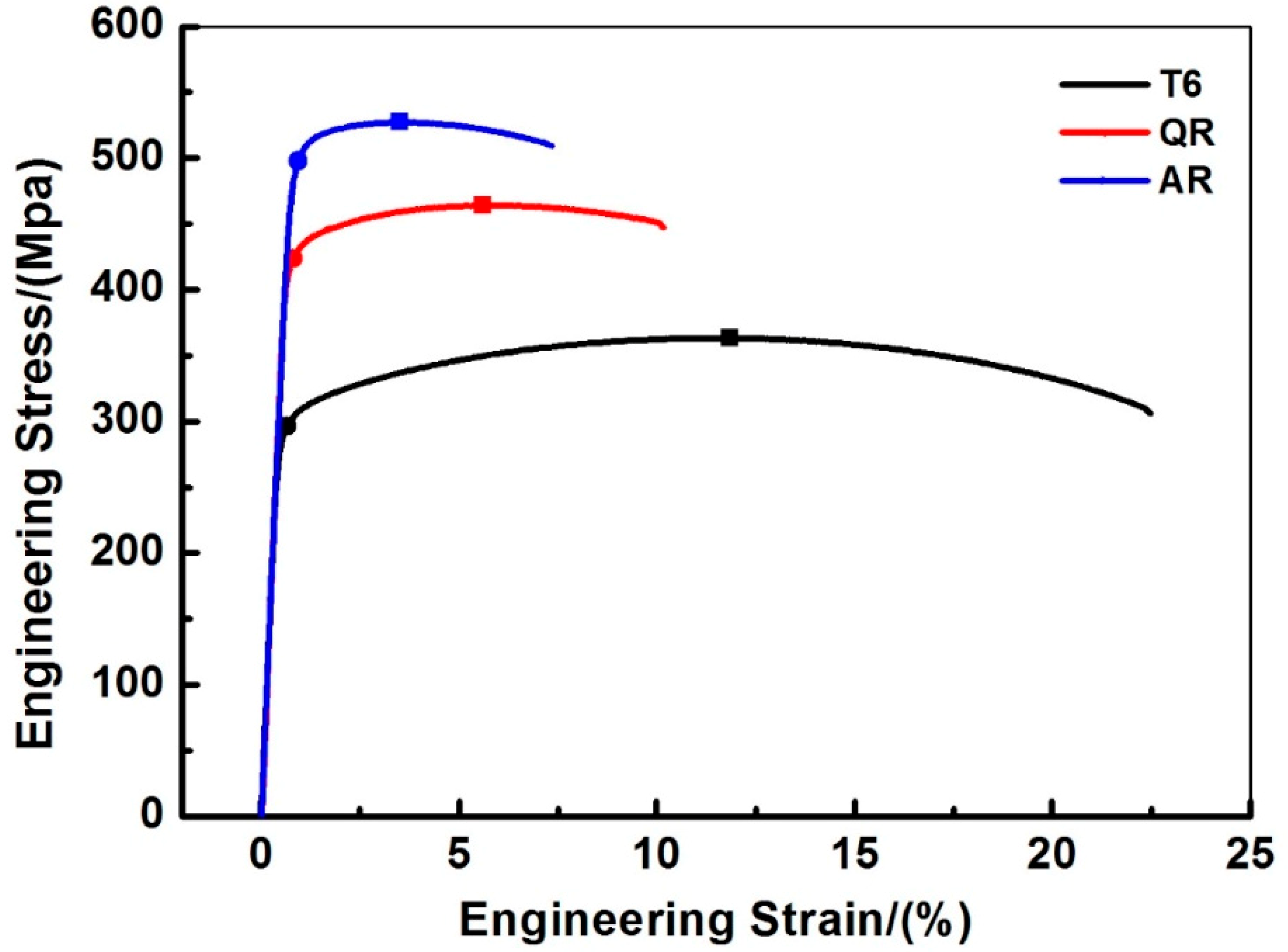

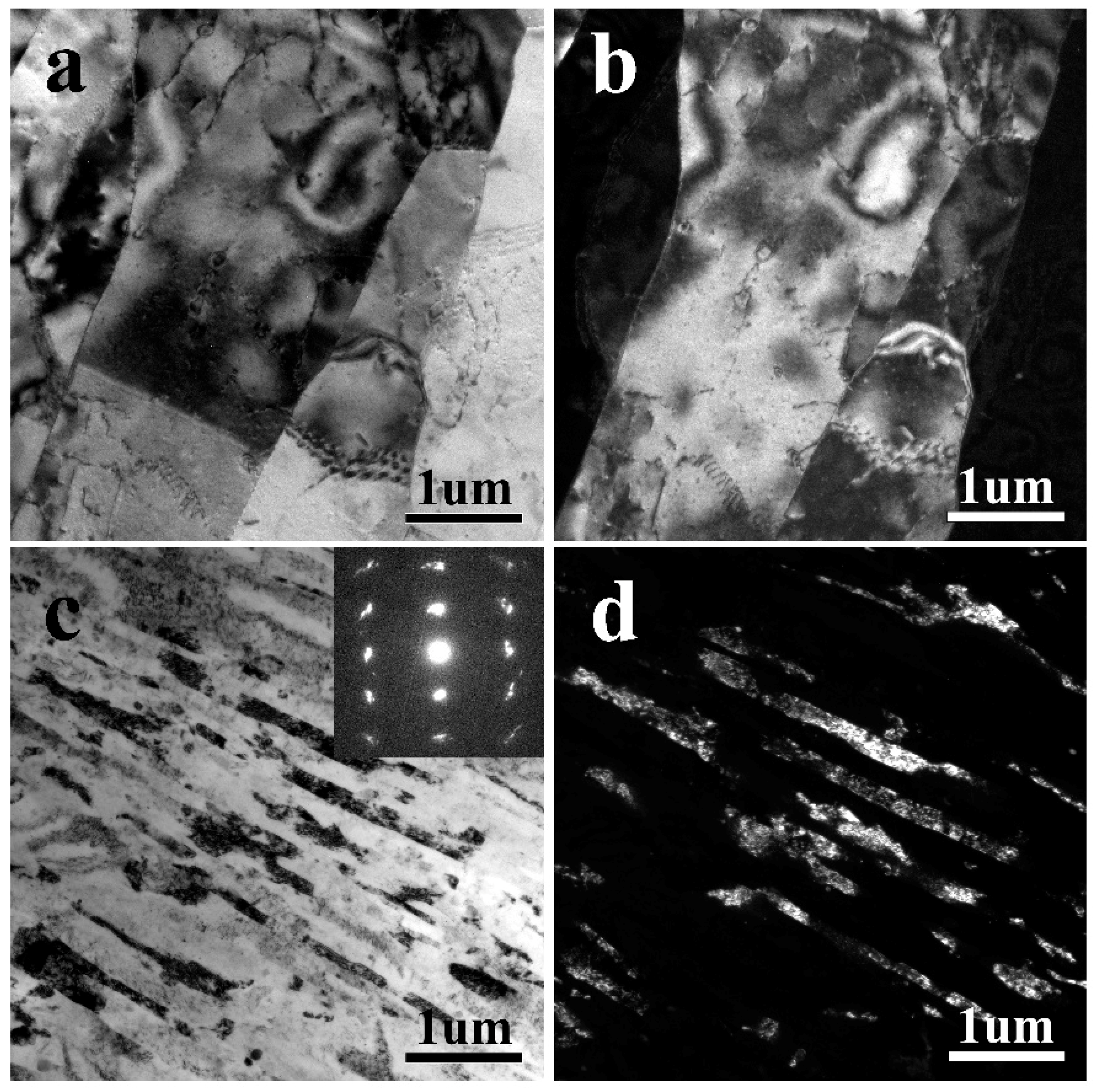

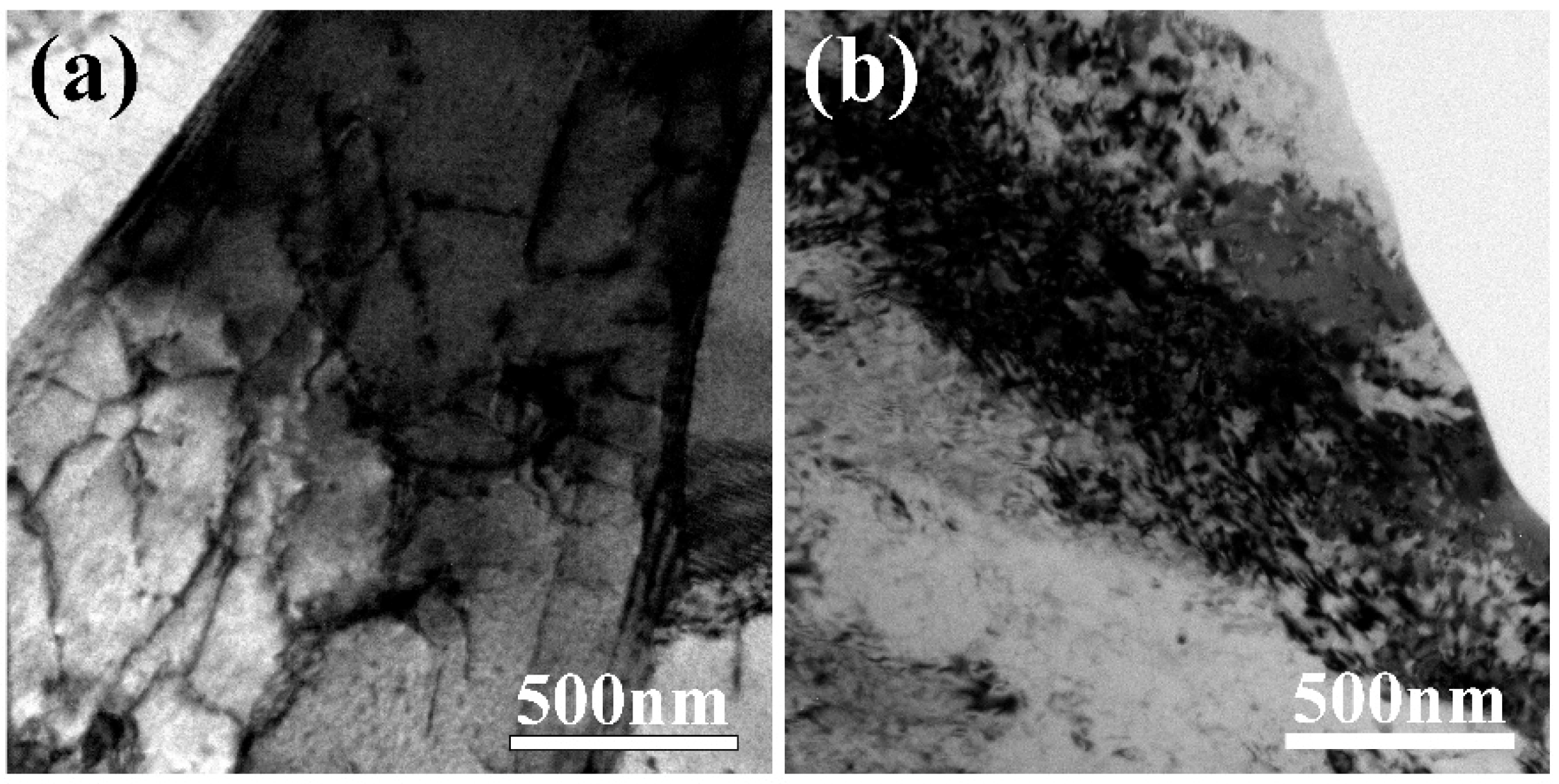

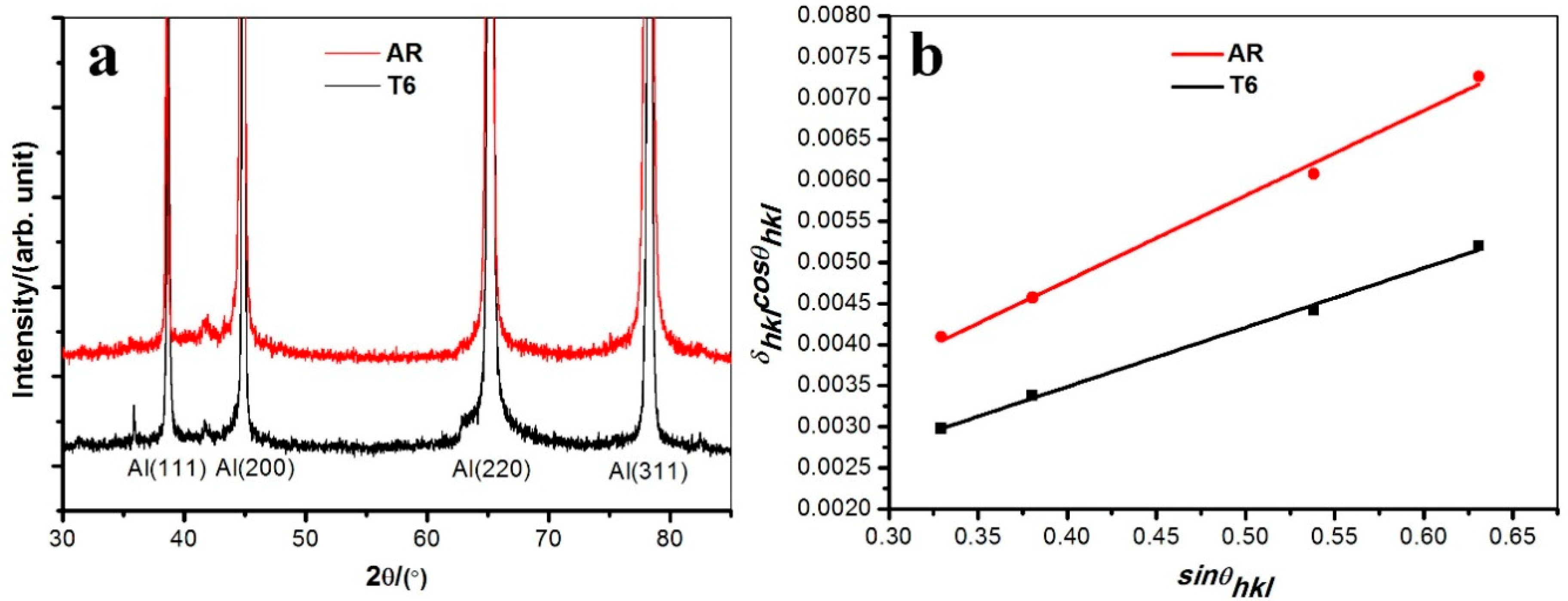

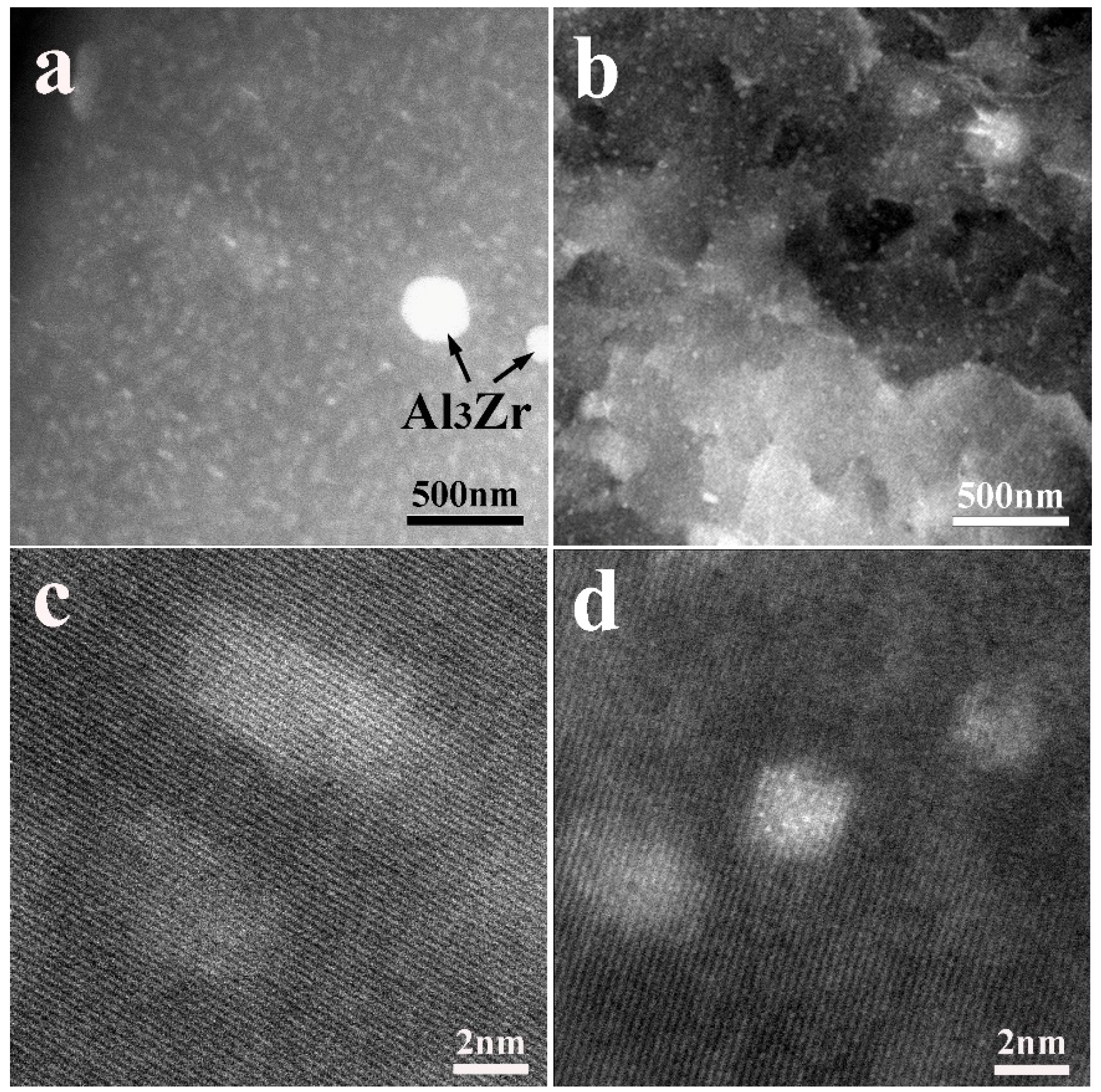

3. Experimental Results

4. Discussion

4.1. Mechanical Properties and Strengthening Mechanism

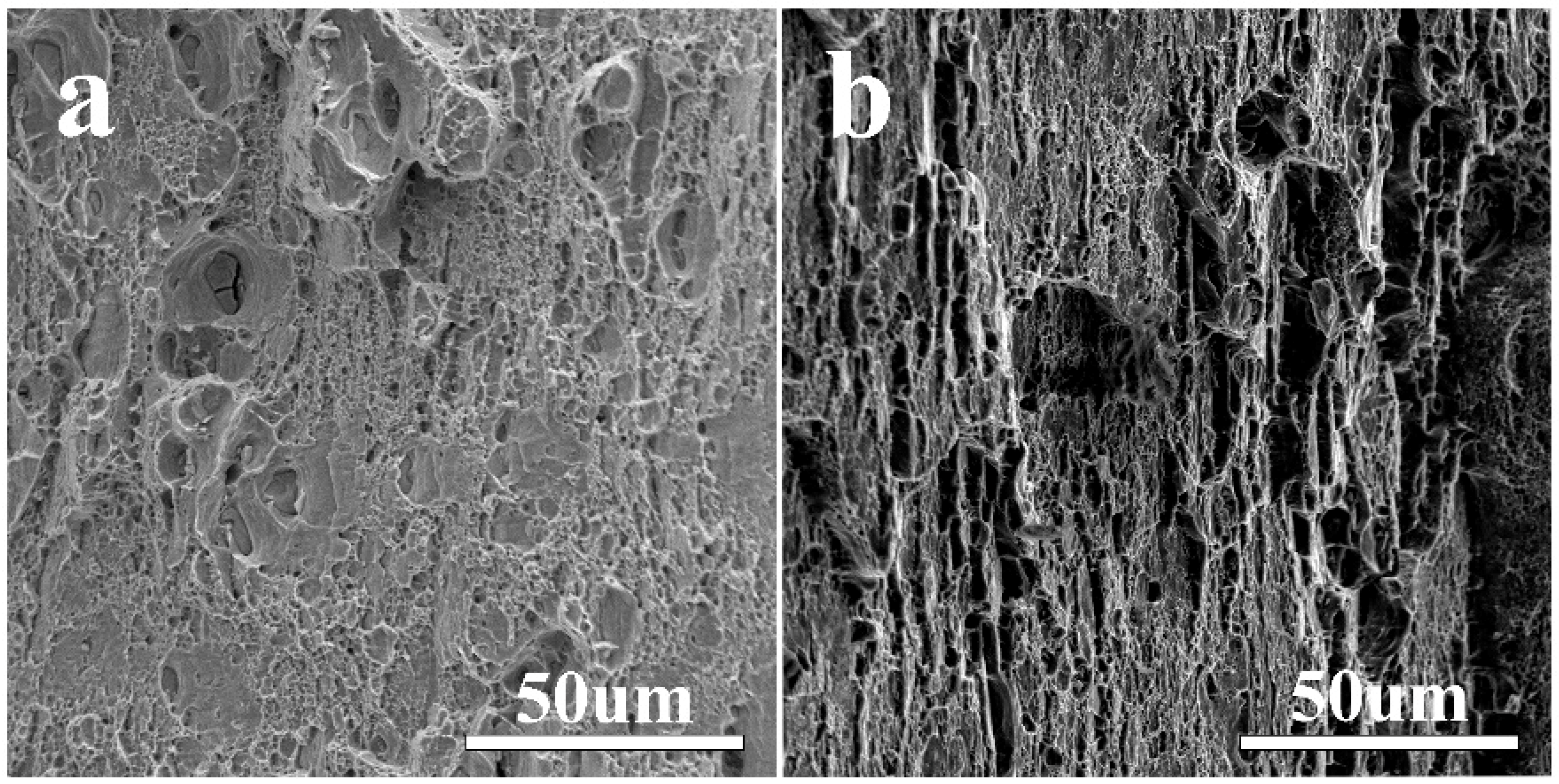

4.2. Tensile Fracture Analysis

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Williams, J.C.; Starke, E.A. Progress in structural materials for aerospace systems 11 The Golden Jubilee Issue-Selected topics in Materials Science and Engineering: Past, Present and Future, edited by S. Suresh. Acta Mater. 2003, 51, 5775–5799. [Google Scholar] [CrossRef]

- Liu, J.Z.; Chen, J.H.; Yuan, D.W.; Wu, C.L.; Zhu, J.; Cheng, Z.Y. Fine precipitation scenarios of AlZnMg(Cu) alloys revealed by advanced atomic-resolution electron microscopy study Part I: Structure determination of the precipitates in AlZnMg(Cu) alloys. Mater. Charact. 2015, 99, 277–286. [Google Scholar] [CrossRef]

- Liu, J.Z.; Chen, J.H.; Liu, Z.R.; Wu, C.L. Fine precipitation scenarios of AlZnMg(Cu) alloys revealed by advanced atomic-resolution electron microscopy study Part II: Fine precipitation scenarios in AlZnMg(Cu) alloys. Mater. Charact. 2015, 99, 142–149. [Google Scholar] [CrossRef]

- Liu, J.Z.; Chen, J.H.; Yang, X.B.; Ren, S.; Wu, C.L.; Xu, H.Y.; Zou, J. Revisiting the precipitation sequence in Al–Zn–Mg-based alloys by high-resolution transmission electron microscopy. Scr. Mater. 2010, 63, 1061–1064. [Google Scholar] [CrossRef]

- Sha, G.; Cerezo, A. Early-stage precipitation in Al–Zn–Mg–Cu alloy (7050). Acta Mater. 2004, 52, 4503–4516. [Google Scholar] [CrossRef]

- Macchi, C.E.; Somoza, A.; Dupasquier, A.; Polmear, I.J. Secondary precipitation in Al–Zn–Mg–(Ag) alloys. Acta Mater. 2003, 51, 5151–5158. [Google Scholar] [CrossRef]

- Berg, L.K.; Gjønnes, J.; Hansen, V.; Li, X.Z.; Knutson-Wedel, M.; Waterloo, G.; Schryvers, D.; Wallenberg, L.R. GP-zones in Al–Zn–Mg alloys and their role in artificial aging. Acta Mater. 2001, 49, 3443–3451. [Google Scholar] [CrossRef]

- Ma, K.; Hu, T.; Yang, H.; Topping, T.; Yousefiani, A.; Lavernia, E.J.; Schoenung, J.M. Coupling of dislocations and precipitates: Impact on the mechanical behavior of ultrafine grained Al–Zn–Mg alloys. Acta Mater. 2016, 103, 153–164. [Google Scholar] [CrossRef]

- Ma, K.; Wen, H.; Hu, T.; Topping, T.D.; Isheim, D.; Seidman, D.N.; Lavernia, E.J.; Schoenung, J.M. Mechanical behavior and strengthening mechanisms in ultrafine grain precipitation-strengthened aluminum alloy. Acta Mater. 2014, 62, 141–155. [Google Scholar] [CrossRef]

- Hu, T.; Ma, K.; Topping, T.D.; Schoenung, J.M.; Lavernia, E.J. Precipitation phenomena in an ultrafine-grained Al alloy. Acta Mater. 2013, 61, 2163–2178. [Google Scholar] [CrossRef]

- Han, Y.S.; Hong, S.H. The effects of thermo-mechanical treatments on superplasticity of Fe-24Cr-7Ni-3Mo-0.14N duplex stainless steel. Scr. Mater. 1997, 36, 557–563. [Google Scholar] [CrossRef]

- Wert, J.A.; Paton, N.E.; Hamilton, C.H.; Mahoney, M.W. Grain refinement in 7075 aluminum by thermomechanical processing. Metall. Trans. A. 1981, 12, 1267–1276. [Google Scholar] [CrossRef]

- Bailey, J.E.; Hirsch, P.B. The dislocation distribution, flow stress, and stored energy in cold-worked polycrystalline silver. Philos. Mag. 1960, 5, 485–497. [Google Scholar] [CrossRef]

- Panigrahi, S.K.; Jayaganthan, R. A study on the mechanical properties of cryorolled Al–Mg–Si alloy. Mater Sci. Eng. A. 2008, 480, 299–305. [Google Scholar] [CrossRef]

- Cheng, S.; Zhao, Y.H.; Zhu, Y.T.; Ma, E. Optimizing the strength and ductility of fine structured 2024 Al alloy by nano-precipitation. Acta Mater. 2007, 55, 5822–5832. [Google Scholar] [CrossRef]

- Tajally, M.; Emadoddin, E. Mechanical and anisotropic behaviors of 7075 aluminum alloy sheets. Mater. Des. 2011, 32, 1594–1599. [Google Scholar] [CrossRef]

- Huang, L.P.; Chen, K.H.; Li, S.; Song, M. Influence of high-temperature pre-precipitation on local corrosion behaviors of Al–Zn–Mg alloy. Scr. Mater. 2007, 56, 305–308. [Google Scholar] [CrossRef]

- Tash, M.; Alkahtani, S. Effect of thermo-mechanical treatment (TMT) on hardness of heat-treated Al-Mg-Si (6082) alloys: Experimental correlation using (DOE) method. Appl. Mech. Mater. 2013, 376, 163–172. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhu, Y.; Lavernia, E.J. Strategies for Improving Tensile Ductility of Bulk Nanostructured Materials. Adv. Eng. Mater. 2010, 12, 769–778. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Liao, X.Z.; Cheng, S.; Ma, E.; Zhu, Y.T. Simultaneously Increasing the Ductility and Strength of Nanostructured Alloys. Adv.Mater. 2006, 18, 2280–2283. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Liao, X.Z.; Jin, Z.; Valiev, R.Z.; Zhu, Y.T. Microstructures and mechanical properties of ultrafine grained 7075 Al alloy processed by ECAP and their evolutions during annealing. Acta Mater. 2004, 52, 4589–4599. [Google Scholar] [CrossRef]

- Huang, Y.J.; Chen, Z.G.; Zheng, Z.Q. A conventional thermo-mechanical process of Al–Cu–Mg alloy for increasing ductility while maintaining high strength. Scr. Mater. 2011, 64, 382–385. [Google Scholar] [CrossRef]

- Horita, Z.; Fujinami, T.; Nemoto, M.; Langdon, T.G. Improvement of mechanical properties for Al alloys using equal-channel angular pressing. J. Mater. Process. Technol. 2001, 117, 288–292. [Google Scholar] [CrossRef]

- Williamson, G.K.; Hall, W.H. X-ray line broadening from filed aluminium and wolfram. Acta Metall. 1953, 1, 22–31. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, Y.; Lin, S.; Jin, S.; Liu, J. Strengthening Al-Zn-Mg Alloys via Ultra-Fine Lamella Structures Containing a High Density of Dislocations and Clusters. Metals 2019, 9, 140. https://doi.org/10.3390/met9020140

Qin Y, Lin S, Jin S, Liu J. Strengthening Al-Zn-Mg Alloys via Ultra-Fine Lamella Structures Containing a High Density of Dislocations and Clusters. Metals. 2019; 9(2):140. https://doi.org/10.3390/met9020140

Chicago/Turabian StyleQin, Yonggui, Sicong Lin, Shenbao Jin, and Jizi Liu. 2019. "Strengthening Al-Zn-Mg Alloys via Ultra-Fine Lamella Structures Containing a High Density of Dislocations and Clusters" Metals 9, no. 2: 140. https://doi.org/10.3390/met9020140

APA StyleQin, Y., Lin, S., Jin, S., & Liu, J. (2019). Strengthening Al-Zn-Mg Alloys via Ultra-Fine Lamella Structures Containing a High Density of Dislocations and Clusters. Metals, 9(2), 140. https://doi.org/10.3390/met9020140