Modification of Microstructure and Texture in Highly Non-Flammable Mg-Al-Zn-Y-Ca Alloy Sheets by Controlled Thermomechanical Processes

Abstract

1. Introduction

2. Materials and Methods

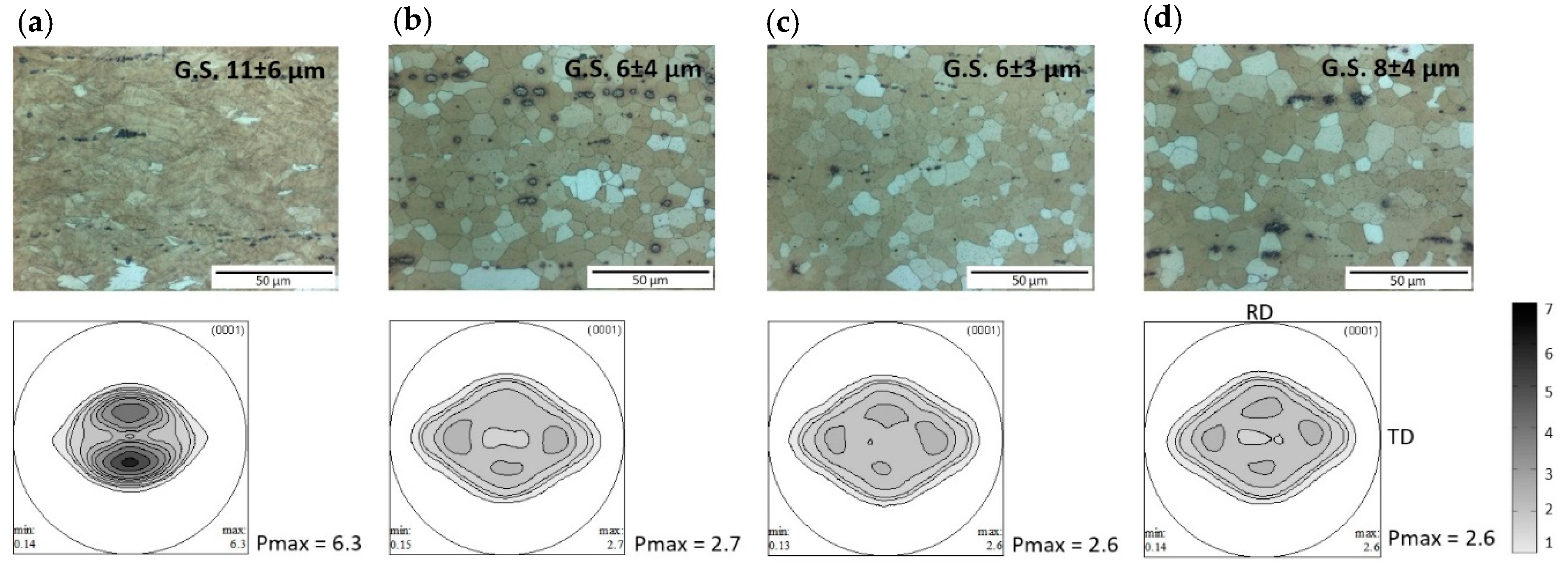

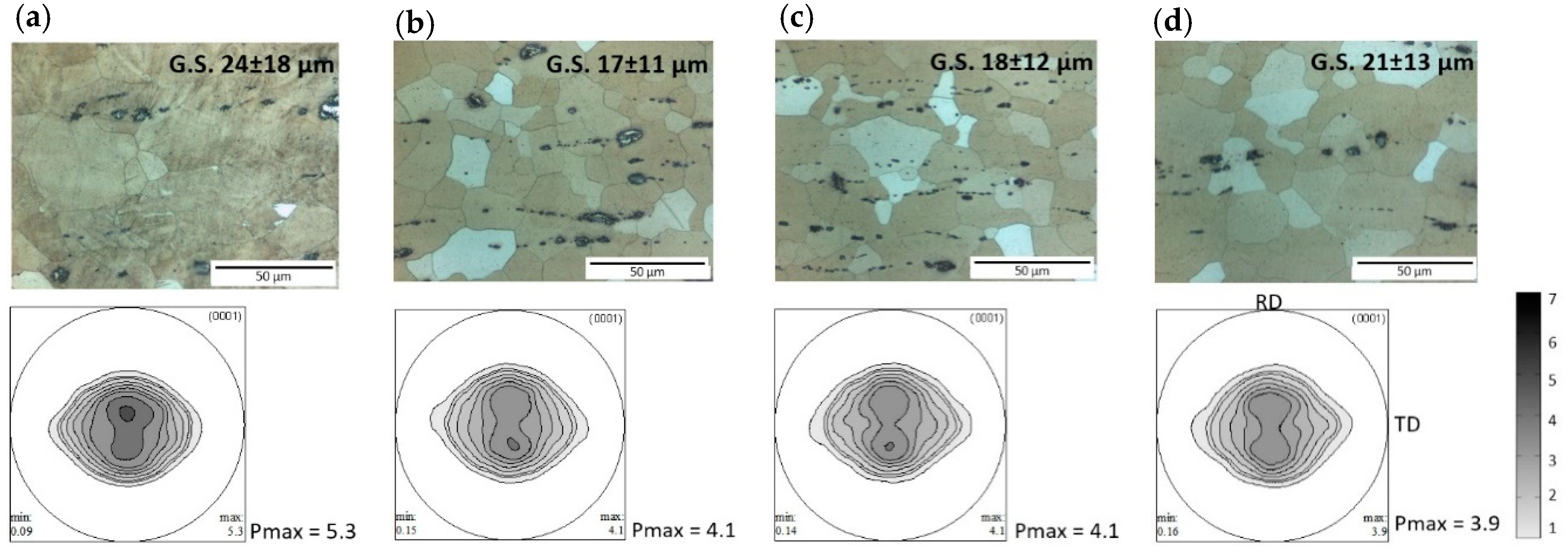

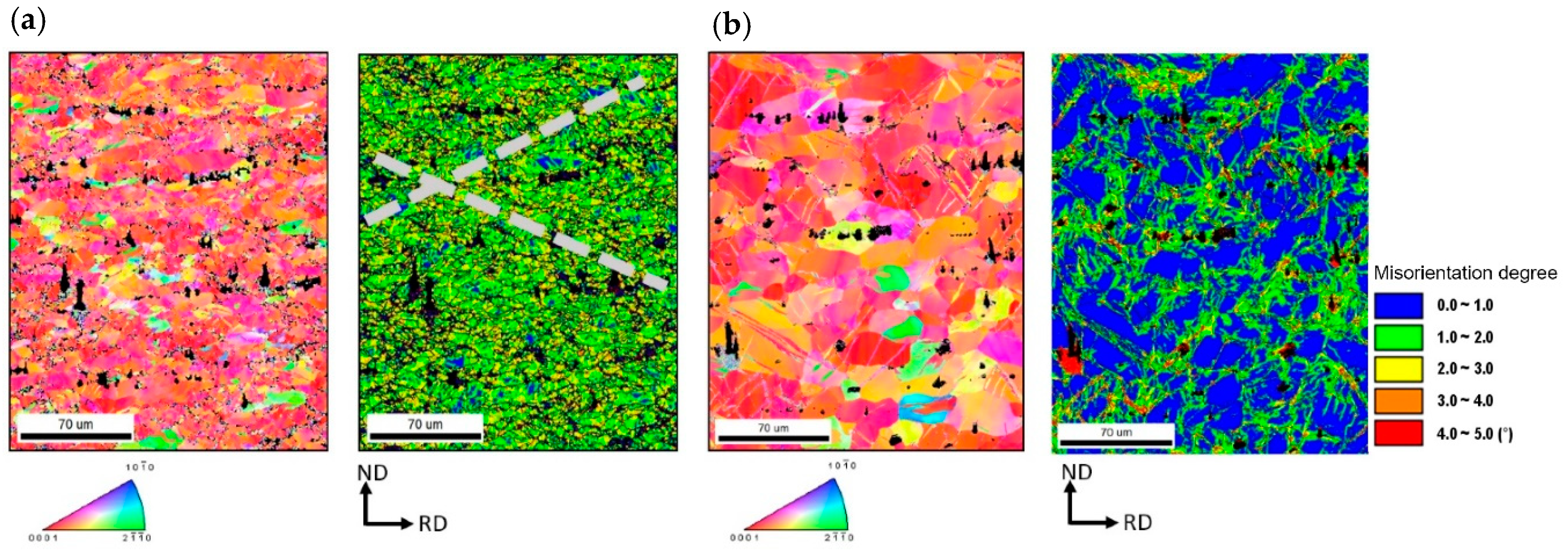

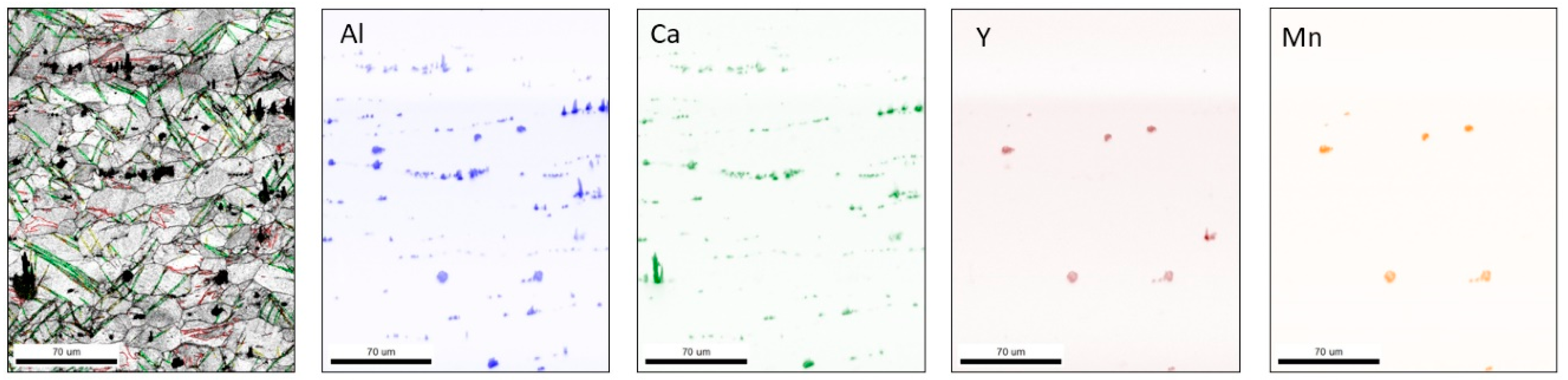

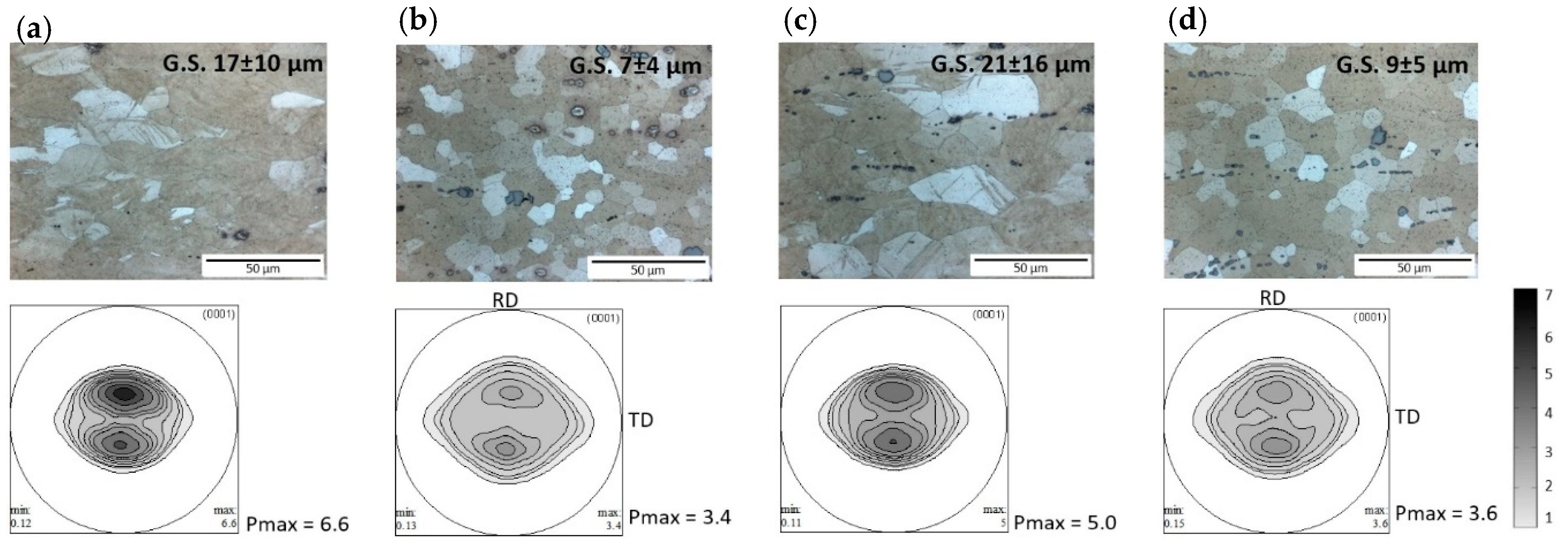

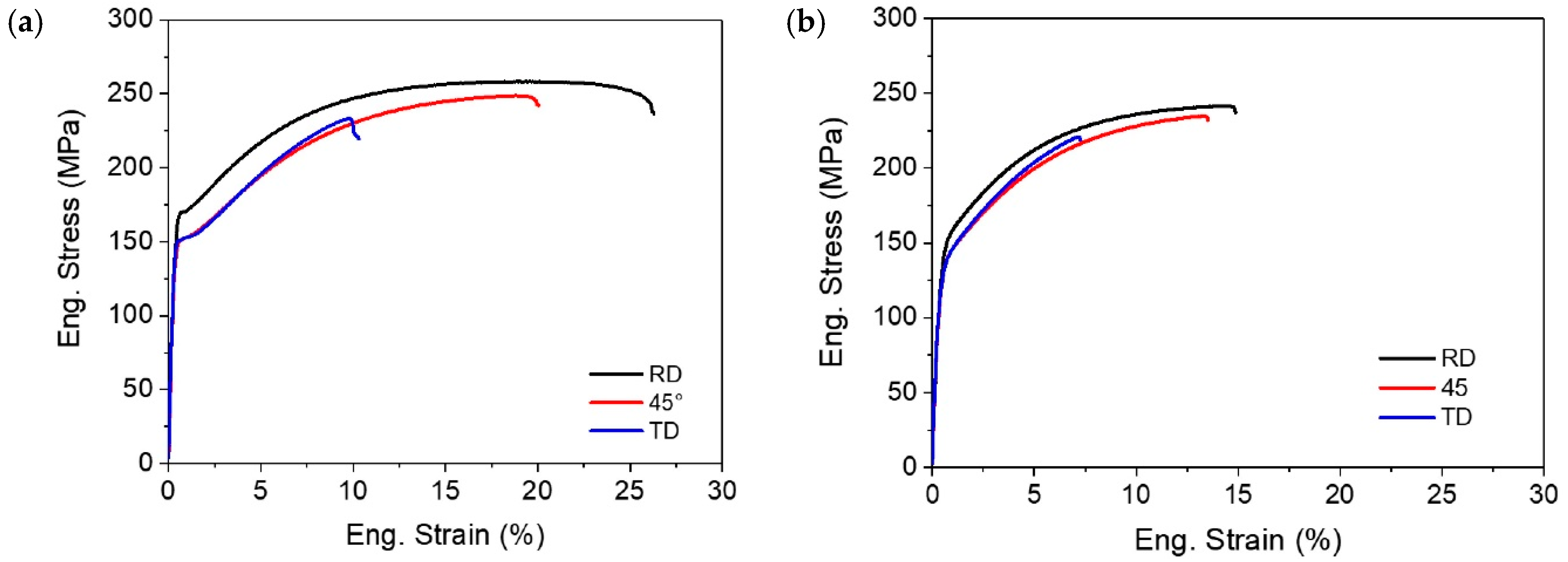

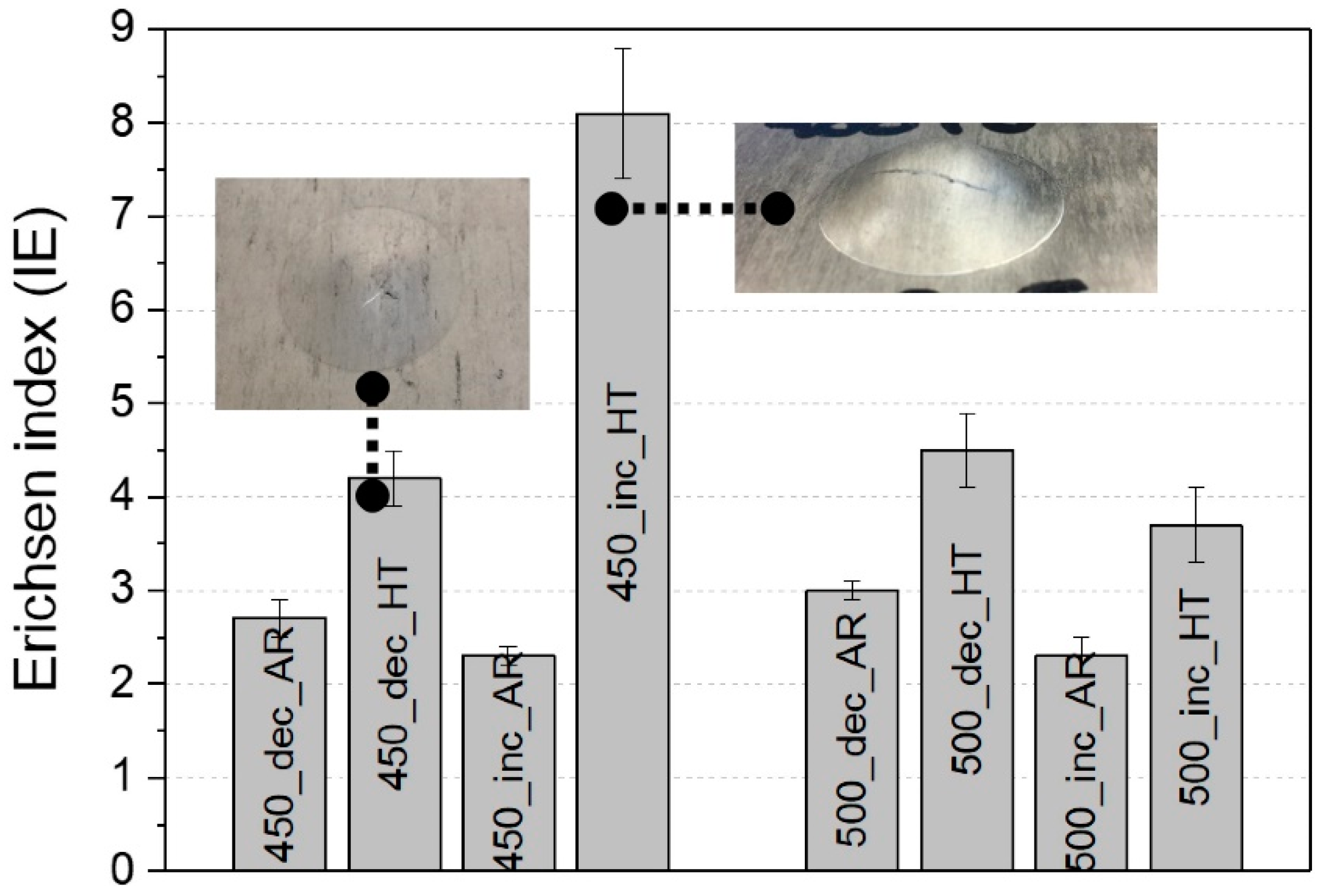

3. Results and Discussion

4. Summary

Author Contributions

Acknowledgments

References

- Bohlen, J.; Nürnberg, M.R.; Senn, J.W.; Letzig, D.; Agnew, S.R. The texture and anisotropy of magnesium-zinc-rare earth alloy sheets. Acta Mater. 2007, 55, 2101–2112. [Google Scholar] [CrossRef]

- Stanford, N.; Barnett, M. Effect of composition on the texture and deformation behaviour of wrought Mg alloys. Scr. Mater. 2008, 58, 179–182. [Google Scholar] [CrossRef]

- Chino, Y.; Kado, M.; Mabuchi, M. Enhancement of Tensile Ductility and Stretch Formability of Magnesium by Addition of 0.2 wt%(0.035 at%)Ce. Mater. Sci. Eng. 2008, A494, 343–349. [Google Scholar] [CrossRef]

- Bohlen, J.; Cano, G.; Drozdenko, D.; Dobron, P.; Kainer, K.U.; Gall, S.; Müller, S.; Letzig, D. Processing Effects on the Formability of Magnesium Alloy Sheets. Metals 2018, 8, 147. [Google Scholar] [CrossRef]

- Tekumalla, S.; Seetharaman, S.; Almajid, A.; Gupta, M. Mechanical Properties of Magnesium-Rare Earth Alloy Systems: A Review. Metals 2015, 5, 1–39. [Google Scholar] [CrossRef]

- Yi, S.; Bohlen, J.; Heinemann, F.; Letzig, D. Mechanical anisotropy and deep drawing behaviour of AZ31 and ZE10 magnesium alloy sheets. Acta Mater. 2010, 58, 592–605. [Google Scholar] [CrossRef]

- Kim, Y.M.; Kim, H.S.; You, B.S.; Yim, C.D. Non-Flammable Magnesium Alloy with Excellent Mechanical Properties, and Preparation Method Thereof. U.S. Patent 2013/0183193 A1, 18 July 2013. [Google Scholar]

- Gneiger, S.; Papenberg, N.; Frank, S.; Gradinger, R. Investigations on Microstructure and Mechanical Properties of Non-Flammable Mg–Al–Zn–Ca–Y Alloys, Magnesium Technology 2018, TMS Annual Meeting & Exhibition, Phoenix, USA, March 11–15, 2018; Orlov, D., Joshi, V., Solanki, K.N., Neelameggham, N.R., Eds.; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- Go, Y.; Jo, S.M.; Park, S.H.; Kim, H.S.; You, B.S.; Kim, Y.M. Microstructure and mechanical properties of non-flammable Mg-8Al-0.3Zn-0.1Mn-0.3Ca-0.2Y alloy subjected to low-temperature, low-speed extrusion. J. Alloys Compd. 2018, 739, 69–76. [Google Scholar] [CrossRef]

- You, B.S.; Kim, Y.M.; Yim, C.D.; Kim, H.S. Oxidation and Corrosion Behavior of Non-Flammable Magnesium Alloys Containing Ca and Y. Magnesium Technology 2014, TMS Annual Meeting & Exhibition, San Diego, USA, Feb. 16–20, 2014; Alderman, M., Manuel, M.V., Hort, N., Neelameggham, N.R., Eds.; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar] [CrossRef]

- Stanford, N. The effect of calcium on the texture, microstructure and mechanical properties of extruded Mg–Mn–Ca alloys. Mater. Sci. Eng. 2010, A528, 314–322. [Google Scholar] [CrossRef]

- Kim, D.W.; Suh, B.C.; Shim, M.S.; Bae, J.H.; Kim, D.H.; Kim, N.J. Texture Evolution in Mg-Zn-Ca Alloy Sheets. Metall. Mater. Trans. 2013, A44, 2950–2961. [Google Scholar] [CrossRef]

- Chino, Y.; Huang, X.; Suzuki, K.; Mabuchi, M. Enhancement of Stretch Formability at Room Temperature by Addition of Ca in Mg-Zn Alloy. Mater. Trans. 2010, 51, 818–821. [Google Scholar] [CrossRef]

- Bhattacharjee, T.; Suh, B.C.; Sasaki, T.T.; Ohkubo, T.; Kim Nack, J.; Hono, K. High strength and formable Mg–6.2Zn–0.5Zr–0.2Ca alloy sheet processed by twin roll casting. Mater. Sci. Eng. 2014, A609, 154–160. [Google Scholar] [CrossRef]

- Hofstetter, J.; Becker, M.; Martinelli, E.; Weinberg, A.M.; Mingler, B.; Kilian, H.; Pogatscher, S.; Uggowitzer, P.J.; Löffler, J.F. High-Strength Low-Alloy (HSLA) Mg–Zn–Ca Alloys with Excellent Biodegradation Performance. JOM 2014, 66, 566–572. [Google Scholar] [CrossRef]

- Kree, V.; Bohlen, J.; Letzig, D.; Kainer, K.U. The metallographical examination of magnesium alloys. Pract. Metallogr. 2004, 41, 233–246. [Google Scholar]

- MTEX Toolbox. Available online: http://mtex-toolbox.github.io/ (accessed on 28 December 2018).

- Agnew, S.R.; Yoo, M.H.; Tomé, C.N. Application of texture simulation to understanding mechanical behavior of Mg and solid solution alloys containing Li or Y. Acta Mater. 2001, 49, 4277–4289. [Google Scholar] [CrossRef]

- Al-Samman, T.; Gottstein, G. Room temperature formability of a magnesium AZ31 alloy: Examining the role of texture on the deformation mechanisms. Mater. Sci. Eng. 2008, A488, 406–414. [Google Scholar] [CrossRef]

- Hantzsche, K.; Bohlen, J.; Wendt, J.; Kainer, K.U.; Yi, S.B.; Letzig, D. Effect of rare earth additions on microstructure and texture development of magnesium alloy sheets. Scr. Mater. 2010, 63, 725–730. [Google Scholar] [CrossRef]

- Stutz, L.; Bohlen, J.; Kurz, G.; Letzig, D.; Kainer, K.U. Influence of the processing of magnesium alloys AZ31 and ZE10 on the sheet formability at elevated temperature. Key Eng. Mater. 2011, 473, 335–342. [Google Scholar] [CrossRef]

- Suh, J.; Victoria-Hernández, J.; Letzig, D.; Golle, R. Effect of processing route on texture and cold formability of AZ31 alloy sheets processed by ECAP. Mater. Sci. Eng. 2016, A669, 159–170. [Google Scholar] [CrossRef]

| Rolling Condition | Rolling Temperature (°C) | Deformation Degree per Pass (φ) (Total 11 Rolling Steps) | Remarks |

|---|---|---|---|

| 450-inc | 450 | 0.1 → 0.3 (increasing with rolling step) | where, tn = sheet thickness at the nth rolling step. |

| 450-dec | 450 | 0.3 → 0.1 (decreasing with rolling step) | |

| 500-inc | 500 | 0.1 → 0.3 (increasing with rolling step) | |

| 500-dec | 500 | 0.3 → 0.1 (decreasing with rolling step) |

| Tensile Properties | Annealing for 600 s at 400 °C | |||||

|---|---|---|---|---|---|---|

| 450-inc | 450-dec | |||||

| RD | 45° | TD | RD | 45° | TD | |

| Yield strength (MPa) | 166 ± 6.7 | 151 ± 1.7 | 150 ± 0.9 | 149 ± 0.1 | 138 ± 0.9 | 137 ± 0.3 |

| Tensile strength (MPa) | 258 ± 1.0 | 243 ± 8.0 | 224 ± 12.2 | 242 ± 1.6 | 235 ± 0.9 | 204 ± 23.8 |

| Fracture strain (%) | 25.0 ± 1.8 | 17.0 ± 5.2 | 8.9 ± 2.0 | 14.4 ± 0.6 | 12.2 ± 0.6 | 4.7 ± 2.5 |

| Uniform elongation (%) | 18.0 ± 1.1 | 15.0 ± 4.7 | 8.1 ± 1.6 | 13.9 ± 0.6 | 12.0 ± 0.5 | 4.6 ± 2.4 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yi, S.; Victoria-Hernández, J.; Kim, Y.M.; Letzig, D.; You, B.S. Modification of Microstructure and Texture in Highly Non-Flammable Mg-Al-Zn-Y-Ca Alloy Sheets by Controlled Thermomechanical Processes. Metals 2019, 9, 181. https://doi.org/10.3390/met9020181

Yi S, Victoria-Hernández J, Kim YM, Letzig D, You BS. Modification of Microstructure and Texture in Highly Non-Flammable Mg-Al-Zn-Y-Ca Alloy Sheets by Controlled Thermomechanical Processes. Metals. 2019; 9(2):181. https://doi.org/10.3390/met9020181

Chicago/Turabian StyleYi, Sangbong, José Victoria-Hernández, Young Min Kim, Dietmar Letzig, and Bong Sun You. 2019. "Modification of Microstructure and Texture in Highly Non-Flammable Mg-Al-Zn-Y-Ca Alloy Sheets by Controlled Thermomechanical Processes" Metals 9, no. 2: 181. https://doi.org/10.3390/met9020181

APA StyleYi, S., Victoria-Hernández, J., Kim, Y. M., Letzig, D., & You, B. S. (2019). Modification of Microstructure and Texture in Highly Non-Flammable Mg-Al-Zn-Y-Ca Alloy Sheets by Controlled Thermomechanical Processes. Metals, 9(2), 181. https://doi.org/10.3390/met9020181