Multilayered-Sheet Hot Stamping and Application in Electric-Power-Fitting Products

Abstract

:1. Introduction

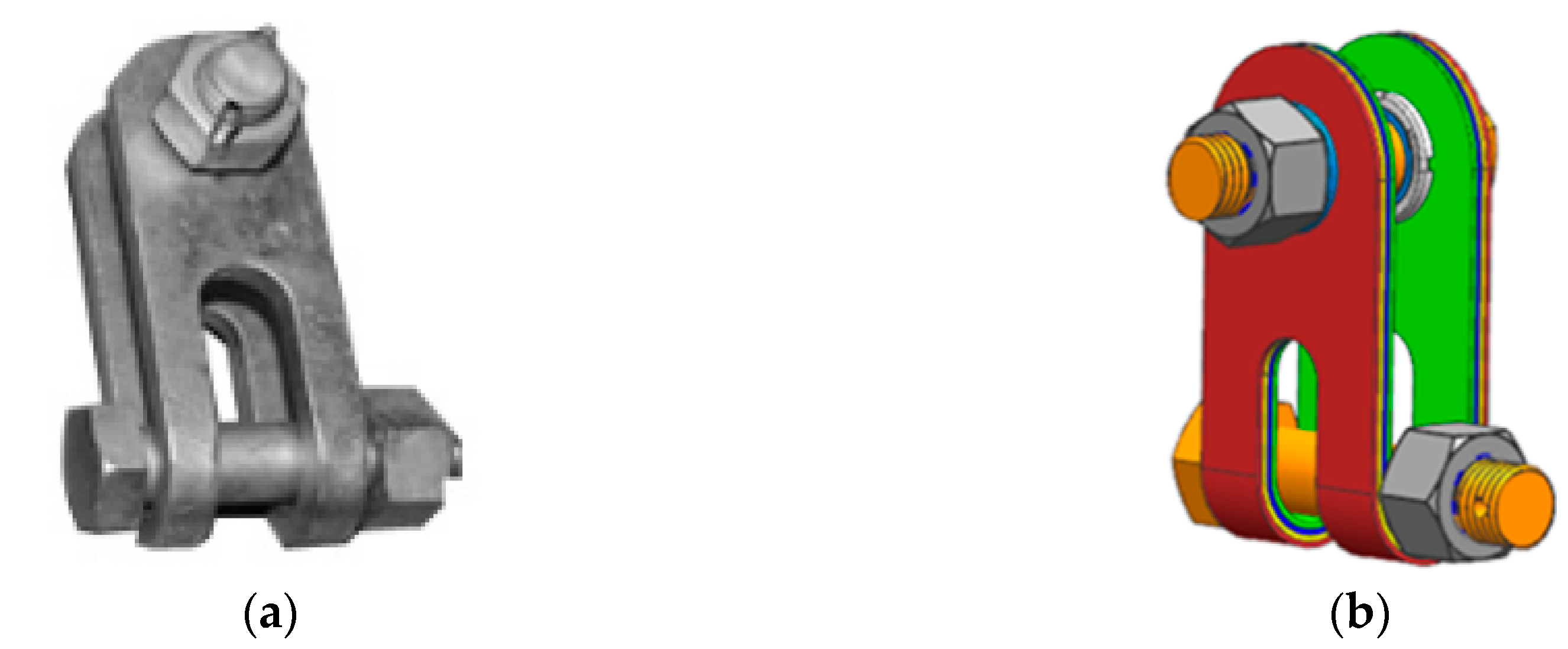

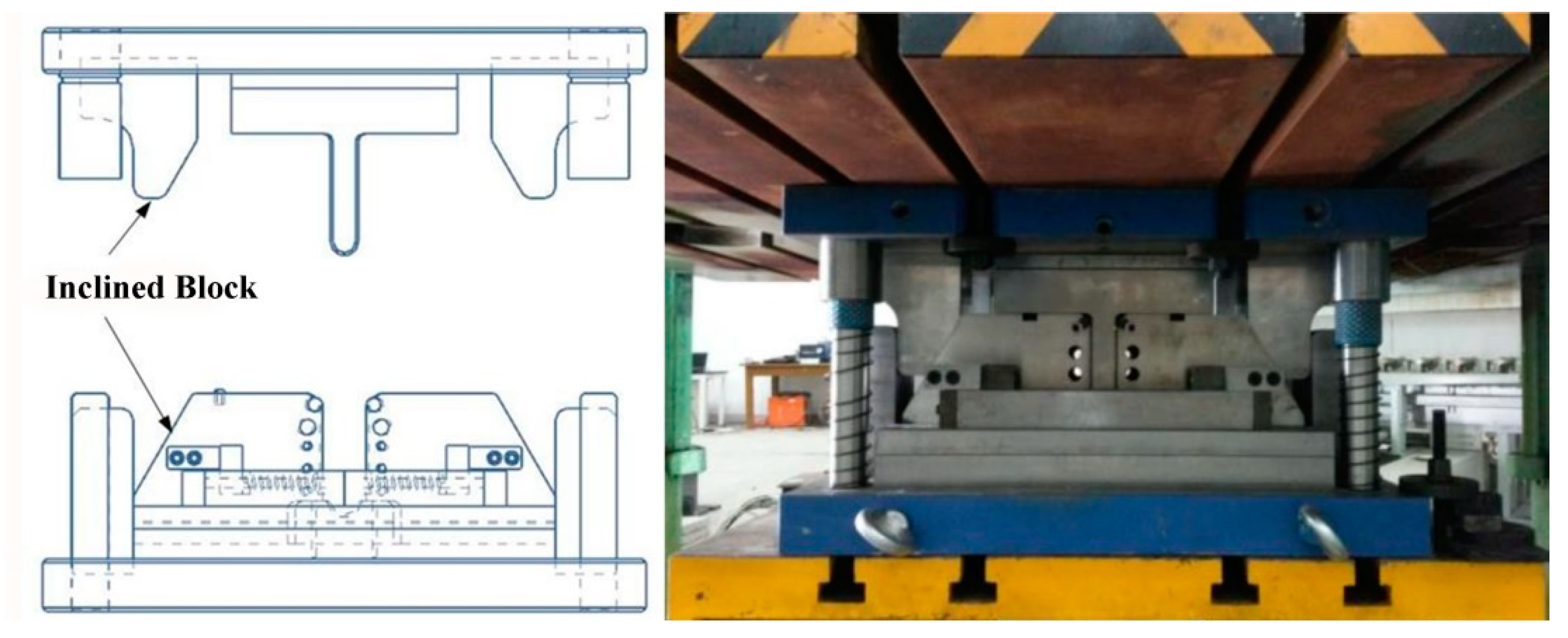

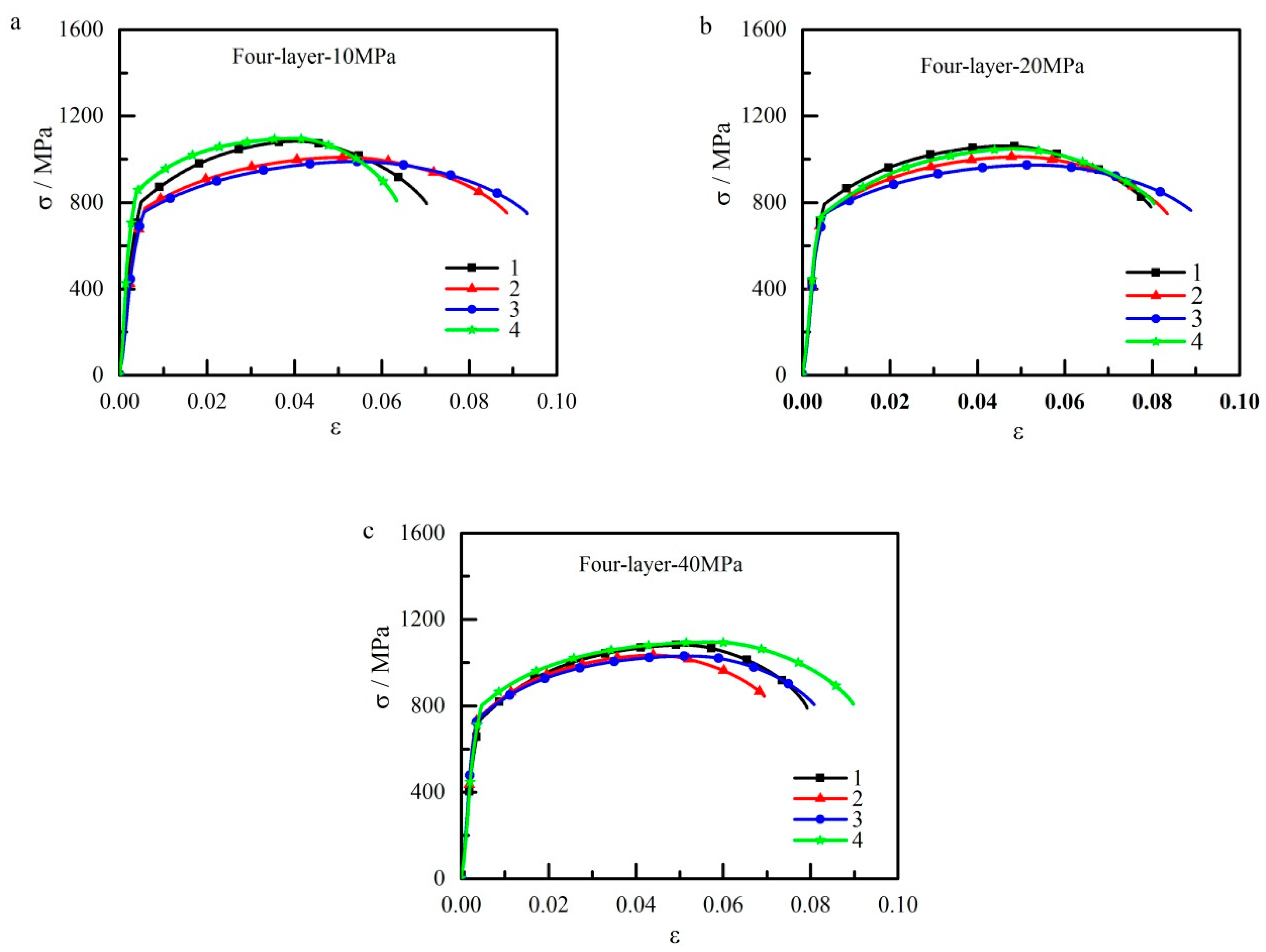

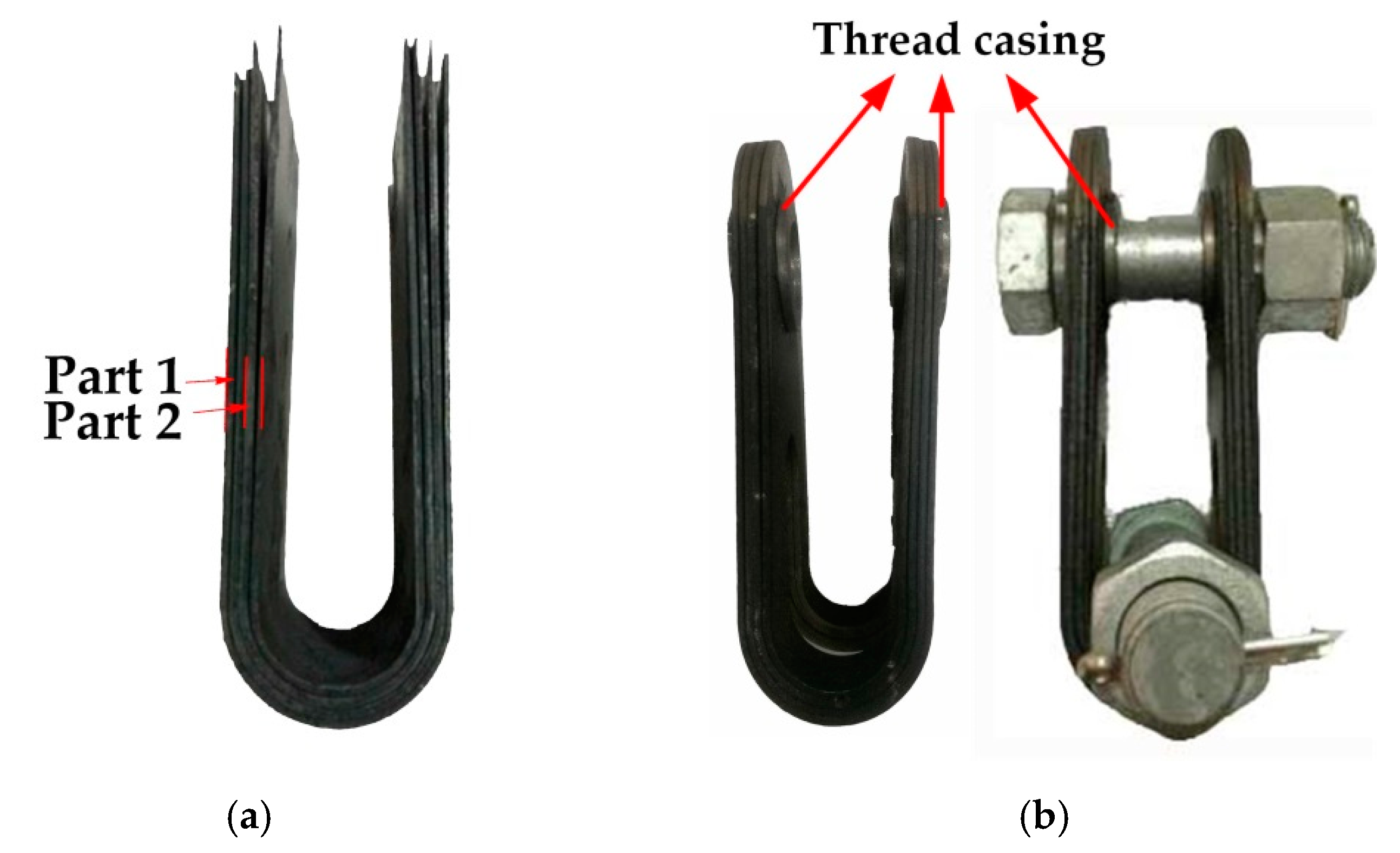

2. Features of the New Product and U-Shaped Tool

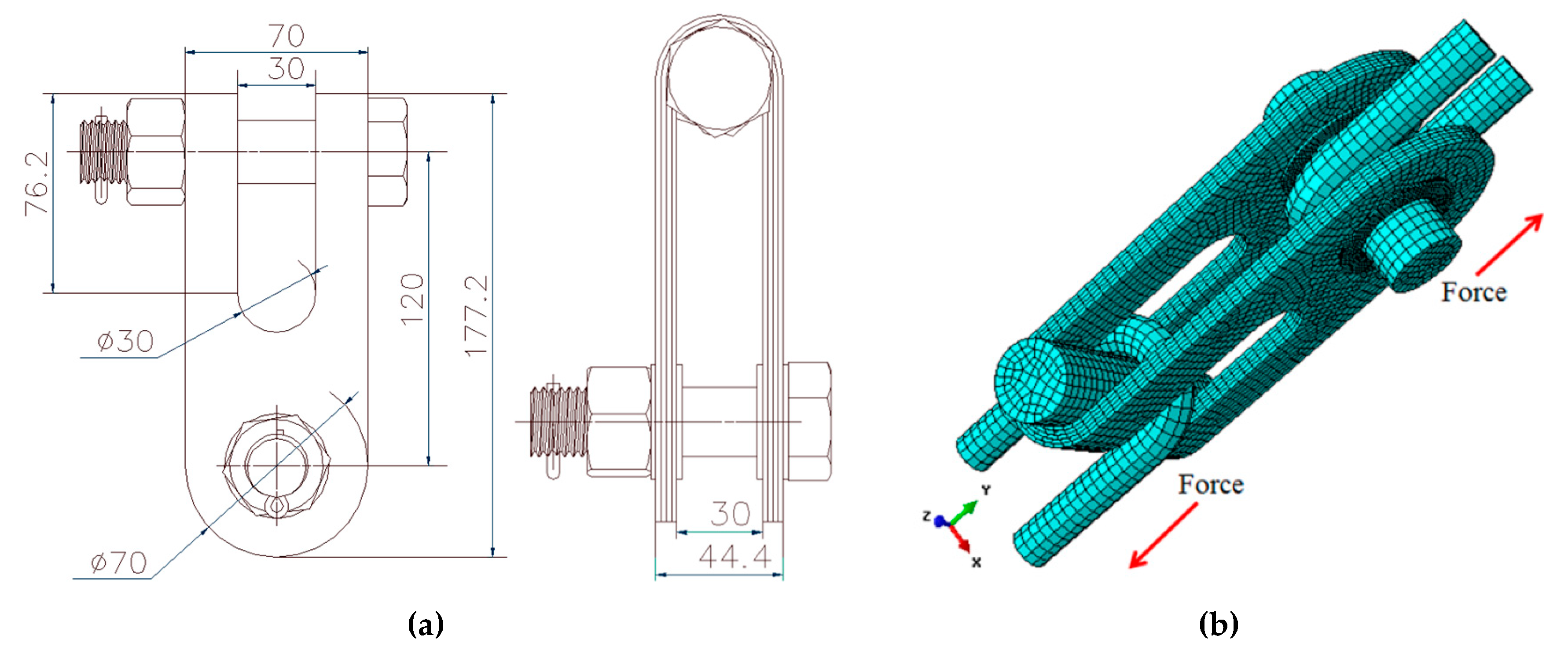

2.1. Light Weight of Clevis-Clevis Component and Features of the U-Shaped Tool

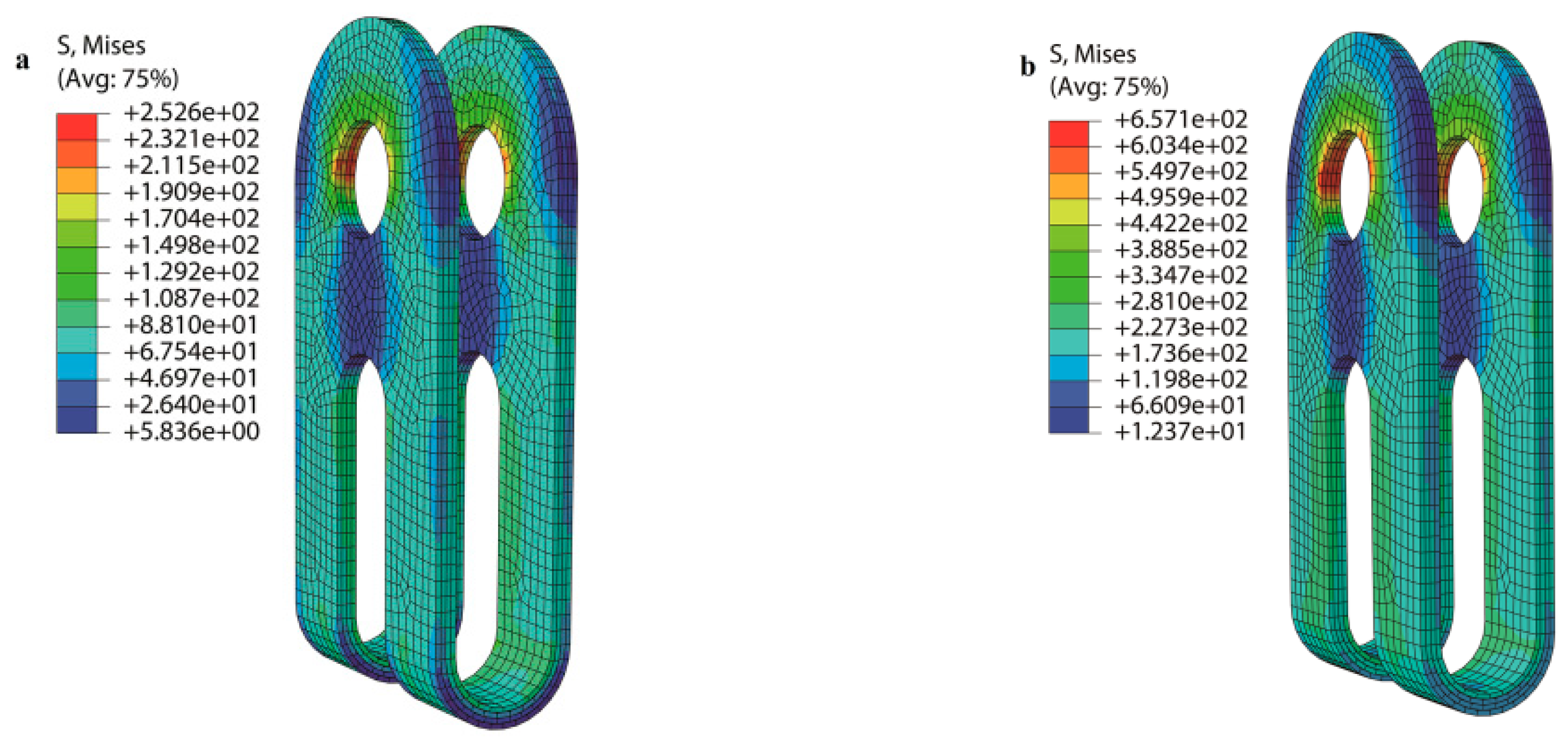

2.2. Numerical Analysis of the Product

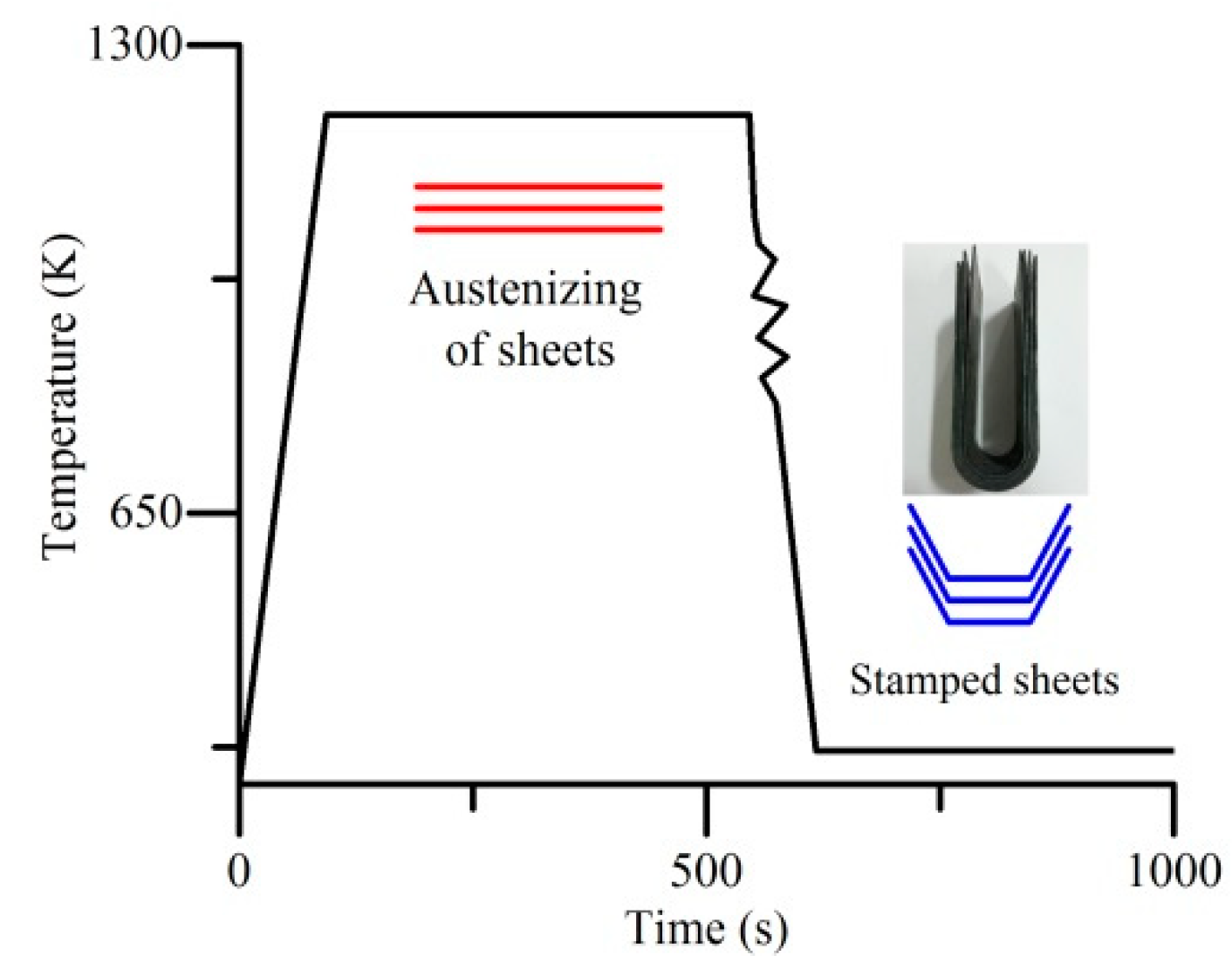

3. Multilayered-Sheet Heat Transfer Experiment

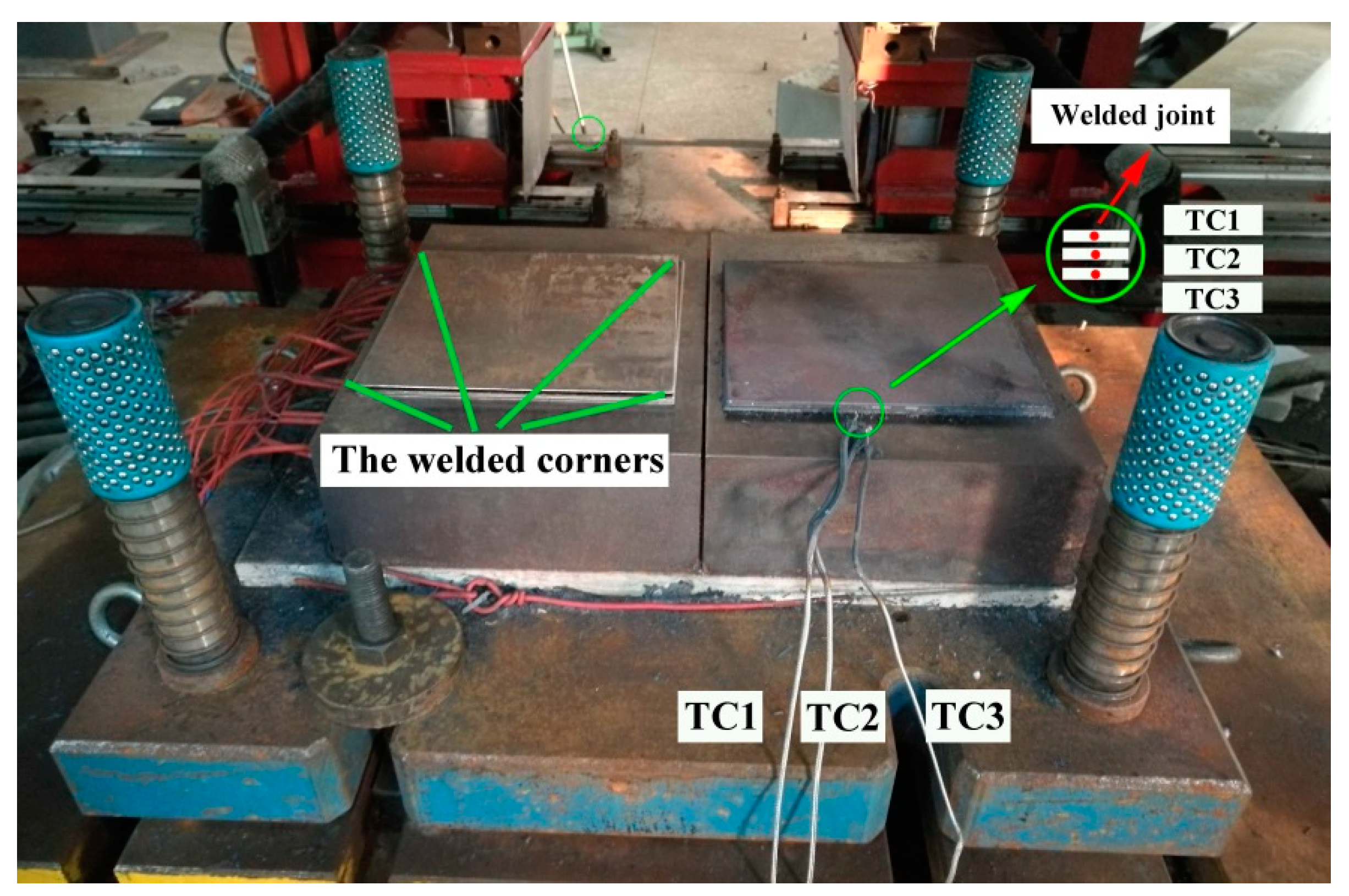

3.1. Experiment Procedure

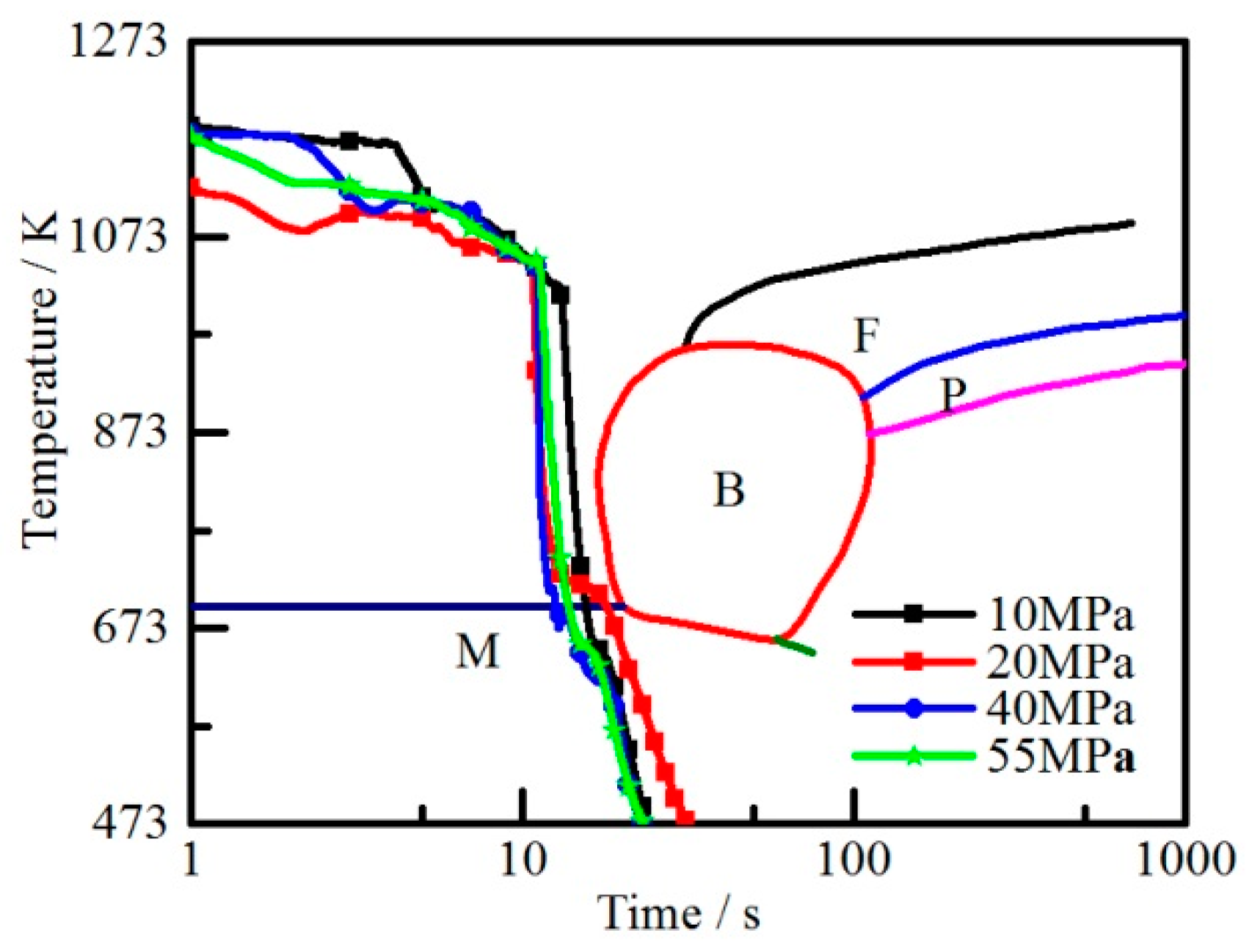

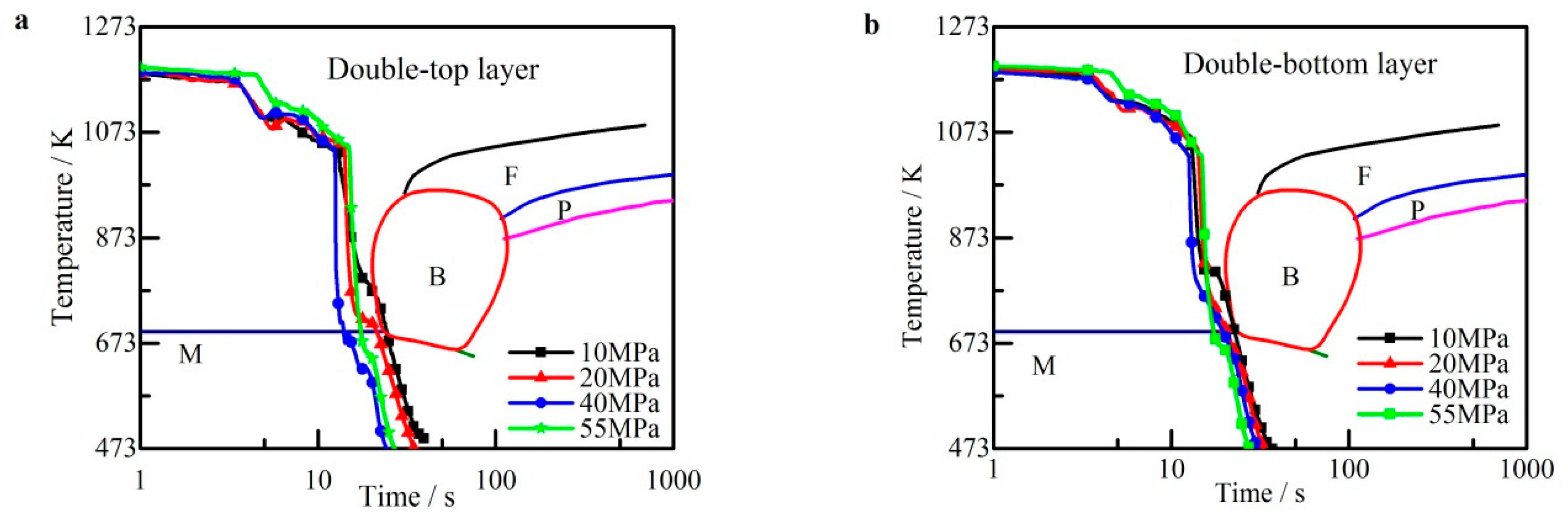

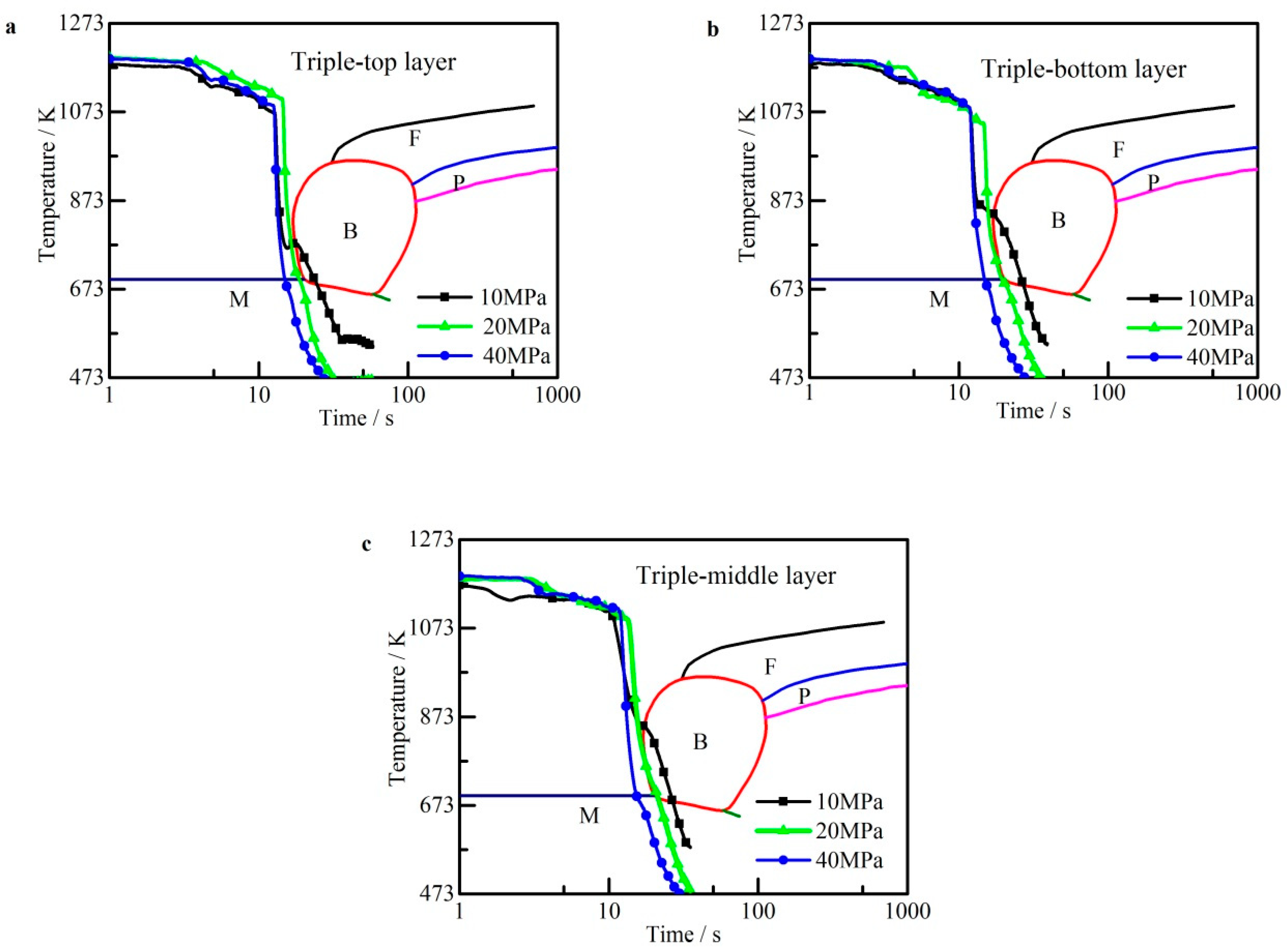

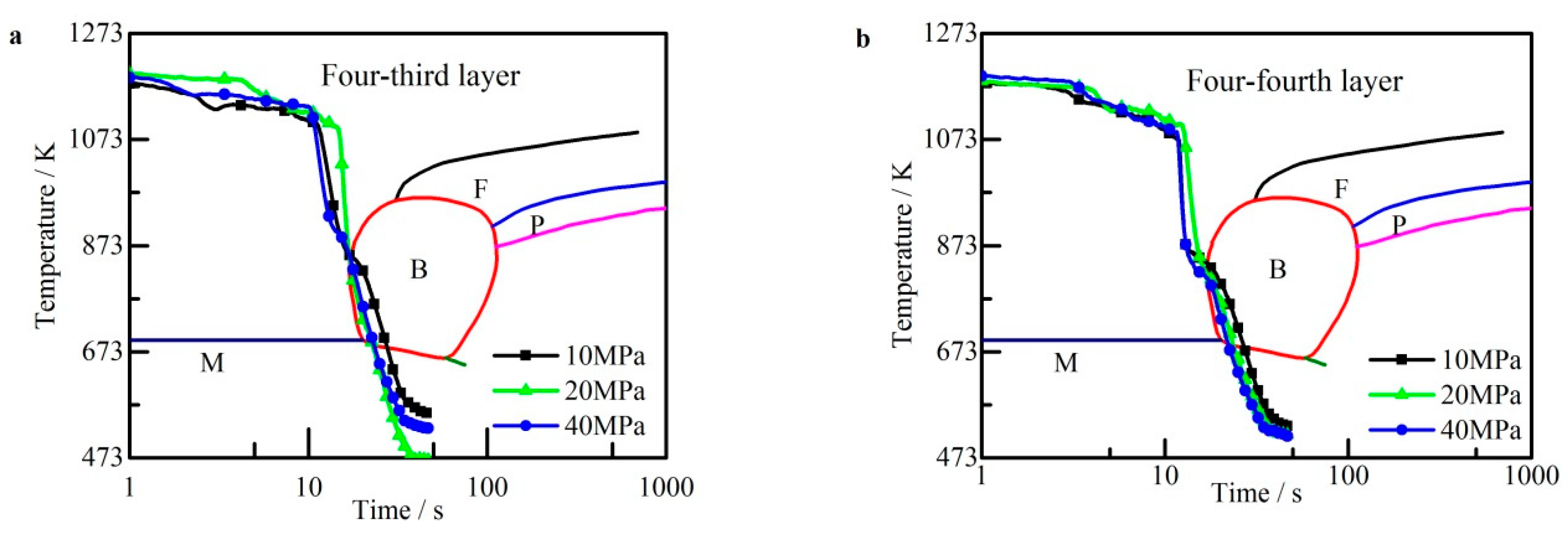

3.2. Temperature Measurement Result

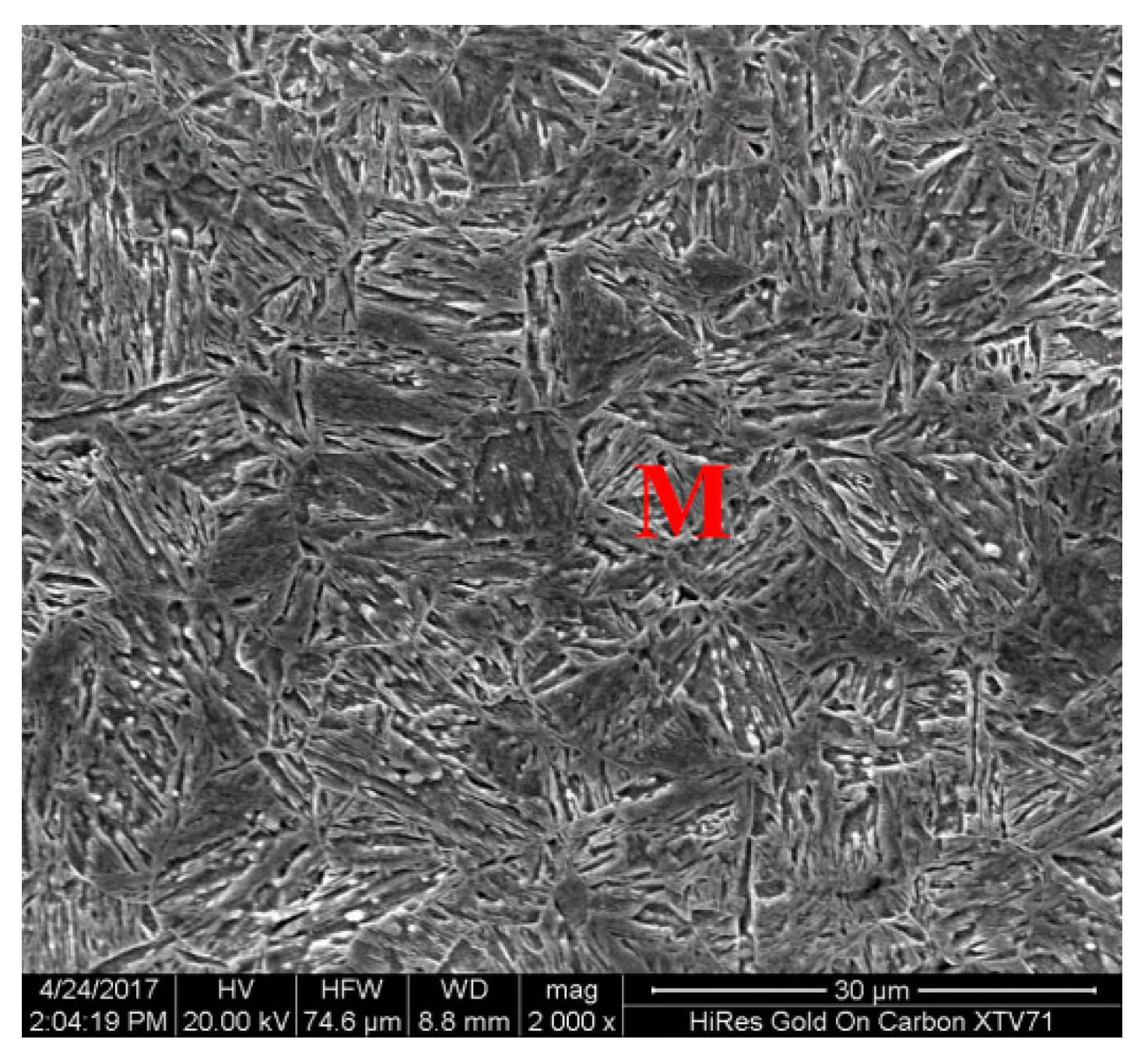

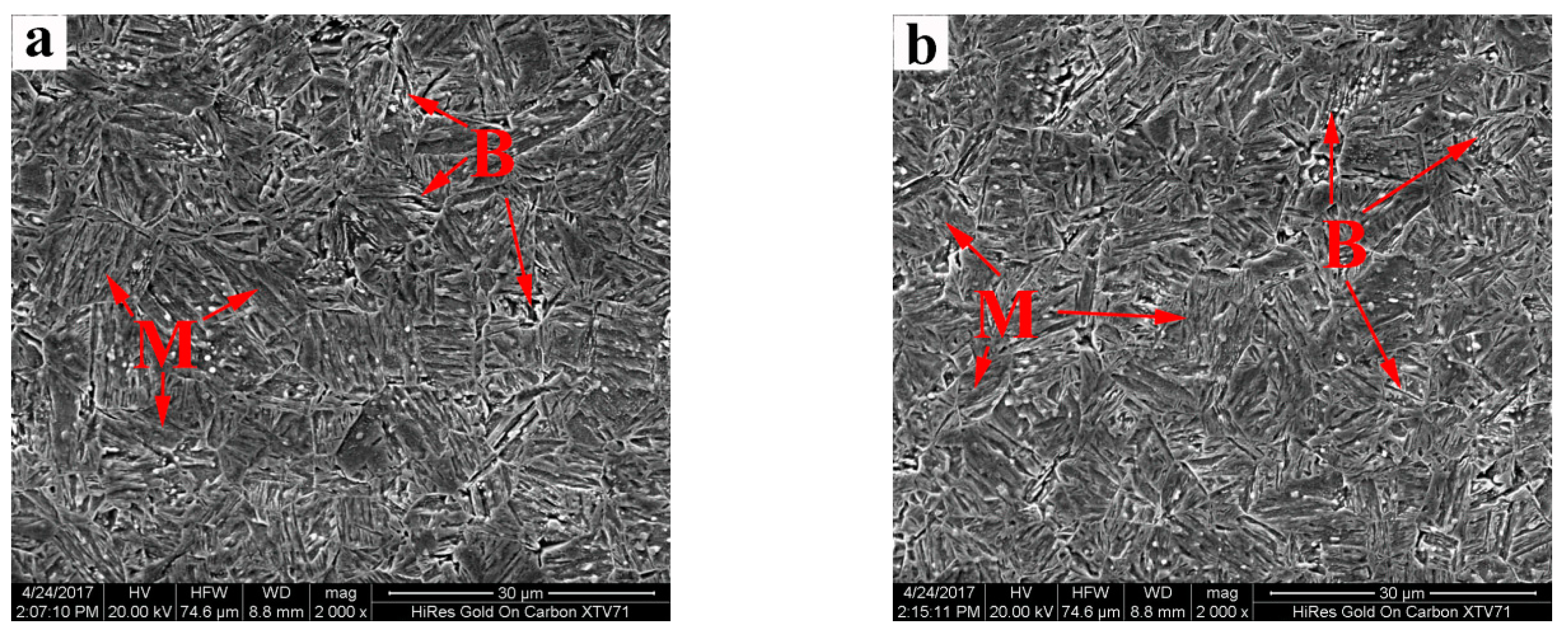

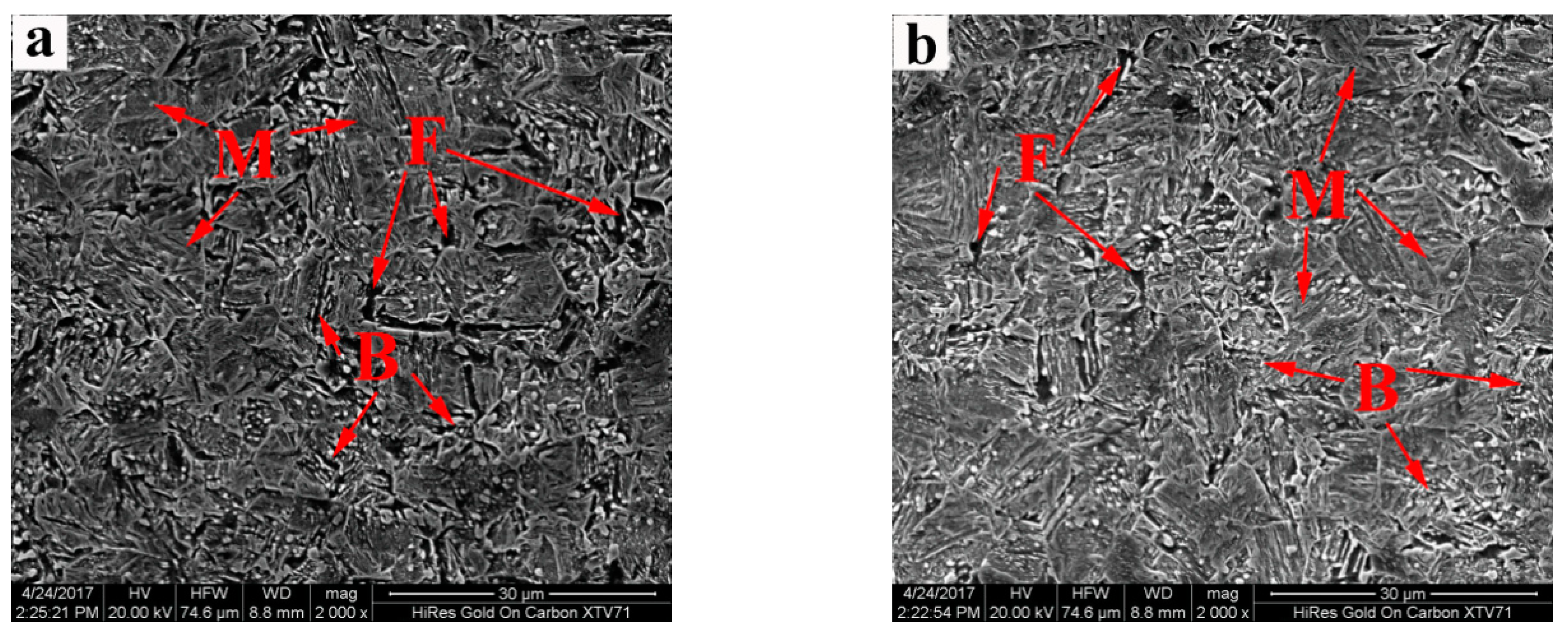

3.3. Microscopic Morphologies of Stamped Sheets

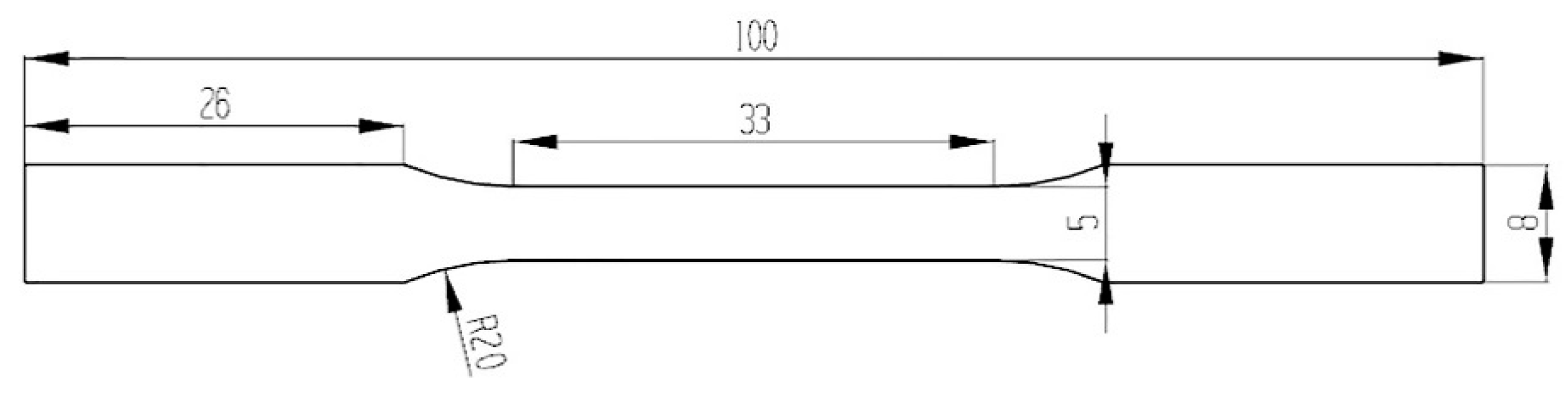

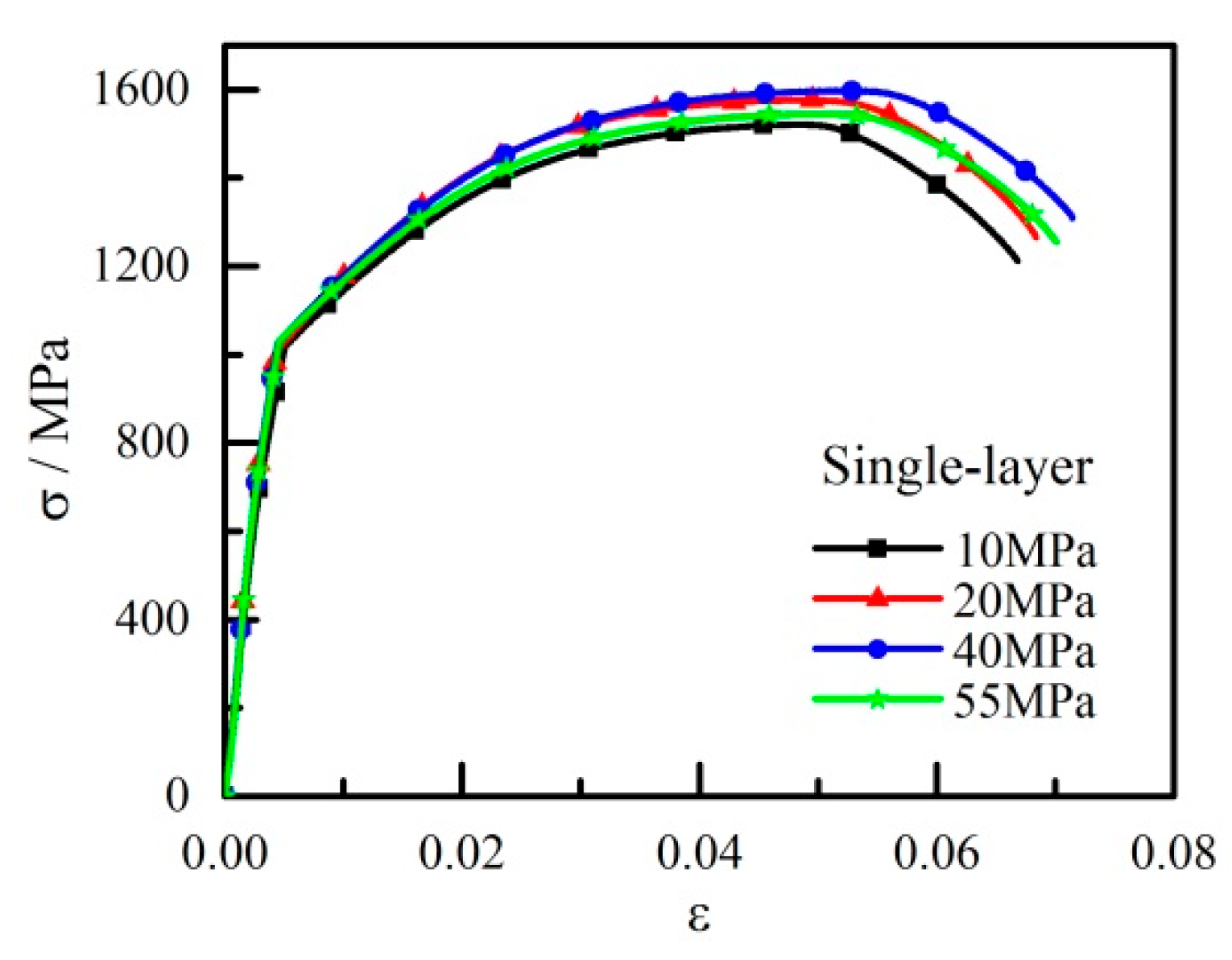

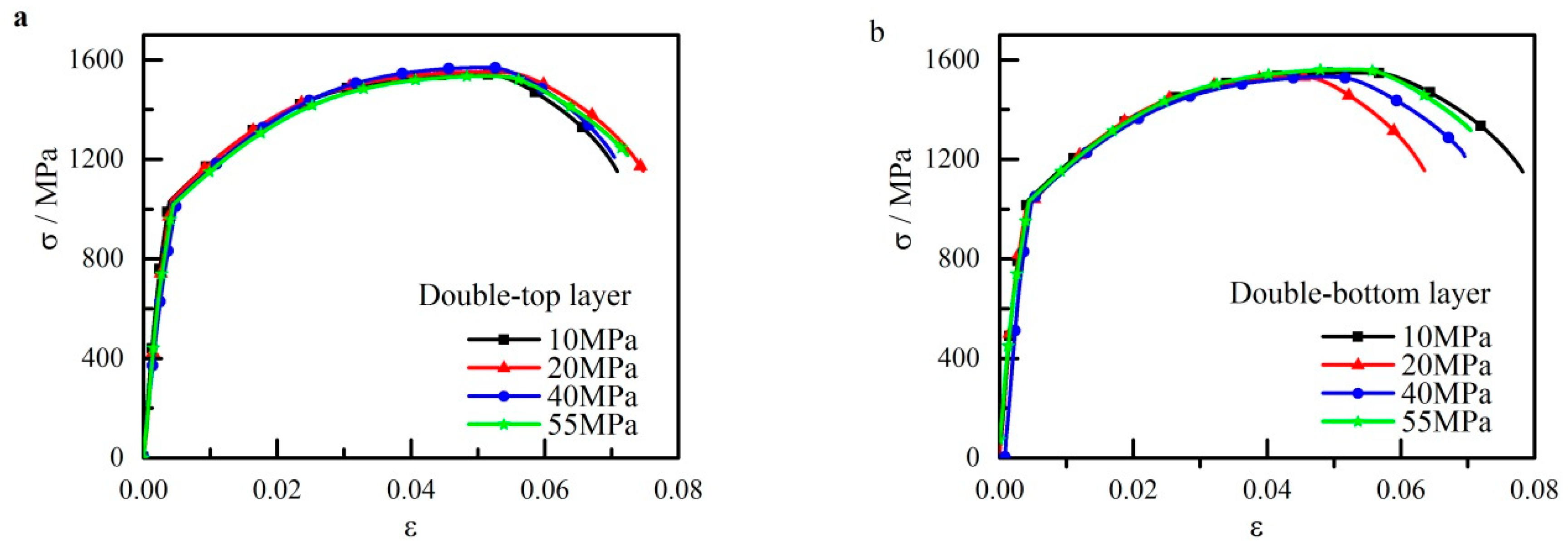

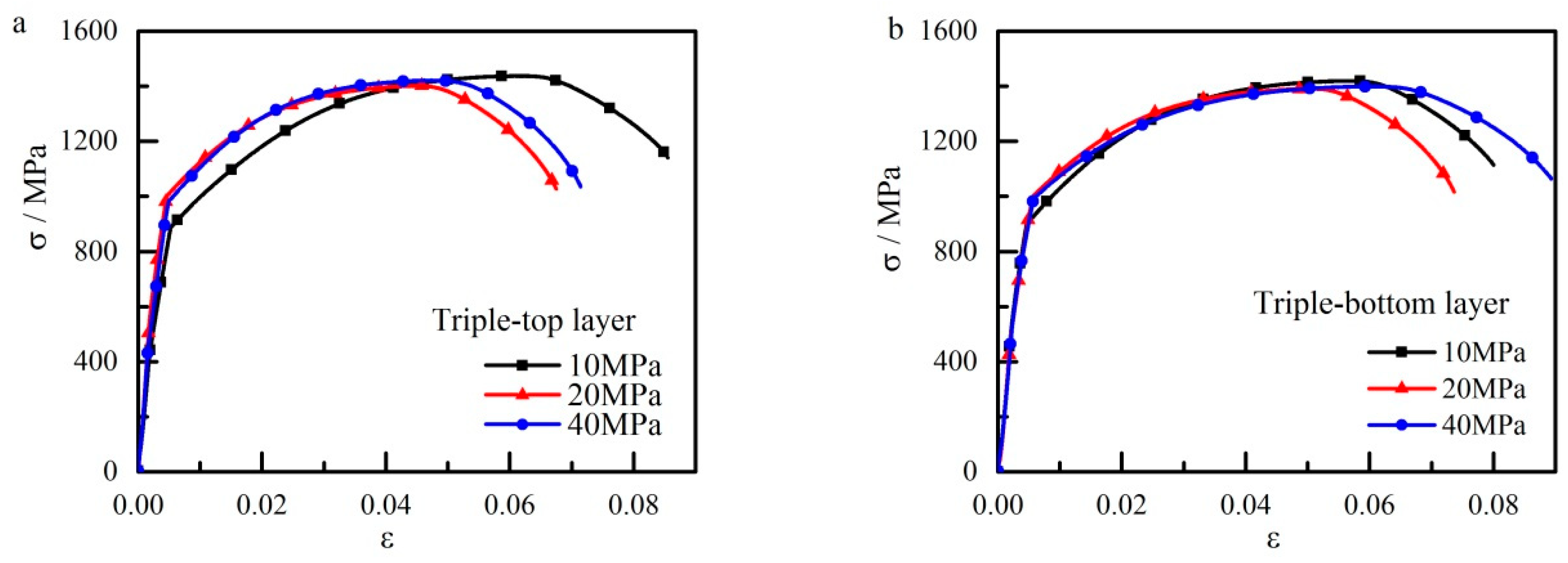

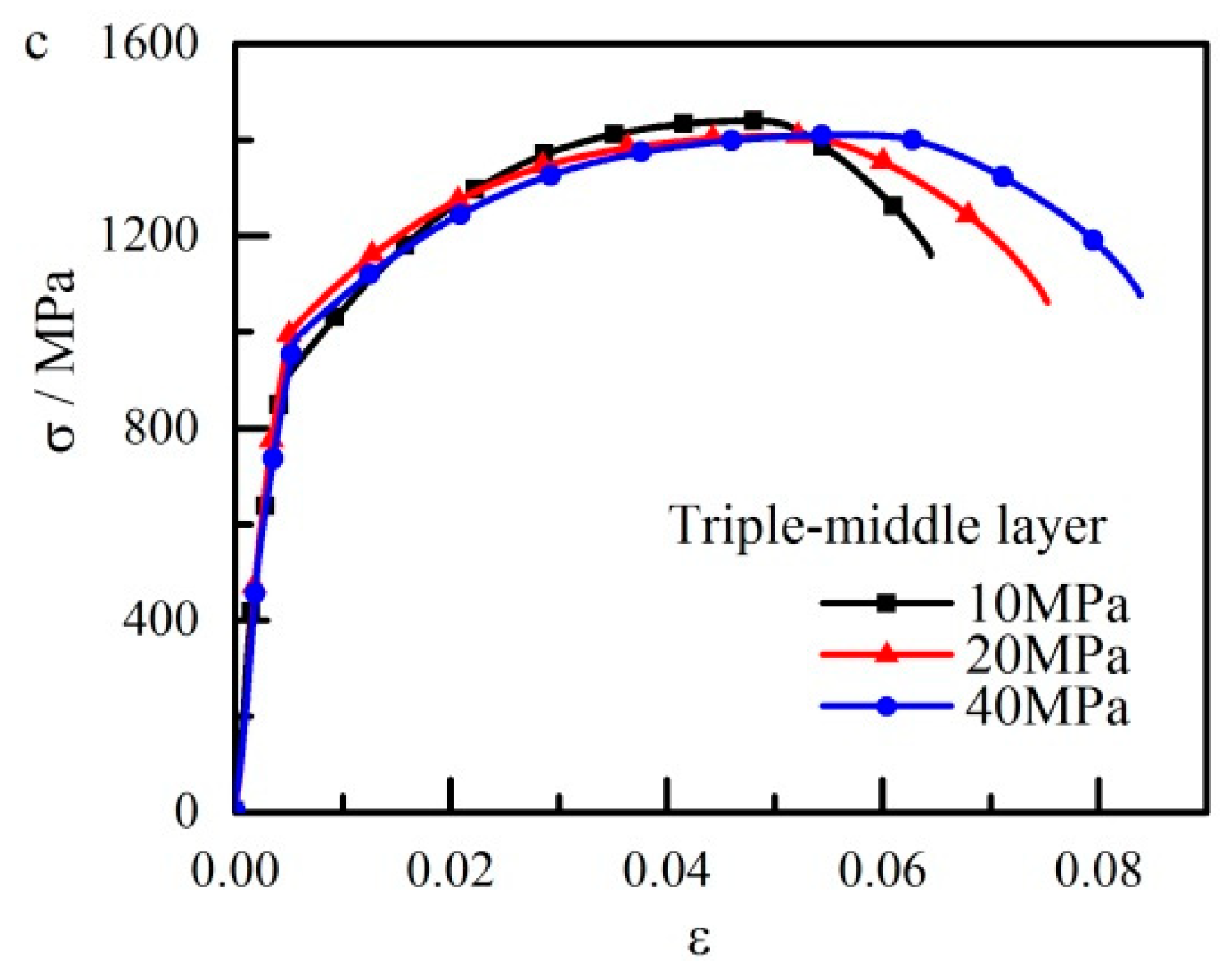

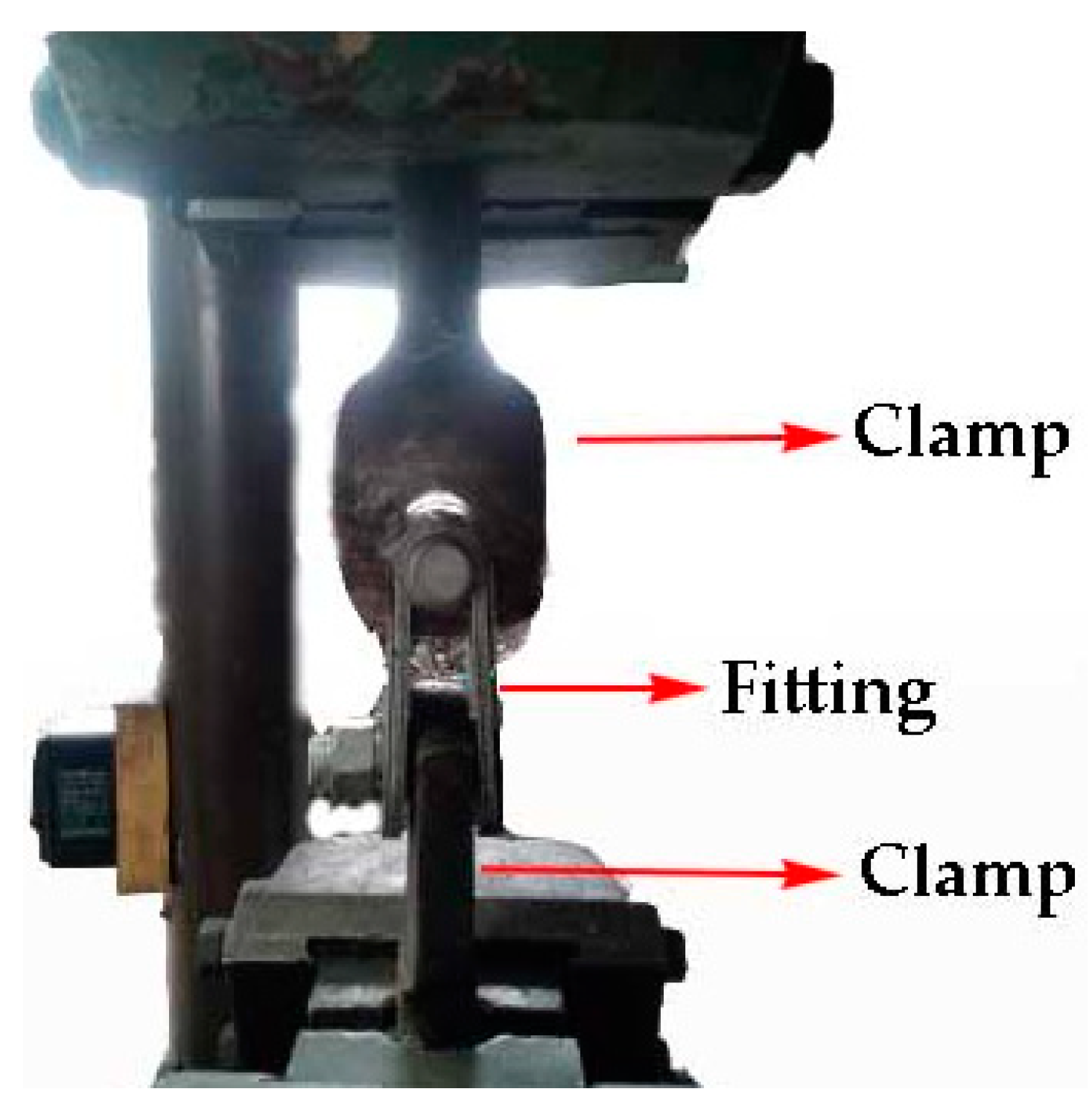

3.4. Tensile Tests

4. New Product and Its Performance Tests

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Meah, K.; Ula, S. Comparative Evaluation of HVDC and HVAC Transmission Systems. In Proceedings of the Power Engineering Society General Meeting, Tampa, FL, USA, 24–28 June 2007. [Google Scholar]

- Liu, S.; Fan, Z.; Gao, M. Analysis of the reasons behind the fracture of the 220kV pipe busbar horizontal line clamp. In Proceedings of the 2016 International Conference on Applied Engineering, Materials and Mechanics (ICAEMM 2016), Weihai, China, 15–17 January 2016. [Google Scholar]

- Karbasian, H.; Tekkaya, A.E. A review on hot stamping. J. Mater. Process. Tech. 2010, 210, 2103–2118. [Google Scholar] [CrossRef]

- Maider, M.; Garikoitz, A.; Anton, G.; Carlos, A. Effect of the martensitic transformation on the stamping force and cycle time of hot stamping parts. Metals 2018, 8, 385. [Google Scholar]

- Mulidrán, P.; Šiser, M.; Ján, S.; Spišák, E.; Sleziak, T. Numerical prediction of forming car body parts with emphasis on springback. Metals 2018, 8, 435. [Google Scholar] [CrossRef]

- Hall, J.N.; Fekete, J.R. Steels for Auto Bodies: A General Overview, 1st ed.; Cambridge Woodhead Publishing Press: Cambridge, UK, 2017; pp. 19–45. [Google Scholar]

- Zhou, M.L.; Wang, L.; Wang, Z.J.; Wang, Y.L.; Zhang, Y.S. Analysis of the design and mechanical performance about hot stamping power fitting products. Adv. Mater. Res. 2014, 1063, 272–275. [Google Scholar] [CrossRef]

- Chang, Y.; Meng, Z.H.; Ying, L.; Xiao-Dong, L.I.; Ning, M.A.; Ping, H.U. Influence of hot press forming techniques on properties of vehicle high strength steels. J. Iron Steel Res. 2011, 18, 59–63. [Google Scholar] [CrossRef]

- Yoon, S.H.; Kyu, J.C.; Gil, K.C. Effect on blank holding force on blank deformation at direct and indirect hot deep drawings of boron steel sheets. Metals 2018, 8, 574. [Google Scholar]

- Seung, H.L.; Jaewoong, P.; Kiyoung, P.; Dong, K.K.; Hyunwoo, L.; Daeho, Y.; Hongrae, P.; Jaeseung, K. A study on the cooling performance of newly developed slice die in the hot press forming process. Metals 2018, 8, 947. [Google Scholar]

- Hay, B.A.; Bourouga, B.; Dessain, C. Thermal contact resistance estimation at the blank/tool interface: Experimental approach to simulate the blank cooling during the hot stamping process. Int. J. Mater. Form. 2010, 3, 147–163. [Google Scholar]

- Abdulhay, B.; Bourouga, B.; Dessain, C.; Brun, G.; Wilsius, J. Development of estimation procedure of contact heat transfer coefficient at the part-tool interface in hot stamping process. Heat Transfer Eng. 2011, 32, 497–505. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, Y.S.; Tian, X.W.; Zhu, B.; Li, J. Thermal contact conductance estimation and experimental validation in hot stamping process. Sci. China Technol. Sci. 2012, 55, 1852–1857. [Google Scholar] [CrossRef]

- Zhu, B.; Zhang, Y.S.; Li, J.; Wang, H.; Ye, Z. Simulation research of hot stamping and phase transition of automotive high strength steel. Material. Res. Innov. 2015, 15, s426–s430. [Google Scholar] [CrossRef]

- Wang, Z.J.; Xu, Y.; Zhou, M.L.; Wang, Y.L.; Zhang, Y.S. Valuation method for effects of hot stamping parameters on tailored properties. Adv. Mater. Res. 2014, 1063, 202–206. [Google Scholar] [CrossRef]

- Gui, Z.X.; Zhang, Y.S.; Wang, Z.J. Simulation of lightweight B-pillar during hot stamping process with thermo-mechanical-metallurgical model. Stamping Techn. 2012, 37, 193–197. [Google Scholar]

- Lee, M.G.; Kim, S.J.; Han, H.N.; Jeong, W.C. Application of hot press forming process to manufacture an automotive part and its finite element analysis considering phase transformation plasticity. Int. J. Mech. Sci. 2009, 51, 888–898. [Google Scholar] [CrossRef]

- Bok, H.H.; Lee, M.G.; Pavlina, E.J.; Barlat, F.; Kim, H.D. Comparative study of the prediction of microstructure and mechanical properties for a hot-stamped B-pillar reinforcing part. Int. J. Mech. Sci. 2011, 53, 744–752. [Google Scholar] [CrossRef]

- Tang, B.; Wang, Q.; Wei, Z.; Meng, X.; Yuan, Z. FE simulation models for hot stamping an automobile component with tailor-welded high-strength steels. J. Mater. Eng. Perform. 2016, 25, 1709–1721. [Google Scholar] [CrossRef]

- Yanzhong, J.U.; Jiang, F.; Dehong, W.; Lili, M.; Shuzhen, Z. Ultimate bearing capacity analysis of safety pin based on nonlinear contact. Water Resour. Power 2012, 7, 173–175. [Google Scholar]

- DžUpon, M.; Falat, L.; Slota, J.; Hvizdoš, P. Failure analysis of overhead power line yoke connector. Engineering Fai. Anal. 2013, 33, 66–74. [Google Scholar] [CrossRef]

| Material | Density (kg/m3) | Modulus of Elasticity (GPa) | Poisson’s Ratio | Yield Strength (MPa) | Tensile Strength (MPa) | Tangent Modulus (GPa) |

|---|---|---|---|---|---|---|

| Fully martensitic boron steel | 7830 | 180 | 0.293 | 1100 | 1550 | 1.2 |

| C | Mn | B | P | S | Si | Cr | Ti | Ni |

|---|---|---|---|---|---|---|---|---|

| 0.23 | 1.2 | 0.0019 | 0.01 | 0.002 | 0.17 | 0.24 | 0.023 | 1.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, B.; Zhu, Z.; Jin, Y.; Wang, K.; Wang, Y.; Zhang, Y. Multilayered-Sheet Hot Stamping and Application in Electric-Power-Fitting Products. Metals 2019, 9, 215. https://doi.org/10.3390/met9020215

Zhu B, Zhu Z, Jin Y, Wang K, Wang Y, Zhang Y. Multilayered-Sheet Hot Stamping and Application in Electric-Power-Fitting Products. Metals. 2019; 9(2):215. https://doi.org/10.3390/met9020215

Chicago/Turabian StyleZhu, Bin, Zhoujie Zhu, Yongmin Jin, Kai Wang, Yilin Wang, and Yisheng Zhang. 2019. "Multilayered-Sheet Hot Stamping and Application in Electric-Power-Fitting Products" Metals 9, no. 2: 215. https://doi.org/10.3390/met9020215

APA StyleZhu, B., Zhu, Z., Jin, Y., Wang, K., Wang, Y., & Zhang, Y. (2019). Multilayered-Sheet Hot Stamping and Application in Electric-Power-Fitting Products. Metals, 9(2), 215. https://doi.org/10.3390/met9020215