Impact of Short-Range Clustering on the Multistage Work-Hardening Behavior in Cu–Ni Alloys

Abstract

1. Introduction

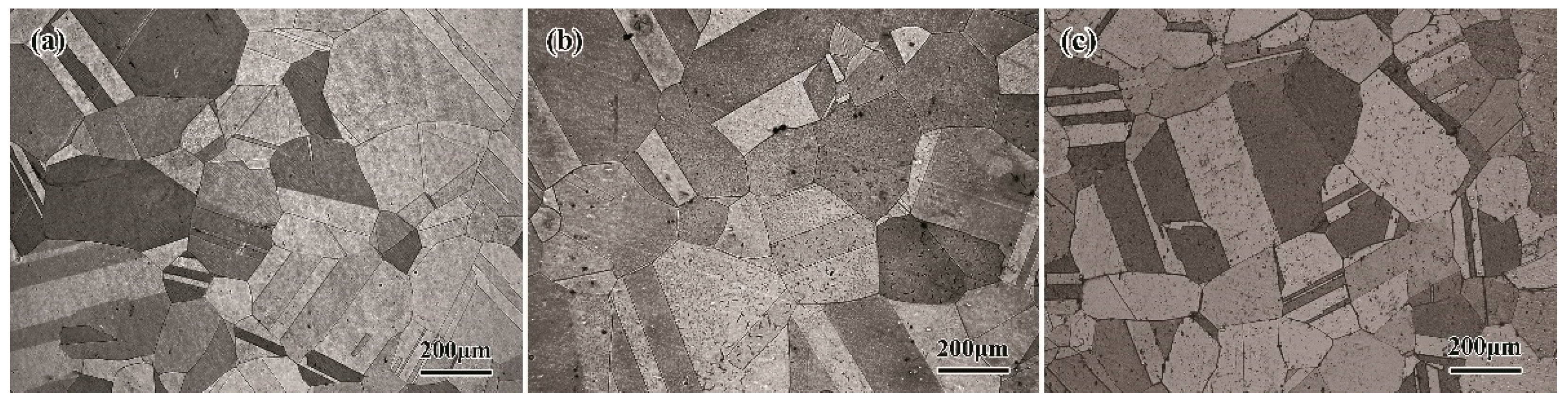

2. Materials and Methods

3. Results and Discussion

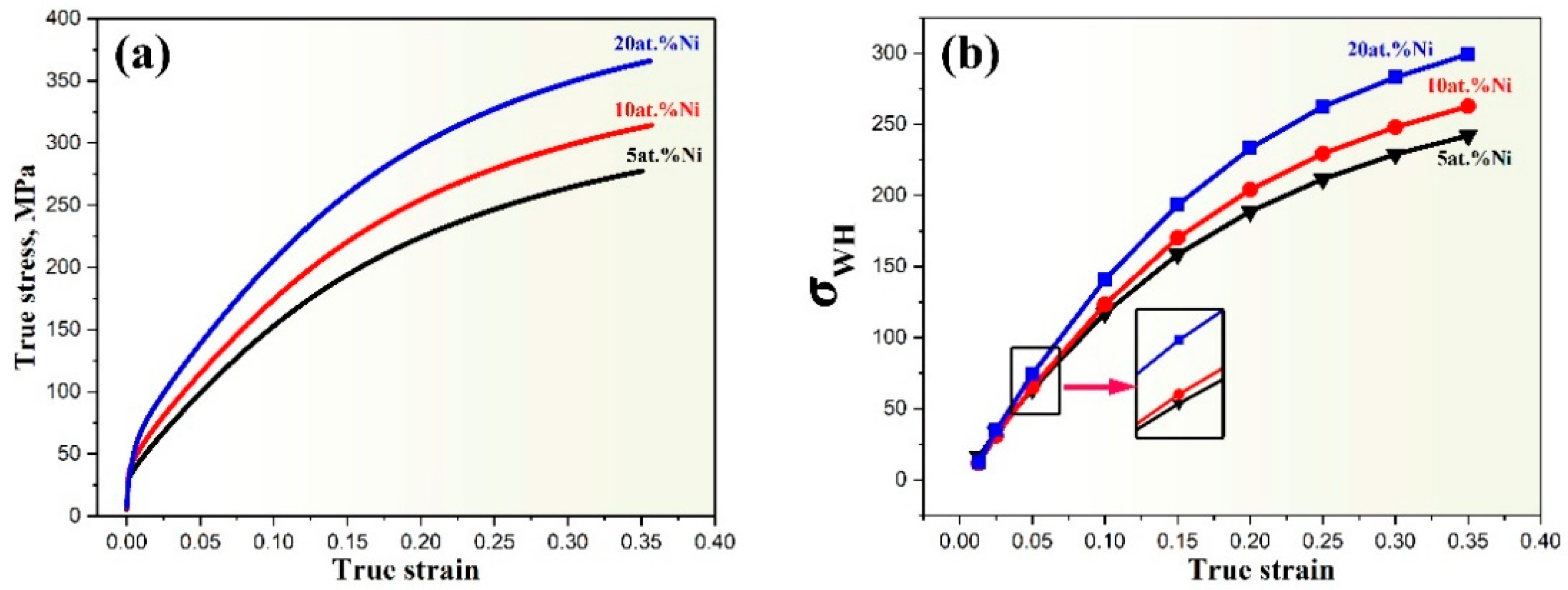

3.1. Compressive Mechanical Property

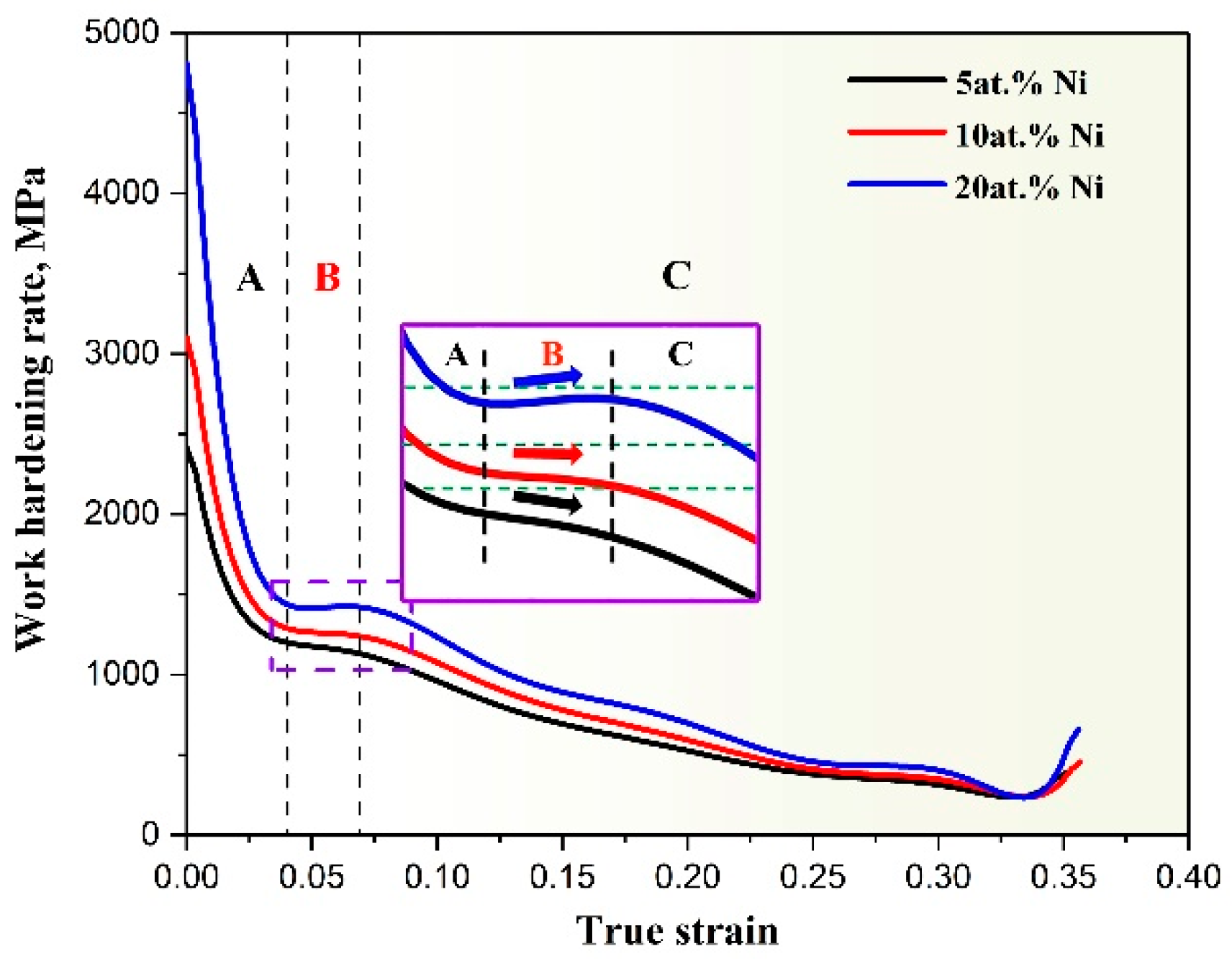

3.2. Unexpected Multistage Work-Hardening Behavior of Cu–Ni Alloys

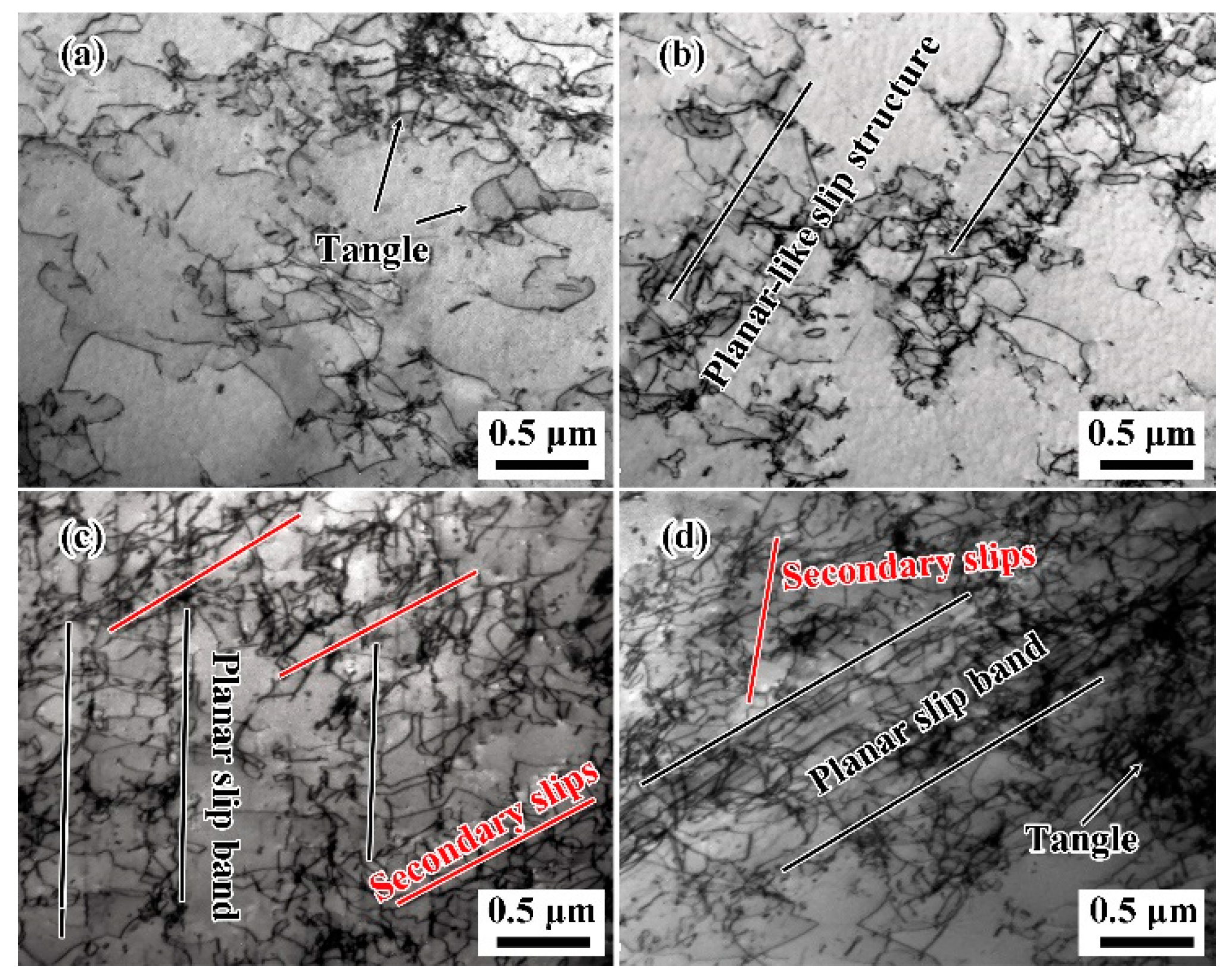

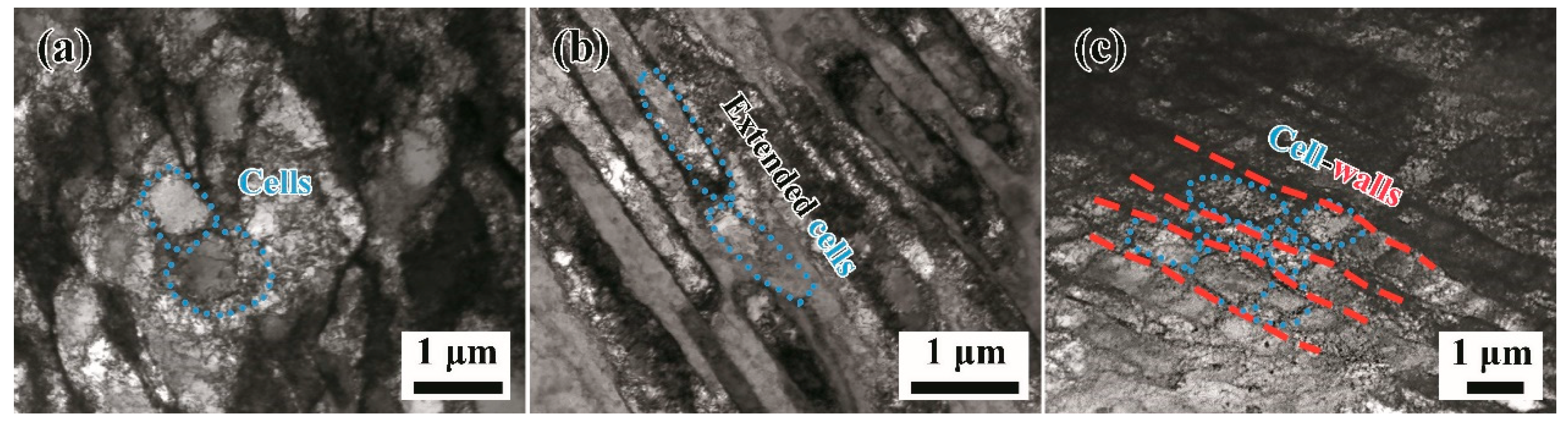

3.3. Microstructural Evolution

4. Conclusions

- (1)

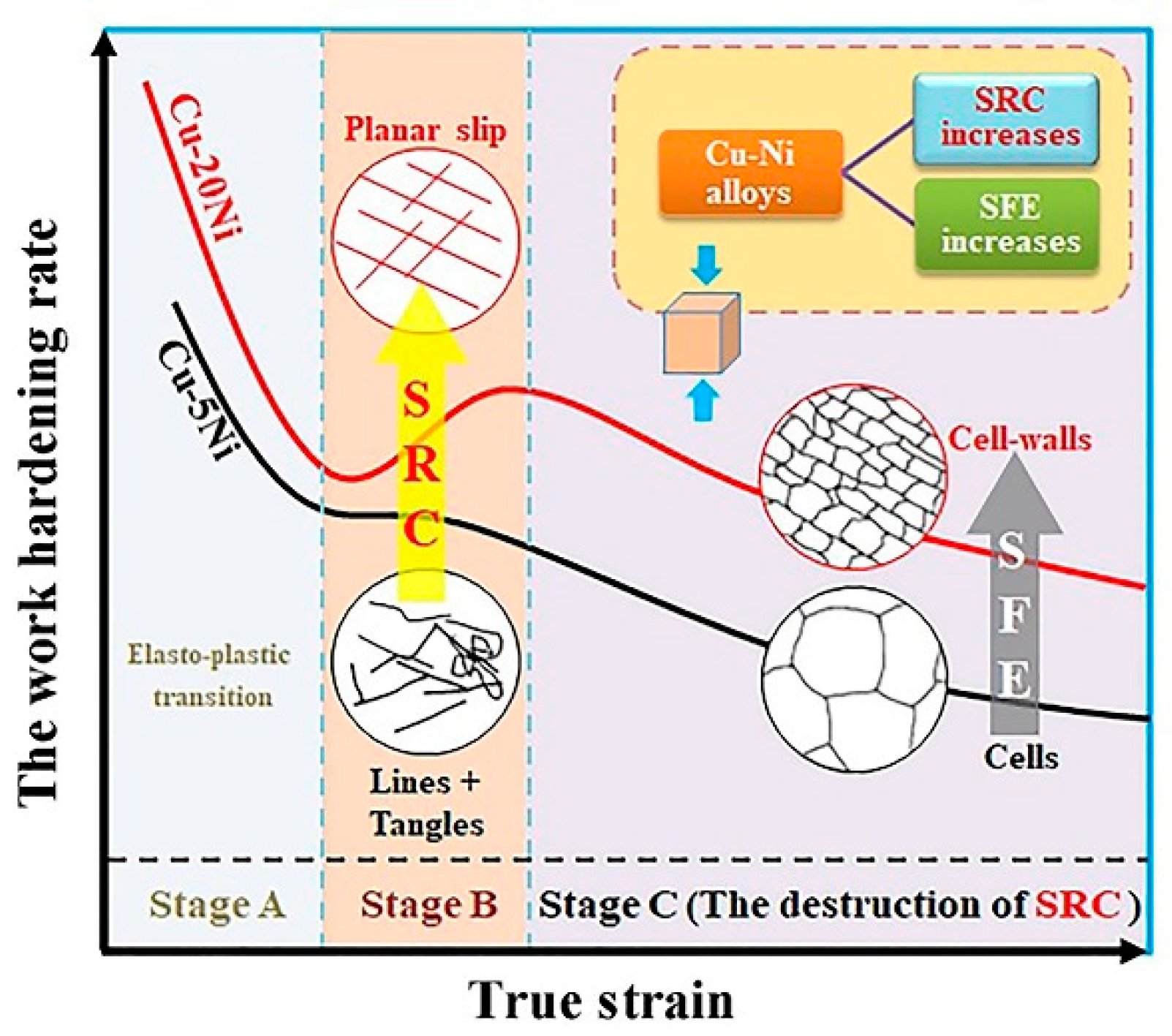

- An unexpected multistage (including Stages A, B, and C) work-hardening process was found in high-SFE Cu–Ni alloys. With the increase of Ni content (or SRC content), the flow stress of Cu–Ni alloys is significantly increased, which is mainly attributed to the improvement of work-hardening capacity.

- (2)

- The work-hardening behavior of Stage B strongly depends on the SRC content in Cu–Ni alloys. With increasing SRC content, a gradual transition of dislocation structures occurs from loose tangles to planar-slip structures, which effectively suppress dislocation cross slip and increase the density of movable dislocations during deformation. Consequently, a noticeable recovery of work-hardening rate was found in Stage B in the Cu–20at.% Ni alloy.

- (3)

- With increase of strain to Stage C, a second decrease of work-hardening rate was observed for all Cu–Ni alloys, ascribing to the prevalence of dislocation cross slip due to the overall destruction of SRC by moving dislocations. The oriented cell walls structures formed in the Cu–20at.% Ni alloy can, more or less, relieve the rate of dynamic recovery of dislocations, so that it still exhibits a higher work-hardening rate in this stage.

Author Contributions

Funding

Conflicts of Interest

References

- Rai, R.K.; Sahu, J.K. Strength-ductility paradox in a directionally solidified nickel base superalloy. Mater. Lett. 2018, 220, 90–93. [Google Scholar] [CrossRef]

- Nene, S.S.; Frank, M.; Liu, K.; Sinha, S.; Mishra, R.S.; McWilliams, B.; Cho, K.C. Reversed strength-ductility relationship in microstructurally flexible high entropy alloy. Scr. Mater. 2018, 154, 163–167. [Google Scholar] [CrossRef]

- Dang, B.; Zhang, X.; Chen, Y.Z.; Chen, C.X.; Wang, H.T.; Liu, F. Breaking through the strength-ductility trade-off dilemma in an Al-Si-based casting alloy. Sci. Rep. 2016, 6, 30874. [Google Scholar] [CrossRef] [PubMed]

- Tian, Y.Z.; Zhao, L.J.; Park, N.; Liu, R.; Zhang, P.; Zhang, Z.J.; Shibata, A.; Zhang, Z.F.; Tsuji, N. Revealing the deformation mechanisms of Cu-Al alloys with high strength and good ductility. Acta Mater. 2016, 110, 61–72. [Google Scholar] [CrossRef]

- Zhang, D.D.; Zhang, D.P.; Bu, F.Q.; Li, X.L.; Li, B.S.; Yan, T.L.; Guan, K.; Yang, Q.; Liu, X.J.; Meng, J. Excellent ductility and strong work hardening effect of as-cast Mg-Zn-Zr-Yb alloy at room temperature. J. Alloys Compd. 2017, 728, 404–412. [Google Scholar] [CrossRef]

- Cao, Z.H.; Sun, W.; Yang, X.B.; Zhao, J.W.; Ma, Y.J.; Meng, X.K. Intersectant coherent twin boundaries governed strong strain hardening behavior in nanocrystalline Cu. Int. J. Plasticity 2018, 103, 81–94. [Google Scholar] [CrossRef]

- Ning, J.L.; Xu, B.; Sun, M.S.; Zhao, C.Y.; Feng, Y.L.; Tong, W.P. Strain hardening and tensile behaviors of gradient structure mg alloys with different orientation relationships. Mater. Sci. Eng. A 2018, 735, 275–287. [Google Scholar] [CrossRef]

- Yang, X.C.; Ma, X.L.; Moering, J.; Zhou, H.; Wang, W.; Gong, Y.L.; Tao, J.M.; Zhu, Y.T.; Zhu, X.K. Influence of gradient structure volume fraction on the mechanical properties of pure copper. Mater. Sci. Eng. A 2015, 645, 280–285. [Google Scholar] [CrossRef]

- Yin, Z.; Yang, X.C.; Ma, X.L.; Moering, J.; Yang, J.; Gong, Y.L.; Zhu, Y.T.; Zhu, X.K. Strength and ductility of gradient structured copper obtained by surface mechanical attrition treatment. Mater. Des. 2016, 105, 89–95. [Google Scholar] [CrossRef]

- Wu, X.L.; Yang, M.X.; Yuan, F.P.; Chen, L.; Zhu, Y.T. Combining gradient structure and trip effect to produce austenite stainless steel with high strength and ductility. Acta Mater. 2016, 112, 337–346. [Google Scholar] [CrossRef]

- Qu, S.; An, X.H.; Yang, H.J.; Huang, C.X.; Yang, G.; Zang, Q.S.; Wang, Z.G.; Wu, S.D.; Zhang, Z.F. Microstructural evolution and mechanical properties of Cu-Al alloys subjected to equal channel angular pressing. Acta Mater. 2009, 57, 1586–1601. [Google Scholar] [CrossRef]

- Rohatgi, A.; Vecchio, K.S.; Gray, G.T., III. A metallographic and quantitative analysis of the influence of stacking fault energy on shock-hardening in Cu and Cu-Al alloys. Acta Mater. 2001, 49, 427–438. [Google Scholar] [CrossRef]

- Zhang, P.; An, X.H.; Zhang, Z.J.; Wu, S.D.; Li, S.X.; Zhang, Z.F.; Figueiredo, R.B.; Gao, N.; Langdon, T.G. Optimizing strength and ductility of Cu-Zn alloys through severe plastic deformation. Scr. Mater. 2012, 67, 871–874. [Google Scholar] [CrossRef]

- Asgari, S.; El-Danaf, E.; Kalidindi, S.R.; Doherty, R.D. Strain hardening regimes and microstructural evolution during large strain compression of low stacking fault energy FCC alloys that form deformation twins. Metall. Mater. Trans. A 1997, 28, 1781–1795. [Google Scholar] [CrossRef]

- Gong, Y.L.; Wen, C.E.; Wu, X.X.; Ren, S.Y.; Cheng, L.P.; Zhu, X.K. The influence of strain rate, deformation temperature and stacking fault energy on the mechanical properties of Cu alloys. Mater. Sci. Eng. A 2013, 583, 199–204. [Google Scholar] [CrossRef]

- Kocks, U.F.; Mecking, H. Physics and phenomenology of strain hardening: The FCC case. Prog. Mater. Sci. 2003, 48, 171–273. [Google Scholar] [CrossRef]

- Nakajima, K.; Numakura, K. Effect of solute atoms on stacking faults Cu-Ni and Cu-Mn systems. Philos. Mag. A 1965, 12, 361–368. [Google Scholar] [CrossRef]

- Lu, S.; Hu, Q.M.; Delczeg-Czirjak, E.K.; Johansson, B.; Vitos, L. Determining the minimum grain size in severe plastic deformation process via first-principles calculations. Acta Mater. 2012, 60, 4506–4513. [Google Scholar] [CrossRef]

- Nakano, J.; Jacques, P.J. Effects of the thermodynamic parameters of the hcp phase on the stacking fault energy calculations in the Fe-Mn and Fe-Mn-C systems. Calphad 2010, 34, 167–175. [Google Scholar] [CrossRef]

- Karnthaler, H.P.; Schügerl, B. Dislocation structures in plastically deformed, disordered Ni3Fe. In Strength of Metals and Alloys, Proceedings of the 5th International Conference, Aachen, GER, 27–31 August 1979; Haasen, P., Gerold, V., Kostorz, G., Eds.; Pergamon Press: Oxford, UK, 1979; pp. 205–210. [Google Scholar]

- Gerold, V.; Karnthaler, H.P. On the origin of planar slip in f.c.c. alloys. Acta Metall. 1989, 37, 2177–2183. [Google Scholar] [CrossRef]

- Han, D.; Wang, Z.Y.; Yan, Y.; Shi, F.; Li, X.W. A good strength-ductility match in Cu-Mn alloys with high stacking fault energies: Determinant effect of short range ordering. Scr. Mater. 2017, 133, 59–64. [Google Scholar] [CrossRef]

- Hong, H.L.; Wang, Q.; Dong, C. Composition formulas of Cu-Ni industrial alloy specifications. Sci. China Mater. 2015, 58, 355–362. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Han, D.; Li, X.W. Competitive effect of stacking fault energy and short-range clustering on the plastic deformation behavior of Cu-Ni alloys. Mater. Sci. Eng. A 2017, 679, 484–492. [Google Scholar] [CrossRef]

- Taylor, G.I. The mechanism of plastic deformation of crystals. Part Ⅰ.—Theoretical. Proc. R. Soc. Lond. 1934, 145, 362–387. [Google Scholar] [CrossRef]

- Li, P.; Li, S.X.; Wang, Z.G.; Zhang, Z.F. Fundamental factors on formation mechanism of dislocation arrangements in cyclically deformed FCC single crystals. Prog. Mater. Sci. 2011, 56, 328–377. [Google Scholar] [CrossRef]

- Argon, A.S.; Haasen, P. A new mechanism of work hardening in the late stages of large strain plastic flow in F.C.C. and diamond cubic crystals. Acta Metall. Mater. 1993, 41, 3289–3306. [Google Scholar] [CrossRef]

- Pfeiler, W. Investigation of short-range order by electrical resistivity measurement. Acta Metall. 1988, 36, 2417–2434. [Google Scholar] [CrossRef]

- Perrier, J.P.; Tissier, B.; Tournier, R. Nearest-neighbor model of magnetism for copper-nickel alloys and clustering of magnetic moments. Phys. Rev. Lett. 1970, 24, 313–316. [Google Scholar] [CrossRef]

- Hamdi, F.; Asgari, S. Influence of stacking fault energy and short-range ordering on dynamic recovery and work hardening behavior of copper alloys. Scr. Mater. 2010, 62, 693–696. [Google Scholar] [CrossRef]

- Mittra, J.; Dubey, J.S.; Kulkarni, U.D.; Dey, G.K. Role of dislocation density in raising the stage Ⅱ work-hardening rate of alloy 625. Mater. Sci. Eng. A 2009, 512, 87–91. [Google Scholar] [CrossRef]

- Kula, A.; Jia, X.; Mishra, R.K.; Niewczas, M. Flow stress and work hardening of Mg-Y alloys. Int. J. Plasticity 2017, 92, 96–121. [Google Scholar] [CrossRef]

- Tian, Y.Z.; Zhao, L.J.; Chen, S.; Shibata, A.; Zhang, Z.F.; Tsuji, N. Significant contribution of stacking faults to the strain hardening behavior of Cu-15% Al alloy with different grain sizes. Sci. Rep. 2015, 5, 16707. [Google Scholar] [CrossRef] [PubMed]

- Hamdi, F.; Asgari, S. Evaluation of the role of deformation twinning in work hardening behavior of face-centered-cubic polycrystals. Metall. Mater. Trans. A 2008, 39, 294–303. [Google Scholar] [CrossRef]

- Liu, T.T.; Pan, F.S.; Zhang, X.Y. Effect of Sc addition on the work-hardening behavior of ZK60 magnesium alloy. Mater. Des. 2013, 43, 572–577. [Google Scholar] [CrossRef]

- Wang, Z.R.; Gong, B.; Wang, Z.G. Cyclic deformation behavior of Cu-30wt% Zn single crystals oriented for single slip-I. Cyclic deformation response and slip band behavior. Acta Mater. 1998, 47, 307–315. [Google Scholar] [CrossRef]

- Niewczas, M. Latent hardening effects in low cycle fatigue of copper single crystals. Philos. Mag. 2013, 93, 272–303. [Google Scholar] [CrossRef]

- Li, X.W.; Wang, X.M.; Yan, Y.; Guo, W.W.; Qi, C.J. Effect of pre-fatigue on the monotonic deformation behavior of a coplanar double-slip-oriented Cu single crystal. Metals 2016, 6, 293. [Google Scholar] [CrossRef]

- Ma, X.G.; Chen, J.; Liu, Y.Z.; Wang, X.H.; Huang, S.Y.; Chen, Z. Effect of short-range order on microstructure, texture and strain hardening of cold drawn Cu-10at.% Mn alloy. Mater. Charact. 2018, 135, 32–39. [Google Scholar] [CrossRef]

- Gutierrez-Urrutia, I.; Raabe, D. Dislocation and twin substructure evolution during strain hardening of an Fe-22wt.% Mn-0.6wt.% C TWIP steel observed by electron channeling contrast imaging. Acta Mater. 2011, 59, 6449–6462. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, D.; He, J.-X.; Guan, X.-J.; Zhang, Y.-J.; Li, X.-W. Impact of Short-Range Clustering on the Multistage Work-Hardening Behavior in Cu–Ni Alloys. Metals 2019, 9, 151. https://doi.org/10.3390/met9020151

Han D, He J-X, Guan X-J, Zhang Y-J, Li X-W. Impact of Short-Range Clustering on the Multistage Work-Hardening Behavior in Cu–Ni Alloys. Metals. 2019; 9(2):151. https://doi.org/10.3390/met9020151

Chicago/Turabian StyleHan, Dong, Jin-Xian He, Xian-Jun Guan, Yan-Jie Zhang, and Xiao-Wu Li. 2019. "Impact of Short-Range Clustering on the Multistage Work-Hardening Behavior in Cu–Ni Alloys" Metals 9, no. 2: 151. https://doi.org/10.3390/met9020151

APA StyleHan, D., He, J.-X., Guan, X.-J., Zhang, Y.-J., & Li, X.-W. (2019). Impact of Short-Range Clustering on the Multistage Work-Hardening Behavior in Cu–Ni Alloys. Metals, 9(2), 151. https://doi.org/10.3390/met9020151