Inconel 625/TiB2 Metal Matrix Composites by Direct Laser Deposition

Abstract

1. Introduction

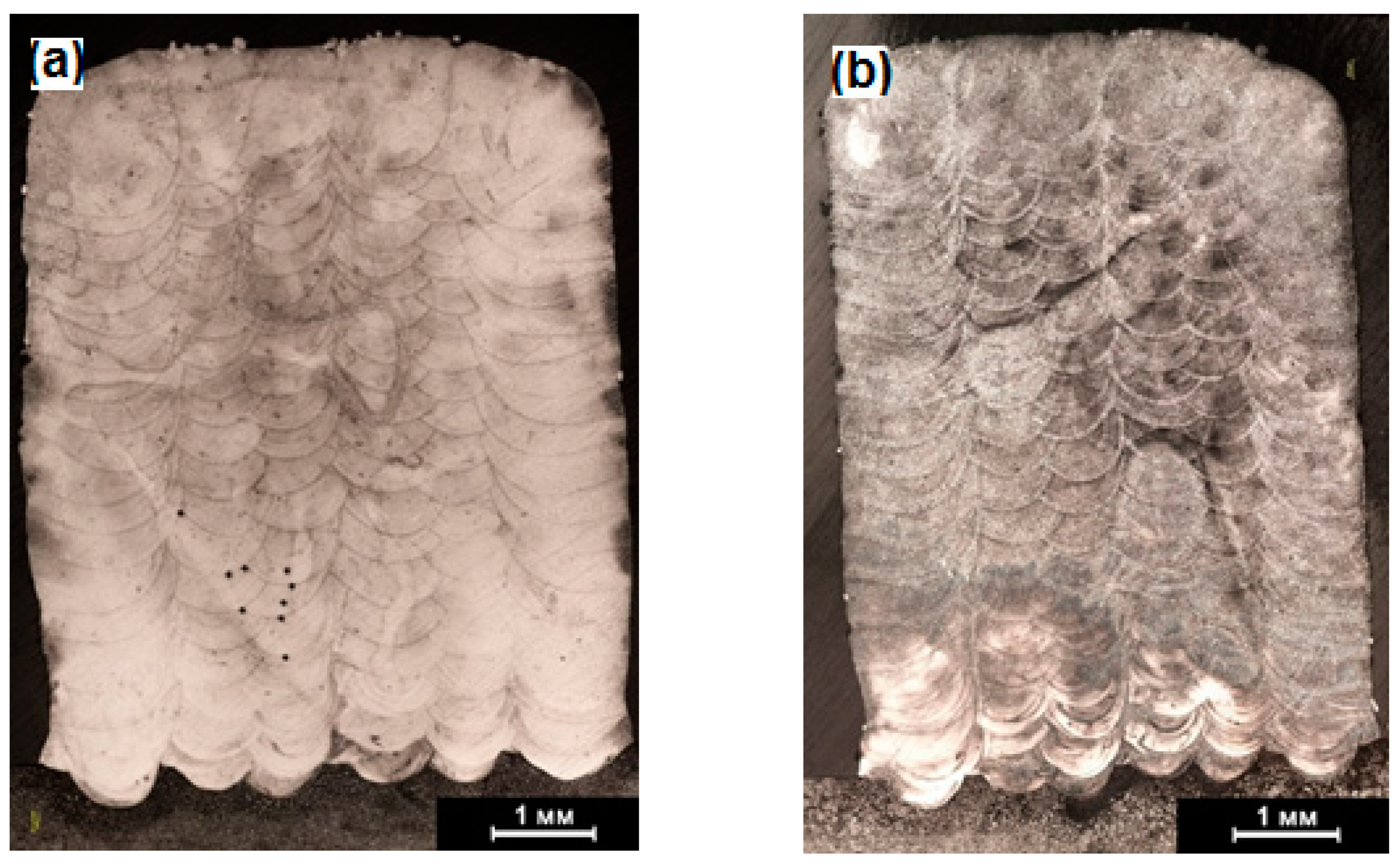

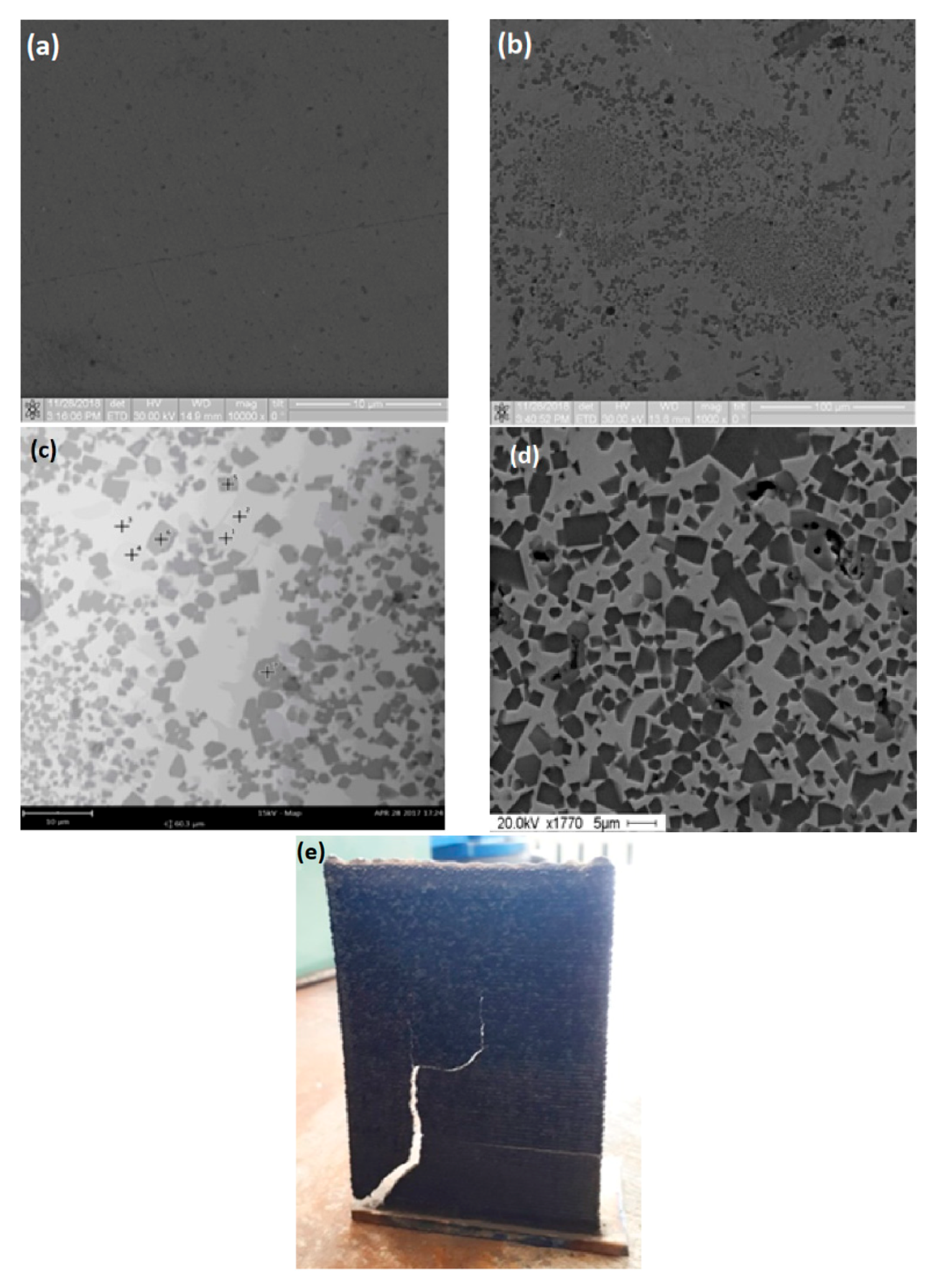

2. Experiment Details

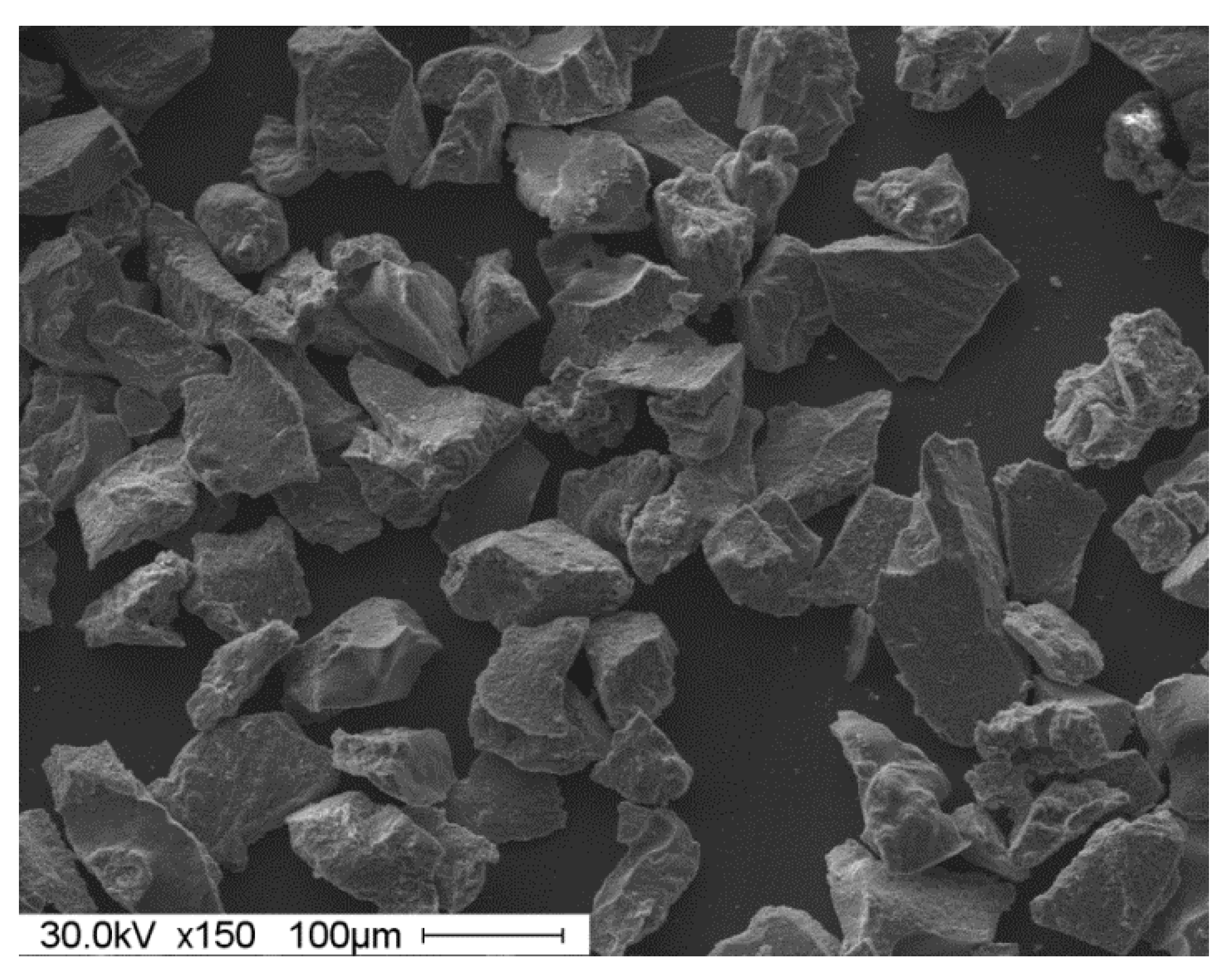

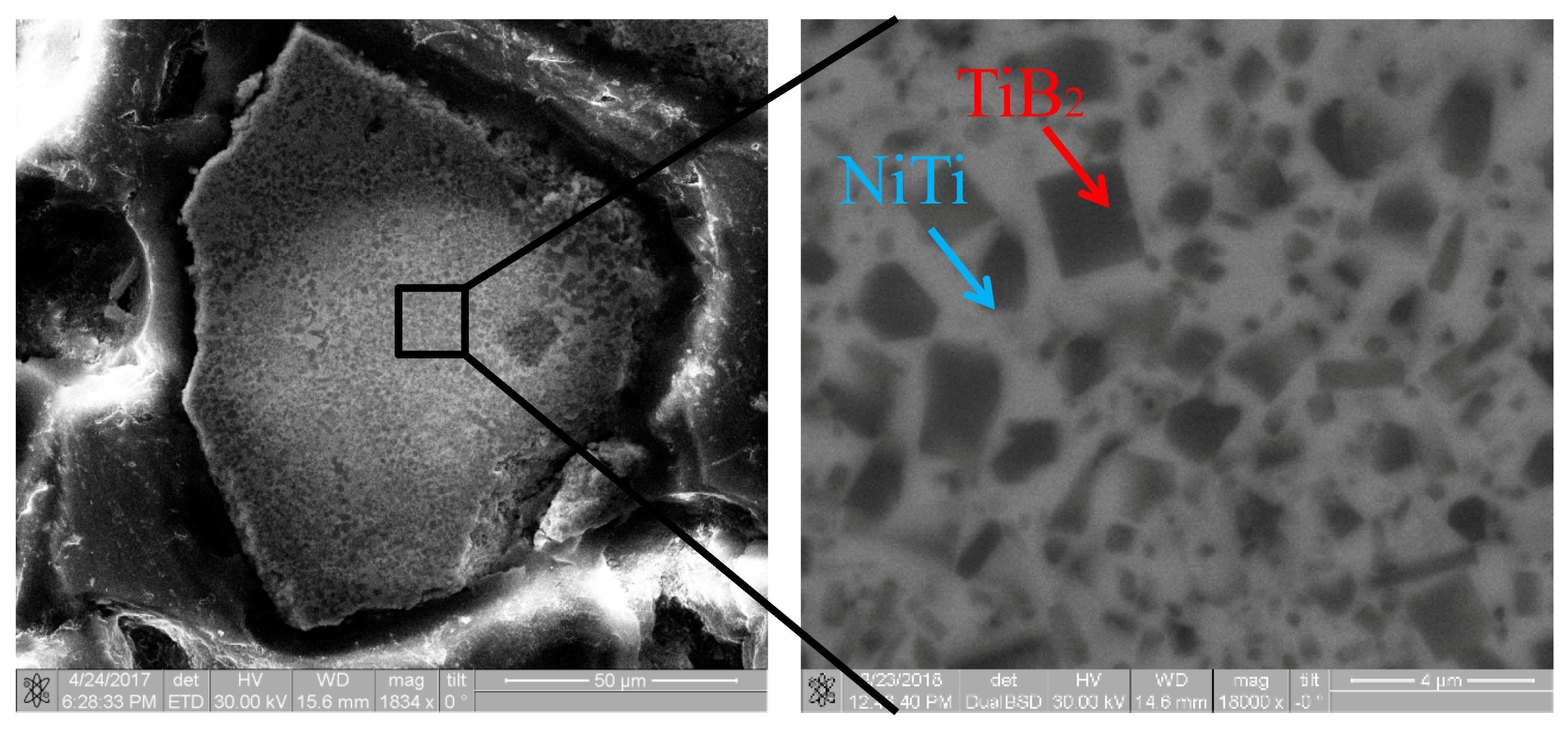

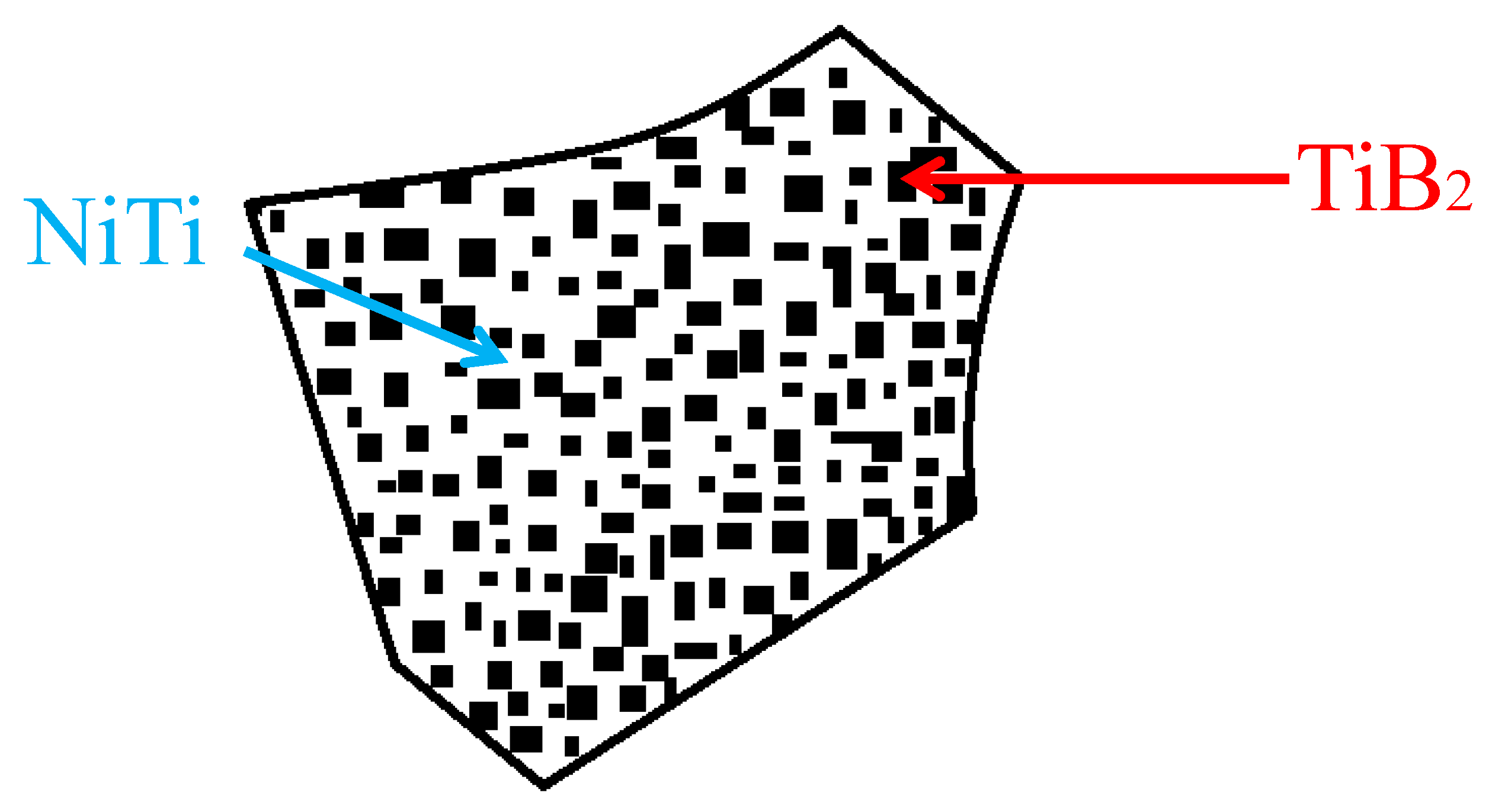

2.1. Powder Preparation

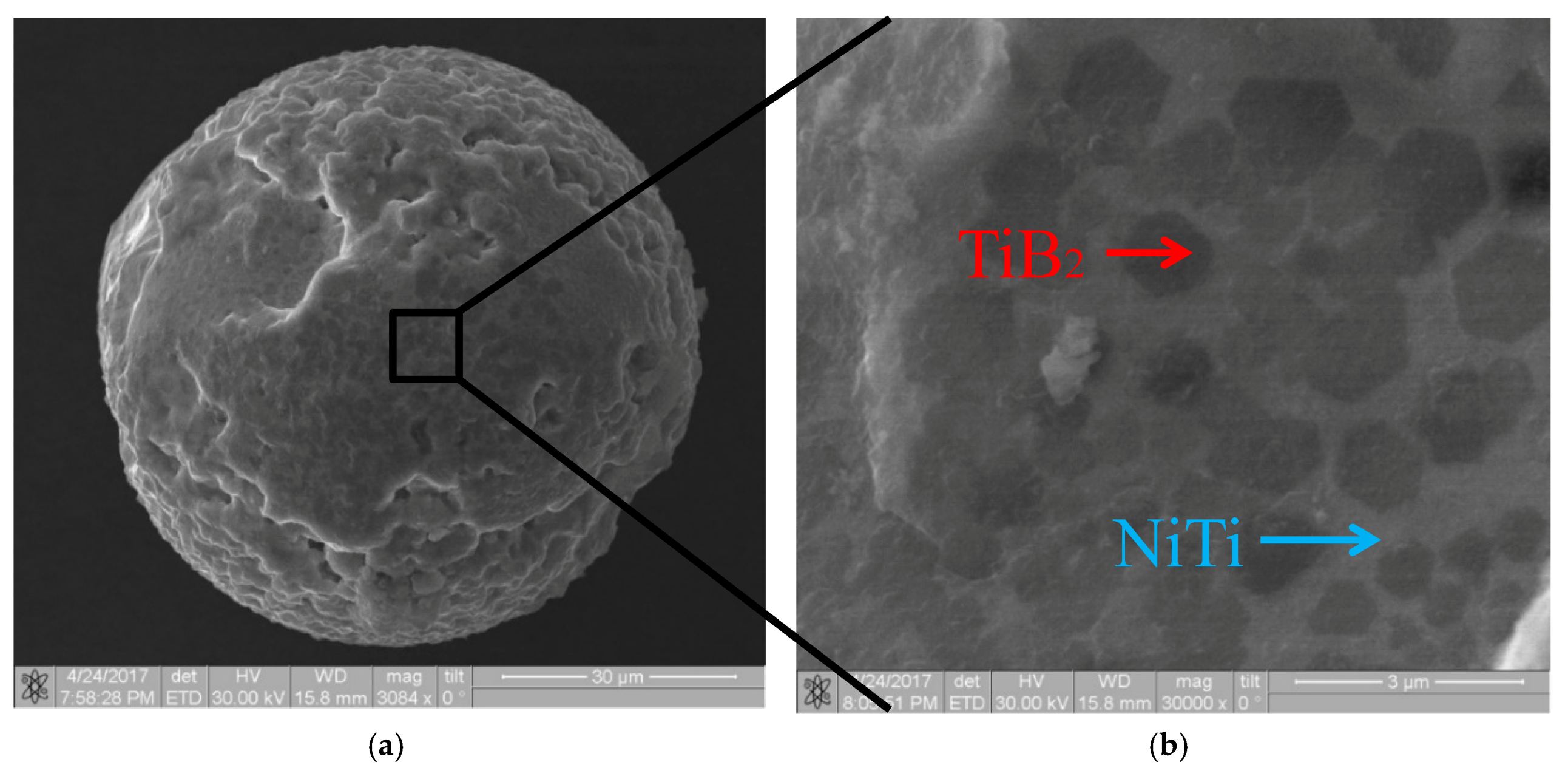

2.2. Plasma Spheroidization Technology

2.3. DLD Process

3. Results and Discussion

4. Conclusions

- (1)

- The most promising technique lies in introducing the obtained metal matrix composites in the amount of less than 5 wt% into the metal matrix. This conclusion is based on a more even distribution of ceramic particles in the metal matrix. Apparently, several strengthening mechanisms can be simultaneously realized for such a distribution of particles; namely, dislocation and dispersion strengthening [47].

- (2)

- When the content of titanium diboride particles in the metal matrix is over 70 wt%, the powders cannot be used with laser deposition technologies. That is because the samples destruct, due to high internal stresses and brittle fracturing.

- (3)

- In the opinion of the authors of the present research, composite ceramic metal powders produced by SHS can demonstrate rather good efficiency if introduced into liquid metal, and then the melt must be atomized to obtain composite powders for additive manufacturing technologies.

Author Contributions

Funding

Conflicts of Interest

References

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Murr, L.E.; Gaytan, S.M.; Ramirez, D.A.; Martinez, E.; Hernandez, J.; Amato, K.N.; Shindo, P.W.; Medina, F.R.; Wicker, R.B. Metal fabrication by additive manufacturing using laser and electron beam melting technologies. J. Mater. Sci. Technol. 2012, 28, 1–14. [Google Scholar] [CrossRef]

- Sedlaka, J.; Rican, D. Study of Materials Produced by Powder Metallurgy Using Classical and Modern Additive Laser Technology. Procedia Eng. 2015, 100, 1232–1241. [Google Scholar] [CrossRef]

- Lyons, B. Additive manufacturing in aerospace: Examples and research outlook. Bridge 2014, 44, 13–19. [Google Scholar]

- Guo, N.; Leu, M.C. Additive manufacturing: Technology, applications and research needs. Front. Mech. Eng. 2013, 8, 215–243. [Google Scholar] [CrossRef]

- Mueller, B. Additive manufacturing technologies—Rapid prototyping to direct digital manufacturing. Assem. Autom. 2012, 32. [Google Scholar] [CrossRef]

- Uriondo, A.; Esperon-Miguez, M.; Perinpanayagam, S. The present and future of additive manufacturing in the aerospace sector: A review of important aspects. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2015, 229, 2132–2147. [Google Scholar] [CrossRef]

- Khajavi, S.H.; Partanen, J.; Holmström, J. Additive manufacturing in the spare parts supply chain. Comput. Ind. 2014, 65, 50–63. [Google Scholar] [CrossRef]

- Baufeld, B.; Van der Biest, O.; Gault, R. Additive manufacturing of Ti–6Al–4V components by shaped metal deposition: Microstructure and mechanical properties. Mater. Des. 2010, 31, 106–111. [Google Scholar] [CrossRef]

- Jia, Q.; Gu, D. Selective laser melting additive manufacturing of Inconel 718 superalloy parts: Densification, microstructure and properties. J. Alloys Compd. 2014, 585, 713–721. [Google Scholar] [CrossRef]

- Lewandowski, J.J.; Seifi, M. Metal additive manufacturing: A review of mechanical properties. Annu. Rev. Mater. Res. 2016, 46, 151–186. [Google Scholar] [CrossRef]

- Campoli, G.; Borleffs, M.S.; Amin Yavari, S.; Wauthle, R.; Weinans, H.; Zadpoor, A.A. Mechanical properties of open-cell metallic biomaterials manufactured using additive manufacturing. Mater. Des. 2013, 49, 957–965. [Google Scholar] [CrossRef]

- Bertsch, A.; Jiguet, S.; Renaud, P.J. Microfabrication of ceramic components by microstereolithography. Micromech. Microeng. 2004, 14, 197–203. [Google Scholar] [CrossRef]

- Zocca, A.; Colombo, P.; Gomes, C.M.; Günster, J. Additive manufacturing of ceramics: Issues, potentialities, and opportunities. J. Am. Ceram. Soc. 2015, 98, 1983–2001. [Google Scholar] [CrossRef]

- Promakhov, V.; Zhukov, A.; Dubkova, Y.; Zhukov, I.; Kovalchuk, S.; Zhukova, T.; Olisov, O.; Klimenko, V.; Savkina, N. Structure and Properties of ZrO2–20% Al2O3 Ceramic Composites Obtained Using Additive Technologies. Materials 2018, 11, 2361. [Google Scholar] [CrossRef] [PubMed]

- Carroll, B.E.; Palmer, T.A.; Beese, A.M. Anisotropic tensile behavior of Ti–6Al–4V components fabricated with directed energy deposition additive manufacturing. Acta Mater. 2015, 87, 309–320. [Google Scholar] [CrossRef]

- Barekat, M.; Shoja Razavi, R.; Ghasemi, A. Nd: YAG laser cladding of Co–Cr–Mo alloy on γ-TiAl substrate. Opt. Laser Technol. 2016, 80, 145–152. [Google Scholar] [CrossRef]

- Moussaoui, K.; Rubio, W.; Mousseigne, M.; Sultan, T.; Rezai, F. Effects of Selective Laser Melting additive manufacturing parameters of Inconel 718 on porosity, microstructure and mechanical properties. Mater. Sci. Eng. A 2018, 735, 182–190. [Google Scholar] [CrossRef]

- Weng, Z.; Wang, A.; Wang, Y.; Xiong, D.; Tang, H. Diode laser cladding of Fe-based alloy on ductile cast iron and related interfacial behavior. Surf. Coat. Technol. 2016, 286, 64–71. [Google Scholar] [CrossRef]

- Hashim, J.; Looney, L.; Hashmi, M.S.J. Metal matrix composites: Production by the stir casting method. J. Mater. Process. Technol. 1999, 92, 1–7. [Google Scholar] [CrossRef]

- Tjong, S.C. Novel nanoparticle-reinforced metal matrix composites with enhanced mechanical properties. Adv. Eng. Mater. 2007, 9, 639–652. [Google Scholar] [CrossRef]

- Vorozhtsov, S.A.; Eskin, D.G.; Tamayo, J.; Vorozhtsov, A.B.; Promakhov, V.V.; Averin, A.A.; Khrustalyov, A.P. The Application of External Fields to the Manufacturing of Novel Dense Composite Master Alloys and Aluminum-Based Nanocomposites. Metall. Mater. Trans. A 2015, 46, 2870–2875. [Google Scholar] [CrossRef]

- Rawal, S.P. Metal-matrix composites for space applications. JOM 2001, 53, 14–17. [Google Scholar] [CrossRef]

- Alba-Baena, N.; Eskin, D. Kinetics of ultrasonic degassing of aluminum alloys. In Light Metals 2013; Minerals, Metals and Materials Series; Springer: Cham, Switzerland, 2016; pp. 957–962. [Google Scholar]

- Grandfield, J.; Eskin, D.G.; Bainbridge, I. Direct-Chill Casting of Light Alloys: Science and Technology; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Vorozhtsov, S.; Zhukov, I.; Promakhov, V.; Naydenkin, E.; Khrustalyov, A.; Vorozhtsov, A. The Influence of ScF3 Nanoparticles on the Physical and Mechanical Properties of New Metal Matrix Composites Based on A356 Aluminum Alloy. JOM 2016, 68, 3101–3106. [Google Scholar] [CrossRef]

- Martin, J.H.; Yahata, B.D.; Hundley, J.M.; Mayer, J.A.; Schaedler, T.A.; Pollock, T.M. 3D printing of high-strength aluminium alloys. Nature 2017, 549, 365. [Google Scholar] [CrossRef]

- Zhang, B.; Bi, G.; Nai, S.; Sun, C.N.; Wei, J. Microhardness and microsructure evolution of TiB2 reinficed Inconel 625/TiB2 composite produced by selective laser melting. Opt. Laser Technol. 2016, 80, 186–195. [Google Scholar] [CrossRef]

- Vorozhtsov, S.; Zhukov, I.; Vorozhtsov, A.; Zhukov, A.; Eskin, D.; Kvetinskaya, A. Synthesis of micro-and nanoparticles of metal oxides and their application for reinforcement of Al-based alloys. Adv. Mater. Sci. Eng. 2015, 2015, 718207. [Google Scholar] [CrossRef]

- Nikhilesh, C.; Shen, Y.-L. Mechanical behavior of particle reinforced metal matrix composites. Adv. Eng. Mater. 2001, 3, 357–370. [Google Scholar]

- Casati, R.; Vedani, M. Metal matrix composites reinforced by nano-particles—A review. Metals 2014, 4, 65–83. [Google Scholar] [CrossRef]

- Tong, J.B.; Lu, X.; Liu, C.C.; Wang, L.N.; Qu, X.H. Compact Process for the Preparation of Microfine Spherical High-Niobium-Containing TiAl Alloy Powders. JOM 2015, 67, 573–579. [Google Scholar] [CrossRef]

- Schmidt, J.; Boehling, M.; Burkhardt, U.; Grin, Y. Preparation of titanium diboride TiB2 by spark plasma sintering at slow heating rate. Sci. Technol. Adv. Mater. 2007, 8, 376–382. [Google Scholar] [CrossRef]

- Schmidt, J.; Boehling, M.; Burkhardt, U.; Grin, Y. Micromechanism in self-lubrication of TiB2/Al composite. ACS Appl. Mater. Interfaces 2015, 7, 12688–12694. [Google Scholar]

- Basu, B.; Raju, G.B.; Suri, A.K. Processing and properties of monolithic TiB2 based materials. Int. Mater. Rev. 2016, 51, 352–374. [Google Scholar] [CrossRef]

- Merzhanov, A.G. Self-propagating high-temperature synthesis: Twenty years of search and findings. Combust. Plasma Synth. High-Temp. Mater. 1990, 225, 83–90. [Google Scholar]

- Yi, H.C.; Moore, J.J. Self-propagating high-temperature (combustion) synthesis (SHS) of powder-compacted materials. J. Mater. Sci. 1990, 25, 1159–1168. [Google Scholar] [CrossRef]

- King, W.E. Laser powder bed fusion additive manufacturing of metals; physics, computational, and materials challenges. Appl. Phys. Rev. 2015, 2, 041304. [Google Scholar] [CrossRef]

- Shanmugavelayutham, G.; Selvarajan, V. Plasma spheroidization of nickel powders in a plasma reactor. Bull. Mater. Sci. 2004, 27, 453–457. [Google Scholar] [CrossRef]

- Gomez, E.; Rani, D.A.; Cheeseman, C.R.; Deegan, D.; Wise, M.; Boccaccin, A.R. Thermal plasma technology for the treatment of wastes: A critical review. J. Hazard. Mater. 2009, 161, 614–626. [Google Scholar] [CrossRef] [PubMed]

- Károly, Z.; Szépvölgyi, J. Plasma spheroidization of ceramic particles. Chem. Eng. Process. Process Intensif. 2015, 44, 221–224. [Google Scholar] [CrossRef]

- Chaturvedi, V.; Ananthapadmanabhan, P.V.; Chakravarthy, Y.; Bhandari, S.; Tiwari, N.; Pragatheeswaran, A.; Das, A.K. Thermal plasma spheroidization of aluminum oxide and characterization of the spheroidized alumina powder. Ceram. Int. 2014, 40, 8273–8279. [Google Scholar] [CrossRef]

- Turichin, G.A.; Klimova, O.G.; Zemlyakov, E.V.; Babkin, K.D.; Kolodyazhnyy, D.Y.; Shamray, F.A.; Travyanov, A.Y.; Petrovskiy, P.V. Technological aspects of high speed direct laser deposition based on heterophase powder metallurgy. Phys. Procedia 2015, 78, 397–406. [Google Scholar] [CrossRef]

- Turichin, G.A.; Somonov, V.V.; Klimova, O.G. Investigation and modeling of the process of formation of the pad weld and its microstructure during laser cladding by radiation of high power fiber laser. Appl. Mech. Mater. 2014, 682, 160–165. [Google Scholar] [CrossRef]

- Dinda, G.P.; Dasgupta, A.K.; Mazumder, J. Laser aided direct metal deposition of Inconel 625 superalloy: Microstructural evolution and thermal stability. Mater. Sci. Eng. A 2009, 509, 98–104. [Google Scholar] [CrossRef]

- Bakeev, R.A.; Makarov, P.V.; Pereskin, A.Y.; Promakhov, V.V.; Zhukov, A.S.; Klimova-Korsmik, O.G. Experimental and numerical study of the mechanical properties and features of the deformation and destruction of the metal-ceramic composite TiNi–TiB2, obtained by direct laser growth. Phys. Mesomech. 2018, 21, 56–66. [Google Scholar]

- Lorusso, M.; Aversa, A.; Manfredi, D.; Calignano, F.; Ambrosio, E.P.; Ugues, D.; Pavese, M. Tribological behavior of aluminum alloy AlSi10Mg-TiB2 composites produced by direct metal laser sintering (DMLS). J. Mater. Eng. Perform. 2016, 25, 3152–3190. [Google Scholar] [CrossRef]

| Laser Beam Diameter in the Treatment Zone, mm (D) | Power, W (P) | Edge Layers Deposition Rate, mm/s (Vk) | Intermittent Layers Deposition Rate, mm/s (Vz) | Powder Flow Rate, g/min (G) | X Offset, mm (ΔX) | Z Offset, mm (ΔZ) |

|---|---|---|---|---|---|---|

| 1.5–2.4 | 500–1400 | 10–15 | 15–25 | 5.1–25 | 0.7–1.6 | 0.2–0.8 |

| Laser Beam Diameter in the Treatment Zone, mm (D) | Power, W (P) | Edge Layers Claddingrate, mm/s (Vk) | Intermittent Layers Claddingrate, mm/s (Vz) | Powder Flow Rate, g/min (G) | X Offset, mm (ΔX) | Z Offset, mm (ΔZ) |

|---|---|---|---|---|---|---|

| 2.1 | 1000 | 15 | 25 | 23 | 1.4 | 0.6 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Promakhov, V.; Zhukov, A.; Ziatdinov, M.; Zhukov, I.; Schulz, N.; Kovalchuk, S.; Dubkova, Y.; Korsmik, R.; Klimova-Korsmik, O.; Turichin, G.; et al. Inconel 625/TiB2 Metal Matrix Composites by Direct Laser Deposition. Metals 2019, 9, 141. https://doi.org/10.3390/met9020141

Promakhov V, Zhukov A, Ziatdinov M, Zhukov I, Schulz N, Kovalchuk S, Dubkova Y, Korsmik R, Klimova-Korsmik O, Turichin G, et al. Inconel 625/TiB2 Metal Matrix Composites by Direct Laser Deposition. Metals. 2019; 9(2):141. https://doi.org/10.3390/met9020141

Chicago/Turabian StylePromakhov, Vladimir, Alexander Zhukov, Mansur Ziatdinov, Ilya Zhukov, Nikita Schulz, Sergey Kovalchuk, Yana Dubkova, Rudolf Korsmik, Olga Klimova-Korsmik, Gleb Turichin, and et al. 2019. "Inconel 625/TiB2 Metal Matrix Composites by Direct Laser Deposition" Metals 9, no. 2: 141. https://doi.org/10.3390/met9020141

APA StylePromakhov, V., Zhukov, A., Ziatdinov, M., Zhukov, I., Schulz, N., Kovalchuk, S., Dubkova, Y., Korsmik, R., Klimova-Korsmik, O., Turichin, G., & Perminov, A. (2019). Inconel 625/TiB2 Metal Matrix Composites by Direct Laser Deposition. Metals, 9(2), 141. https://doi.org/10.3390/met9020141