Material Characterization, Thermal Analysis, and Mechanical Performance of a Laser-Polished Ti Alloy Prepared by Selective Laser Melting

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussions

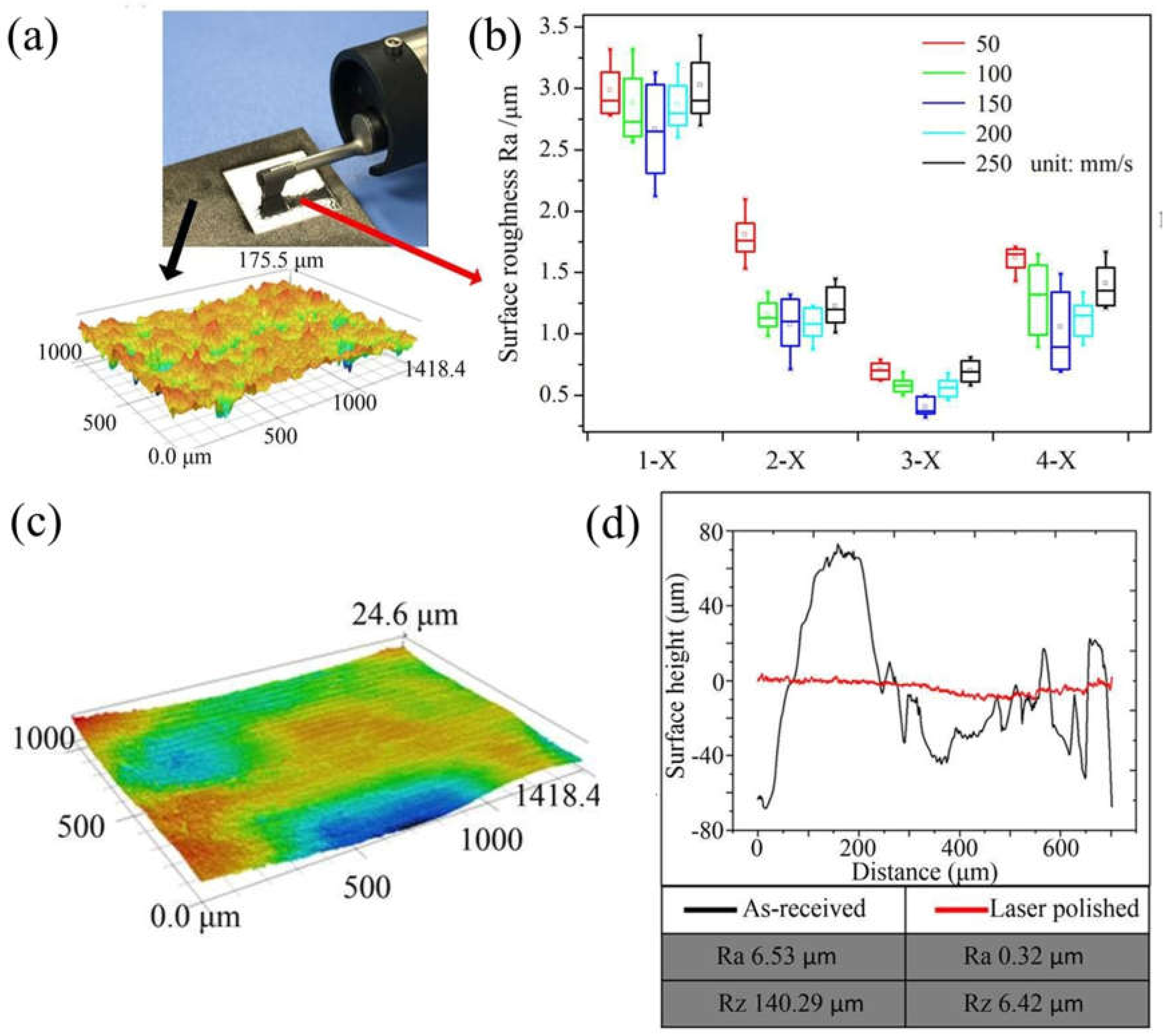

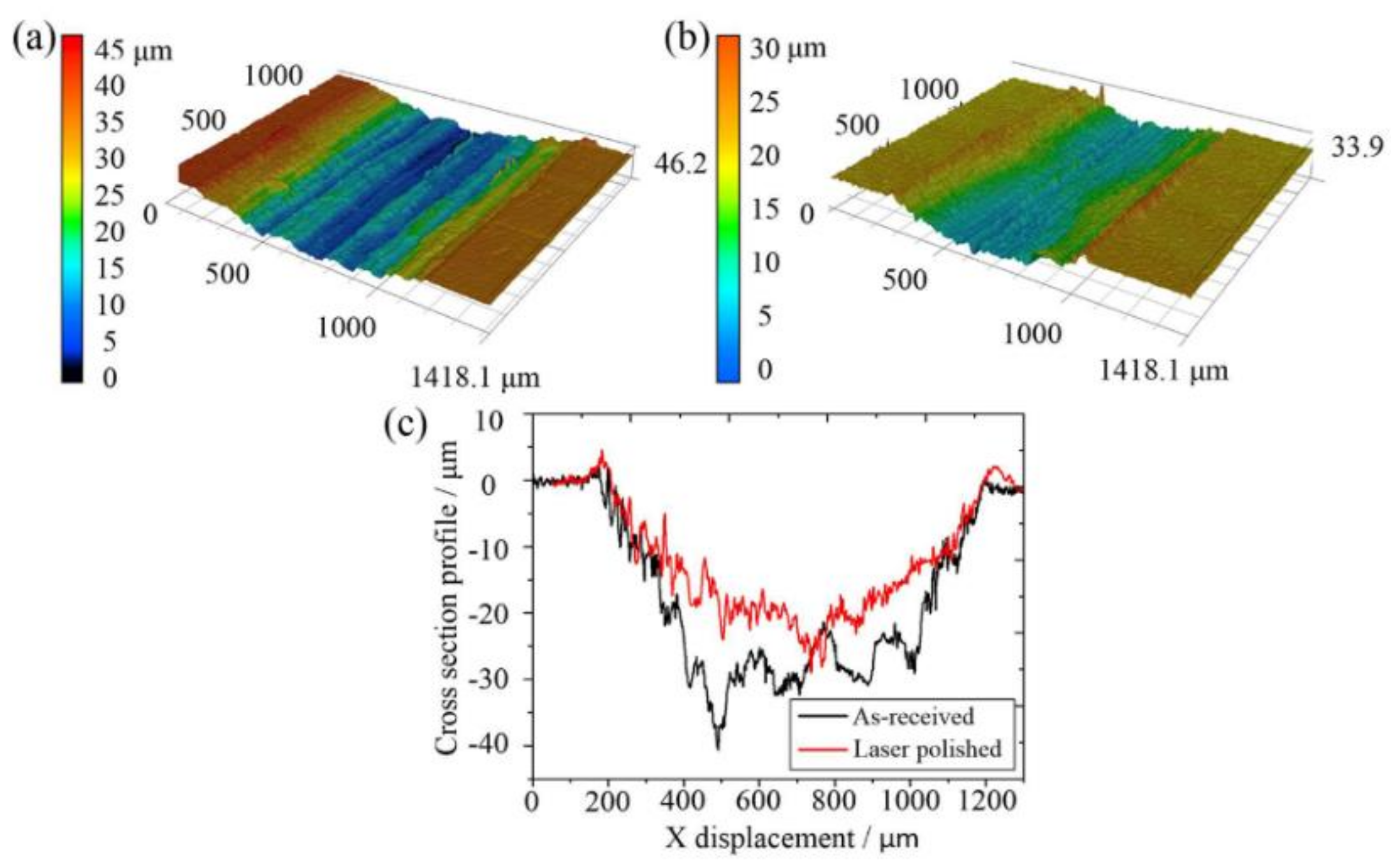

3.1. Surface Topography

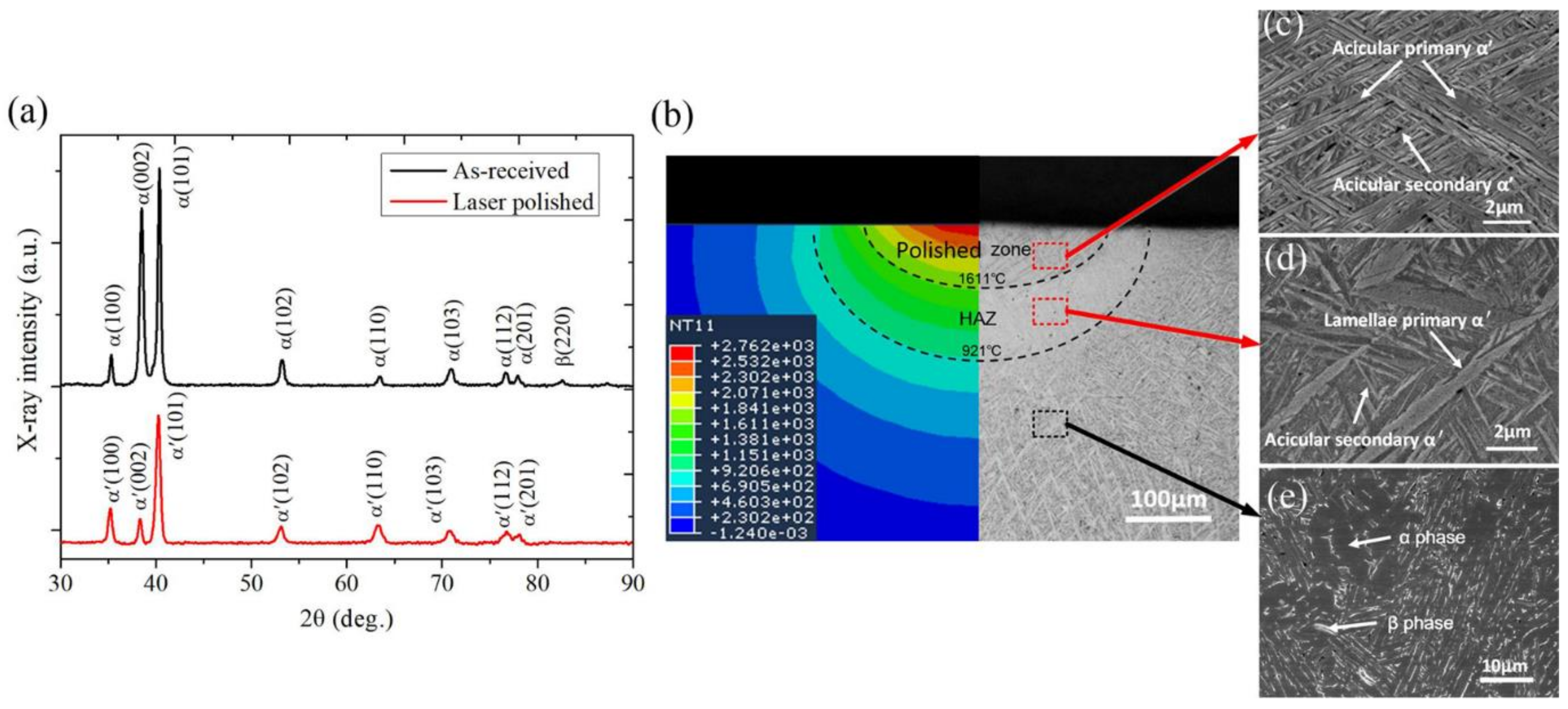

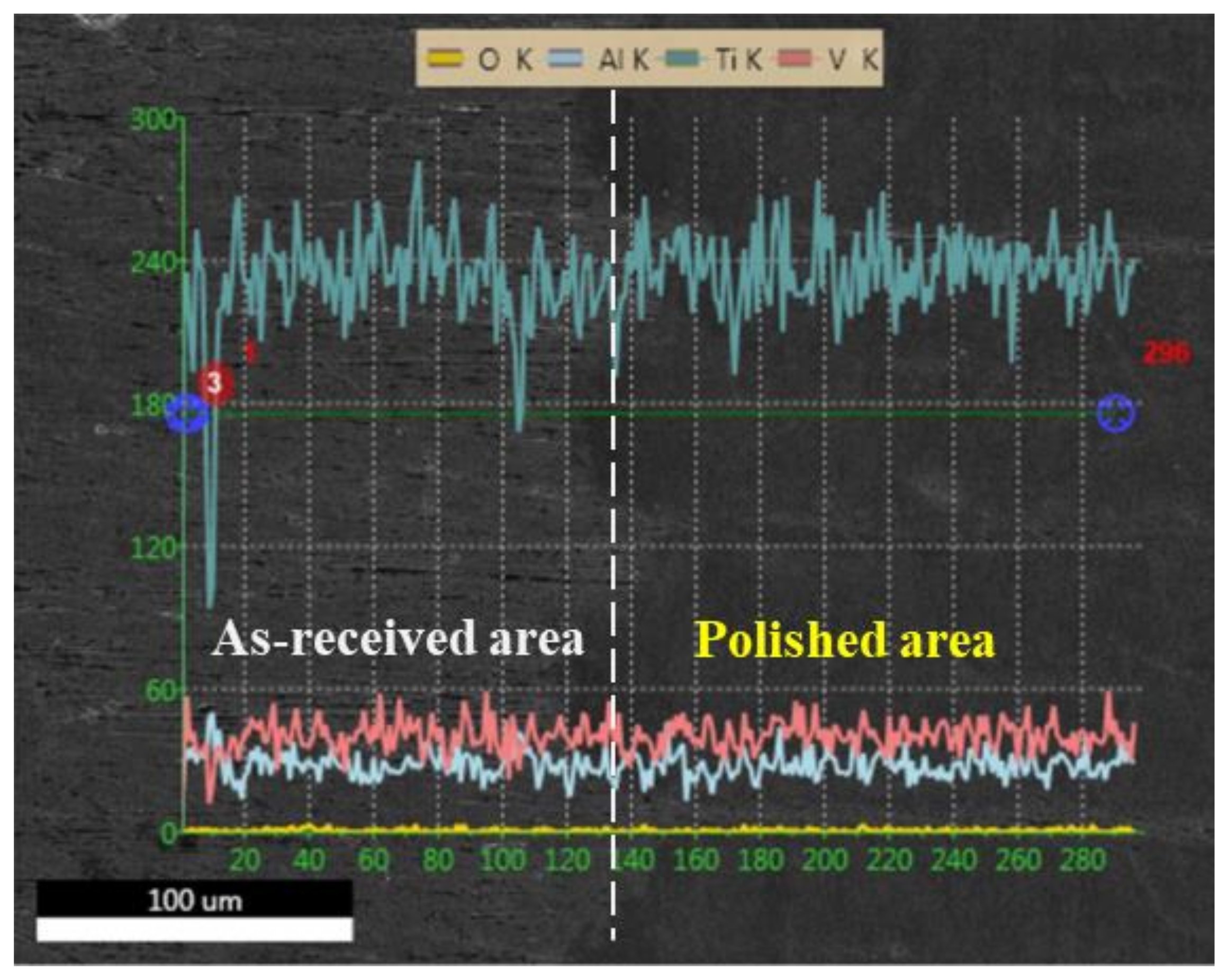

3.2. Microstructure Evolution

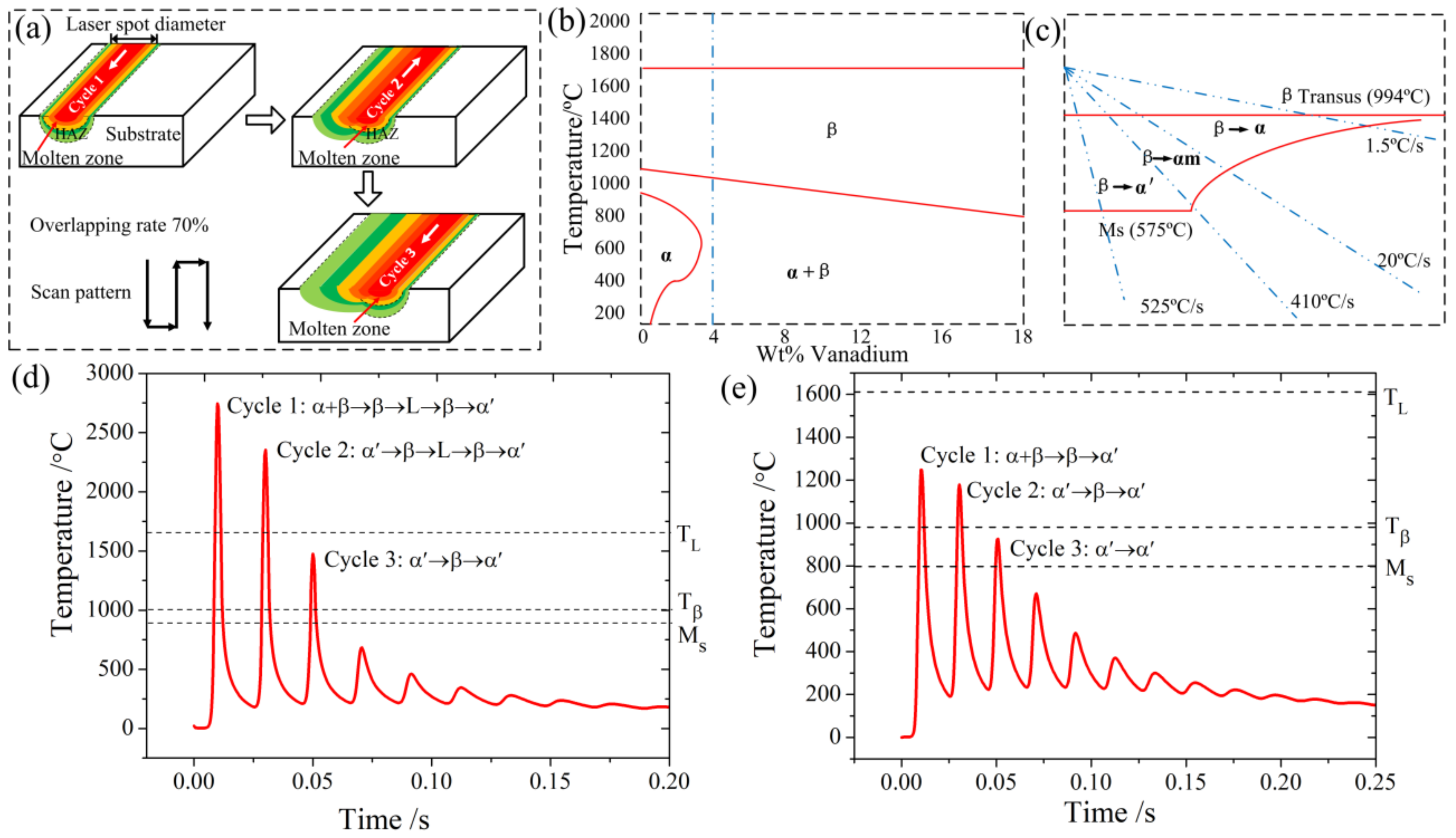

3.3. Thermal Analysis

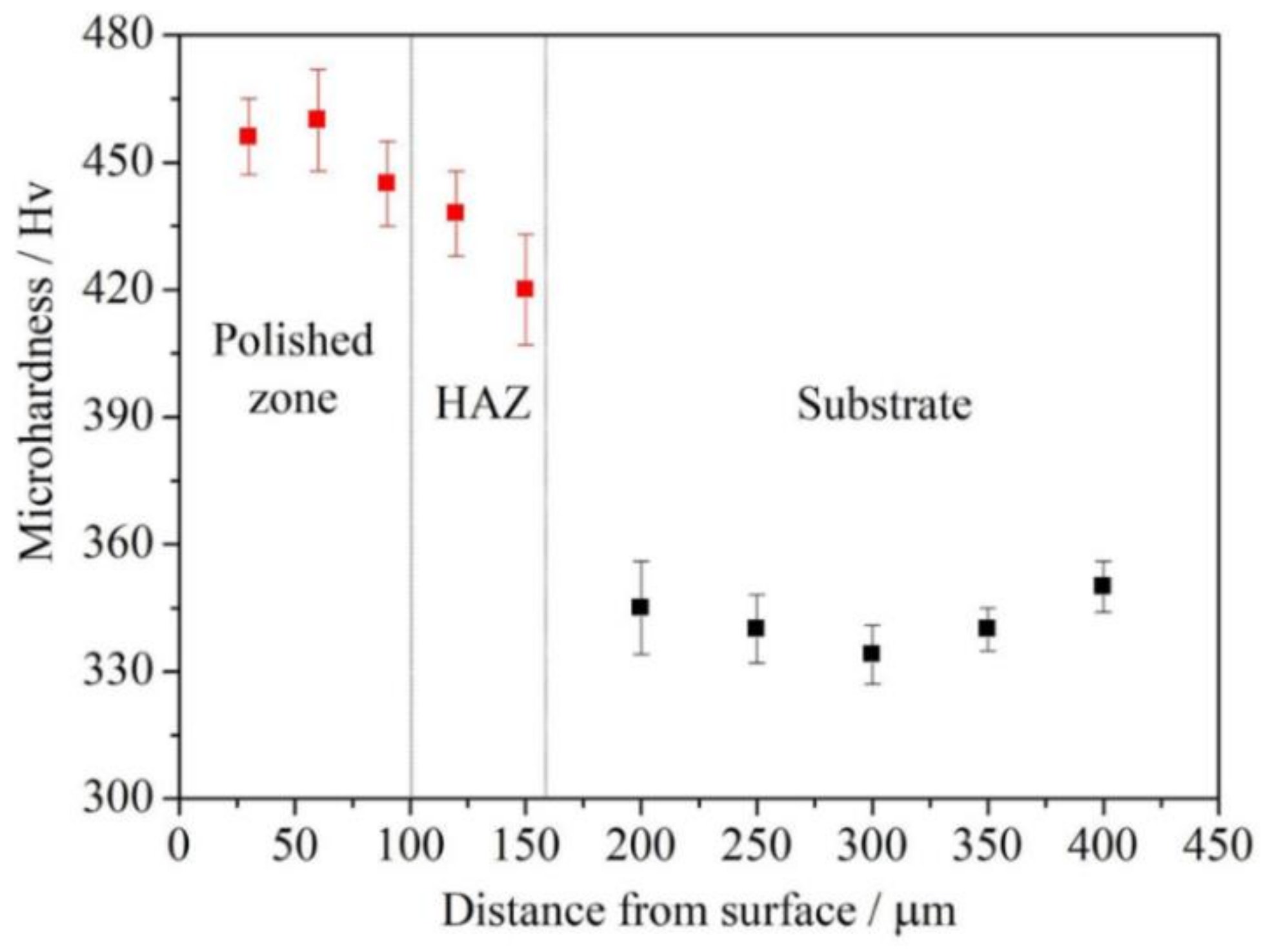

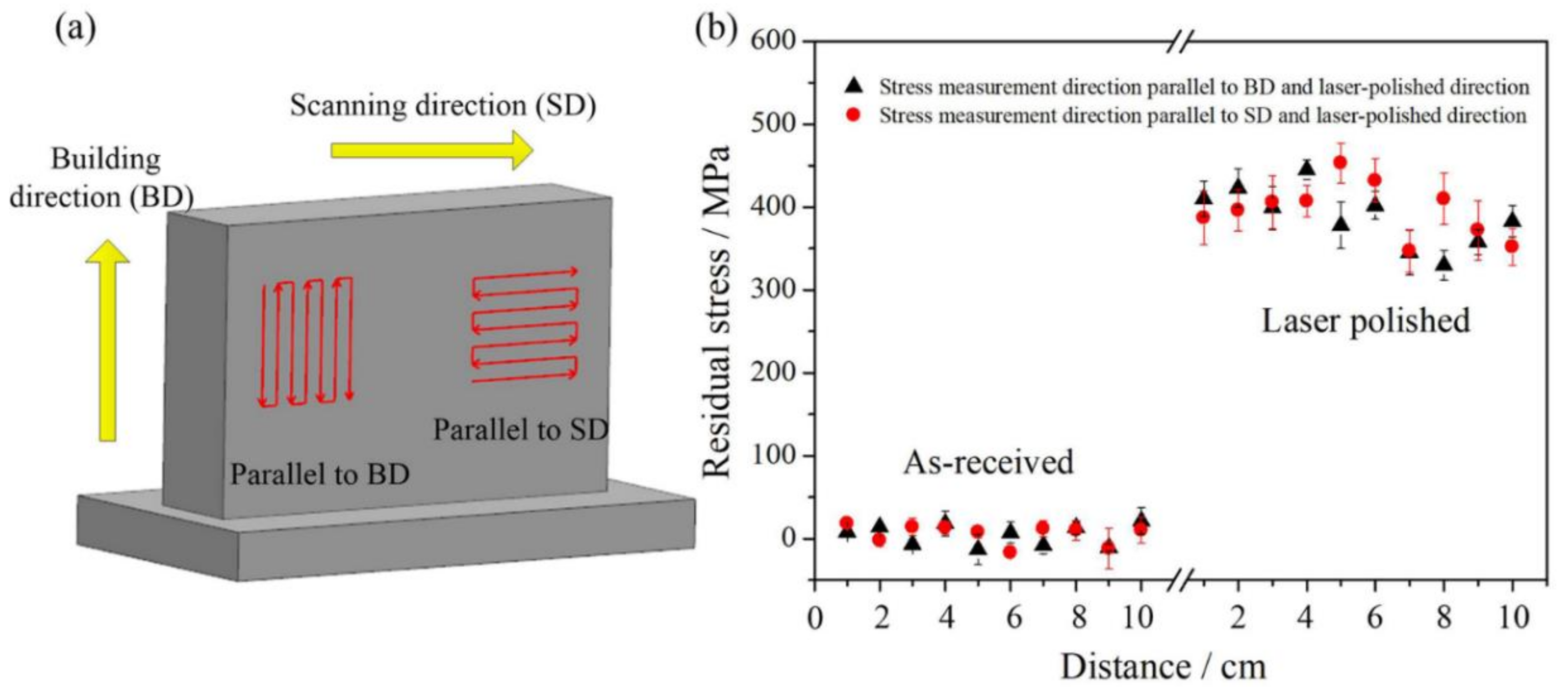

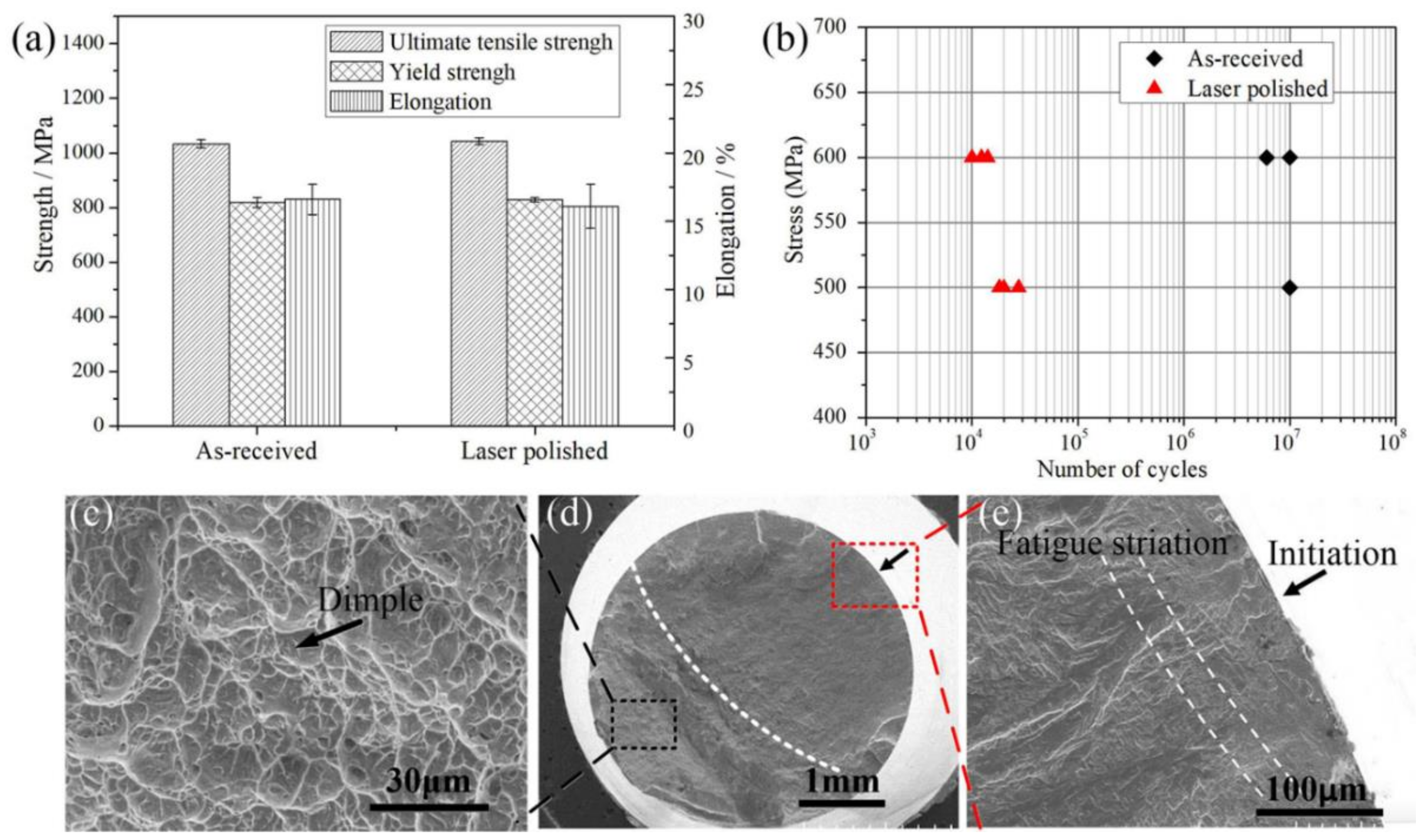

3.4. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Okulov, I.V.; Bonisch, M.; Okulov, A.V.; Volegov, A.S.; Attar, H.; Ehternam-Haghighi, S.; Calin, M.; Wang, Z.; Hohenwarter, A.; Kaban, I.; et al. Phase formation, microstructure and deformation behavior of heavily alloyed TiNb- and TiV-based titanium alloys. Mater. Sci. Eng. A 2018, 733, 80–86. [Google Scholar] [CrossRef]

- Barriobero-Vila, P.; Gussone, J.; Haubrich, J.; Sandlobes, S.; Da Silva, J.C.; Cloetens, P.; Schell, N.; Requena, G. Inducing stable alpha + beta microstructures during selective laser melting of Ti-6Al-4V using intensified intrinsic heat treatments. Materials 2017, 10, 268. [Google Scholar] [CrossRef] [PubMed]

- Barriobero-Vila, P.; Gussone, J.; Stark, A.; Schell, N.; Haubrich, J.; Requena, G. Peritectic titanium alloys for 3D printing. Nat. Commun. 2018, 9, 3426. [Google Scholar] [CrossRef] [PubMed]

- Lamikiz, A.; Sanchez, J.A.; de Lacalle, L.N.L.; Arana, J.L. Laser polishing of parts built up by selective laser sintering. Int. J. Mach. Tools Manuf. 2007, 47, 2040–2050. [Google Scholar] [CrossRef]

- Pakkanen, J.; Calignano, F.; Trevisan, F.; Lorusso, M.; Ambrosio, E.P.; Manfredi, D.; Fino, P. Study of internal channel surface roughnesses manufactured by selective laser melting in aluminum and titanium alloys. Metall. Mater. Trans. A 2016, 47A, 3837–3844. [Google Scholar] [CrossRef]

- Wang, M.; Lin, X.; Huang, W. Laser additive manufacture of titanium alloys. Mater. Technol. 2016, 31, 90–97. [Google Scholar] [CrossRef]

- Lyczkowska, E.; Szymczyk, P.; Dybala, B.; Chlebus, E. Chemical polishing of scaffolds made of Ti-6Al-7Nb alloy by additive manufacturing. Arch. Civ. Mech. Eng. 2014, 14, 586–594. [Google Scholar] [CrossRef]

- Witkin, D.; Helvajian, H.; Steffeney, L.; Hansen, W. Laser post-processing of inconel 625 made by selective laser melting. Proc. SPIE 2016, 2016, 9738. [Google Scholar]

- Ukar, E.; Lamikiz, A.; Martinez, S.; Tabernero, I.; de Lacalle, L.N.L. Roughness prediction on laser polished surfaces. J. Mater. Process. Technol. 2012, 212, 1305–1313. [Google Scholar] [CrossRef]

- Marimuthu, S.; Triantaphyllou, A.; Antar, M.; Wimpenny, D.; Morton, H.; Beard, M. Laser polishing of selective laser melted components. Int. J. Mach. Tools Manuf. 2015, 95, 97–104. [Google Scholar] [CrossRef]

- Wang, Q.H.; Morrow, J.D.; Ma, C.; Duffie, N.A.; Pfefferkorn, F.E. Surface prediction model for thermocapillary regime pulsed laser micro polishing of metals. J. Manuf. Process. 2015, 20, 340–348. [Google Scholar] [CrossRef]

- Rosa, B.; Mognol, P.; Hascoet, J.Y. Modelling and optimization of laser polishing of additive laser manufacturing surfaces. Rapid Prototyp. J. 2016, 22, 956–964. [Google Scholar] [CrossRef]

- Bhaduri, D.; Penchev, P.; Batal, A.; Dimov, S.; Soo, S.L.; Sten, S.; Harrysson, U.; Zhang, Z.X.; Dong, H.S. Laser polishing of 3D printed mesoscale components. Appl. Surf. Sci. 2017, 405, 29–46. [Google Scholar] [CrossRef]

- Ma, C.P.; Guan, Y.C.; Zhou, W. Laser polishing of additive manufactured Ti alloys. Opt. Laser Eng. 2017, 93, 171–177. [Google Scholar] [CrossRef]

- Ukar, E.; Lamikiz, A.; Tabernero, I.; Liebana, F.; del Pozo, D. An Approach to thermal modeling of laser polishing process. AIP Conf. Proc. 2009, 1181, 474. [Google Scholar]

- Guan, Y.C.; Zhou, W.; Li, Z.L.; Zheng, H.Y. Influence of overlapping tracks on microstructure evolution and corrosion behavior in laser-melt magnesium alloy. Mater Des. 2013, 52, 452–458. [Google Scholar] [CrossRef]

- He, X.; Elmer, J.W.; DebRoy, T. Heat transfer and fluid flow in laser microwelding. J. Appl. Phys. 2005, 97, 084909. [Google Scholar] [CrossRef]

- Xu, W.; Lui, E.W.; Pateras, A.; Qian, M.; Brandt, M. In situ tailoring microstructure in additively manufactured Ti-6Al-4V for superior mechanical performance. Acta Mater. 2017, 125, 390–400. [Google Scholar] [CrossRef]

- Vilaro, T.; Colin, C.; Bartout, J.D. As-fabricated and heat-treated microstructures of the Ti-6Al-4V alloy processed by selective laser melting. Metall. Mater. Trans. A 2011, 42A, 3190–3199. [Google Scholar] [CrossRef]

- Yang, J.J.; Han, J.; Yu, H.C.; Yin, J.; Gao, M.; Wang, Z.M.; Zeng, X.Y. Role of molten pool mode on formability, microstructure and mechanical properties of selective laser melted Ti-6A1-4V alloy. Mater. Des. 2016, 110, 558–570. [Google Scholar] [CrossRef]

- Tian, Y.T.; Gora, W.S.; Cabo, A.P.; Parimi, L.L.; Hand, I.D.P.; Tammas-Williams, S.; Prangnell, P.B. Material interactions in laser polishing powder bed additive manufactured Ti6Al4V components. Addit. Manuf. 2018, 20, 11–22. [Google Scholar] [CrossRef]

- Wang, H.; Warnken, N.; Reed, R.C. Thermodynamic and kinetic modeling of bcc phase in the Ti-Al-V ternary system. Mater. Sci. Eng. A Struct. 2010, 528, 622–630. [Google Scholar] [CrossRef]

- Hong, K.-M.; Shin, Y.C. Analysis of microstructure and mechanical properties change in laser welding of Ti6Al4V with a multiphysics prediction model. J. Mater. Process. Technol. 2016, 237, 420–429. [Google Scholar] [CrossRef]

- Nassar, A.R.; Reutzel, E.W. Additive manufacturing of Ti-6Al-4V using a pulsed laser beam. Metall. Mater. Trans. A 2015, 46A, 2781–2789. [Google Scholar] [CrossRef]

- Yang, J.J.; Yu, H.C.; Yin, J.; Gao, M.; Wang, Z.M.; Zeng, X.Y. Formation and control of martensite in Ti-6Al-4V alloy produced by selective laser melting. Mater. Des. 2016, 108, 308–318. [Google Scholar] [CrossRef]

- Ehtemam-Haghighi, S.; Prashanth, K.G.; Attar, H.; Chaubey, A.K.; Cao, G.H.; Zhang, L.C. Evaluation of mechanical and wear properties of Ti-xNb-7Fe alloys designed for biomedical applications. Mater. Des. 2016, 111, 592–599. [Google Scholar] [CrossRef]

- Zheng, Y.K.; Wang, D.X.; Wang, Z.Q.; Zhang, Y.; Zhang, Y.R.; Xu, W.L. Design of a lightweight force-feedback glove with a large workspace. Engineering 2018, 4, 869–880. [Google Scholar] [CrossRef]

- Iyakutti, K.; Louis, C.N.; Anuratha, S.; Mahalakshmi, S. Pressure-induced electronic phase transitions and superconductivity in titanium. Int. J. Mod. Phys. B 2009, 23, 723–741. [Google Scholar] [CrossRef]

- Li, Z.; Cheng, X.; Li, J.; Wang, H.M. Formation of face-centered cubic titanium in laser surface re-melted commercially pure titanium plate. J. Mater. Sci. Technol. 2018, 34, 767–773. [Google Scholar] [CrossRef]

- Mohd Yusuf, S.; Nie, M.; Chen, Y.; Yang, S.F.; Gao, N. Microstructure and corrosion performance of 316L stainless steel fabricated by selective laser melting and processed through high-pressure torsion. J. Alloy. Compd. 2018, 763, 360–375. [Google Scholar] [CrossRef]

| Specimen | Laser Power (W) | Scanning Velocity (mm/s) | Overlapping Ratio (%) |

|---|---|---|---|

| 1-X | 70 | 50; 100; 150; 200; 250 | 10 |

| 2-X | 80 | 50; 100; 150; 200; 250 | 10 |

| 3-X | 90 | 50; 100; 150; 200; 250 | 10 |

| 4-X | 100 | 50; 100; 150; 200; 250 | 10 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.-H.; Wang, B.; Ma, C.-P.; Fang, Z.-H.; Chen, L.-F.; Guan, Y.-C.; Yang, S.-F. Material Characterization, Thermal Analysis, and Mechanical Performance of a Laser-Polished Ti Alloy Prepared by Selective Laser Melting. Metals 2019, 9, 112. https://doi.org/10.3390/met9020112

Li Y-H, Wang B, Ma C-P, Fang Z-H, Chen L-F, Guan Y-C, Yang S-F. Material Characterization, Thermal Analysis, and Mechanical Performance of a Laser-Polished Ti Alloy Prepared by Selective Laser Melting. Metals. 2019; 9(2):112. https://doi.org/10.3390/met9020112

Chicago/Turabian StyleLi, Yu-Hang, Bing Wang, Cheng-Peng Ma, Zhi-Hao Fang, Long-Fei Chen, Ying-Chun Guan, and Shou-Feng Yang. 2019. "Material Characterization, Thermal Analysis, and Mechanical Performance of a Laser-Polished Ti Alloy Prepared by Selective Laser Melting" Metals 9, no. 2: 112. https://doi.org/10.3390/met9020112

APA StyleLi, Y.-H., Wang, B., Ma, C.-P., Fang, Z.-H., Chen, L.-F., Guan, Y.-C., & Yang, S.-F. (2019). Material Characterization, Thermal Analysis, and Mechanical Performance of a Laser-Polished Ti Alloy Prepared by Selective Laser Melting. Metals, 9(2), 112. https://doi.org/10.3390/met9020112