The Effect of Mo and Dispersoids on Microstructure, Sintering Behavior, and Mechanical Properties of W-Mo-Ni-Fe-Co Heavy Tungsten Alloys

Abstract

:1. Introduction

2. Materials and Methods

3. Results

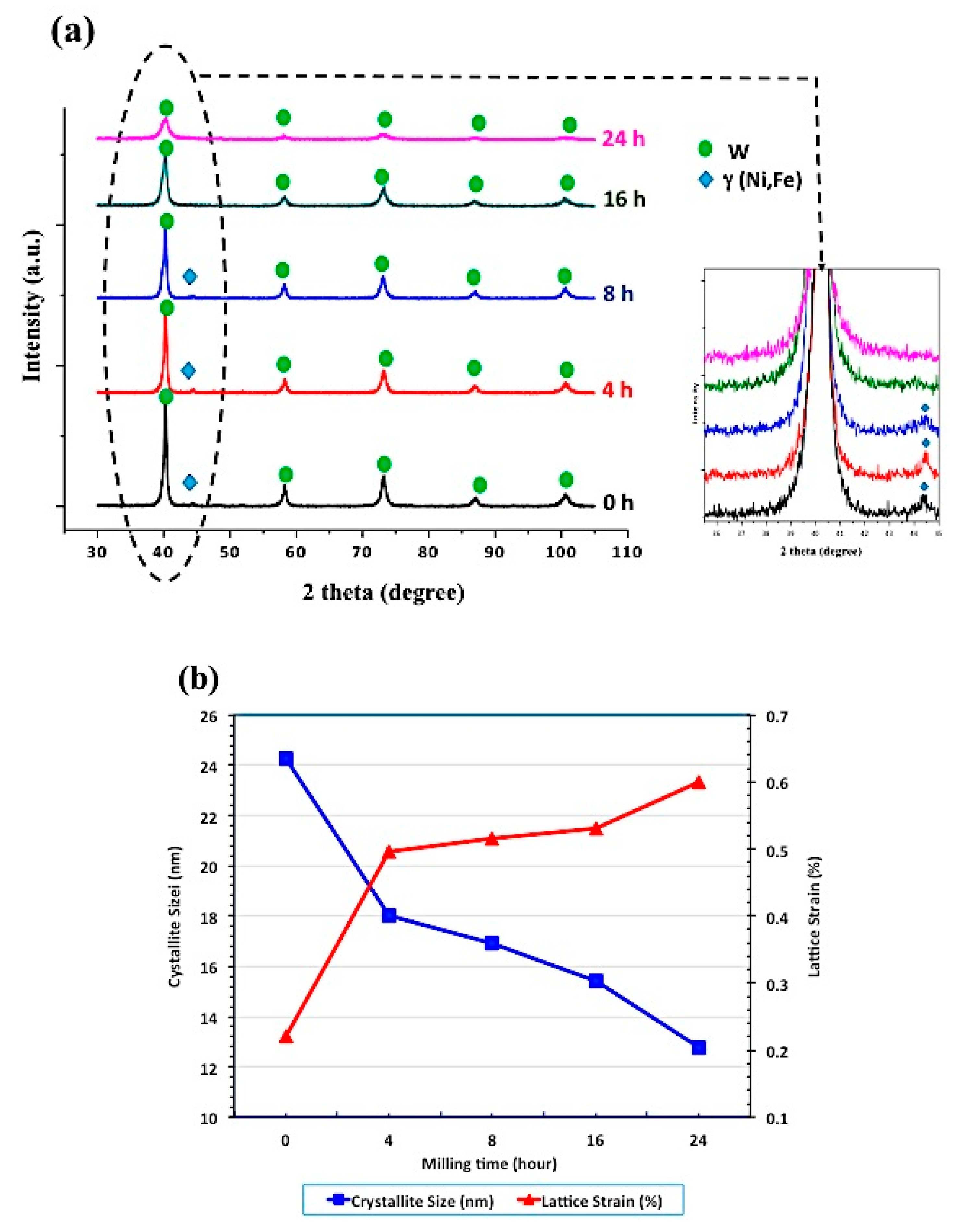

3.1. Characterization of the Milled Powders

3.2. Characterization of the Sintered Model Alloys

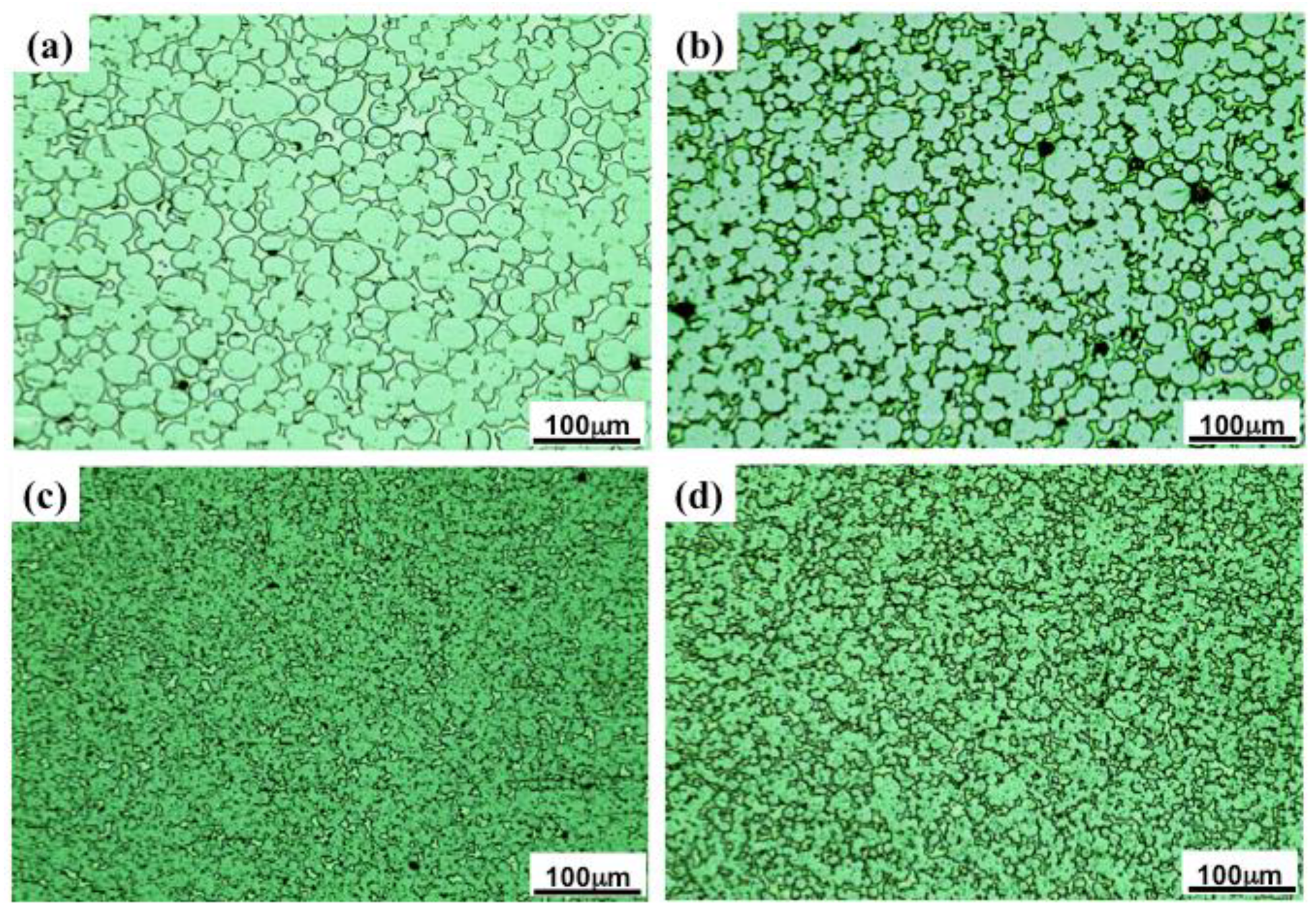

3.2.1. Optical Microscope

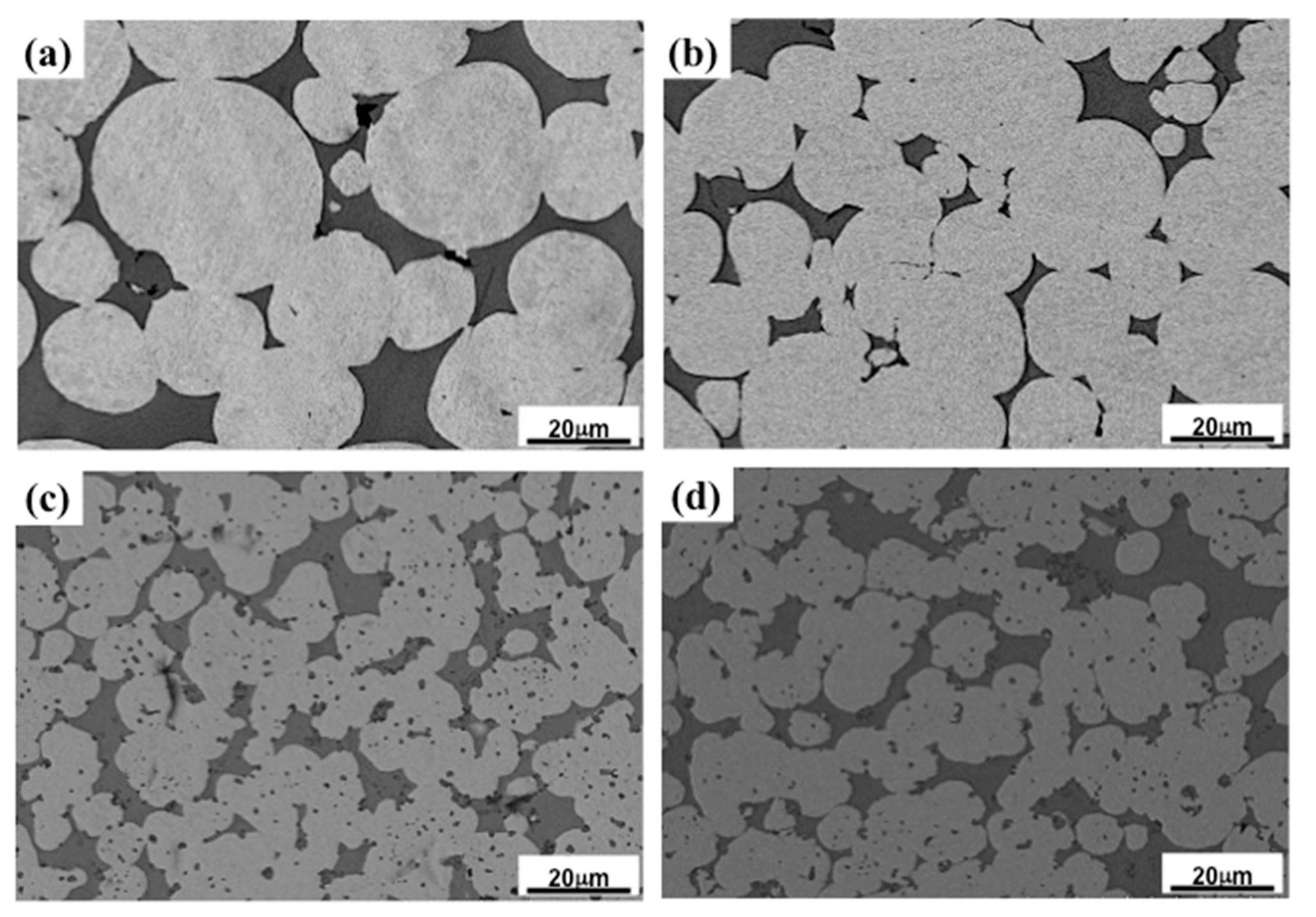

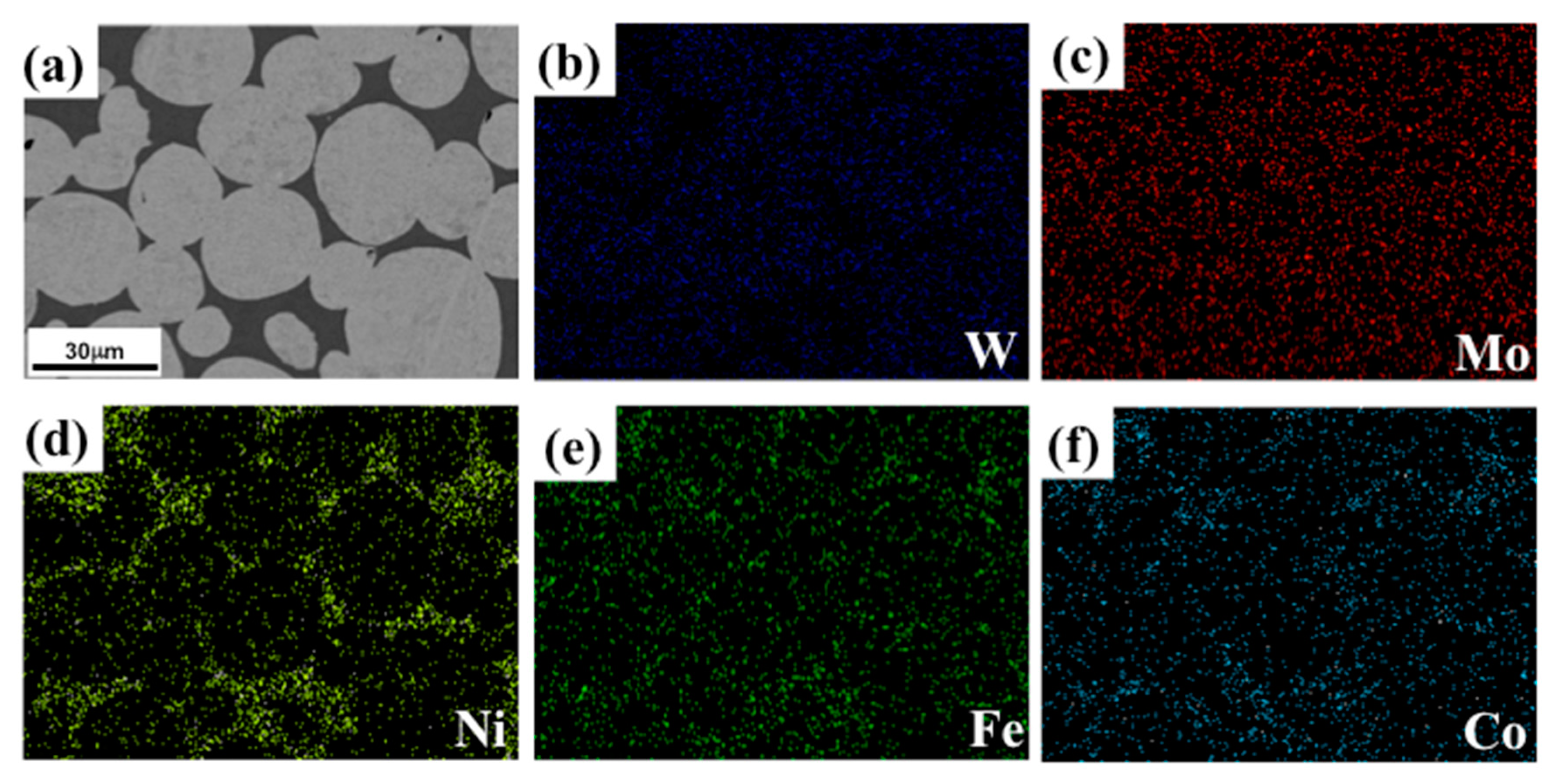

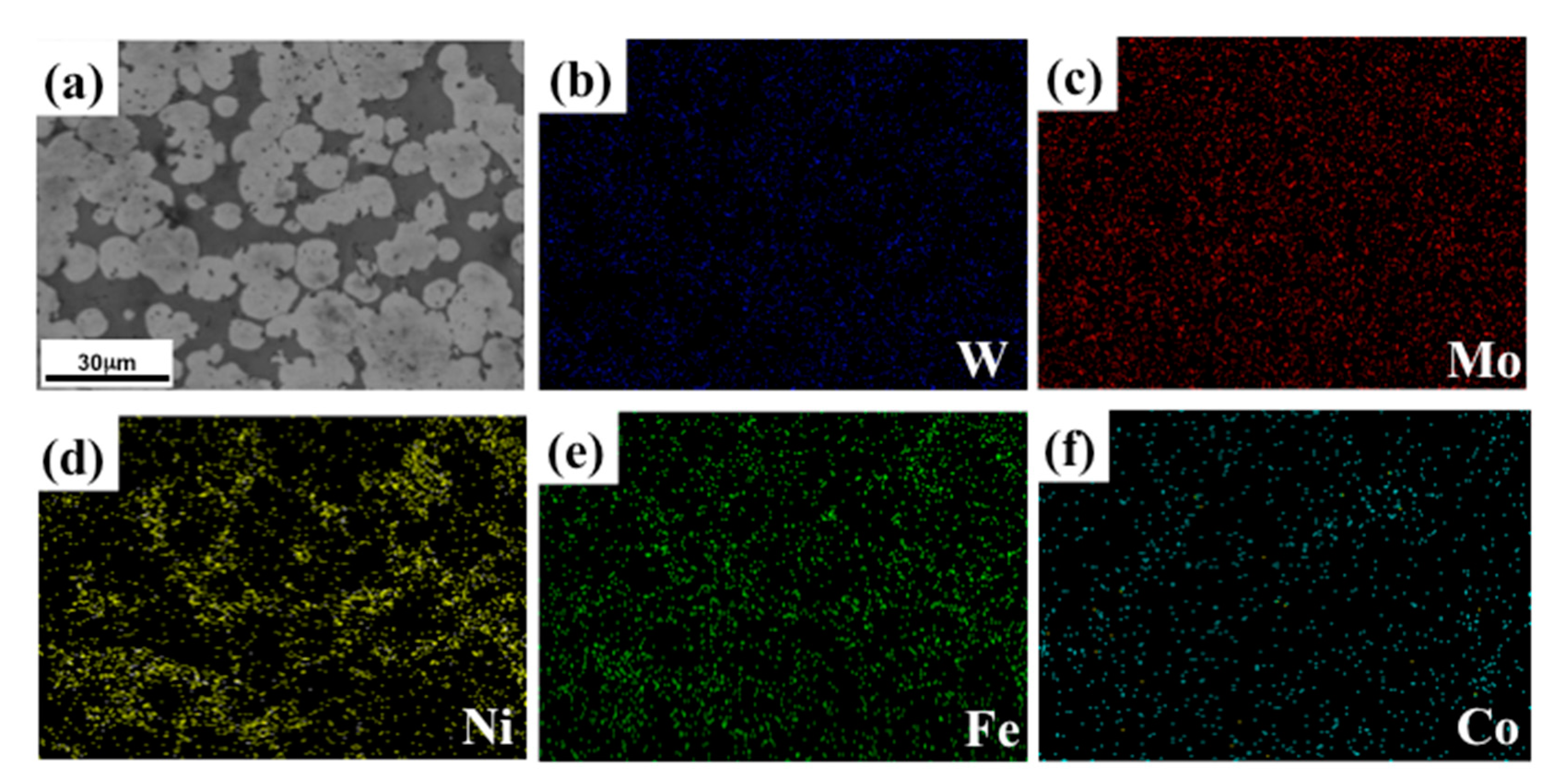

3.2.2. SEM Observation

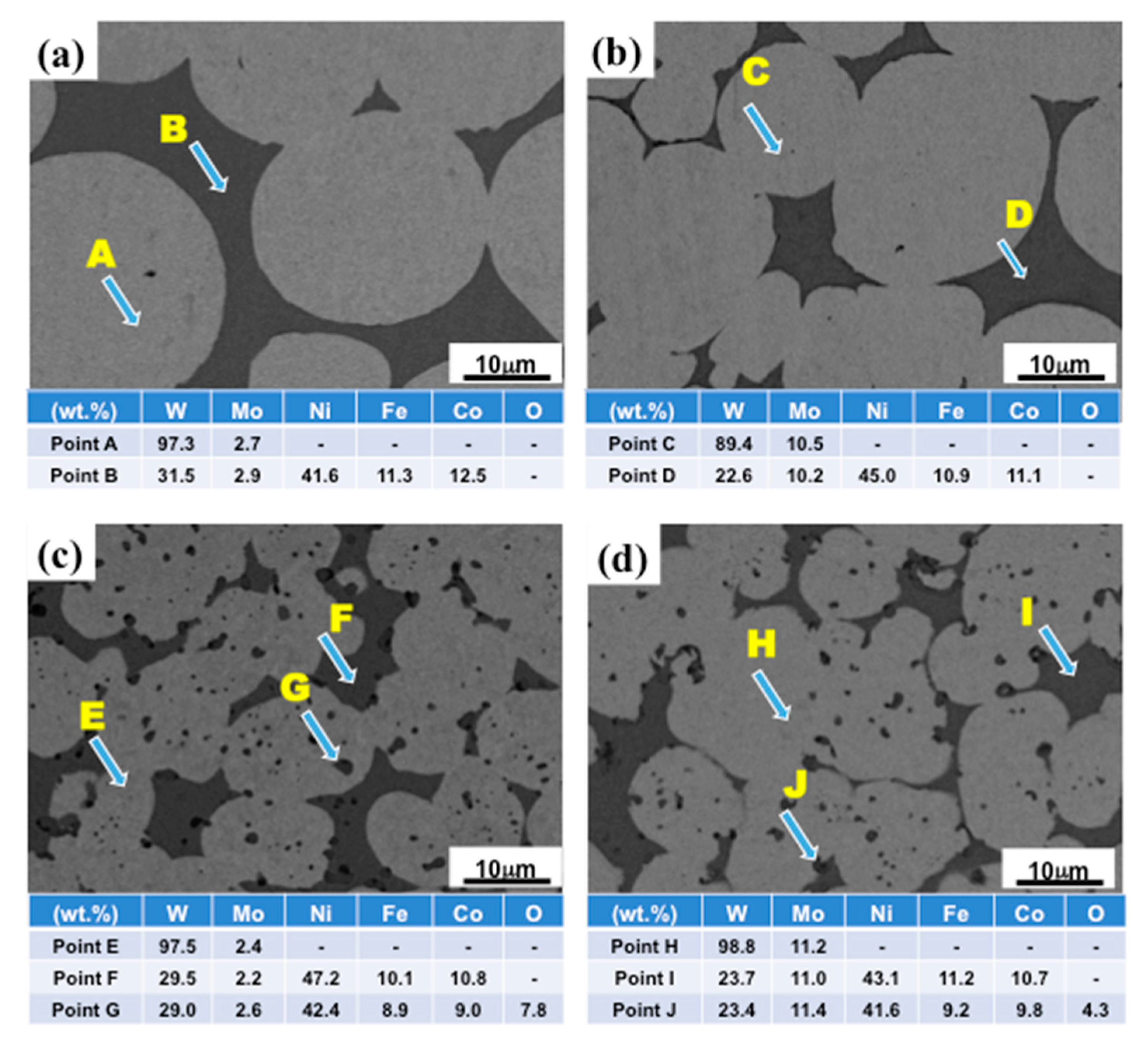

3.2.3. EDS Analysis

3.2.4. Relative Density

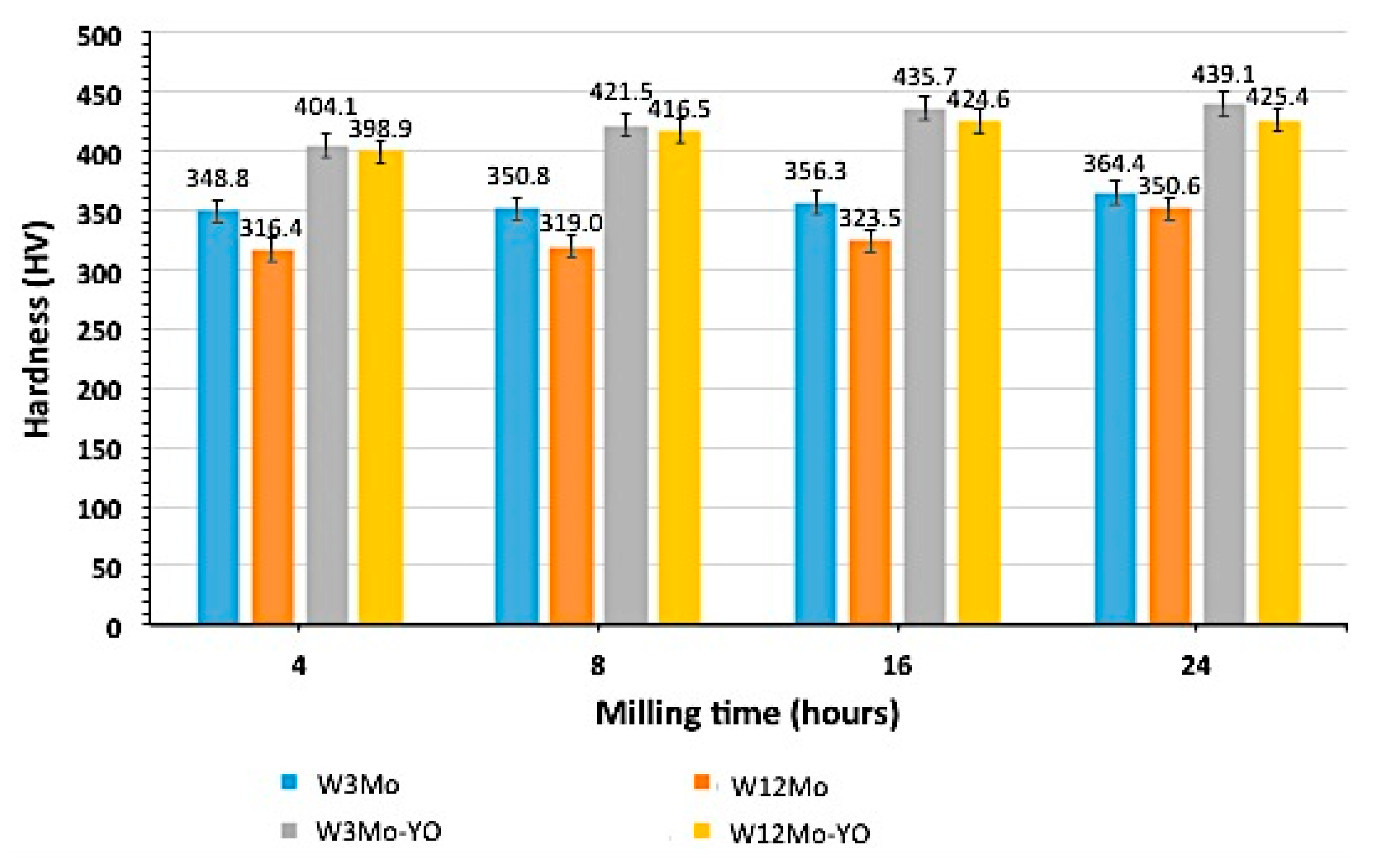

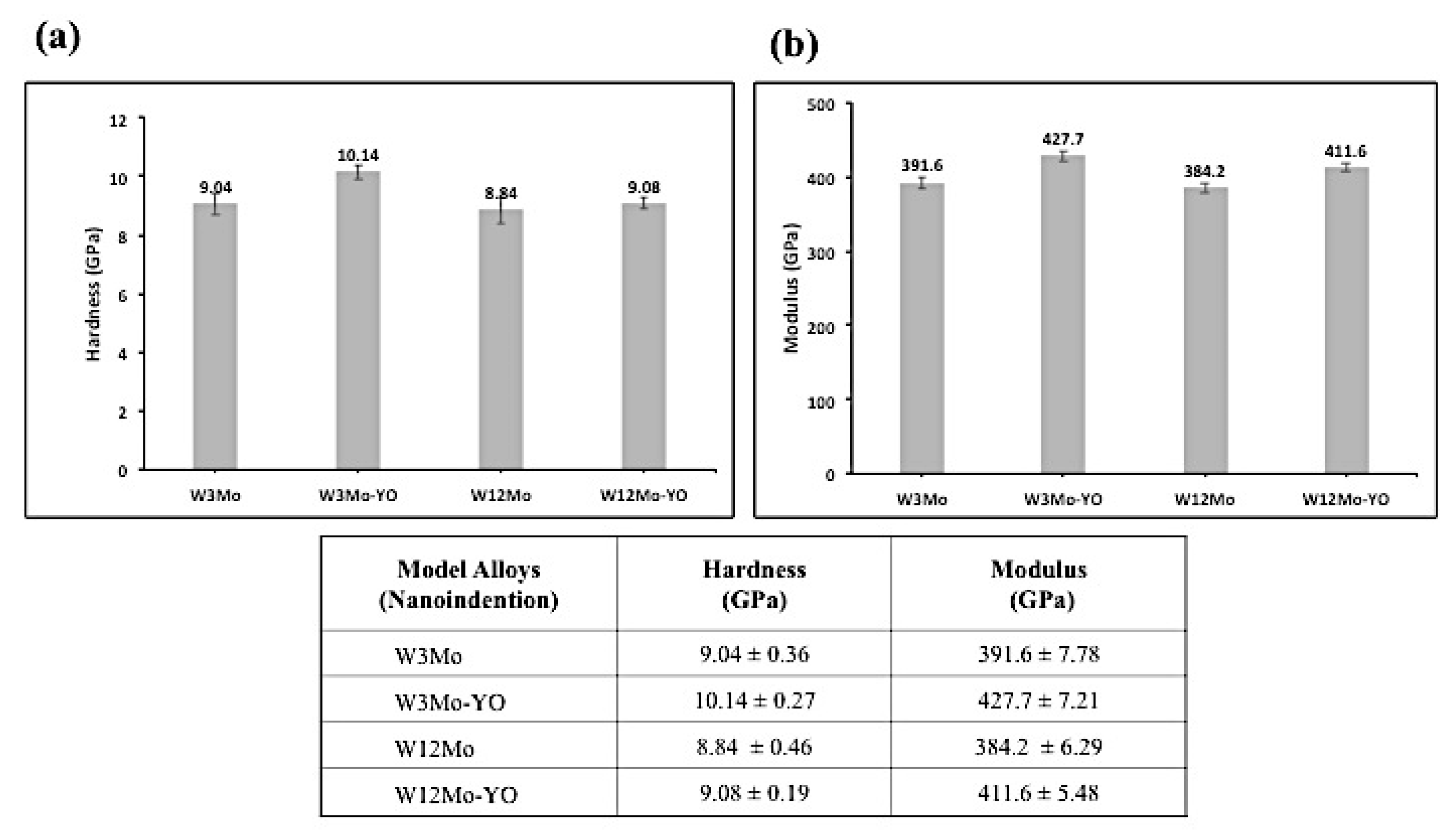

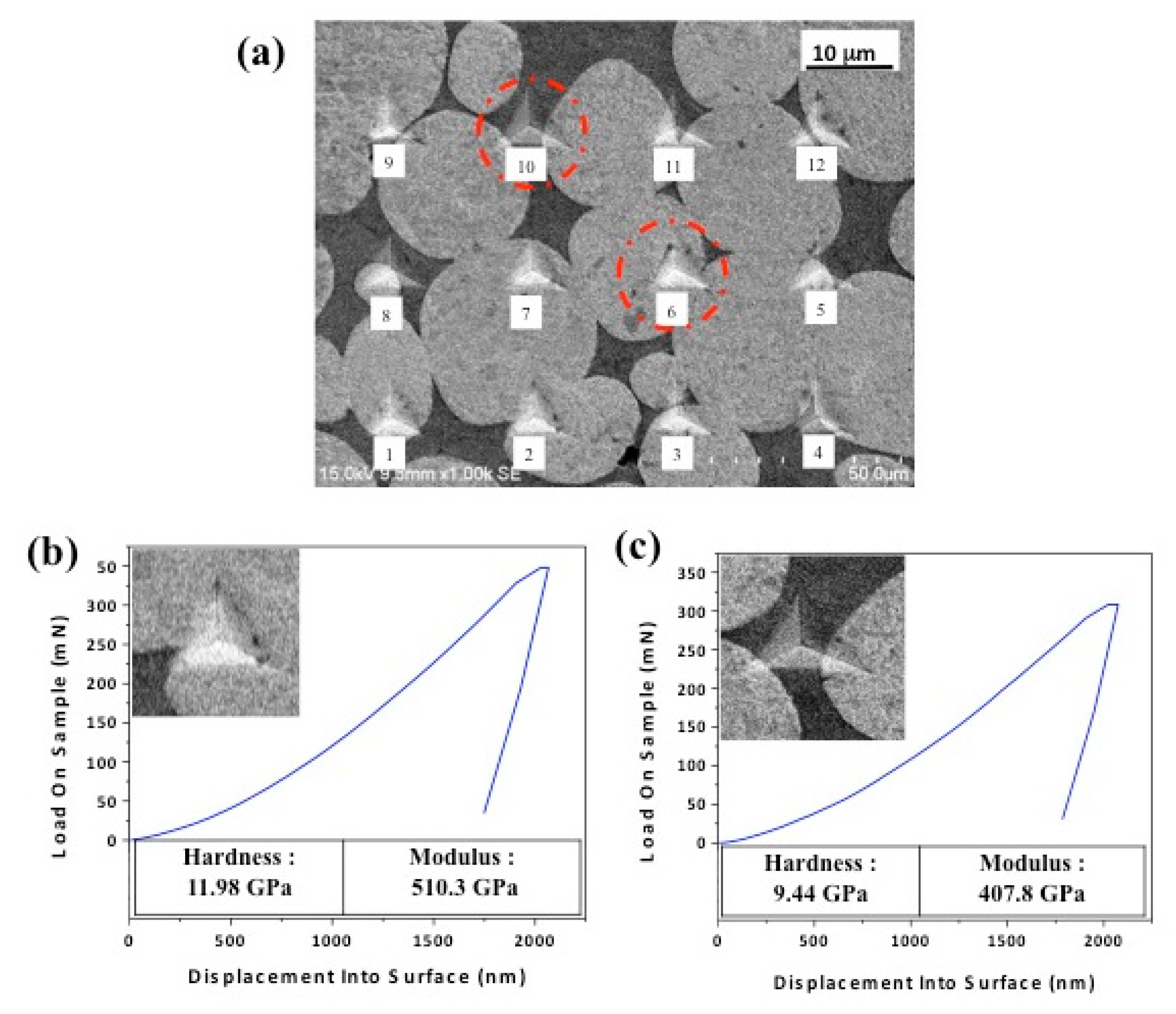

3.3. Hardness and Nanoindentation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lee, K.H.; Cha, S.I.; Ryu, H.J.; Hong, S.H. Effect of two-stage sintering process on microstructure and mechanical properties of ODS tungsten heavy alloy. Mater. Sci. Eng. A 2007, 458, 323–329. [Google Scholar] [CrossRef]

- Arora, A.; Rao, V.G. Tungsten Heavy Alloy for Defence Applications. Mater. Technol. 2004, 19, 210–215. [Google Scholar] [CrossRef]

- Lu, P.; German, R.M. Multiple grain growth events in liquid phase sintering. J. Mater. Sci. 2001, 36, 3385–3394. [Google Scholar] [CrossRef]

- German, R.M. Sintering Atmosphere Effects on the Ductility Sintering Atmosphere Effects on the Ductility of W-Ni-Fe Heavy Metals. Metall. Trans. A 2017, 15, 747–754. [Google Scholar] [CrossRef]

- Ryu, H.J.; Hong, S.H. Effects of sintering conditions on mechanical properties of mechanically alloyed tungsten heavy alloys. Key Eng. Mater. 2000, 7, 2–7. [Google Scholar] [CrossRef]

- Ryu, H.J.; Hong, S.H. Fabrication and properties of mechanically alloyed oxide-dispersed tungsten heavy alloys. Mater. Sci. Eng. A 2003, 363, 179–184. [Google Scholar] [CrossRef]

- Zhu, Y.B.; Wang, Y.; Zhang, X.Y.; Qin, G.W. W/NiFe phase interfacial characteristics of liquid-phase sintered W-Ni-Fe alloy. Int. J. Refract. Met. Hard Mater. 2007, 25, 275–279. [Google Scholar] [CrossRef]

- Chen, C.L.; Huang, C.L.; Zeng, Y. Synthesis of ODS heavy tungsten alloys through post-annealing and secondary ball milling. Int. J. Refract. Met. Hard Mater. 2015, 48, 359–364. [Google Scholar] [CrossRef]

- Chen, C.L.; Huang, C.L. Milling media and alloying effects on synthesis and characteristics of mechanically alloyed ODS heavy tungsten alloys. Int. J. Refract. Met. Hard Mater. 2014, 44, 19–26. [Google Scholar] [CrossRef]

- Chen, C.L.; Huang, C.L. The effects of alloying and milling on the formation of intermetallics in ODS tungsten heavy alloys. Intermetallics 2013, 41, 10–15. [Google Scholar] [CrossRef]

- Chen, C.L.; Ma, S.H. Study on characteristics and sintering behavior of W-Ni-Co tungsten heavy alloy by a secondary ball milling method. J. Alloys Compd. 2018, 731, 78–83. [Google Scholar] [CrossRef]

- Chen, C.L.; Ma, S.H. Effects of Ni/Co ratio and mechanical alloying on characteristics and sintering behavior of W-Ni-Co tungsten heavy alloys. J. Alloys Compd. 2017, 711, 488–494. [Google Scholar] [CrossRef]

- Bose, A.; German, R.M. Microstructural Refinement of W-Ni-Fe Heavy Alloys by Alloying Additions. Metall. Trans. A 1988, 19, 3100–3101. [Google Scholar] [CrossRef]

- Kemp, P.B.; German, R.M. Mechanical Properties of Molybdenum Alloyed Liquid Phase- Sintered Tungsten-Based Composites. Metall. Trans. A 1995, 26, 2187–2189. [Google Scholar] [CrossRef]

- Hamid, Z.A.; Moustafa, S.F.; Daoush, W.M.; Mouez, F.A.; Hassan, M. Fabrication and Characterization of Tungsten Heavy Alloys Using Chemical Reduction and Mechanical Alloying Methods. Open J. Appl. Sci. 2013, 03, 15–27. [Google Scholar] [CrossRef]

- Zhang, G.; Xiong, W.; Yang, Q.; Yao, Z.; Chen, S.; Chen, X. Effect of Mo addition on microstructure and mechanical properties of (Ti, W) C solid solution based cermets. Int. J. Refract. Met. Hard Mater. 2014, 43, 77–82. [Google Scholar] [CrossRef]

- Chen, C.L. Sutrisna Study of W-Co ODS coating on stainless steels by mechanical alloying. Surf. Coat. Technol. 2018, 350, 954–961. [Google Scholar] [CrossRef]

| Model Alloys | W | Mo | Ni | Fe | Co | Y2O3 |

|---|---|---|---|---|---|---|

| W3Mo | Bal. | 3 | 7 | 1.5 | 1.5 | - |

| W12Mo | Bal. | 12 | 7 | 1.5 | 1.5 | - |

| W3Mo-YO | Bal. | 3 | 7 | 1.5 | 1.5 | 2 |

| W12Mo-YO | Bal. | 12 | 7 | 1.5 | 1.5 | 2 |

| Model Alloys | Relative Density (%) |

|---|---|

| W3Mo | 93.02 |

| W12Mo | 92.36 |

| W3Mo-YO | 96.56 |

| W12Mo-YO | 94.13 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, C.-L.; Sutrisna. The Effect of Mo and Dispersoids on Microstructure, Sintering Behavior, and Mechanical Properties of W-Mo-Ni-Fe-Co Heavy Tungsten Alloys. Metals 2019, 9, 111. https://doi.org/10.3390/met9020111

Chen C-L, Sutrisna. The Effect of Mo and Dispersoids on Microstructure, Sintering Behavior, and Mechanical Properties of W-Mo-Ni-Fe-Co Heavy Tungsten Alloys. Metals. 2019; 9(2):111. https://doi.org/10.3390/met9020111

Chicago/Turabian StyleChen, Chun-Liang, and Sutrisna. 2019. "The Effect of Mo and Dispersoids on Microstructure, Sintering Behavior, and Mechanical Properties of W-Mo-Ni-Fe-Co Heavy Tungsten Alloys" Metals 9, no. 2: 111. https://doi.org/10.3390/met9020111

APA StyleChen, C.-L., & Sutrisna. (2019). The Effect of Mo and Dispersoids on Microstructure, Sintering Behavior, and Mechanical Properties of W-Mo-Ni-Fe-Co Heavy Tungsten Alloys. Metals, 9(2), 111. https://doi.org/10.3390/met9020111