Analysis of Ductile Fracture Obtained by Charpy Impact Test of a Steel Structure Created by Robot-Assisted GMAW-Based Additive Manufacturing

Abstract

1. Introduction

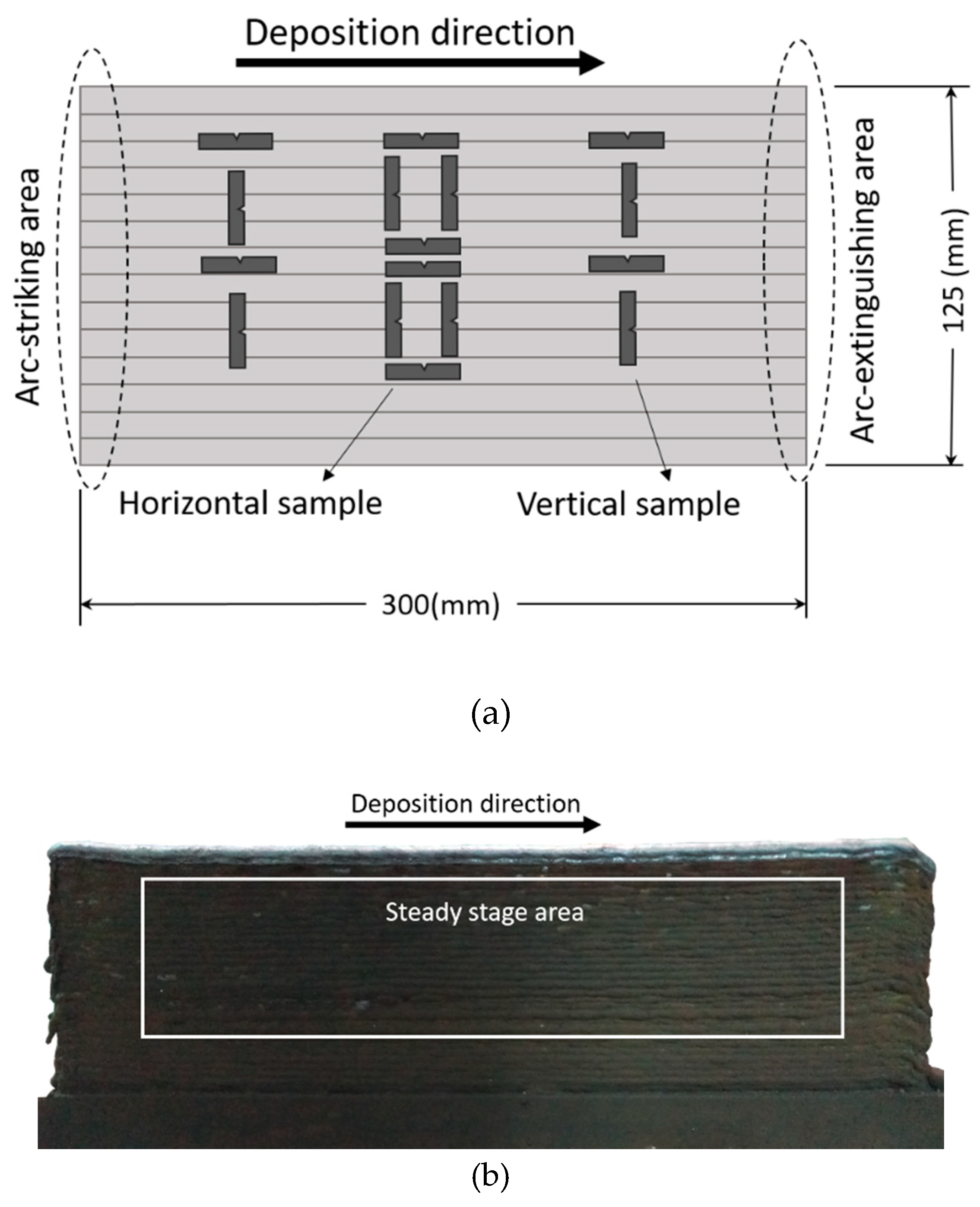

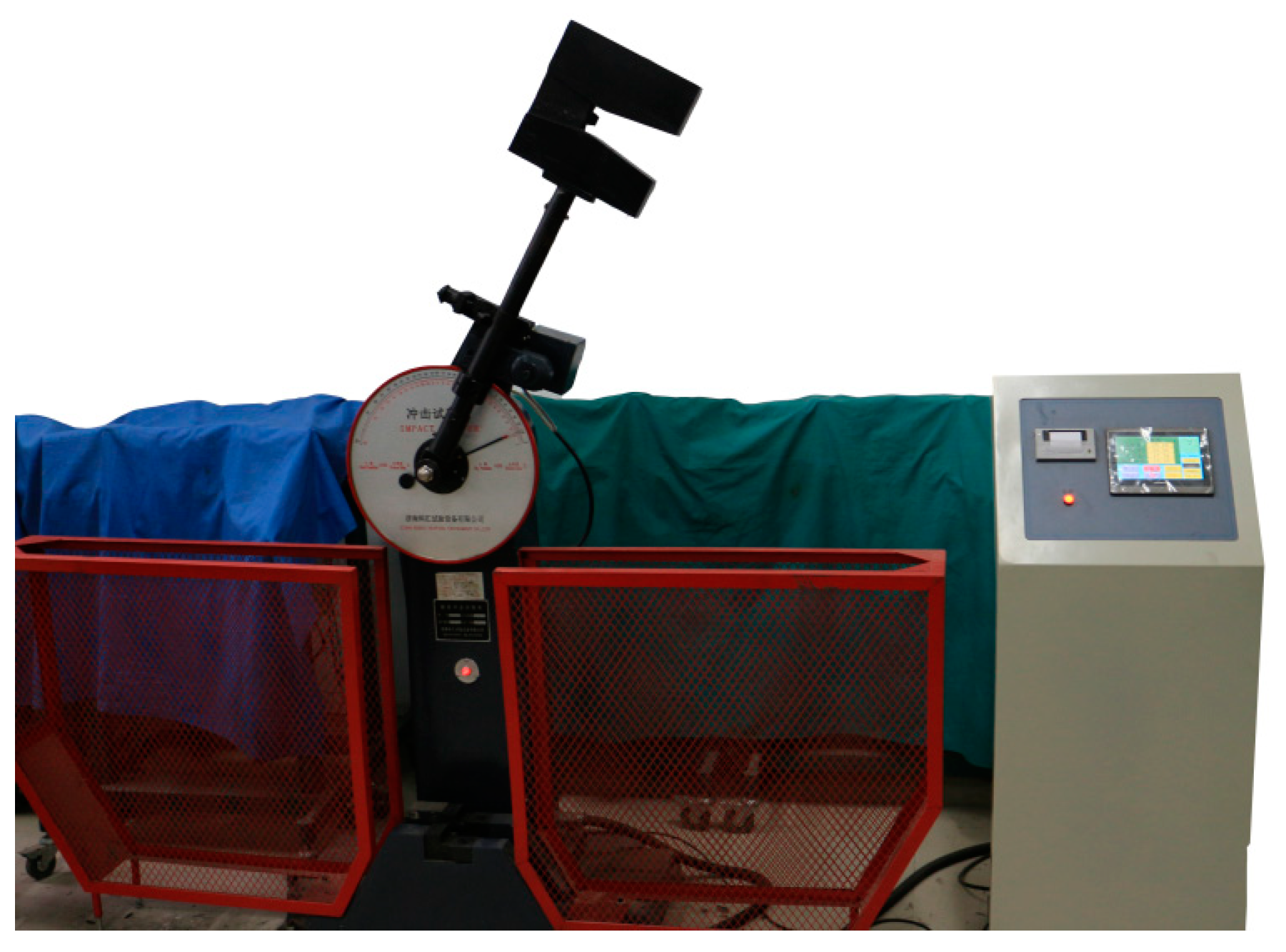

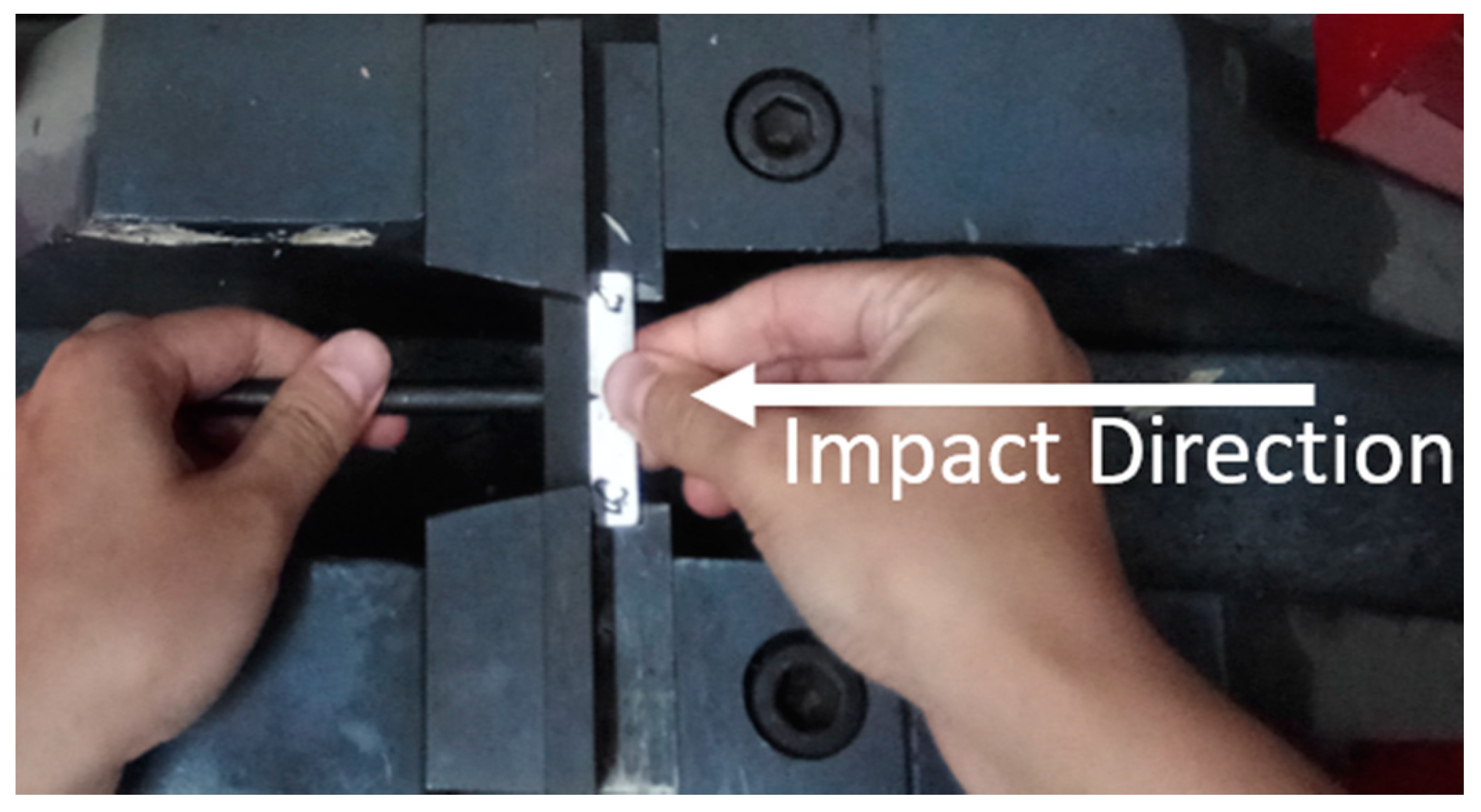

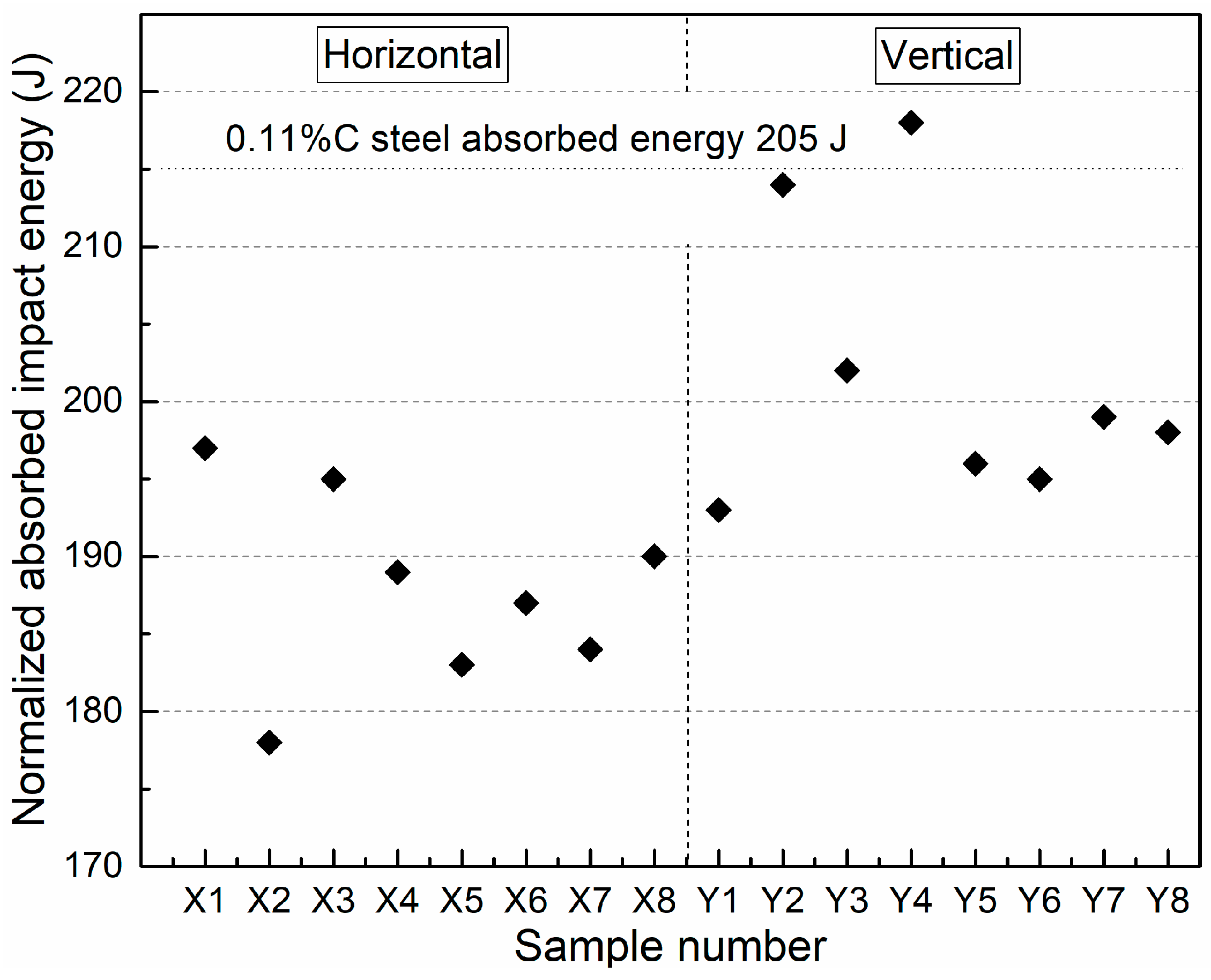

2. Method and Experiment

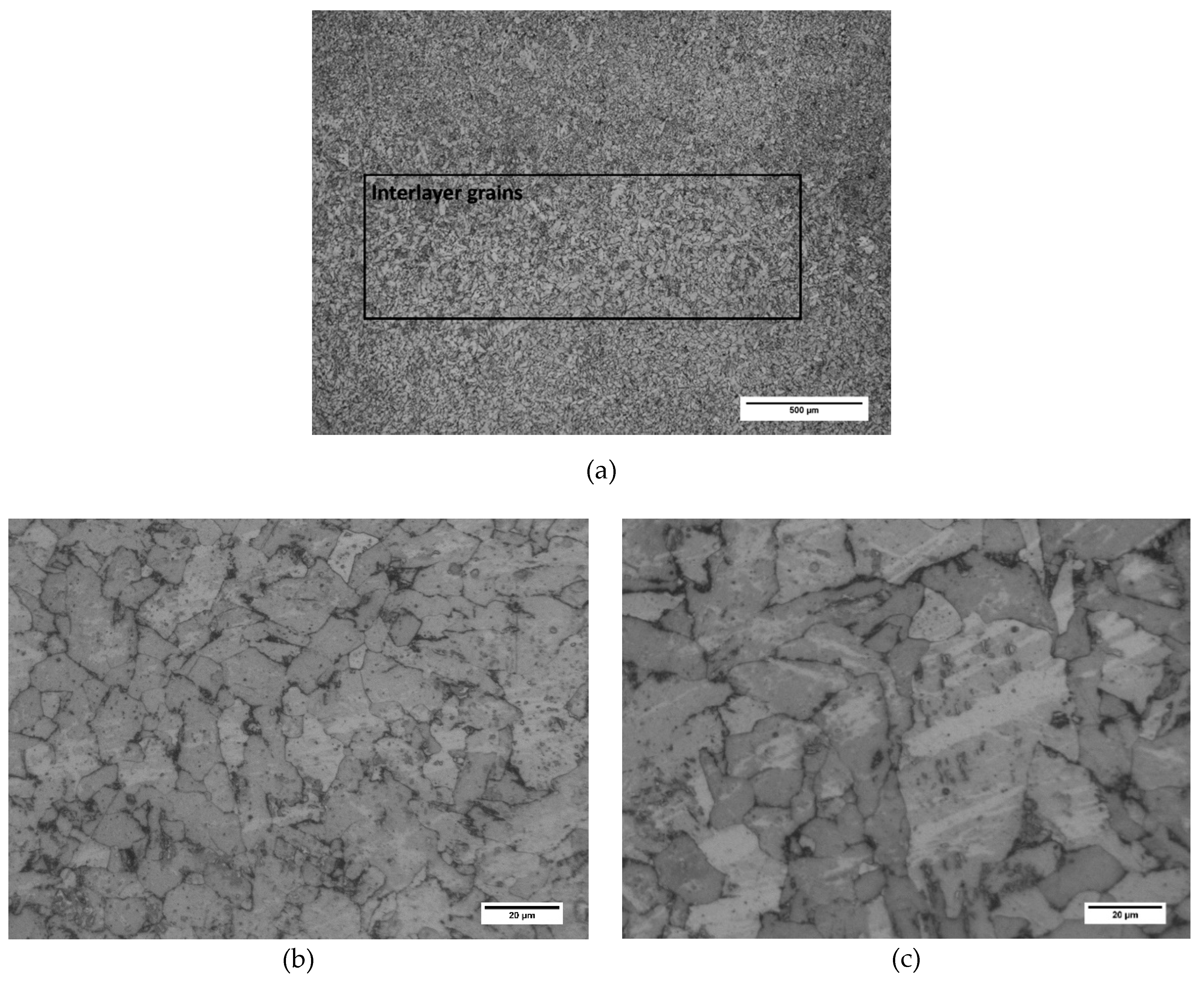

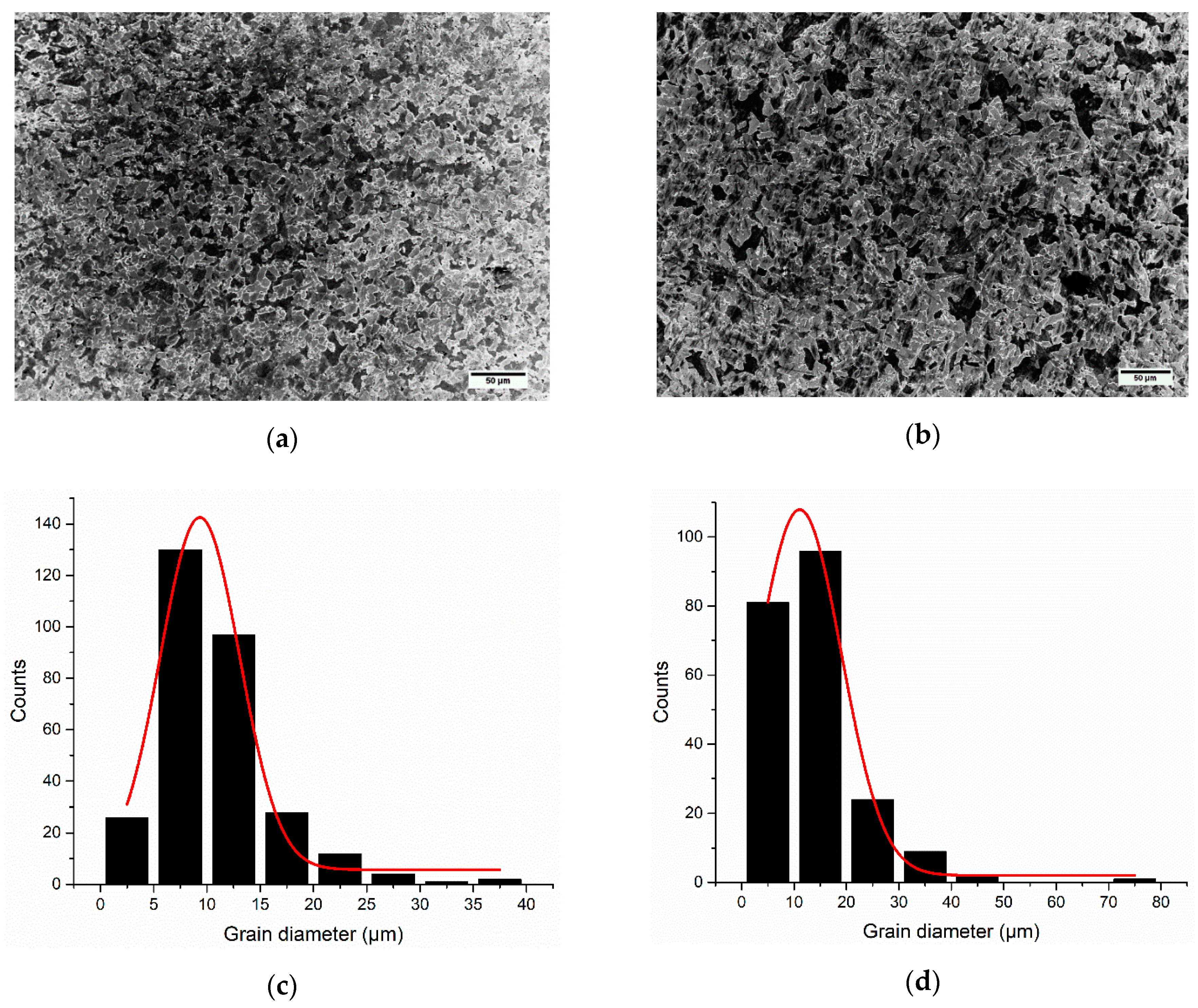

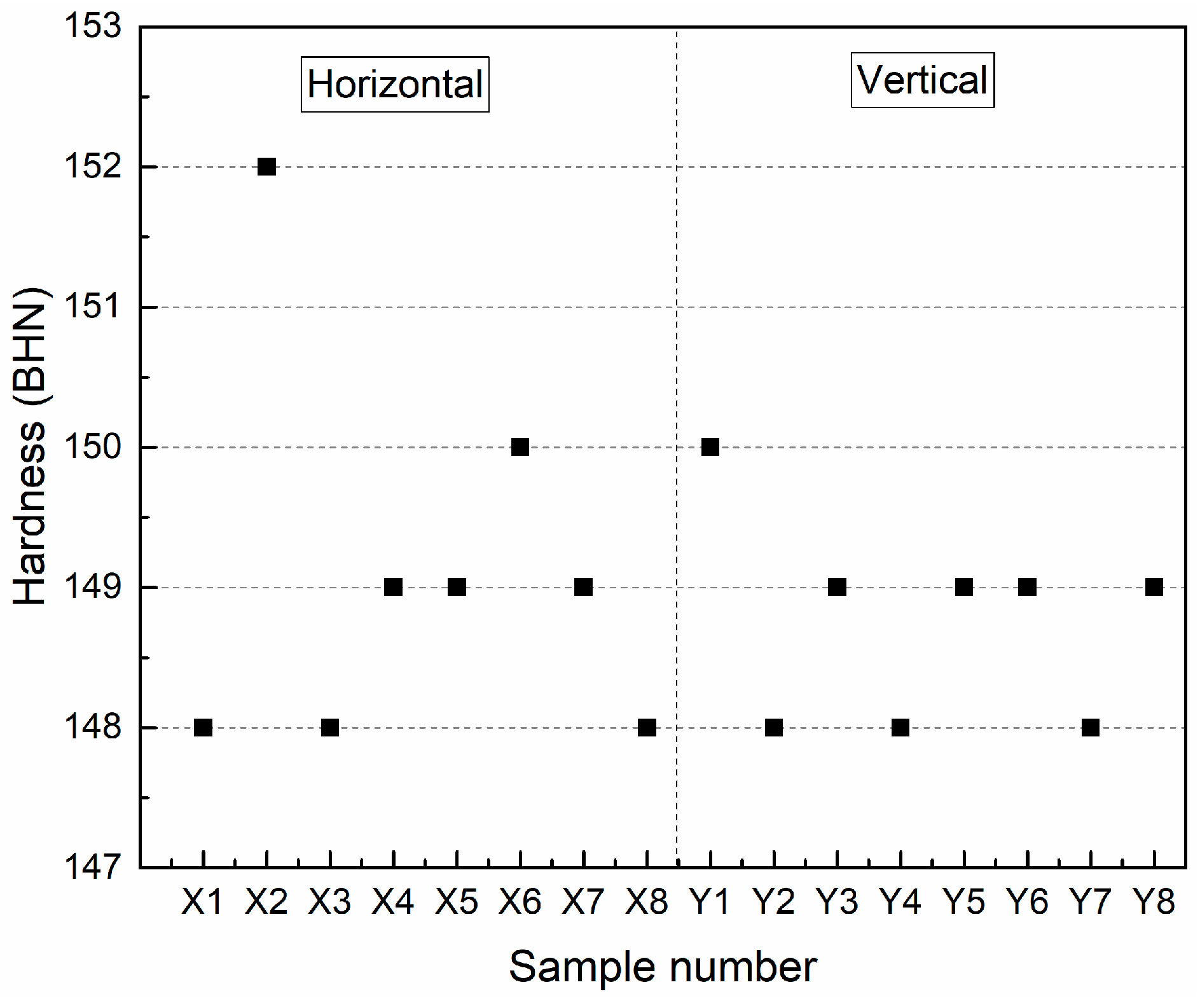

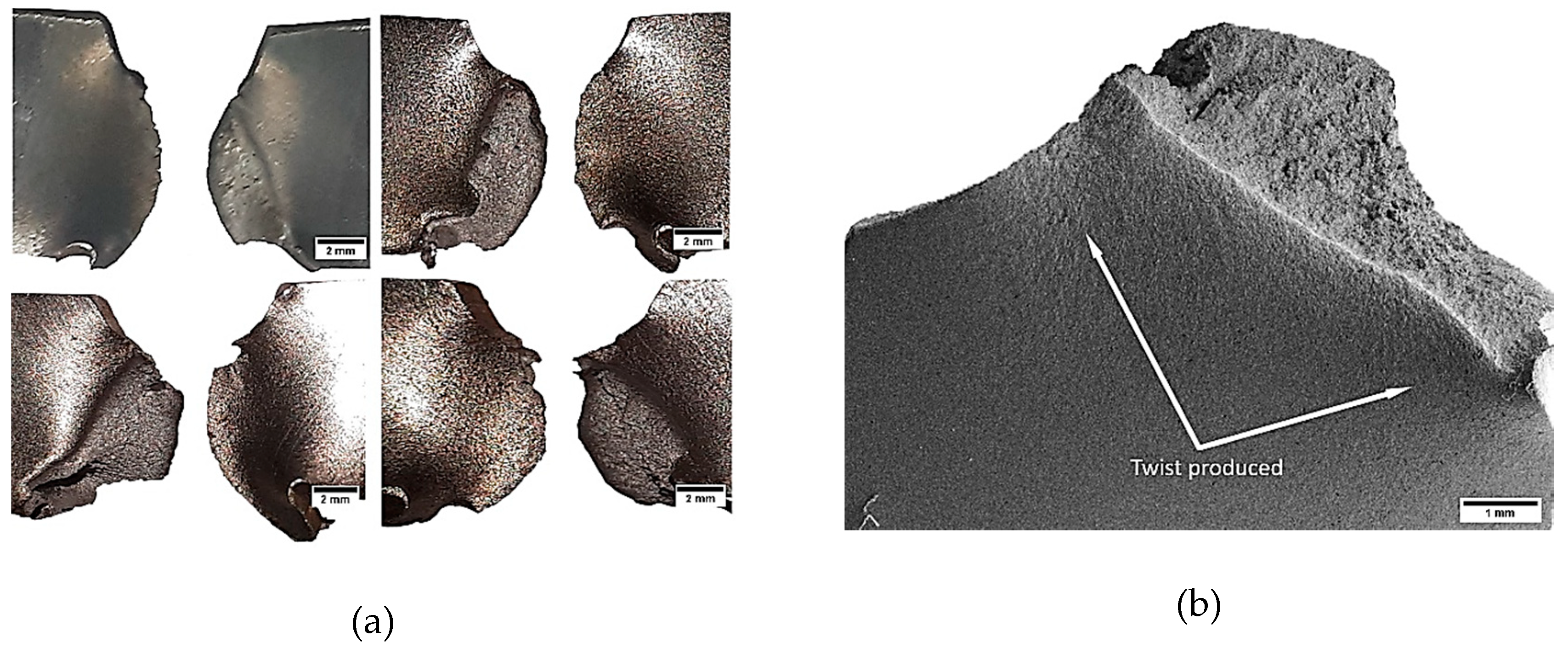

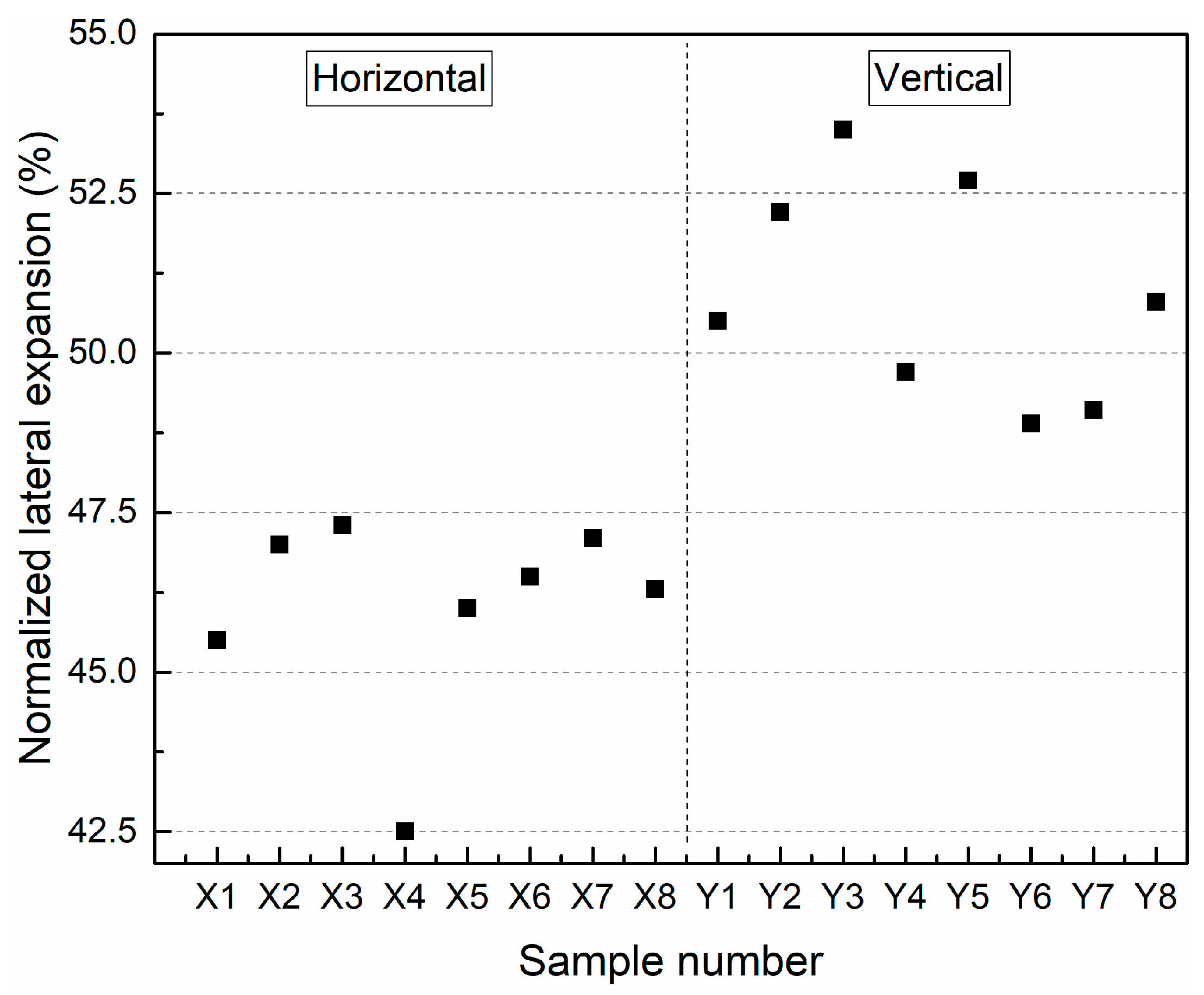

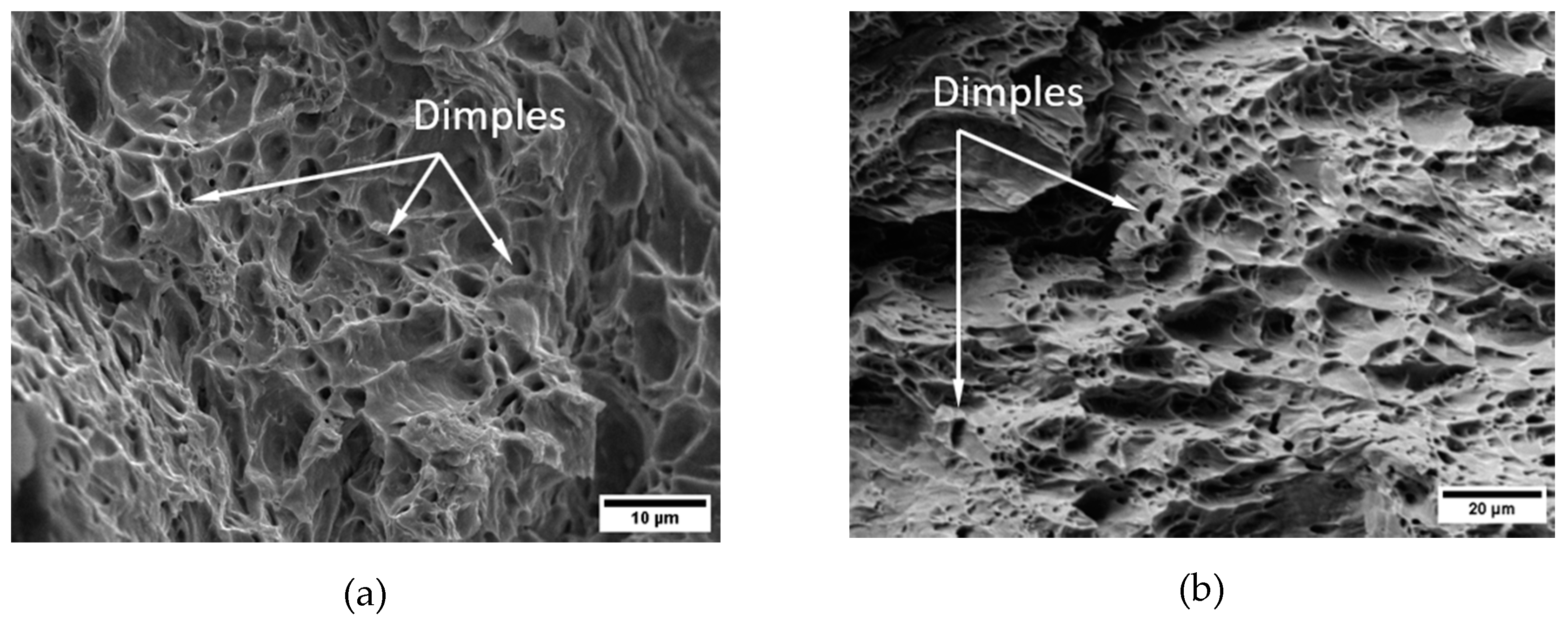

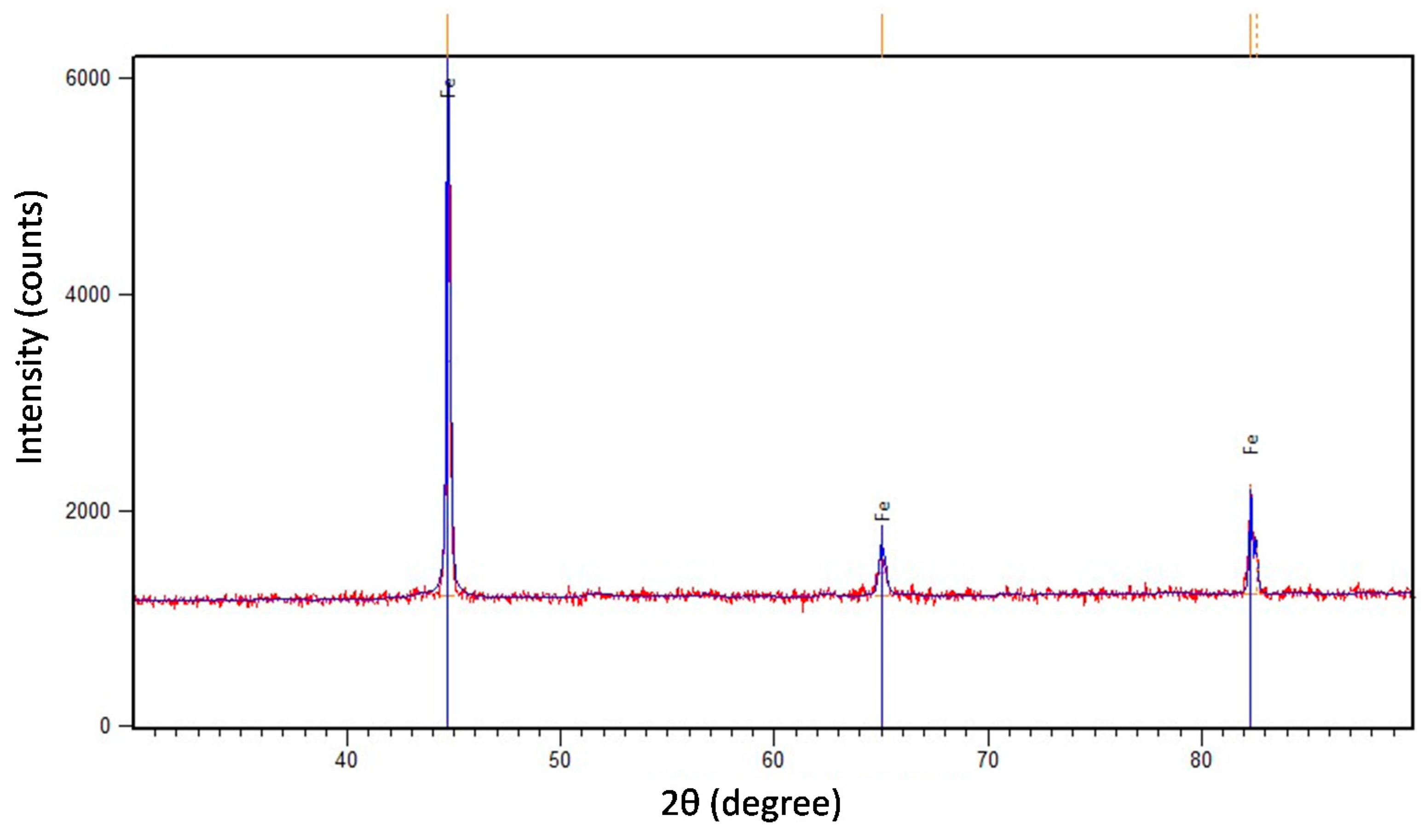

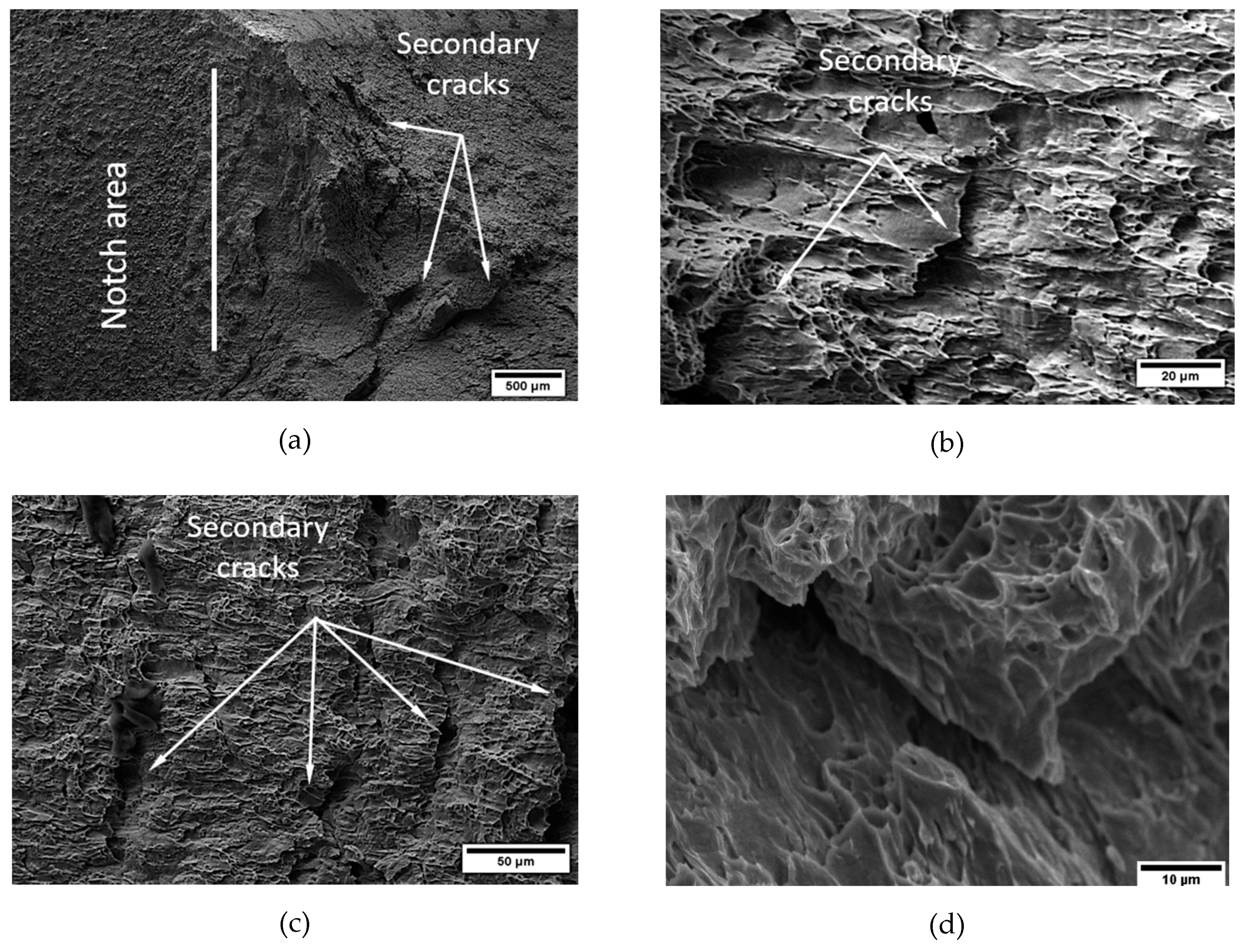

3. Results and Discussion

4. Conclusion

Author Contributions

Funding

Conflicts of Interest

References

- Frazier, E.W. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Antonysamy, A. Microstructure, texture and mechanical property evolution during additive manufacturing of Ti6Al4V alloy for aerospace applications. PhD Thesis, University of Manchester, Manchester, UK, 2012. [Google Scholar]

- Buckner, M.; Lonnie, J. Automating and accelerating the additive manufacturing design process with multi-objective constrained evolutionary optimization and HPC/Cloud computing. In Proceedings of the 2012 Future of Instrumentation International Workshop (FIIW), Gatlinburg, TN, USA, 8–9 October 2012. [Google Scholar]

- Brandl, E.; Baufeld, B.; Leyens, C. Additive manufactured Ti-6Al-4V using welding wire: comparison of laser and arc beam deposition and evaluation with respect to aerospace material specifications. Physics Procedia 2010, 5(Part B), 595–606. [Google Scholar] [CrossRef]

- Pandremenos, J.; Doukas, C.; Stavropoulos, P.; Chryssolouris, G. Machining with robots: a critical review. In Proceedings of the 7th International Conference on Digital Enterprise Technology, Athens, Greece, 28–30 September 2011. [Google Scholar]

- Wang, Y.; Chen, X.; Konovalov, S. Additive manufacturing based on welding arc: a low-cost method. J. Surf. Invest. 2017, 11, 1317–1328. [Google Scholar] [CrossRef]

- Chen, X.; Su, C.; Wang, Y.; Siddiquee, A.N.; Sergey, K.; Jayalakshmi, S.; Singh, R.A. Cold Metal Transfer (CMT) Based Wire and Arc Additive Manufacture (WAAM) System. J. Surf. Invest. 2018, 12, 1278–1284. [Google Scholar] [CrossRef]

- Müller, J.; Grabowski, M.; Müller, C.; Hensel, J.; Unglaub, J.; Thiele, K.; Kloft, H.; Dilger, K. Design and Parameter Identification of Wire and Arc Additively Manufactured (WAAM) Steel Bars for Use in Construction. Metals 2019, 9, 725. [Google Scholar] [CrossRef]

- Rodrigues, T.A.; Duarte, V.; Avila, J.A.; Santos, T.G.; Miranda, R.; Oliveira, J. Wire and arc additive manufacturing of HSLA steel: Effect of thermal cycles on microstructure and mechanical properties. Addit. Manuf. 2019, 27, 440–450. [Google Scholar] [CrossRef]

- Oliveira, J.; Santos, T.; Miranda, R. Revisiting fundamental welding concepts to improve additive manufacturing: From theory to practice. Prog. Mater. Sci. 2019, 107, 100590. [Google Scholar] [CrossRef]

- Rodrigues, T.A.; Duarte, V.; Miranda, R.; Santos, T.G.; Oliveira, J. Current Status and Perspectives on Wire and Arc Additive Manufacturing (WAAM). Materials 2019, 12, 1121. [Google Scholar] [CrossRef]

- Cunningham, C.; Flynn, J.; Shokrani, A.; Dhokia, V.; Newman, S. Invited review article: Strategies and processes for high quality wire arc additive manufacturing. Addit. Manuf. 2018, 22, 672–686. [Google Scholar] [CrossRef]

- Xiong, J.; Yin, Z.Q.; Zhang, W.H. Forming appearance control of arc striking and extinguishing area in multi-layer single-pass GMAW-based additive manufacturing. Int. J. Adv. Manuf. Tech. 2016, 87, 579–586. [Google Scholar] [CrossRef]

- Hu, Z.; Qin, X.; Shao, T.; Liu, H. Understanding and overcoming of abnormity at start and end of the weld bead in additive manufacturing with GMAW. Int. J. Adv. Manuf. Tech. 2018, 95, 2357–2368. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, Y.; Li, P.; Male, A.T. Weld deposition-based rapid prototyping: a preliminary study. J. Mater. Process. Technol. 2003, 135, 347–357. [Google Scholar] [CrossRef]

- Waqas, A.; Qin, X.; Xiong, J.; Wang, H.; Zheng, C. Optimization of Process Parameters to Improve the Effective Area of Deposition in GMAW-Based Additive Manufacturing and its Mechanical and Microstructural Analysis. Metals 2019, 9, 775. [Google Scholar] [CrossRef]

- Zhao, H.H.; Zhang, G.J.; Yin, Z.Q.; Wu, L. A 3D dynamic analysis of thermal behavior during single-pass multi-layer weld-based rapid prototyping. J. Mater. Process. Technol. 2011, 211, 488–495. [Google Scholar] [CrossRef]

- Cao, W.; Zhang, M.; Huang, C.; Xiao, S.; Dong, H.; Weng, Y. Ultrahigh Charpy impact toughness (~450 J) achieved in high strength ferrite/martensite laminated steels. Sci. Rep. 2017, 7, 41459. [Google Scholar] [CrossRef]

- Rojas, P.; Martinez, C.; Vera, R.; Puentes, M. Toughness of SAE 1020 Steel with and without Galvanization Exposed to Different Corrosive Environments in Chile. Int. J. Electrochem. Sci. 2014, 9, 2848–2858. [Google Scholar]

- Salimi, A.; Zadeh, H.M.; Toroghinejad, M.R.; Asefi, D.; Ansaripour, A. Influence of Sample Direction on the Impact Toughness of the Api-X42 Microalloyed Steel with a Banded Structure. Mater. Technol.. 2013, 47, 385–389. [Google Scholar]

- Lucon, E.; McCowan, C.N.; Santoyo, R.L. Certification of NIST Room Temperature Low-Energy and High-Energy Charpy Verification Specimens. J. Res. Nat. Inst. Stand. Technol. 2015, 120, 316–328. [Google Scholar] [CrossRef]

- Dean, S.W.; Manahan, M.P.; Mccowan, C.N. Percent Shear Area Determination in Charpy Impact Testing. J. ASTM Int. 2008, 5, 101662–101676. [Google Scholar] [CrossRef]

- Parrington, R.J. Fractographic features in metals and plastics. Adv. Mater. Processes 2003, 161, 37–40. [Google Scholar]

- Wei, R.P. Fracture mechanics: Integration of mechanics, materials science and chemistry; Cambridge University Press: Cambridge, UK, 2010; pp. 24–54. [Google Scholar]

- ASTM E23: Standard Test Methods for Notched Bar Impact Testing of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2007.

- Davis, J. Metals Handbook, Desk, Edition, 2nd ed.; ASM International, The Materials Information Society: West Conshohocken, PA, USA, 1998; pp. 560–564. [Google Scholar]

- Arzt, E. Size effects in materials due to microstructural and dimensional constraints: a comparative review. Acta Mater. 1998, 46, 5611–5626. [Google Scholar] [CrossRef]

- Calcagnotto, M.; Adachi, Y.; Ponge, D.; Raabe, D. Deformation and fracture mechanisms in fine-and ultrafine-grained ferrite/martensite dual-phase steels and the effect of aging. Acta. Mater. 2011, 59, 658–670. [Google Scholar] [CrossRef]

- ASTM E112: Standard Test Methods for Determining Average Grain Size; ASTM International: West Conshohocken, PA, USA, 1996; pp. 4–20.

- Gharibshahiyan, E.; Raouf, A.H.; Parvin, N.; Rahimian, M. The effect of microstructure on hardness and toughness of low carbon welded steel using inert gas welding. Mater. Des. 2011, 32, 2042–2048. [Google Scholar] [CrossRef]

- Zhao, Y.; Tong, X.; Wei, X.; Xu, S.; Lan, S.; Wang, X.-L.; Zhang, Z. Effects of microstructure on crack resistance and low-temperature toughness of ultra-low carbon high strength steel. Int. J. Plast. 2019, 116, 203–215. [Google Scholar] [CrossRef]

- Thompson, S. Interrelationships between yield strength, low-temperature impact toughness, and microstructure in low-carbon, copper-precipitation-strengthened, high-strength low-alloy plate steels. Mater. Sci. Eng. A 2018, 711, 424–433. [Google Scholar] [CrossRef]

- Kocatepe, K.; Cerah, M.; Erdogan, M. The tensile fracture behaviour of intercritically annealed and quenched+ tempered ferritic ductile iron with dual matrix structure. Mater. Des. 2007, 28, 172–181. [Google Scholar] [CrossRef]

- Kysar, J.W. Energy dissipation mechanisms in ductile fracture. J. Mech. Phys. Solids 2003, 51, 795–824. [Google Scholar] [CrossRef]

- Das, A.; Viehrig, H.-W.; Altstadt, E.; Bergner, F.; Hoffmann, J. Why Do Secondary Cracks Preferentially Form in Hot-Rolled ODS Steels in Comparison with Hot-Extruded ODS Steels? Crystals 2018, 8, 306. [Google Scholar] [CrossRef]

- Chao, Y.J.; Ward Jr, J.; Sands, R.G. Charpy impact energy, fracture toughness and ductile-brittle transition temperature of dual-phase 590 Steel. Mater. Des. 2007, 28, 551–557. [Google Scholar] [CrossRef]

- Barsom, J.M.; Rolfe, S.T. Fracture and Fatigue Control in Structures: Applications of Fracture Mechanics; ASTM International: West Conshohocken, PA, USA, 1977; pp. 121–132. [Google Scholar]

| Elements | C | Mn | Si | S | P | Ni | Cr | Mo | V | Cu | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| wt. % | 0.1 | 1.56 | 0.88 | 0.012 | 0.011 | 0.01 | 0.02 | <0.01 | <0.01 | 0.24 | Bal. |

| Parameters | Current | Voltage | Welding Energy | Travel Speed |

|---|---|---|---|---|

| Value (units) | 120 (A) | 19 (V) | 660 (J/mm) | 3.5 (mm/s) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Waqas, A.; Qin, X.; Xiong, J.; Zheng, C.; Wang, H. Analysis of Ductile Fracture Obtained by Charpy Impact Test of a Steel Structure Created by Robot-Assisted GMAW-Based Additive Manufacturing. Metals 2019, 9, 1208. https://doi.org/10.3390/met9111208

Waqas A, Qin X, Xiong J, Zheng C, Wang H. Analysis of Ductile Fracture Obtained by Charpy Impact Test of a Steel Structure Created by Robot-Assisted GMAW-Based Additive Manufacturing. Metals. 2019; 9(11):1208. https://doi.org/10.3390/met9111208

Chicago/Turabian StyleWaqas, Ali, Xiansheng Qin, Jiangtao Xiong, Chen Zheng, and Hongbo Wang. 2019. "Analysis of Ductile Fracture Obtained by Charpy Impact Test of a Steel Structure Created by Robot-Assisted GMAW-Based Additive Manufacturing" Metals 9, no. 11: 1208. https://doi.org/10.3390/met9111208

APA StyleWaqas, A., Qin, X., Xiong, J., Zheng, C., & Wang, H. (2019). Analysis of Ductile Fracture Obtained by Charpy Impact Test of a Steel Structure Created by Robot-Assisted GMAW-Based Additive Manufacturing. Metals, 9(11), 1208. https://doi.org/10.3390/met9111208