Research on the Micro-Extrusion Process of Copper T2 with Different Ultrasonic Vibration Modes

Abstract

1. Introduction

2. Materials and Methods

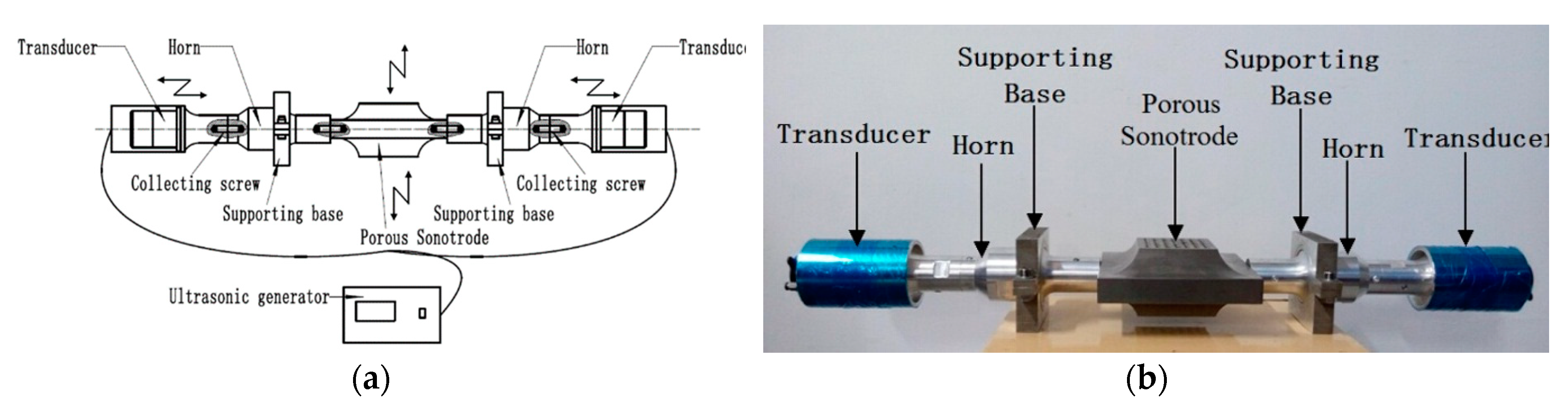

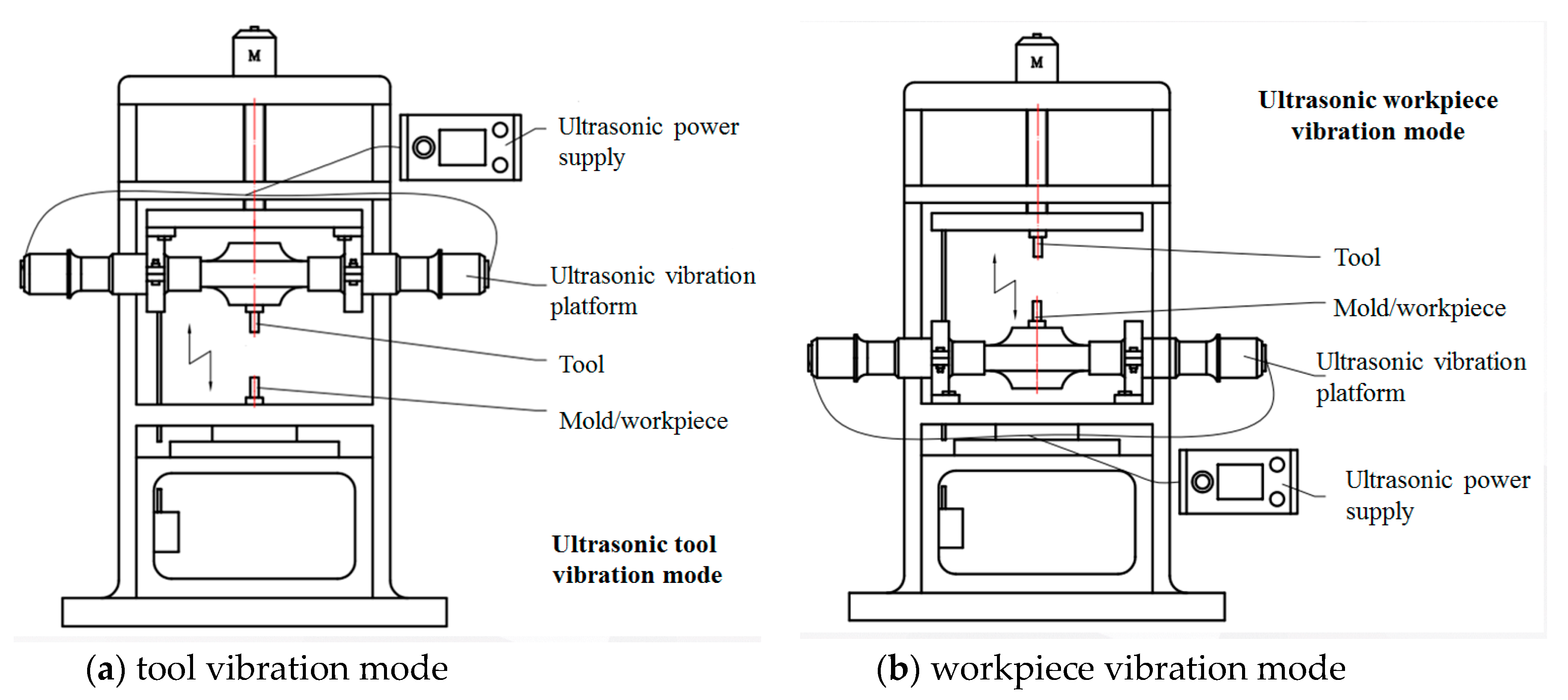

2.1. Experimental Set-Up

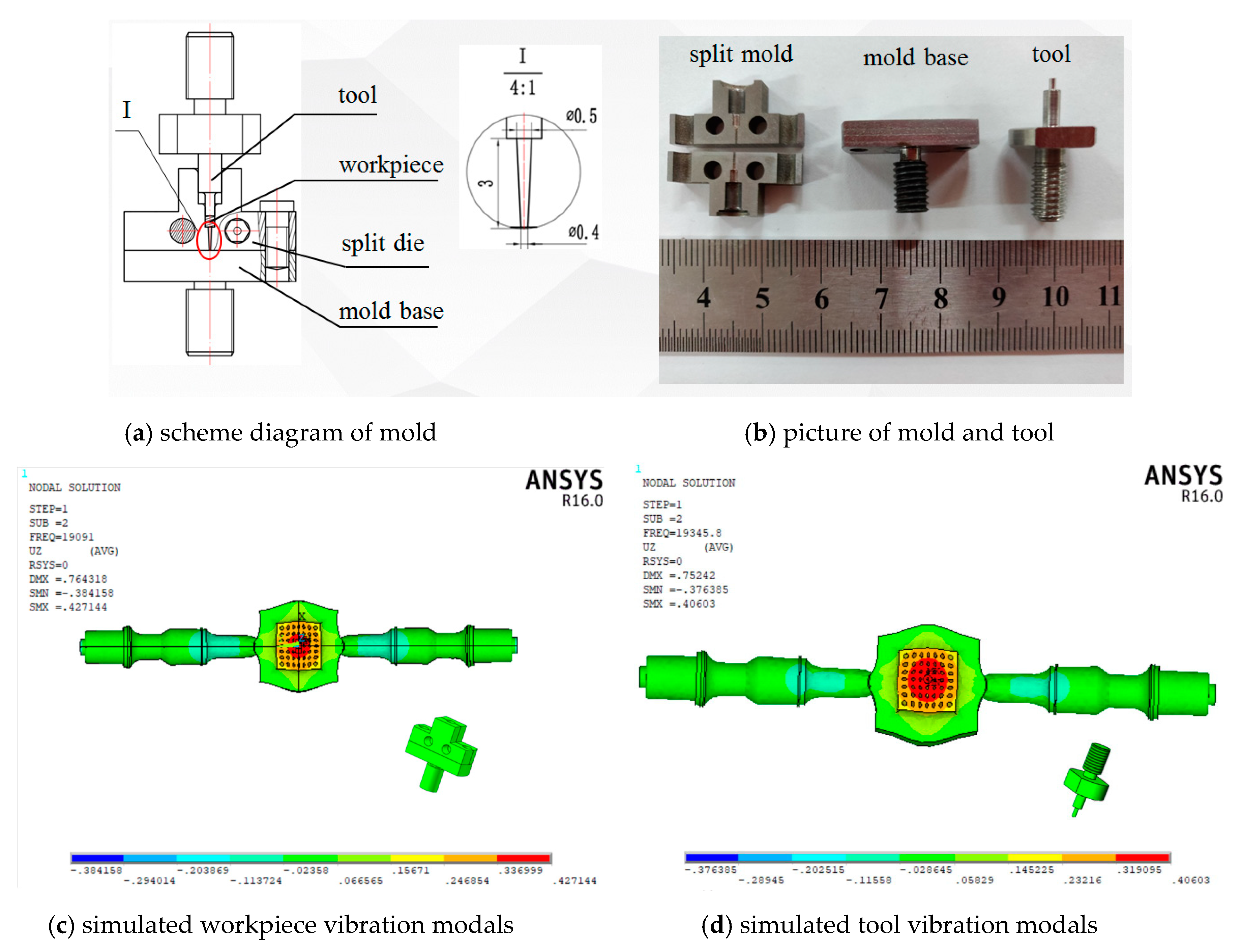

2.2. Specimens and Mold

2.3. Experimental Procedure

3. Results

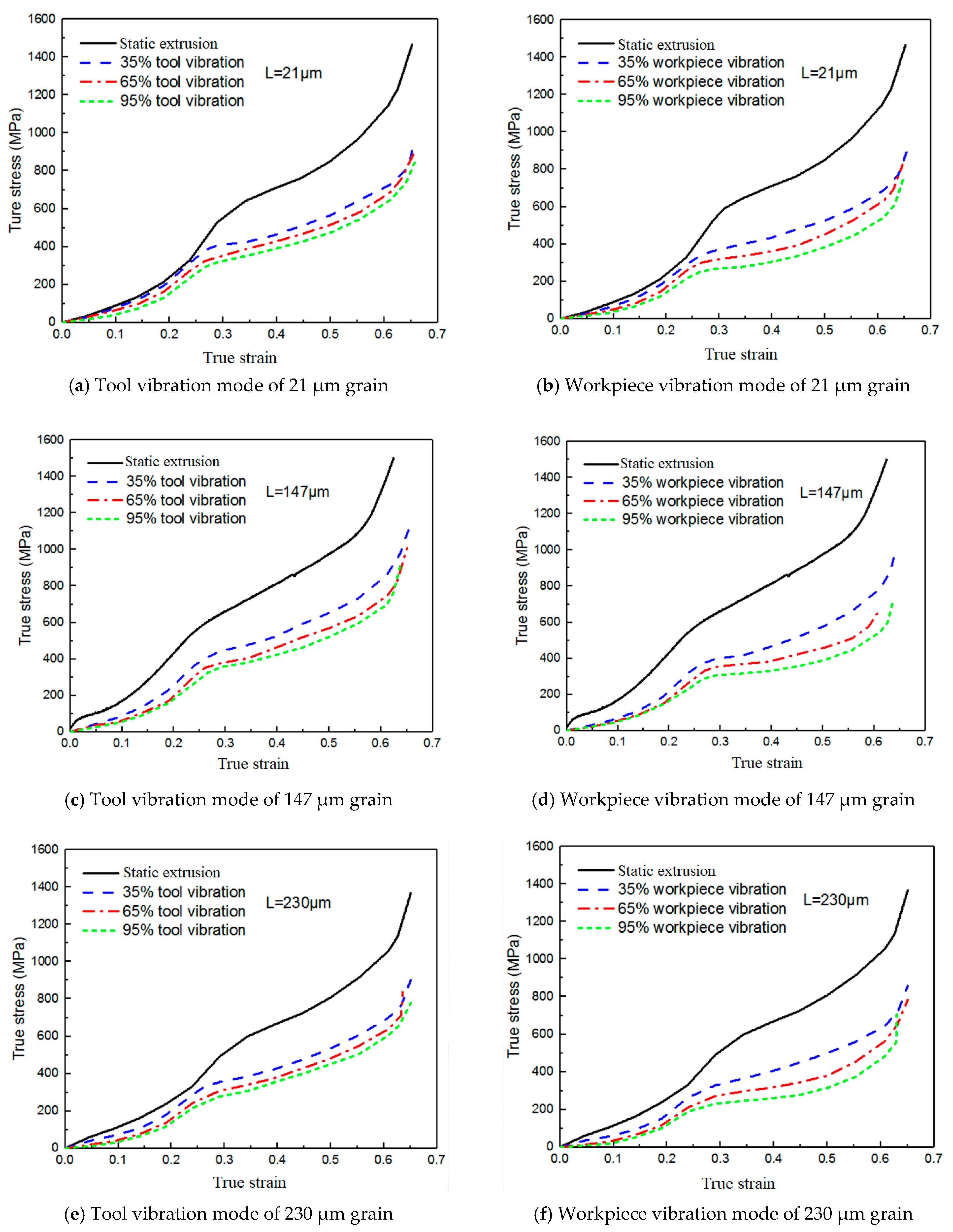

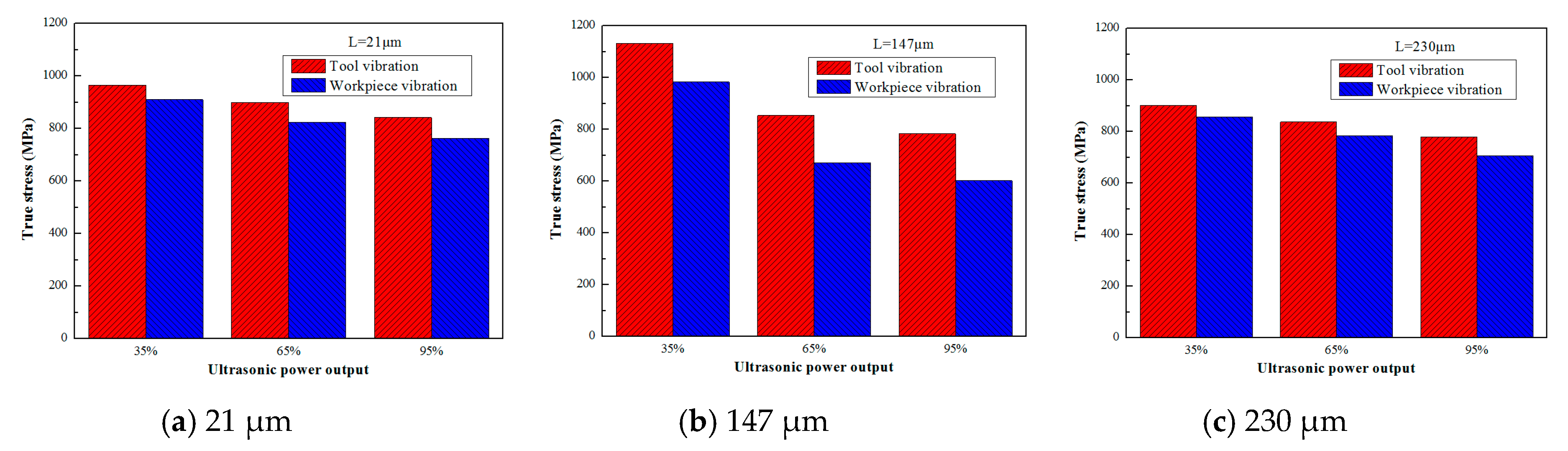

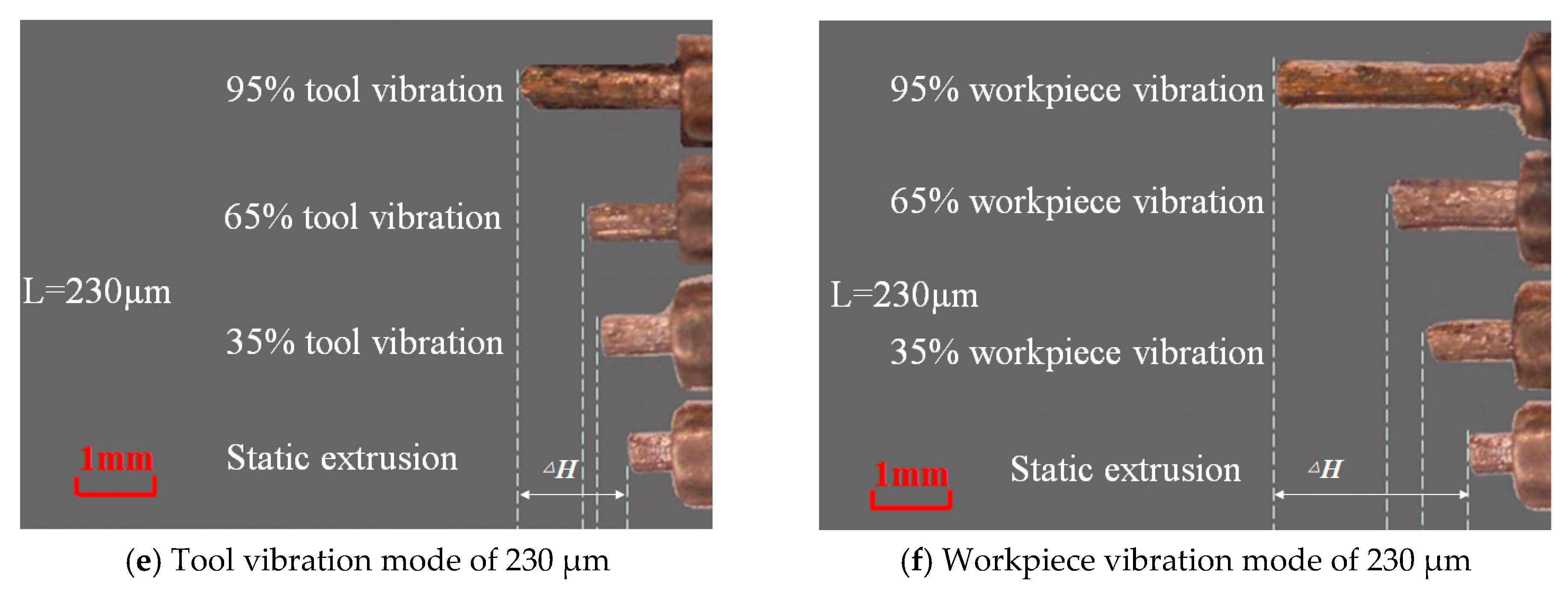

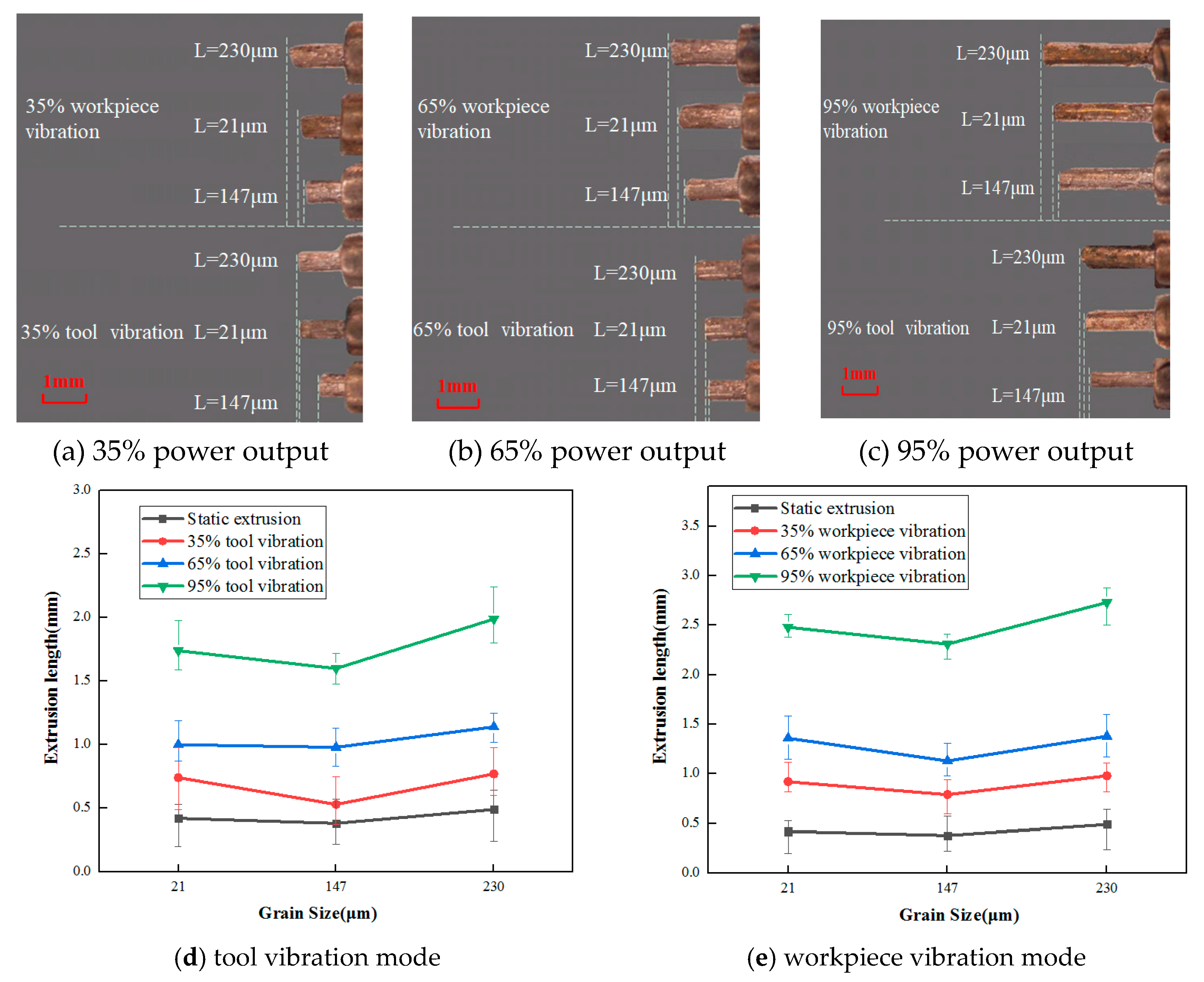

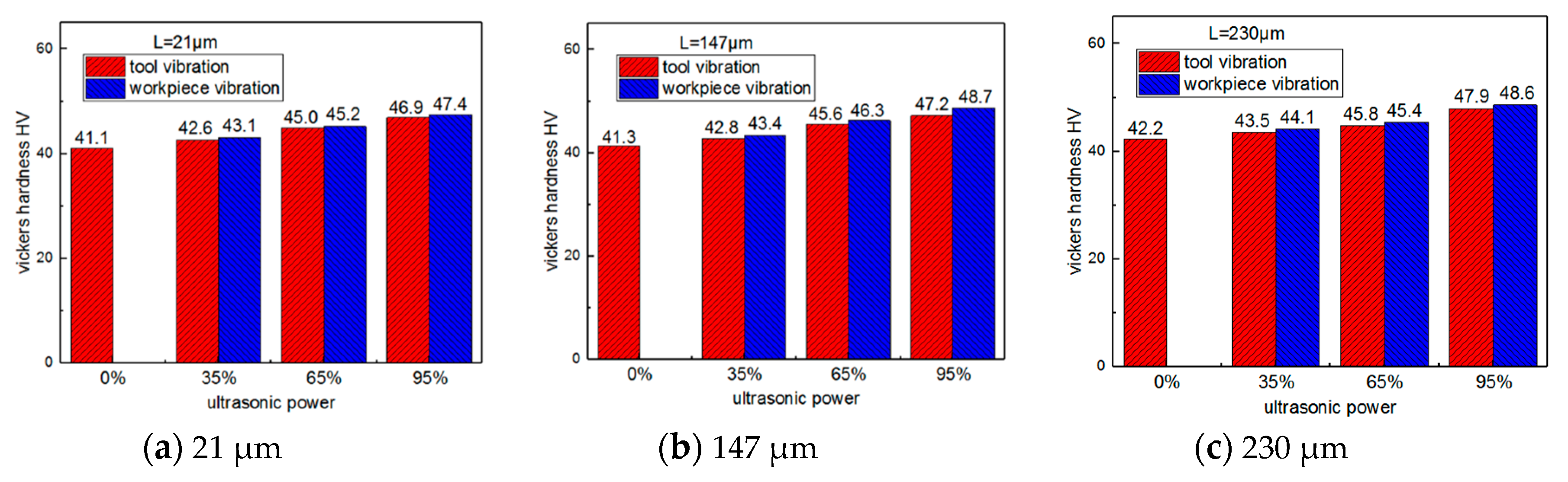

3.1. Effect of Ultrasonic Power Output and Vibration Modes

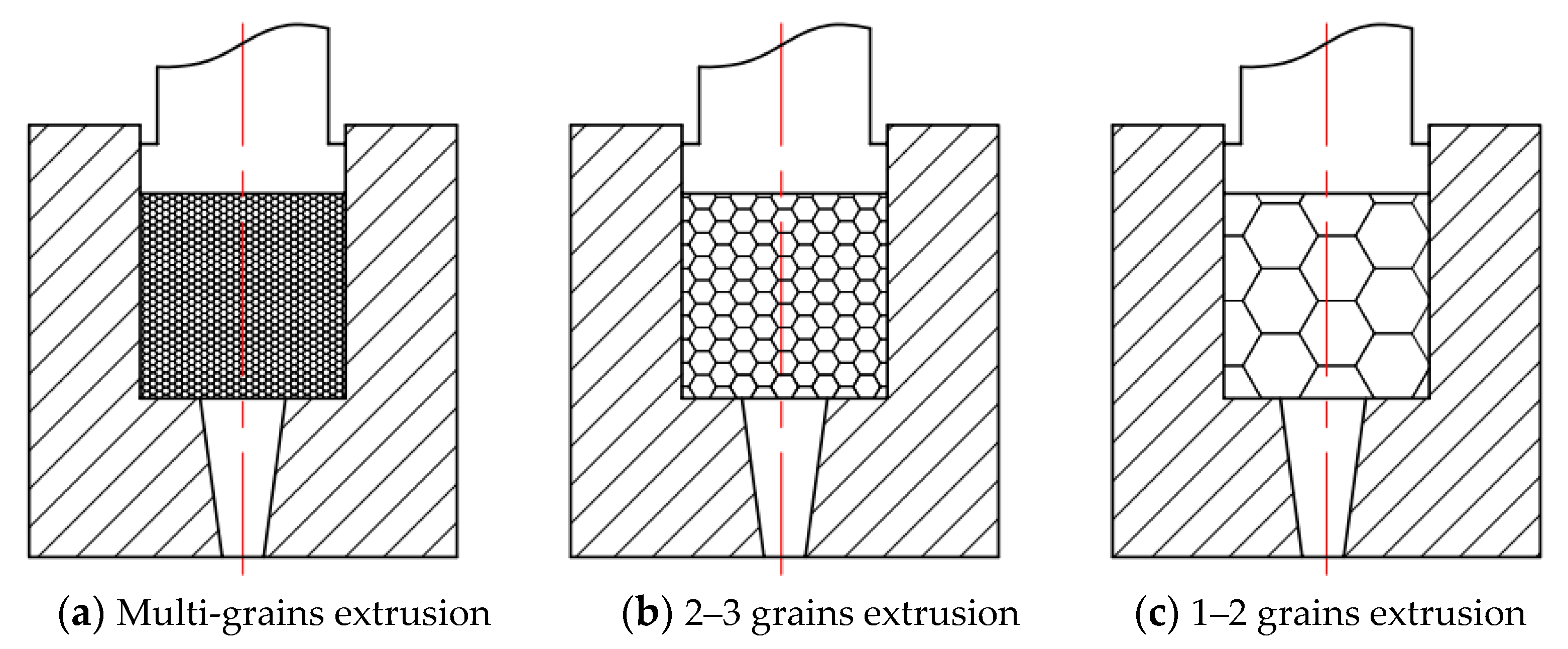

3.2. Effect of Copper Grain Size

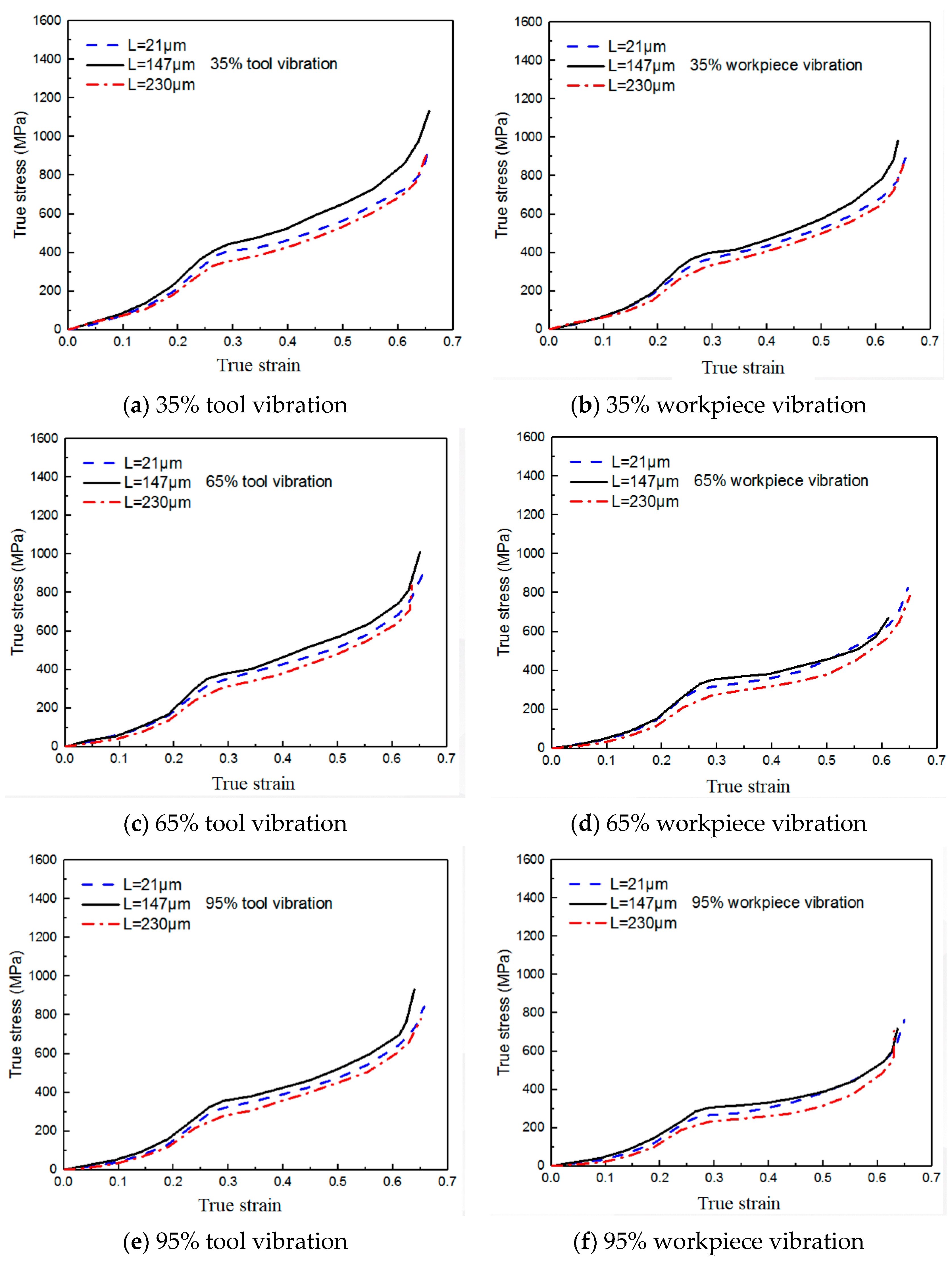

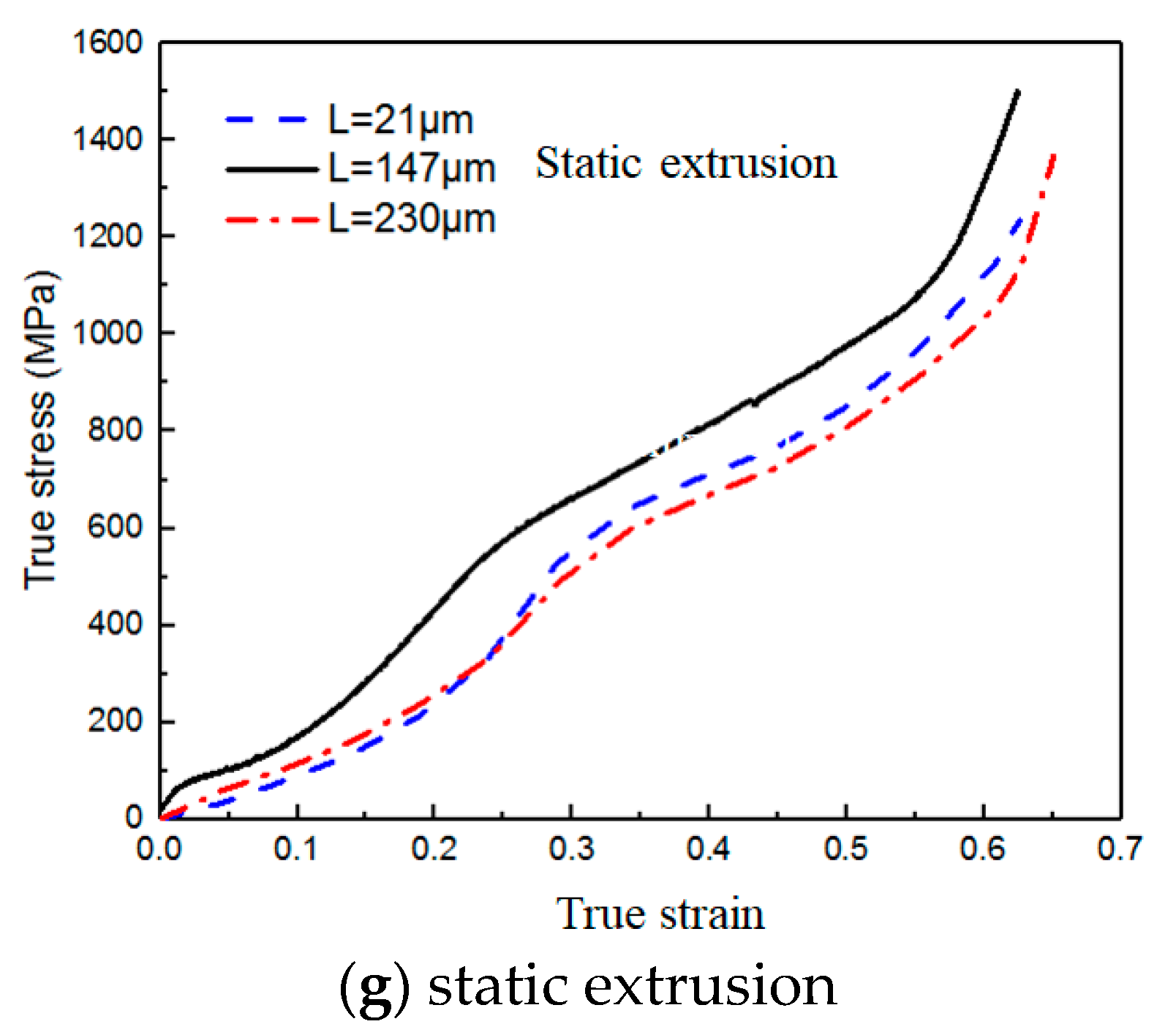

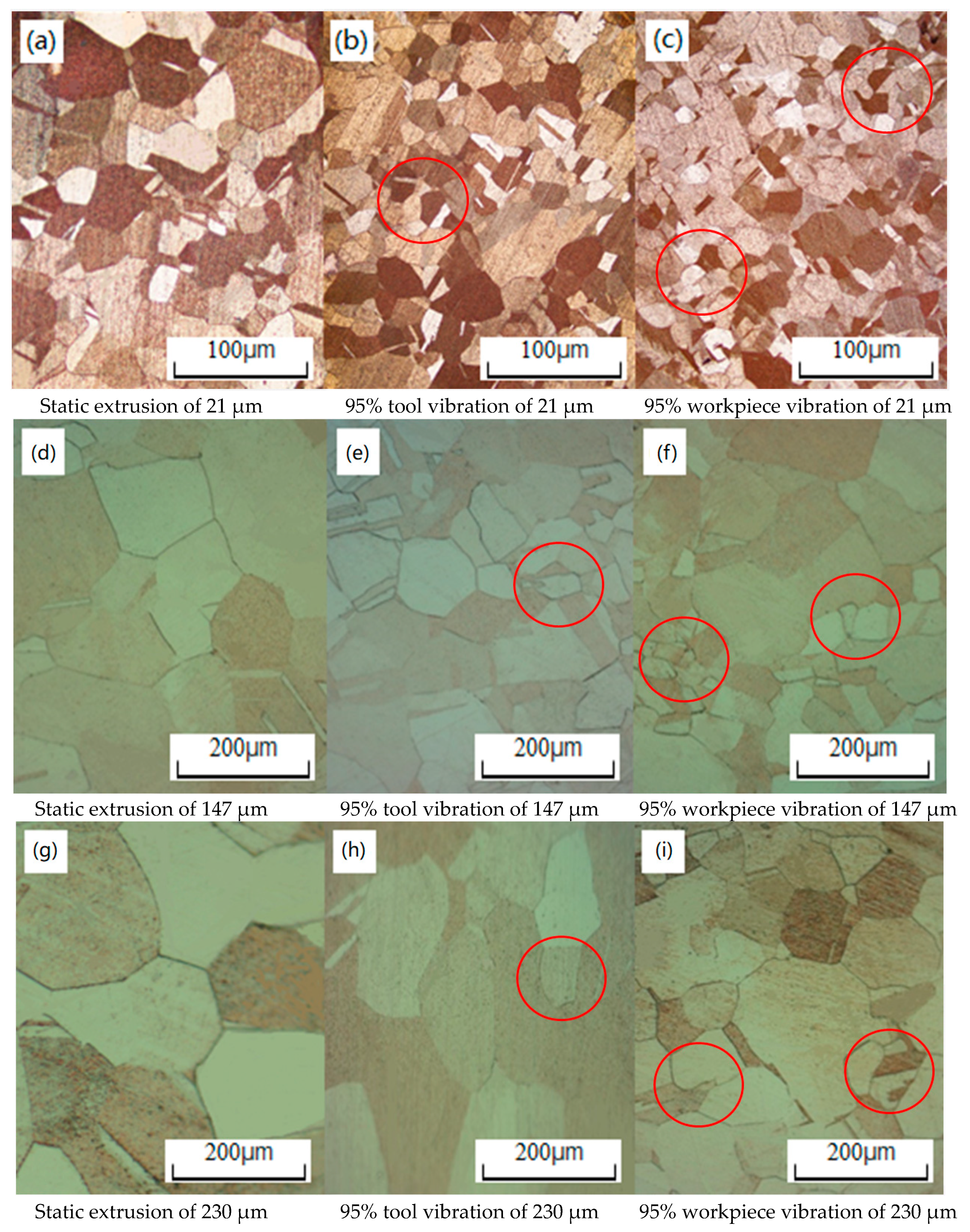

3.3. Microstructure Properties of Different Vibration Modes

3.4. Discussions

3.4.1. Ultrasonic Softening Effect

3.4.2. Grain Size Effect

4. Conclusions

- The ultrasonic vibration system and plastic forming press machine with porous sonotrode realized micro-extrusion process with ultrasonic vibration of tool or workpiece, respectively.

- The ultrasonic micro extrusion process with the workpiece vibration mode had better ultrasonic energy transmission and absorption capacity, which made the micro forming characteristics of copper T2 better than that of tool vibration mode.

- The ultrasonic vibration assisted energy helped to improve the grain size effect on double crystal scale micro-extrusion process of copper T2, in which the workpiece vibration mode usually obtained better micro-forming ability than that of tool vibration mode.

Author Contributions

Funding

Conflicts of Interest

References

- Sedaghat, H.; Xu, W.X.; Zhang, L.C. Ultrasonic vibration-assisted metal forming: Constitutive modelling of acoustoplasticity and applications. J. Mater. Process. Technol. 2019, 265, 122–129. [Google Scholar] [CrossRef]

- Fu, M.W.; Wang, J.L.; Korsunsky, A.M. A review of geometrical and microstructural size effects in micro-scale deformation processing of metallic alloy components. Int. J. Mach. Tools Manuf. 2016, 109, 94–125. [Google Scholar] [CrossRef]

- Jun, H.; Tetsuhide, S.; Tomoaki, Y.; Tomomi, S.; Ming, Y. Ultrasonic dynamic impact effect on deformation of aluminum during micro-compression tests. J. Mater. Process. Technol. 2018, 258, 144–154. [Google Scholar]

- Lou, Y.; Liu, X.; He, J.S.; Long, M. Ultrasonic-assisted extrusion of ZK60Mg alloy micropins at room temperature. Ultrasonics 2018, 83, 194–202. [Google Scholar] [CrossRef] [PubMed]

- Yao, Z.H.; Kim, G.Y.; Faidley, L.A.; Zou, Q.Z.; Mei, D.Q.; Chen, Z.C. Effects of superimposed high-frequency vibration on deformation of aluminum in micro/meso-scale upsetting. J. Mater. Process. Technol. 2012, 212, 640–646. [Google Scholar] [CrossRef]

- Hung, J.C.; Tsai, Y.C. Investigation of the effects of ultrasonic vibration-assisted micro-upsetting on brass. Mater. Sci. Eng. A 2013, 580, 125–132. [Google Scholar] [CrossRef]

- Bai, Y.; Yang, M. Optimization of metal foils surface finishing using vibration-assisted micro-forging. J. Mater. Process. Technol. 2014, 214, 21–28. [Google Scholar] [CrossRef]

- Azarhoushang, B.; Tawakoli, T. Developing a special block sonotrode for ultrasonic-assisted grinding process. Int. J. Mechatron. Manuf. Syst. 2012, 5, 165–174. [Google Scholar] [CrossRef]

- Daud, Y.; Lucas, M.; Huang, Z.H. Superimposed ultrasonic oscillations in compression tests of aluminium. Ultrasonics 2006, 44, 511–515. [Google Scholar] [CrossRef] [PubMed]

- Bunget, C.; Ngaile, G. Influence of ultrasonic vibration on micro-extrusion. Ultrasonics 2011, 51, 606–616. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.J.; Liu, Y.; Shan, D.J.; Guo, B.; Han, H.B. Investigations on mechanical properties of copper foil under ultrasonic vibration considering size effect. Procedia Eng. 2017, 207, 1057–1062. [Google Scholar] [CrossRef]

- Lu, T.T.; Shen, Y.; Yu, H.P.; Dong, X.H.; Hu, J. Influence of ultrasonic vibration on pure titanium TA1 micro cylinder compression. J. Plast. Eng. 2016, 23, 14–18. (In Chinese) [Google Scholar]

- Zhou, H.Y.; Cui, H.Z.; Qin, Q.H. Influence of ultrasonic vibration on the plasticity of metals during compression process. J. Mater. Process. Technol. 2018, 251, 146–159. [Google Scholar] [CrossRef]

- Han, G.C.; Li, K.; Peng, Z.; Jin, J.S.; Sun, M.; Wang, X.Y. A new porous block sonotrode for ultrasonic assisted micro plastic forming. Int. J. Adv. Manuf. Technol. 2017, 89, 2193–2202. [Google Scholar] [CrossRef]

- Han, G.C.; Peng, Z.; Xu, L.H.; Li, N. Ultrasonic Vibration Facilitates the Micro-Formability of a Zr-Based Metallic Glass. Materials 2018, 11, 2568. [Google Scholar] [CrossRef] [PubMed]

- Lei, Y.L.; Han, G.C.; Sheng, C.J.; Zhang, Z.C. Design of 10kN ultrasonic-assisted plastic forming press machine and experimental research. J. Beijing Univ. Aeronaut. Astronaut. 2019, 45, 1622–1629. (In Chinese) [Google Scholar]

- Yao, Z.H.; Kim, G.Y.; Wang, Z.H.; Faidley, L.A.; Zou, Q.Z.; Mei, D.Q.; Chen, Z.C. Acoustic softening and residual hardening in aluminum: Modeling and experiments. Int. J. Plast. 2012, 39, 75–87. [Google Scholar] [CrossRef]

- Wang, C.J.; Liu, Y.; Guo, B.; Shan, D.B.; Zhang, B. Acoustic softening and stress superposition in ultrasonic vibration assisted uniaxial tension of copper foil: Experiments and modeling. Mater. Des. 2016, 112, 246–253. [Google Scholar] [CrossRef]

- Wang, C.J.; Wang, H.Y.; Xue, S.X.; Chen, G.; Wang, Y.B.; Wang, S.T.; Zhang, P. Size effect affected mechanical properties and formability in micro plane strain deformation process of pure nickel. J. Mater. Process. Technol. 2018, 258, 319–325. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, L.; Lei, Y.; Zhang, H.; Zhang, Z.; Sheng, Y.; Han, G. Research on the Micro-Extrusion Process of Copper T2 with Different Ultrasonic Vibration Modes. Metals 2019, 9, 1209. https://doi.org/10.3390/met9111209

Xu L, Lei Y, Zhang H, Zhang Z, Sheng Y, Han G. Research on the Micro-Extrusion Process of Copper T2 with Different Ultrasonic Vibration Modes. Metals. 2019; 9(11):1209. https://doi.org/10.3390/met9111209

Chicago/Turabian StyleXu, Linhong, Yulan Lei, Haiou Zhang, Zhaochen Zhang, Yuchu Sheng, and Guangchao Han. 2019. "Research on the Micro-Extrusion Process of Copper T2 with Different Ultrasonic Vibration Modes" Metals 9, no. 11: 1209. https://doi.org/10.3390/met9111209

APA StyleXu, L., Lei, Y., Zhang, H., Zhang, Z., Sheng, Y., & Han, G. (2019). Research on the Micro-Extrusion Process of Copper T2 with Different Ultrasonic Vibration Modes. Metals, 9(11), 1209. https://doi.org/10.3390/met9111209