Experimental and Numerical Study on Microstructure and Mechanical Properties of Ti-6Al-4V/Al-1060 Explosive Welding

Abstract

1. Introduction

2. Experimental Procedure

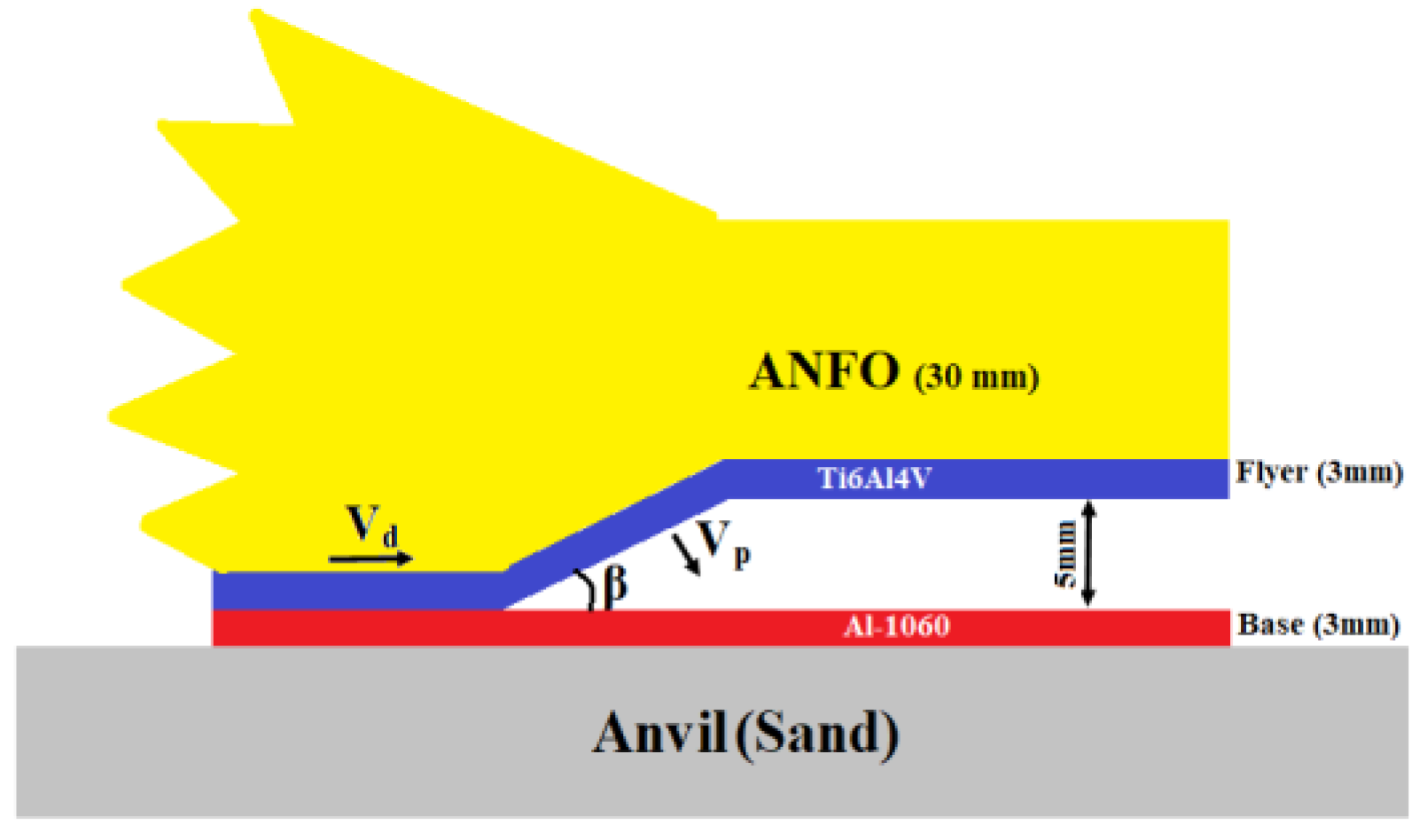

2.1. Materials and Explosive Welding Setup

2.2. Microstructure Test

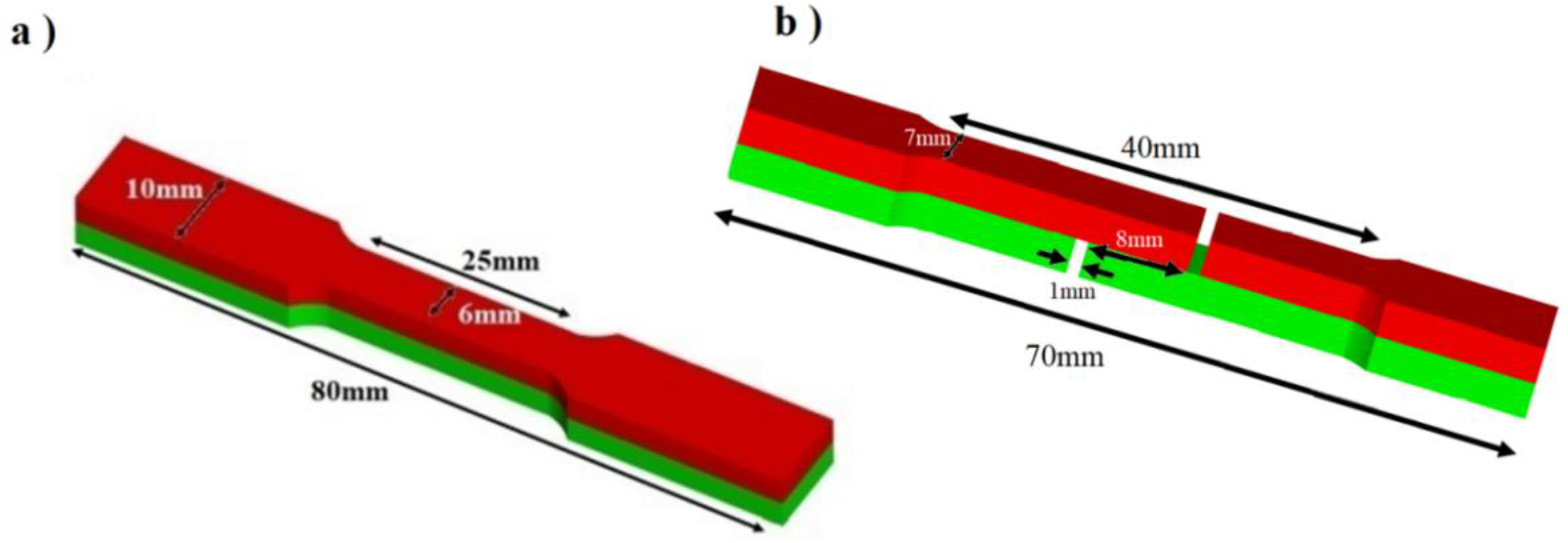

2.3. Mechanical Test

3. Simulation of Explosive Welding

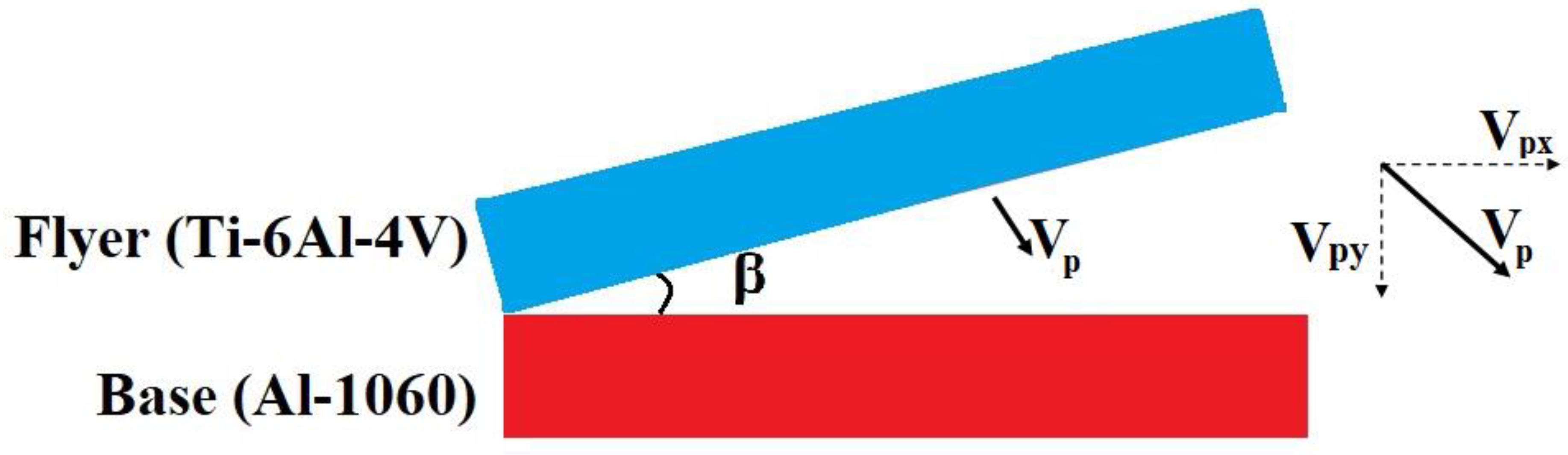

3.1. Calculation of Plate Velocity

3.2. Equation of State and Constitutive Model

3.3. Smooth Particle Hydrodynamics (SPH)

4. Results and Discussion

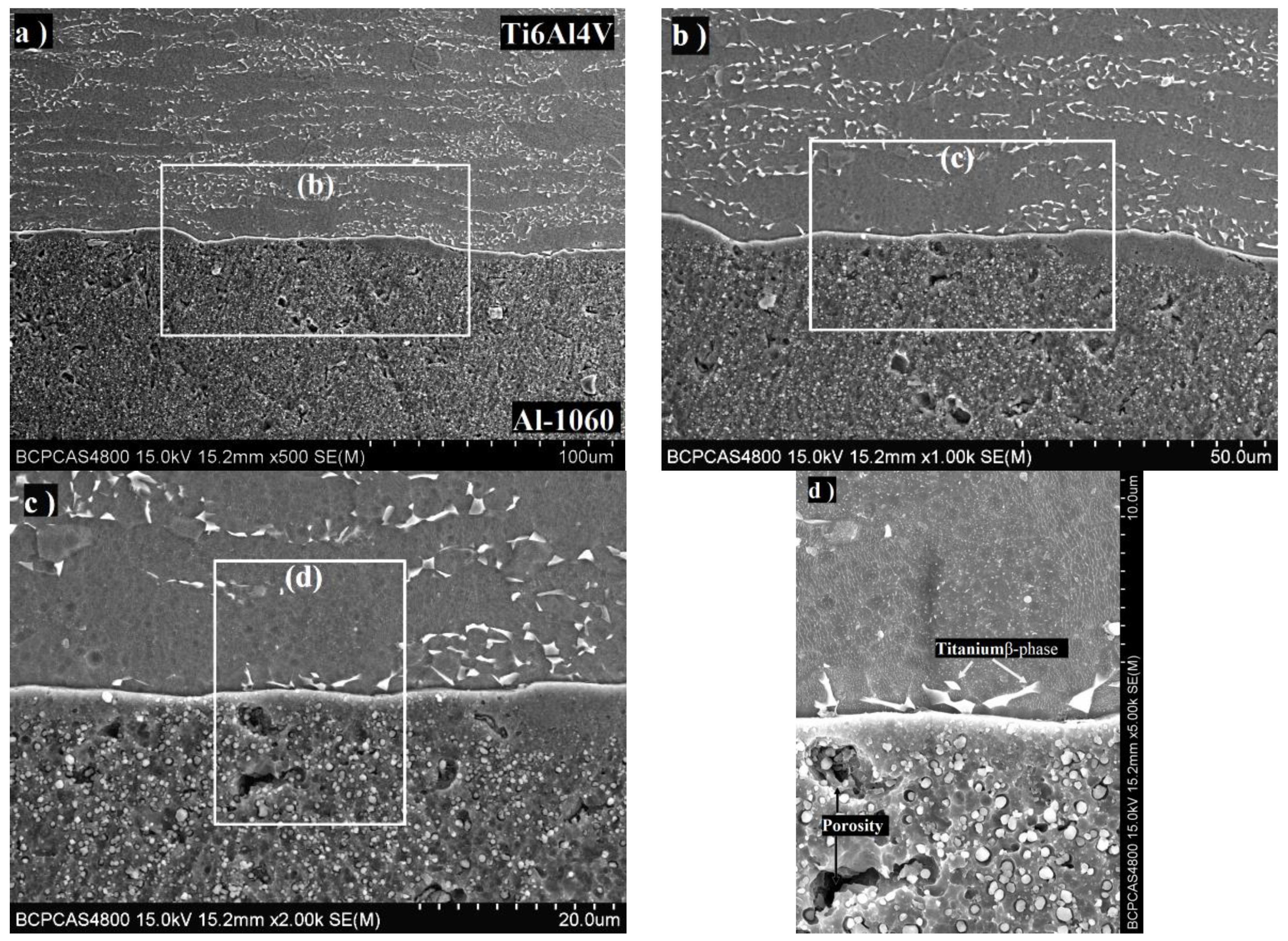

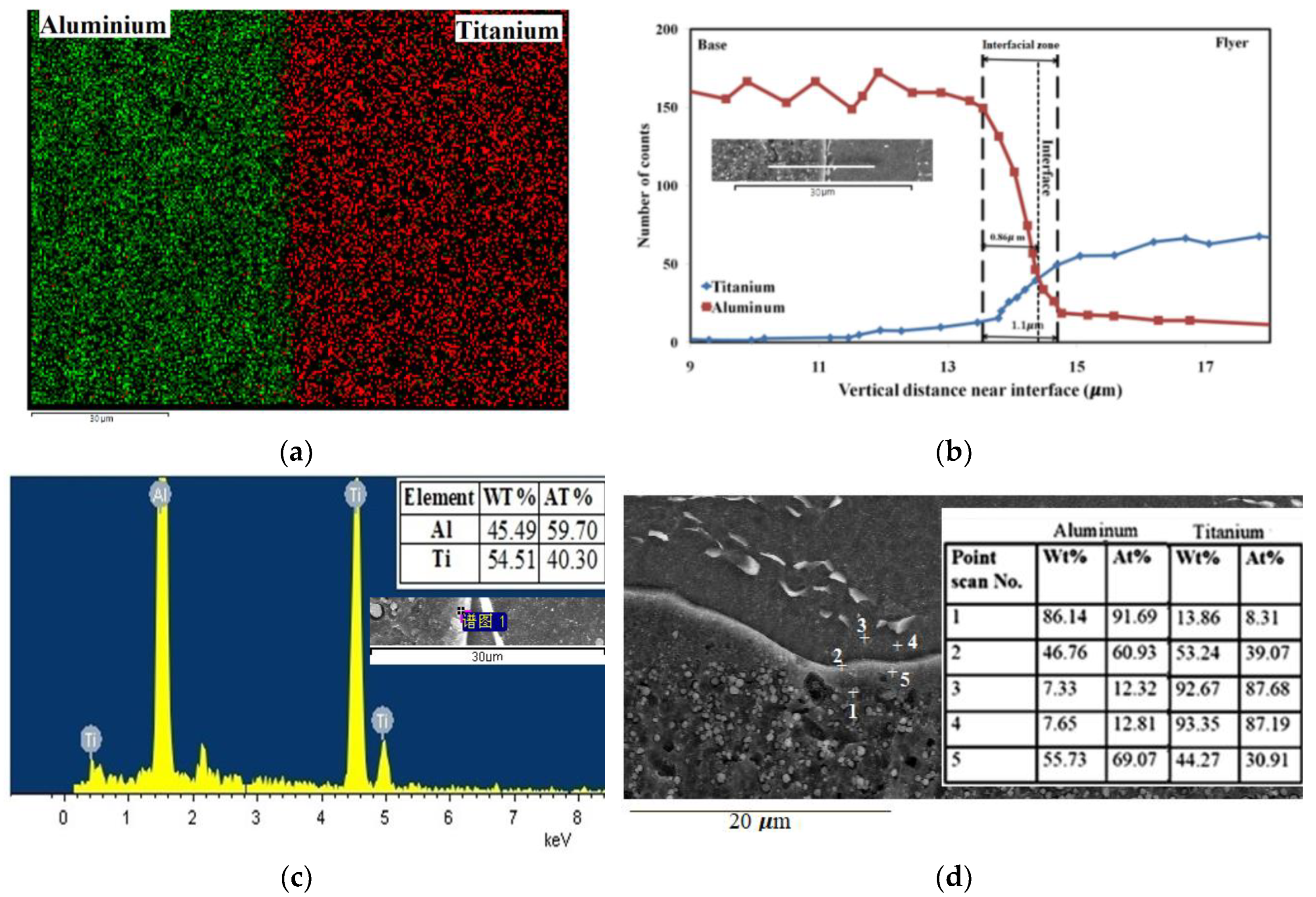

4.1. Microstructure of Welding Interface before Heat Treatment

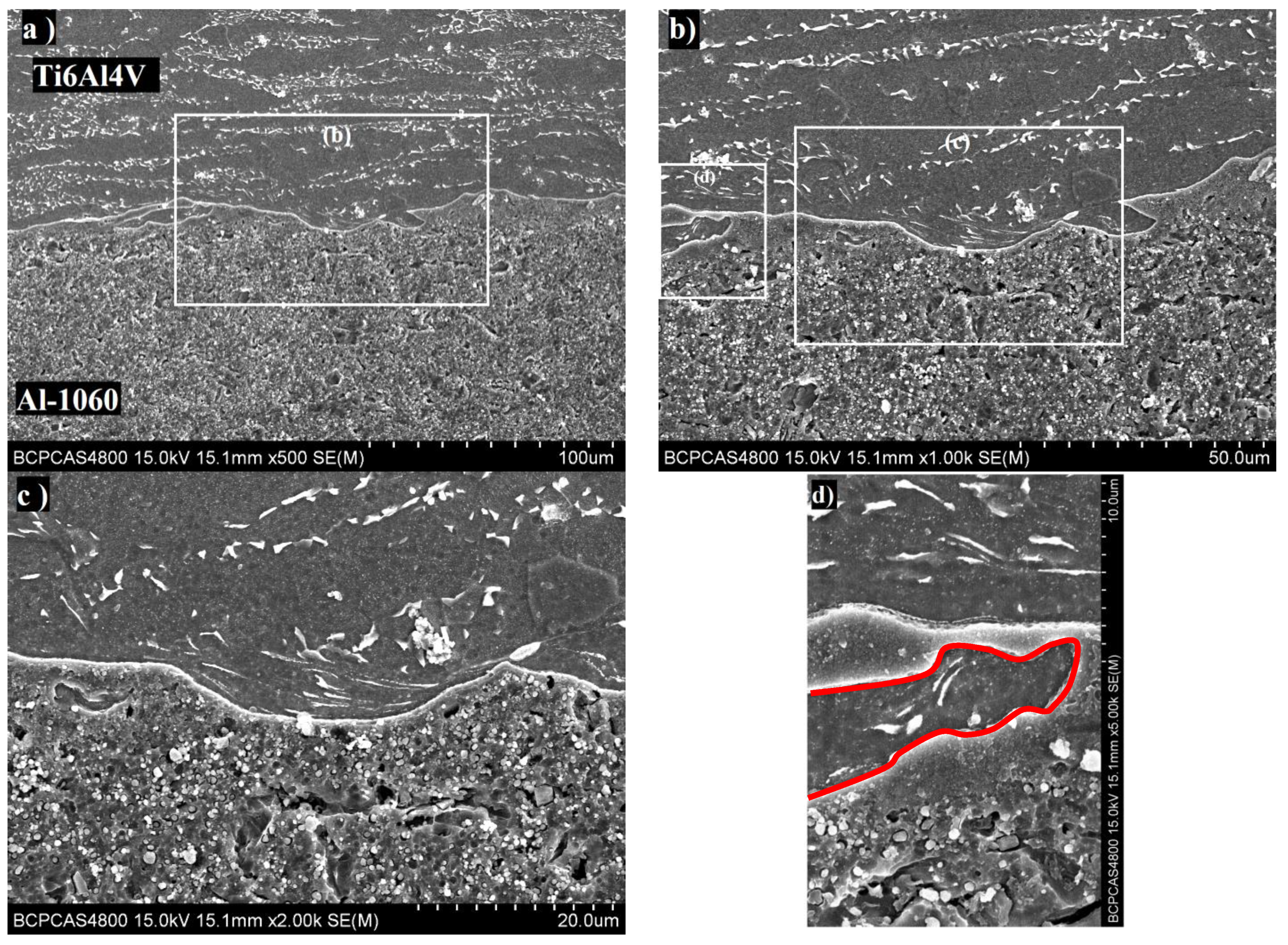

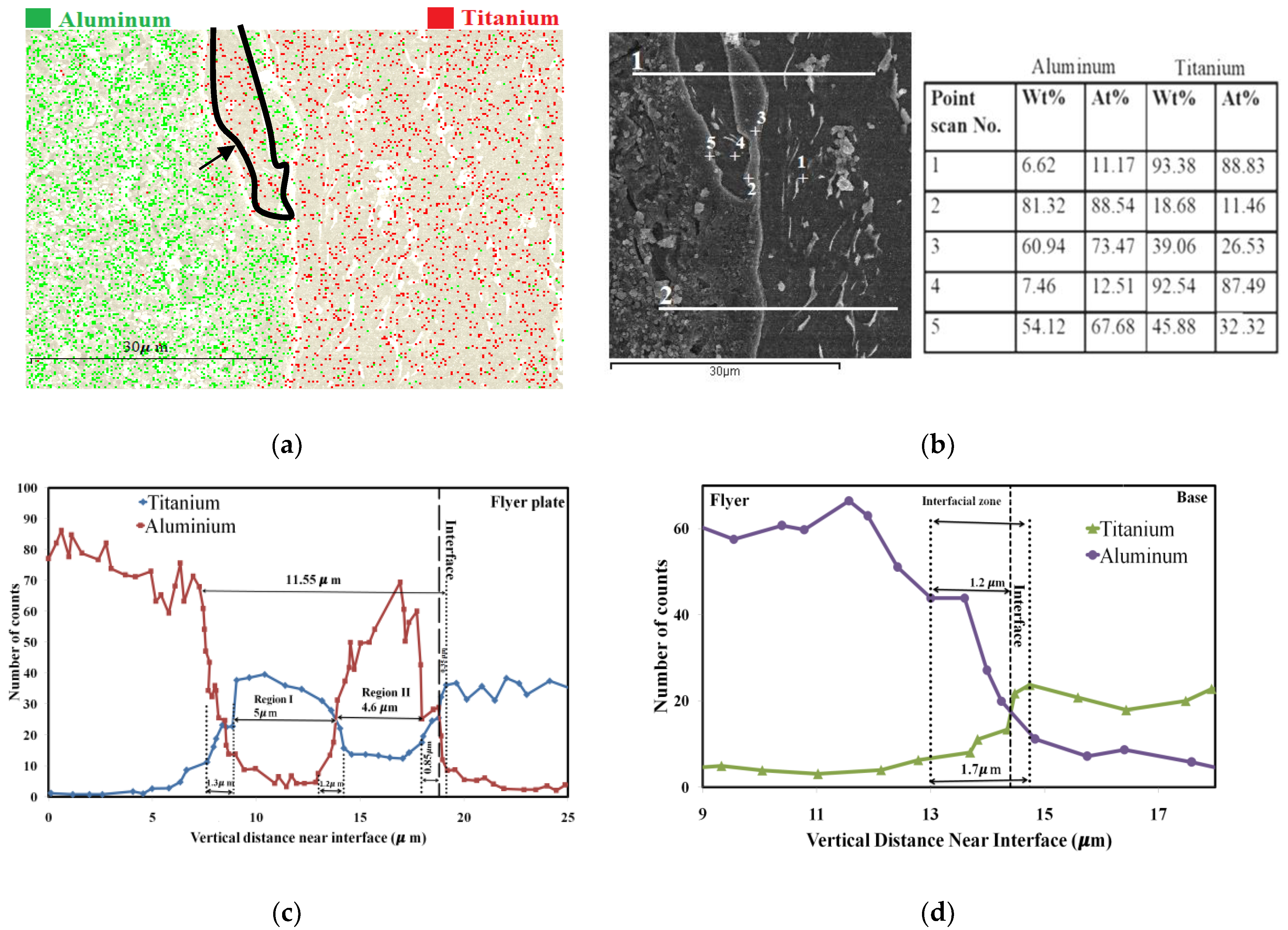

4.2. Microstructure of Welding Interface after Heat Treatment

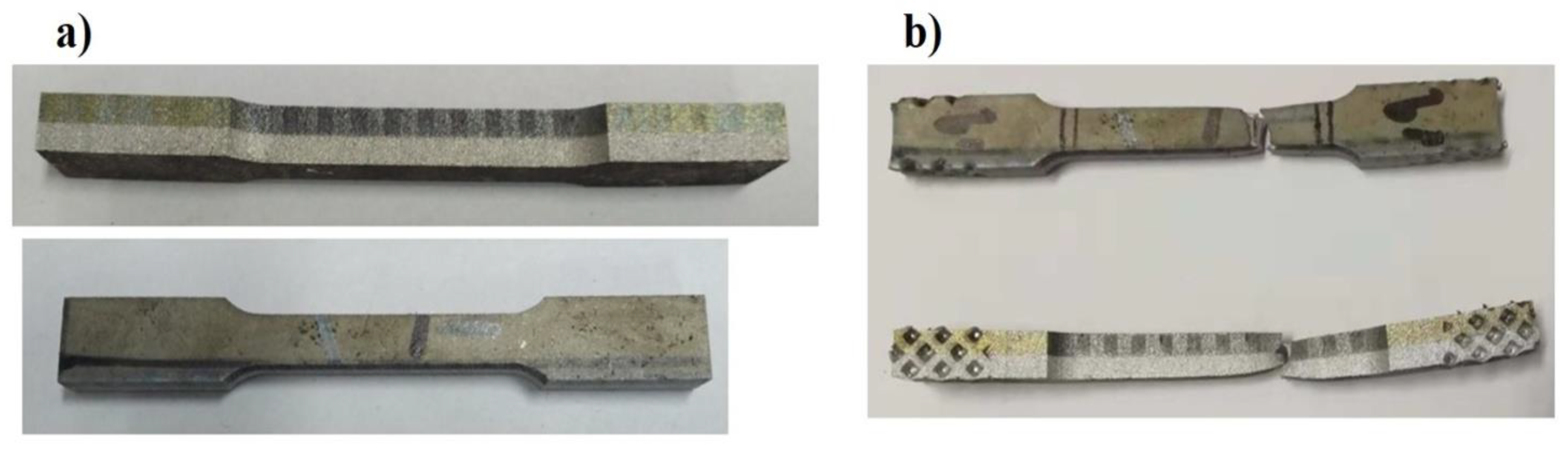

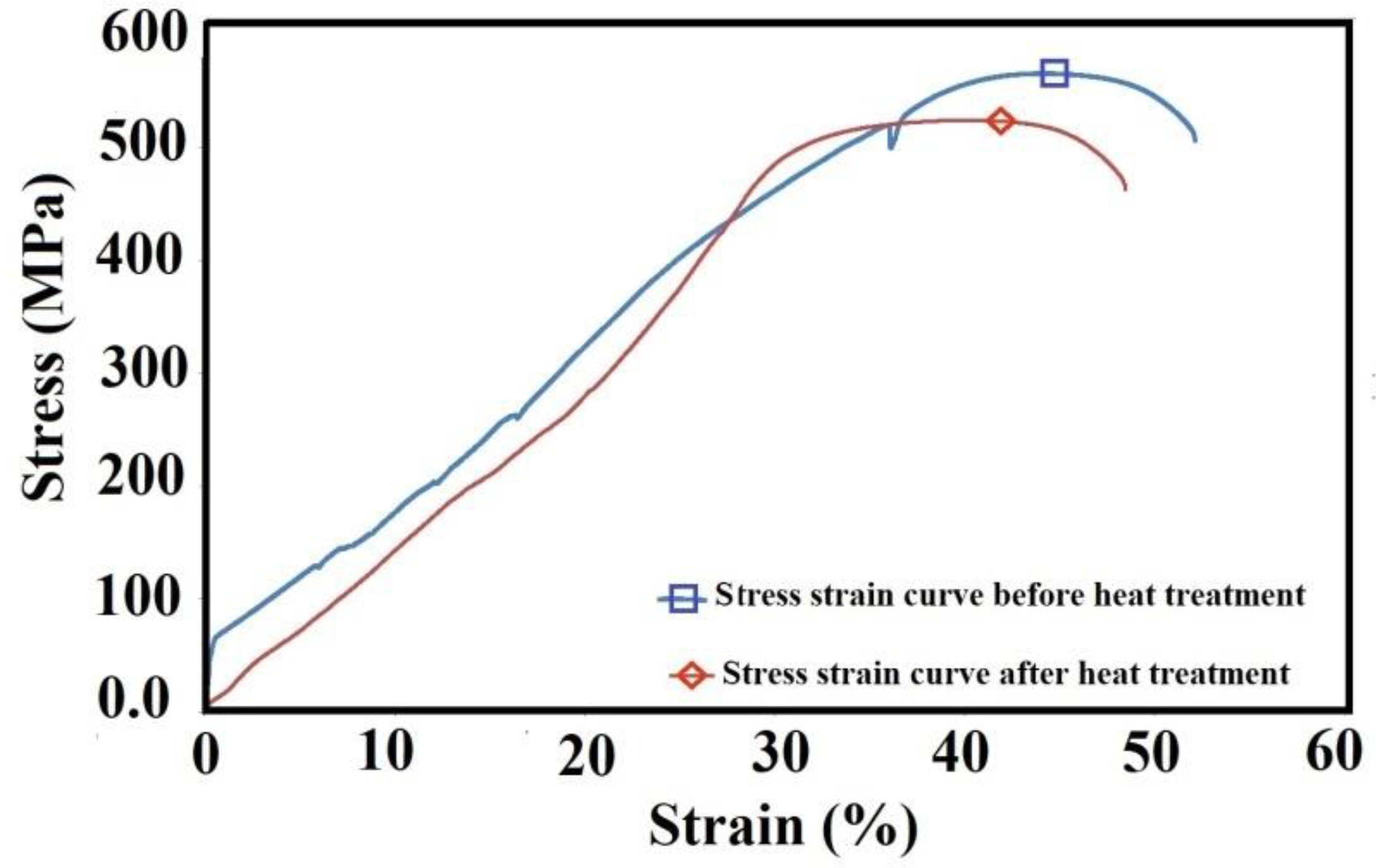

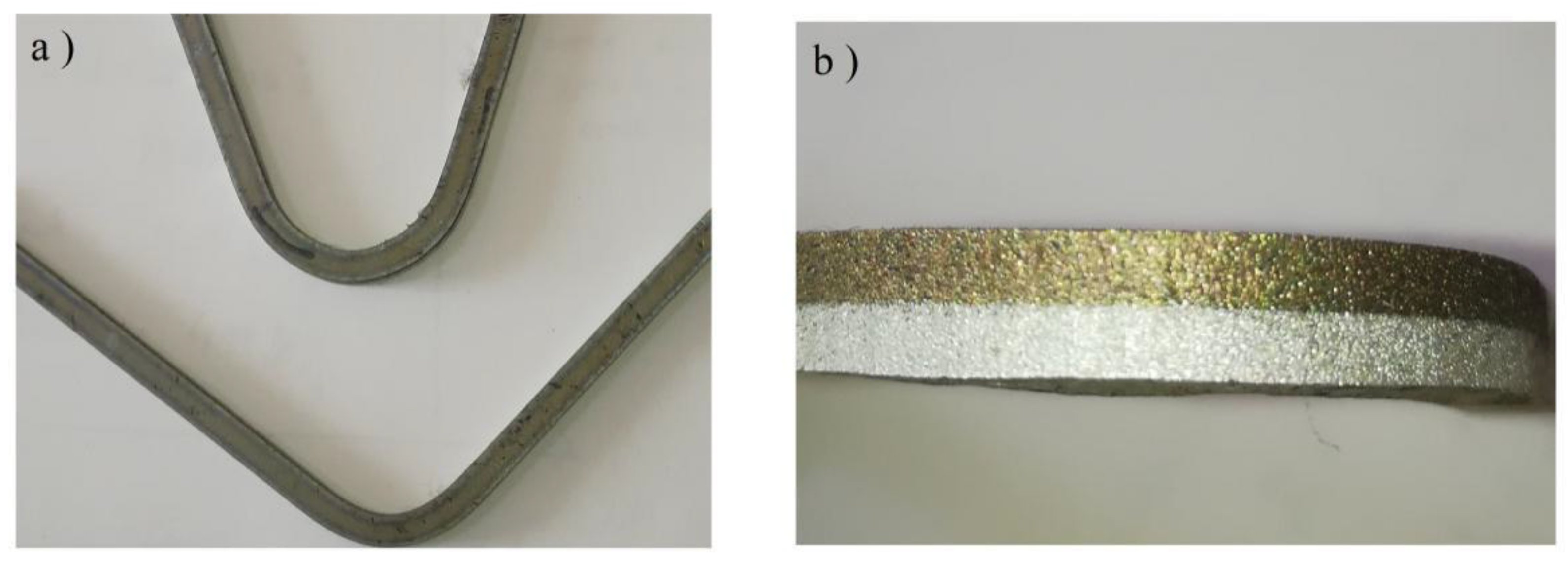

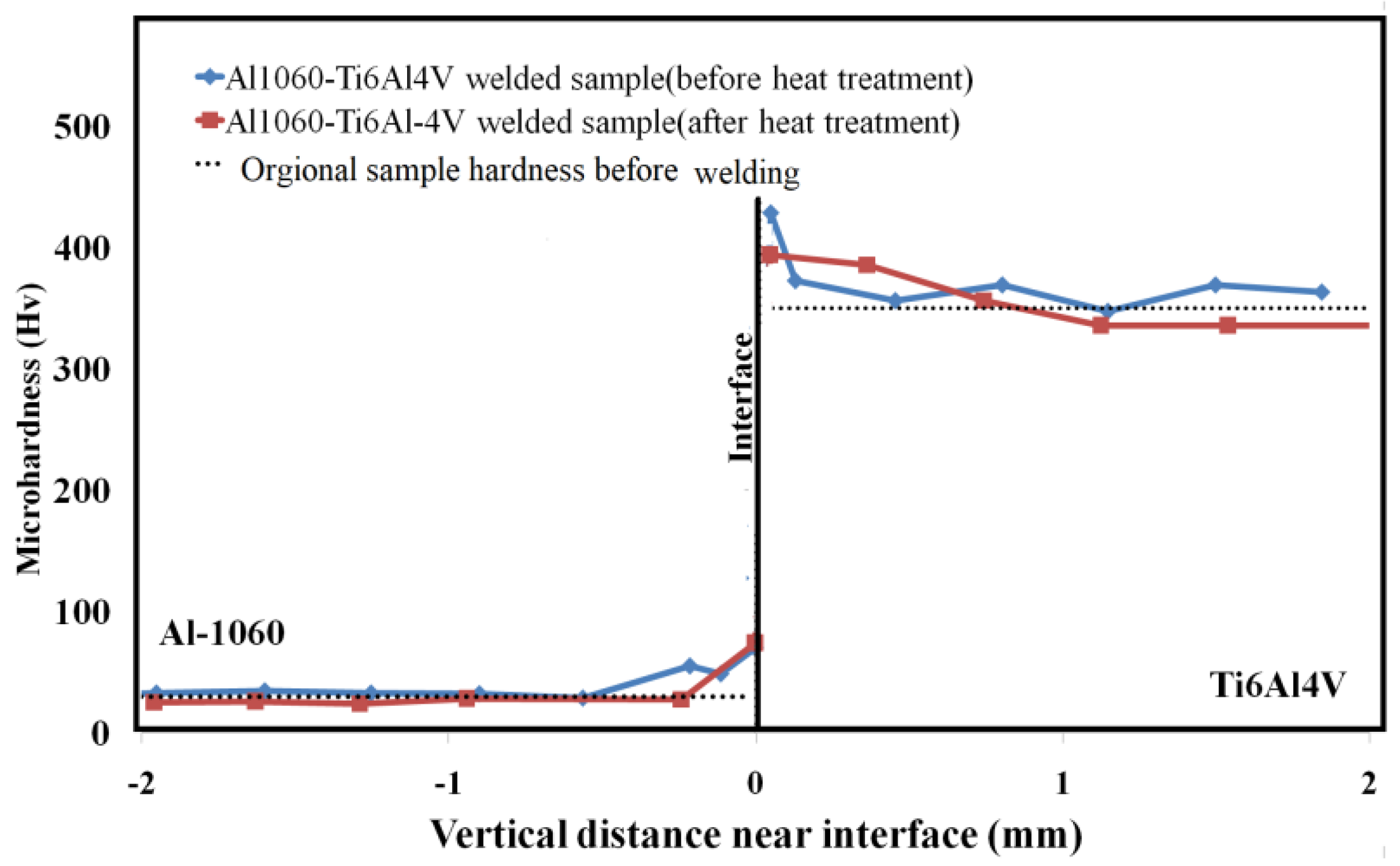

4.3. Mechanical Tests

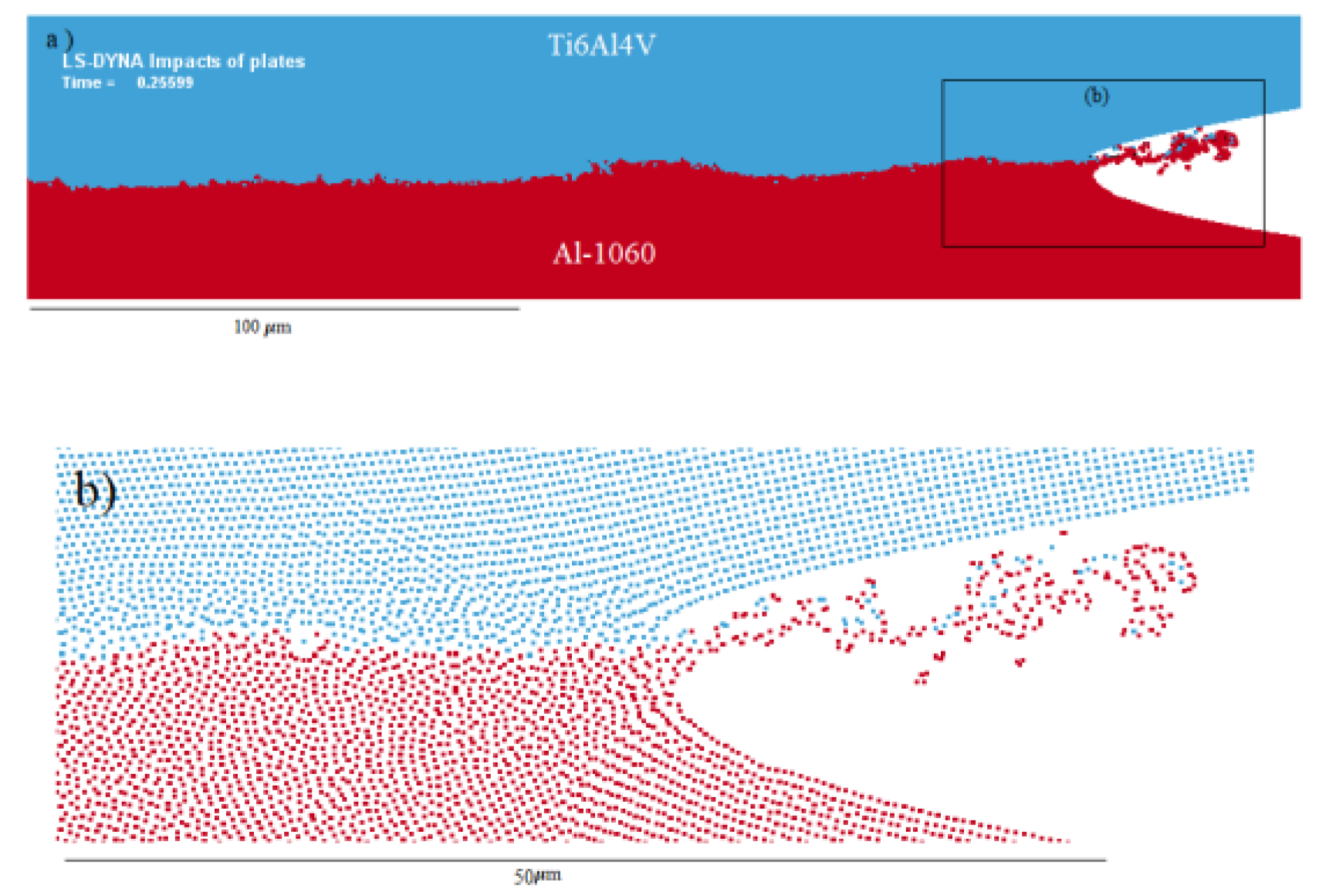

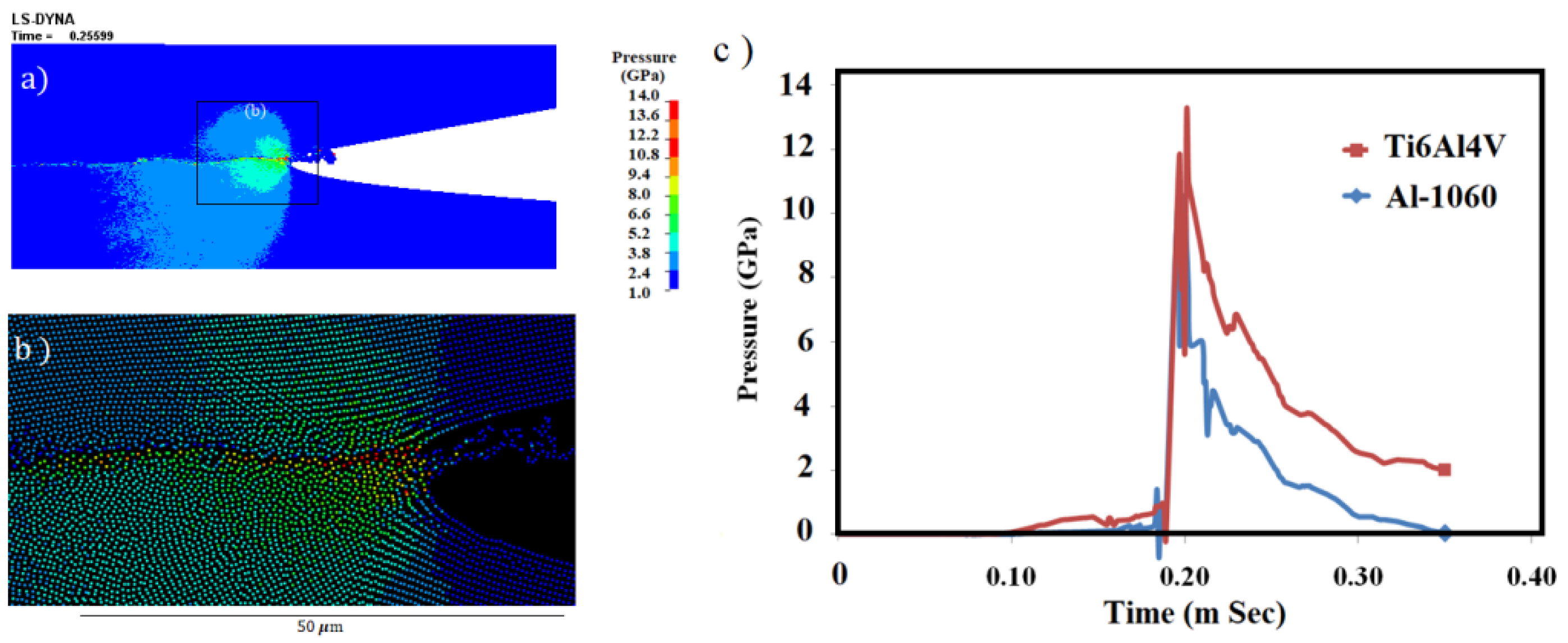

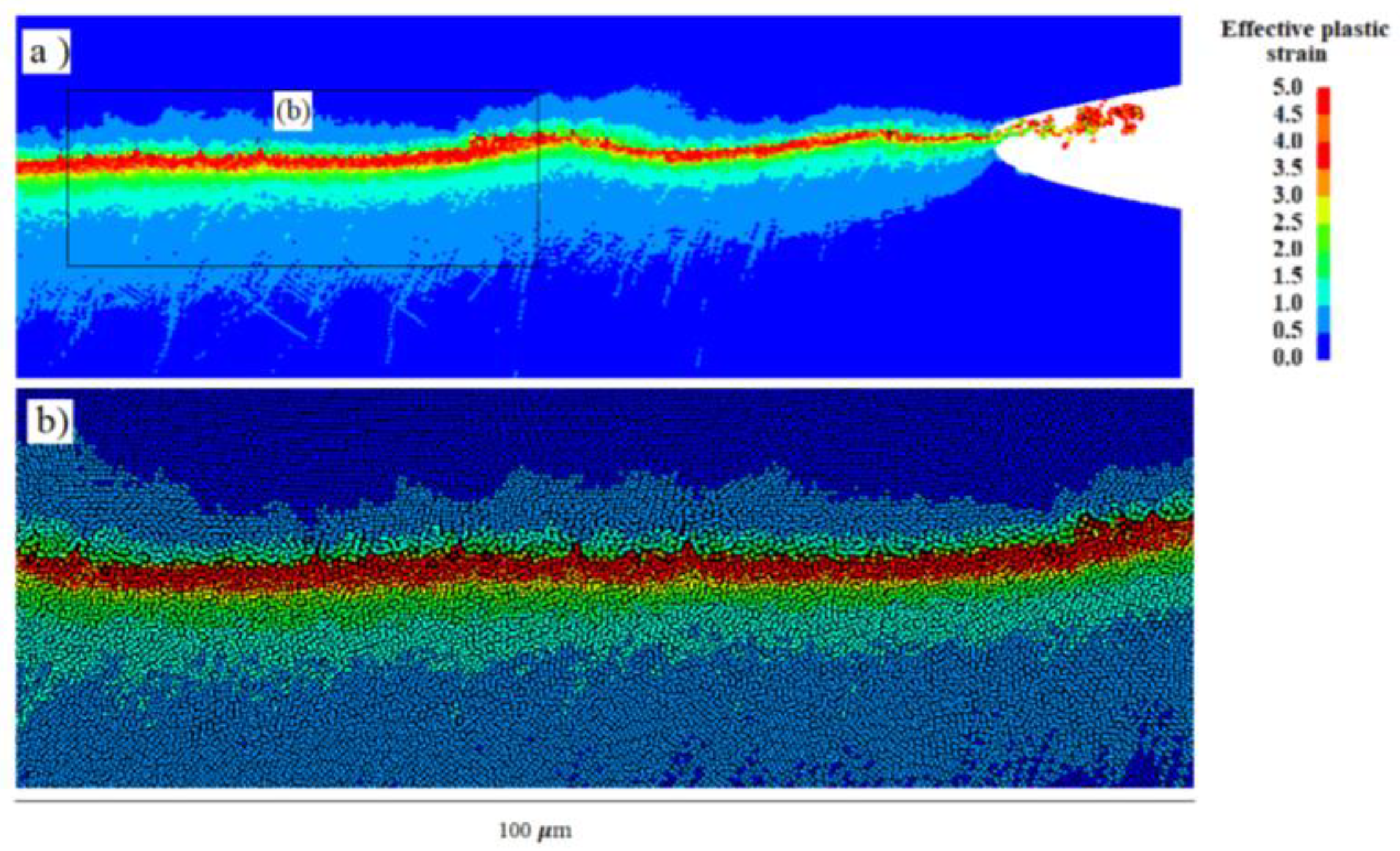

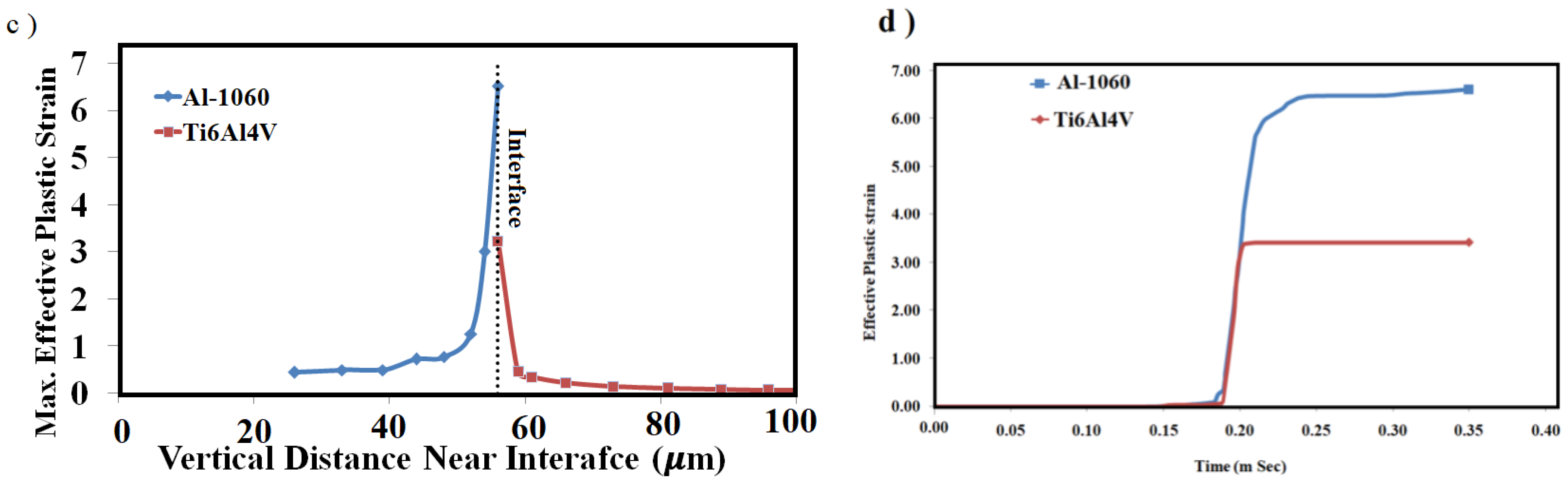

4.4. Simulation Results

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Findik, F. Recent developments in explosive welding. Mater. Des. 2011, 32, 1081–1093. [Google Scholar] [CrossRef]

- Wang, B.F.; Luo, X.Z.; Wang, B.; Zhao, S.T.; Xie, F.Y. Microstructure and its formation mechanism in the interface of Ti/NiCr explosive cladding bar. J. Mater. Eng. Perform. 2014, 24, 1050–1058. [Google Scholar] [CrossRef]

- Wang, B.F.; Xie, F.Y.; Wang, B.; Luo, X.Z. Microstructure and properties of the Ti/Al2O3/NiCr composites fabricated by explosive compaction/cladding. Mater. Sci. Eng. C 2015, 50, 324–331. [Google Scholar] [CrossRef] [PubMed]

- Blazynski, T.Z. Explosive Welding, Forming and Compact; Springer: Dordrecht, The Netherlands, 1983. [Google Scholar]

- Perusko, D.; Petrovic, S.; Stojianovic, M.; Mitric, M.; Cizmovic, M.; Panjan, M.; Milosavljevic, M. Formation of intermetallics by ion implantation of multilatered Al/Ti nano-structures. Nucl. Instrum. Methods Phys. Res. 2012, 282, 4–7. [Google Scholar] [CrossRef]

- Adeli, M.; Seyedein, S.H.; Aboutalebi, M.R.; Kobashi, M.; Kanetake, N. A study on the combustion synthesis of titanium aluminide in the self-propagating mode. J. Alloys Compd. 2010, 497, 100–104. [Google Scholar] [CrossRef]

- Arakawa, Y.Y.; Kobashi, M.; Kanetake, N. Foaming behavior of long-scale Al-Ti intermetallic foam by SHS mode combustion reaction. Intermetallics 2013, 41, 22–27. [Google Scholar] [CrossRef]

- Goda, D.J.; Richards, N.L.; Caley, W.F.; Chaturvedi, M.C. The effect of processing variables on the structure and chemistry of Ti-aluminide based LMCS. Mater. Sci. Eng. A 2002, 334, 280–290. [Google Scholar] [CrossRef]

- Ramos, A.S.; Calinas, R.; Vieira, M.T. The formation of γ-TiAl from Ti/Al multilayers with different periods. Surf. Coatings Technol. 2006, 200, 6196–6200. [Google Scholar] [CrossRef]

- Romankov, S.E.; Mukashev, B.N.; Ermakov, E.L.; Muhamedshina, D.N. Structural formation of aluminide phases on titanium substrate. Surf. Coat. Technol. 2004, 180, 280–285. [Google Scholar] [CrossRef]

- Kahraman, N.; Gulenc, B.; Findik, F. Corrosion and mechanical-microstructural aspects of dissimilar joints of Ti-6Al-4V and Al plates. Int. J. Impact Eng. 2007, 34, 1423–1432. [Google Scholar] [CrossRef]

- E, J.C.; Huang, J.Y.; Bie, B.X.; Sun, T.; Fezzaa, K.; Xiao, X.H.; Sun, W.; Lou, S.N. Deformation and fracture of explosion-welded Ti/Al plates: A synchrotron-based study. Mater. Sci. Eng. A 2016, 674, 308–317. [Google Scholar] [CrossRef]

- Xia, H.B.; Wang, S.G.; Ben, H.F. Microstructure and mechanical properties of Ti/Al explosive cladding. Mater. Des. 2014, 56, 1014–1019. [Google Scholar] [CrossRef]

- Fronczek, D.M.; Wojewoda-Budka, J.; Chulist, R.; Sypien, A.; Korneva, A.; Szulc, Z.; Schell, N.; Zieba, P. Structural properties of Ti/Al clads manufactured by explosive welding and annealing. Mater. Des. 2016, 91, 80–89. [Google Scholar] [CrossRef]

- Bazarnik, P.; Adamczyk-Cieslak, B.; Galka, A.; Plonka, B.; Sniezek, L.; Cantoni, M.; Lewandowska, M. Mechanical and microstructural characteristics of Ti6Al4V/AA2519 and Ti6Al4V/AA1050/AA2519 laminates manufactured by explosive welding. Mater. Des. 2016, 111, 146–157. [Google Scholar] [CrossRef]

- Ege, E.S.; Inal, O.T.; Zimmerly, C.A. Response surface study on production of explosively-welded aluminum-titanium laminates. J. Mater. Sci. 1998, 33, 5327–5338. [Google Scholar] [CrossRef]

- Inal, O.T.; Szecket, A.; Vigueras, D.J.; Pak, H. Explosive welding of Ti–6Al–4V to mild-steel substrates. J. Vac. Sci. Technol. A Vac. Surf. Film 1985, 3, 2605–2609. [Google Scholar] [CrossRef]

- Ege, E.S.; Inal, O.T. Stability of interfaces in explosively-welded aluminum-titanium. J. Mater. Sci. Lett. 2000, 19, 1533–1535. [Google Scholar] [CrossRef]

- Lazurenko, D.V.; Bataev, I.A.; Mali, V.I.; Bataev, A.A.; Maliutina, I.N.; Lozhkin, V.S.; Esikov, M.A.; Jorge, A.M.J. Explosively welded multilayer Ti-Al composites: Structure and transformation during heat treatment. Mater. Des. 2016, 102, 122–130. [Google Scholar] [CrossRef]

- Pavliukova, D.V.; Bataev, I.A.; Bataev, A.A.; Smirnov, A.I. Formation of the intermetallic layers in Ti-Al multilayer composites. Adv. Mater. Res. 2011, 311, 236–239. [Google Scholar]

- Bataev, I.A.; Bataev, A.A.; Pavliukova, D.V.; Yartsev, P.S.; Golovin, E.D. Nucleation and growth of titanium aluminide in an explosion welded laminate composite. Phys. Met. Metallogr. 2012, 113, 998–1007. [Google Scholar] [CrossRef]

- Fan, M.Y.; Domblesky, J.; Jin, K.; Qin, L.; Cui, S.Q.; Guo, X.Z.; Kim, N.; Tao, J. Effect of original layer thicknesses on the interface bonding and mechanical properties of Ti-Al laminate composites. Mater. Des. 2016, 99, 535–542. [Google Scholar] [CrossRef]

- Fan, M.Y.; Yu, W.W.; Wang, W.T.; Guo, X.Z.; Jin, K.; Miao, R.J.; Hou, W.Q.; Kim, N.; Tao, J. Microstructure and mechanical properties of thin-multilayer Ti/Al laminates prepared by one-step explosive bonding. J. Mater. Eng. Perform. 2017, 26, 277–284. [Google Scholar] [CrossRef]

- Foadian, F.; Soltanieh, M.; Adeli, M.; Etinanbakhsh, M. A study on the formation of intermetallics during the heat treatment of explosively welded Al-Timultilayers. Metall. Mater. Trans. A 2014, 45, 1823–1832. [Google Scholar] [CrossRef]

- Mousavi, A.A.A.; Al-Hassani, S.T.S. Numerical and experimental studies of the mechanism of the wavy interface formations in explosive/impact welding. J. Mech. Phys. Solids 2005, 53, 2501–2528. [Google Scholar]

- Nassiri, A.; Kinsey, B. Numerical studies on high-velocity impact welding: smoothed particle hydrodynamics (SPH) and arbitrary Lagrangian–Eulerian (ALE). J. Manuf. Process. 2016, 24, 376–381. [Google Scholar] [CrossRef]

- Wang, X.; Zheng, Y.Y.; Liu, H.X.; Shen, Z.B.; Hu, Y.; Li, W.; Gao, Y.Y.; Guo, C. Numerical study of the mechanism of explosive/impact welding using Smoothed Particle Hydrodynamics method. Mater. Des. 2012, 35, 210–219. [Google Scholar] [CrossRef]

- Wang, Y.; Beom, H.G.; Sun, M.; Lin, S. Numerical simulation of explosive welding using the material point method. Int. J. Impact Eng. 2011, 38, 51–60. [Google Scholar] [CrossRef]

- Saravanan, S.; Raghukandan, K.; Hokamoto, K. Improved microstructure and mechanical properties of dissimilar explosive cladding by means of interlayer technique. Arch. Civ. Mech. Eng. 2016, 16, 563–568. [Google Scholar] [CrossRef]

- Tanaka, K. Numerical studies on the explosive welding by smoothed particle hydrodynamics (SPH). Shock Compress. Condens. Matter. 2007, 955, 1301–1304. [Google Scholar]

- Brows, W.B.; Braithwaite, M. Analytical reprsentation of the adiabatic equation for detonation products based on statistical mechanics and intermolecular forces. Phil. Trans. Roy. Soc. A 1992, 339, 345–353. [Google Scholar]

- Deribas, A.A. Acceleration of metal plates by a tangential detonation wave. J. Appl. Mech. Tech. Phys. 2000, 41, 824–830. [Google Scholar] [CrossRef]

- Manikandan, P.; Hokamoto, K.; Fujita, M.; Raghukandan, K.; Tomoshige, R. Control of energetic conditions by employing interlayer of different thickness for explosive welding of titanium/304 stainless steel. J. Mater. Process. Technol. 2008, 195, 232–240. [Google Scholar] [CrossRef]

- Cooper, P. Explosives Engineering; Wiley: New York, NY, USA, 1996. [Google Scholar]

- Zukas, J.A.; Walters, W.P. Explosive Effects and Applications; Springer: New York, NY, USA, 1998. [Google Scholar]

- Kamlet, M.J.; Jacobs, S.J. Chemistry of detonations. I. A simple method for calculating detonation properties of C-H-N-O explosives. J. Chem. Phys. 1968, 48, 23–35. [Google Scholar] [CrossRef]

- Mousavi, S.A.A.A.; Al-Hassani, S.T.S. Finite element simulation of explosively-driven plate impact with application to explosive welding. Mater. Des. 2008, 29, 1–19. [Google Scholar] [CrossRef]

- Crossland, B. Explosive Welding of Metals and Its Application; Oxford University Press: New York, NY, USA, 1982. [Google Scholar]

- Lesuer, D. Experiment Investigations of Material Models for Ti–6Al–4V Titanium and 2024-T3 Aluminum; Final Report, DOT/FAA/AR-00/25; US Department of Transportation, Federal Aviation Administration: Washington, DC, USA, 2000.

- Ye, L.; Zhu, X. Analysis of the effect of impact of near-wall acoustic bubble collapse micro-jet on Al 1060. Ultrason. Sonochem. 2017, 36, 507–516. [Google Scholar] [CrossRef]

- Zhang, L.J.; Pei, Q.; Zhang, J.X.; Bi, Z.Y.; Li, P.C. Study on the microstructure and mechanical properties of explosive welded 2205/X65 bimetallic sheet. Mater. Des. 2014, 64, 462–476. [Google Scholar] [CrossRef]

- Gloc, M.; Wachowski, M.; Plocinski, T.; Kurzydlowski, K.J. Microstructural and microanalysis investigations of bond titanium grade1/low alloy steel st52-3N obtained by explosive welding. J. Alloys Compd. 2016, 671, 446–451. [Google Scholar] [CrossRef]

- Raoelison, R.N.; Racine, D.; Zhang, Z.; Buiron, N.; Marceau, D.; Rachik, M. Magnetic pulse welding: Interface of Al/Cu joint and investigation of intermetallic formation effect on the weld features. J. Manuf. Process. 2015, 16, 427–434. [Google Scholar] [CrossRef]

- Su, Y.C.; Hua, X.M.; Wu, Y.X. Quantitative characterization of porosity in Fe-Al dissimilar materials lap joint made by gas metal arc welding with different current modes. J. Mater. Process. Technol. 2014, 214, 81–86. [Google Scholar] [CrossRef]

- Tomashchuk, I.; Sallamand, P.; Cicala, E.; Peyre, P.; Grevey, D. Direct keyhole laser welding of aluminum alloy AA5754 to titanium alloy Ti6Al4V. J. Mater. Process. Technol. 2015, 217, 96–104. [Google Scholar] [CrossRef]

- Murr, L.E.; Ferreyra, E.; Pappu, T.S.; Garcia, E.P.; Sanchez, J.C.; Huang, W.; Rivas, J.M.; Kennedy, C.; Ayala, A.; Niou, C.S. Novel deformation processes and microstructures involving ballistic penetrator formation and hypervelocity impact and penetration phenomena. Mater. Charact. 1996, 37, 245–276. [Google Scholar] [CrossRef]

- Kacar, R.; Acarer, M. An investigation on the explosive cladding of 316L stainless steel-din-P355GH steel. J. Mater. Process. Technol. 2004, 152, 91–96. [Google Scholar] [CrossRef]

- Prasanthi, T.N.; Kirana, R.; Saroja, S. Explosive cladding and post-weld heat treatment of mild steel and titanium. Mater. Des. 2016, 93, 180–193. [Google Scholar] [CrossRef]

- Chulist, R.; Fronczek, D.M.; Szulc, Z.; Wojewoda-Budka, J. Texture transformations near the bonding zones of the three-layer Al/Ti/Al explosively welded clads. Mater. Charact. 2017, 129, 242–246. [Google Scholar] [CrossRef]

- Szecket, A.; Inal, O.T.; Vigueras, D.J.; Rocco, J. A wavy versus straight interface in the explosive welding of aluminum to steel. J. Vac. Sci. Technol. A 1985, 3, 2588–2593. [Google Scholar] [CrossRef]

- Wang, Z.J.; Wang, Z.; Li, M.X. Failure analysis of Al 1060 sheets under double-sided pressure deformation conditions. Key Eng. Mater. 2007, 353, 603–606. [Google Scholar] [CrossRef]

- Kimura, M.; Iijima, T.; Kusaka, M.; Kaizu, K.; Fuji, A. Joining phenomena and tensile strength of friction welded joint between Ti–6Al–4V titanium alloy and low carbon steel. J. Manuf. Process. 2016, 24, 203–211. [Google Scholar] [CrossRef]

- Boroński, D.; Kotyk, M.; Maćkowiak, P.; Śnieżek, L. Mechanical properties of explosively welded AA2519-AA1050-Ti6Al4V layered material at ambient and cryogenic conditions. Mater. Des. 2017, 133, 390–403. [Google Scholar] [CrossRef]

- Holtzman, A.H.; Cowan, G.R. Bonding of metals with explosives. Weld. Res. Counc. 1965, 104, 1–40. [Google Scholar]

- Cowan, G.R.; Holtzman, A.H. Flow configurations in colliding plates: explosive bonding. J. Appl. Phys. 1962, 34, 928–939. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahmood, Y.; Dai, K.; Chen, P.; Zhou, Q.; Bhatti, A.A.; Arab, A. Experimental and Numerical Study on Microstructure and Mechanical Properties of Ti-6Al-4V/Al-1060 Explosive Welding. Metals 2019, 9, 1189. https://doi.org/10.3390/met9111189

Mahmood Y, Dai K, Chen P, Zhou Q, Bhatti AA, Arab A. Experimental and Numerical Study on Microstructure and Mechanical Properties of Ti-6Al-4V/Al-1060 Explosive Welding. Metals. 2019; 9(11):1189. https://doi.org/10.3390/met9111189

Chicago/Turabian StyleMahmood, Yasir, Kaida Dai, Pengwan Chen, Qiang Zhou, Ashfaq Ahmad Bhatti, and Ali Arab. 2019. "Experimental and Numerical Study on Microstructure and Mechanical Properties of Ti-6Al-4V/Al-1060 Explosive Welding" Metals 9, no. 11: 1189. https://doi.org/10.3390/met9111189

APA StyleMahmood, Y., Dai, K., Chen, P., Zhou, Q., Bhatti, A. A., & Arab, A. (2019). Experimental and Numerical Study on Microstructure and Mechanical Properties of Ti-6Al-4V/Al-1060 Explosive Welding. Metals, 9(11), 1189. https://doi.org/10.3390/met9111189