Mechanical Behavior and Microstructure Evolution of a Ti-15Mo/TiB Titanium–Matrix Composite during Hot Deformation

Abstract

:1. Introduction

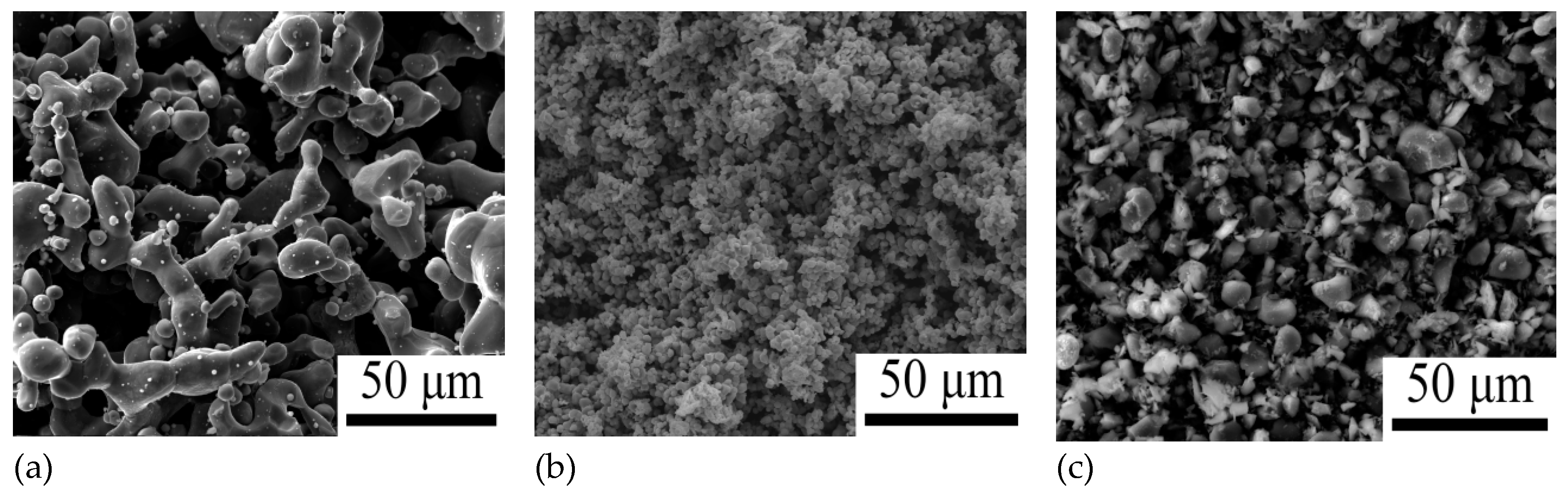

2. Materials and Procedure

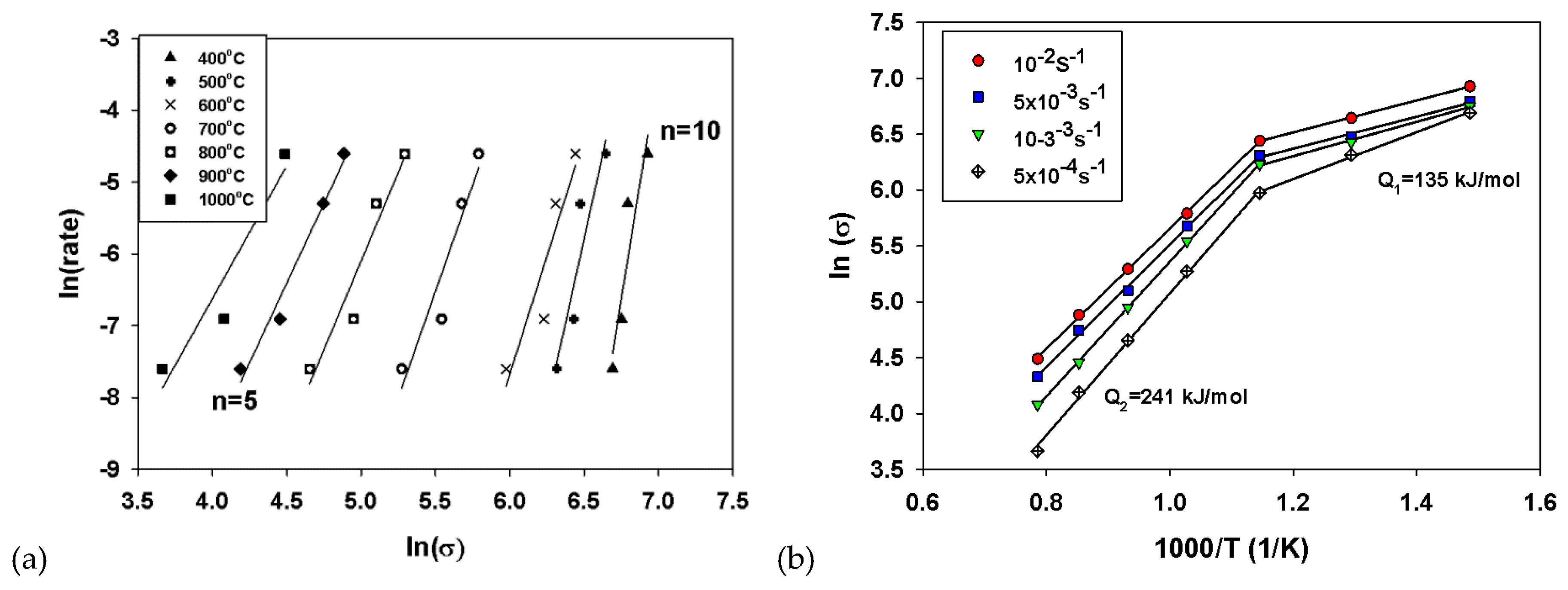

3. Results

4. Discussion

5. Summary

- (1)

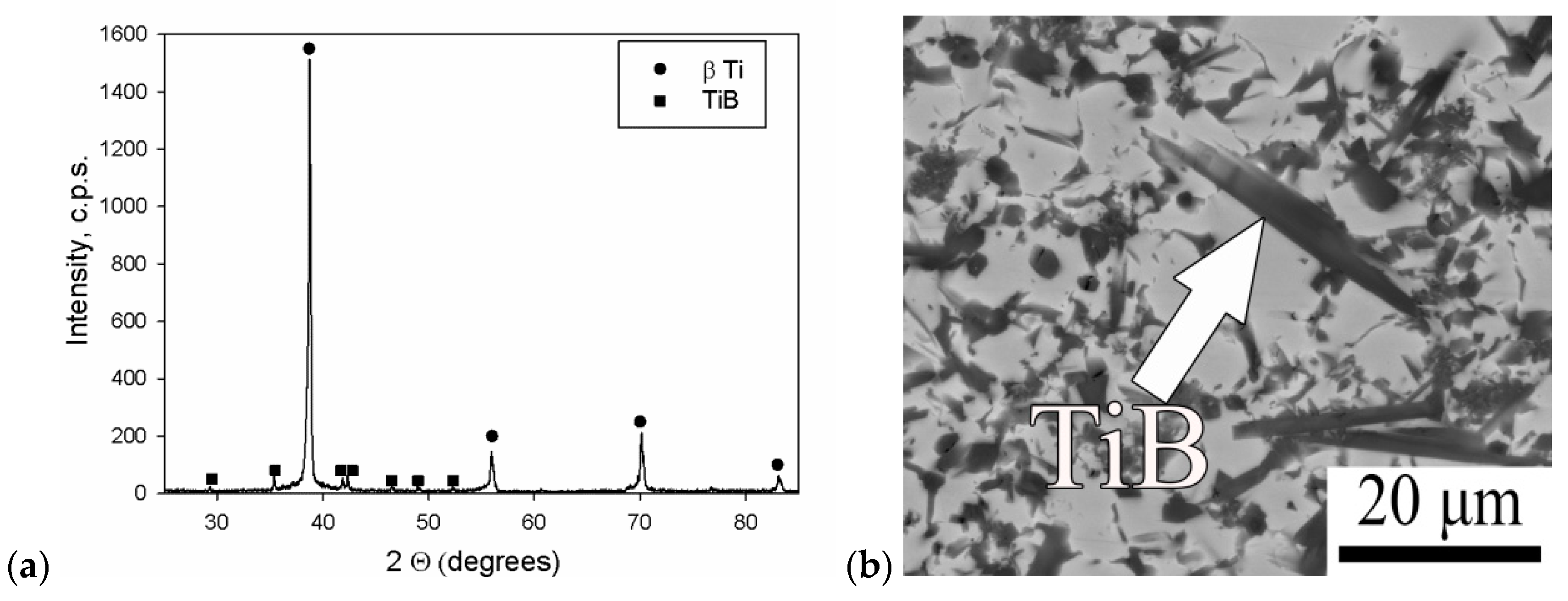

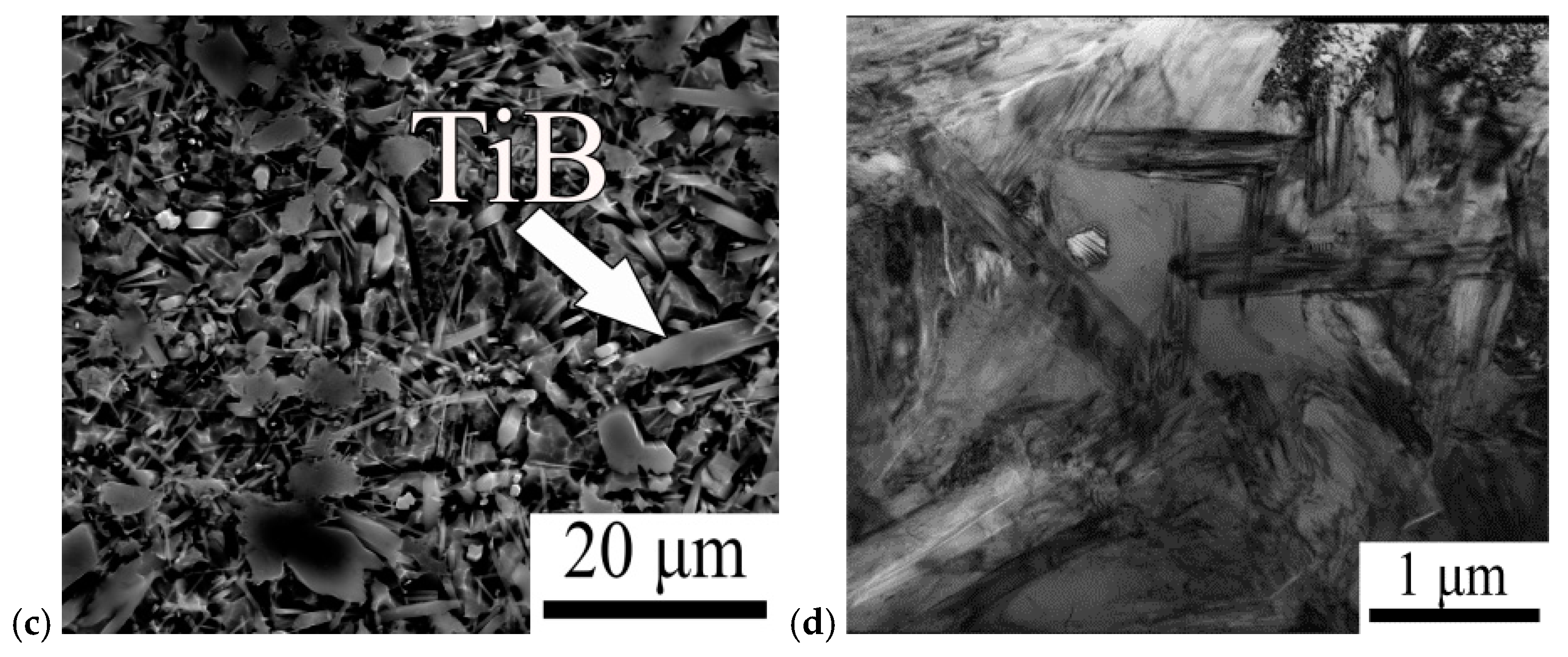

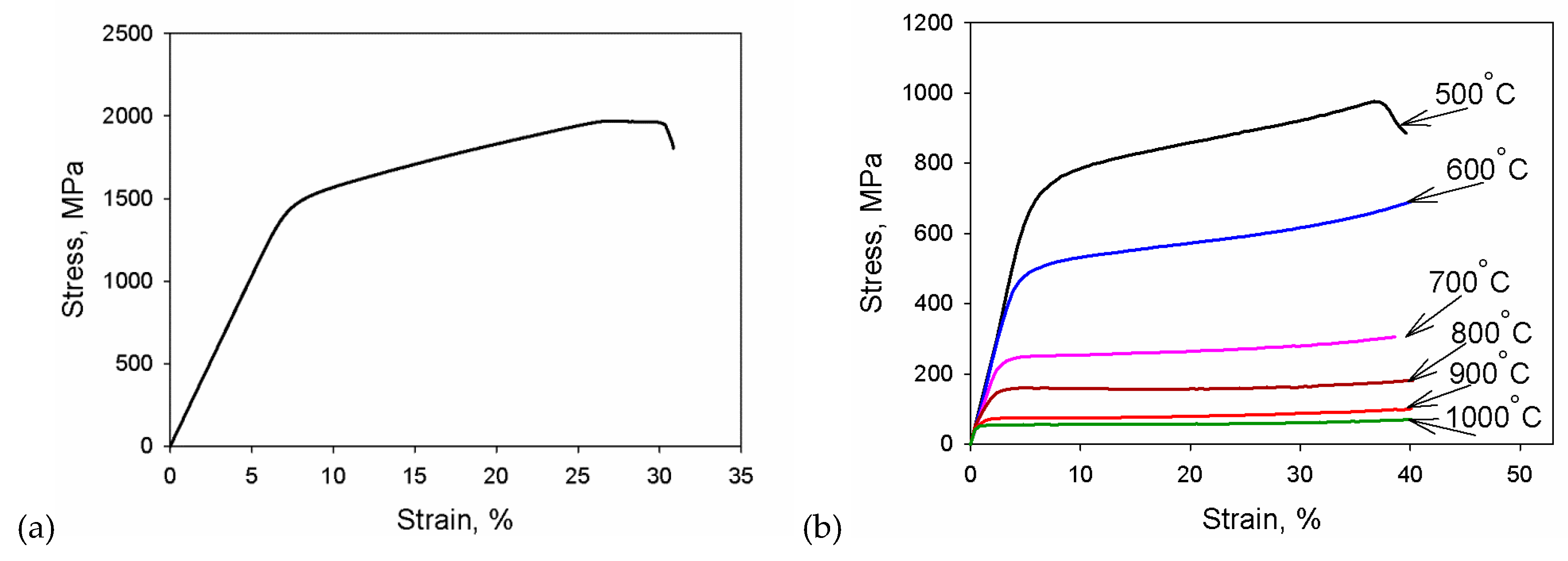

- The Ti-15Mo/TiB TMC fabricated by spark plasma sintering at 1400 °C under a load of 40 MPa for 15 min using a Ti-14.25(wt.)%Mo-5(wt.)%TiB2 powder mixture was composed of β-Ti matrix reinforced with TiB whiskers with the average diameter of 200 nm. The as-sintered TMC had attractive compression mechanical properties at room temperature: yield strength ~1480 MPa and ductility ~22%.

- (2)

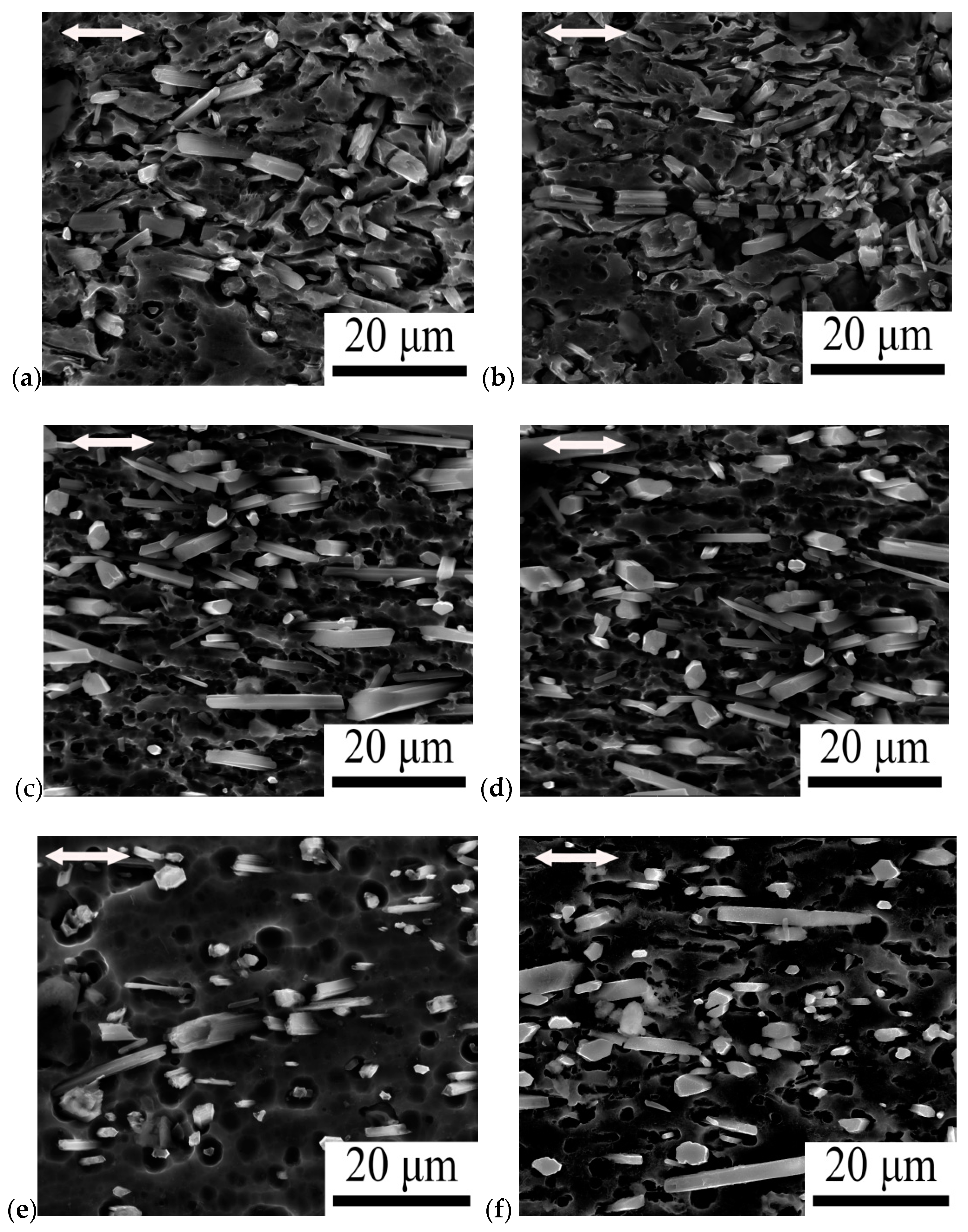

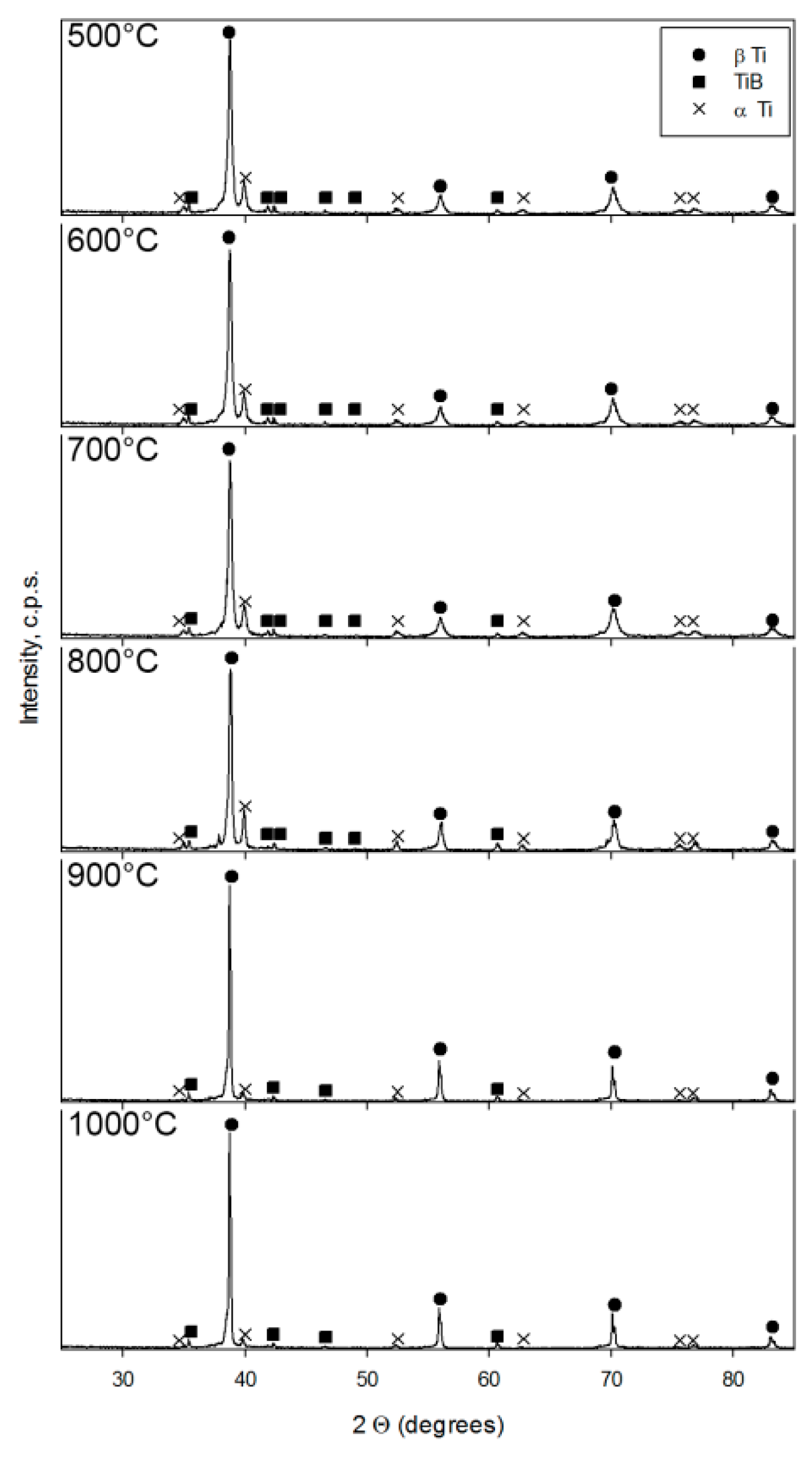

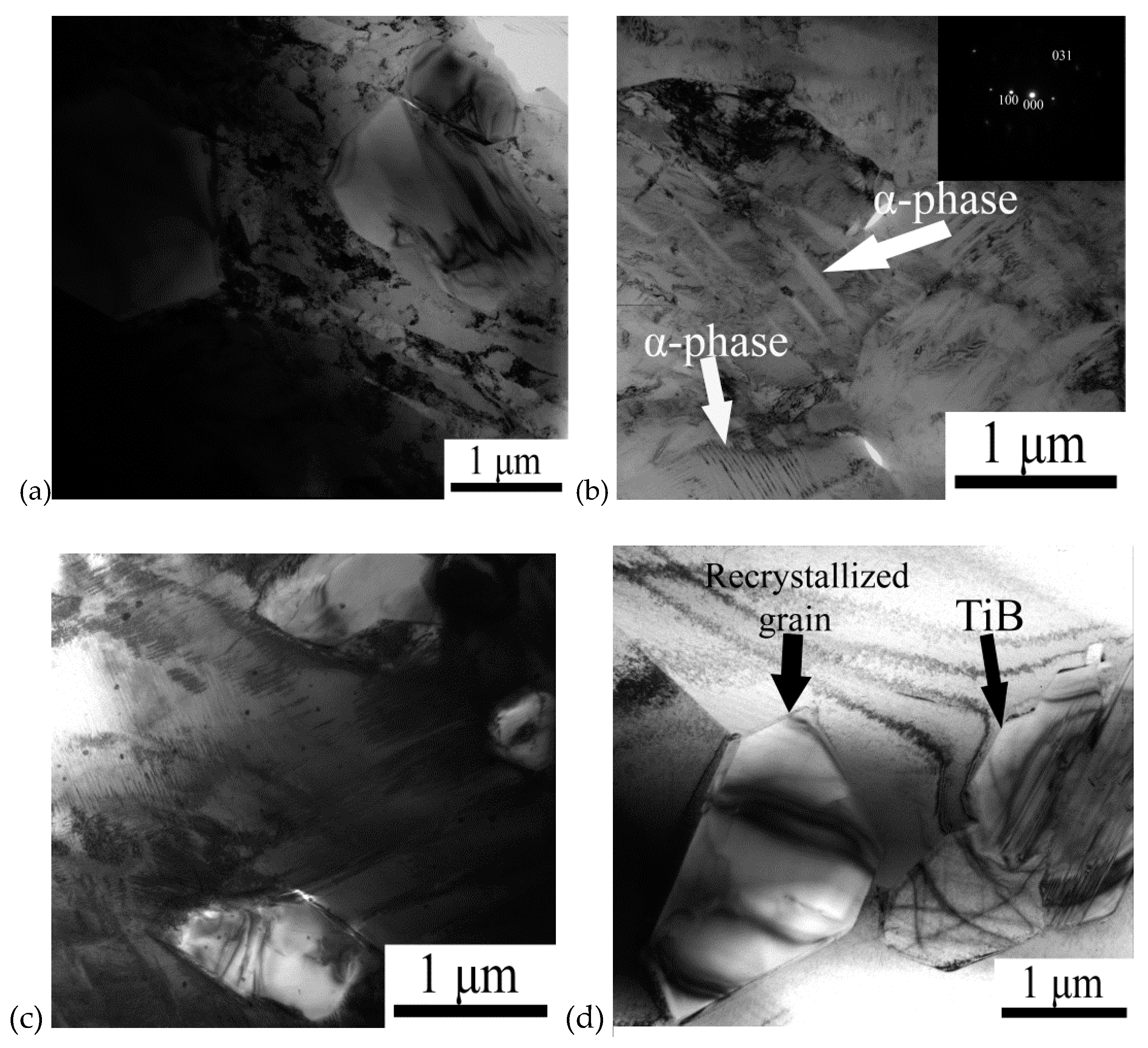

- The uniaxial compression in the temperature range of 500–1000 °C demonstrated gradual softening with an increase in deformation temperature. Microstructure evolution of the Ti-15Mo matrix was associated with the development of dynamic recovery at 500–700 °C and dynamic recrystallization at temperatures ≥800 °C. Reorientation of TiB whiskers toward the metal flow direction and some shortening of the whiskers also occurred. In addition, the precipitation of the α particles was found after deformation at 500–1000 °C.

- (3)

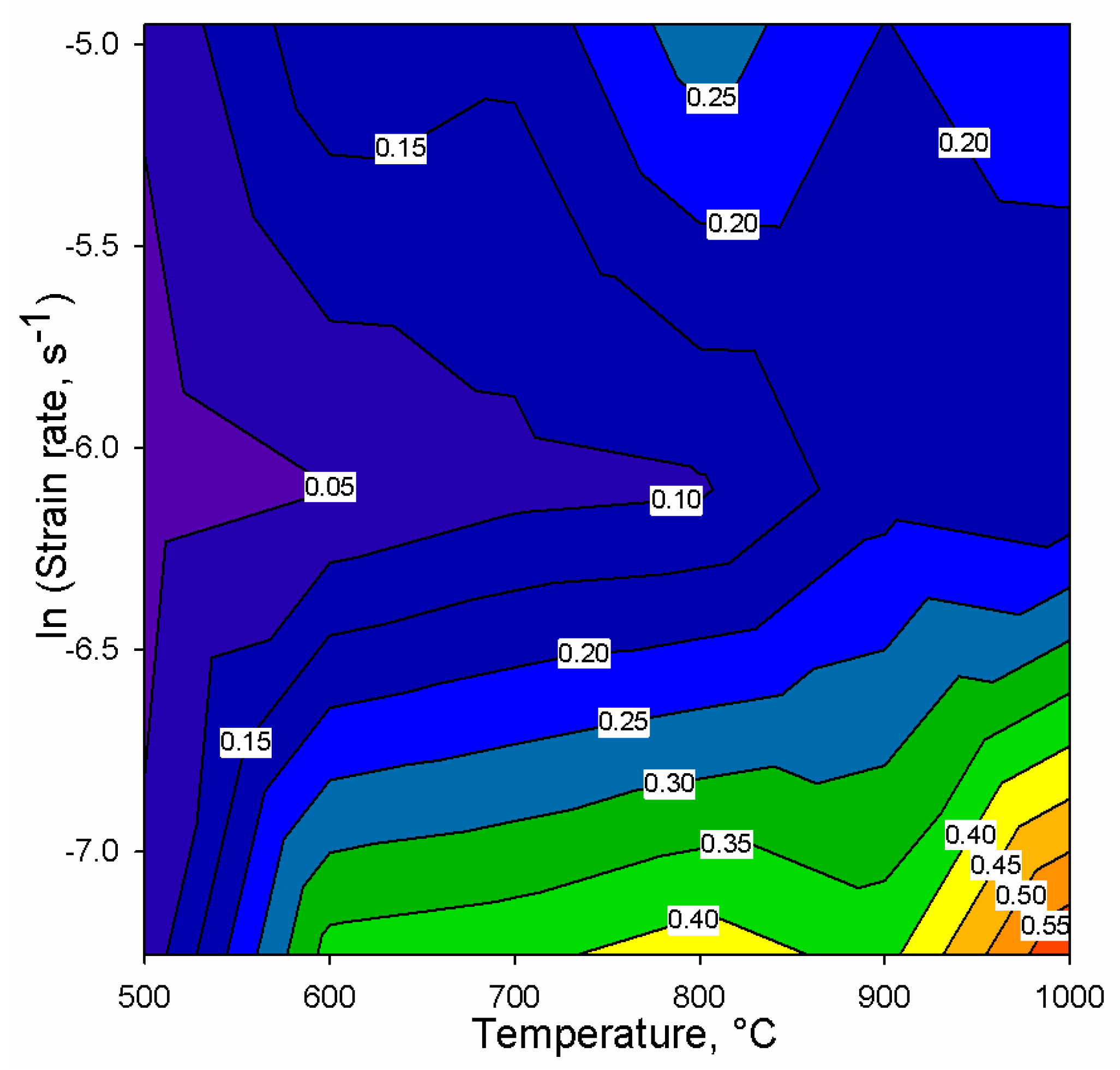

- The optimal parameters of thermomechanical processing for the Ti-15Mo/TiB TMC were associated with deformation temperatures of 700–800 °C and strain rates of 5 × 10−4–10−3 s−1.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Leyens, C.; Peters, M. Titanium and Titanium Alloys: Fundamentals and Applications; Wiley-VCH: Weinheim, Germany, 2003; pp. 1–499. [Google Scholar]

- Khorasani, A.M.; Goldberg, M.; Doeven, E.H.; Littlefair, G. Titanium in biomedical applications—Properties and fabrication: A review. J. Biomater. Tissue Eng. 2015, 5, 593–619. [Google Scholar] [CrossRef]

- Chen, Q.; Thouas, G.A. Metallic implant biomaterials. Mater. Sci. Eng. R Rep. 2015, 87, 1–57. [Google Scholar] [CrossRef]

- Saito, T.; Furuta, T.; Yamaguchi, T. Development of low cost titanium matrix composite. In Advances in Titanium Metal Matrix Composites, the Minerals, Metals and Materials Society; Froes, F.H., Storer, J., Eds.; TMS: Warrendale, PA, USA, 1995; pp. 33–44. [Google Scholar]

- Godfrey, T.M.T.; Goodwin, P.S.; Ward-Close, C.M. Titanium Particulate Metal Matrix Composites—Reinforcement, Production Methods, and Mechanical Properties. Adv. Eng. Mater. 2000, 2, 85–91. [Google Scholar] [CrossRef]

- Morsi, K.; Patel, V.V. Processing and properties of titanium-titanium boride (TiBw) matrix composites—A review. J. Mater. Sci. 2007, 42, 2037–2047. [Google Scholar] [CrossRef]

- Ravi Chandran, K.S.; Panda, K.B.; Sahay, S.S. TiBw-reinforced Ti composites: Processing, properties, application, prospects, and research needs. JOM 2004, 56, 42–48. [Google Scholar] [CrossRef]

- Feng, H.; Zhou, Y.; Jia, D.; Meng, Q.; Rao, J. Growth mechanism of in situ TiB whiskers in spark plasma sintered TiB/Ti metal matrix composites. Cryst. Growth Des. 2006, 6, 1626–1630. [Google Scholar] [CrossRef]

- Ozerov, M.; Stepanov, N.; Kolesnikov, A.; Sokolovsky, V.; Zherebtsov, S. Brittle-to-ductile transition in a Ti–TiB metal-matrix composite. Mater. Lett. 2017, 187, 28–31. [Google Scholar] [CrossRef]

- Ozerov, M.; Klimova, M.; Vyazmin, A.; Stepanov, N.; Zherebtsov, S. Orientation relationship in a Ti/TiB metal-matrix composite. Mater. Lett. 2017, 186, 168–170. [Google Scholar] [CrossRef]

- Gaisin, R.A.; Imayev, V.M.; Imayev, R.M. Effect of hot forging on microstructure and mechanical properties of near α titanium alloy/TiB composites produced by casting. J. Alloys Compd. 2017, 723, 385–394. [Google Scholar] [CrossRef]

- Ozerov, M.S.; Gazizova, M.Y.; Klimova, M.V.; Stepanov, N.D.; Zherebtsov, S.V. Effect of Plastic Deformation on the Structure and Properties of the Ti/TiB Composite Produced by Spark Plasma Sintering. Russ. Metall. (Met.) 2018, 7, 638–644. [Google Scholar] [CrossRef]

- Zherebtsov, S.; Ozerov, M.; Stepanov, N.; Klimova, M.; Ivanisenko, Y. Effect of high-pressure torsion on structure and microhardness of Ti/TiB metal-matrix composite. Metals 2017, 7, 507. [Google Scholar] [CrossRef]

- Ozerov, M.; Klimova, M.; Sokolovsky, V.; Stepanov, N.; Popov, A.; Boldin, M.; Zherebtsov, S. Evolution of microstructure and mechanical properties of Ti/TiB metal-matrix composite during isothermal multiaxial forging. J. Alloys Compd. 2019, 770, 840–848. [Google Scholar] [CrossRef]

- Imayev, V.; Gaisin, R.; Gaisina, E.; Imayev, R.; Fecht, H.-J.; Pyczak, F. Effect of hot forging on microstructure and tensile properties of Ti–TiB. Mater. Sci. Eng. A 2014, 609, 34–41. [Google Scholar] [CrossRef]

- Ozerov, M.S.; Klimova, M.V.; Stepanov, N.D.; Zherebtsov, S.V. Microstructure evolution of a Ti/TiB metal-matrix composite during high-temperature deformation. Mater. Phys. Mech. 2018, 38, 54–63. [Google Scholar] [CrossRef]

- Zherebtsov, S.; Ozerov, M.; Stepanov, N.; Klimova, M. Structure and properties of Ti/TiB metal–matrix composite after isothermal multiaxial forging. Acta Phys. Pol. A 2018, 134, 695–698. [Google Scholar] [CrossRef]

- Will, G. Powder Diffraction: The Rietveld Method and the Two-Stage Method to Determine and Refine Crystal Structures from Powder Diffraction Data; Springer: Berlin, Germany, 2005. [Google Scholar]

- Prasad, Y.V.R.K.; Rao, K.P.; Sasidhara, S. Hot Working Guide: A Compendium of Processing Maps; ASM International: Materials Park, OH, USA, 2015; pp. 1–625. [Google Scholar]

- Weiss, I.; Semiatin, S.L. Thermomechanical processing of beta titanium alloys—An overview. Mater. Sci. Eng. A 1998, 243, 46–65. [Google Scholar] [CrossRef]

- Jiang, B.; Tsuchiya, K.; Emura, S.; Min, X. Effect of high-pressure torsion process on precipitation behavior of α phase in β-type Ti-15Mo alloy. Mater. Trans. 2014, 55, 877–884. [Google Scholar] [CrossRef]

- Ilyin, A.A.; Kolachev, B.A.; Polkin, I.S. Titanium Alloys. Composition, Structure, Properties; VILS-MATI Publishing: Moscow, Russia, 2009. [Google Scholar]

- Jeong, H.W.; Kim, S.J.; Hyun, Y.T.; Lee, Y.T. Densification and Compressive Strength of In-situ Processed Ti/TiB Composites by Powder Metallurgy. Metals Mater. Int. 2002, 8, 25–35. [Google Scholar] [CrossRef]

- Attar, H.; Bönisch, M.; Calin, M.; Zhang, L.-C.; Scudino, S.; Eckert, J. Selective laser melting of in situ titanium–titanium boride composites: Processing, microstructure and mechanical properties. Acta Mater. 2014, 76, 13–22. [Google Scholar] [CrossRef]

- Meyers, M.A.; Chawla, K.K. Mechanical Behavior of Materials; Cambridge University Press: New York, NY, USA, 2009. [Google Scholar]

- Casati, R.; Vedani, M. Metal Matrix Composites Reinforced by Nano-Particles—A review. Metals 2004, 4, 65–83. [Google Scholar] [CrossRef]

- Zherebtsov, S.; Ozerov, M.; Klimova, M.; Stepanov, N.; Vershinina, T.; Ivanisenko, Y.; Salishchev, G. Effect of High-Pressure Torsion on Structure and Properties of Ti-15Mo/TiB Metal-Matrix Composite. Materials 2018, 11, 2426. [Google Scholar] [CrossRef] [PubMed]

- Morsi, K. Review: Titanium–titanium boride composites. J. Mater. Sci. 2019, 54, 6753–6771. [Google Scholar] [CrossRef]

- Ozerov, M.; Klimova, M.; Kolesnikov, A.; Stepanov, N.; Zherebtsov, S. Deformation behavior and microstructure evolution of a Ti/TiB metal-matrix composite during high-temperature compression tests. Mater. Des. 2016, 112, 17–26. [Google Scholar] [CrossRef]

- Rao, K.P.; Prasad, Y.V.R.K. Advanced Techniques to Evaluate Hot Workability of Materials. Compr. Mater. Process. 2014, 3, 397–426. [Google Scholar] [CrossRef]

- Frost, H.J.; Ashby, M.F. Deformation-Mechanism Maps; Pergamon Press: Oxford, UK, 1982; pp. 1–166. [Google Scholar]

- Zhang, Y.; Huang, L.; Liu, B.; Geng, L. Hot deformation behavior of in-situ TiBw/Ti6Al4V composite with novel network reinforcement distribution, Trans. Nonferrous Metals Soc. 2012, 22, 465–471. [Google Scholar] [CrossRef]

- Conrad, H. Effect of interstitial solutes on the strength and ductility of titanium. Prog. Mater. Sci. 1981, 26, 123–403. [Google Scholar] [CrossRef]

- Raj, S.V.; Langdon, T.G. Creep behavior of copper at intermediate temperatures—I. Mechanical characteristics. Acta Metall. 1989, 37, 843–852. [Google Scholar] [CrossRef]

- Walsöe De Reca, N.E.; Libanati, C.M. Autodifusion de titanio beta y hafnio beta. Acta Metall. 1968, 16, 1297–1305. [Google Scholar] [CrossRef]

- Kumari, S.; Prasad, N.E.; Chandran, K.S.R.; Malakondaiah, G. High-temperature deformation behavior of Ti-TiBw in-situ metal-matrix composites. JOM 2004, 56, 51–55. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zherebtsov, S.; Ozerov, M.; Klimova, M.; Moskovskikh, D.; Stepanov, N.; Salishchev, G. Mechanical Behavior and Microstructure Evolution of a Ti-15Mo/TiB Titanium–Matrix Composite during Hot Deformation. Metals 2019, 9, 1175. https://doi.org/10.3390/met9111175

Zherebtsov S, Ozerov M, Klimova M, Moskovskikh D, Stepanov N, Salishchev G. Mechanical Behavior and Microstructure Evolution of a Ti-15Mo/TiB Titanium–Matrix Composite during Hot Deformation. Metals. 2019; 9(11):1175. https://doi.org/10.3390/met9111175

Chicago/Turabian StyleZherebtsov, Sergey, Maxim Ozerov, Margarita Klimova, Dmitry Moskovskikh, Nikita Stepanov, and Gennady Salishchev. 2019. "Mechanical Behavior and Microstructure Evolution of a Ti-15Mo/TiB Titanium–Matrix Composite during Hot Deformation" Metals 9, no. 11: 1175. https://doi.org/10.3390/met9111175

APA StyleZherebtsov, S., Ozerov, M., Klimova, M., Moskovskikh, D., Stepanov, N., & Salishchev, G. (2019). Mechanical Behavior and Microstructure Evolution of a Ti-15Mo/TiB Titanium–Matrix Composite during Hot Deformation. Metals, 9(11), 1175. https://doi.org/10.3390/met9111175