Texture Evolution and Anisotropy of Plastic Flow in Hot Compression of Extruded ZK60-T5 Magnesium Alloy Plate

Abstract

1. Introduction

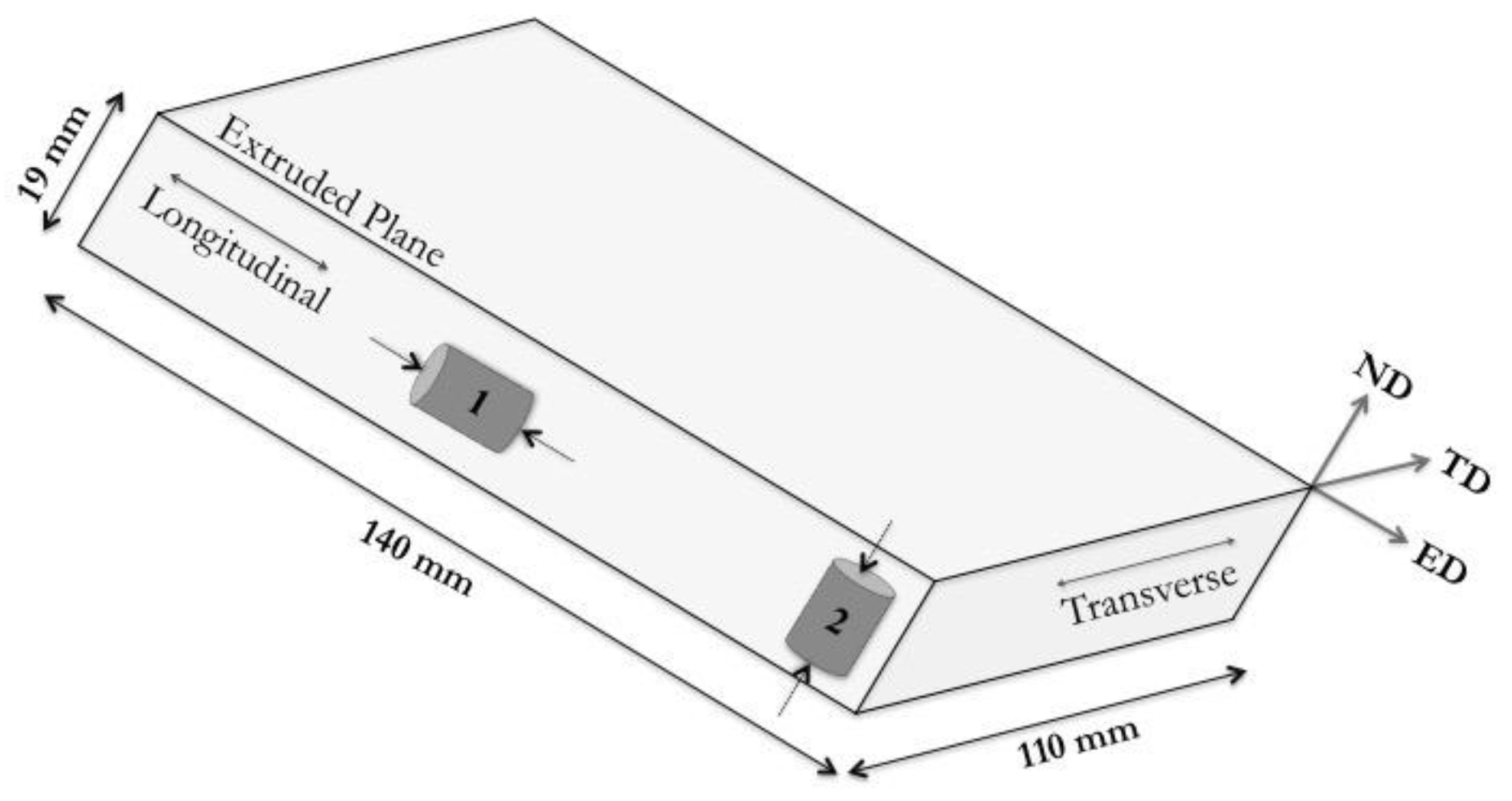

2. Experimental Details

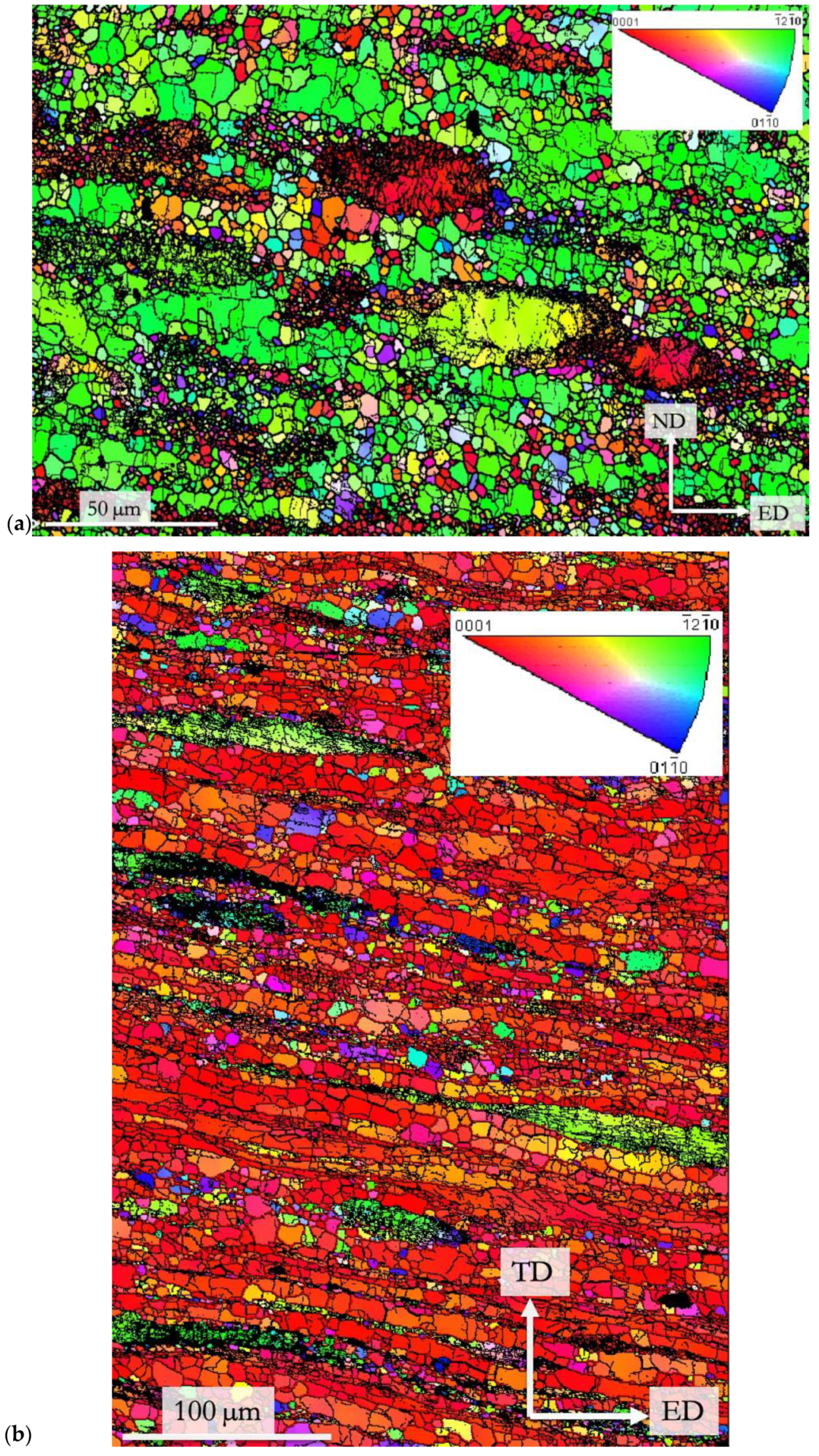

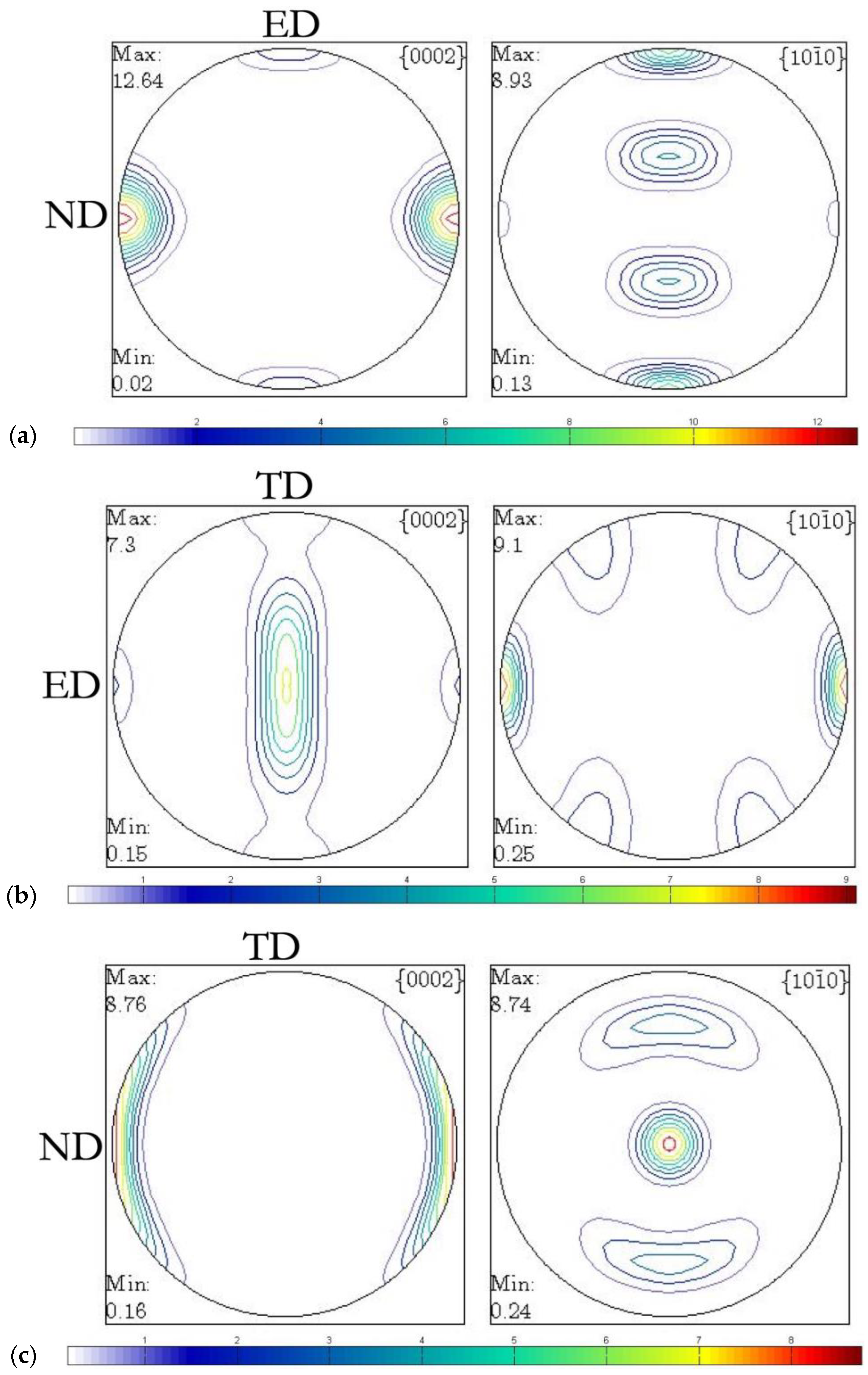

3. Microstructure and Texture of the As-Received ZK60A-T5 Alloy Plate

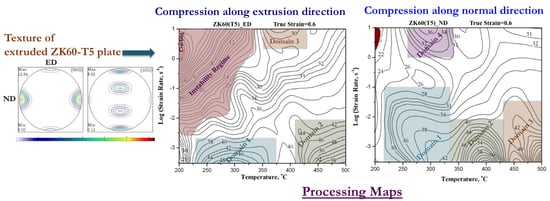

4. Processing Maps for Hot Deformation of Extruded ZK60 Plate by Present Authors: A Brief Summary of Earlier Results

5. Results and Discussion: Texture Evolution and Anisotropy of Flow in Hot Compression

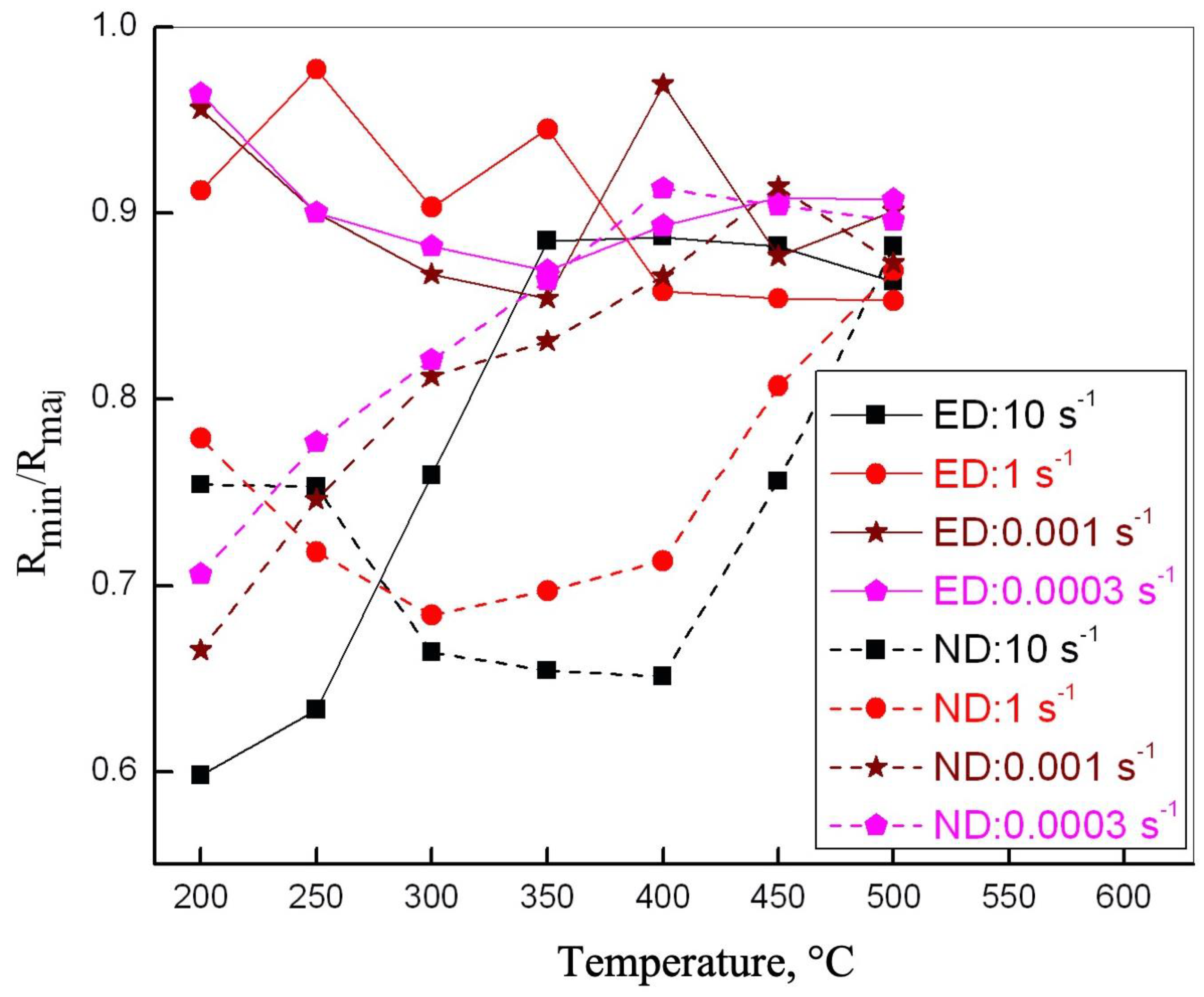

5.1. Shapes of Deformed Specimens

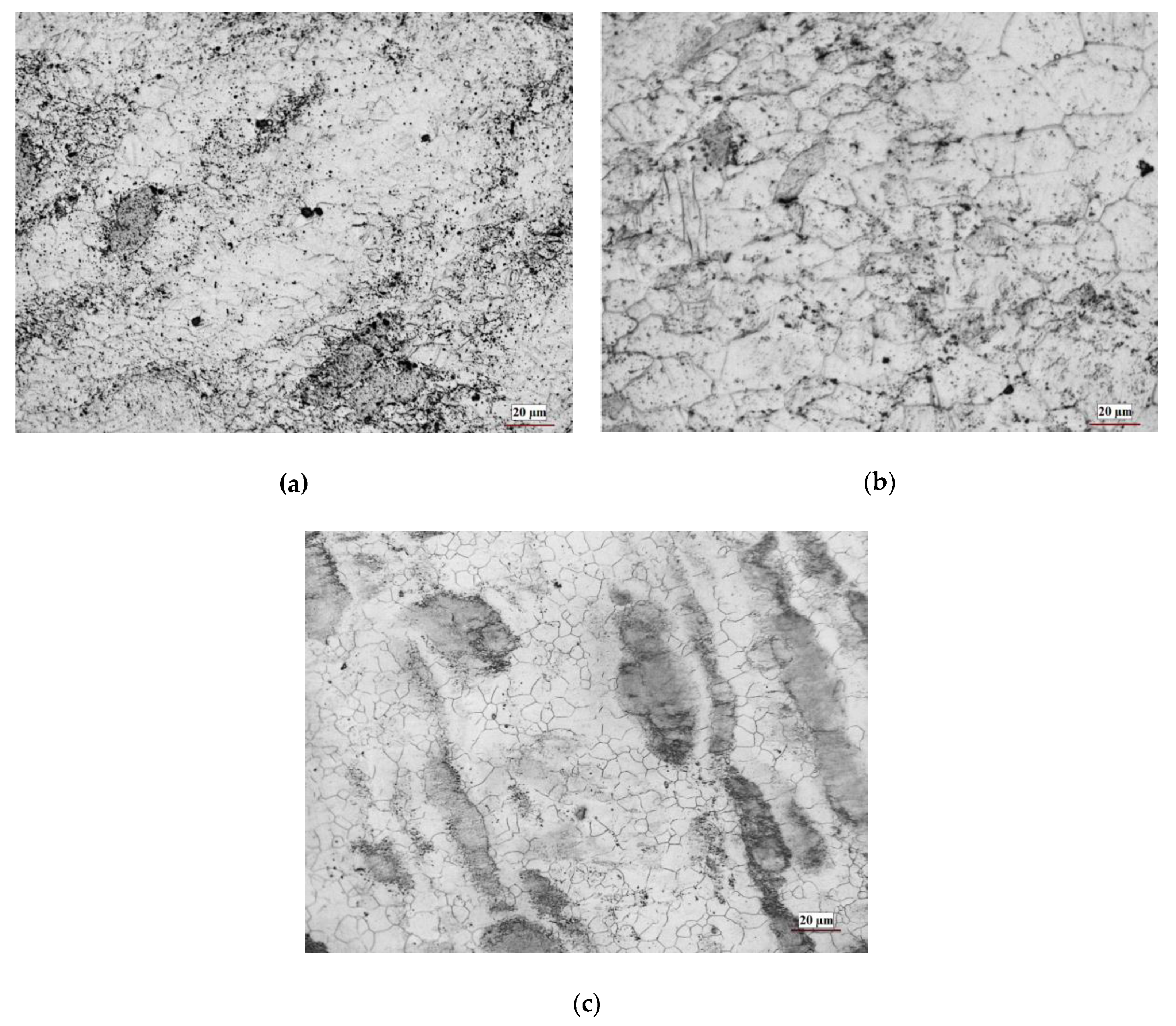

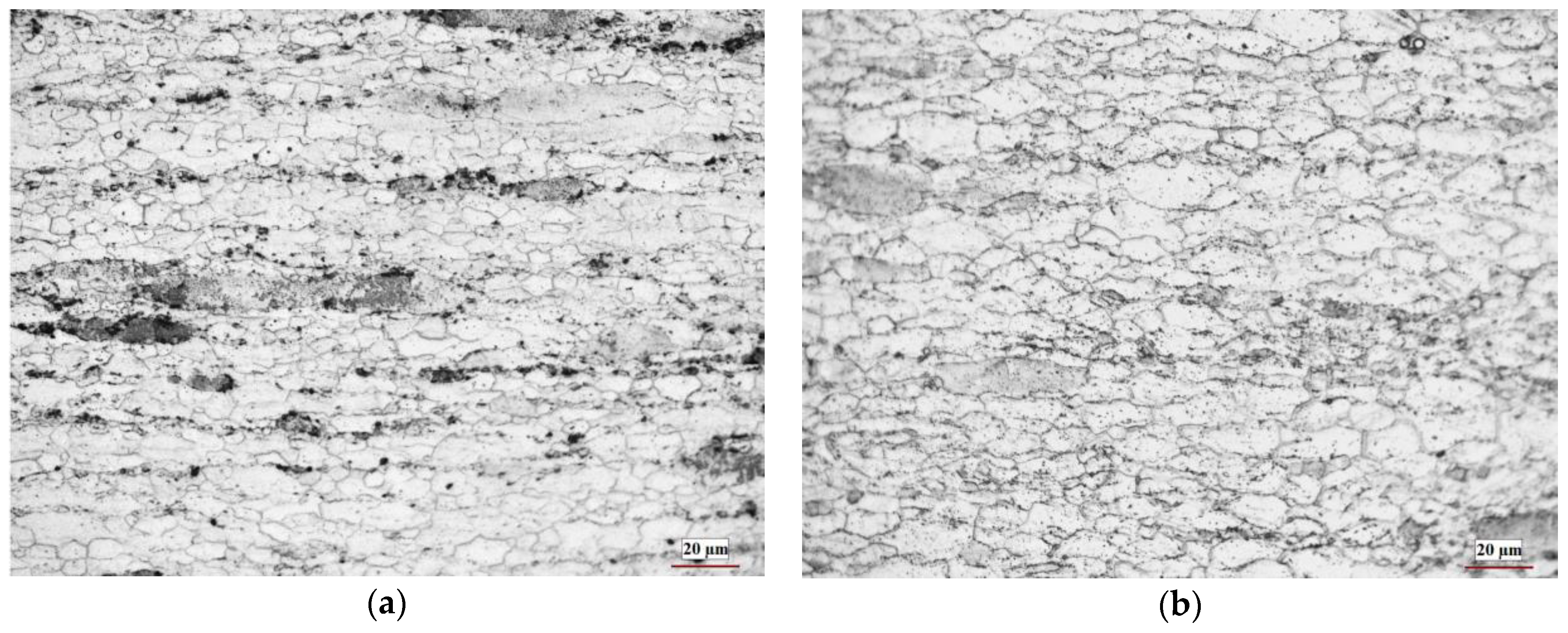

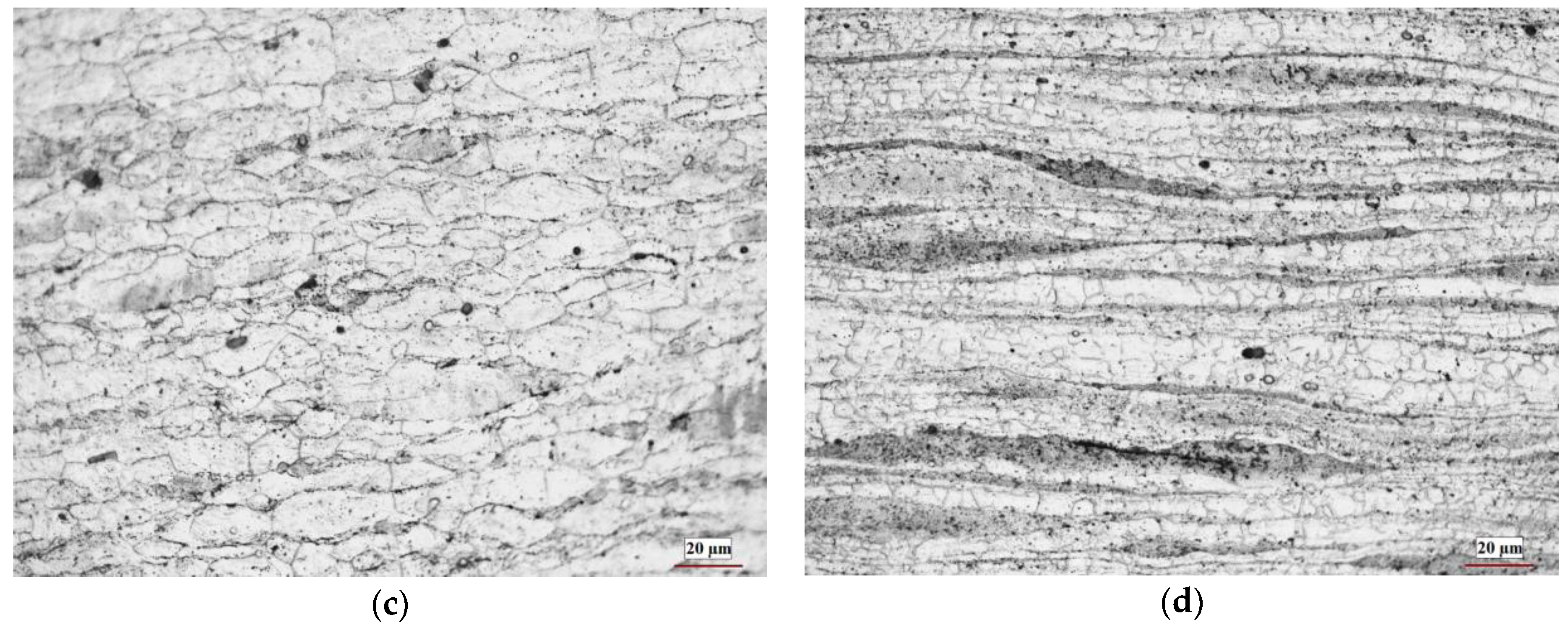

5.2. Microstructural Analysis

5.3. Texture Evolution

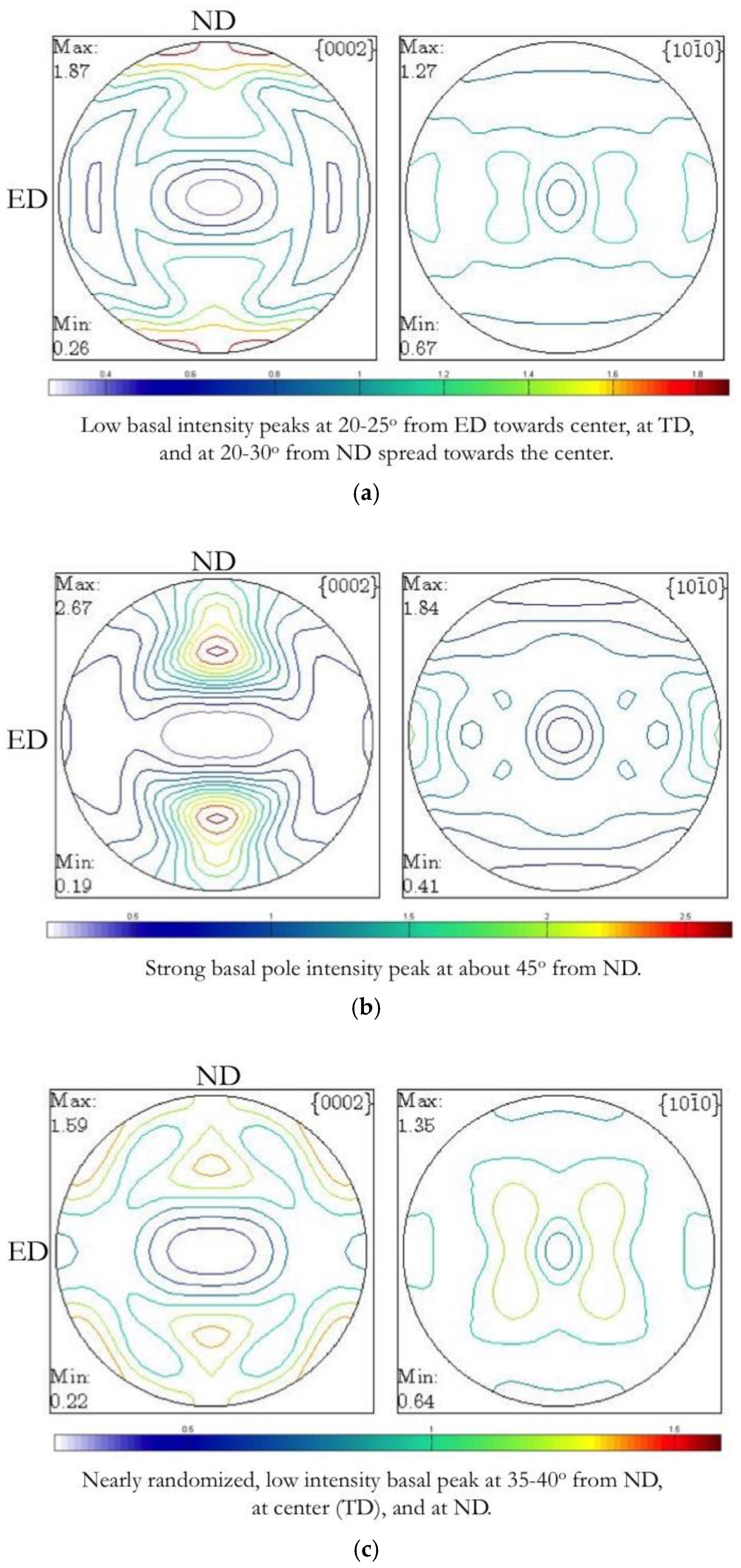

5.3.1. Specimens Compressed Parallel to ED

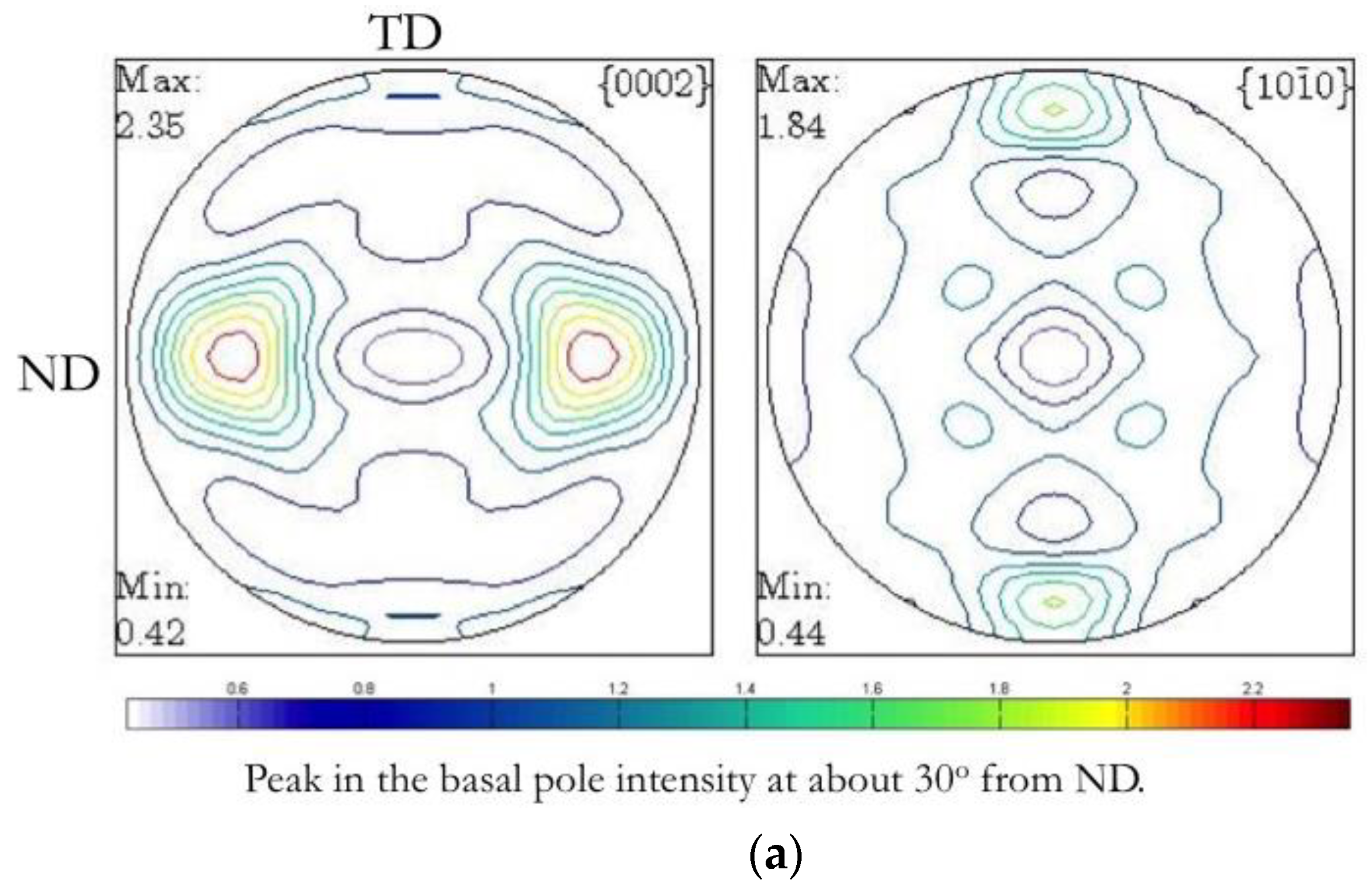

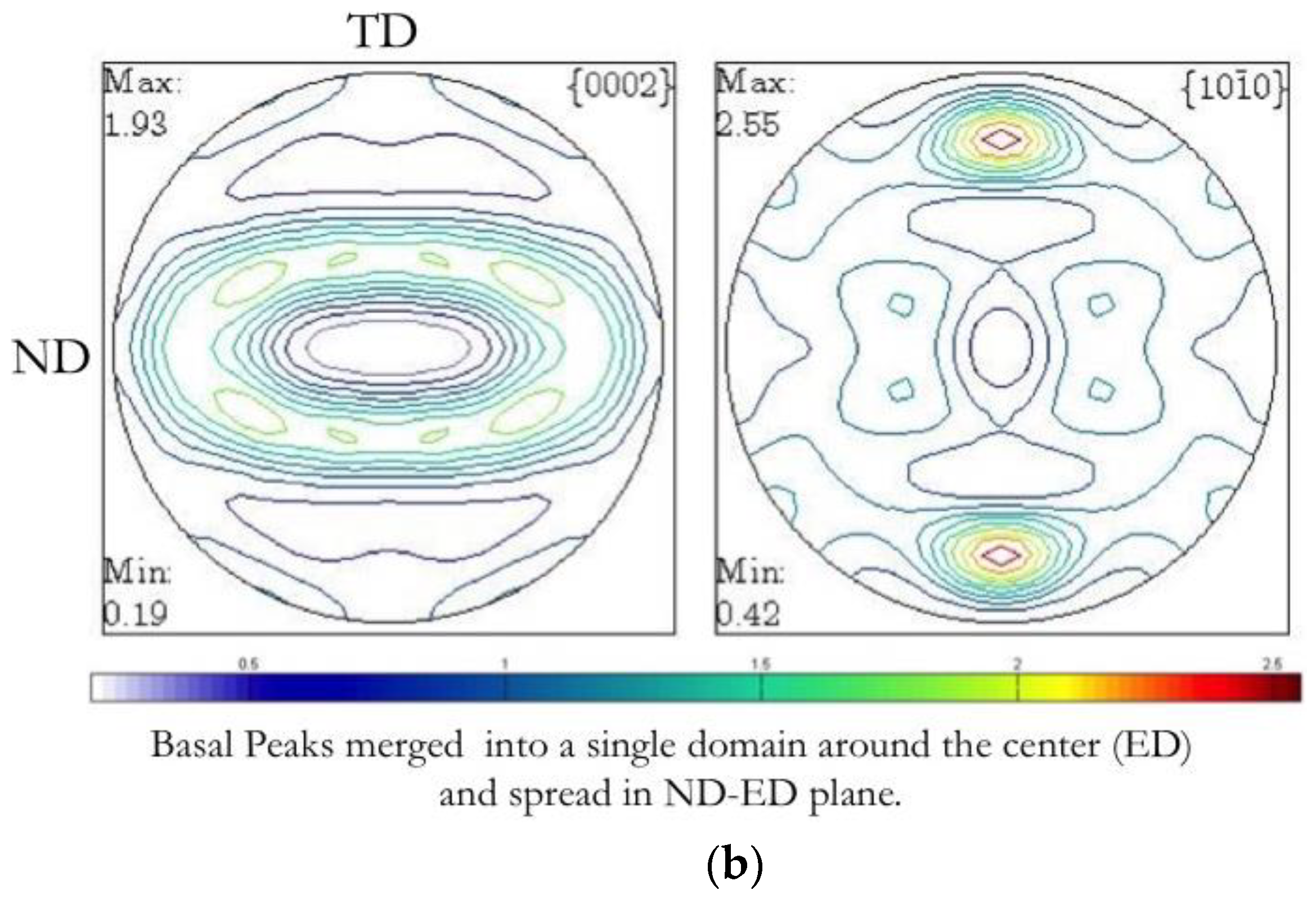

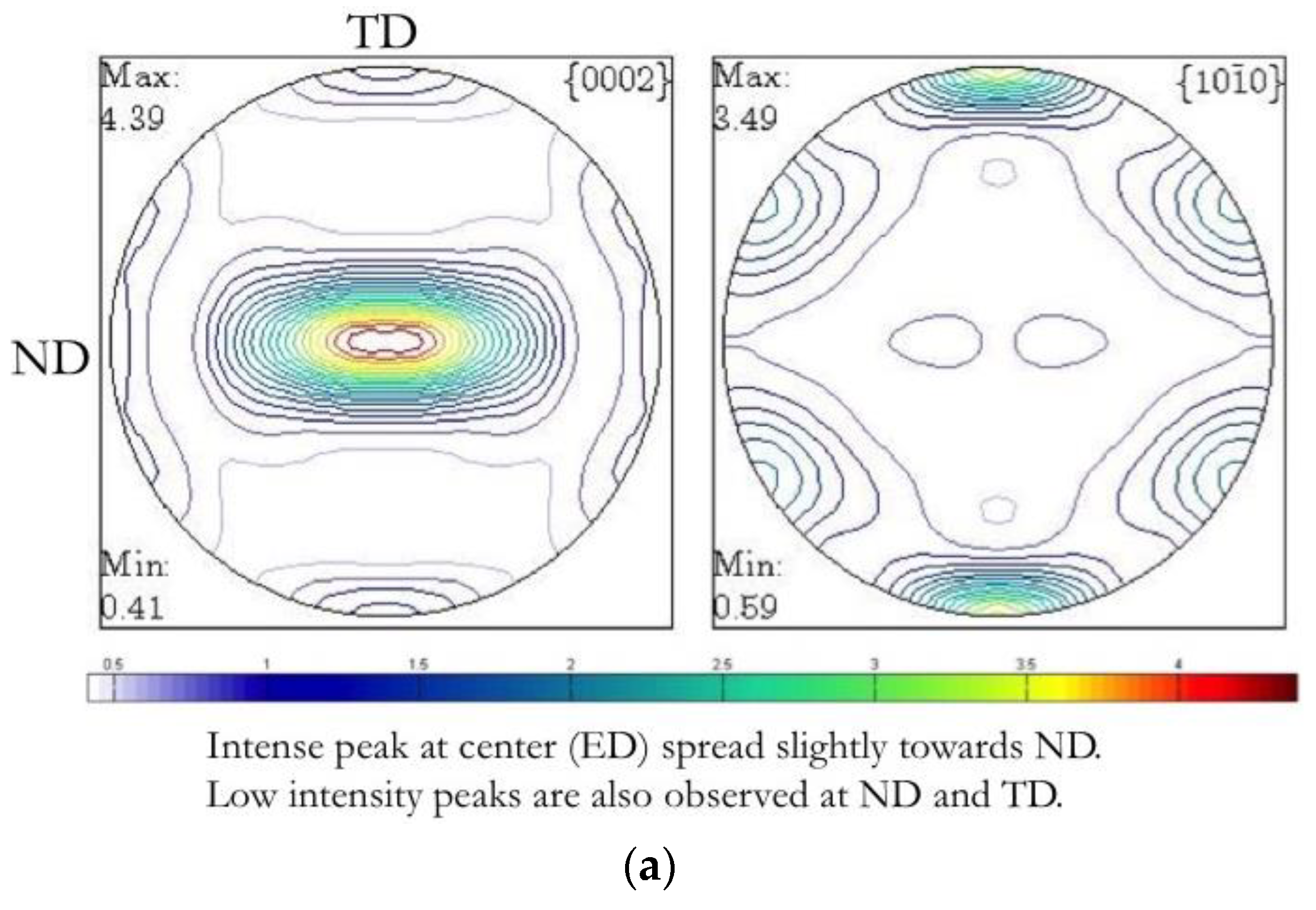

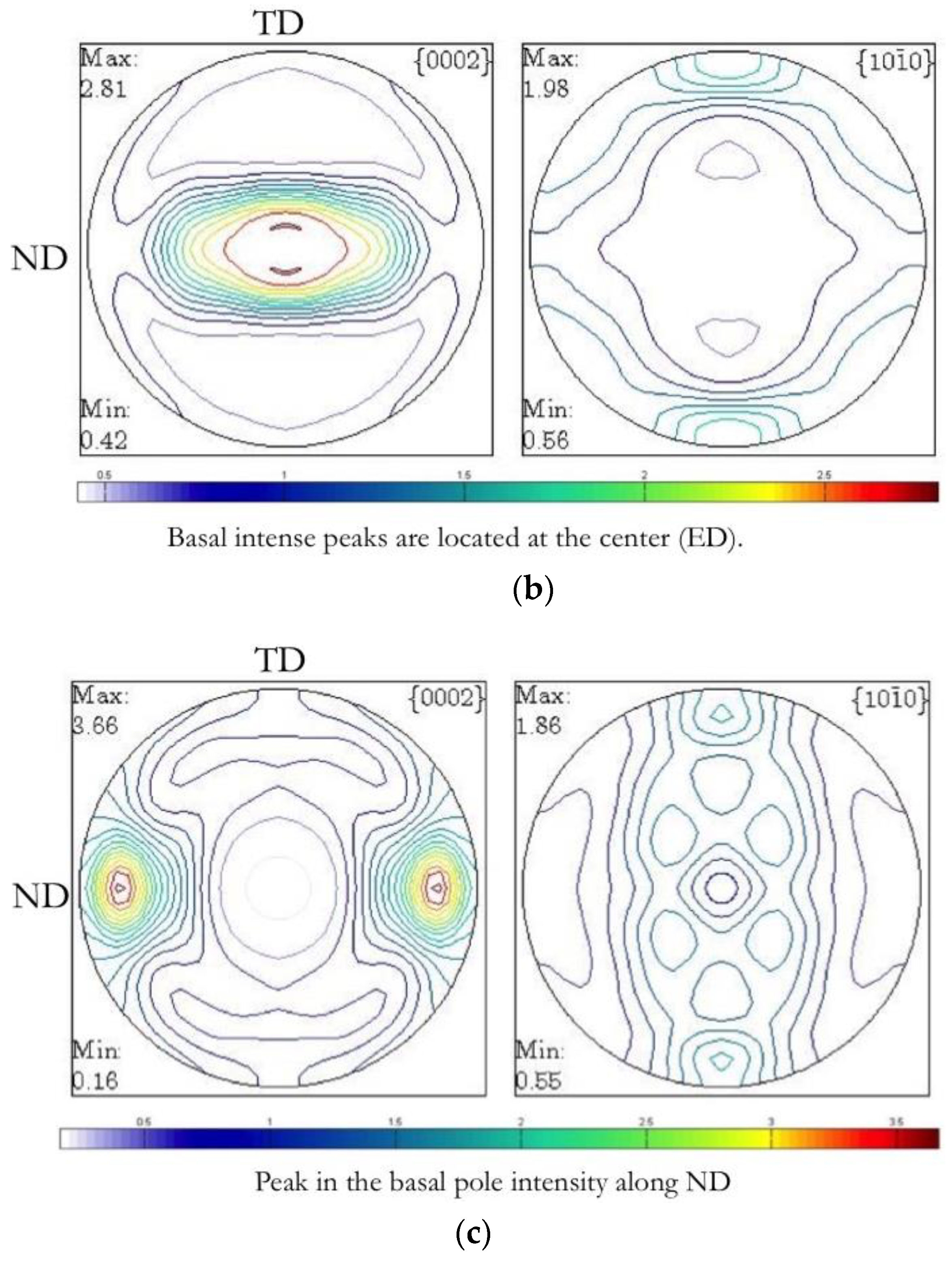

5.3.2. Specimens Compressed Parallel to ND

5.4. Comparison with the Hot Deformation Behavior of Wrought Mg and AZ31 Alloy

6. Conclusions

- When loaded parallel to the extrusion direction (ED), the processing map exhibited three DRX domains in the temperature and strain rate ranges: (1) 230 °C to 375 °C and 0.0003 s−1 to 0.002 s−1, (2) 410 °C to 500 °C and 0.0003 s−1 to 0.008 s−1, (3) 350 °C to 430 °C and 2 s−1 to 10 s−1. ED samples exhibited a flow instability regime at low temperature and high strain rate conditions, whereas at other processing conditions, deformed uniformly to a near-circular cross-section.

- In the first and third domains of the ED map, first-order pyramidal slip {10l} <110> occurs, while second-order pyramidal slip {112} <113> occurs in the second domain. The pole figures obtained on specimens deformed in Domains 1 and 3 are strikingly similar and nearly randomized, while a new texture is generated in the second domain with basal poles at 45° with respect to ND or TD. This new texture will promote basal slip if loaded in the transverse direction.

- When loaded in the normal direction (ND), the processing map exhibited four domains in the temperature and strain rate ranges: (1) 225 °C to 350 °C and 0.0003 s−1 to 0.1 s−1, (2) 350 °C to 430 °C and 0.0003 s−1 to 0.007 s−1, (3) 430 °C to 500 °C and 0.0003 s−1 to 0.03 s−1, and (4) 260 °C to 340 °C and 1 s−1 to 10 s−1. In Domains 1 and 4, {10l} <113> slip occurs, while {112} <113> slip occurs in Domains 2 and 3.

- The pole figures obtained on specimens deformed in Domains 1 and 4 have similar features while those deformed in Domains 2 and 3 are similar, suggesting that the operating slip systems control the texture development since they are the same in each of the pairs.

- The compression along ND produces strong basal textures with the basal planes normal to the ED, which gets intensified with increased temperature of deformation, which will cause strong anisotropy of mechanical properties.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Conrad, H.; Robertson, W.D. Effect of temperature on the flow stress and strain-hardening coefficient of magnesium single crystals. JOM 1957, 9, 503–512. [Google Scholar] [CrossRef]

- Emley, E.F. Principles of Magnesium Technology; Pergamon Press: Oxford, NY, USA, 1966. [Google Scholar]

- Kelley, E.W.; Hosford, W.F. Plane-strain compression of magnesium and magnesium alloy crystals. Trans. Metall. Soc. AIME 1968, 242, 5–13. [Google Scholar]

- Galiyev, A.; Kaibyshev, R. Superplasticity in a magnesium alloy subjected to isothermal rolling. Scr. Mater. 2004, 51, 89–93. [Google Scholar] [CrossRef]

- Watanabe, H.; Mukai, T.; Higashi, K. Superplasticity in a ZK60 magnesium alloy at low temperatures. Scr. Mater. 1999, 40, 477–484. [Google Scholar] [CrossRef]

- Lapovok, R.; Thomson, P.F.; Cotam, R.; Estrin, Y. Processing routes leading to superplastic behavior of magnesium alloy ZK60. Mater. Sci. Eng. A 2005, 4104–4111, 390–393. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Langdon, T.G. Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Kleiner, S.; Uggowitzer, P.J. Mechanical anisotropy of extruded Mg-6% Al-1% Zn alloy. Mater. Sci. Eng. A 2004, 379, 258–263. [Google Scholar] [CrossRef]

- Liu, Q.; Zhou, X.; Zhou, H.; Fan, X.; Liu, K. The effect of extrusion conditions on the properties and textures of AZ31B alloy. J. Magnes. Alloy. 2017, 5, 202–209. [Google Scholar] [CrossRef]

- You, S.; Huang, Y.; Kainer, K.U.; Hort, N. Recent research and developments on wrought magnesium alloys. J. Magnes. Alloy. 2017, 5, 239–253. [Google Scholar]

- Koike, J. Enhanced deformation mechanisms by anisotropic plasticity in polycrystalline Mg alloys at room temperature. Metall. Mater. Trans. A 2005, 36, 1689–1696. [Google Scholar] [CrossRef]

- Yang, Q.; Jiang, B.; Pan, H.; Song, B.; Jiang, Z.; Dai, J.; Wang, L.; Pan, F. Influence of different extrusion processes on mechanical properties of magnesium alloy. J. Magnes. Alloy. 2014, 2, 220–224. [Google Scholar] [CrossRef]

- Gehrmann, R.; Frommert, M.M.; Gottstein, G. Texture effects on plastic deformation of magnesium. Mater. Sci. Eng. A 2005, 395, 338–349. [Google Scholar] [CrossRef]

- Agnew, S.R.; Yoo, M.H.; Tomé, C.N. Application of texture simulation to understanding mechanical behavior of Mg and solid solution alloys containing Li or Y. Acta Mater. 2001, 49, 4277–4289. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K.; Rao, K.P. Processing maps for hot deformation of rolled AZ31 magnesium alloy plate: Anisotropy of hot workability. Mater. Sci. Eng. A 2008, 487, 316–327. [Google Scholar] [CrossRef]

- Catorceno, L.L.C.; de Abreu, H.F.G.; Padilha, A.F. Effects of cold and warm cross-rolling on microstructure and texture evolution of AZ31B magnesium alloy sheet. J. Magnes. Alloy. 2018, 6, 121–133. [Google Scholar] [CrossRef]

- Tripathi, A.; Murthy, S.V.S.N.; Narayanan, P.R. Microstructure and texture evolution in AZ31 magnesium alloy during caliber rolling at different temperatures. J. Magnes. Alloy. 2017, 5, 340–347. [Google Scholar] [CrossRef]

- Nie, J.F. Effects of precipitate shape and orientation on dispersion strengthening in magnesium alloys. Scr. Mater. 2003, 48, 1009–1015. [Google Scholar] [CrossRef]

- Li, J.; Liu, J.; Cui, Z. Characterization of hot deformation behavior of extruded ZK60 magnesium alloy using 3D processing maps. Mater. Des. 2014, 56, 889–897. [Google Scholar] [CrossRef]

- Ai, W.-J.; Fang, G.; Zhou, J.; Leeflang, M.A.; Duszczyk, J. Effect of twinning on the deformation behavior of an extruded Mg-Zn-Zr alloy during hot compression testing. Mater. Sci. Eng. A 2012, 556, 373–381. [Google Scholar] [CrossRef]

- Spigarelli, S.; El Mehtedi, M.; Regev, M.; Gariboldi, E.; Lecis, N. High temperature creep and superplasticity in a Mg-Zn-Zr alloy. J. Mater. Sci. Technol. 2012, 28, 407–413. [Google Scholar]

- Hadadzadeh, A.; Wells, M.A.; Shaha, S.K.; Jahed, H.; Williams, B.W. Role of compression direction on recrystallization behavior and texture evolution during hot deformation of extruded ZK60 magnesium alloy. J. Alloy. Compd. 2017, 702, 274–289. [Google Scholar] [CrossRef]

- Wang, Y.; Xin, Y.; Chapuis, A.; Yu, H.; Liu, Q. Developing a basal texture with two peaks tilting towards the transverse direction in hot rolled Mg-5.7Zn-0.5Zr plates. Metall. Mater. Trans. A 2016, 47, 4275–4286. [Google Scholar] [CrossRef]

- Dharmendra, C.; Rao, K.P.; Jain, M.K.; Prasad, Y.V.R.K. Role of loading direction on compressive deformation behavior of extruded ZK60A-T5 alloy plate in a wide range of temperature. J. Alloy. Compd. 2018, 744, 289–300. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K.; Rao, K.P.; Sasidhara, S. Hot Working Guide: A Compendium of Processing Maps, 2nd ed.; ASM International: Materials Park, OH, USA, 2015; ISBN 978-1-62708-091-0. [Google Scholar]

- Reed-Hill, R.E.; Robertson, W.D. Deformation of magnesium single crystals by nonbasal slip. JOM 1957, 9, 496–502. [Google Scholar] [CrossRef]

- Xie, K.Y.; Alam, Z.; Caffee, A.; Hemker, K.J. Pyramidal I slip in c-axis compressed Mg single crystals. Scr. Mater. 2016, 112, 75–78. [Google Scholar] [CrossRef]

- Taylor, A. X-ray Metallography; John Wiley & Sons Inc.: Hoboken, NJ, USA, 1961; pp. 572–612. [Google Scholar]

- Frost, H.J.; Ashby, M.F. Deformation-Mechanism Maps; Pergamon Press: Oxford, UK, 1982; p. 44. [Google Scholar]

- Obara, T.; Yoshinaga, H.; Morozumi, S. {11} <113> Slip system in magnesium. Acta Metall. 1973, 21, 845–853. [Google Scholar] [CrossRef]

- Morris, J.R.; Scharaff, J.; Ho, K.M.; Turner, D.E.; Ye, Y.Y.; Yoo, M.H. Prediction of a {1122} hcp stacking fault using a modified generalized stacking-fault calculation. Philos. Mag. 1997, 76, 1065–1077. [Google Scholar] [CrossRef]

- Beer, A.G.; Barnett, M.R. Influence of initial microstructure on the hot working flow stress of Mg-3Al-1Zn. Mater. Sci. Eng. A 2006, 423, 292–299. [Google Scholar] [CrossRef]

- Dzwonczyk, J. Influence of Different Extrusion Methods on Microstructure and Mechanical Properties of AZ31 Alloy. Ph.D. Thesis, Center for Magnesium Technology, GKSS Research Center, Geesthacht, Germany, 2004. [Google Scholar]

- Rao, K.P.; Prasad, Y.V.R.K.; Dzwonczyk, J.; Hort, N.; Kainer, K.U. Hot deformation mechanisms in AZ31 magnesium alloy extruded at different temperatures: Impact of texture. Metals 2012, 2, 292–312. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K.; Rao, K.P. Hot deformation mechanisms and microstructural control in high temperature extruded AZ31 magnesium alloy. Adv. Eng. Mater. 2007, 9, 558–565. [Google Scholar] [CrossRef]

| Loading Direction | Domain No. | Temp. (°C) | Strain Rate (s−1) | Qapp, (kJ/mole) | Slip System | Recovery Mechanism |

|---|---|---|---|---|---|---|

| Extrusion Direction (ED) | 1 | 230–375 | 0.0003–0.002 | 90 | {10l} <110> First-order pyramidal | Climb by lattice self-diffusion |

| 2 | 410–500 | 0.0003–0.008 | 133 | {11} <113> Second-order pyramidal | Cross-slip | |

| 3 | 350–430 | 2–10 | 100 | {10l} <110> First-order pyramidal | Climb by grain boundary self-diffusion | |

| Normal Direction (ND) | 1 | 215–335 | 0.0003–0.1 | 128 | {10l} <113> First-order pyramidal | Climb by lattice self-diffusion |

| 2 | 335–430 | 0.0003–0.007 | 130 | {112} <113> Second-order pyramidal | Cross-slip | |

| 3 | 430–500 | 0.0003–0.03 | 138 | {112} <113> + Grain boundary sliding | Super-plasticity | |

| 4 | 260–340 | 1–10 | 95 | {10l} <113> First-order pyramidal | Climb by grain boundary self-diffusion |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dharmendra, C.; Jain, M.K.; Prasad, Y.V.R.K.; Pitcheswara Rao, K. Texture Evolution and Anisotropy of Plastic Flow in Hot Compression of Extruded ZK60-T5 Magnesium Alloy Plate. Metals 2019, 9, 1170. https://doi.org/10.3390/met9111170

Dharmendra C, Jain MK, Prasad YVRK, Pitcheswara Rao K. Texture Evolution and Anisotropy of Plastic Flow in Hot Compression of Extruded ZK60-T5 Magnesium Alloy Plate. Metals. 2019; 9(11):1170. https://doi.org/10.3390/met9111170

Chicago/Turabian StyleDharmendra, Chalasani, Mukesh Kumar Jain, Yellapregada Venkata Rama Krishna Prasad, and Kamineni Pitcheswara Rao. 2019. "Texture Evolution and Anisotropy of Plastic Flow in Hot Compression of Extruded ZK60-T5 Magnesium Alloy Plate" Metals 9, no. 11: 1170. https://doi.org/10.3390/met9111170

APA StyleDharmendra, C., Jain, M. K., Prasad, Y. V. R. K., & Pitcheswara Rao, K. (2019). Texture Evolution and Anisotropy of Plastic Flow in Hot Compression of Extruded ZK60-T5 Magnesium Alloy Plate. Metals, 9(11), 1170. https://doi.org/10.3390/met9111170