Experimental Optimization of Nimonic 263 Laser Cutting Using a Particle Swarm Approach

Abstract

1. Introduction

2. Literature Review

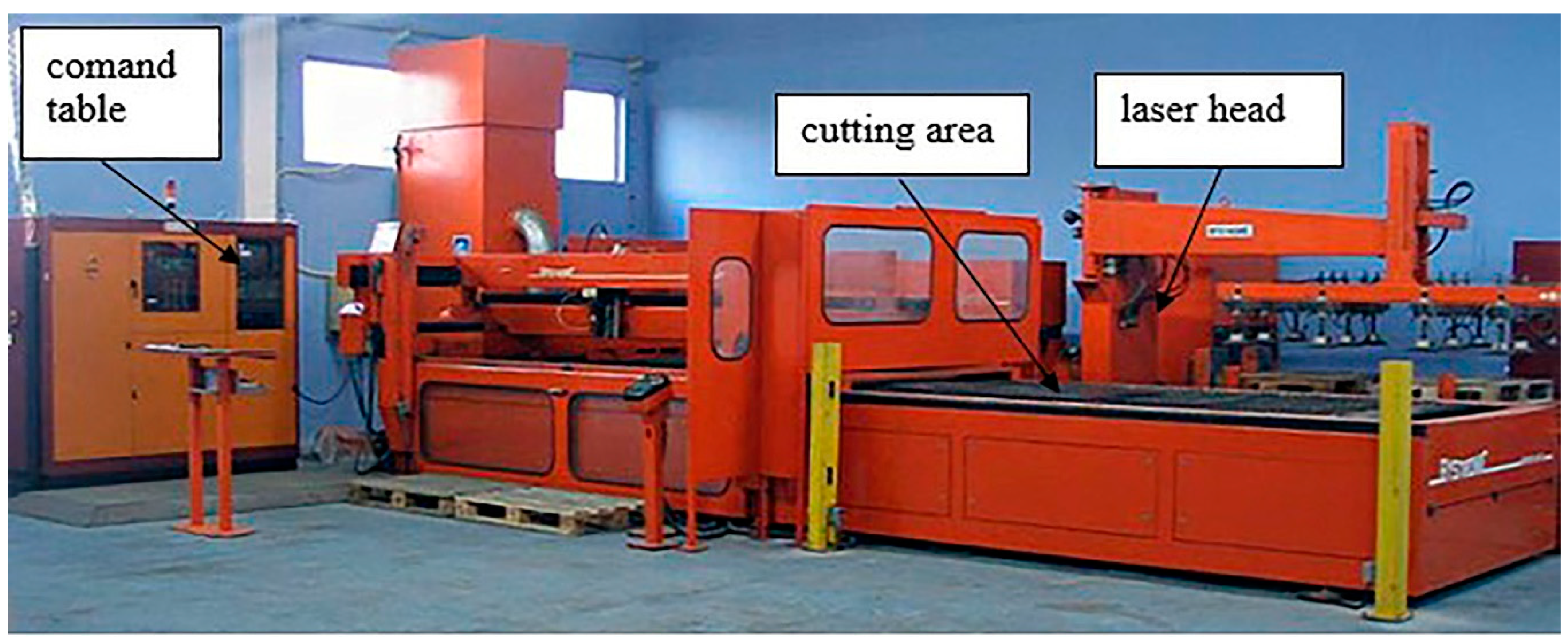

3. Experiments

4. Methodology for the Process Parameters’ Design

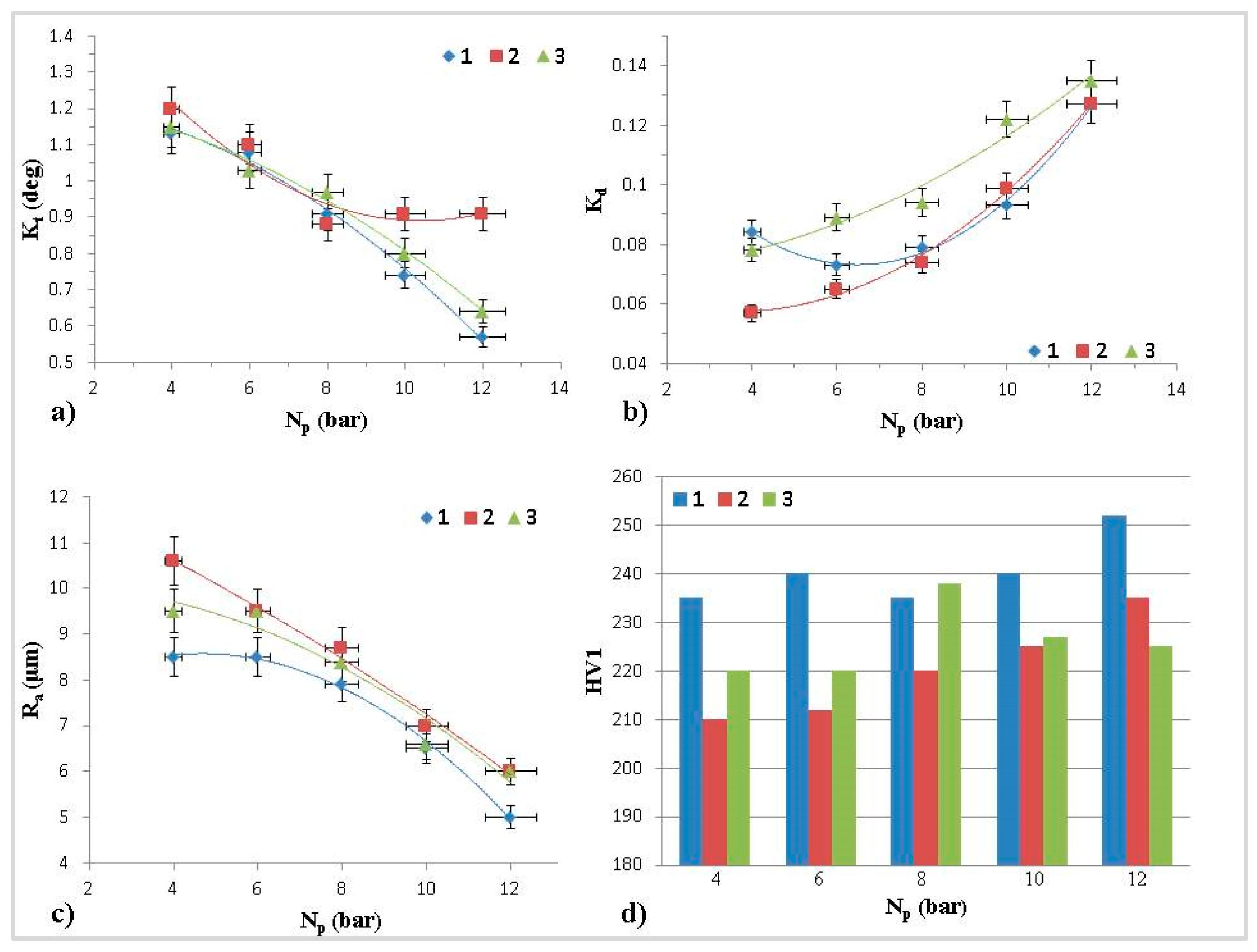

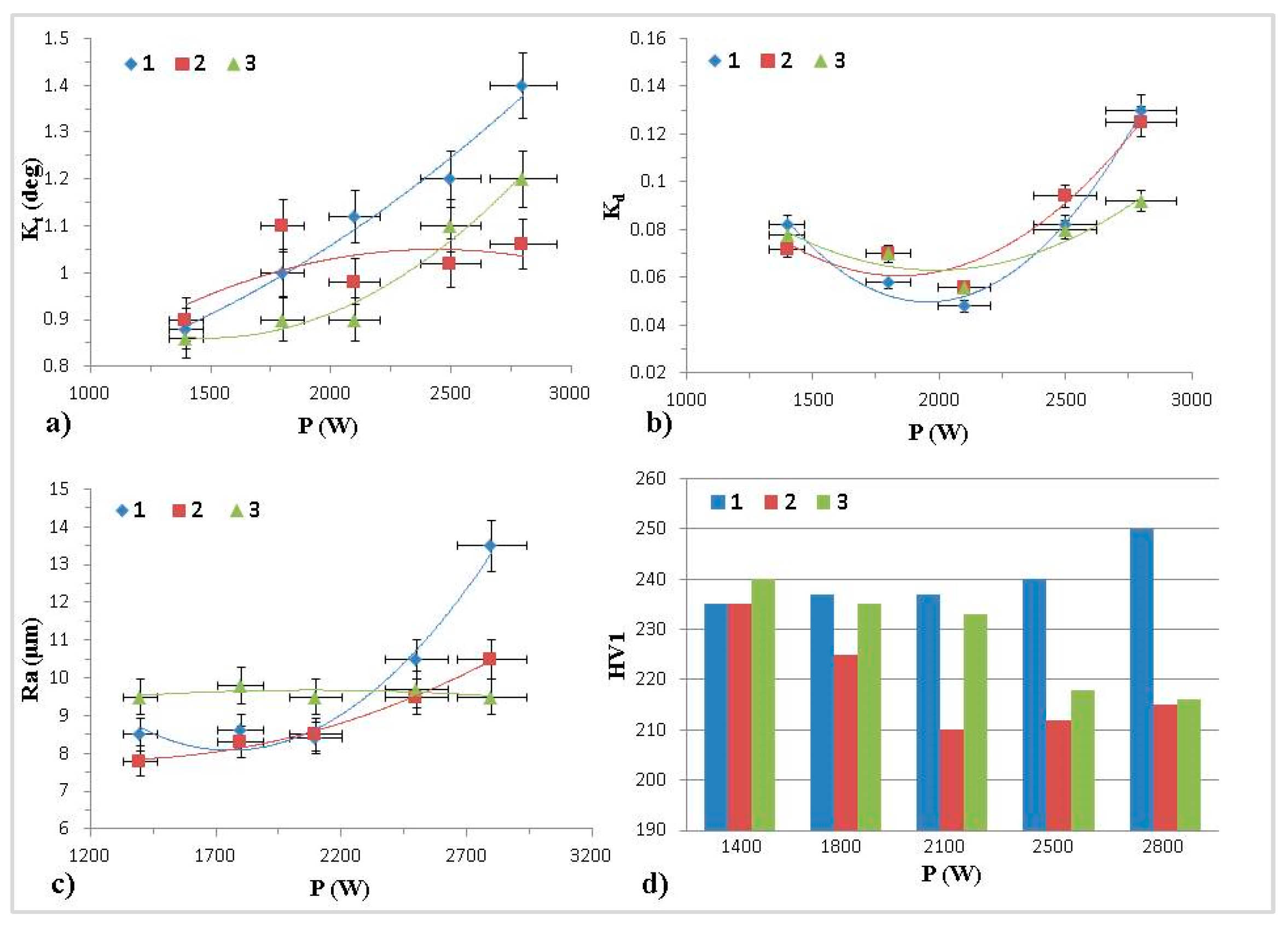

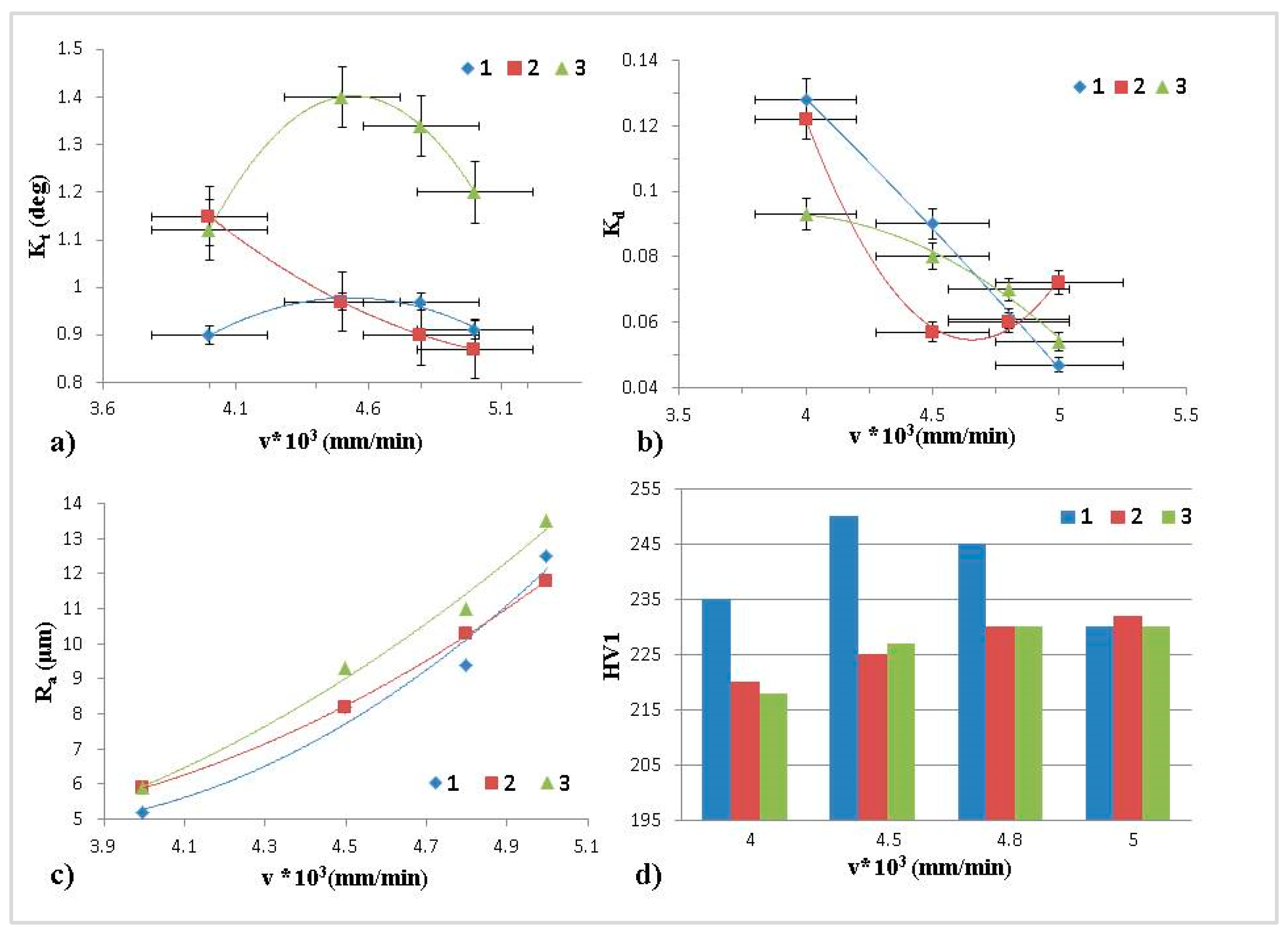

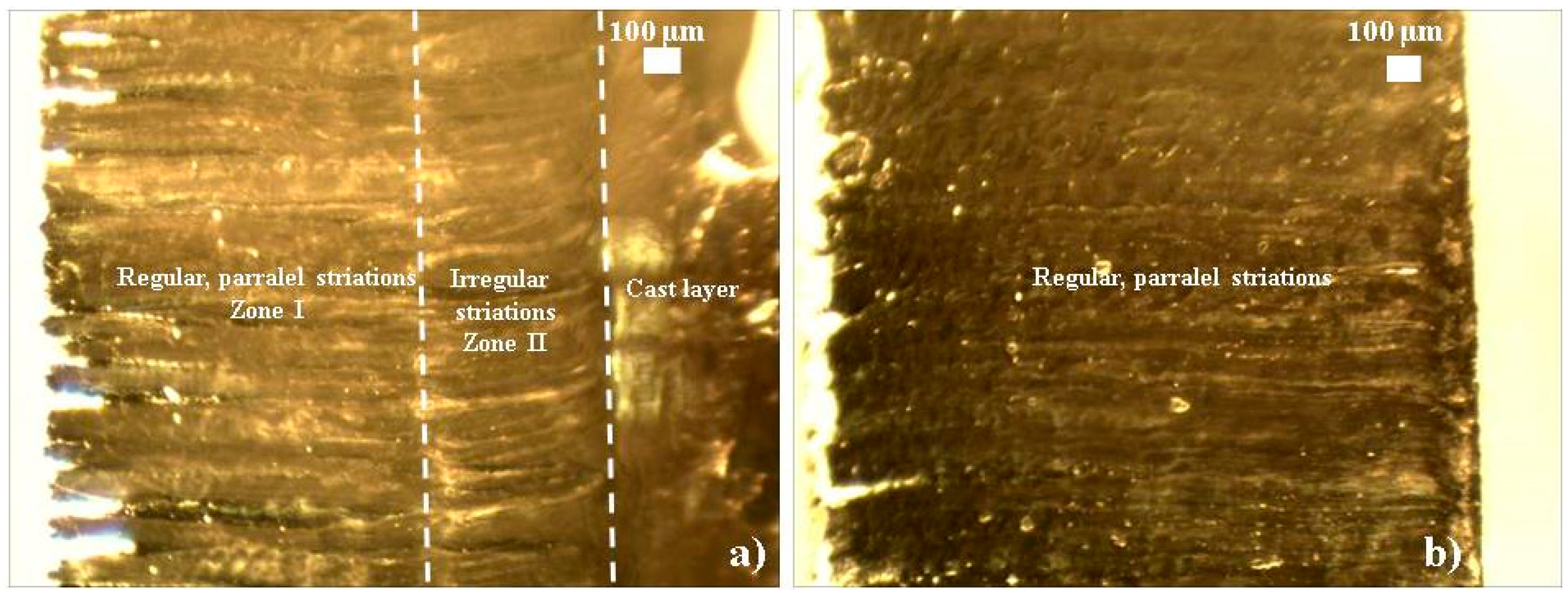

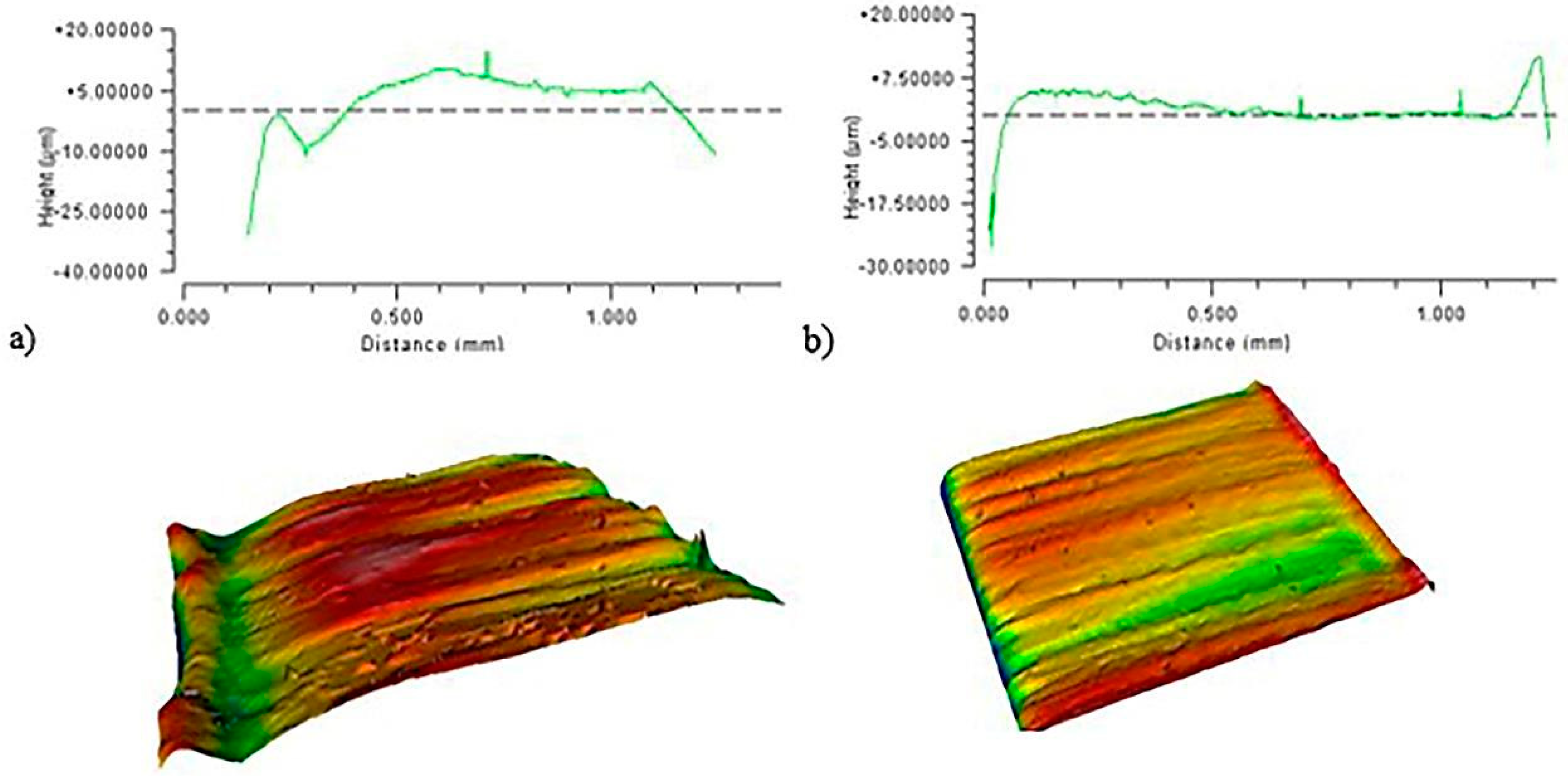

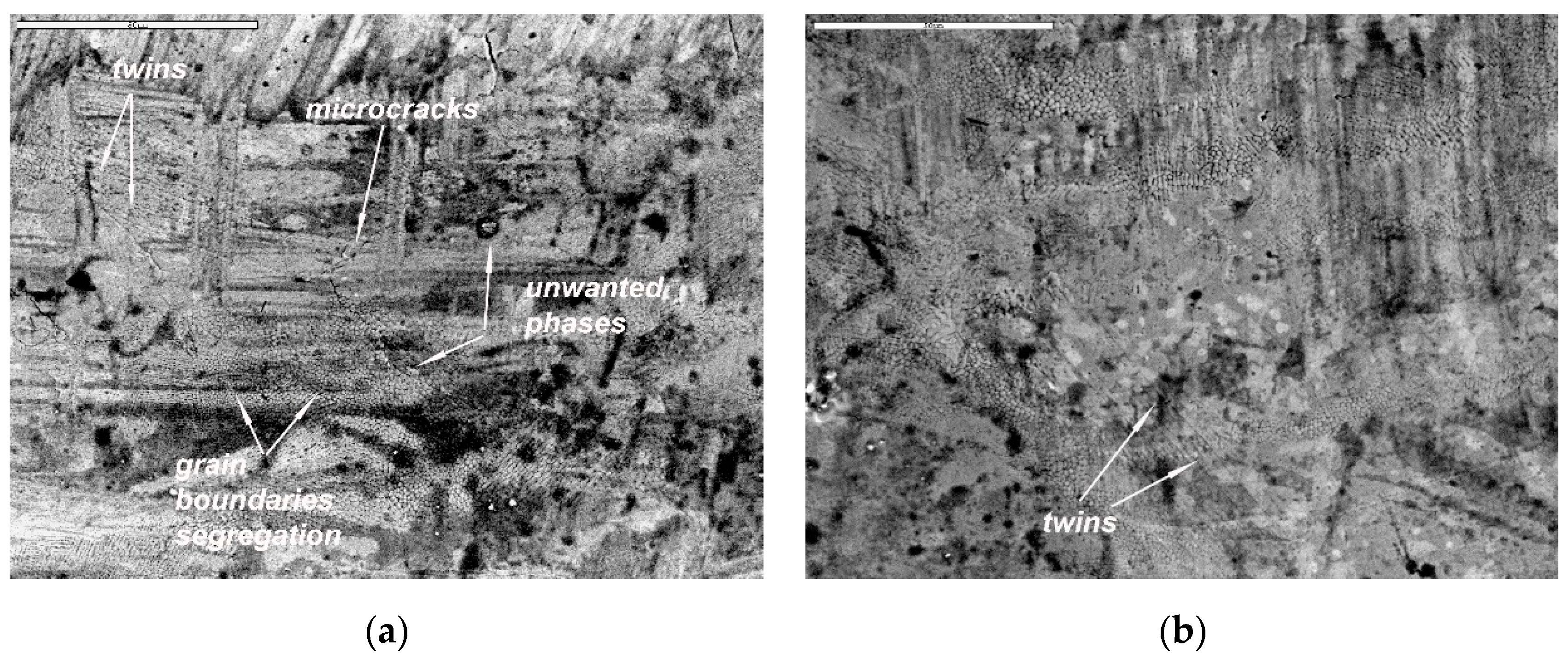

4.1. Analysis of Experimental Results

- -

- For the responses Ra, Rms, and PV, all four process parameters are significant.

- -

- For the response Kd, the following process parameters are significant: Np, p, and v.

- -

- For the response Kt, the following parameters are significant: f, p, and v.

- -

- For the response HV, only parameter f is significant.

- -

- For the response G, the following parameters are significant: Np, f, and p.

- -

- Parameter f is significant for all responses except for Kd;

- -

- Parameter P is significant for all responses except for HV;

- -

- Parameter Np is significant for all response except for Kt and HV;

- -

- Parameter v is significant for all responses except for HV and G.

4.2. Process Modeling

4.3. Process Optimization

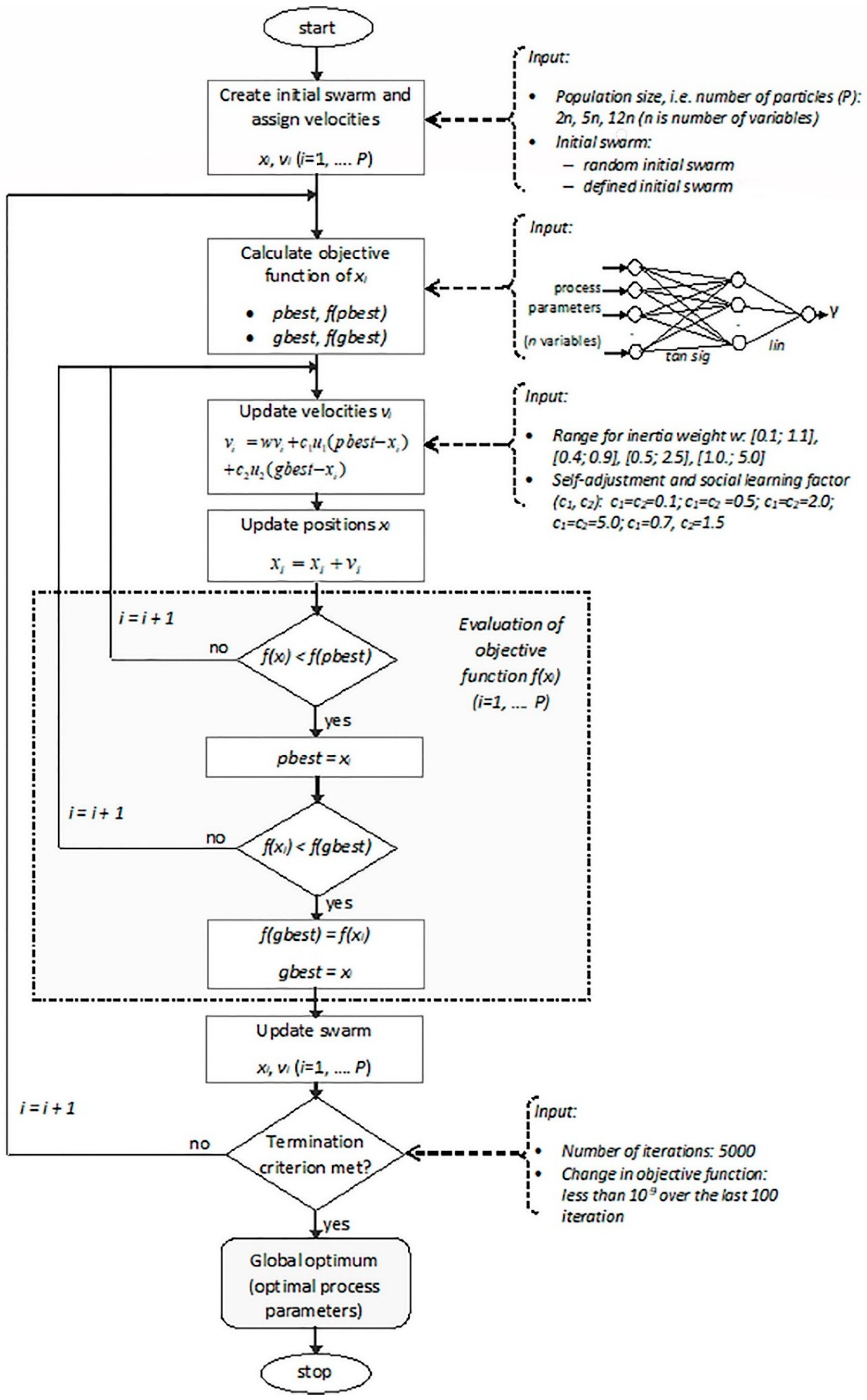

4.3.1. PSO-Based Process Optimization

- -

- The initial swarm: While a majority of studies use a random initial swarm, it has been proven that the benefits of initializing particles to good positions could be significant [46]. However, some authors claim that, in contrast to the other metaheuristic methods, the initial swarm does not significantly affect the PSO accuracy. In this study, two options are tested: (a) a randomly generated initial swarm; (b) an initial swarm seeded in the vicinity of the solution that yielded the highest process measure in the experiment (Table 4).

- -

- The swarm size can take different values from 20 to 40, or up to 100 for very complex problems with a large number of variables. The proposed swarm size is 2n to 5n [47]; n is the number of process parameters in this case. It has been noted that a large swarm size significantly improves the success rate of the algorithm [44]. Since there are four cutting parameters analyzed in this study, the following swarm sizes are tested: 8, 20, and 50.

- -

- Inertia weight is used to restrict the particle velocity, since a particle could miss out on a good solution due to an excessively large velocity. This parameter has rarely been discussed in the literature. Pant [47] suggested the range [0.4; 0.9] for moderately sized problems with a number of variables from 2 to 20. The following inertia weight ranges are tested: [0.1; 1.1], [0.4; 0.9], [0.5; 2.5], and [1.0.; 5.0].

- -

- Typically, learning factors c1 and c2 are equal, and have values from 0 to 4. For moderately sized problems, it has been suggested to use c1 = c2 = 2.0 [47]. Since premature convergence is a major weakness of PSO, velocity reduction is recommended to improve the probability of obtaining a global optimum [44]. Therefore, the following values are tested: c1 = c2 = 0.1; c1 = c2 = 0.5; c1 = c2 = 2.0; c1 = c2 = 5, and c1 = 0.7, c2 = 1.5.

- -

- The algorithm termination usually refers to the specified number of iterations, which typically varies from a few hundred up to a few thousand. In this study, the algorithm terminates when it accomplishes 5000 iterations or when the objective function change over the last 100 iterations is less than 10−9, whichever is earlier.

4.3.2. SA-Based Process Optimization

- -

- The starting, i.e., initial point is placed near the best solution from the experiment.

- -

- Initial temperature values of 100 °C and 500 °C are tested.

- -

- The Boltzmann annealing function and fast annealing function are adopted for the annealing function.

- -

- For the temperature function, the Boltzmann and the fast temperature functions are tested.

- -

- The following combinations of reannealing interval and initial temperature are used: [10; 100], [10; 500], [100; 100], [100; 500].

- -

- The same termination condition as for PSO is used.

5. Experimental Validation and Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- De Oliveira, M.M.; Couto, A.A.; Almeida, G.F.C.; Reis, D.A.P.; de Lima, N.B.; Baldan, R. Mechanical Behavior of Inconel 625 at Elevated Temperatures. Metals 2019, 9, 301. [Google Scholar] [CrossRef]

- Petronic, S.; Sibalija, T.; Burzic, M.; Polic, S.; Colic, K.; Milovanovic, D. Picosecond Laser Shock Peening of Nimonic 263 at 1064 nm and 532 nm Wavelength. Metals 2016, 6, 41. [Google Scholar] [CrossRef]

- Kondaya, D.; Krishna, A.G. An integrated evolutionary approach for modelling and optimization of laser beam cutting process. Int. J. Adv. Manuf. Technol. 2013, 65, 259–274. [Google Scholar] [CrossRef]

- Petru, J.; Zlamal, T.; Cep, R.; Monkova, K.; Monka, P. Influence of Cutting Parameters on Heat-affected Zone After Laser Cutting. Tehnički Vjesnik 2013, 20, 225–230. [Google Scholar]

- Eltawahni, H.A.; Hagino, M.; Benyounis, K.Y.; Inoue, T.; Olabi, A.G. Effect of CO2 laser cutting process parameters on edge quality and operating cost of AISI316L. Opt. Laser Technol. 2012, 44, 1068–1082. [Google Scholar] [CrossRef]

- Sibalija, T.; Majstorovic, V. The Advanced Multiresponse Process. Optimisation: An Intelligent and Integrated Approach; Springer International Publishing: Cham, Switzerland, 2016. [Google Scholar]

- Russo Spena, P. CO2 Laser Cutting of Hot Stamping Boron Steel Sheets. Metals 2017, 7, 456. [Google Scholar] [CrossRef]

- Riveiro, A.; Quintero, F.; Lusquinos, F.; Comesaña, R.; Pou, J. Effects of processing parameters on laser cutting of aluminum–copper alloys using off-axial supersonic nozzles. Appl. Surf. Sci. 2011, 257, 5393–5397. [Google Scholar] [CrossRef]

- Reck, A.; Zeuner, A.T.; Zimmermann, M. Fatigue Behavior of Non-Optimized Laser-Cut Medical Grade Ti-6Al-4V-ELI Sheets and the Effects of Mechanical Post-Processing. Metals 2019, 9, 843. [Google Scholar] [CrossRef]

- Yilbas, B.S.; Ahktar, S.S.; Chatwin, C. Laser hole cutting into bronze: Thermal stress analysis. Opt. Laser Technol. 2011, 43, 1119–1127. [Google Scholar] [CrossRef]

- Yilbas, B.S.; Shaukat, M.M.; Ashraf, F. Laser cutting of various materials: Kerf width size analysis and life cycle assessment of cutting process. Opt. Laser Technol. 2017, 93, 67–73. [Google Scholar] [CrossRef]

- Kim, B.C.; Kim, T.H.; Jang, Y.S.; Chung, K.H. Investigation of striation formation in thin stainless steel tube during pulsed Nd: YAG laser cutting process by numerical simulation. Metall. Mater. Trans. A 2001, 32, 2623–2632. [Google Scholar] [CrossRef]

- Hascalık, A.; Ay, M. CO2 laser cut quality of Inconel 71 8 nickel–based superalloy. Opt. Laser Technol. 2013, 48, 554–564. [Google Scholar] [CrossRef]

- Tadavani, S.A.; Razavi, R.S.; Vafaei, R. Pulsed laser-assisted machining of Inconel 718 superalloy. Opt. Laser Technol. 2017, 87, 72–78. [Google Scholar] [CrossRef]

- Leone, C.; Genna, S.; Caggiano, A.; Tagliaferri, V.; Molitierno, R. Influence of process parameters on kerf geometry and surface roughness in Nd:YAG laser cutting of Al 6061T6 alloy sheet. Int. J. Adv. Manuf. Technol. 2016, 87, 2745–2762. [Google Scholar] [CrossRef]

- Adalarasan, R.; Santhanakumar, M.; Thileepan, S. Selection of optimal machining parameters in pulsed CO2 laser cutting of Al6061/Al2O3 composite using Taguchi-based response surface methodology (T-RSM). Int. J. Adv. Manuf. Technol. 2017, 93, 305–317. [Google Scholar] [CrossRef]

- Sharma, A.; Yadava, V. Optimization of cut quality characteristics during Nd: YAG laser straight cutting of Ni-based superalloy thin sheet using grey relational analysis with entropy measurement. Mater. Manuf. Process. 2011, 26, 1522–1529. [Google Scholar] [CrossRef]

- Tamilarasan, A.; Rajamani, D. Multi-response optimization of Nd: YAG laser cutting parameters of Ti-6Al-4V superalloy sheet. J. Mech. Sci. Technol. 2017, 31, 813–821. [Google Scholar] [CrossRef]

- Pandey, A.K.; Dubey, A.K. Simultaneous optimization of multiple quality characteristics in laser cutting of titanium alloy sheet. Opt. Laser Technol. 2012, 44, 1858–1865. [Google Scholar] [CrossRef]

- Teixidor, D.; Grzenda, M.; Bustillo, A.; Ciurana, J. Modeling pulsed laser micromachining of micro geometries using machine-learning techniques. J. Intell. Manuf. 2015, 26, 801–814. [Google Scholar] [CrossRef]

- Savriama, G.; Jarry, V.; Barreau, L.; Boulmer-Leborgn, C.; Semmar, N. A novel patterning effect during high frequency laser micro-cutting of hard ceramics for microelectronics applications. Appl. Surf. Sci. 2014, 302, 163–168. [Google Scholar] [CrossRef]

- Jarosz, K.; Löschner, P.; Niesłony, P. Effect of cutting speed on surface quality and heat-affected zone in laser cutting of 316L stainless steel. Procedia Eng. 2016, 149, 155–162. [Google Scholar] [CrossRef]

- Tahira, F.M.; Aqida, N.A. An investigation of laser cutting quality of 22MnB5 ultra high strength steel using response surface methodology. Opt. Laser Technol. 2017, 92, 142–149. [Google Scholar] [CrossRef]

- Anicic, O.; Jovic, S.; Skrijelj, H.; Nedic, B. Prediction of laser cutting heat affected zone by extreme learning machine. Opt. Lasers Eng. 2017, 88, 1–4. [Google Scholar] [CrossRef]

- Prashant, K.S.; Gavendra, N.; Pandey, A.K. Modelling and Optimization of Kerf Deviation in Laser Cutting of Inconel-718 Sheet. In Proceedings of the 6th International & 27th All India Manufacturing Technology, Design and Research Conference (AIMTDR-2016), Maharashtra, India, 16–18 December 2016; pp. 515–521. [Google Scholar]

- Riveiro, A.; Quintero, F.; Lusquiños, F.; Comesana, R.; Pou, J. Parametric investigation of CO2 laser cutting of 2024-T3 alloy. J. Mat. Process. Technol. 2010, 210, 1138–1152. [Google Scholar] [CrossRef]

- Pandey, A.K.; Dubey, A.K. Taguchi based fuzzy logic optimization of multiple quality characteristics in laser cutting of Duralumin sheet. Opt. Lasers Eng. 2012, 50, 328–335. [Google Scholar] [CrossRef]

- Dubey, A.K.; Yadava, V. Multi-objective optimization of Nd:YAG laser cutting of nickelbased superalloy sheet using orthogonal array with principal component analysis. Opt. Lasers Eng. 2008, 46, 124–132. [Google Scholar] [CrossRef]

- Sharma, A.; Yadava, V.; Rao, R. Optimization of kerf quality characteristics during Nd:YAG laser cutting of nickel based superalloy sheet for straightand curved cut profiles. Opt. Lasers Eng. 2010, 48, 915–925. [Google Scholar] [CrossRef]

- Alizadeh, A.; Omrani, H. An integrated multi response Taguchi-neural network-robust data envelopment analysis model for CO2 laser cutting. Measurement 2019, 131, 69–78. [Google Scholar] [CrossRef]

- Tamrin, K.F.; Nukman, Y.; Choudhury, I.A.; Shirley, S. Multiple-objective optimization inprecision laser cutting of different thermoplastics. Opt. Lasers Eng. 2015, 67, 57–65. [Google Scholar] [CrossRef]

- Sharma, A.; Yadava, V. Modelling and optimization of cut quality during pulsed Nd:YAG laser cutting of thin Al-alloy sheet for curved profile. Opt. Lasers Eng. 2013, 51, 77–88. [Google Scholar] [CrossRef]

- Adalarasan, R.; Santhanakumar, M.; Rajmohan, M. Optimization of laser cutting parameters for Al6061/SiCp/Al2O3 composite using grey based response surface methodology (GRSM). Measurement 2015, 73, 596–606. [Google Scholar] [CrossRef]

- Venkatesan, K.; Ramanujam, R. Statistical approach for optimization of influencing parameters in laser assisted machining (LAM) of Inconel alloy. Measurement 2016, 89, 97–108. [Google Scholar] [CrossRef]

- Murphy, T.E.; Tsui, K.L.; Allen, J.K. A review of robust design methods for multiple responses. Res. Eng. Des. 2005, 16, 118–132. [Google Scholar] [CrossRef]

- Chaki, S.; Bathe, R.N.; Ghosal, S.; Padmanabham, G. Multi-objective optimisation of pulsed Nd:YAG laser cutting process using integrated ANN–NSGAII model. J. Intell. Manuf. 2019, 29, 175–190. [Google Scholar] [CrossRef]

- Yan, H.; Xia, J. An approach to the optimal design of technological parameters in the profile extrusion process. Sci. Technol. Adv. Mater. 2006, 7, 127–131. [Google Scholar] [CrossRef]

- Singh, G.; Grandhi, R.V.; Stargel, D.S. Modified particle swarm optimization for a multimodal mixed-variable laser peening process. Struct. Multidis. Optim. 2010, 42, 769–782. [Google Scholar] [CrossRef]

- Bharathi Raja, S.; Baskar, N. Application of Particle Swarm Optimization technique for achieving desired milled surface roughness in minimum machining time. Expert Syst. Appl. 2012, 37, 878–885. [Google Scholar] [CrossRef]

- Katherasan, D.; Elias, J.V.; Sathiya, P. Simulation and parameter optimization of flux cored arc welding using artificial neural network and particle swarm optimization algorithm. J. Intell. Manuf. 2014, 25, 67–76. [Google Scholar] [CrossRef]

- Zhou, J.; Ren, J.; Yao, C. Optimisation of multi-axis ball-end milling in processing Inconel 718 was performed using a hybrid GRA-NN-PSO method. Measurement 2017, 102, 271–285. [Google Scholar] [CrossRef]

- Mohanty, C.P.; Mahapatra, S.S.; Singh, M.R. A particle swarm approach for multi-objective optimization of electrical discharge machining process. J. Intell. Manuf. 2016, 27, 1171–1190. [Google Scholar] [CrossRef]

- Escamilla-Salazar, I.G.; Torres-Treviño, L.M.; González-Ortíz, B.; Zambrano, C.P. Machining optimization using swarm intelligence in titanium (6Al 4V) alloy. Int. J. Adv. Manuf. Technol. 2013, 67, 535–544. [Google Scholar] [CrossRef]

- Sibalija, T. Particle Swarm Optimisation in Designing Parameters of Manufacturing Processes: A Review (2008–2018). Appl. Soft Comput. J. 2019, 84, 105743. [Google Scholar] [CrossRef]

- Sibalija, T.; Petronic, S.; Majstorovic, V.; Milosavljevic, A. Modelling and optimisation of laser shock peening using an integrated simulated annealing-based method. Int. J. Adv. Manuf. Technol. 2014, 73, 1141–1158. [Google Scholar] [CrossRef]

- Banks, A.; Vincent, J.; Anyakoha, C. A review of particle swarm optimization. Part I: Background and development. Nat. Comput. 2007, 6, 467–484. [Google Scholar] [CrossRef]

- Pant, M.; Thangaraj, R.; Abraham, A. Particle Swarm Optimization: Performance Tuning and Empirical Analysis. In Foundations of Computational Intelligence; Springer: Berlin/Heidelberg, Germany, 2009; Volume 3, pp. 101–128. [Google Scholar]

- Spall, J. Introduction to Stochastic Search and Optimisation; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2003. [Google Scholar]

- Ren, X.D.; Zhang, Y.K.; Zhang, T.; Jiang, D.W.; Yongzhuo, H.F.; Jiang, Y.F.; Chen, K.M. Comparison of the simulation and experimental fatigue crack behaviours in the nanosecond’s laser shocked aluminum alloy. Mat. Des. 2011, 32, 1138–1143. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | Al | Co | Cr | Cu | Fe | Mo | Ti | Ni |

|---|---|---|---|---|---|---|---|---|---|---|---|

| % | 0.06 | 0.30 | 0.50 | 0.50 | 20.00 | 20.00 | 0.10 | 0.50 | 5.90 | 2.20 | 49.94 |

| Laser Beam Power | 2800 W |

|---|---|

| Polarization | circular |

| Speed | 6000 mm/min |

| Pulse Frequency | 2500 Hz |

| Assisting Gas | Nitrogen |

| Pressure of Assisting Gas | 20 bar |

| Responses | Unit | Symbol | Required Value | Response Type in SNR Analysis |

|---|---|---|---|---|

| Kerf deviation | mm | Kd | Minimal value | STB |

| Kerf tapper | ° | Kt | Minimal value | STB |

| Microhardness | HV1 | HV | Maximal value | LTB |

| Grate | - | G | Minimal value | STB |

| Roughness | µm | Ra | Minimal value | STB |

| Roughness root mean square | µm | Rms | Minimal value | STB |

| Roughness peak-to-valley | - | PV | Minimal value | STB |

| Process Parameters | Unit | Symbol | Levels | ||

|---|---|---|---|---|---|

| 1 | 2 | 3 | |||

| Nitrogen pressure | bar | Np | 4 | 8 | 12 |

| Focus position | - | f | 1 (on the top of the material) | 2 (on the bottom of the material) | 3 (0.5 mm in front of the material) |

| Laser power | W | P | 1400 | 2100 | 2800 |

| Cutting speed | mm/min | v | 4000 | 4500 | 5000 |

| No. | Parameter Levels | Responses | Principal Component Scores Yj(k) (j = 1, … 7; k = 1, … 18) | γk (k = 1, … 18) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Np | f | P | v | Kd | Kt | HV | G | Ra | Rms | PV | Y1(k) | Y2(k) | Y3(k) | Y4(k) | Y5(k) | Y6(k) | Y7(k) | ||

| 1 | 1 | 1 | 1 | 1 | 0.063 | 1.13 | 235.2 | 0 | 8.5 | 10.7 | 104.9 | 0.51 | −0.57 | −0.31 | 0.04 | 0.24 | 0.06 | −0.11 | 0.6974 |

| 2 | 1 | 2 | 2 | 2 | 0.057 | 0.97 | 209.7 | 0 | 8.6 | 10.7 | 106.3 | 0.25 | −0.80 | −0.65 | −0.40 | 0.22 | −0.20 | −0.09 | 0.6932 |

| 3 | 1 | 3 | 3 | 3 | 0.077 | 1.20 | 219.4 | 0 | 9.5 | 11.4 | 190.6 | 0.75 | −0.38 | −0.82 | −0.46 | 0.61 | 0.09 | −0.15 | 0.5799 |

| 4 | 2 | 1 | 2 | 3 | 0.047 | 0.90 | 236.3 | 1 | 5.9 | 7.4 | 159.6 | 0.52 | −0.11 | 0.38 | −0.76 | 0.57 | −0.18 | −0.10 | 0.7042 |

| 5 | 2 | 2 | 3 | 1 | 0.123 | 1.15 | 219.6 | 1 | 10.5 | 11.8 | 158.1 | 1.33 | −1.14 | −0.11 | −1.09 | 0.17 | 0.10 | −0.13 | 0.4965 |

| 6 | 2 | 3 | 1 | 2 | 0.093 | 0.87 | 240.6 | 0 | 9.5 | 12.0 | 209.7 | 0.83 | 0.11 | −0.68 | −0.45 | 0.29 | 0.11 | −0.05 | 0.6427 |

| 7 | 3 | 1 | 3 | 2 | 0.127 | 1.40 | 251.5 | 1 | 13.4 | 18.4 | 183.1 | 2.26 | −0.79 | −0.08 | −0.48 | 0.29 | −0.06 | −0.12 | 0.4641 |

| 8 | 3 | 2 | 1 | 3 | 0.073 | 0.57 | 234.9 | 0 | 5.9 | 11.0 | 198.5 | 0.36 | 0.25 | −0.57 | −0.52 | 0.23 | −0.05 | −0.20 | 0.7272 |

| 9 | 3 | 3 | 2 | 1 | 0.057 | 0.90 | 230.4 | 0 | 5.2 | 6.3 | 106.6 | 0.07 | −0.40 | −0.22 | −0.16 | 0.18 | 0.09 | −0.15 | 0.8744 |

| … | |||||||||||||||||||

| 18 | 3 | 3 | 2 | 1 | 0.058 | 0.91 | 231.0 | 0 | 5.3 | 6.3 | 107.0 | 0.09 | −0.40 | −0.22 | −0.15 | 0.18 | 0.10 | −0.14 | 0.8672 |

| ANN Topology | 4-10-1 | 4-12-1 | 4-15-1 | 4-16-1 | 4-17-1 | 4-18-1 | 4-20-1 |

|---|---|---|---|---|---|---|---|

| MSE | 2.68 × 10−5 | 4.22 × 10−6 | 3.48 × 10−6 | 1.85 × 10−6 | 1.51 × 10−6 | 8.45 × 10−6 | 1.32 × 10−5 |

| R for training data | 0.97 | 0.97 | 0.98 | 0.98 | 0.99 | 0.99 | 0.98 |

| R for all data | 0.99 | 0.99 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| Optimization Algorithm | PSO with a Random Initial Population | PSO with a Defined Initial Population | SA |

|---|---|---|---|

| The range of the obtained process measure γ | 0.894012 ÷ 0.900825 | 0.893701 ÷ 0.900825 | 0.890861 ÷ 0.900762 |

| The best process measure γ | 0.900825 | 0.900825 | 0.900762 |

| The optimal process parameters setting that corresponds to the best γ | [14; 3; 2034; 4000] | [14; 3; 2034; 4000] | [14; 3; 2039; 4000] |

| The number of iterations at which the best process measure is reached | 30 ÷ 70 | 6 ÷ 30 | 40 ÷ 1520 |

| The total number of iterations performed by the algorithm | 121 ÷ 341 | 105 ÷ 291 | 2027 ÷ 3530 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sibalija, T.; Petronic, S.; Milovanovic, D. Experimental Optimization of Nimonic 263 Laser Cutting Using a Particle Swarm Approach. Metals 2019, 9, 1147. https://doi.org/10.3390/met9111147

Sibalija T, Petronic S, Milovanovic D. Experimental Optimization of Nimonic 263 Laser Cutting Using a Particle Swarm Approach. Metals. 2019; 9(11):1147. https://doi.org/10.3390/met9111147

Chicago/Turabian StyleSibalija, Tatjana, Sanja Petronic, and Dubravka Milovanovic. 2019. "Experimental Optimization of Nimonic 263 Laser Cutting Using a Particle Swarm Approach" Metals 9, no. 11: 1147. https://doi.org/10.3390/met9111147

APA StyleSibalija, T., Petronic, S., & Milovanovic, D. (2019). Experimental Optimization of Nimonic 263 Laser Cutting Using a Particle Swarm Approach. Metals, 9(11), 1147. https://doi.org/10.3390/met9111147