Constitutive Equation of GH4169 Superalloy and Microstructure Evolution Simulation of Double-Open Multidirectional Forging

Abstract

1. Introduction

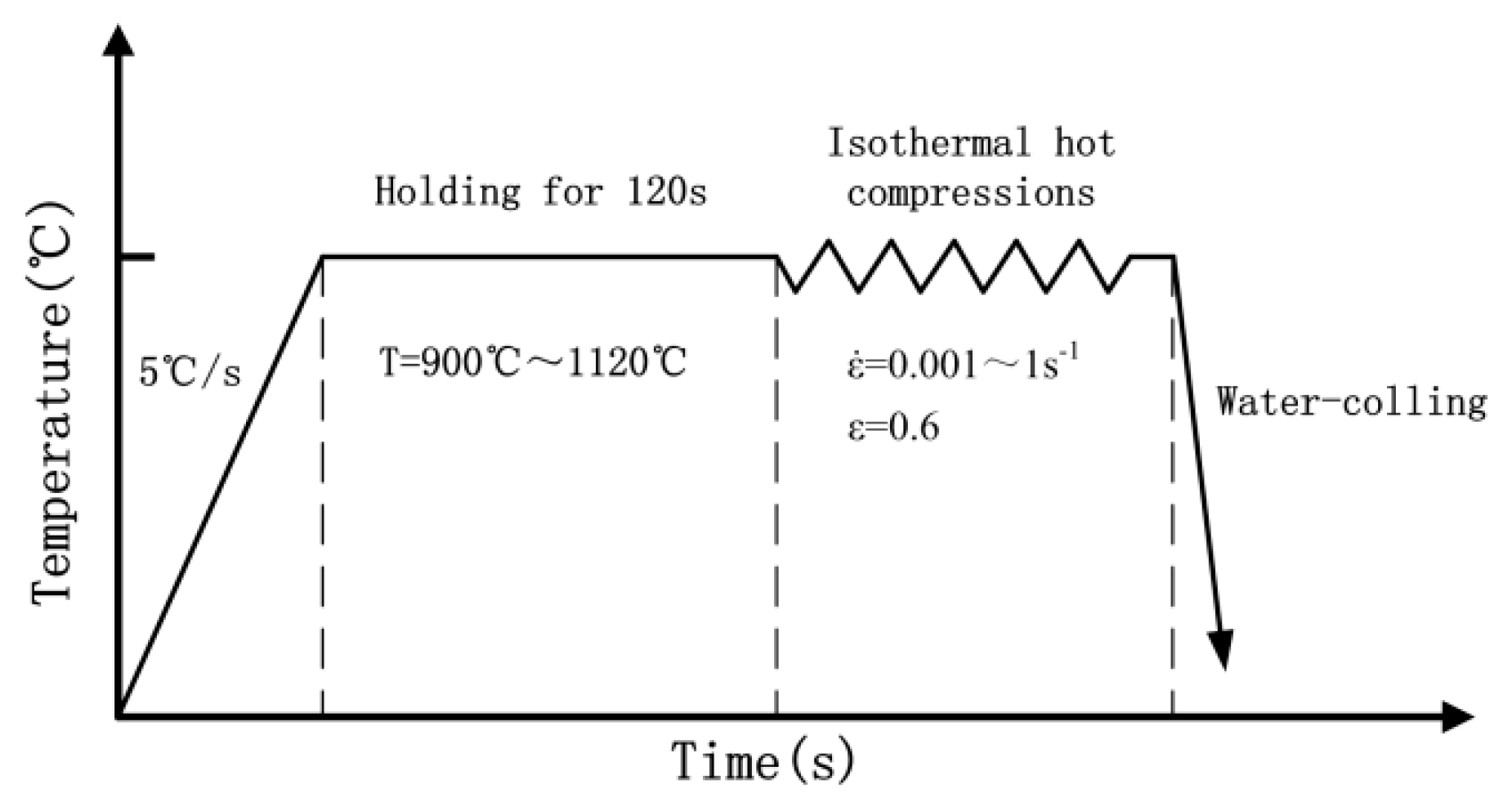

2. Experimental Materials and Methods

3. Results and Discussion

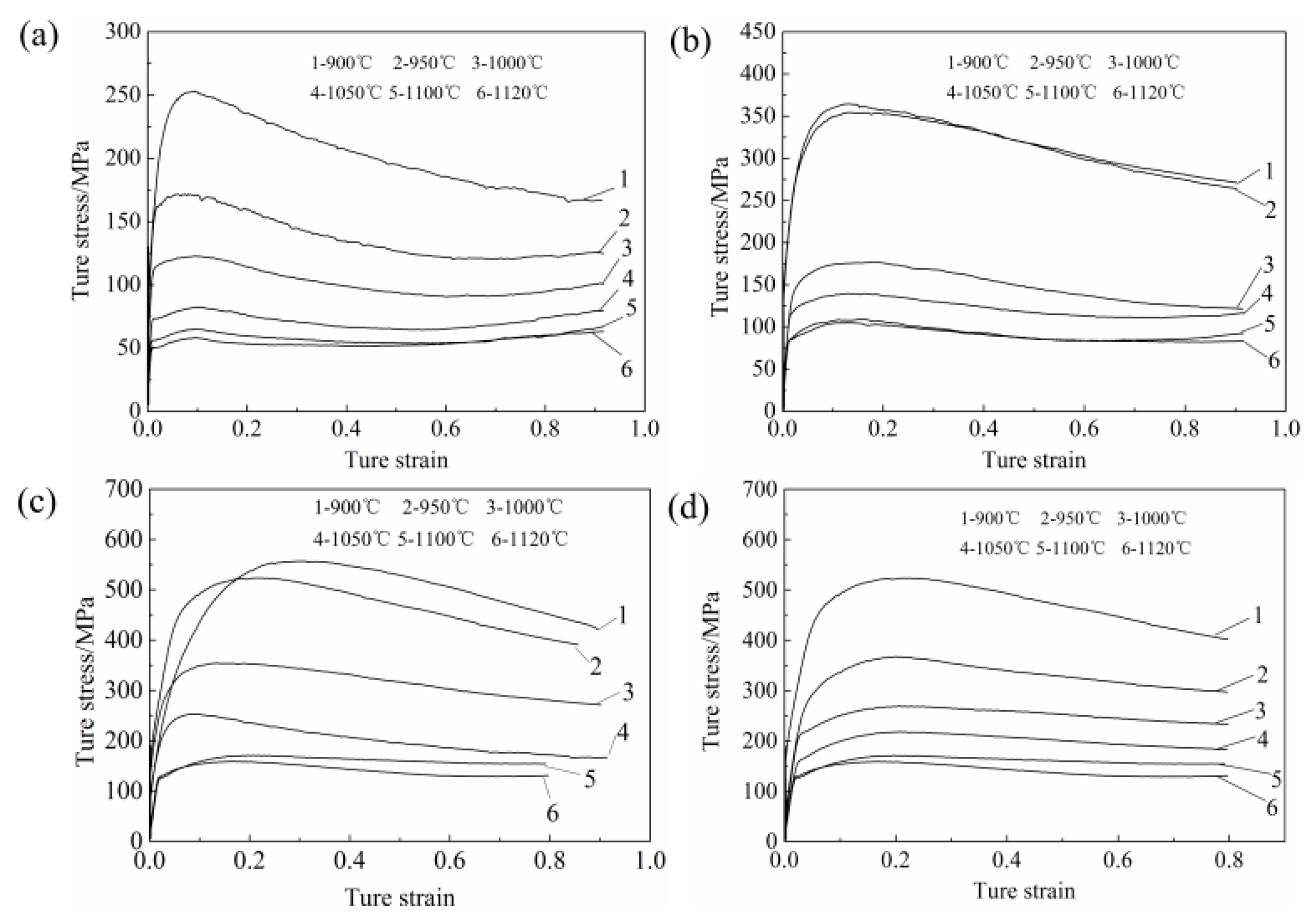

3.1. True Stress-Strain Curve at Different Strain Rates

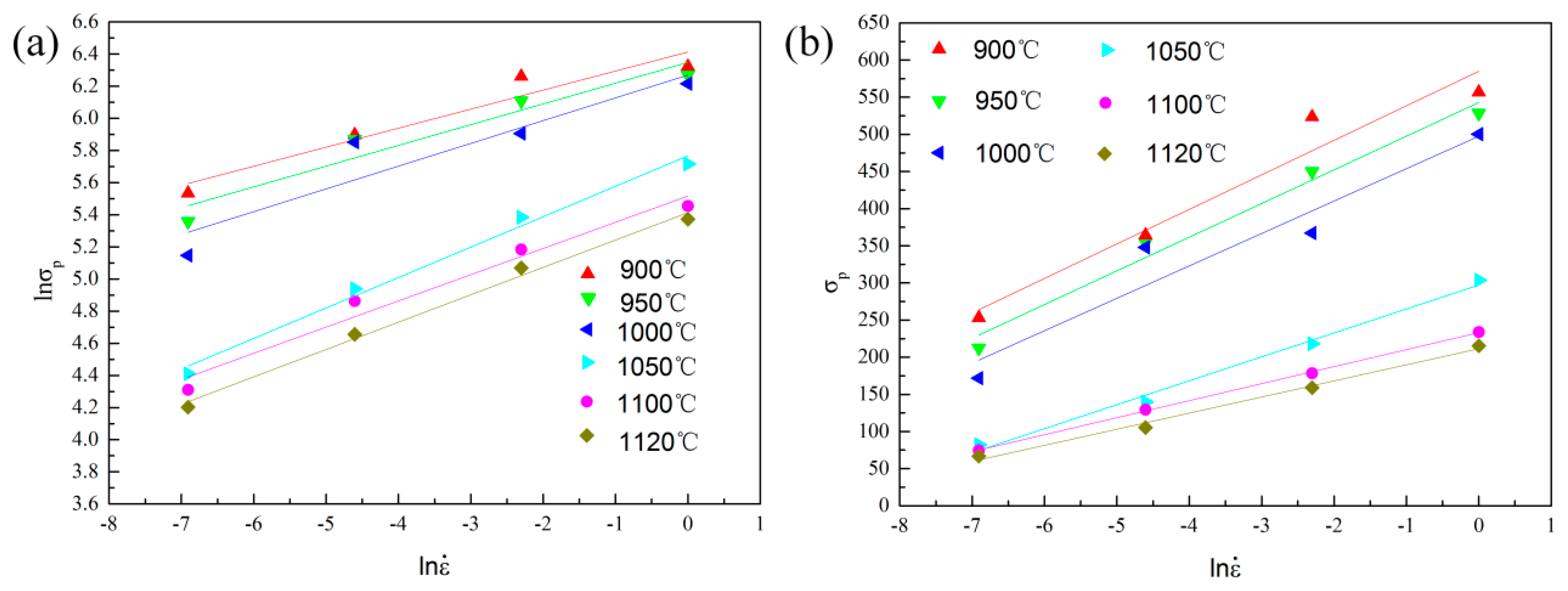

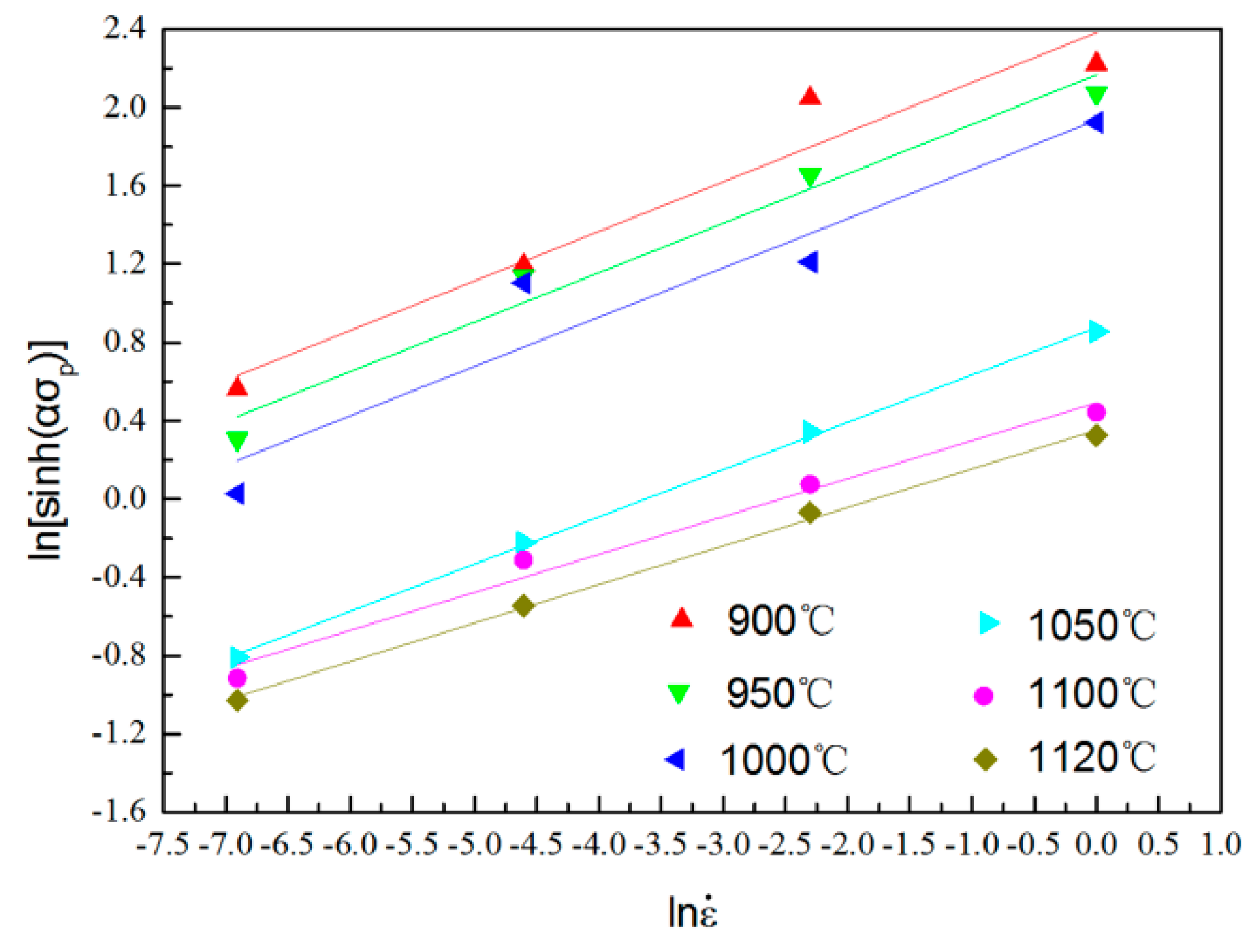

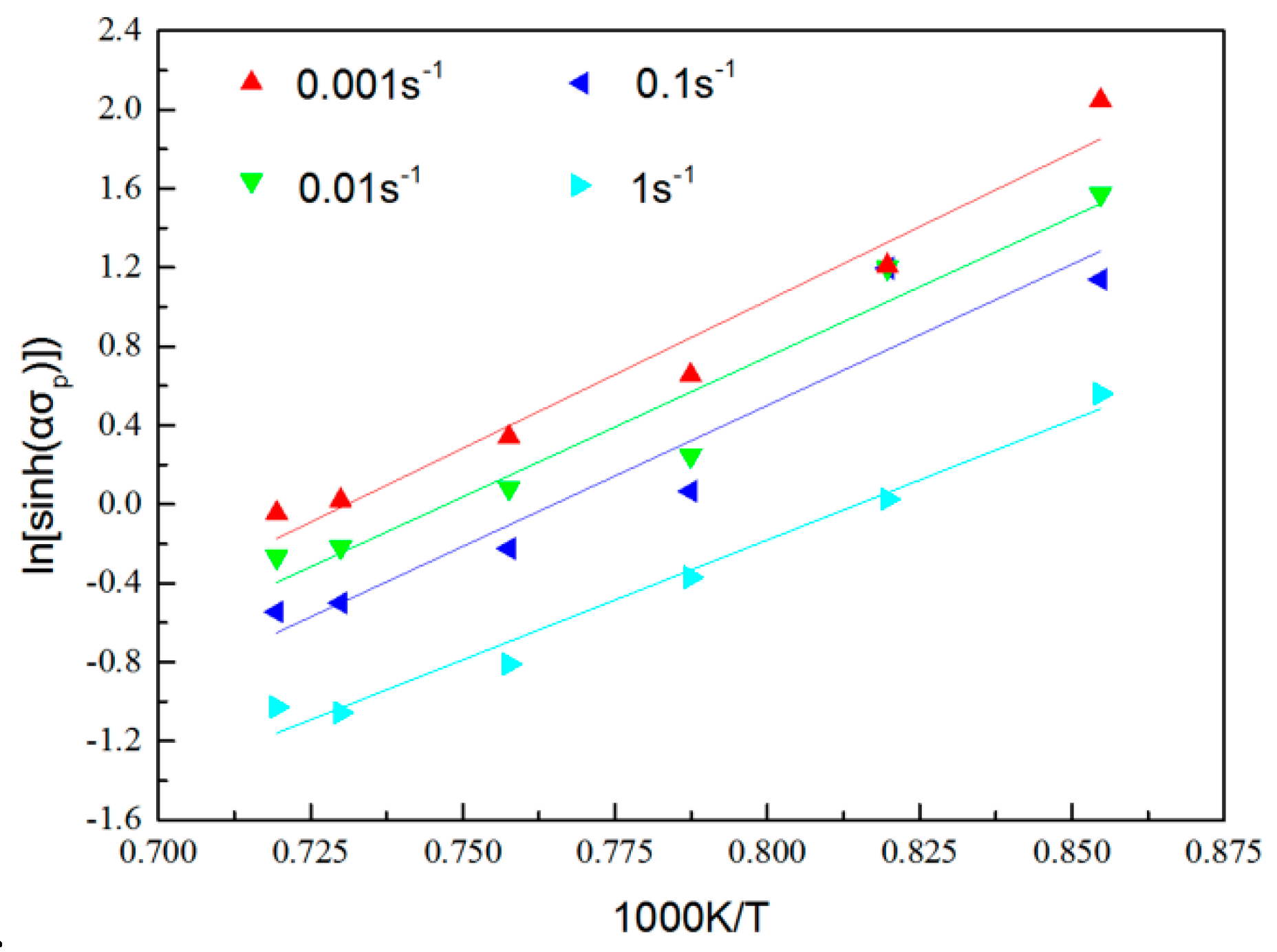

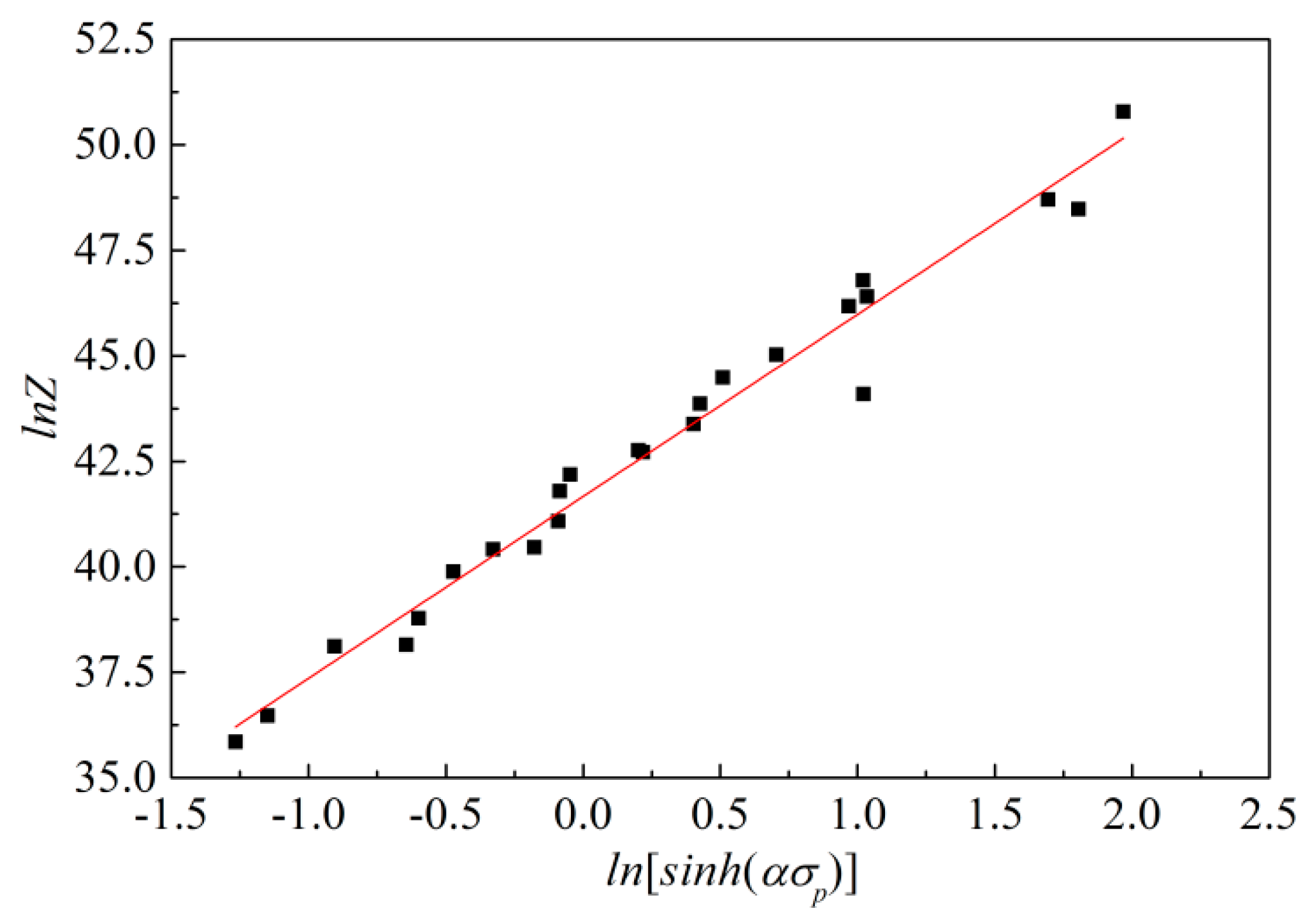

3.2. Construction of Constitutive Equations

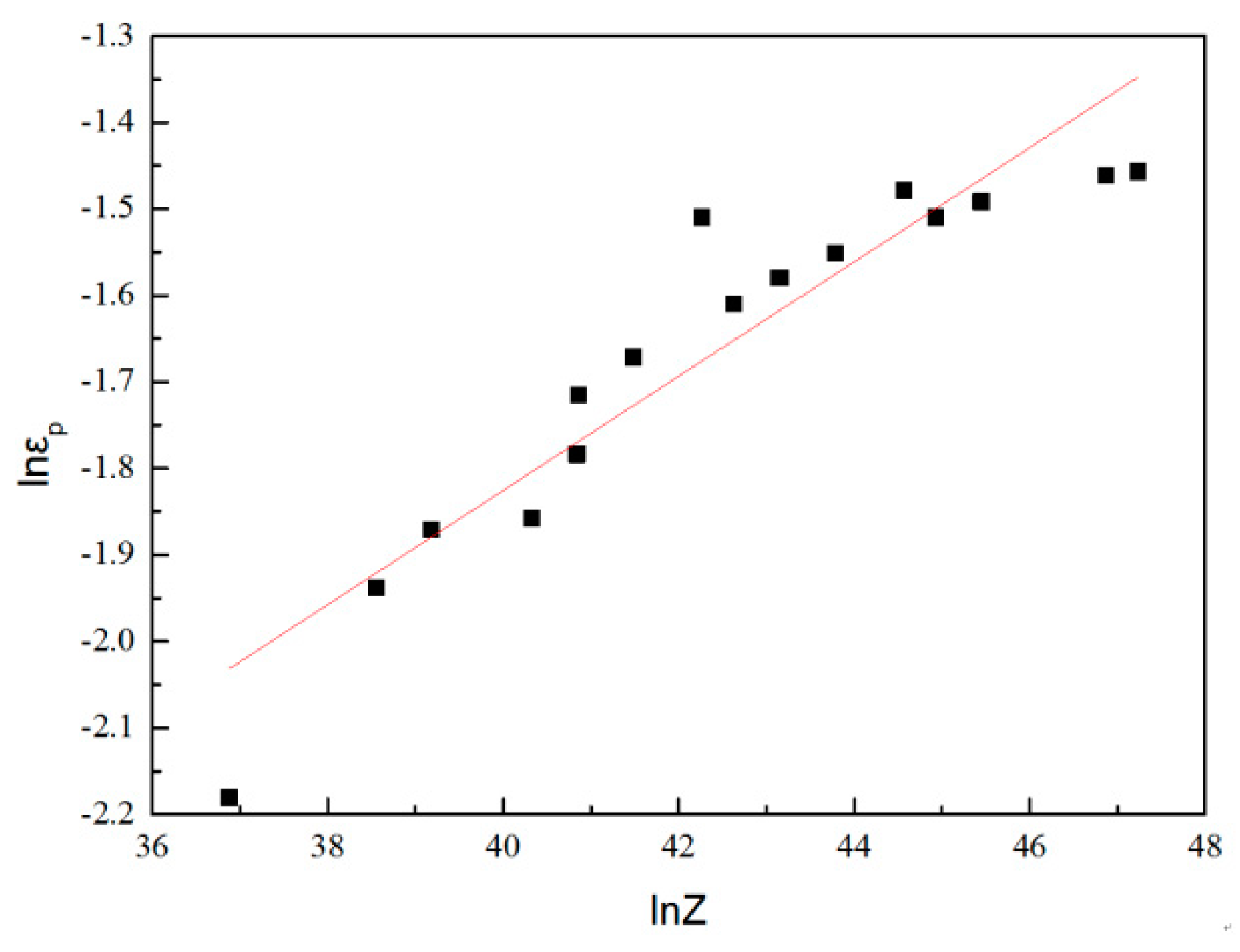

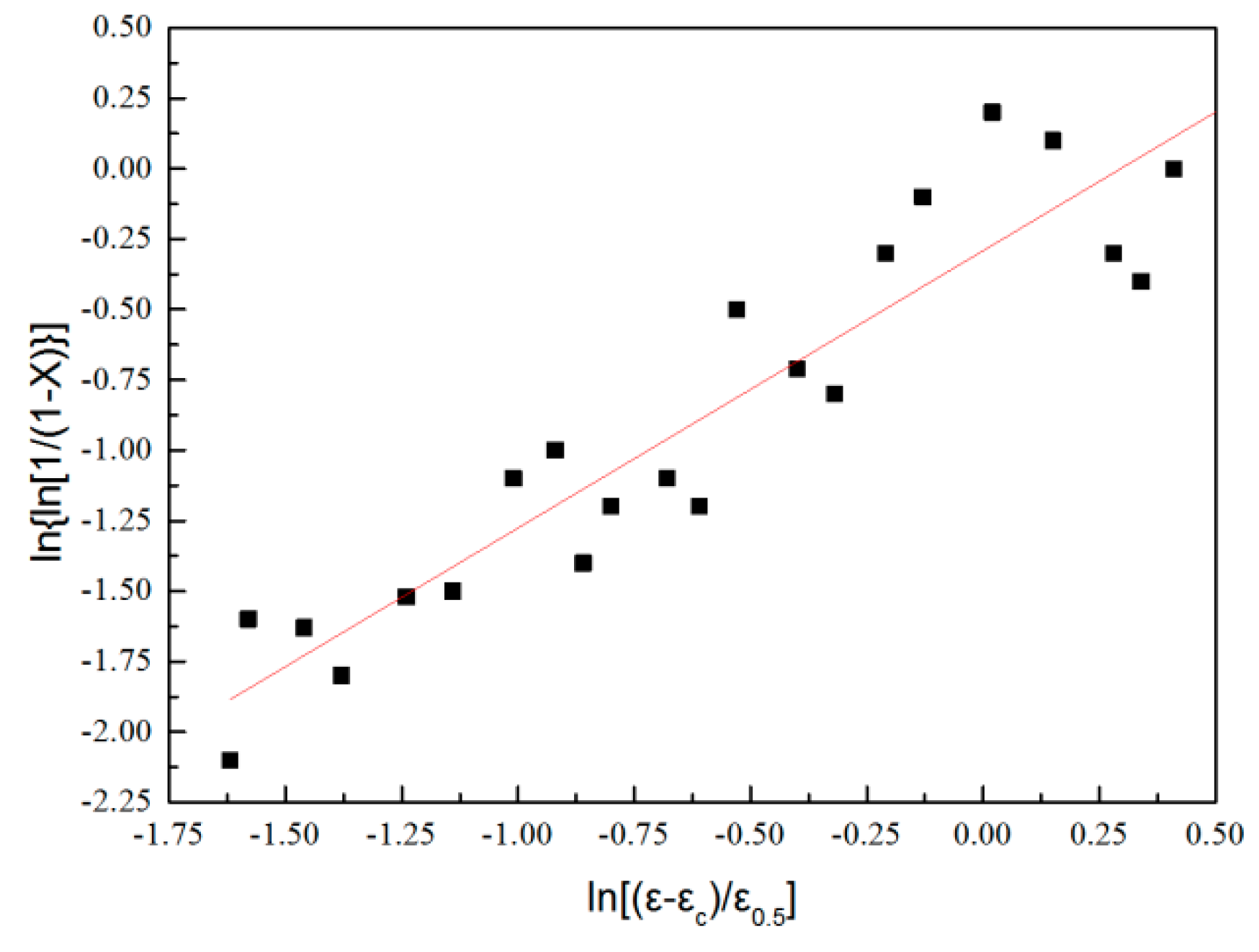

3.3. Dynamic Recrystallization Model

3.3.1. Proposed Model

3.3.2. Model Establishment

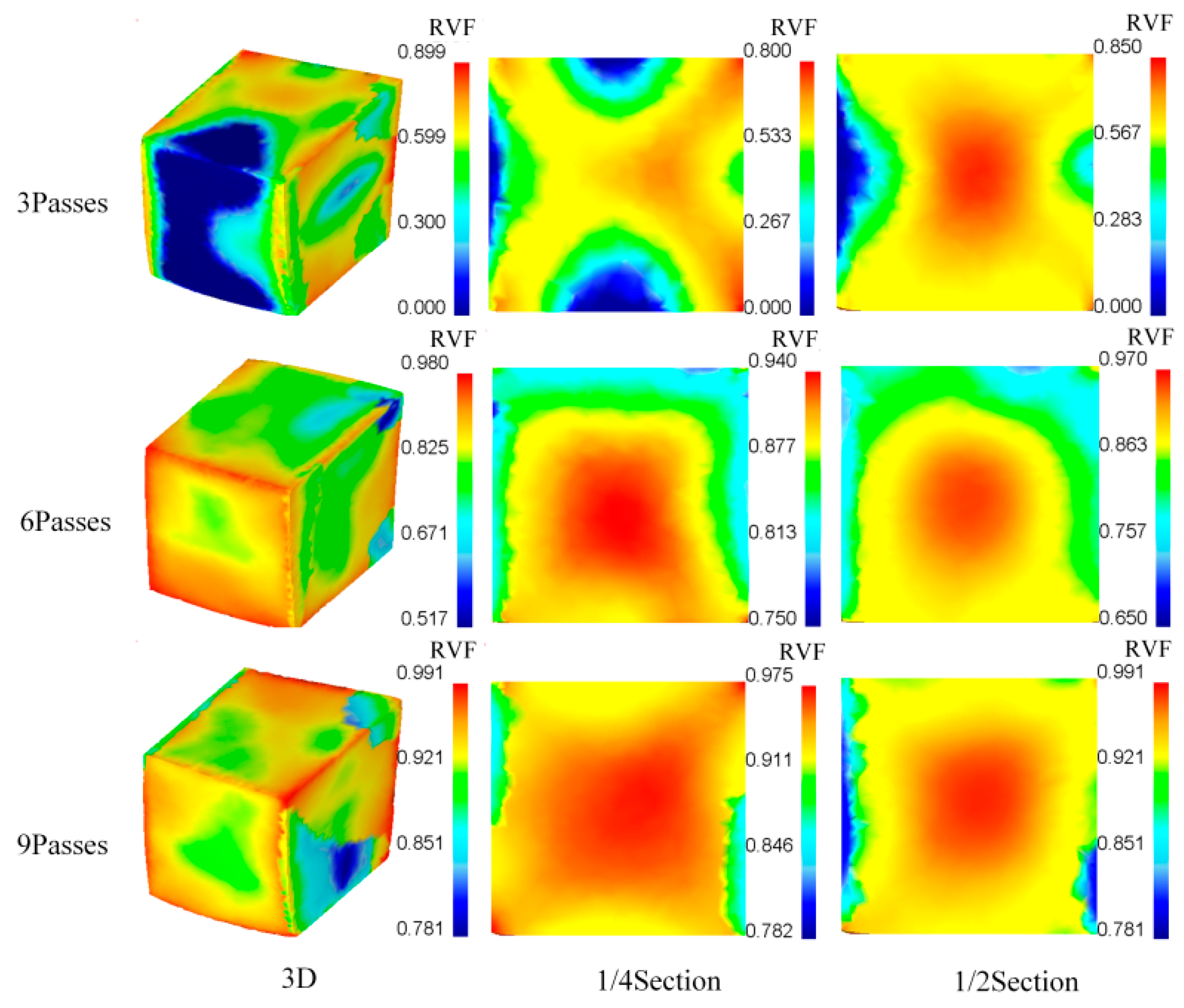

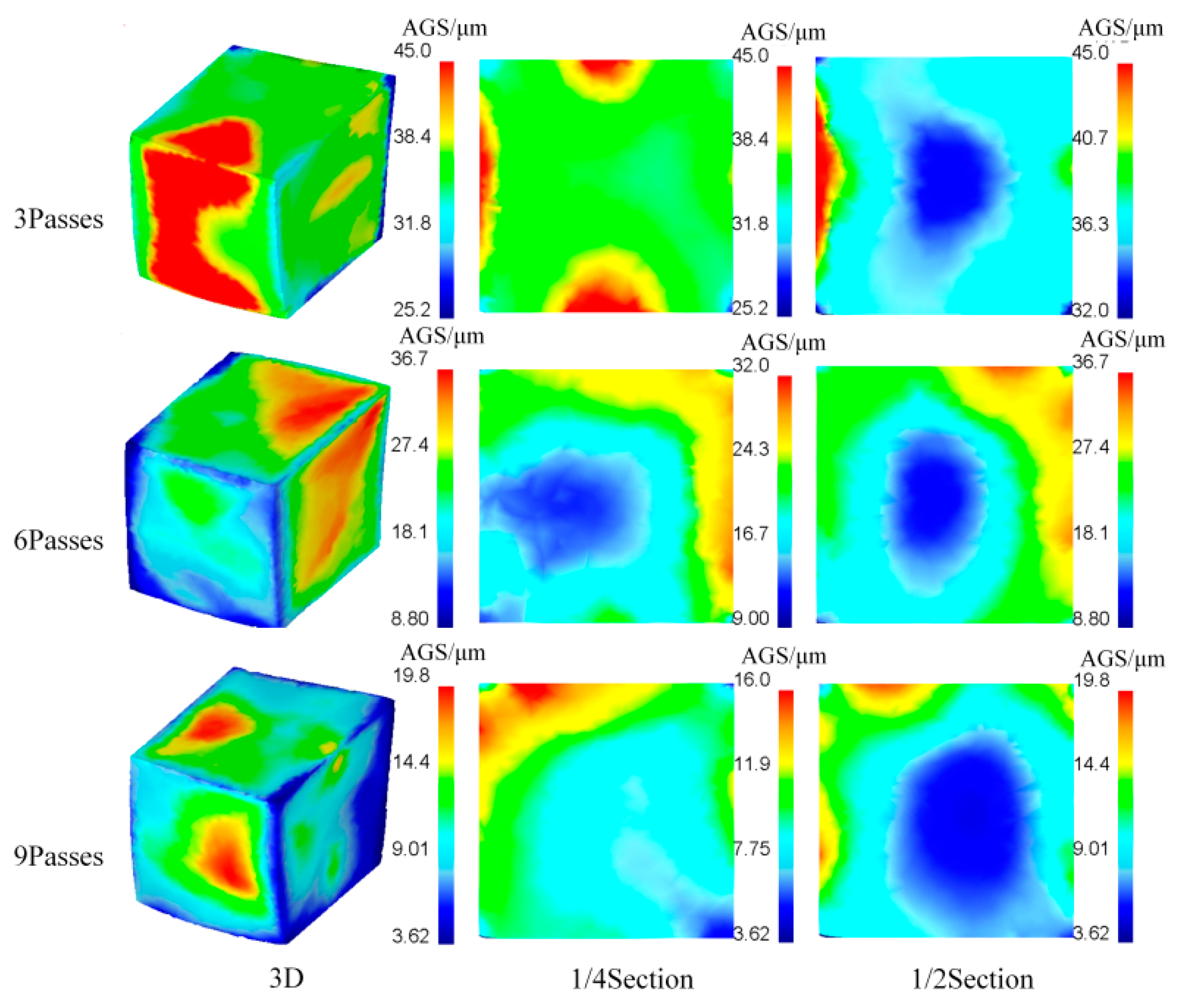

3.4. Double-Open Multidirectional Forging Simulation

3.4.1. Process and Finite Element Model

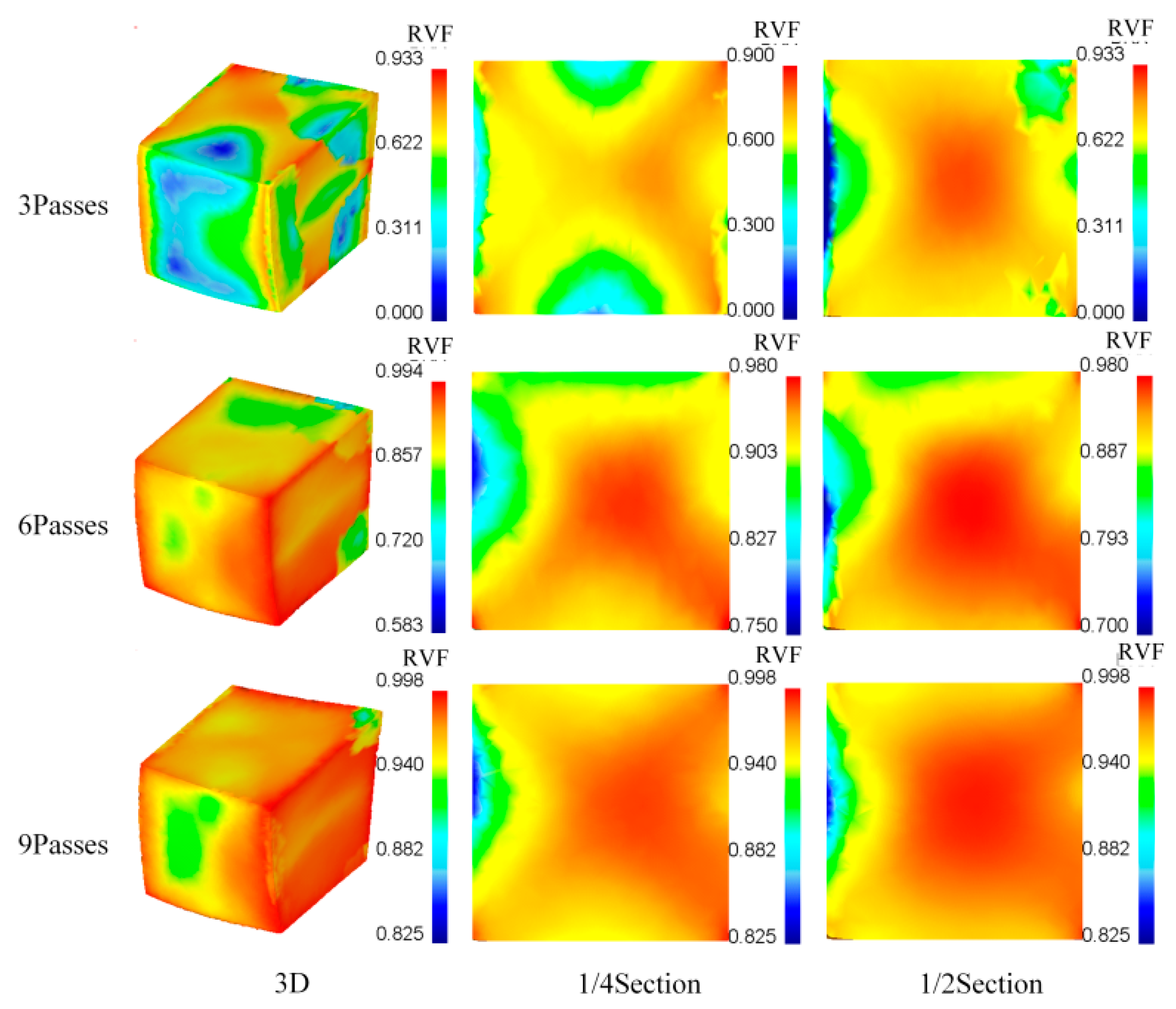

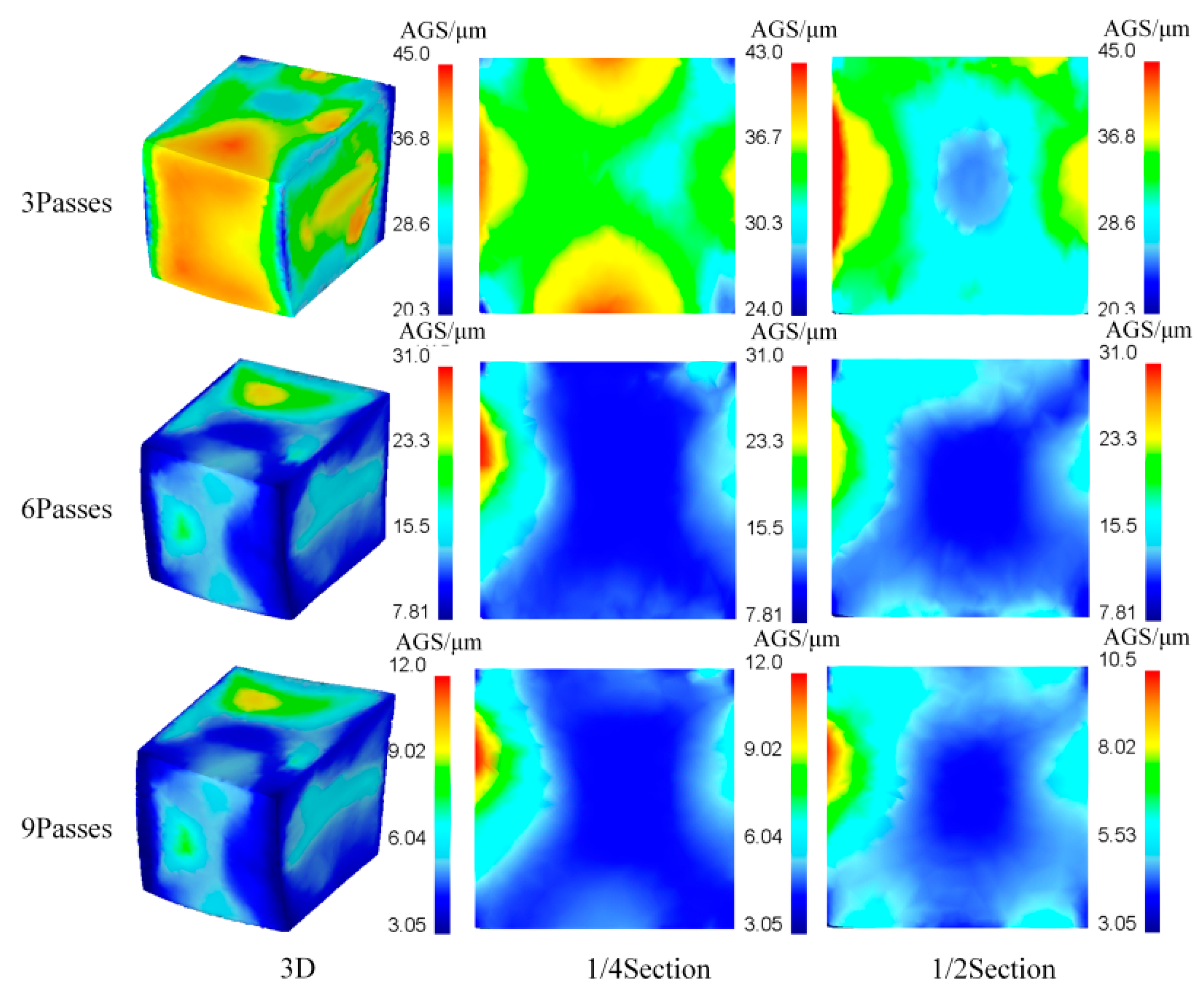

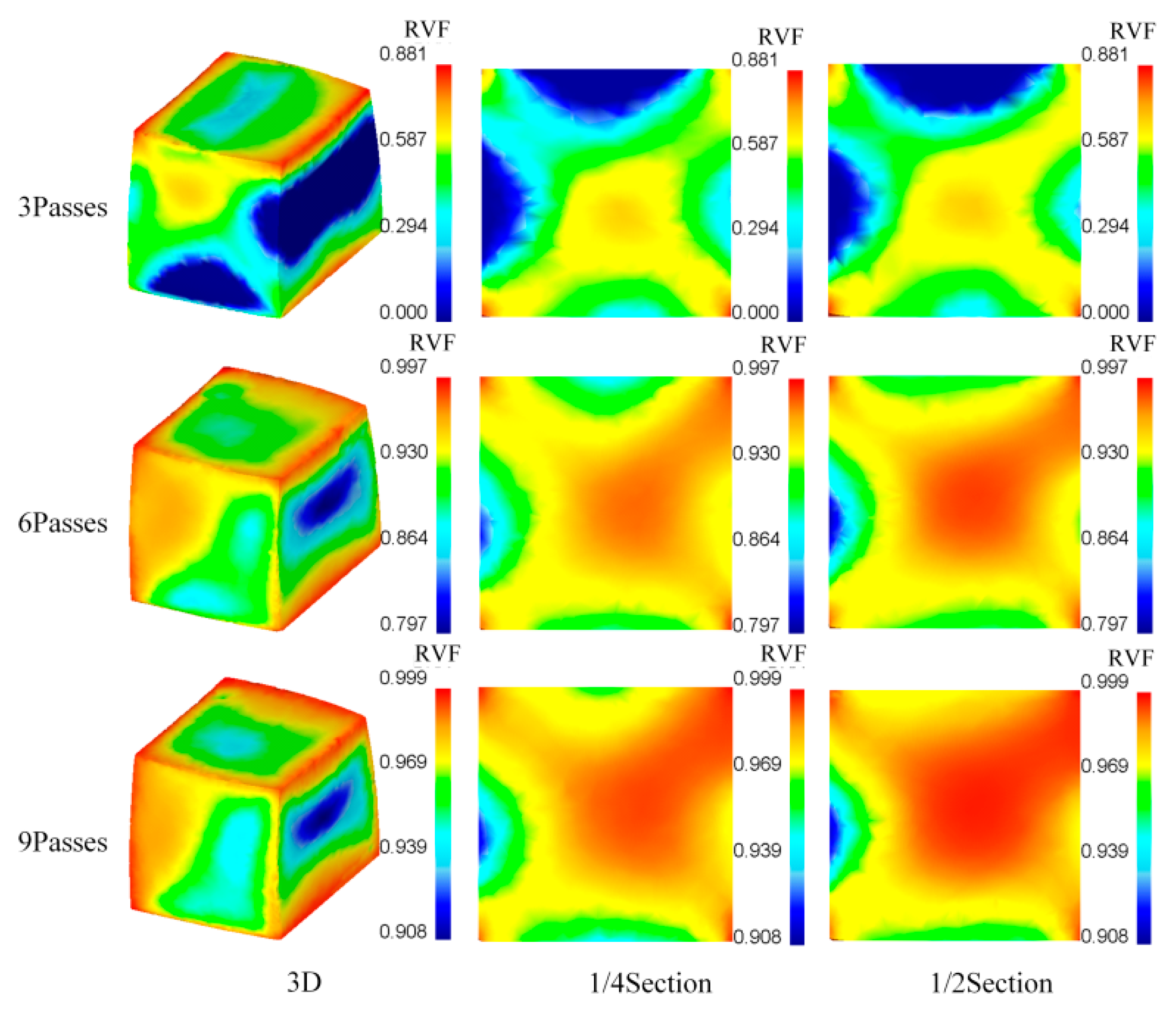

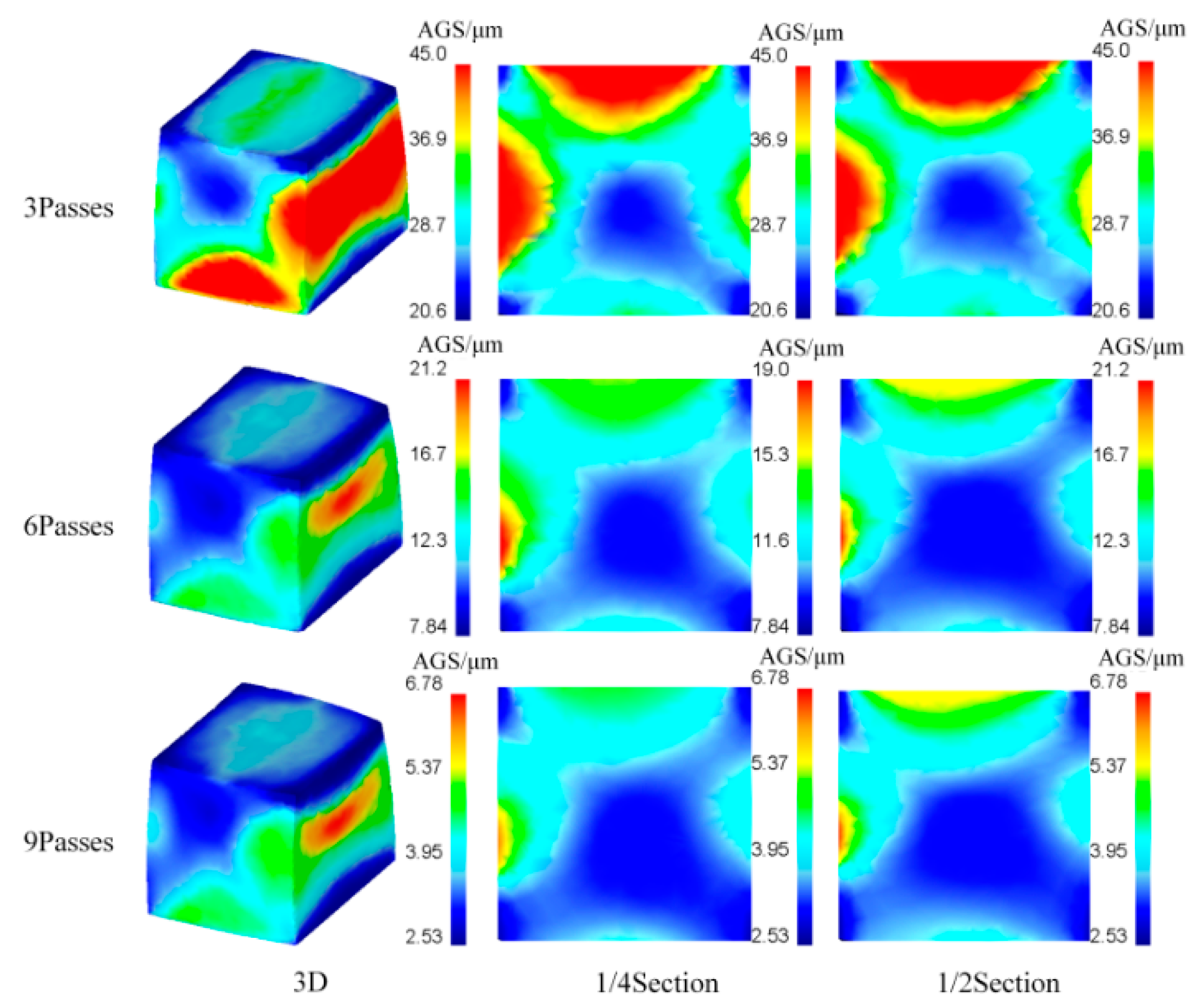

3.4.2. Numerical Simulation Results and Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhou, L.X.; Baker, T.N. Eeffct of strain rate and temperuatre on deofrmation behvaior of IN718 during high temperuatre deformation. Mater. Sci. Eng. 1994, 177, 1–9. [Google Scholar] [CrossRef]

- Du, J.H.; Lu, X.D.; Deng, Q.; Bi, Z.B. Progress in the Research and Manufacture of GH4169 alloy. J. Iron Steel Res. Int. 2015, 22, 657–663. [Google Scholar] [CrossRef]

- Li, H.Y.; Kong, Y.H.; Chen, G.S.; Xie, L.X.; Zhu, S.G.; Sheng, X. Effect of different processing technologies and heat treatments on the microstructure and creep behavior of GH4169 superalloy. Mater. Sci. Eng. 2013, 582, 368–373. [Google Scholar] [CrossRef]

- Zhou, X.; Zhang, J.; Chen, X.; Zhang, X.; Li, M. Fabrication of high-strength AZ80 alloys via multidirectional forging in air with no need of ageing treatment. J. Alloys Compd. 2019, 787, 551–559. [Google Scholar] [CrossRef]

- Na, Y.S.; Yeom, J.T.; Park, N.K.; Lee, J.Y. Simulation of microstructures for Alloy 718 blade forging using 3D FEM simulator. J. Mater. Process. Technol. 2003, 141, 337–342. [Google Scholar] [CrossRef]

- Salevati, M.A.; Akbaripanah, F.; Mahmudi, R. Microstructure, Texture, and Mechanical Properties of AM60 Magnesium Alloy Processed by Extrusion and Multidirectional Forging. J. Mater. Eng. Perform. 2019, 28, 3021–3030. [Google Scholar] [CrossRef]

- Miura, H.; Maruoka, T.; Yang, X.; Jonas, J.J. Microstructure and mechanical properties of multi-directionally forged Mg–Al–Zn alloy. Scr. Mater. 2012, 66, 49–51. [Google Scholar] [CrossRef]

- Kishchik, M.S.; Mikhaylovskaya, A.V.; Kotov, A.D.; Mosleh, A.O.; AbuShanab, W.S.; Portnoy, V.K. Effect of multidirectional forging on the grain structure and mechanical properties of the Al–Mg–Mn alloy. Materials 2018, 11, 2166. [Google Scholar] [CrossRef]

- Xia, X.S.; Wang, C.P.; Wu, Y.; Zhang, K.; Ma, M.L.; Yuan, B.G. Grain refinement, microstructure and mechanical properties homogeneity of Mg-Gd-Y-Nd-Zr alloy during multidirectional forging. J. Mater. Eng. Perform. 2018, 27, 5689–5699. [Google Scholar] [CrossRef]

- Aoba, T.; Kobayashi, M.; Miura, H. Microstructural evolution and enhanced mechanical properties by multi-directional forging and aging of 6000 series aluminum alloy. Mater. Trans. 2018, 59, 373–379. [Google Scholar] [CrossRef]

- Lin, J.; Liu, Y. A set of unified constitutive equations for modellling microstructure evolution in hot deformation. J. Mater. Process. Technol. 2003, 143, 281–285. [Google Scholar] [CrossRef]

- Kermanpur, A.; Lee, P.D.; Mclean, M.; Tin, S. Integrated modeling for the manufacture of aerospace discs: Grain structure evolution. JOM 2004, 56, 72–78. [Google Scholar] [CrossRef][Green Version]

- Tin, S.; Lee, P.D.; Kermanpur, A.; Mclean, M.; Rist, M. Integrated modeling for the manufacture of Ni-based superalloy discs from solidification to final heat treatment. Metall. Mater. Trans. A 2005, 36, 2493–2504. [Google Scholar] [CrossRef]

- Park, N.K.; Kim, I.S.; Na, Y.S.; Yeom, J.T. Hot forging of a nickel-base superalloy. J. Mater. Process. Technol. 2001, 111, 98–102. [Google Scholar] [CrossRef]

- Murty, S.V.S.N.; Rao, B.N. On the development of instability criteria during hotworking with reference to IN 718. Mater. Sci. Eng. 1998, 254, 76–82. [Google Scholar] [CrossRef]

- Cao, F.R.; Zhang, J.; Ding, X.; Xue, G.Q.; Liu, S.Y.; Sun, C.F. Mechanical properties and microstructural evolution in a superlight Mg-6.4Li-3.6Zn-0.37Al-0.36Y alloy processed by multidirectional forging and rolling. Mater. Sci. Eng. 2019, 760, 377–393. [Google Scholar] [CrossRef]

- Marty, B.; Guedou, J.; Gergaud, P.; Lebrun, J.L. Recrystallization and work-hardening prediction during forging process of inconel 718. Superalloys 1997, 718, 625–706. [Google Scholar]

- Zhang, Z.X.; Qu, S.J.; Feng, A.H.; Hu, X.; Shen, J. Microstructural mechanisms during multidirectional isothermal forging of as-cast Ti-6Al-4V alloy with an initial lamellar microstructure. J. Alloys Compd. 2019, 773, 277–287. [Google Scholar] [CrossRef]

- Zhang, J.M.; Gao, Z.Y.; Zhuang, J.Y.; Zhong, Z.Y. Mathematical modeling of the hot deformation behavior of superally IN718. Metall. Mater. Trans. A 1999, 30, 2701–2713. [Google Scholar] [CrossRef]

- Thomas, A.; El-Wahabi, M.; Cabrera, J.M.; Prado, J.M. High temperature deformation of Inconel 718. J. Mater. Process. Technol. 2006, 177, 469–472. [Google Scholar] [CrossRef]

- Hu, J.P.; Zhuang, J.Y.; Du, J.H.; Deng, Q.; Feng, D. Constitutive equation of superalloy In718 in hammer forging process. J. Iron Steel Res. Int. 2001, 8, 50–54. [Google Scholar]

- Dandre, C.A.; Roberts, S.M.; Evans, R.W.; Reed, R.C. Microstructural evolution of Inconel* 718 during ingot breakdown: Process modelling and validation. Mater. Sci. Technol. 2000, 16, 14–25. [Google Scholar] [CrossRef]

| Temperature/°C | 900 | 950 | 1000 | 1050 | 1120 |

|---|---|---|---|---|---|

| Strain rate/s−1 | 0.001, 0.01, 0.1, 1 | ||||

| Heating rate/°C·s−1 | 5 | ||||

| Compression ratio | 0.6 | ||||

| Temperature T/°C | )/s−1 | Peak Stress (σp)/Mpa | lnσp | ln[sinh(ασp)] | |

|---|---|---|---|---|---|

| 900 | 0.001 | 253.1 | −6.908 | 5.533785 | 0.5608306 |

| 0.01 | 364.32 | −4.605 | 5.898033 | 1.1947405 | |

| 0.1 | 523.39 | −2.303 | 6.260327 | 2.0467375 | |

| 1 | 556.85 | 0 | 6.322296 | 2.2233897 | |

| 950 | 0.001 | 212.46 | −6.908 | 5.358754 | 0.3067085 |

| 0.01 | 354.28 | −4.605 | 5.870088 | 1.139611 | |

| 0.1 | 450.13 | −2.303 | 6.109536 | 1.6578382 | |

| 1 | 528.47 | 0 | 6.269986 | 2.0735863 | |

| 1000 | 0.001 | 171.81 | −6.908 | 5.146389 | 0.0272396 |

| 0.01 | 347.85 | −4.605 | 5.851771 | 1.1041569 | |

| 0.1 | 367.16 | −2.303 | 5.905798 | 1.2102875 | |

| 1 | 500.3 | 0 | 6.215208 | 1.9245429 | |

| 1050 | 0.001 | 82.3 | −6.908 | 4.410371 | −0.809689 |

| 0.01 | 139.68 | −4.605 | 4.939354 | −0.22371 | |

| 0.1 | 218.02 | −2.303 | 5.384587 | 0.3426757 | |

| 1 | 303.52 | 0 | 5.715448 | 0.8557846 | |

| 1100 | 0.001 | 74.45 | −6.908 | 4.310128 | −0.915507 |

| 0.01 | 129.43 | −4.605 | 4.86314 | −0.31216 | |

| 0.1 | 178.39 | −2.303 | 5.183972 | 0.0748297 | |

| 1 | 233.89 | 0 | 5.454851 | 0.443079 | |

| 1120 | 0.001 | 66.847 | −6.908 | 4.202406 | −1.028105 |

| 0.01 | 105.18 | −4.605 | 4.655673 | −0.54505 | |

| 0.1 | 158.97 | −2.303 | 5.068716 | −0.06898 | |

| 1 | 215.31 | 0 | 5.372079 | 0.3252004 |

| Temperature/°C | /s−1 | Peak Strain εp/MPa | lnZ | X |

|---|---|---|---|---|

| 950 | 0.001 | 0.221 | 42.26602 | 0.724 |

| 0.01 | 0.156 | 40.33004 | 0.658 | |

| 0.1 | 0.105 | 38.54073 | 0.543 | |

| 1 | 0.113 | 36.88203 | 0.287 | |

| 1000 | 0.001 | 0.1 | 36.25196 | 0.927 |

| 0.01 | 0.228 | 44.5686 | 0.843 | |

| 0.1 | 0.2 | 42.63263 | 0.706 | |

| 1 | 0.168 | 40.84331 | 0.504 | |

| 1050 | 0.001 | 0.154 | 39.18461 | 0.895 |

| 0.01 | 0.144 | 38.55454 | 0.919 | |

| 0.1 | 0.232 | 46.87119 | 0.817 | |

| 1 | 0.221 | 44.93521 | 0.665 | |

| 1100 | 0.001 | 0.206 | 43.1459 | 0.905 |

| 0.01 | 0.188 | 41.4872 | 0.928 | |

| 0.1 | 0.18 | 40.85713 | 0.886 | |

| 1 | 0.237 | 49.17377 | 0.780 | |

| 1120 | 0.001 | 0.233 | 47.2378 | 0.887 |

| 0.01 | 0.225 | 45.44848 | 0.928 | |

| 0.1 | 0.212 | 43.78978 | 0.904 | |

| 1 | 0.206 | 43.15971 | 0.815 |

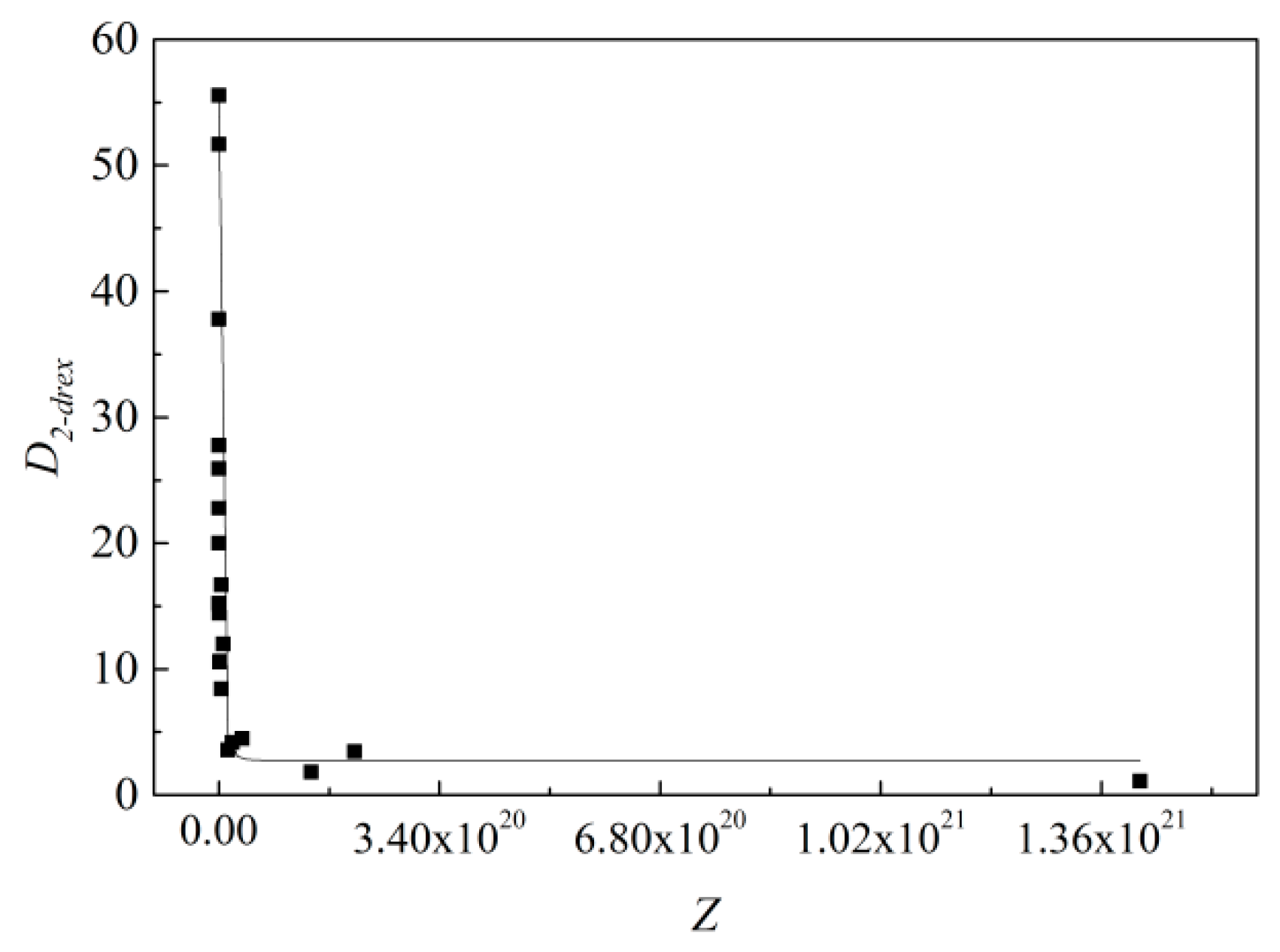

| Temperature/°C | Strain Rate/s−1 | Z | D2-drex/μm |

|---|---|---|---|

| 950 | 0.001 | 1.42 × 1018 | 10.556 |

| 0.01 | 1.42 × 1019 | 3.578 | |

| 0.1 | 1.42 × 1020 | 1.818 | |

| 1 | 1.42 × 1021 | 1.111 | |

| 1000 | 0.001 | 2.09 × 1017 | 22.78 |

| 0.01 | 2.09 × 1018 | 10.603 | |

| 0.1 | 2.09 × 1019 | 4.167 | |

| 1 | 2.09 × 1020 | 3.442 | |

| 1050 | 0.001 | 3.57 × 1016 | 37.78 |

| 0.01 | 3.57 × 1017 | 15.2 | |

| 0.1 | 3.57 × 1018 | 8.425 | |

| 1 | 3.57 × 1019 | 4.487 | |

| 1100 | 0.001 | 6.93 × 1015 | 51.67 |

| 0.01 | 6.93 × 1016 | 25.92 | |

| 0.1 | 6.93 × 1017 | 14.444 | |

| 1 | 6.93 × 1018 | 12 | |

| 1120 | 0.001 | 3.72 × 1015 | 55.56 |

| 0.01 | 3.72 × 1016 | 27.78 | |

| 0.1 | 3.72 × 1017 | 20 | |

| 1 | 3.72 × 1018 | 16.667 |

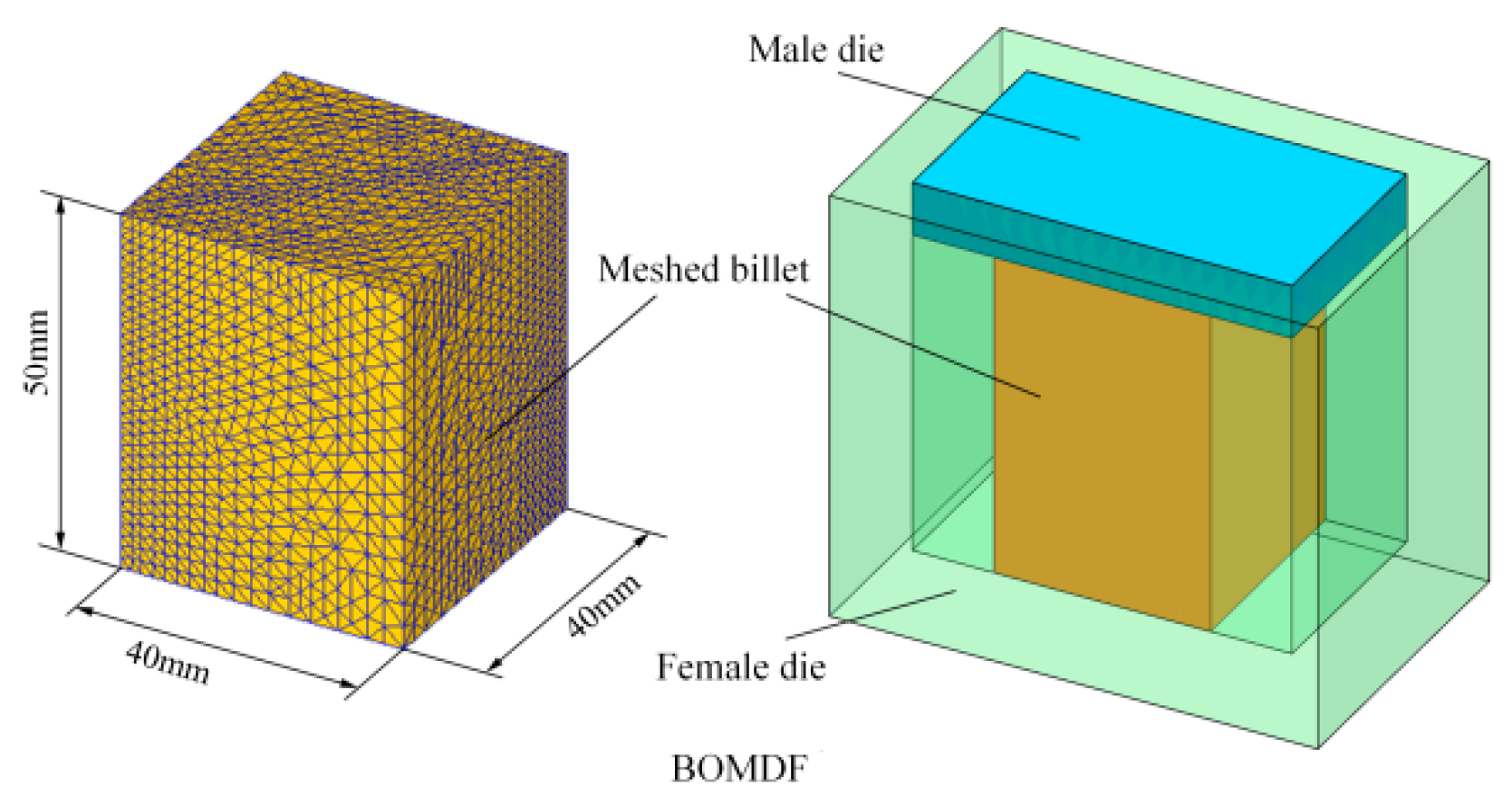

| Process Parameters | Symbol | Unit | Value |

|---|---|---|---|

| Forging size | - | mm | 40 × 40 × 50 |

| Mold material | - | - | H13 |

| Forging temperature | T | ℃ | 800–1000 |

| Coefficient of friction | f | - | 0.3 |

| Thermal conductivity | λ | W/(m·K) | 20–40 |

| Specific heat | C | N/(mm2·K) | 3–5 |

| Initial grain size | d | μm | 45 |

| Upper die size | - | mm | 50 × 40 × 10 |

| Lower die size | - | mm | 70 × 60 × 60 |

| Reduction rate | - | % | 20 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, Y.; Xue, H.; Yang, Z.; Zhang, L.; Zhang, C.; Wang, S.; Luo, J. Constitutive Equation of GH4169 Superalloy and Microstructure Evolution Simulation of Double-Open Multidirectional Forging. Metals 2019, 9, 1146. https://doi.org/10.3390/met9111146

Jin Y, Xue H, Yang Z, Zhang L, Zhang C, Wang S, Luo J. Constitutive Equation of GH4169 Superalloy and Microstructure Evolution Simulation of Double-Open Multidirectional Forging. Metals. 2019; 9(11):1146. https://doi.org/10.3390/met9111146

Chicago/Turabian StyleJin, Yongbo, Hao Xue, Zheyi Yang, Lili Zhang, Chunxiang Zhang, Sirui Wang, and Junting Luo. 2019. "Constitutive Equation of GH4169 Superalloy and Microstructure Evolution Simulation of Double-Open Multidirectional Forging" Metals 9, no. 11: 1146. https://doi.org/10.3390/met9111146

APA StyleJin, Y., Xue, H., Yang, Z., Zhang, L., Zhang, C., Wang, S., & Luo, J. (2019). Constitutive Equation of GH4169 Superalloy and Microstructure Evolution Simulation of Double-Open Multidirectional Forging. Metals, 9(11), 1146. https://doi.org/10.3390/met9111146