The Effect of Position of Materials on a Build Platform on the Hardness, Roughness, and Corrosion Resistance of Ti6Al4V Produced by DMLS Technology

Abstract

1. Introduction

2. Materials and Methods

2.1. DMLS Parameters

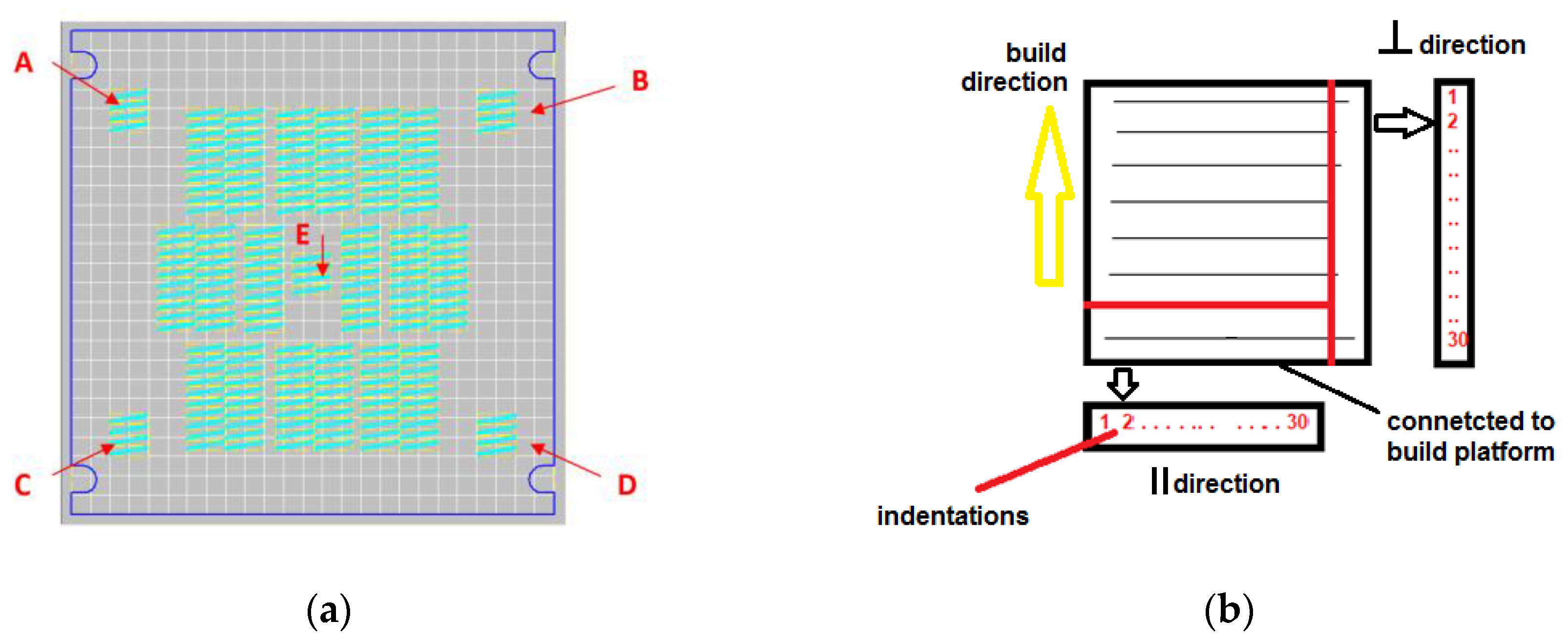

2.2. Test Samples

2.3. Collection of Samples for Metallographic Observation

2.4. Material Hardness Testing

2.5. Material Roughness Testing

- arithmetical mean deviation of the assessed profile (Ra),

- maximum height of profile (Rz),

- mean width of the profile elements (RSm).

2.6. Methodology of Statistical Analysis of Material Hardness

- in different position on the build platform, evaluated in particular direction-comparisons within samples A–E in the perpendicular direction and separate comparison within samples A–E in the parallel direction (analysis of variance (ANOVA), Tukey’s honest significant difference (HSD) test),

- in two different directions within particular positions on the build platform—comparison between perpendicular and parallel directions within position A, and similarly in position B, C, D, and E (t-test).

2.7. Methodology of Statistical Analysis of Surface Microgeometry

2.7.1. Kruskal–Wallis Test

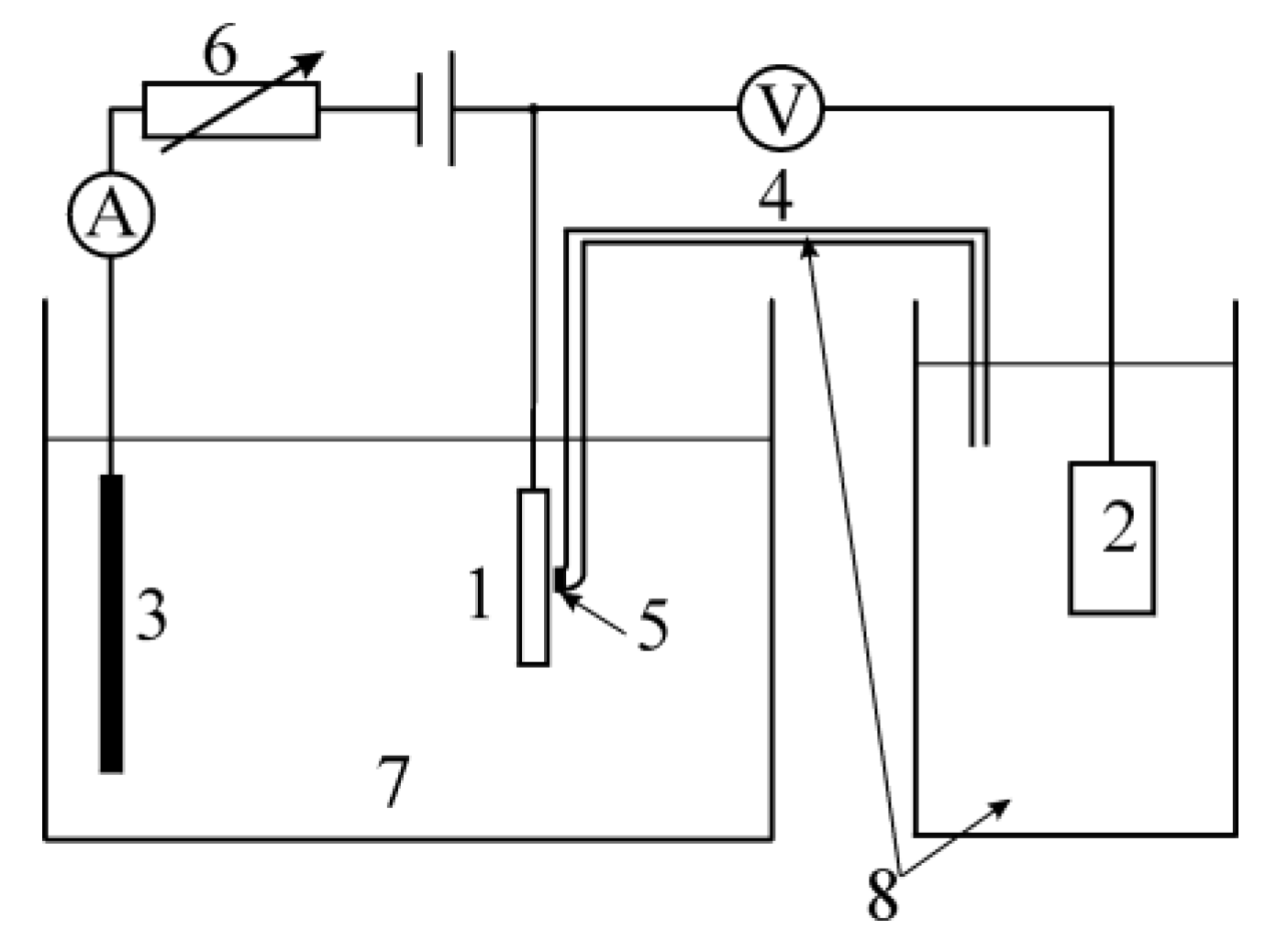

2.7.2. Corrosion Properties of Sintered Material

3. Results

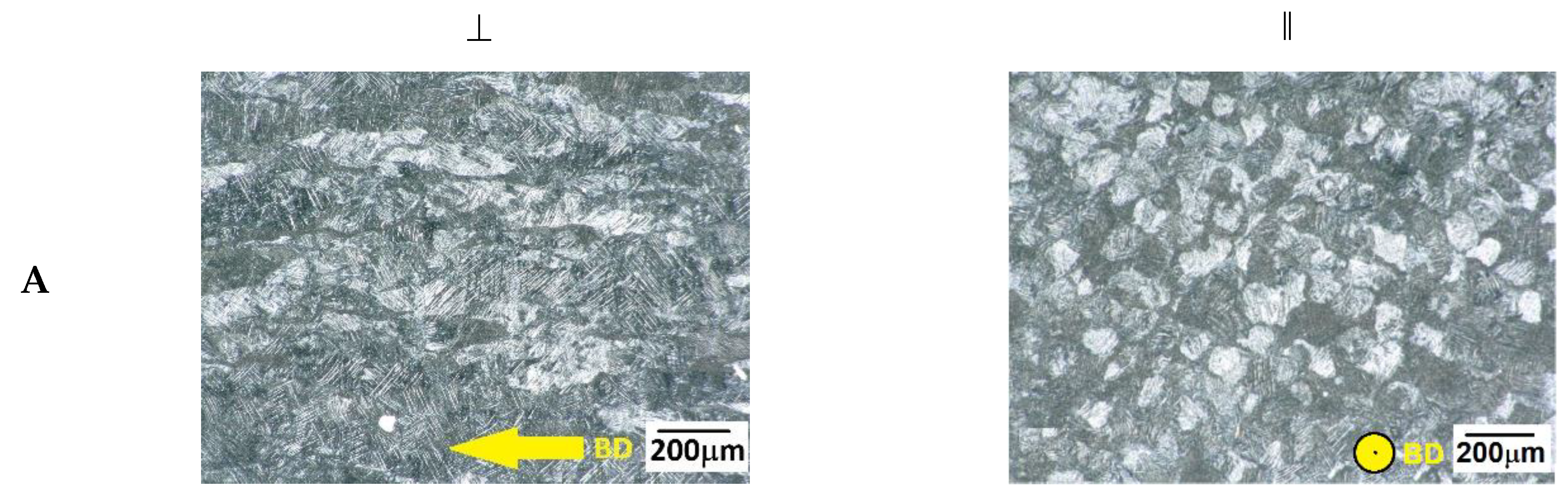

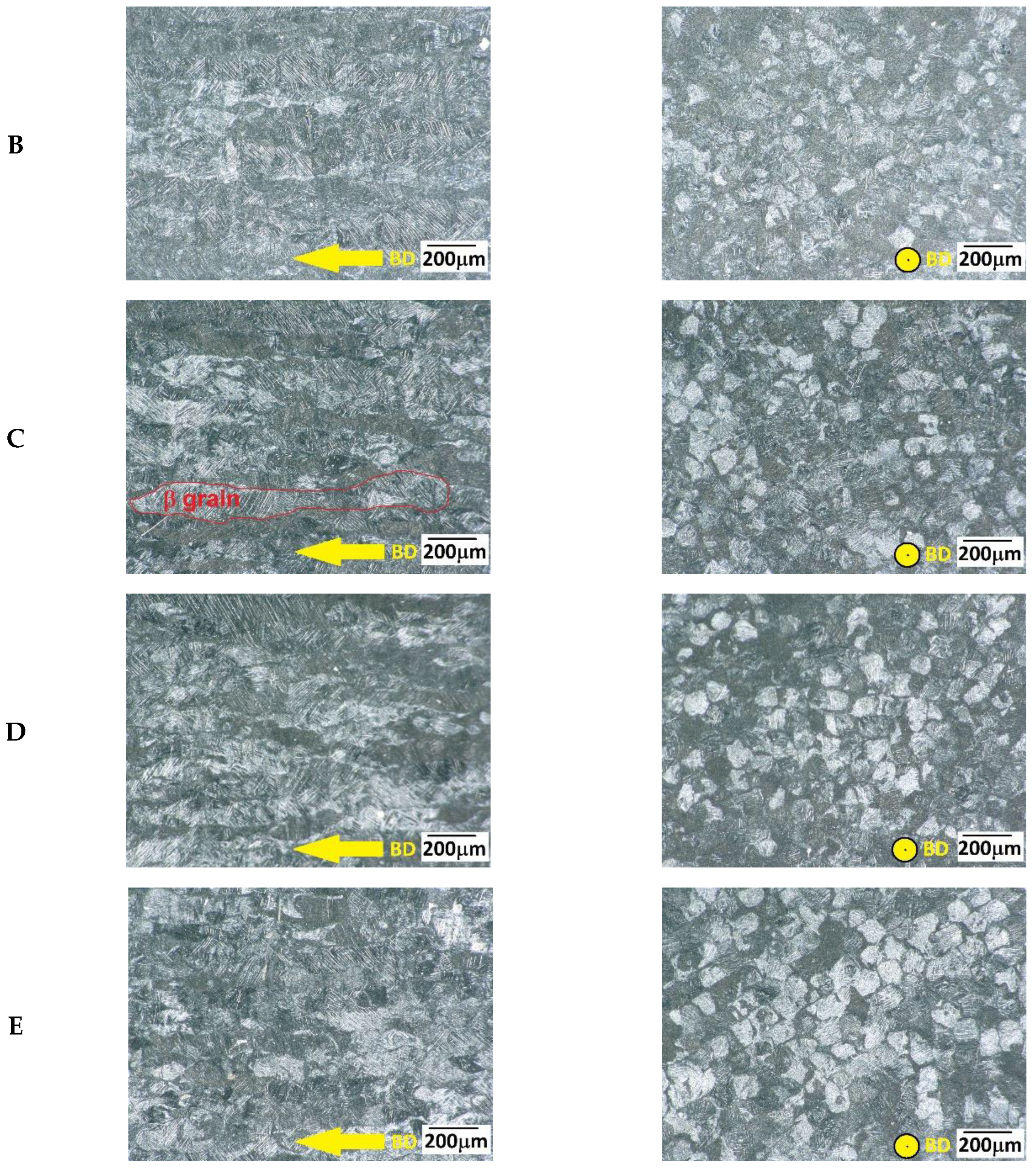

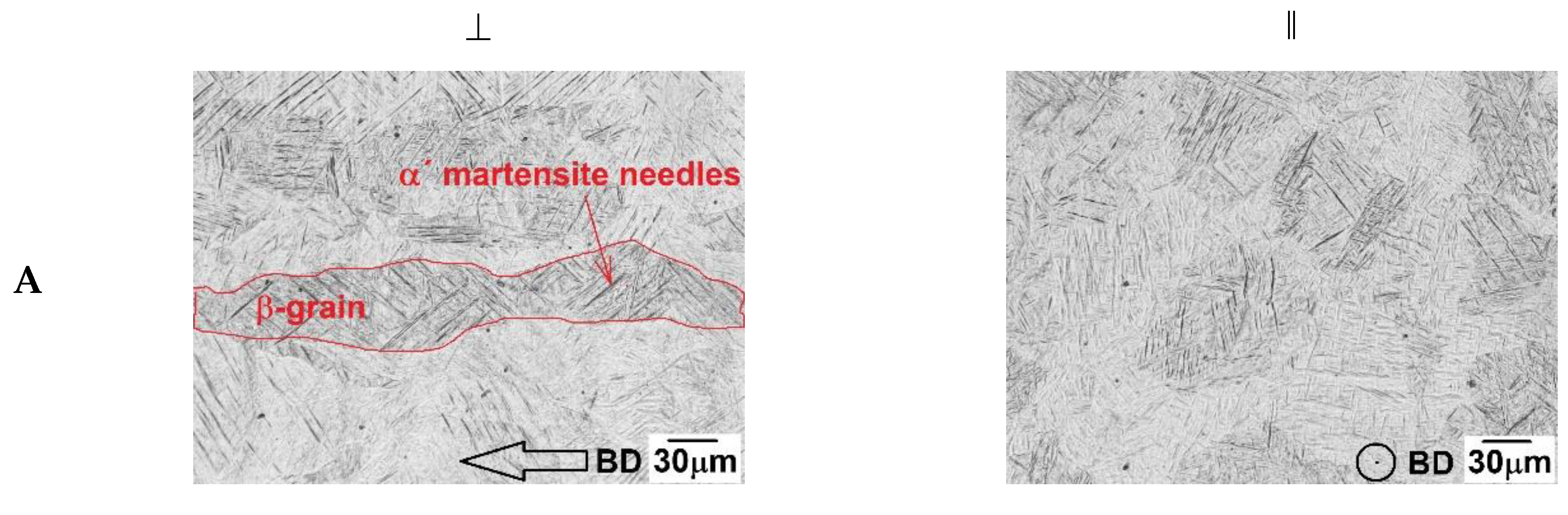

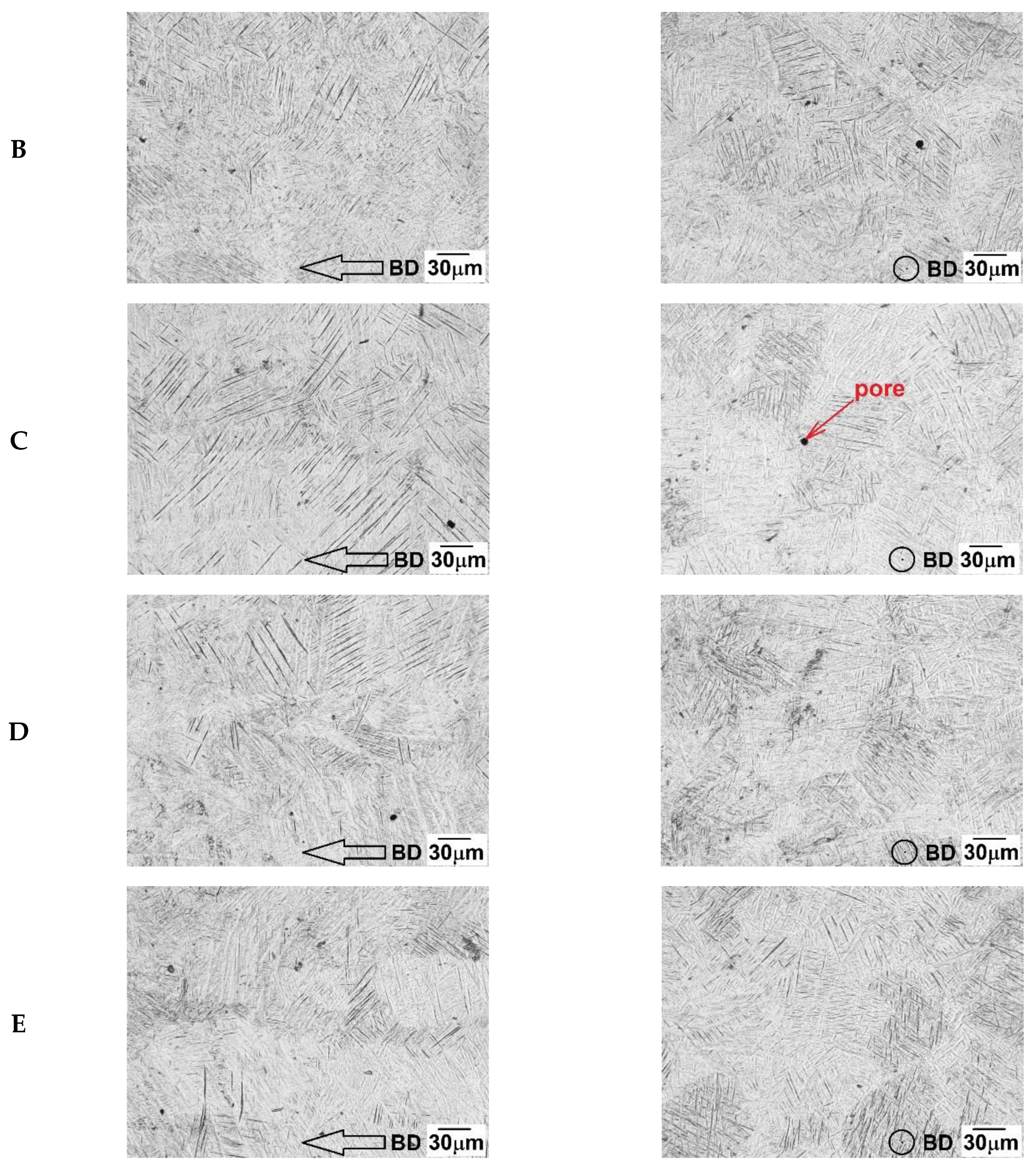

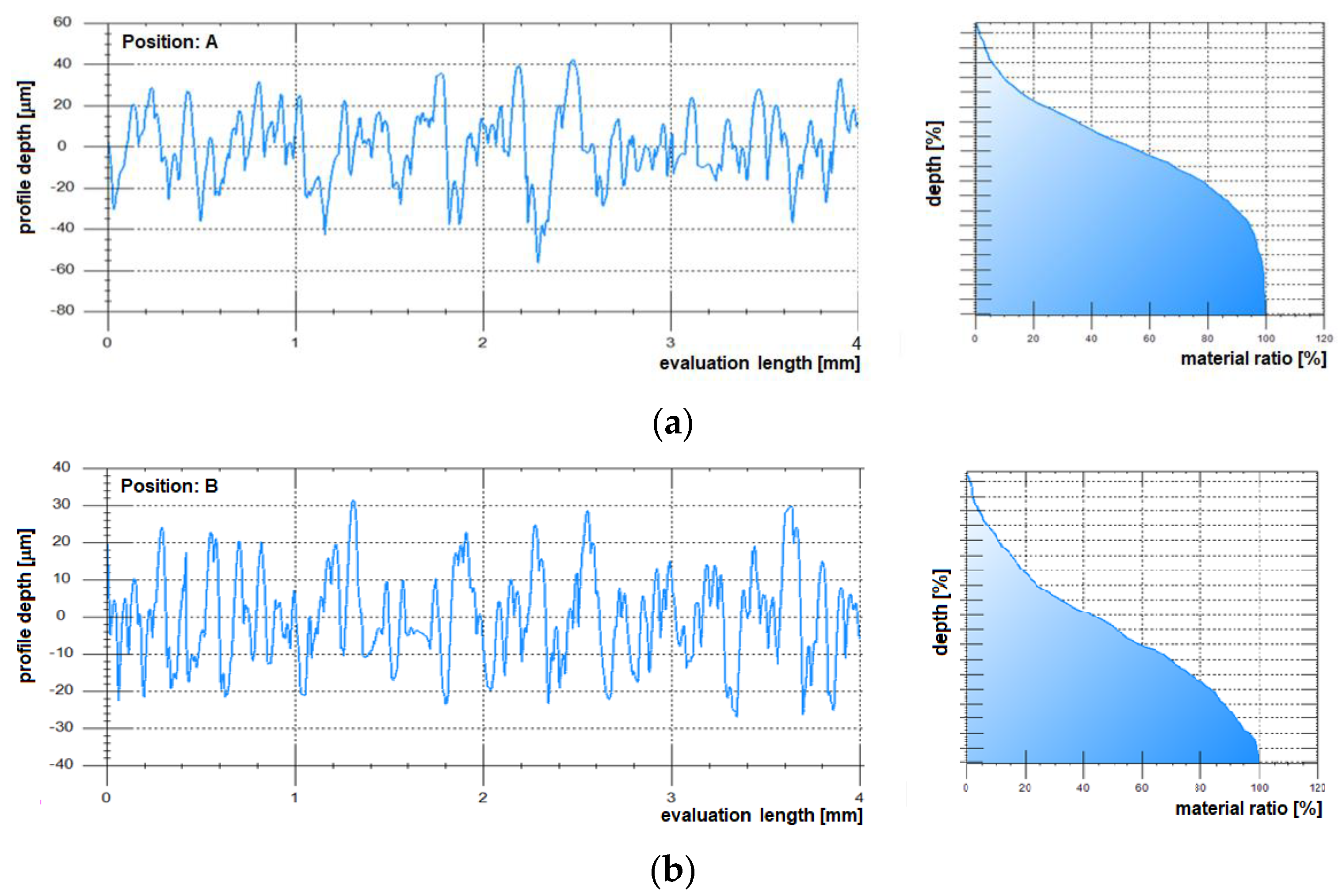

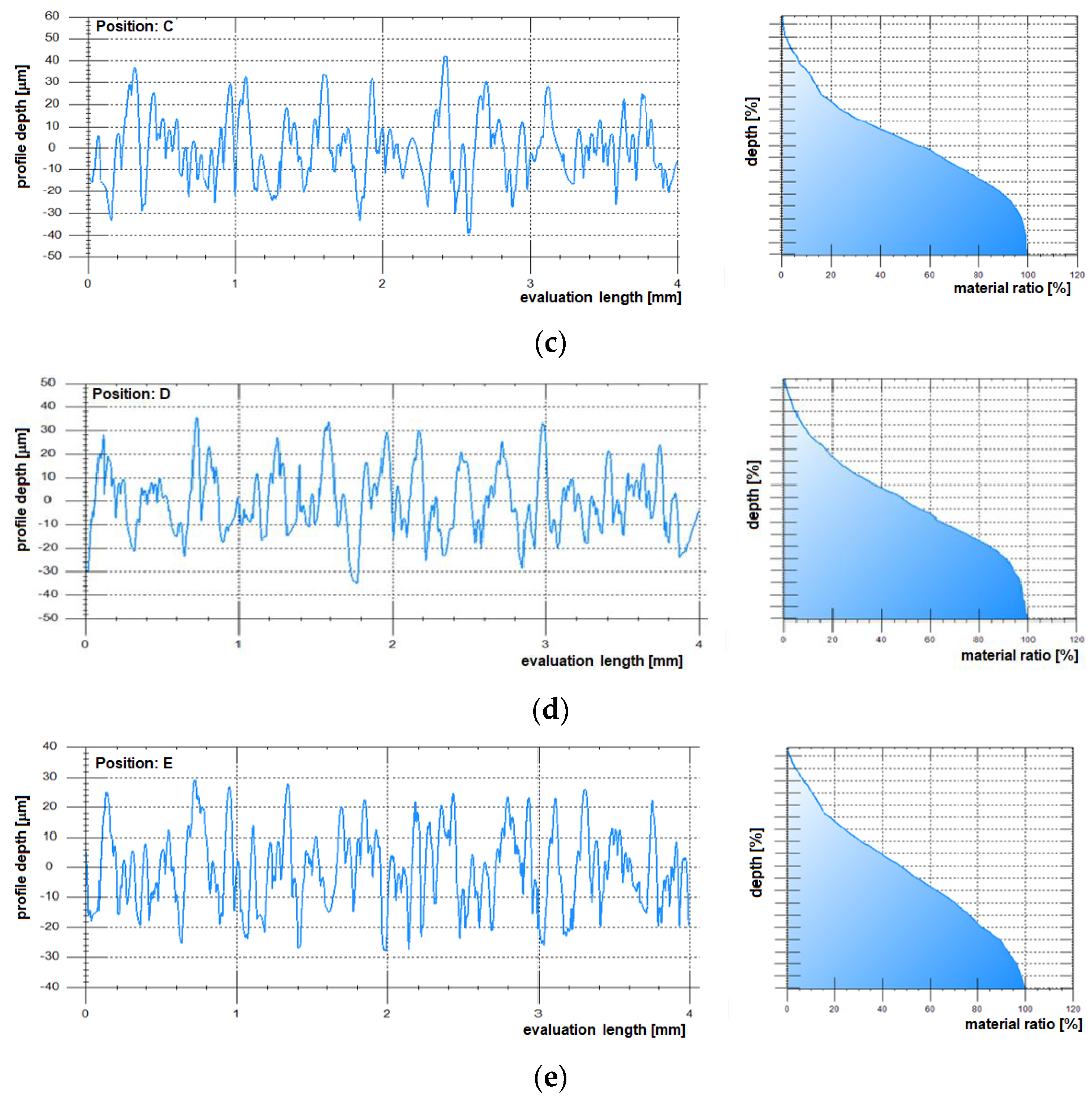

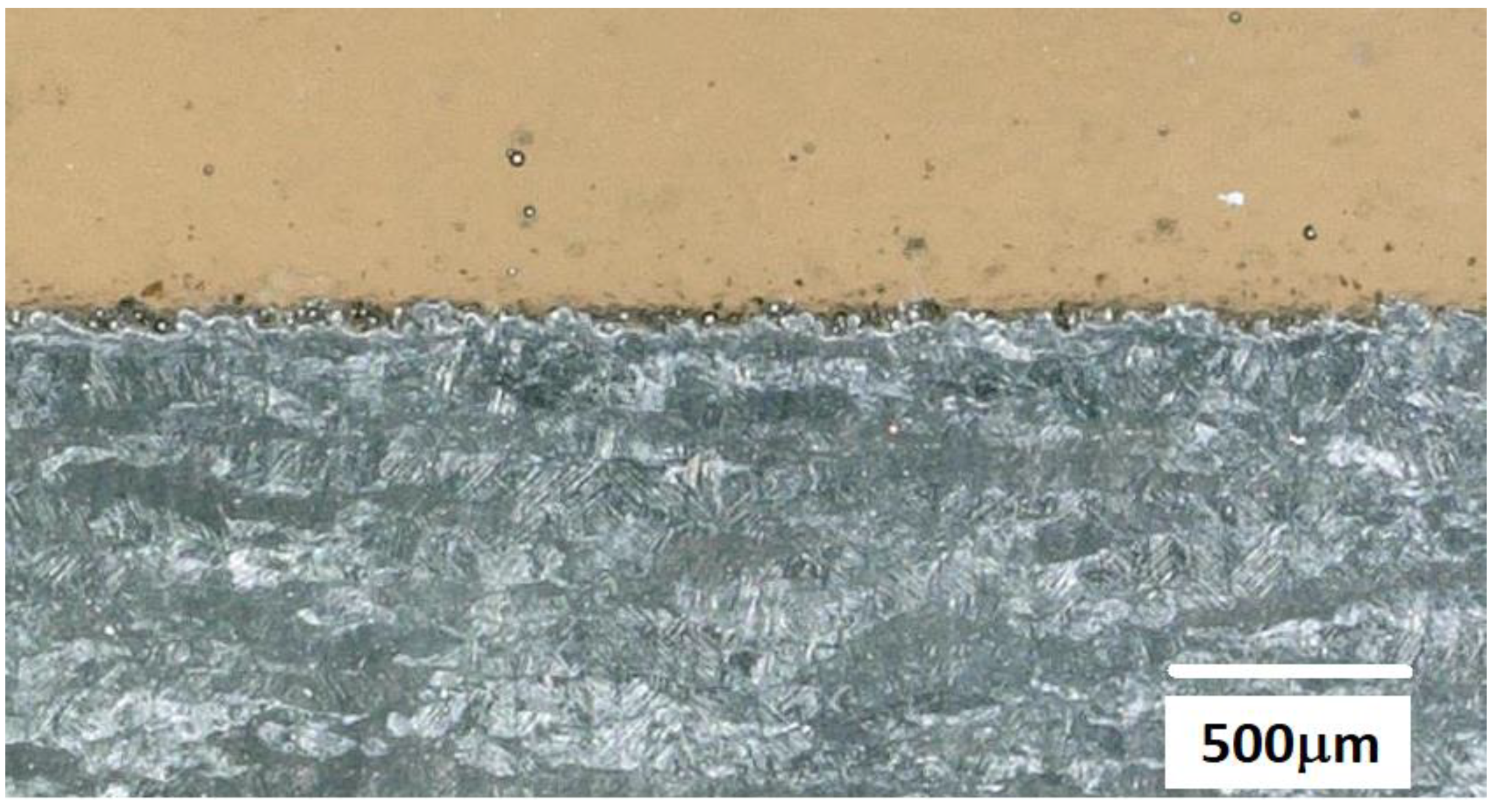

3.1. Microstructure Characterization of Material

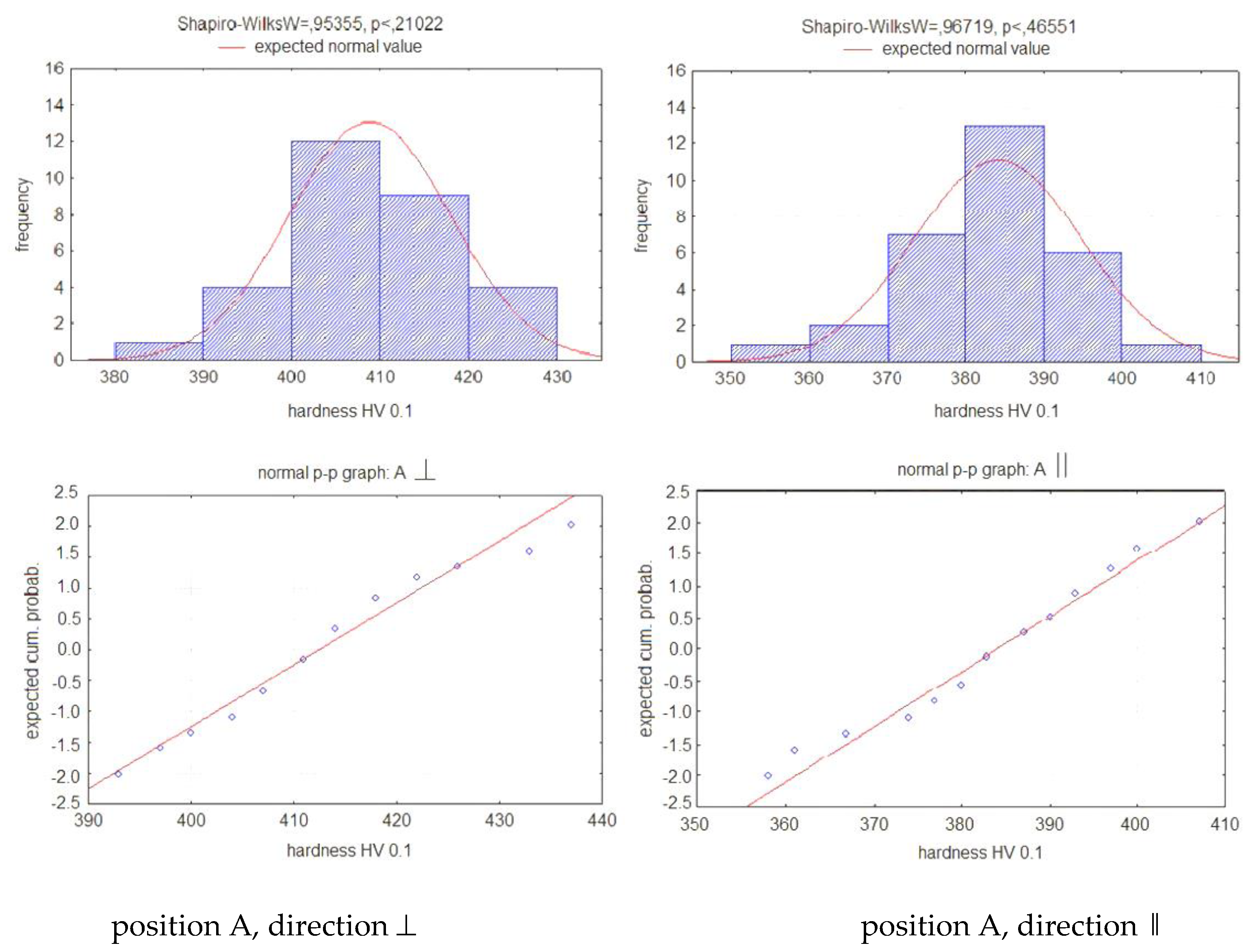

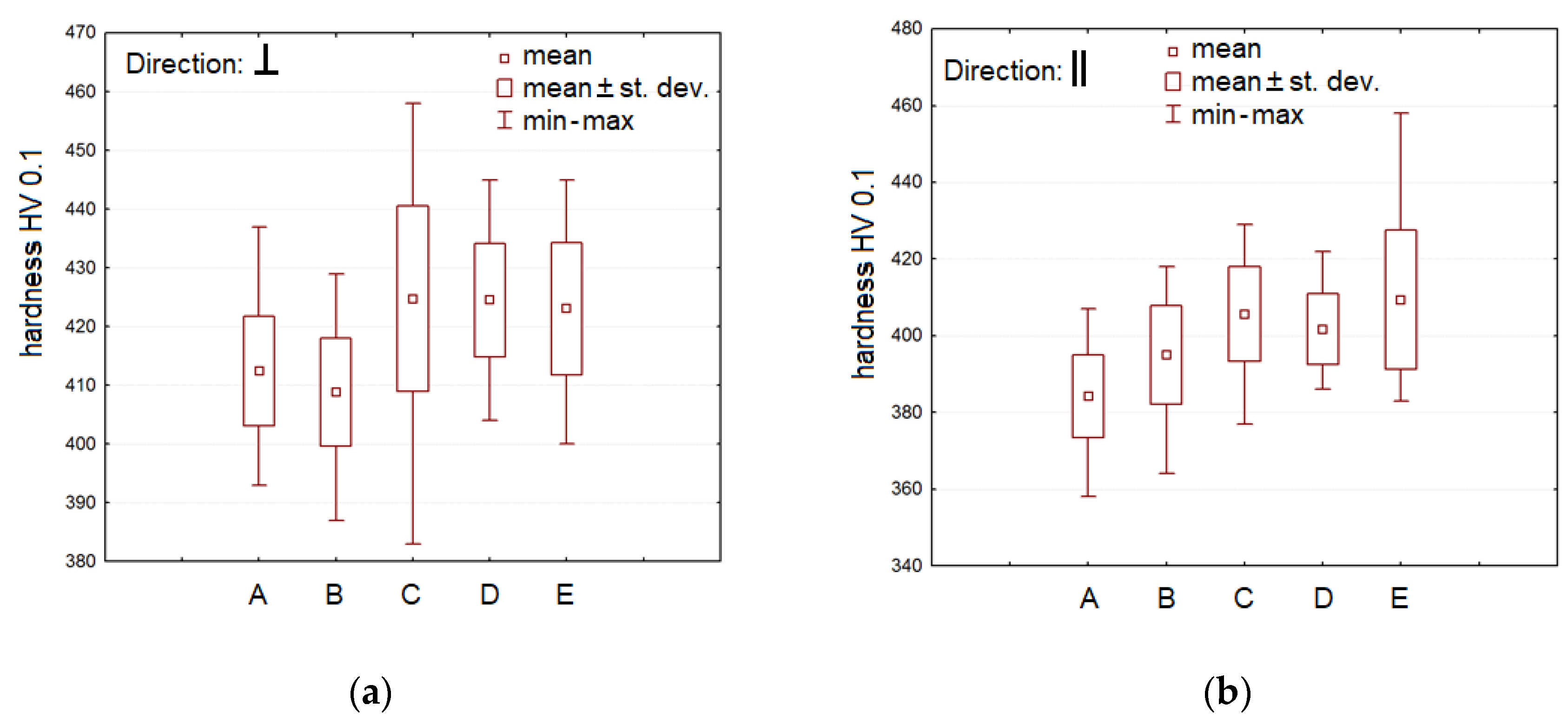

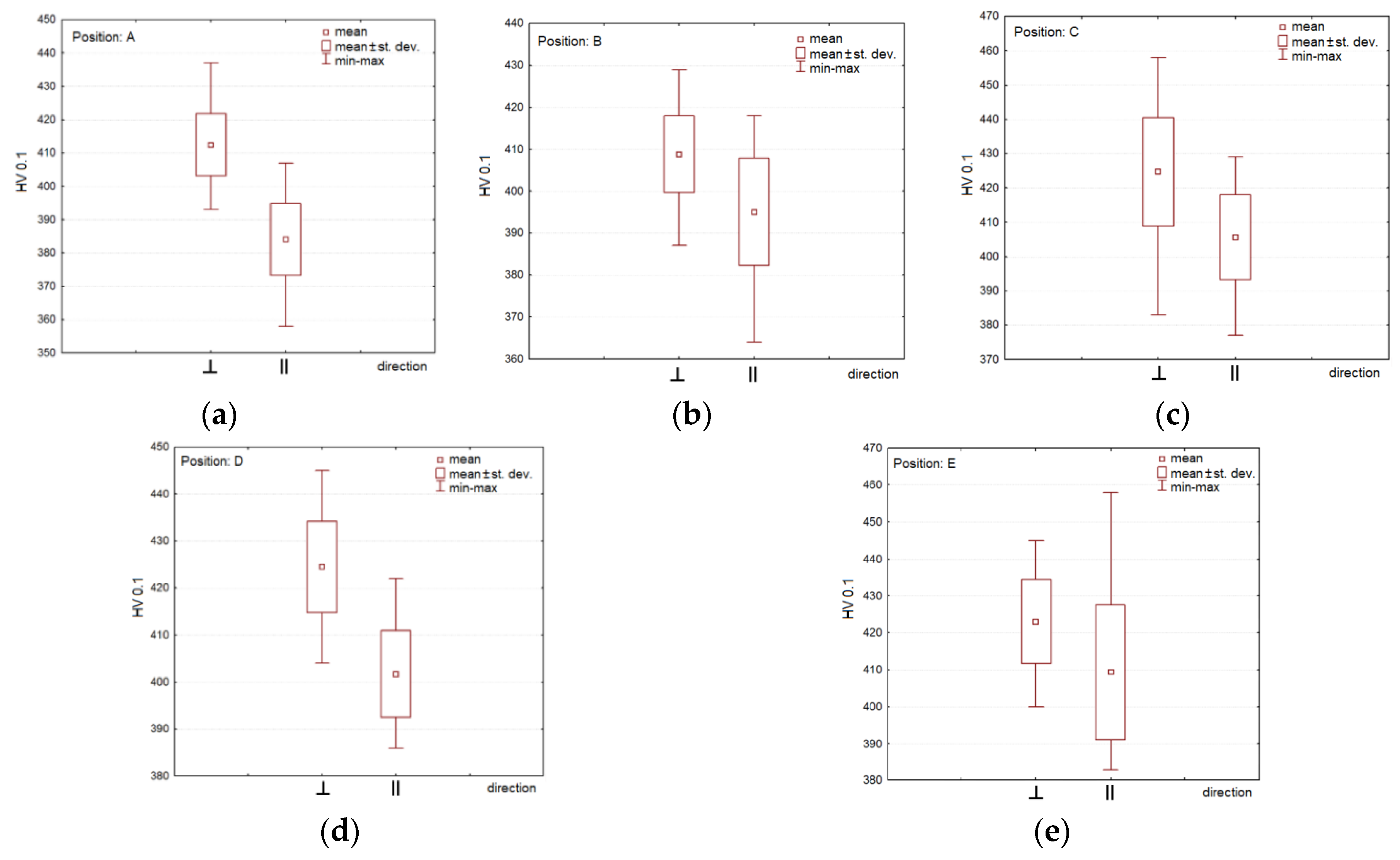

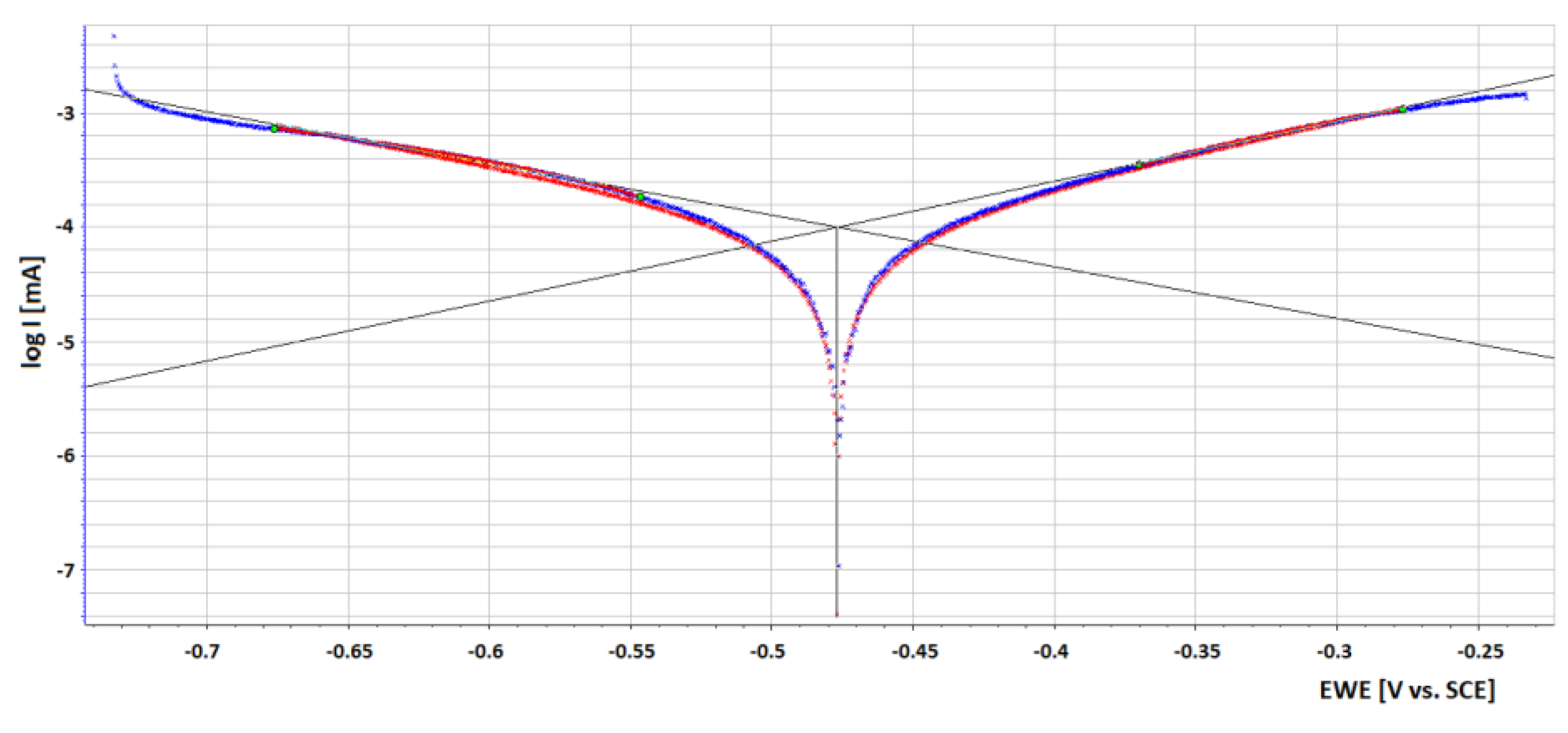

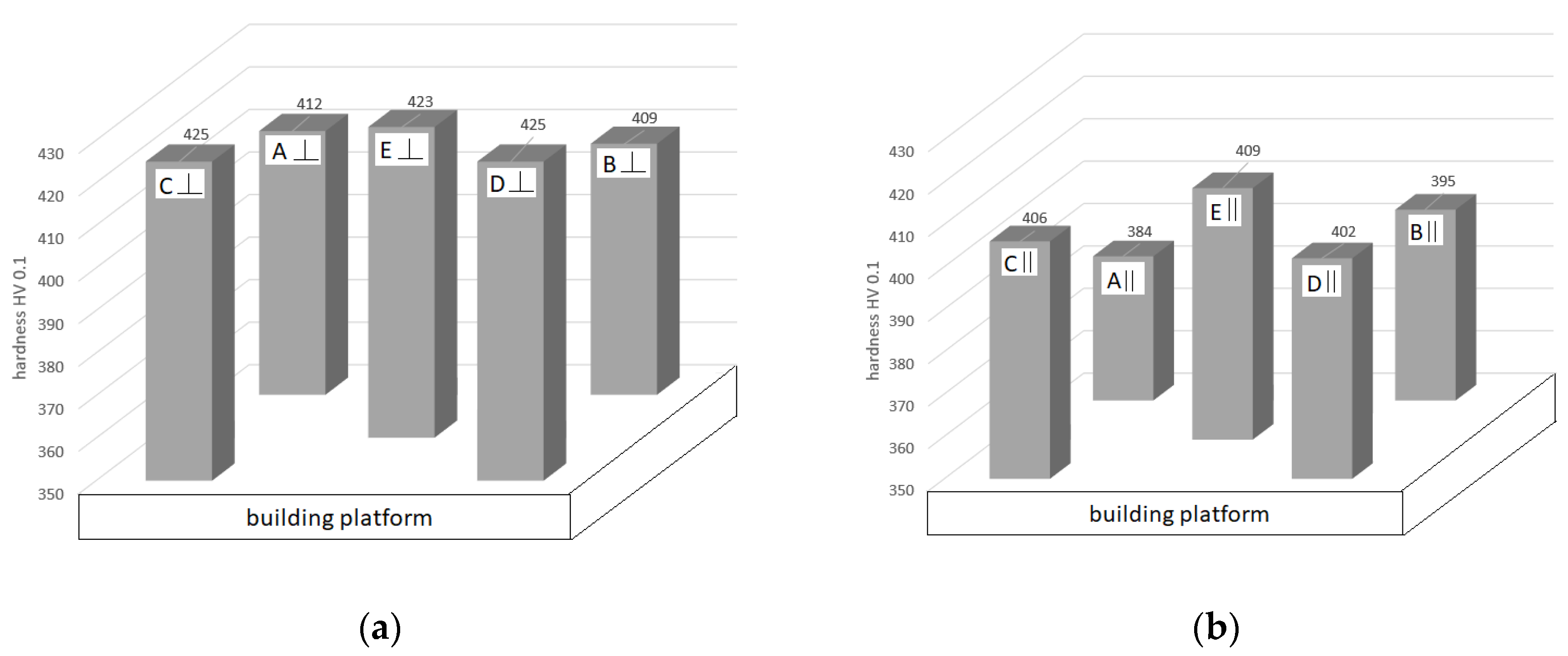

3.2. Statistical Analysis of Hardness

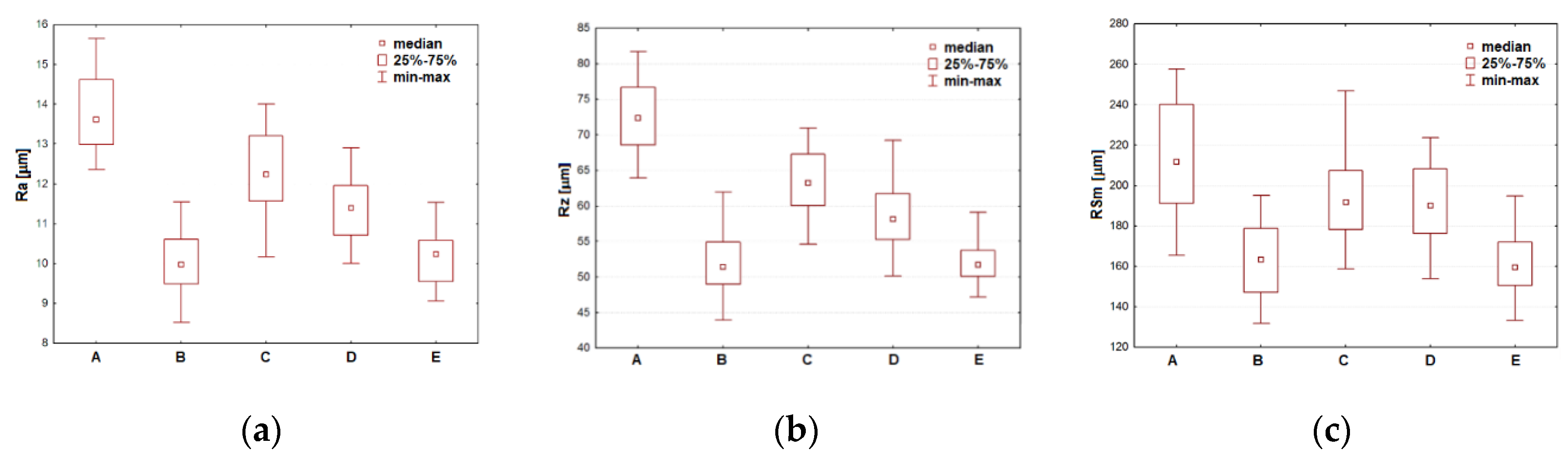

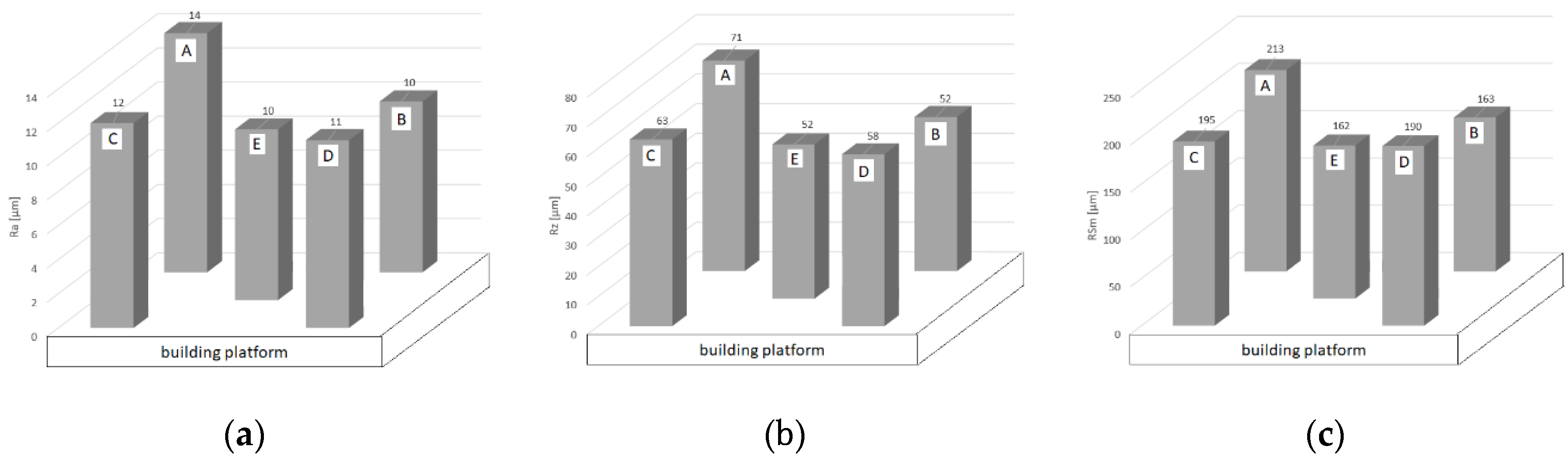

3.3. Statistical Analysis of Roughness

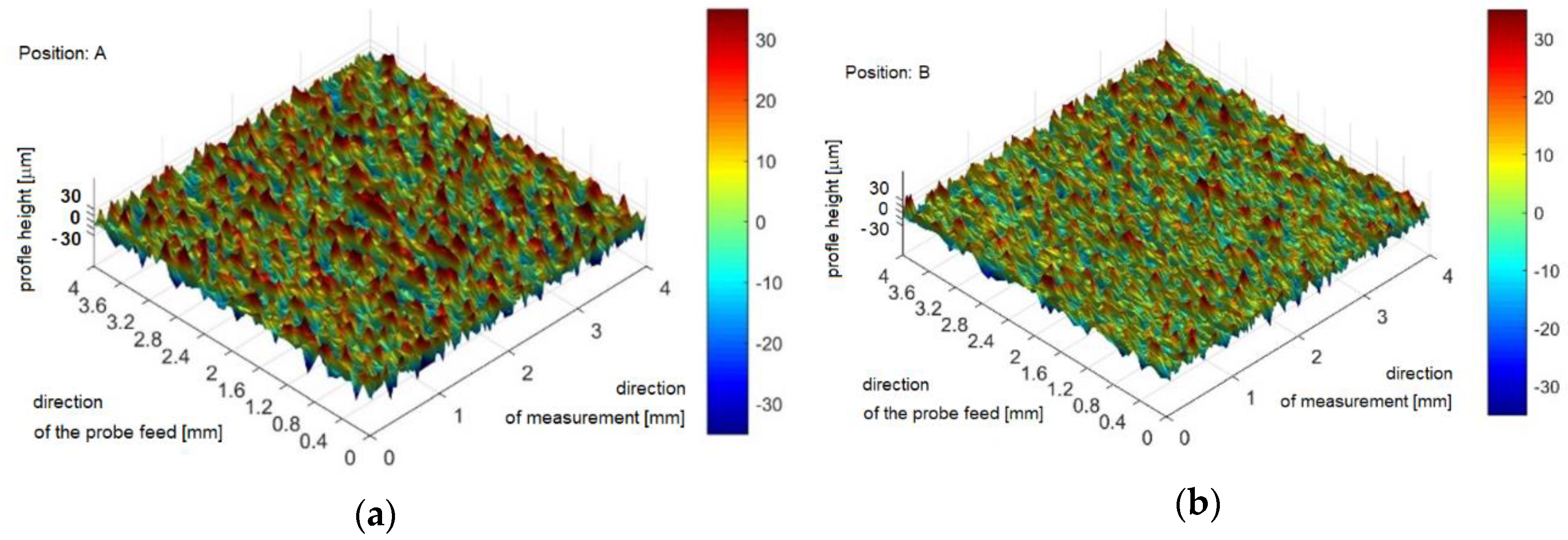

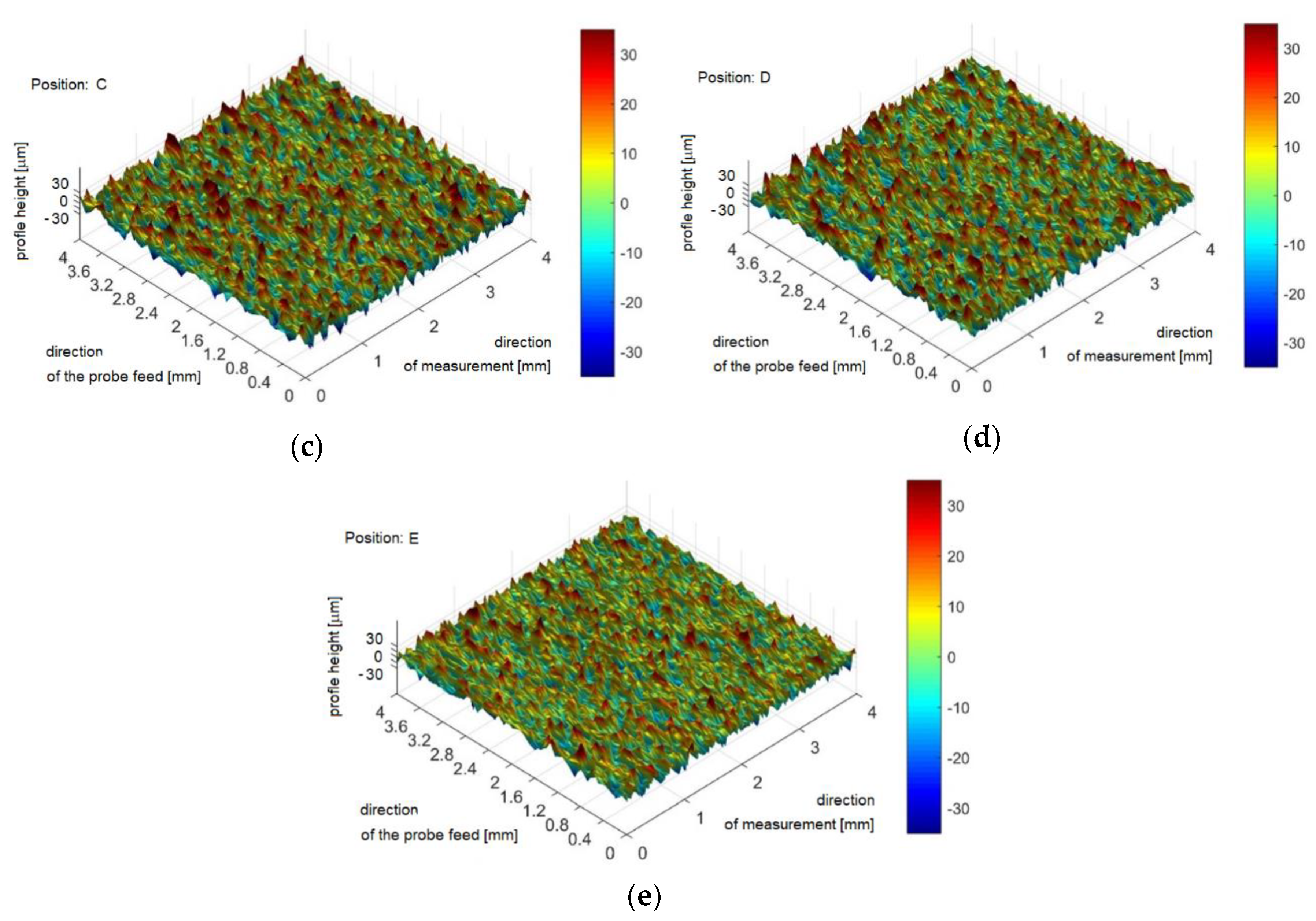

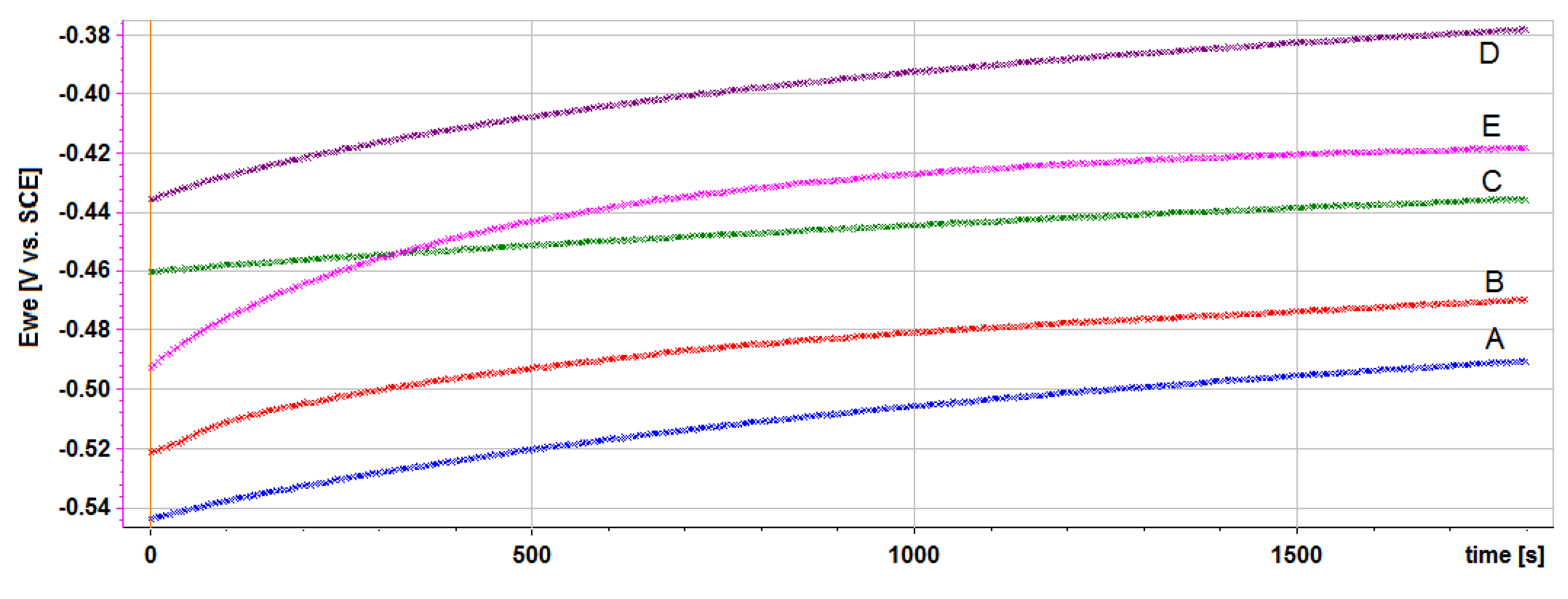

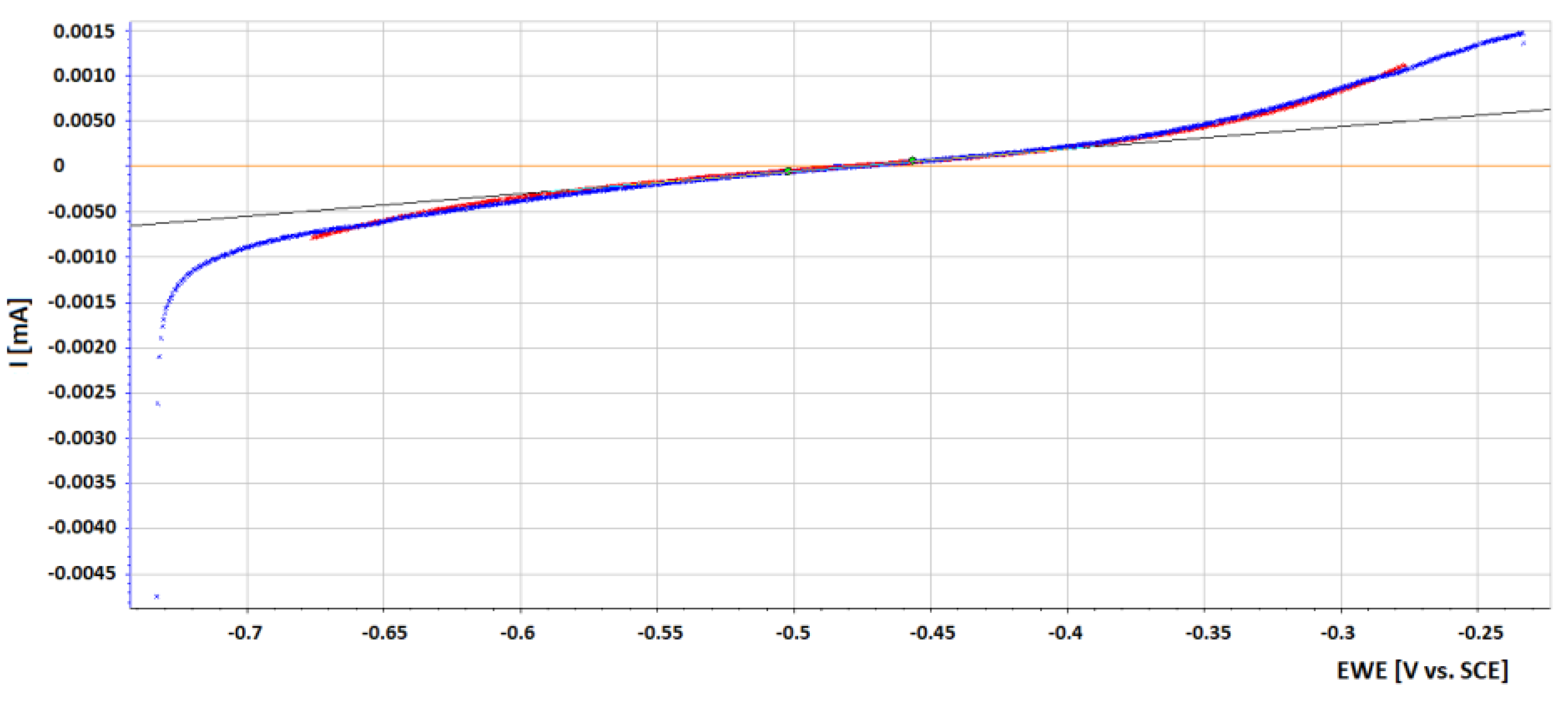

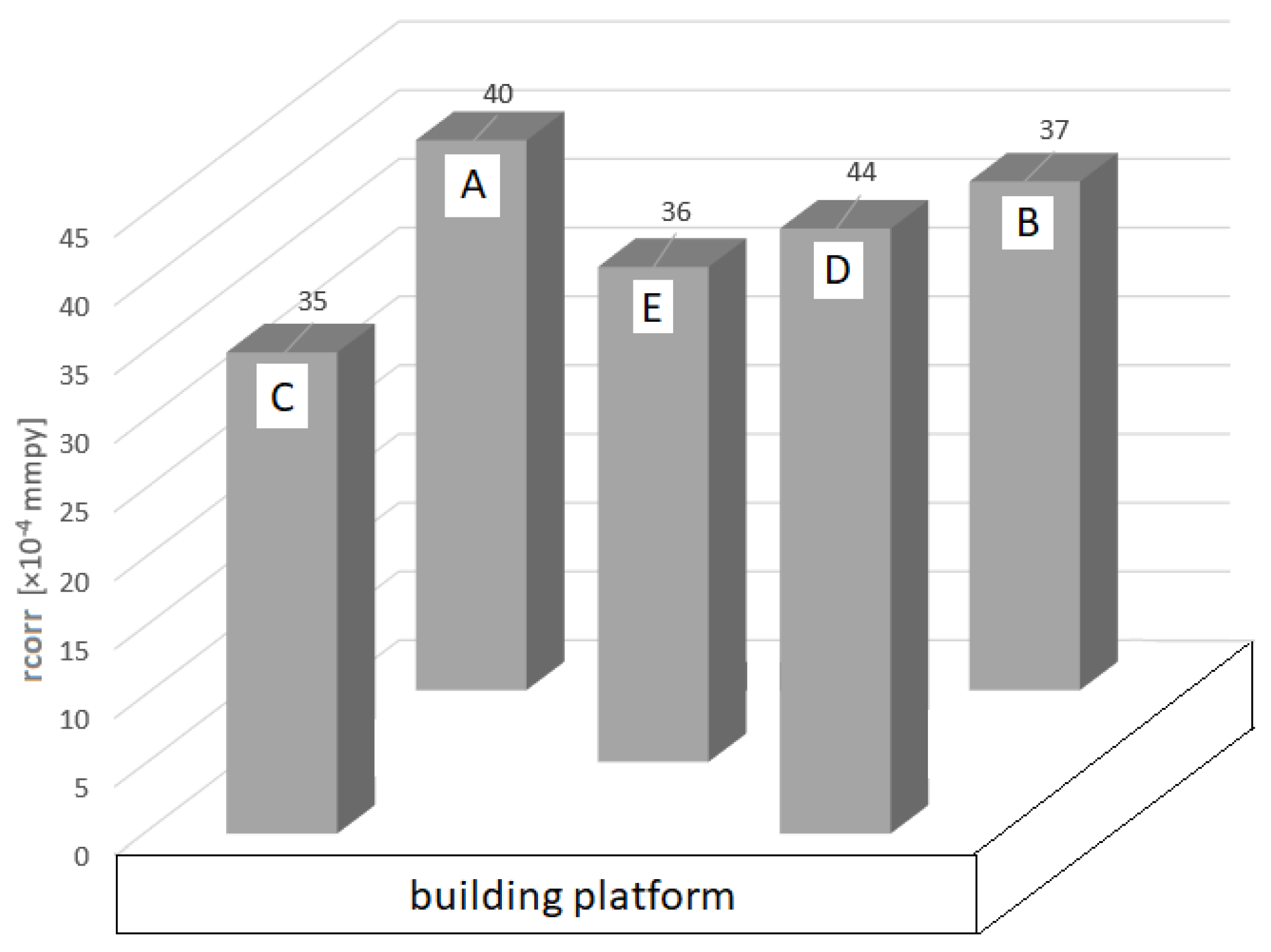

3.4. Measurement of Corrosion Properties

4. Discussion

4.1. Microhardness of Material

4.2. Roughness of Material

4.3. Corrosion Resistance of Material

5. Conclusions

- Microstructure: Material produced by DMLS technology under the given conditions contained fine Widmanstätten α′-martensite needles in primary β grains. The material contained a few gas micropores, and lack-of-fusion pores were not identified. This proves that parameters were sufficient for the creation of a compact, fully fused structure. In the direction parallel to fused layers, almost equiaxial grains of very close diameter oriented in the laying direction were observed. In the direction perpendicular to fused layers, the dominant β grains grew across several sintered layers. No change in microstructure in relation to position was observed.

- Hardness: In both directions assessed, there was a statistically significant difference between the mean values of hardness in all positions on the platform. In the direction perpendicular to fused layers, the mean hardness in positions A and B differed significantly from the mean hardness in positions C, D, and E. The hardness value in the direction parallel to fused layers in position A differed significantly from all other positions, position B differed from all other positions except D, position C differed from A and B, position D from A, and position E differed most from positions A and B. The mean hardness values in the parallel direction (408–425 HV 0.1) were lower than in the perpendicular direction (384–409 HV 0.1) in all positions on the platform. The hardness of Ti6Al4V samples in two perpendicular directions showed a statistically significant difference at the α significance level at each position.

- Roughness: Values of roughness parameters varied as follows within the studied positions: Ra 10–14 µm, Rz 52–70 µm, RSm 160–213 µm. Pairs of close values that did not exhibit statistically significant differences are: for Ra positions, B–E and C–D, for Rz positions, B-E, and for RSm positions, A–C, A–D, B–E, and C–D.

- Corrosion characteristics: The course of the open circuit potential indicates that anodic reaction controls the electrochemical process, and a protective titanium oxide layer begins to form on the surface. rcorr values indicate the existence of a protective passive film on the alloy surface. It ranged between 3.5–4.4 × 10−3 mmpy in particular positions; significant differences in the corrosion rate of as-built material in individual sectors on the plate were not observed.

Author Contributions

Funding

Conflicts of Interest

References

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Damborenea, J.J.; Larosa, M.A.; Arenas, M.A.; Hernández-López, J.M.; Jardini, A.L.; Ierardi, M.C.F.; Zavaglia, C.A.C.; Filho, R.M.; Conde, A. Functionalization of Ti6Al4V scaffolds produced by direct metal laser for biomedical applications. Mater. Des. 2015, 83, 6–13. [Google Scholar] [CrossRef]

- Palmquist, A.; Shah, F.A.; Emanuelsson, L.; Omar, O.; Suska, F. A technique for evaluating bone ingrowth into 3D printed, porous Ti6Al4V implants accurately using X-ray micro-computed tomography and histomorphometry. Micron 2017, 94, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Wauthle, R.; Vrancken, B.; Beynaerts, B.; Jorissen, K.; Schrooten, J.; Kruth, J.P.; Humbeeck, J.V. Effects of build orientation and heat treatment on the microstructure and mechanical properties of selective laser melted Ti6Al4V lattice structures. Addit. Manuf. 2015, 5, 77–84. [Google Scholar] [CrossRef]

- Cuadrado, A.; Yánez, A.; Martel, O.; Deviaene, S.; Monopoli, D. Influence of load orientation and of types of loads on the mechanical properties of porous Ti6Al4V biomaterials. Mater. Des. 2017, 135, 309–318. [Google Scholar] [CrossRef]

- Bartolomeu, F.; Costa, M.M.; Gomes, J.R.; Alves, N.; Abreu, C.S.; Silva, F.S.; Miranda, G. Implant surface design for improved implant stability—A study on Ti6Al4V dense and cellular structures produced by Selective Laser Melting. Tribol. Int. 2019, 129, 272–282. [Google Scholar] [CrossRef]

- Weißmann, V.; Bader, R.; Hansmann, H.; Laufer, N. Influence of the structural orientation on the mechanical properties of selective laser melted Ti6Al4V open-porous scaffolds. Mater. Des. 2016, 95, 188–197. [Google Scholar] [CrossRef]

- Saxena, A.K.; Tewari, A.; Pant, P. Quantitative analysis of orientation and near neighbor interaction effects during deformation of polycrystalline Ti6Al4V. Mater. Sci. Eng. A 2015, 648, 1–8. [Google Scholar] [CrossRef]

- Konečná, R.; Kunz, L.; Bača, A.; Nicoletto, G. Resistance of direct metal laser sintered Ti6Al4V alloy against growth of fatigue cracks. Eng. Fract. Mech. 2017, 185, 82–91. [Google Scholar] [CrossRef]

- Syed, A.K.; Ahmad, B.; Guo, H.; Machry, T.; Eatock, D.; Meyer, J.; Fitzpatrick, M.E.; Zhang, X. An experimental study of residual stress and direction-dependence of fatigue crack growth behaviour in as-built and stress-relieved selective-laser-melted Ti6Al4V. Mater. Sci. Eng. A 2019, 755, 246–257. [Google Scholar] [CrossRef]

- Nicoletto, G.; Konečná, R.; Frkáň, M.; Riva, E. Surface roughness and directional fatigue behavior of as-built EBM and DMLS Ti6Al4V. Int. J. Fatigue 2018, 116, 140–148. [Google Scholar] [CrossRef]

- Konečná, R.; Kunz, L.; Bača, A.; Nicoletto, G. Long fatigue crack growth in Ti6Al4V produced by direct metal laser sintering. Procedia Eng. 2016, 160, 69–76. [Google Scholar] [CrossRef]

- Bača, A.; Konečná, R.; Nicoletto, G.; Kunz, L. Influence of build direction on the fatigue behaviour of Ti6Al4V alloy produced by direct metal laser sintering. Mater. Today Proc. 2016, 3, 921–924. [Google Scholar] [CrossRef]

- Brezinová, J.; Hudák, R.; Guzanová, A.; Draganovská, D.; Ižaríková, G.; Koncz, J. Direct Metal Laser Sintering of Ti6Al4V for Biomedical Applications: Microstructure, Corrosion Properties, and Mechanical Treatment of Implants. Metals 2016, 6, 171. [Google Scholar] [CrossRef]

- Wang, Q.; Bruschi, S.; Ghiotti, A.; Mu, Y. Modelling of fracture occurrence in Ti6Al4V sheets at elevated temperature accounting for anisotropic behavior. Int. J. Mech. Sci. 2019, 150, 471–483. [Google Scholar] [CrossRef]

- Design Guidelines for Direct Metal Laser Sintering (DMLS). Available online: https://www.crucibledesign.co.uk/images/uploaded/guides/bs7000-part-2-a-management-guide-download-original.pdf (accessed on 11 May 2019).

- Grasso, M.; Colosimo, B.M. Process defects and in situ monitoring methods in metal powder bed fusion: A review. Meas. Sci. Technol. 2017, 28, 044005. [Google Scholar] [CrossRef]

- Venkatesh, K.V.; Nandini, V.V. Direct Metal Laser Sintering: A digitised metal casting technology. J. Indian Prosthodont. Soc. 2013, 13, 389–392. [Google Scholar] [CrossRef]

- Agius, D.; Kourousis, K.I.; Wallbrink, C. A Review of the as-built SLM Ti-6Al-4V mechanical properties towards achieving fatigue resistant designs. Metals 2018, 8, 75. [Google Scholar] [CrossRef]

- Sun, D.; Gu, D.; Lin, K.; Ma, J.; Chen, W.; Huang, J.; Sun, X.; Chu, M. Selective laser melting of titanium parts: Influence of laser process parameters on macro- and microstructures and tensile property. Powder Technol. 2019, 342, 371–379. [Google Scholar] [CrossRef]

- Fox, J.C.; Moylan, S.P.; Lane, B.M. Effect of process parameters on the surface roughness of overhanging structures in laser powder bed fusion additive manufacturing. Procedia CIRP 2016, 45, 131–134. [Google Scholar] [CrossRef]

- Hanzl, P.; Zetek, M.; Bakša, T.; Kroupa, T. The influence of processing parameters on the mechanical properties of SLM parts. Procedia Eng. 2015, 100, 1405–1413. [Google Scholar] [CrossRef]

- Öter, Z.; Coşkun, M.; Koç, E. Effect of Building Platform Position on the Surface Quality, Dimensional Accuracy, and Geometrical Precision of Direct Metal Laser Sintering (DMLS) Parts. In Proceedings of the Euro PM2018-AM Beam Based II, Bilbao, Spain, 14–18 October 2018. [Google Scholar]

- Tan, J.H.; Wong, W.L.E.; Dalgarno, K.W. An overview of powder granulometry on feedstock and part performance in the selective laser melting process. Addit. Manuf. 2017, 18, 228–255. [Google Scholar] [CrossRef]

- Leyens, C.H.; Peters, M. Titanium and Titanium Alloys: Fundamentals and Applications; WILEY-VCH Verlag GmbH & Co. KGaA: Weinheim, Gremany, 2003. [Google Scholar]

- ASTM F136-11. Standard Specification for Wrought Titanium-6Aluminum-4Vanadium ELI (Extra Low Interstitial) Alloy for Surgical Implant Applications (UNS R56401). Available online: https://webstore.ansi.org/standards/astm/astmf13611 (accessed on 17 June 2019).

- Fundamental of Statistics. Shapiro-Wilk Test. Available online: http://www.statistics4u.info/fundstat_eng/ee_shapiro_wilk_test.html (accessed on 24 April 2019).

- Raju, R.; Duraiselvam, M.; Petley, V.; Verma, S.; Rajendran, R. Microstructural and mechanical characterization of Ti6Al4V refurbished parts obtained by laser metal deposition. Mater. Sci. Eng. A 2015, 643, 64–71. [Google Scholar] [CrossRef]

- Wu, B.; Pan, Z.; Li, S.; Cuiuri, D.; Ding, D.; Li, H. The anisotropic corrosion behaviour of wire arc additive manufactured Ti-6Al-4V alloy in 3.5% NaCl solution. Corros. Sci. 2018, 137, 176–183. [Google Scholar] [CrossRef]

- Hong, K.M.; Shin, Y.C. Analysis of microstructure and mechanical properties change in laser welding of Ti6Al4V with a multiphysics prediction model. J. Mater. Process. Technol. 2016, 237, 420–429. [Google Scholar] [CrossRef]

- Guzanová, A.; Ižaríková, G.; Brezinová, J.; Živčák, J.; Draganovská, D.; Hudák, R. Influence of build orientation, heat treatment, and laser power on the hardness of Ti6Al4V manufactured using the DMLS process. Metals 2017, 7, 318. [Google Scholar] [CrossRef]

- Miranda, G.; Faria, S.; Bartolomeu, F.; Pinto, E.; Alves, N.; Peixinho, N.; Gasik, M.; Silva, F.S. A study on the production of thin-walled Ti6Al4V parts by selective laser melting. J. Manuf. Process. 2019, 39, 346–355. [Google Scholar] [CrossRef]

- Zhou, G.; Bi, Y.; Ma, Y.; Wang, L.; Wang, X.; Yu, Y.; Mutzke, A. Large current ion beam polishing and characterization of mechanically finished titanium alloy (Ti6Al4V) surface. Appl. Surf. Sci. 2019, 476, 905–913. [Google Scholar] [CrossRef]

- Kümmel, D.; Hamann-Schroer, M.; Hetzner, H.; Schneider, J. Tribological behavior of nanosecond-laser surface textured Ti6Al4V. Wear 2019, 422–423, 261–268. [Google Scholar] [CrossRef]

- Sidambe, A.T. Three dimensional surface topography characterization of the electron beam melted Ti6Al4V. Met. Powder Rep. 2017, 72, 200–205. [Google Scholar] [CrossRef]

- Draganovská, D.; Ižaríková, G.; Guzanová, A.; Brezinová, J. General regression model for predicting surface topography after abrasive blasting. Metals 2018, 8, 938. [Google Scholar] [CrossRef]

- Longhitano, G.A.; Larosa, M.A.; Munhoz, A.L.J.; Zavaglia, C.A.C.; Ierardi, M.C.F. Surface finishes for Ti-6Al-4V alloy produced by direct metal laser sintering. Mater. Res. 2015, 18, 838–842. [Google Scholar] [CrossRef]

- Mierzejewska, Z.A.; Hudák, R.; Sidun, J. Mechanical properties and microstructure of DMLS Ti6Al4V alloy dedicated to biomedical applications. Materials 2019, 12, 176. [Google Scholar] [CrossRef] [PubMed]

- Milton, S.; Morandeau, A.; Chalon, F.; Leroy, R. Influence of finish machining on the surface integrity of Ti6Al4V produced by Selective Laser Melting. Procedia CIRP 2016, 45, 127–130. [Google Scholar] [CrossRef]

- Li, J.; Lin, X.; Wang, J.; Zheng, M.; Guo, P.; Zhang, Y.; Ren, Y.; Liu, J.; Huang, W. Effect of stress-relief annealing on anodic dissolution behaviour of additive manufactured Ti-6Al-4V via laser solid forming. Corros. Sci. 2019, 153, 314–326. [Google Scholar] [CrossRef]

- Benea, L.; Celis, J.P. Reactivity of porous titanium oxide film and chitosan layer electrochemically formed on Ti-6Al-4V alloy in biological solution. Surf. Coat. Technol. 2018, 354, 145–152. [Google Scholar] [CrossRef]

- Hwang, I.J.; Choe, H.C.H. Effects of Zn and Si ions on the corrosion behaviors of PEO-treated Ti-6Al-4V alloy. Appl. Surf. Sci. 2019, 477, 79–90. [Google Scholar] [CrossRef]

- Simsek, I.; Ozyurek, D. Investigation of the wear and corrosion behaviors of Ti5Al2.5Fe andTi6Al4V alloys produced by mechanical alloying method in simulated body fluid environment. Mater. Sci. Eng. C 2019, 94, 357–363. [Google Scholar] [CrossRef]

- Toptan, F.; Alves, A.C.; Carvalho, Ó.; Bartolomeu, F.; Pinto, A.M.P.; Silva, F.; Miranda, G. Corrosion and tribocorrosion behaviour of Ti6Al4V produced by selective laser melting and hot pressing in comparison with the commercial alloy. J. Mater. Process. Technol. 2019, 266, 239–245. [Google Scholar] [CrossRef]

- Huo, W.T.; Zhao, L.Z.; Zhang, W.; Lu, J.W.; Zhao, Y.Q.; Zhang, Y.S. In vitro corrosion behavior and biocompatibility of nanostructured Ti6Al4V. Mater. Sci. Eng. C 2018, 92, 268–279. [Google Scholar] [CrossRef] [PubMed]

- Yu, F.; Addison, O.; Davenport, A.J. A synergistic effect of albumin and H2O2 accelerates corrosion of Ti6Al4V. Acta Biomater. 2015, 26, 355–365. [Google Scholar] [CrossRef] [PubMed]

- Poursaee, A. Corrosion of Ti6Al4V orthopaedic alloy under stress. Materialia 2019, 6, 100271. [Google Scholar] [CrossRef]

- Xu, Y.; Li, Z.; Zhang, G.; Wang, G.; Zeng, Z.; Wang, C.H.; Wang, C.H.; Zhao, S.; Zhang, Y.; Ren, T. Electrochemical corrosion and anisotropic tribological properties of bioinspired hierarchical morphologies on Ti-6Al-4V fabricated by laser texturing. Tribol. Int. 2019, 134, 352–364. [Google Scholar] [CrossRef]

| Count | Mean | Median | Mode | Mode Freq. | Min | Max | Variability | St. Dev. | Coef. Var. | Skew | Kurt | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A⊥ | 30 | 412.43 | 411 | Mult. | 6 | 393 | 437 | 86.67 | 9.31 | 2.26 | 0.58 | 1.33 |

| A‖ | 30 | 384.10 | 383 | 383 | 7 | 358 | 407 | 116.37 | 10.78 | 2.81 | −0.44 | 0.67 |

| B⊥ | 30 | 408.83 | 407 | Mult. | 6 | 387 | 429 | 83.79 | 9.15 | 2.24 | 0.29 | 0.65 |

| B‖ | 30 | 395.03 | 397 | Mult. | 5 | 364 | 418 | 164.45 | 12.82 | 3.25 | −0.67 | 0.02 |

| C⊥ | 30 | 424.73 | 426 | Mult. | 6 | 383 | 458 | 249.78 | 15.80 | 3.72 | −0.98 | 1.63 |

| C‖ | 30 | 405.63 | 405.5 | 414 | 6 | 377 | 429 | 152.72 | 12.35 | 3.05 | −0.16 | −0.43 |

| D⊥ | 30 | 424.50 | 426 | 429 | 6 | 404 | 445 | 94.26 | 9.71 | 2.28 | 0.14 | −0.28 |

| D‖ | 30 | 401.70 | 404 | Mult. | 6 | 386 | 422 | 85.18 | 9.23 | 2.29 | 0.07 | −0.51 |

| E⊥ | 30 | 423.03 | 426 | 426 | 8 | 400 | 445 | 126.24 | 11.24 | 2.66 | -0.27 | −0.04 |

| E‖ | 30 | 409.33 | 405.5 | Mult. | 4 | 383 | 458 | 330.71 | 18.18 | 4.44 | 1.10 | 1.20 |

| Position/Direction | Test Statistic W | p-Value | Table Critical Threshold Wα = 0.9269 | Hyp: H0 |

|---|---|---|---|---|

| A ⊥ | 0.95 | 0.15 | W > Wα | Accepted |

| A ‖ | 0.97 | 0.47 | ||

| B ⊥ | 0.95 | 0.21 | ||

| B ‖ | 0.95 | 0.15 | ||

| C ⊥ | 0.93 | 0.08 | ||

| C ‖ | 0.97 | 0.64 | ||

| D ⊥ | 0.97 | 0.49 | ||

| D ‖ | 0.95 | 0.21 | ||

| E ⊥ | 0.96 | 0.25 | ||

| E ‖ | 0.94 | 0.06 |

| Direction | SS | DF | MS | SS Error | DF Error | MS Error | F-Statistic | p-Value |

|---|---|---|---|---|---|---|---|---|

| ⊥ | 6763.23 | 4 | 1690.81 | 18,581.87 | 145 | 128.15 | 13.19 | 0 |

| ‖ | 11,870.56 | 4 | 2967.64 | 24,633.60 | 145 | 169.89 | 17.47 | 0 |

| ⊥ | A | B | C | D | E |

| A | - | 0.7328 | <0.0005 | <0.0005 | 0.0027 |

| B | 0.7328 | - | <0.0005 | <0.0005 | <0.0005 |

| C | <0.0005 | <0.0005 | - | 0.9999 | 0.9778 |

| D | <0.0005 | <0.0005 | 0.9999 | - | 0.9872 |

| E | 0.0027 | <0.0005 | 0.9778 | 0.9872 | - |

| ‖ | A | B | C | D | E |

| A | - | 0.0102 | <0.0005 | <0.0005 | <0.0005 |

| B | 0.0102 | - | 0.0141 | 0.2753 | <0.0005 |

| C | <0.0005 | 0.0141 | - | 0.7693 | 0.8069 |

| D | <0.0005 | 0.2753 | 0.7693 | - | 0.1553 |

| E | <0.0005 | <0.0005 | 0.8069 | 0.1553 | - |

| Direction | Mean of ⊥ | Mean of ‖ | t-Value | p-Value |

|---|---|---|---|---|

| A ⊥ vs. ‖ | 412.43 | 384.10 | 10.89 | 0 |

| B ⊥ vs. ‖ | 408.83 | 395.03 | 4.79 | <0.0005 |

| C ⊥ vs. ‖ | 424.73 | 405.63 | 5.21 | <0.0005 |

| D ⊥ vs. ‖ | 424.50 | 401.70 | 9.32 | 0 |

| E ⊥ vs. ‖ | 423.03 | 409.33 | 3.51 | 0.0009 |

| Factor | SS | DF | MS | F-Statistic | p-Value |

|---|---|---|---|---|---|

| Positions | 16,306 | 4 | 4076 | 27.4 | 0 |

| Directions | 28,655 | 1 | 28,655 | 192.3 | 0 |

| Positions × Directions | 2328 | 4 | 582 | 3.9 | 0.0042 |

| Position | Ra [µm] | Rz [µm] | RSm [µm] |

|---|---|---|---|

| A | 13.86 ± 0.91 | 70.54 ± 1.97 | 213.03 ± 11.98 |

| B | 10.02 ± 0.82 | 52.29 ± 4.62 | 162.86 ± 18.11 |

| C | 12.31 ± 1.07 | 63.45 ± 4.39 | 195.36 ± 22.95 |

| D | 11.39 ± 0.78 | 58.45 ± 4.19 | 190.37 ± 20.56 |

| E | 10.11 ± 0.71 | 52.39 ± 3.06 | 161.89 ± 15.19 |

| Ra | A | B | C | D | E |

| A | - | 0 | 0.0094 | 0 | 0 |

| B | 0 | - | 0 | <0.0005 | 1 |

| C | 0.0094 | 0 | - | 0.1762 | 0 |

| D | 0 | <0.0005 | 0.1762 | - | <0.0005 |

| E | 0 | 1 | 0 | <0.0005 | - |

| Rz | A | B | C | D | E |

| A | - | 0 | 0.0099 | 0 | 0 |

| B | 0 | - | 0 | 0.0010 | 1 |

| C | 0.0099 | 0 | - | 0.0488 | 0 |

| D | 0 | 0.0010 | 0.0488 | - | 0.0007 |

| E | 0 | 1 | 0 | 0.0007 | - |

| RSm | A | B | C | D | E |

| A | - | 0 | 0.3682 | 0.0821 | 0 |

| B | 0 | - | 0 | <0.0005 | 1 |

| C | 0.3682 | 0 | - | 1 | 0 |

| D | 0.0821 | <0.0005 | 1 | - | <0.0005 |

| E | 0 | 1 | 0 | <0.0005 | - |

| Position | Measurement | mV | uA | mV | mV | mmpy | Ohm |

|---|---|---|---|---|---|---|---|

| Ecorr | Icorr | bc | ba | rcorr | Rp | ||

| A | 1 | −477 | 0.10 | 221 | 190 | 0.0055 | 406,273 |

| 2 | −502 | 0.07 | 192 | 169 | 0.0037 | 521,109 | |

| 3 | −461 | 0.05 | 170 | 174 | 0.0028 | 659,221 | |

| average | −480 | 0.07 | 194 | 178 | 0.0040 | 528,868 | |

| B | 1 | −445 | 0.06 | 265 | 187 | 0.0034 | 681,194 |

| 2 | −445 | 0.04 | 203 | 182 | 0.0024 | 945,942 | |

| 3 | −489 | 0.09 | 198 | 196 | 0.0052 | 434,692 | |

| average | −460 | 0.06 | 222 | 188 | 0.0037 | 687,276 | |

| C | 1 | −432 | 0.06 | 191 | 179 | 0.0032 | 685,597 |

| 2 | −433 | 0.07 | 202 | 188 | 0.0038 | 584,907 | |

| 3 | −430 | 0.07 | 200 | 189 | 0.0035 | 502,400 | |

| average | −432 | 0.07 | 198 | 185 | 0.0035 | 590,968 | |

| D | 1 | −371 | 0.09 | 189 | 189 | 0.0052 | 374,813 |

| 2 | −405 | 0.07 | 226 | 172 | 0.0036 | 600,120 | |

| 3 | −409 | 0.08 | 213 | 174 | 0.0044 | 484,030 | |

| average | −395 | 0.08 | 209 | 178 | 0.0044 | 486,321 | |

| E | 1 | −402 | 0.05 | 225 | 164 | 0.0026 | 805,905 |

| 2 | −421 | 0.07 | 215 | 182 | 0.0037 | 581,262 | |

| 3 | −411 | 0.09 | 205 | 183 | 0.0046 | 455,848 | |

| average | −411 | 0.07 | 215 | 176 | 0.0036 | 614,338 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guzanová, A.; Draganovská, D.; Ižaríková, G.; Živčák, J.; Hudák, R.; Brezinová, J.; Moro, R. The Effect of Position of Materials on a Build Platform on the Hardness, Roughness, and Corrosion Resistance of Ti6Al4V Produced by DMLS Technology. Metals 2019, 9, 1055. https://doi.org/10.3390/met9101055

Guzanová A, Draganovská D, Ižaríková G, Živčák J, Hudák R, Brezinová J, Moro R. The Effect of Position of Materials on a Build Platform on the Hardness, Roughness, and Corrosion Resistance of Ti6Al4V Produced by DMLS Technology. Metals. 2019; 9(10):1055. https://doi.org/10.3390/met9101055

Chicago/Turabian StyleGuzanová, Anna, Dagmar Draganovská, Gabriela Ižaríková, Jozef Živčák, Radovan Hudák, Janette Brezinová, and Róbert Moro. 2019. "The Effect of Position of Materials on a Build Platform on the Hardness, Roughness, and Corrosion Resistance of Ti6Al4V Produced by DMLS Technology" Metals 9, no. 10: 1055. https://doi.org/10.3390/met9101055

APA StyleGuzanová, A., Draganovská, D., Ižaríková, G., Živčák, J., Hudák, R., Brezinová, J., & Moro, R. (2019). The Effect of Position of Materials on a Build Platform on the Hardness, Roughness, and Corrosion Resistance of Ti6Al4V Produced by DMLS Technology. Metals, 9(10), 1055. https://doi.org/10.3390/met9101055