Heat Treatments Effects on Nickel-Based Superalloy Inconel 713C

Abstract

:1. Introduction

2. Material and Methods

2.1. Material

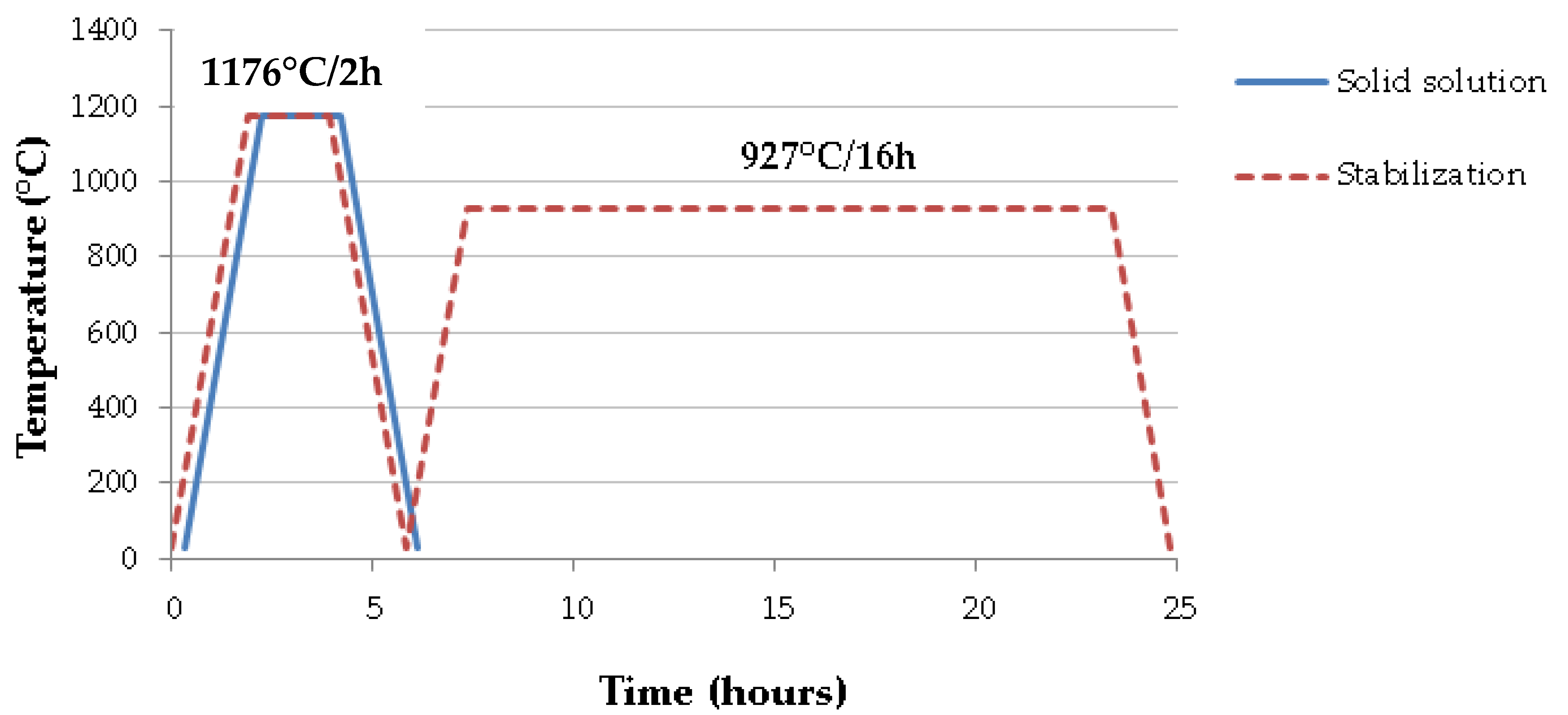

2.2. Heat Treatment

2.3. Chemical Analysis

2.4. Hardness Test

2.5. X-Ray Diffraction

2.6. Microstructural Analysis

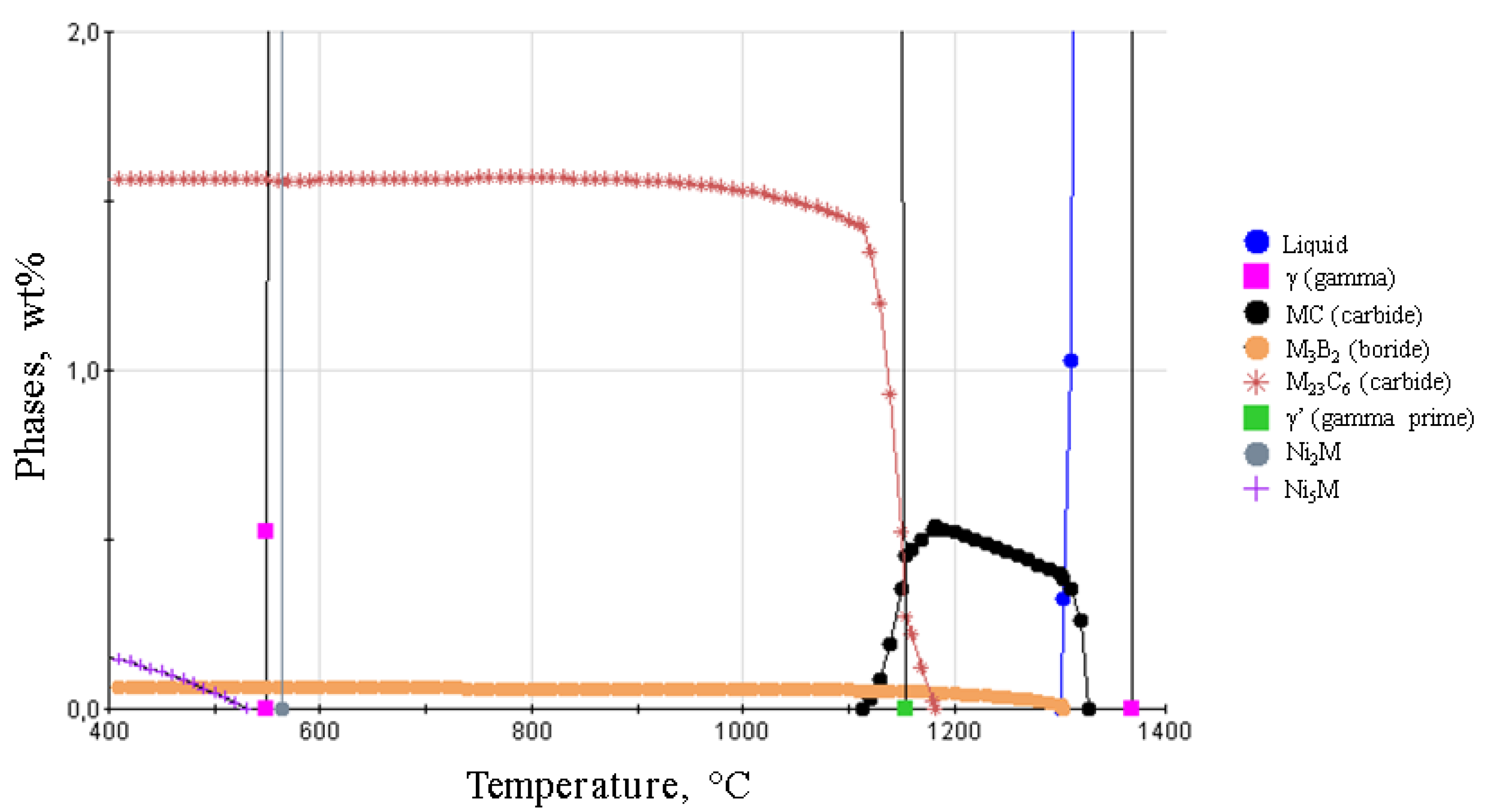

2.7. Thermocalculation

3. Results and Discussion

3.1. Chemical Analysis Results

3.2. Hardness Measurements

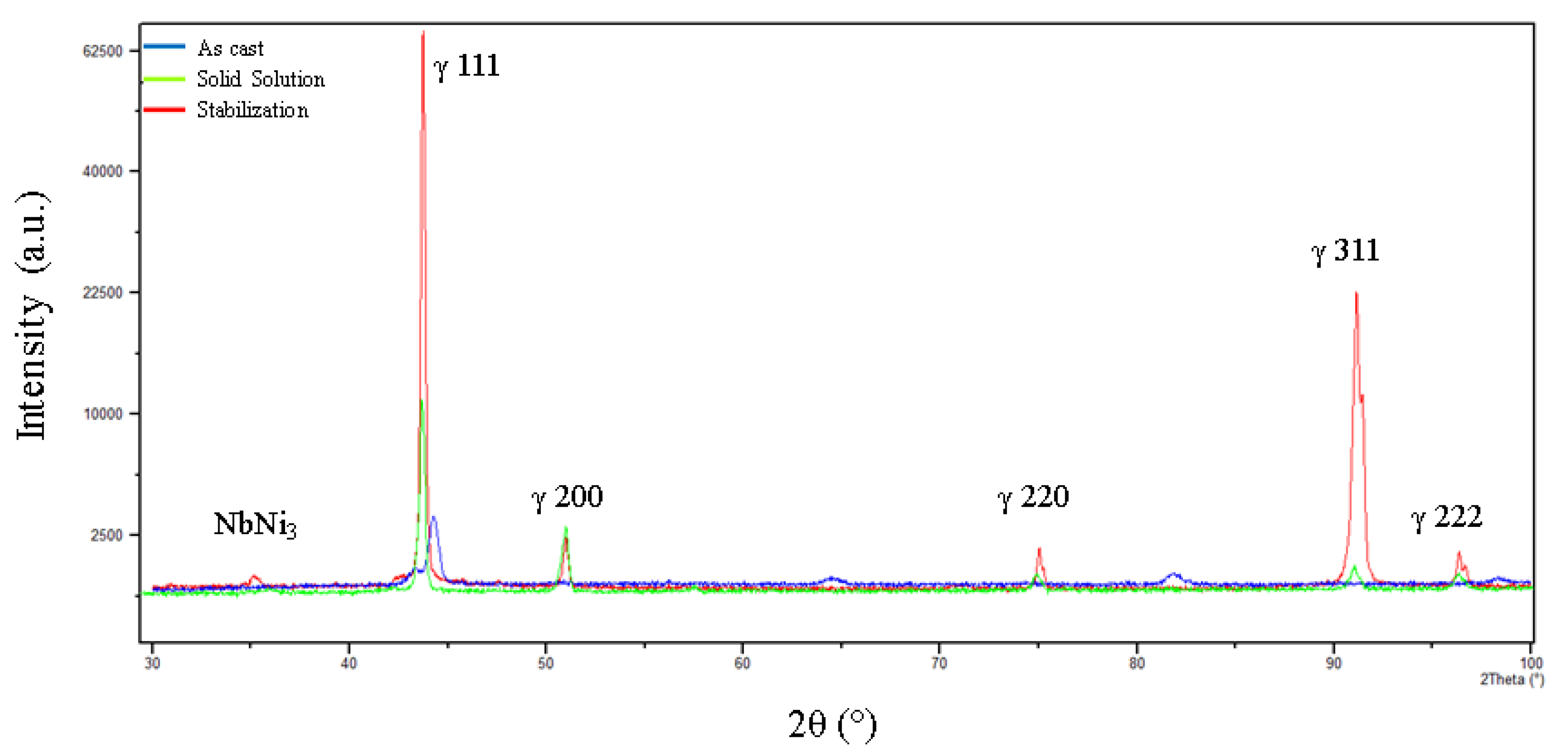

3.3. X-Ray Diffraction Results

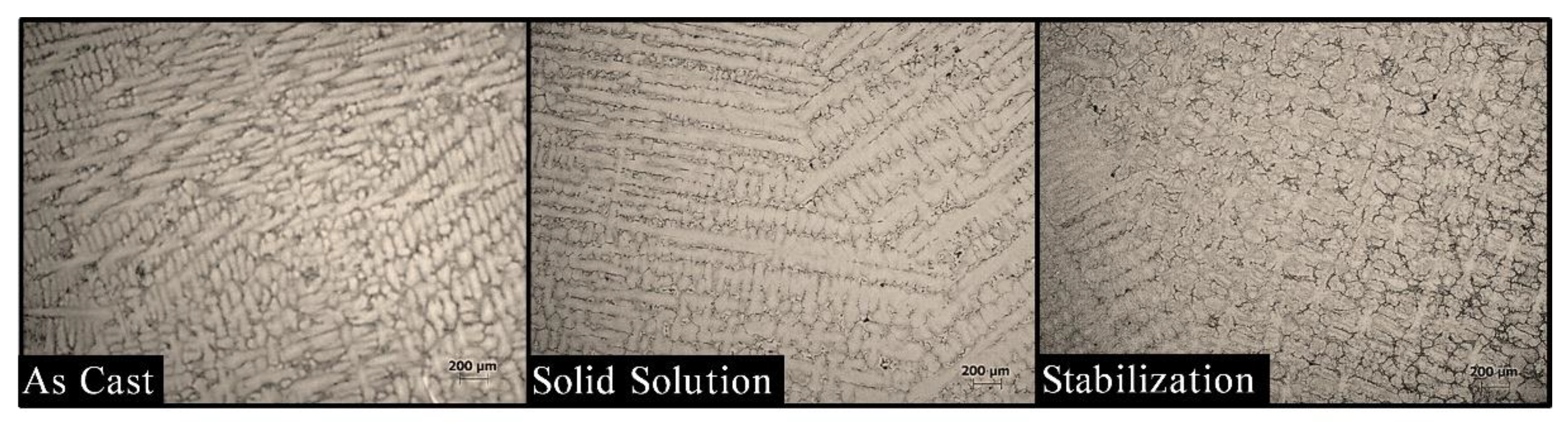

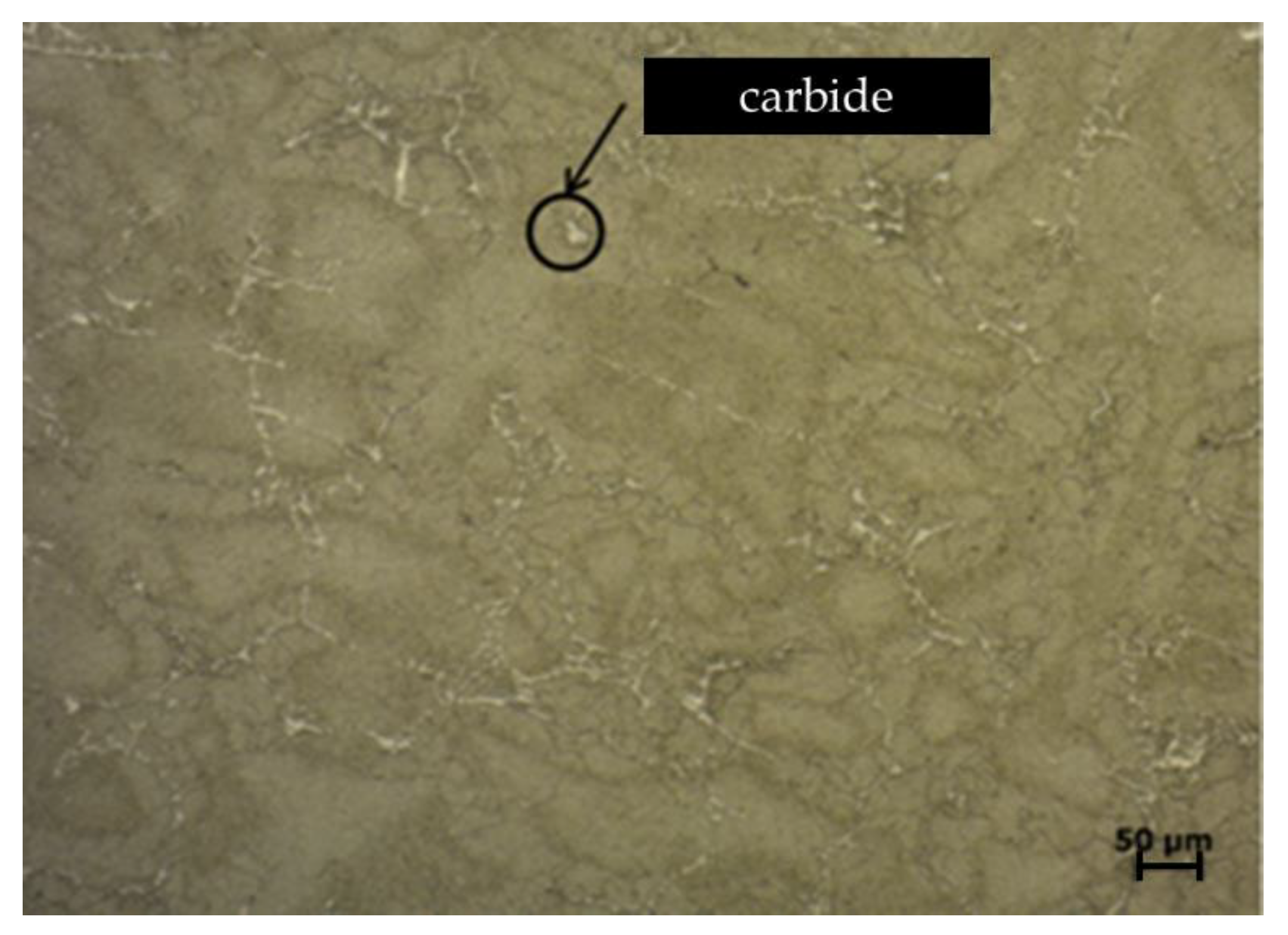

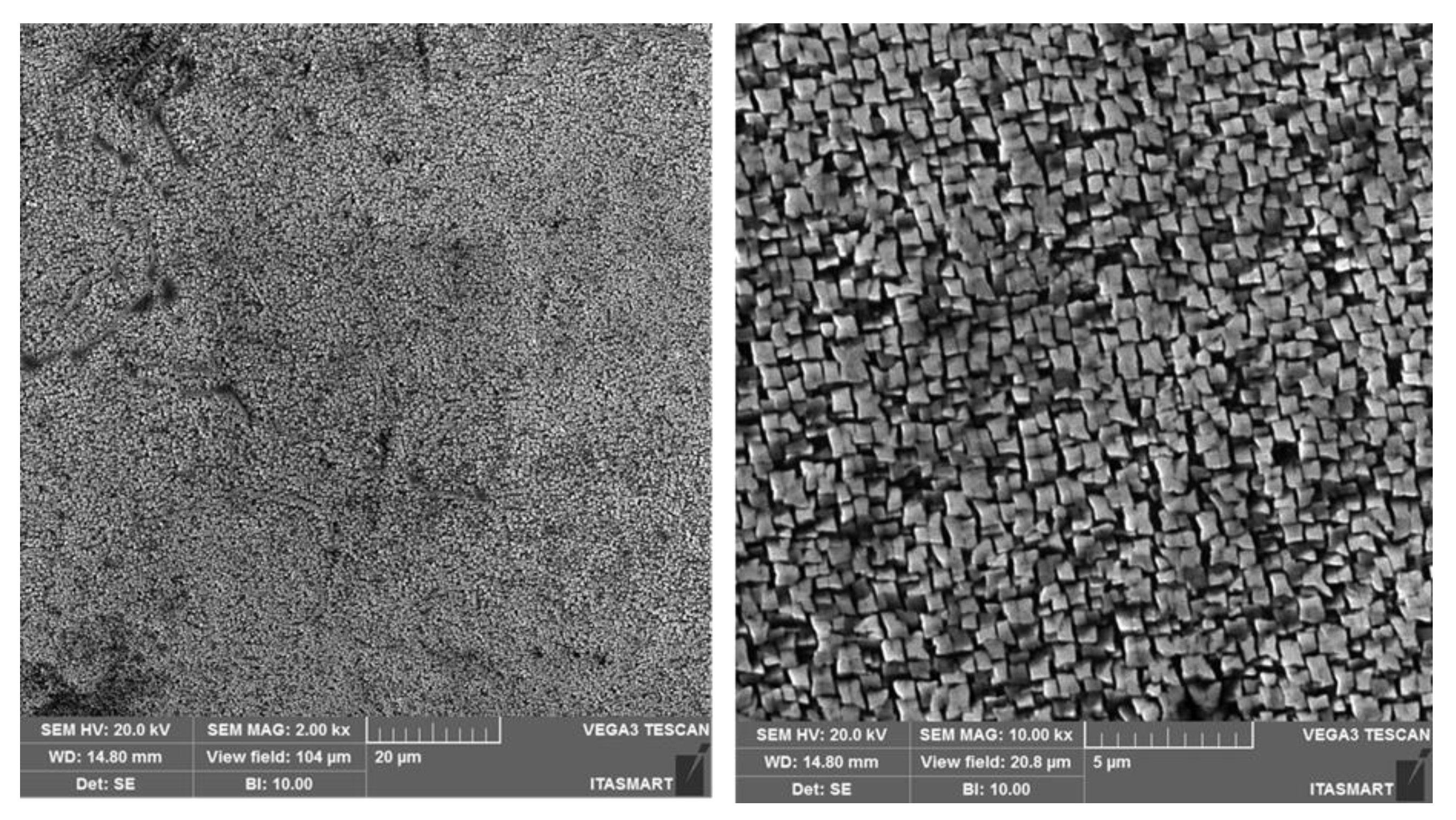

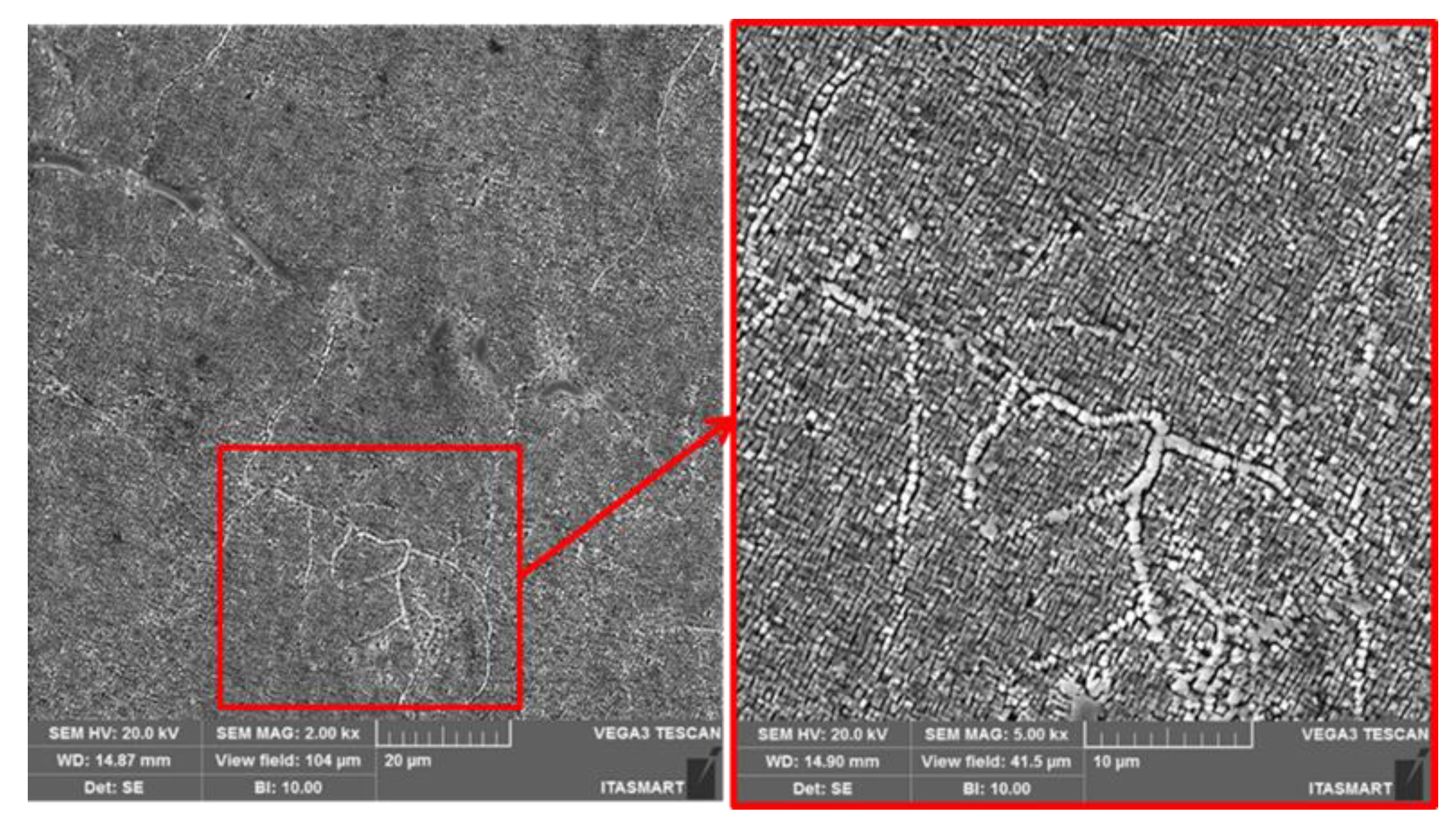

3.4. Microstructural Analysis

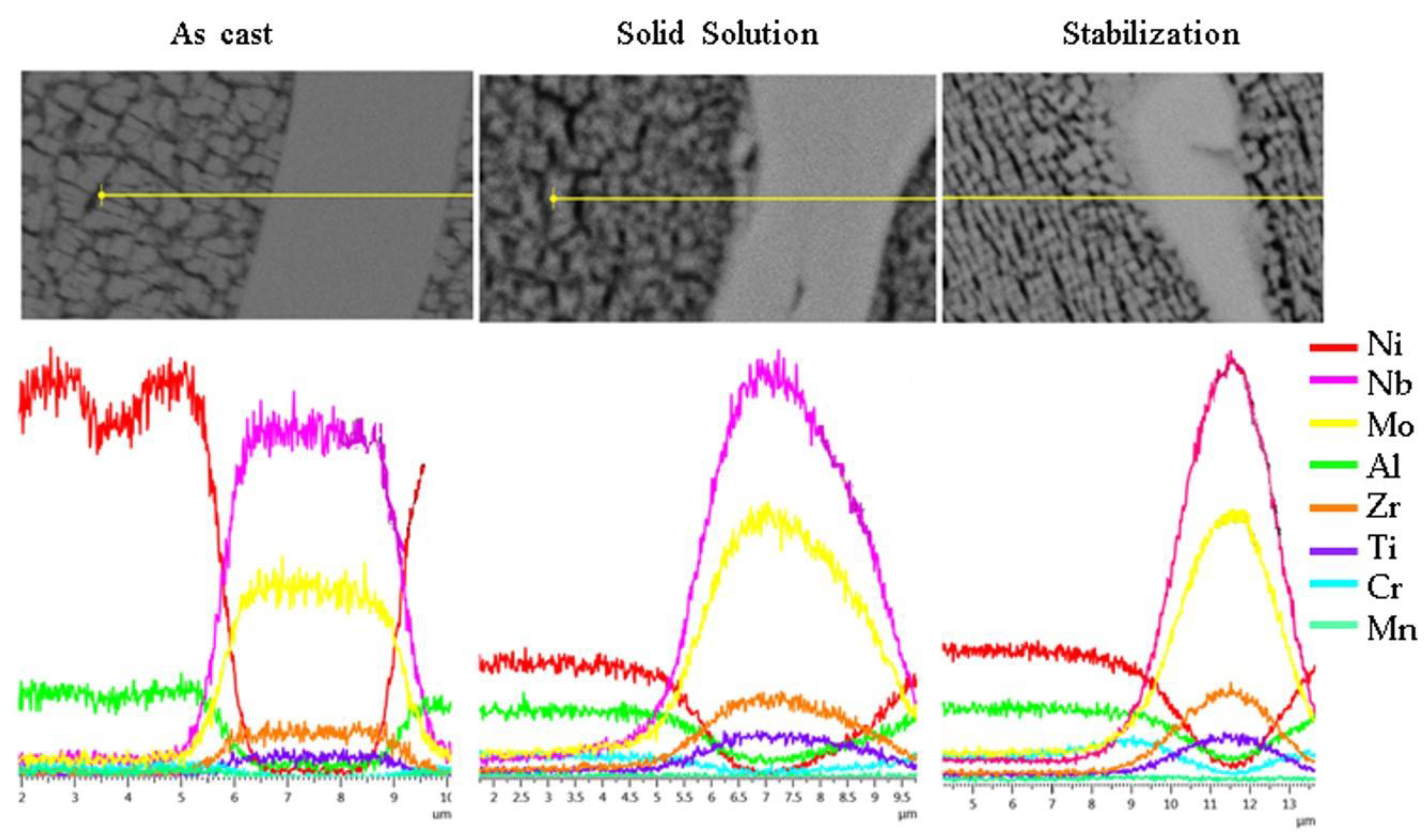

3.5. Energy-Dispersive X-Ray Spectroscopy (EDS)

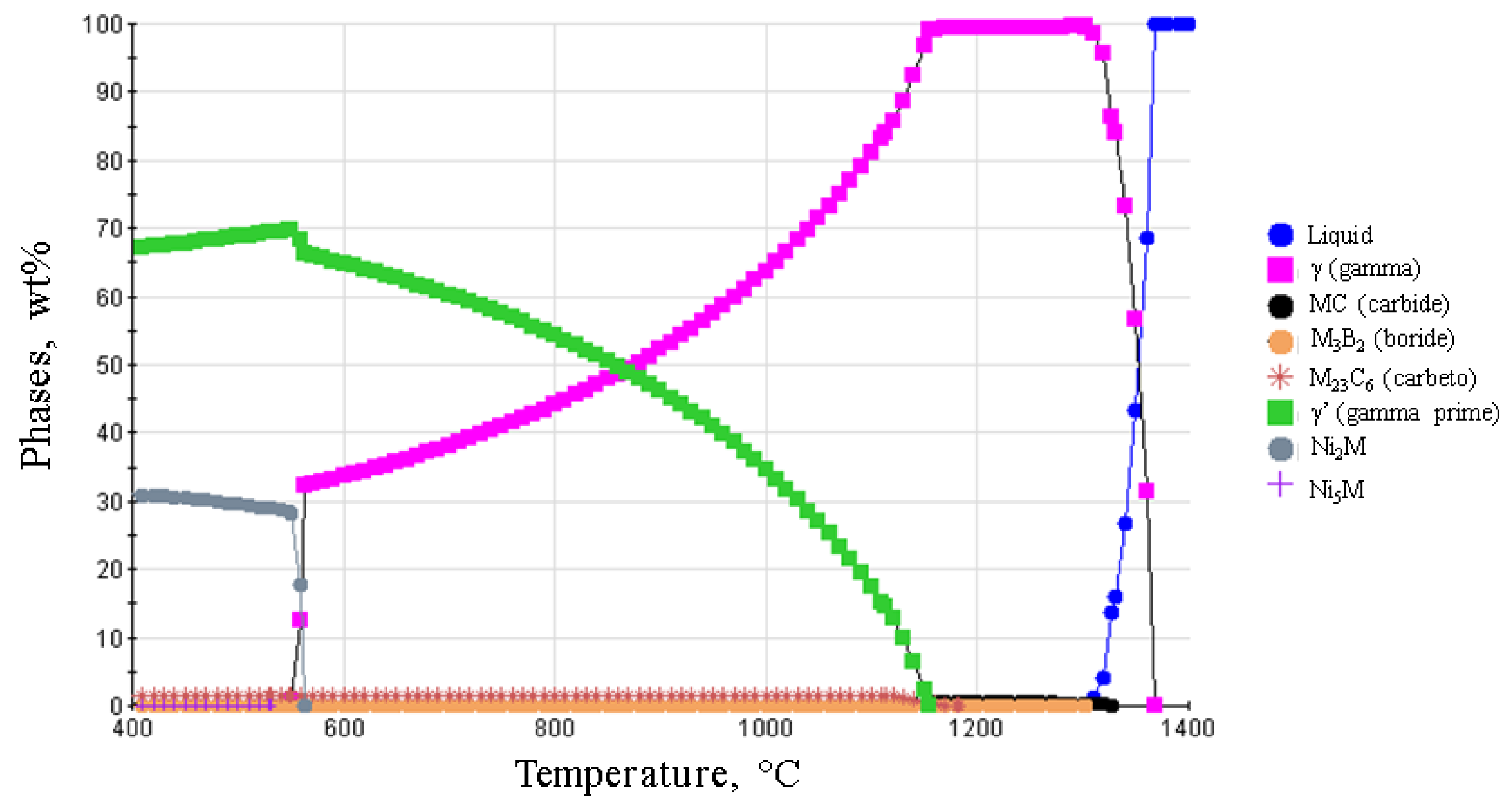

3.6. Thermocalculation of Phase Stability

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Engineering Properties of Alloy 713C (Material Engineering Section); Pratt & Whitney’s Aircraft: East Hartford, CT, USA, 1965.

- Backman, D.G.; Williams, J.C. Advanced materials for aircraft engine applications. Science 1992, 255, 1082–1087. [Google Scholar] [CrossRef] [PubMed]

- Aeromagazine. Novos Aviões, Motores e Combustíveis. Available online: http://aeromagazine.uol.com.br/artigo/novos-avioes-motores-e-combustiveis_890.html (accessed on 30 October 2018).

- Reis, D.A.P.; Silva, C.R.M.; Nono, M.C.A.; Barboza, M.J.R.; Piorino, F.; Perez, E.A.C. Effect of environment on the creep behavior of the Ti-6Al-4V alloy. Mater. Sci. Eng. A 2005, 399, 276–280. [Google Scholar] [CrossRef]

- Muktinutalapati, N.R.A. Materials for Gas Turbines—An Overview. In Advances in Gas Turbine Technology; InTech Open: London, UK, 2011. [Google Scholar]

- Decker, R.F. The evolution of wrought age-hardenable superalloys. JOM 2006, 58, 32–36. [Google Scholar] [CrossRef]

- Farina, A. Metalografia das Ligas e Superligas de Níquel; Villares Metals: Jardim Santa Carolina, Brasil, 2000. [Google Scholar]

- Reed, R.C. The Superalloys: Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2006; pp. 33–114. [Google Scholar]

- Binczyka, F.; Śleziona, J. Macro- and microhardness of IN-713C nickel superalloy constituents. Arch. Foundry Eng. 2009, 9, 9–12. [Google Scholar]

- Sugahara, T.; Martinolli, K.; Reis, D.A.P.; Moura Neto, C.; Couto, A.A.; Neto, F.P.; Barboza, M.J.R. Creep Behavior of the Inconel 718 Superalloy. Defect Diffus. Forum 2012, 326, 509–514. [Google Scholar] [CrossRef]

- Martinolli, K.; Sugahara, T.; Reis, D.A.P.; Moura Neto, C.; Hirschmann, A.C.; Couto, A.A. Evaluation of Inconel 718 Creep Behavior. Defect Diffus. Forum 2012, 326, 525–529. [Google Scholar] [CrossRef]

- Reis, D.A.P.; Moura Neto, C.; Oliveira, A.C.C.; Couto, A.A.; Domingues, N.I.; Sepka, S. Effect of Artificial Aging on the Mechanical Properties of an Aerospace. Defect Diffus. Forum 2012, 326, 193–198. [Google Scholar] [CrossRef]

- Reis, A.G.; Reis, D.A.P.; Moura Neto, C.; Barboza, M.J.R.; Silva, C.R.M.; Piorino Neto, F.; Onoro, J. Influence of Laser Treatment on the Creep of the Ti-6Al-4V Alloy. Metall. Mater. Trans. A 2011, 42, 3031–3034. [Google Scholar] [CrossRef]

- Reis, D.A.P.; Moura Neto, C.; Silva, C.R.M.; Barboza, M.J.R.; Piorino Neto, F. Effect of coating on the creep behavior of the Ti-6Al-4V alloy. Mater. Sci. Eng. A 2008, 486, 421–426. [Google Scholar] [CrossRef]

- Barboza, M.J.R.; Perez, E.A.C.; Medeiros, M.M.; Reis, D.A.P.; Nono, M.C.A.; Piorino, F.; Silva, C.R.M. Creep behavior of the Ti-6Al-4V and a comparison with titanium matrix composites. Mater. Sci. Eng. A 2006, 428, 319–326. [Google Scholar] [CrossRef]

- Kracke, A. Superalloys, the Most Successful Alloy System of Modern Times—Past, Present and Future. In Proceedings of the 7th International Symposium on Superalloy 718 & Derivatives, Pittsburgh, PA, USA, 10–13 October 2010. [Google Scholar]

- Meyer, M.A.; Chawla, K.K. Princípios de Metalurgia Mecânica; Edgard Blüncher: São Paulo, Brazil, 1982; pp. 406–420. [Google Scholar]

- Azevedo, C.R.F.; Moreira, M.F.; Hippert, E. Nickel Superalloy (Inconel 713C); Instituto de Pesquisas Tecnológicas: São Paulo, Brazil, 2001. [Google Scholar]

- Kunz, L.; Lukáš, P.; Konečná, R. High-cycle fatigue of Ni-base superalloy 713C. Int. J. Fatigue 2010, 32, 908–913. [Google Scholar] [CrossRef]

- Nalawade, S.A.; Sundararaman, M.; SINGH, J.B.; Verma, A.; Kishore, R. Precipitation of γ’ phase in δ-precipitated Alloy 718 during deformation at elevated temperatures. Mater. Sci. Eng. A 2010, 527, 2906–2909. [Google Scholar] [CrossRef]

- Valle, L.C.M. Efeitos da Solubilização e do Envelhecimento na Microestrutura e nas Propriedades Mecânicas da Superliga Inconel 718. Master’s Thesis, Universidade Federal do Rio de Janeiro, Rio de Janeiro, Brazil, 2010. [Google Scholar]

- Ezugwu, E.O.; Wang, Z.M.; Machado, A.R. The machinability of nickel-based alloys: A review. J. Mater. Process. Technol. 1999, 86, 1–16. [Google Scholar] [CrossRef]

- AMS 5391: Nickel Alloy, Corrosion and Heat-Resistant, Investment Castings 73Ni-0.14C-4.5Mo-2.3Cb(Nb)-0.75Ti-6.0Al-0.010B-0.12Zr Vacuum Cast, As-Cast; Sae International: Warrendale, PA, USA, 2014.

- Thermo-Calc Software TTNI8/Ni-Based Superalloys Database Version 8. Available online: http://www.thermocalc.com (accessed on 30 October 2018).

| Chemical Analysis of Inconel 713C | ||||

|---|---|---|---|---|

| Elements (wt.%) | AMS 5391 | As Cast | Solid Solution | Stabilization |

| Cr | 12.00–14.00 | 13.32 | 13.58 | 13.70 |

| Mo | 2.80–5.20 | 3.85 | 3.93 | 3.96 |

| Al | 5.50–6.50 | 5.62 | 5.72 | 5.60 |

| Ti | 0.50–1.00 | 0.67 | 0.70 | 0.67 |

| C | 0.08–0.20 | 0.11 | 0.11 | 0.11 |

| B | 0.005–0.015 | 0.009 | 0.01 | 0.009 |

| Zr | 0.05–0.15 | 0.076 | 0.085 | 0.083 |

| Si | max. 0.50 | 0.15 | 0.15 | 0.13 |

| Mn | max. 0.25 | 0.012 | 0.012 | 0.007 |

| Fe | max. 2.50 | 0.89 | 0.86 | 0.89 |

| Cu | max. 0.50 | 0.004 | 0.005 | 0.004 |

| Ni | balance | balance | balance | balance |

| Inconel 713C | Hardness (HRC) |

|---|---|

| As cast | 36 ± 1 |

| Solid solution | 40 ± 1 |

| Stabilization | 37 ± 1 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Galizoni, B.B.; Couto, A.A.; Reis, D.A.P. Heat Treatments Effects on Nickel-Based Superalloy Inconel 713C. Metals 2019, 9, 47. https://doi.org/10.3390/met9010047

Galizoni BB, Couto AA, Reis DAP. Heat Treatments Effects on Nickel-Based Superalloy Inconel 713C. Metals. 2019; 9(1):47. https://doi.org/10.3390/met9010047

Chicago/Turabian StyleGalizoni, Breno Boretti, Antônio Augusto Couto, and Danieli Aparecida Pereira Reis. 2019. "Heat Treatments Effects on Nickel-Based Superalloy Inconel 713C" Metals 9, no. 1: 47. https://doi.org/10.3390/met9010047

APA StyleGalizoni, B. B., Couto, A. A., & Reis, D. A. P. (2019). Heat Treatments Effects on Nickel-Based Superalloy Inconel 713C. Metals, 9(1), 47. https://doi.org/10.3390/met9010047