Hot Tearing of 9Cr3Co3W Heat-Resistant Steel during Solidification

Abstract

1. Introduction

2. Experimental Section

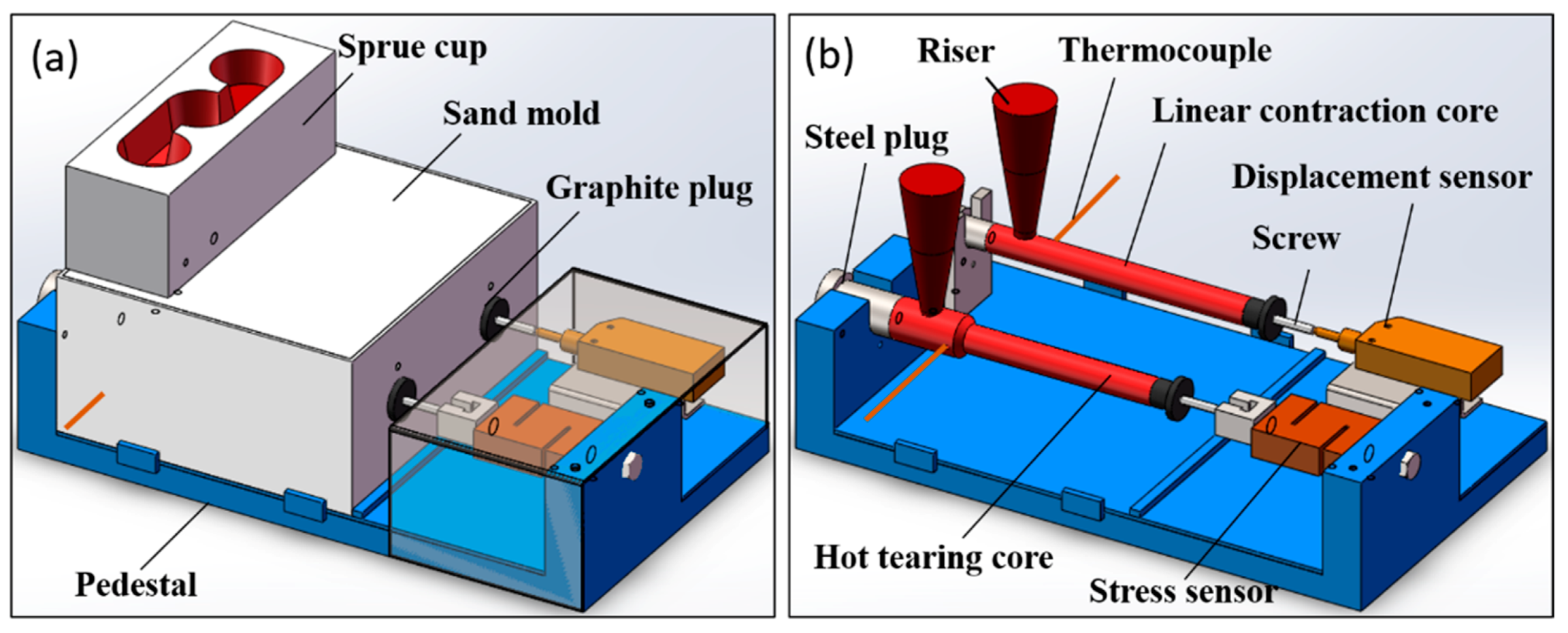

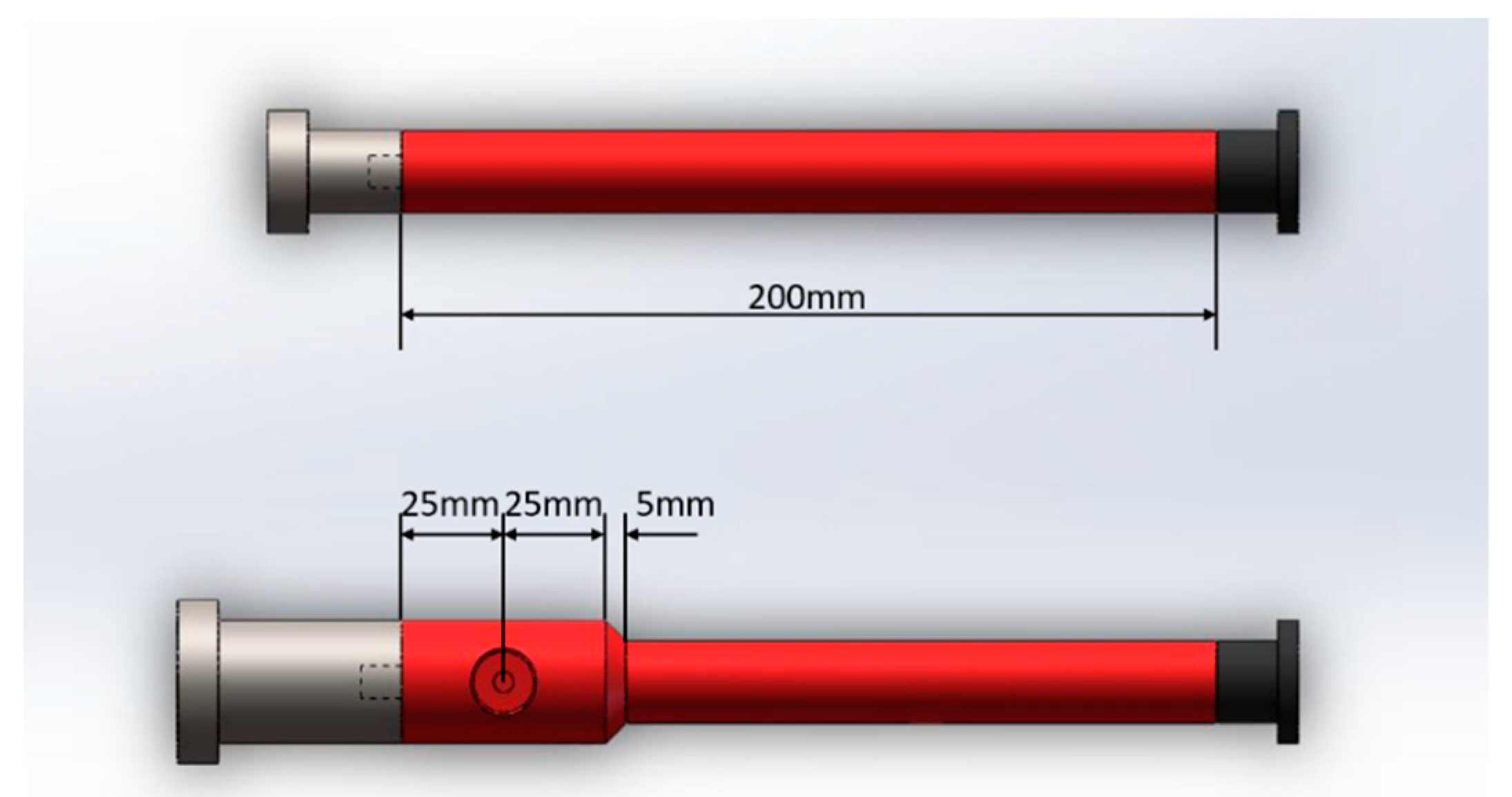

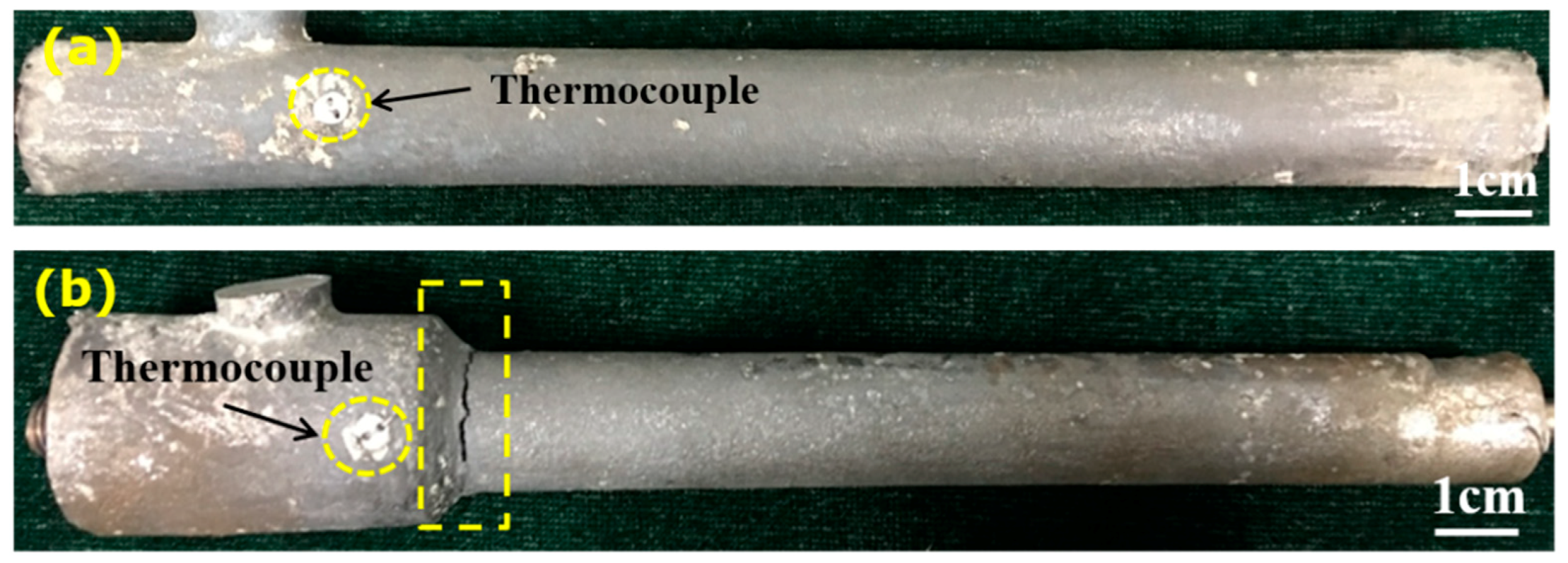

2.1. Method and Device

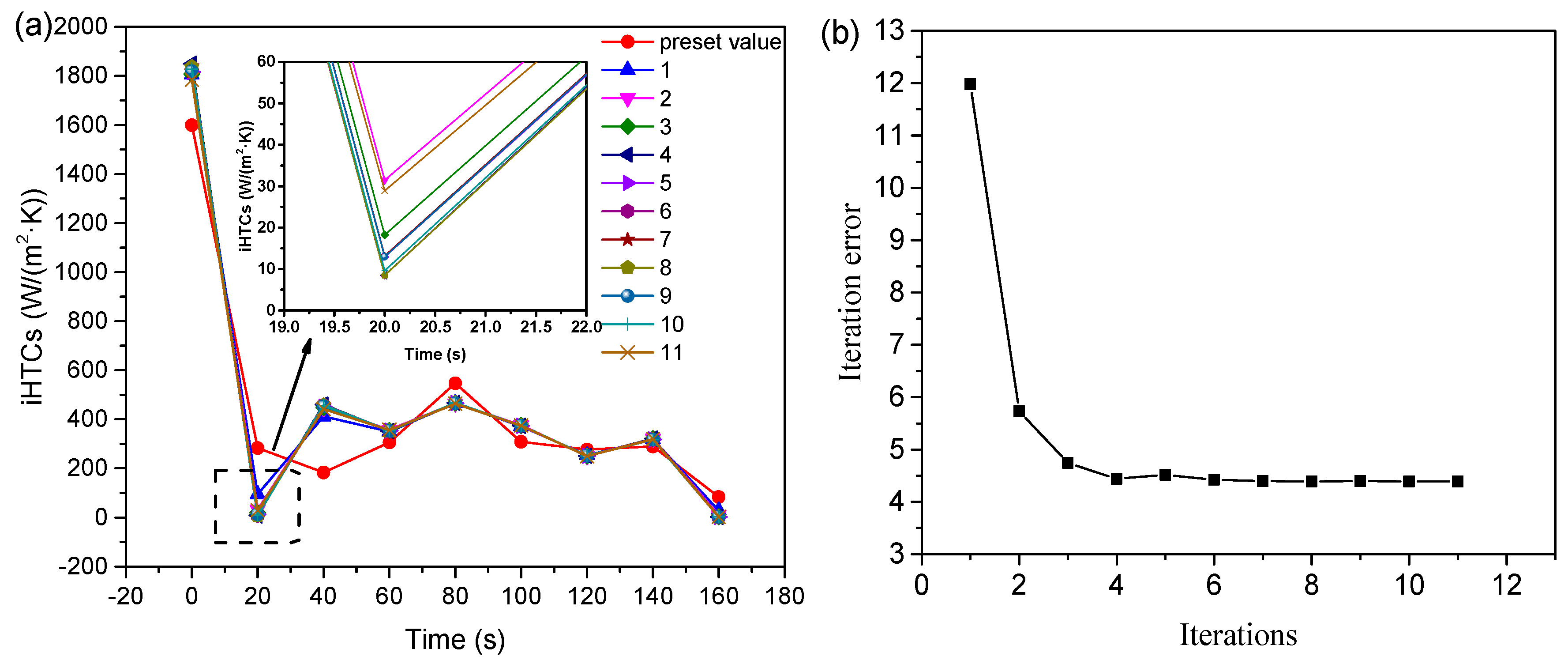

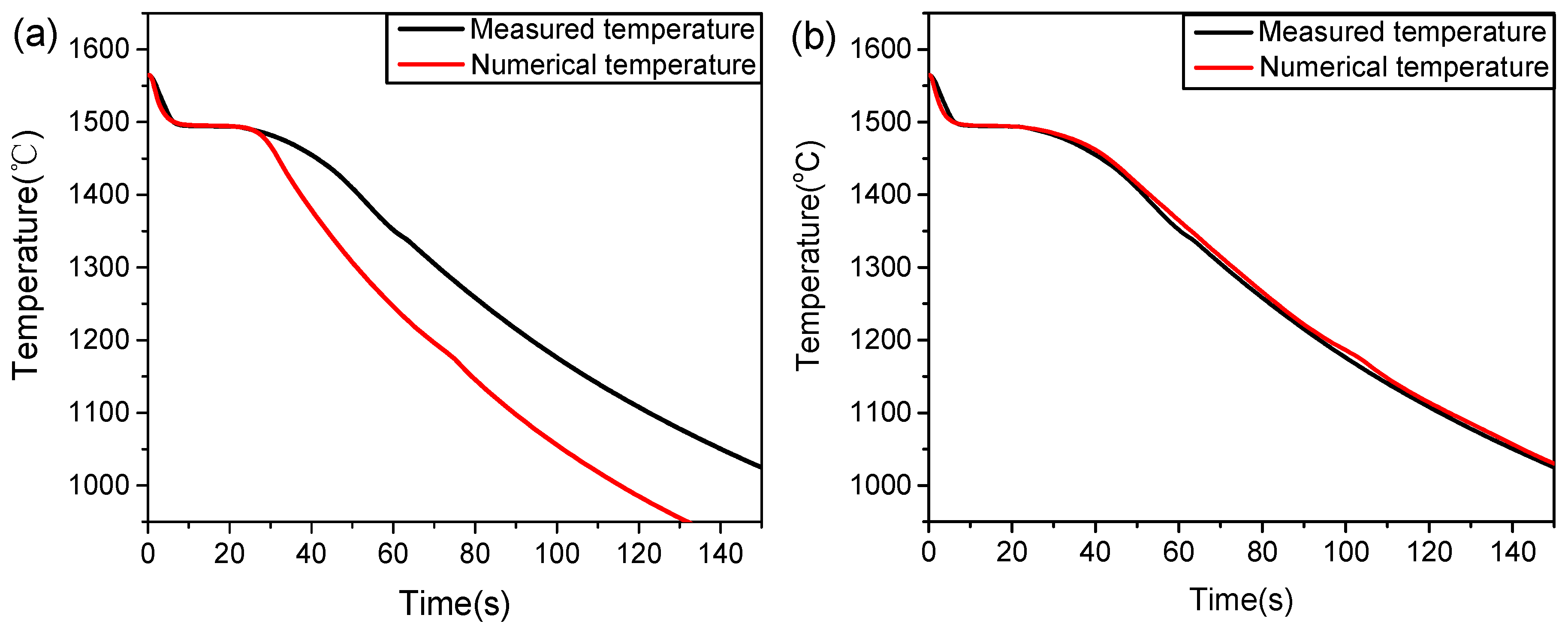

2.2. Interface Heat Transfer Coefficients

3. Results and Discussion

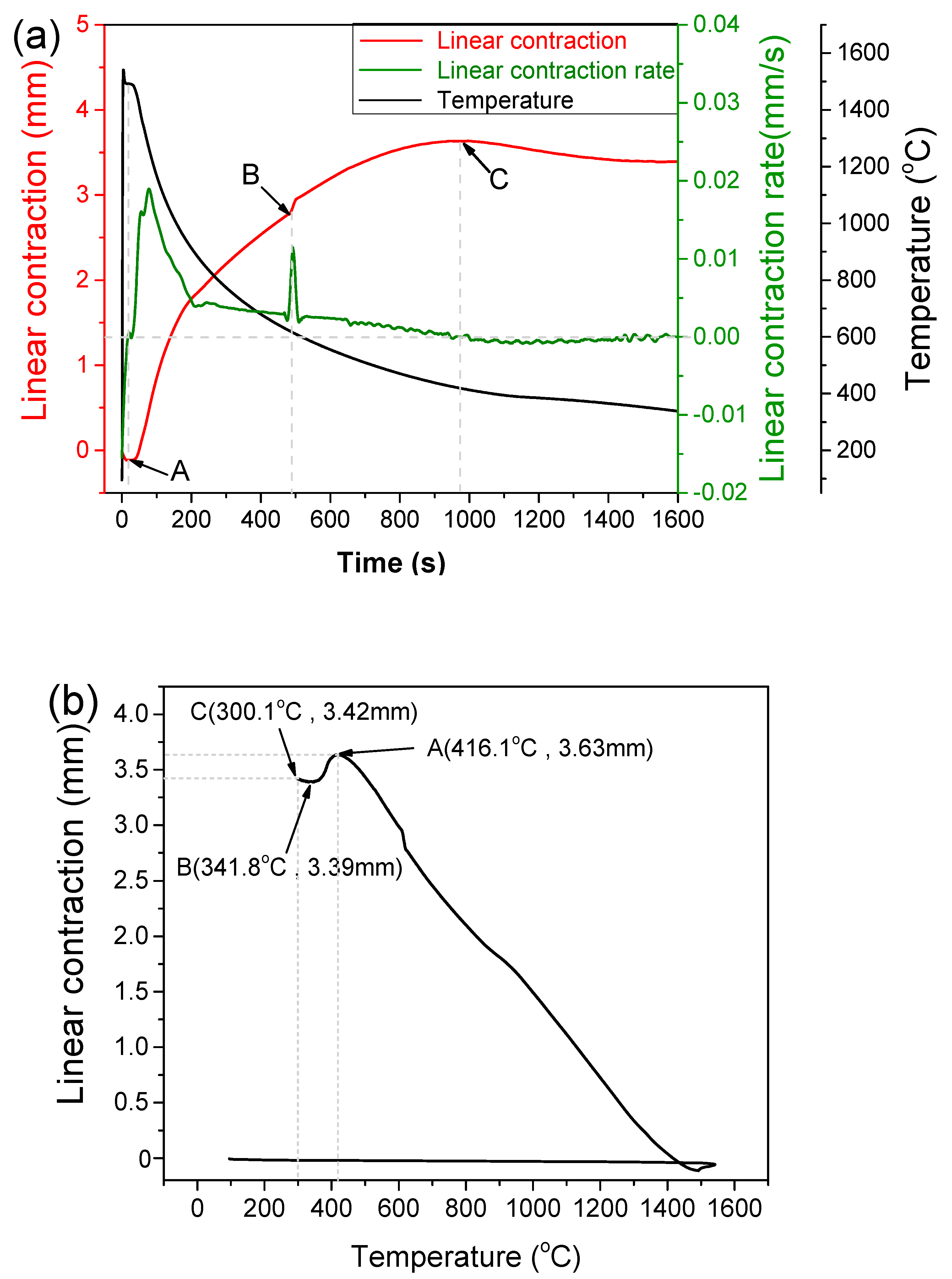

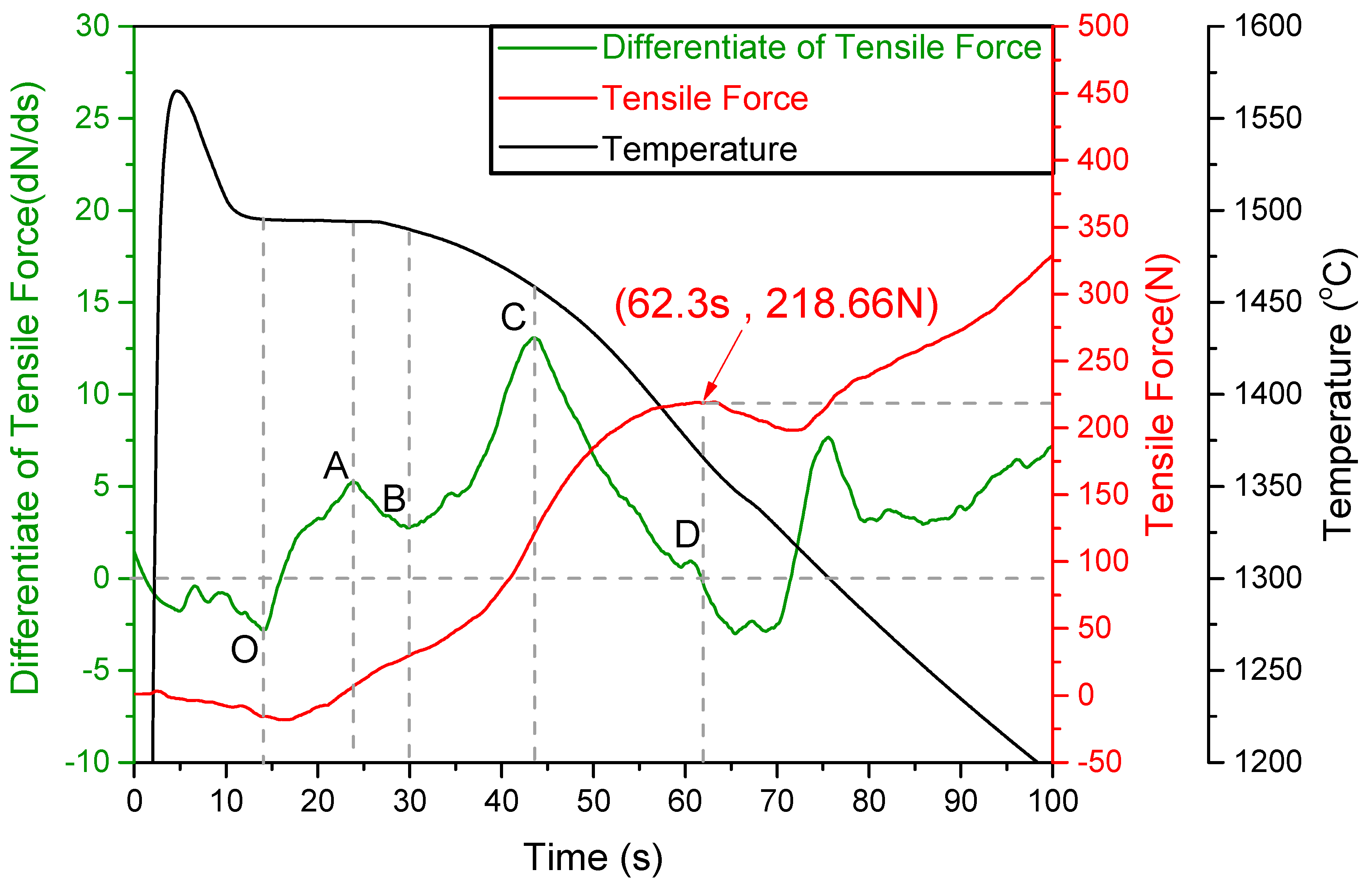

3.1. Linear Contraction Test Result

3.2. Numerical Simulation Result

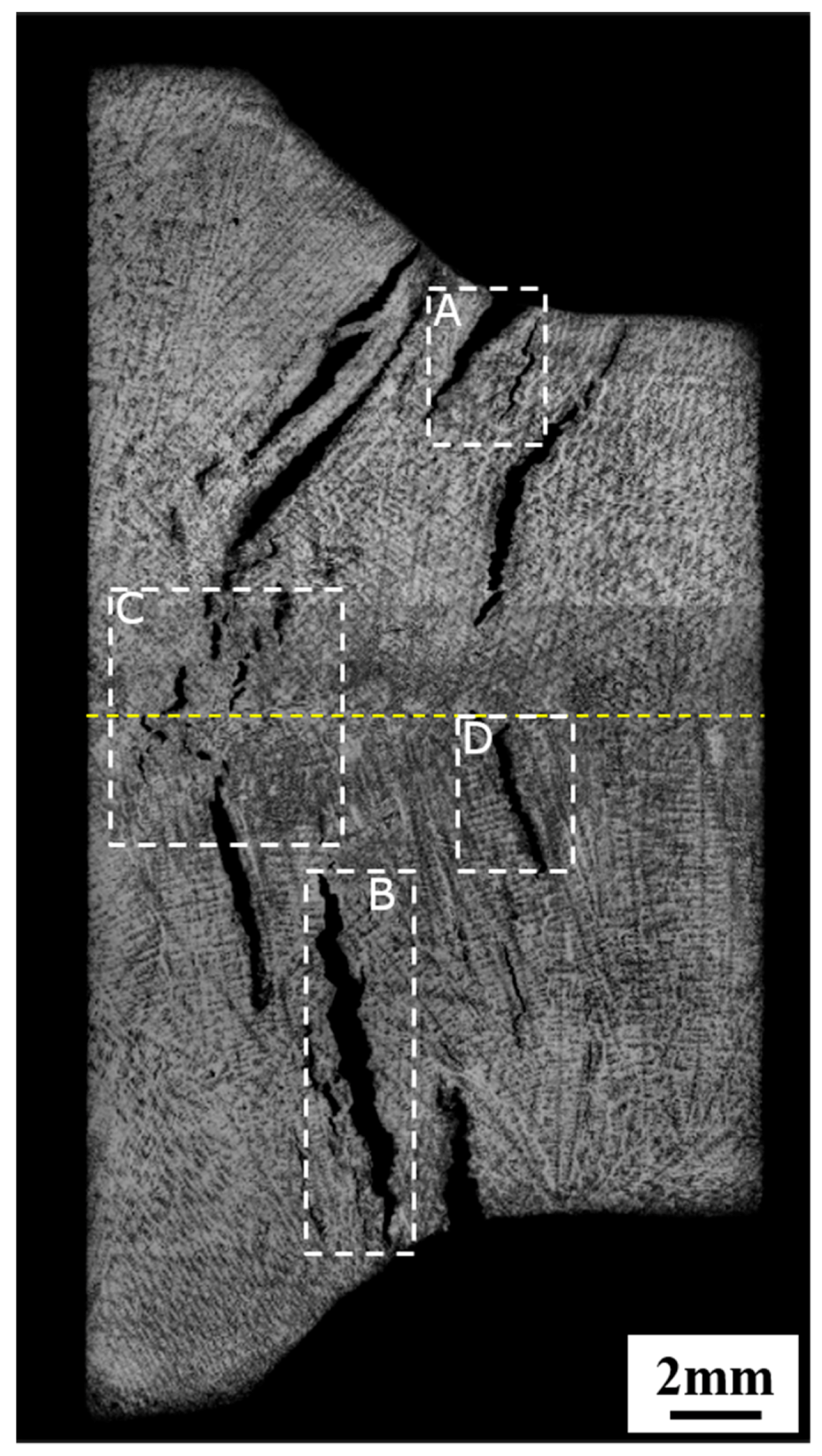

3.3. Hot Tearing Test Result

4. Conclusions

- The measured linear contraction of the steel sample in the sand mold was 1.7% when the temperature was decreased from 1550 °C to 300 °C.

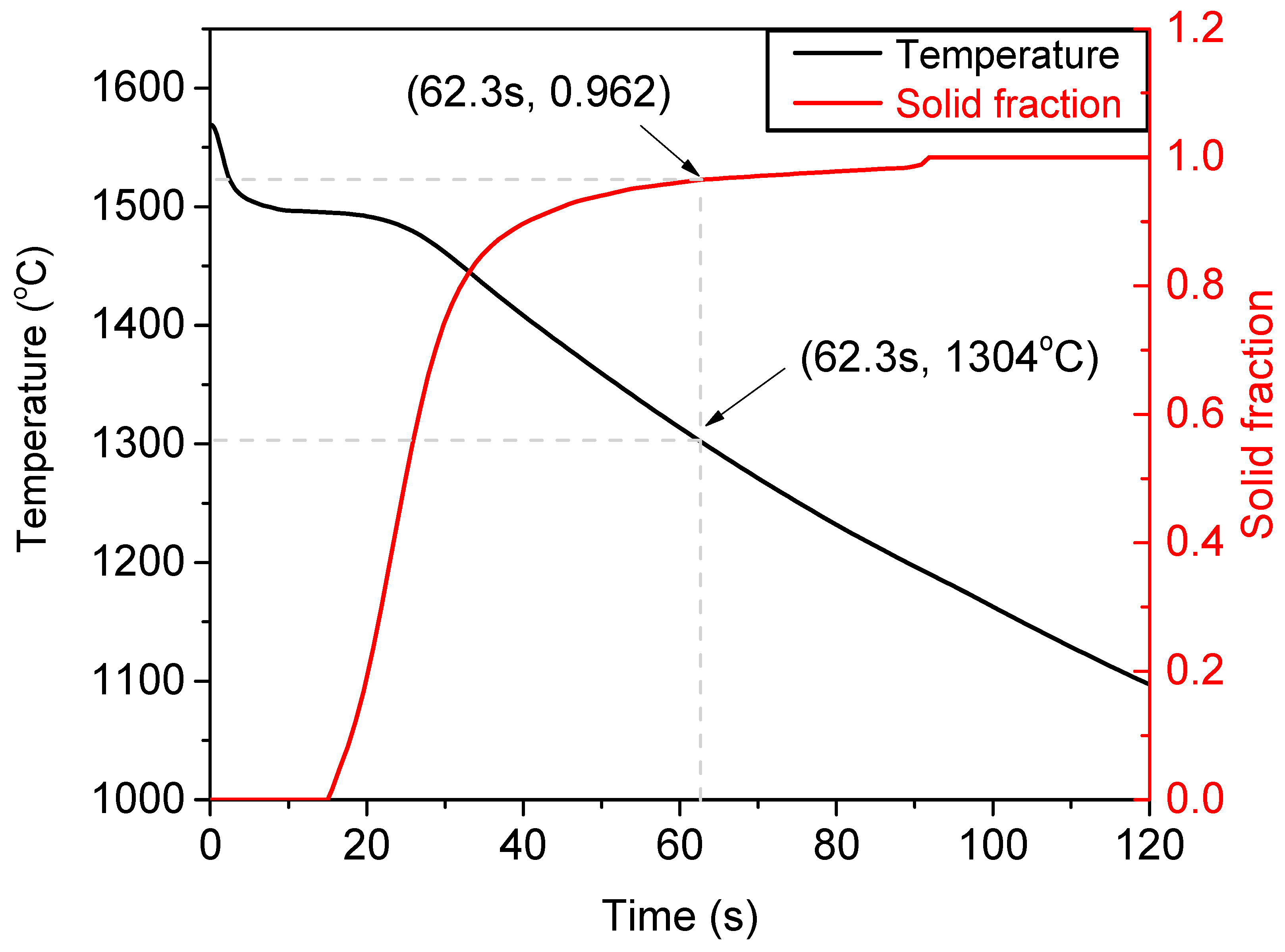

- The solid fraction, temperature and stress corresponding to the stress release point (i.e., the cracks initiation point) in the hot spot were 0.962, 1304 °C and 0.72 MPa, respectively. The achieved solid fraction and stress at the stress release point can be regarded as the criteria for the occurrence of hot tearing under this experiment.

- According to the metallographic results, the trajectory of hot tearing was observed at the tip of the secondary dendrites along the primary dendritic arm, which was in the solute enrichment zone at the final solidification.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| iHTCs | Interface Heat Transfer Coefficients |

| IHCP | Inverse Heat Conduction Problem |

| SEM | Scanning electron microscopy |

References

- Xiao, B.; Xu, L.; Zhao, L.; Jing, H.; Han, Y.; Zhang, Y. Creep properties, creep deformation behavior, and microstructural evolution of 9Cr-3W-3Co-1CuVNbB martensite ferritic steel. Mater. Sci. Eng. A 2018, 711, 434–447. [Google Scholar] [CrossRef]

- Abe, F. Research and Development of Heat-Resistant Materials for Advanced USC Power Plants with Steam Temperatures of 700 °C and Above. Engineering 2015, 1, 211–224. [Google Scholar] [CrossRef]

- Viswanathan, R.; Coleman, K.; Rao, U. Materials for ultra-supercritical coal-fired power plant boilers. Int. J. Press. Ves. Pip. 2006, 83, 778–783. [Google Scholar] [CrossRef]

- U.S. Energy Information Administration. International Energy Outlook 2017; EIA: Washington, DC, USA, 2017; pp. 77–90.

- Zhou, X.; Liu, Y.; Qiao, Z.; Guo, Q.; Liu, C.; Yu, L.; Li, H. Effects of cooling rates on δ-ferrite/γ-austenite formation and martensitic transformation in modified ferritic heat resistant steel. Fusion Eng. Des. 2017, 125, 354–360. [Google Scholar] [CrossRef]

- Li, Y.; Gao, X.; Zhang, Z.R.; Xiao, W.L.; Li, H.X.; Du, Q.; Katgerman, L.; Zhang, J.S.; Zhuang, L.Z. Experimental and Theoretical Studies of the Hot Tearing Behavior of Al-xZn-2Mg-2Cu Alloys. Metall. Mater. Trans. A 2017, 48, 4744–4754. [Google Scholar] [CrossRef]

- Farup, I.; Mo, A. Two-phase modeling of mushy zone parameters associated with hot tearing. Metall. Mater. Trans. A 2000, 31, 1461–1472. [Google Scholar] [CrossRef]

- Dahle, A.K.; StJohn, D.H. Rheological behaviour of the mushy zone and its effect on the formation of casting defects during solidification. Acta Mater. 1998, 47, 31–41. [Google Scholar] [CrossRef]

- Farup, I.; Drezet, J.M.; Rappaz, M. In situ observation of hot tearing formation in succinonitrile-acetone. Acta Mater. 2001, 49, 1261–1269. [Google Scholar] [CrossRef]

- Eskin, D.G.; Suyitno; Katgerman, L. Mechanical properties in the semi-solid state and hot tearing of aluminium alloys. Prog. Mater. Sci. 2004, 49, 629–711. [Google Scholar] [CrossRef]

- Djurdjevic, M.B.; Schmid-Fetzer, R. Thermodynamic calculation as a tool for thixoforming alloy and process development. Mater. Sci. Eng. A 2006, 417, 24–33. [Google Scholar] [CrossRef]

- Eskin, D.G.; Katgerman, L. Quest for a New Hot Tearing Criterion. Metall. Mater. Trans. A 2007, 38, 1511–1519. [Google Scholar] [CrossRef]

- Rappaz, M.; Drezet, J.M.; Gremaud, M. A new hot-tearing criterion. Metall. Mater. Trans. A 1999, 30, 449–455. [Google Scholar] [CrossRef]

- Agarwal, G.; Amirthalingam, M.; Moon, S.C.; Dippenaar, R.J.; Richardson, I.M.; Hermans, M.J.M. Experimental evidence of liquid feeding during solidification of a steel. Scr. Mater. 2018, 146, 105–109. [Google Scholar] [CrossRef]

- Gunde, P.; Schiffl, A.; Uggowitzer, P.J. Influence of yttrium additions on the hot tearing susceptibility of magnesium-zinc alloys. Mater. Sci. Eng. A 2010, 527, 7074–7079. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Q.; Wu, G.; Zhu, Y.; Ding, W. Hot-tearing susceptibility of Mg-9Al-xZn alloy. Mater. Lett. 2002, 57, 929–934. [Google Scholar] [CrossRef]

- Cao, G.; Kou, S. Hot cracking of binary Mg-Al alloy castings. Mater. Sci. Eng. A 2006, 417, 230–238. [Google Scholar] [CrossRef]

- Song, J.; Pan, F.; Jiang, B.; Atrens, A.; Zhang, M.; Lu, Y. A review on hot tearing of magnesium alloys. J. Magnes. Alloys 2016, 4, 151–172. [Google Scholar] [CrossRef]

- Song, J.; Wang, Z.; Huang, Y.; Srinivasan, A.; Beckmann, F.; Kainer, K.U.; Hort, N. Effect of Zn addition on hot tearing behaviour of Mg-0.5Ca-xZn alloys. Mater. Des. 2015, 87, 157–170. [Google Scholar] [CrossRef]

- Li, S.; Sadayappan, K.; Apelian, D. Role of Grain Refinement in the Hot Tearing of Cast Al-Cu Alloy. Metall. Mater. Trans. B 2013, 44, 614–623. [Google Scholar] [CrossRef]

- Wei, Z.; Chen, X.; Zhong, H.; Zhai, Q.; Wang, G. Hot tearing susceptibility of Fe-20.96Cr-2.13Ni-0.15N-4.76Mn-0.01Mo duplex stainless steel. J. Iron Steel Res. Int. 2017, 24, 421–425. [Google Scholar] [CrossRef]

- Kermanpur, A.; Eskandari, M.; Purmohamad, H.; Soltani, M.A.; Shateri, R. Influence of mould design on the solidification of heavy forging ingots of low alloy steels by numerical simulation. Mater. Des. 2010, 31, 1096–1104. [Google Scholar] [CrossRef]

- Wang, D.; Zhou, C.; Xu, G.; Huaiyuan, A. Heat transfer behavior of top side-pouring twin-roll casting. J. Mater. Process. Technol. 2014, 214, 1275–1284. [Google Scholar] [CrossRef]

- Qiang, L.; Chunli, M.; Xiuhong, K.; Dianzhong, L.; Bainian, Q. Numerical simulation of the influence of heat extract boundary conditions and desities on the thermo-solutal convection. Mater. Sci. Technol. 2005, 13, 94–98. [Google Scholar]

- Palumbo, G.; Piglionico, V.; Piccininni, A.; Guglielmi, P.; Sorgente, D.; Tricarico, L. Determination of interfacial heat transfer coefficients in a sand mould casting process using an optimised inverse analysis. Appl. Therm. Eng. 2015, 78, 682–694. [Google Scholar] [CrossRef]

- Zhang, L.; Reilly, C.; Li, L.; Cockcroft, S.; Yao, L. Development of an inverse heat conduction model and its application to determination of heat transfer coefficient during casting solidification. Heat Mass Transf. 2014, 50, 945–955. [Google Scholar] [CrossRef]

- Wendler, M.; Hauser, M.; Fabrichnaya, O.; Krüger, L.; Weiß, A.; Mola, J. Thermal and deformation-induced phase transformation behavior of Fe-15Cr-3Mn-3Ni-0.1N-(0.05-0.25)C austenitic and austenitic-martensitic cast stainless steels. Mater. Sci. Eng. A 2015, 645, 28–39. [Google Scholar] [CrossRef]

- Esfahani, M.R.N.; Niroumand, B. Study of hot tearing of A206 aluminum alloy using Instrumented Constrained T-shaped Casting method. Mater. Charact. 2010, 61, 318–324. [Google Scholar] [CrossRef]

- M’Hamdi, M.; Mo, A.; Fjær, H.G. TearSim: A two-phase model addressing hot tearing formation during aluminum direct chill casting. Metall. Mater. Trans. A 2006, 37, 3069–3083. [Google Scholar] [CrossRef]

- M’Hamdi, M.; Mo, A.; Martin, C.L. Two-phase modeling directed toward hot tearing formation in aluminum direct chill casting. Metall. Mater. Trans. A 2002, 33, 2081–2093. [Google Scholar] [CrossRef]

- Mathier, V.; Drezet, J.; Rappaz, M. Two-phase modelling of hot tearing in aluminium alloys using a semi-coupled approach. Model. Simul. Mater. Sci. Eng. 2007, 15, 121–134. [Google Scholar] [CrossRef]

- Mathier, V.; Jacot, A.; Rappaz, M. Coalescence of equiaxed grains during solidification. Model. Simul. Mater. Sci. Eng. 2004, 12, 479–490. [Google Scholar] [CrossRef]

- Hamadellah, A.; Bouayad, A.; Gerometta, C. Hot tear characterization of AlCu5MgTi and AlSi9 casting alloys usingan instrumented constrained six rods casting method. J. Mater. Process. Technol. 2017, 244, 282–288. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, B.; Wang, Q.; Zhu, Y.; Ding, W. An understanding of the hot tearing mechanism in AZ91 magnesium alloy. Mater. Lett. 2002, 53, 35–39. [Google Scholar] [CrossRef]

| Stage | C | Si | Mn | P | S | Cr | Ni | Al | Co | Cu | W |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 0.087 | 0.282 | 0.508 | 0.0149 | 0.0104 | 8.49 | 0.148 | 0.0134 | 3.04 | 0.043 | 2.80 |

| B | 0.088 | 0.270 | 0.500 | 0.0137 | 0.0067 | 8.48 | 0.149 | 0.0146 | 2.89 | 0.032 | 2.70 |

| Name | Granularity | Elements | Refractoriness |

|---|---|---|---|

| Quartz sand | 80/150 | SiO2 (97%) | 1650 °C |

| Fly ash | 20 | SiO2 + Al2O3 | 1700 °C |

| Coating | \ | Zircon + Ethyl alcohol | 1650 °C |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhong, H.; Li, X.; Wang, B.; Wu, T.; Zhang, Y.; Liu, B.; Zhai, Q. Hot Tearing of 9Cr3Co3W Heat-Resistant Steel during Solidification. Metals 2019, 9, 25. https://doi.org/10.3390/met9010025

Zhong H, Li X, Wang B, Wu T, Zhang Y, Liu B, Zhai Q. Hot Tearing of 9Cr3Co3W Heat-Resistant Steel during Solidification. Metals. 2019; 9(1):25. https://doi.org/10.3390/met9010025

Chicago/Turabian StyleZhong, Honggang, Xihao Li, Biao Wang, Tieming Wu, Yunhu Zhang, Bin Liu, and Qijie Zhai. 2019. "Hot Tearing of 9Cr3Co3W Heat-Resistant Steel during Solidification" Metals 9, no. 1: 25. https://doi.org/10.3390/met9010025

APA StyleZhong, H., Li, X., Wang, B., Wu, T., Zhang, Y., Liu, B., & Zhai, Q. (2019). Hot Tearing of 9Cr3Co3W Heat-Resistant Steel during Solidification. Metals, 9(1), 25. https://doi.org/10.3390/met9010025