Dissimilar Friction Stir Butt Welding of Aluminum and Copper with Cross-Section Adjustment for Current-Carrying Components

Abstract

:1. Introduction

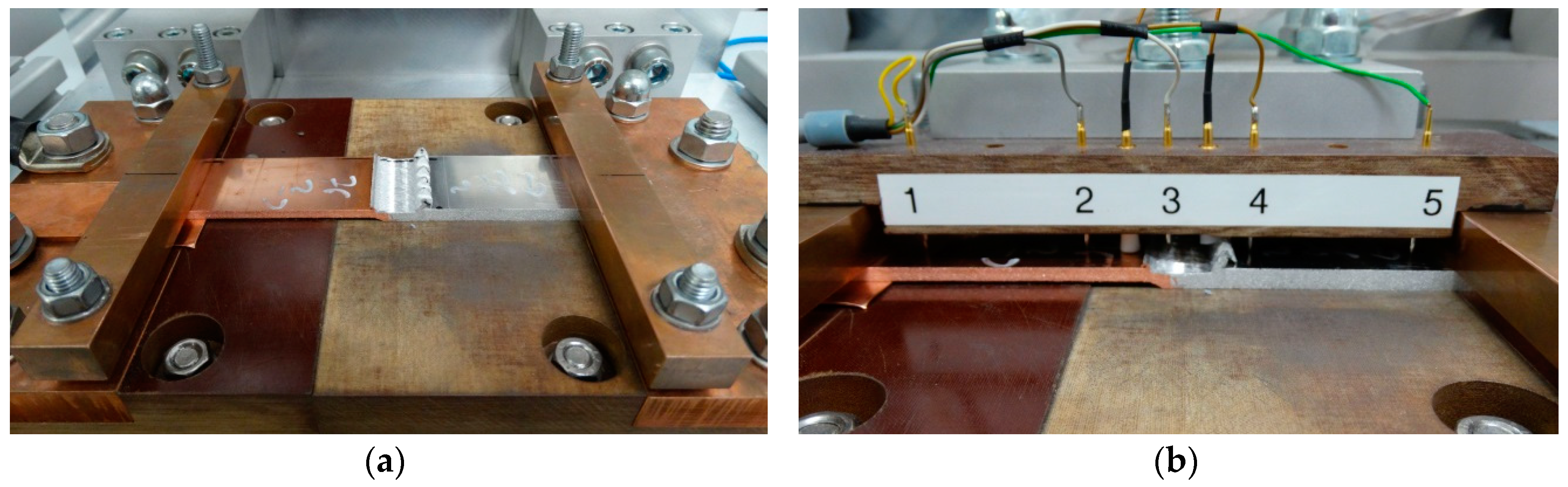

2. Materials and Methods

3. Results and Discussion

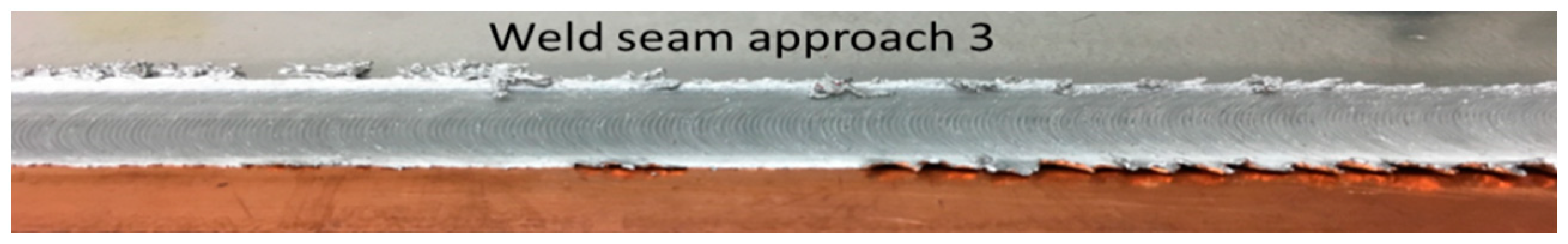

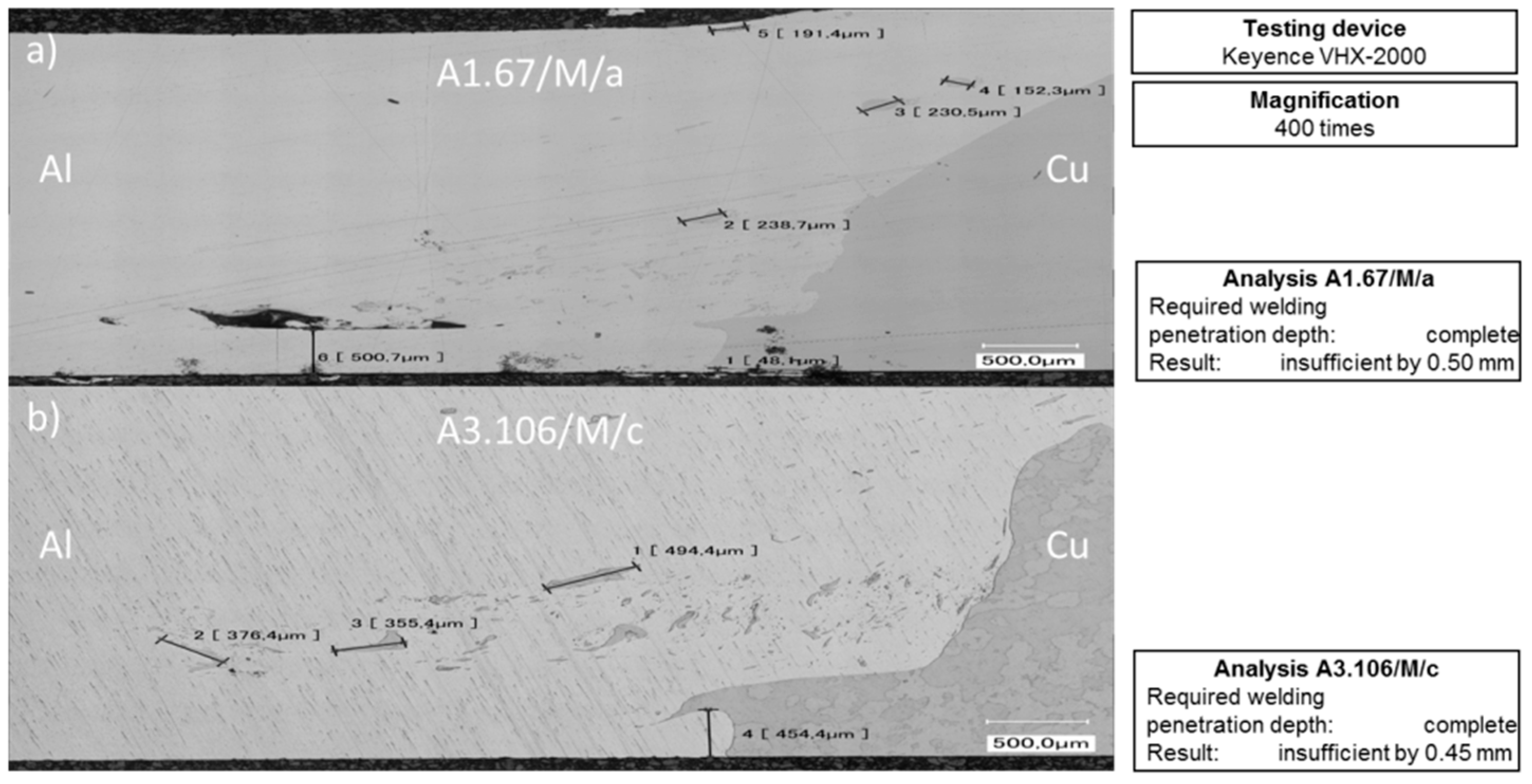

3.1. Appearance of the Al–Cu Friction Stir Welds

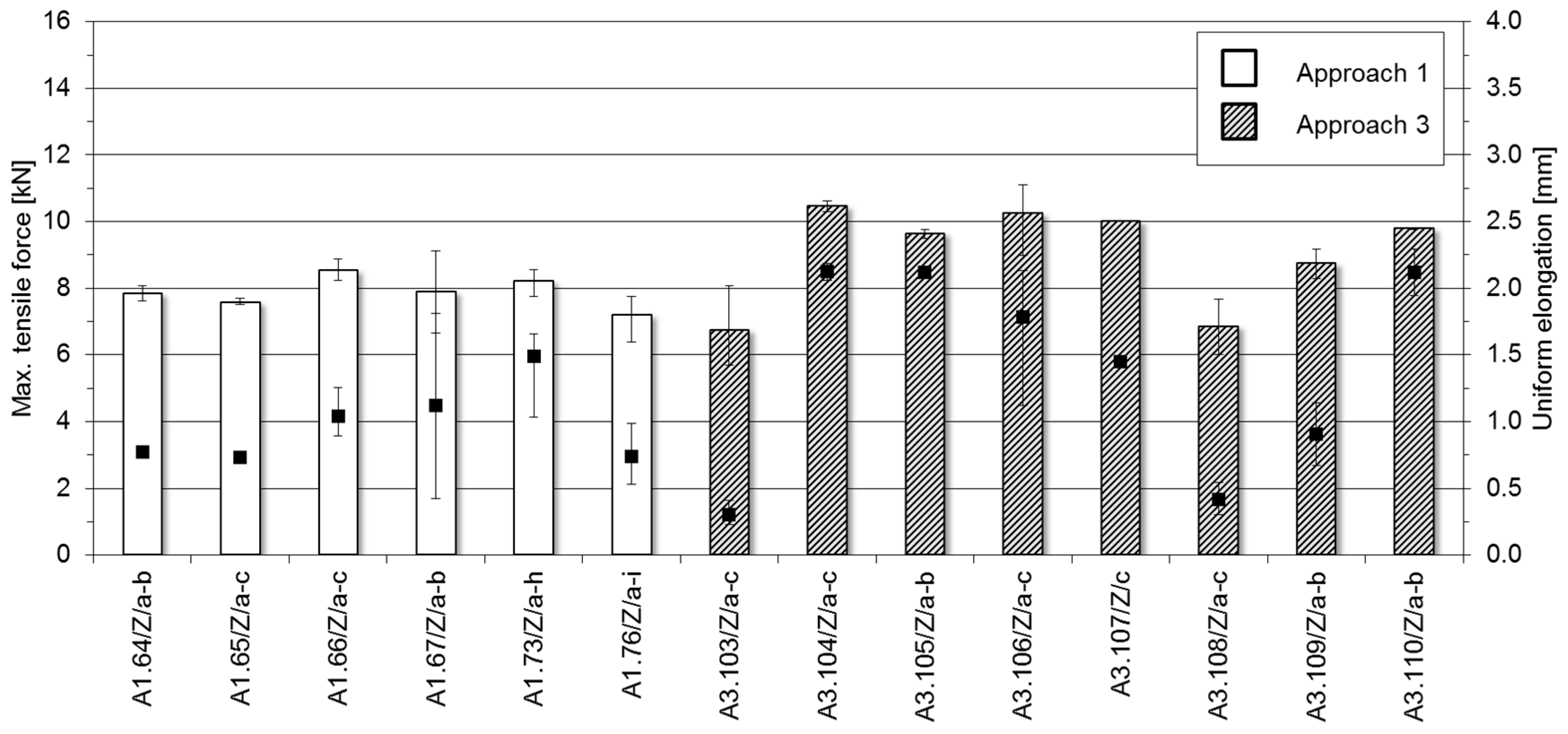

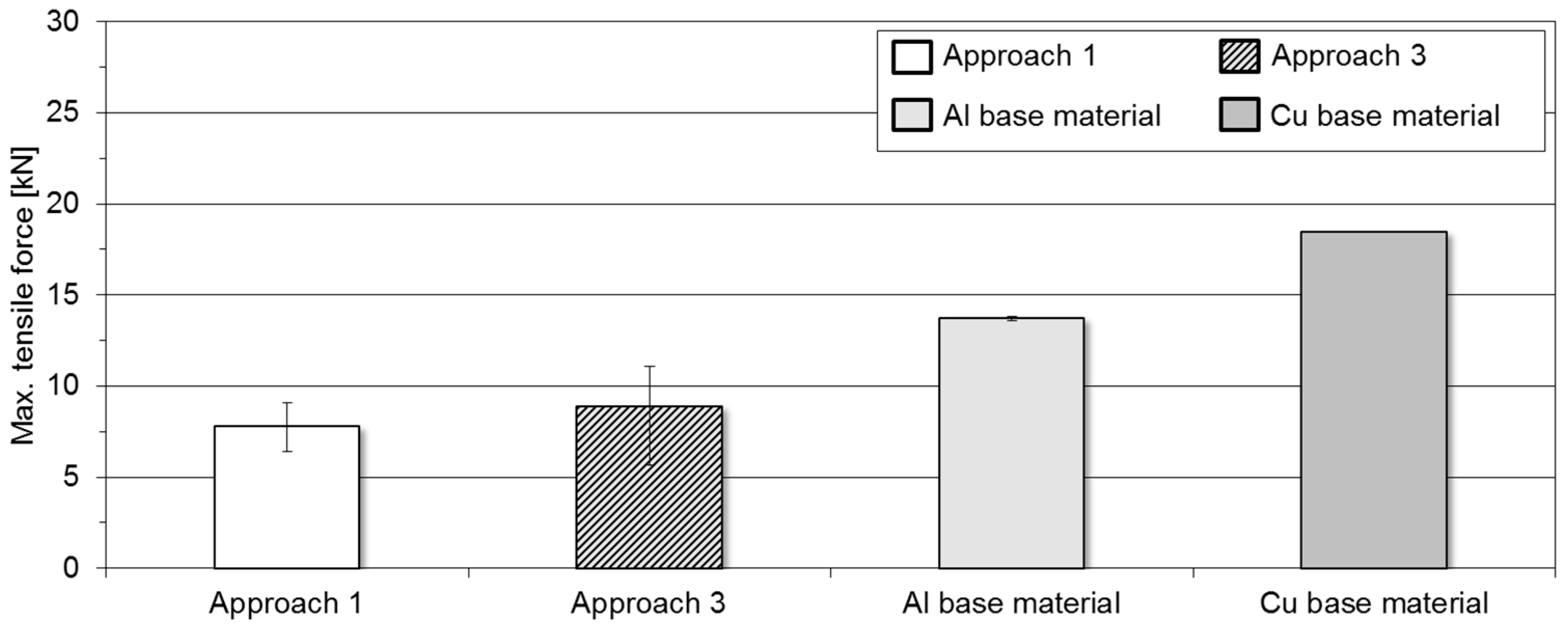

3.2. Results of Tensile Testing

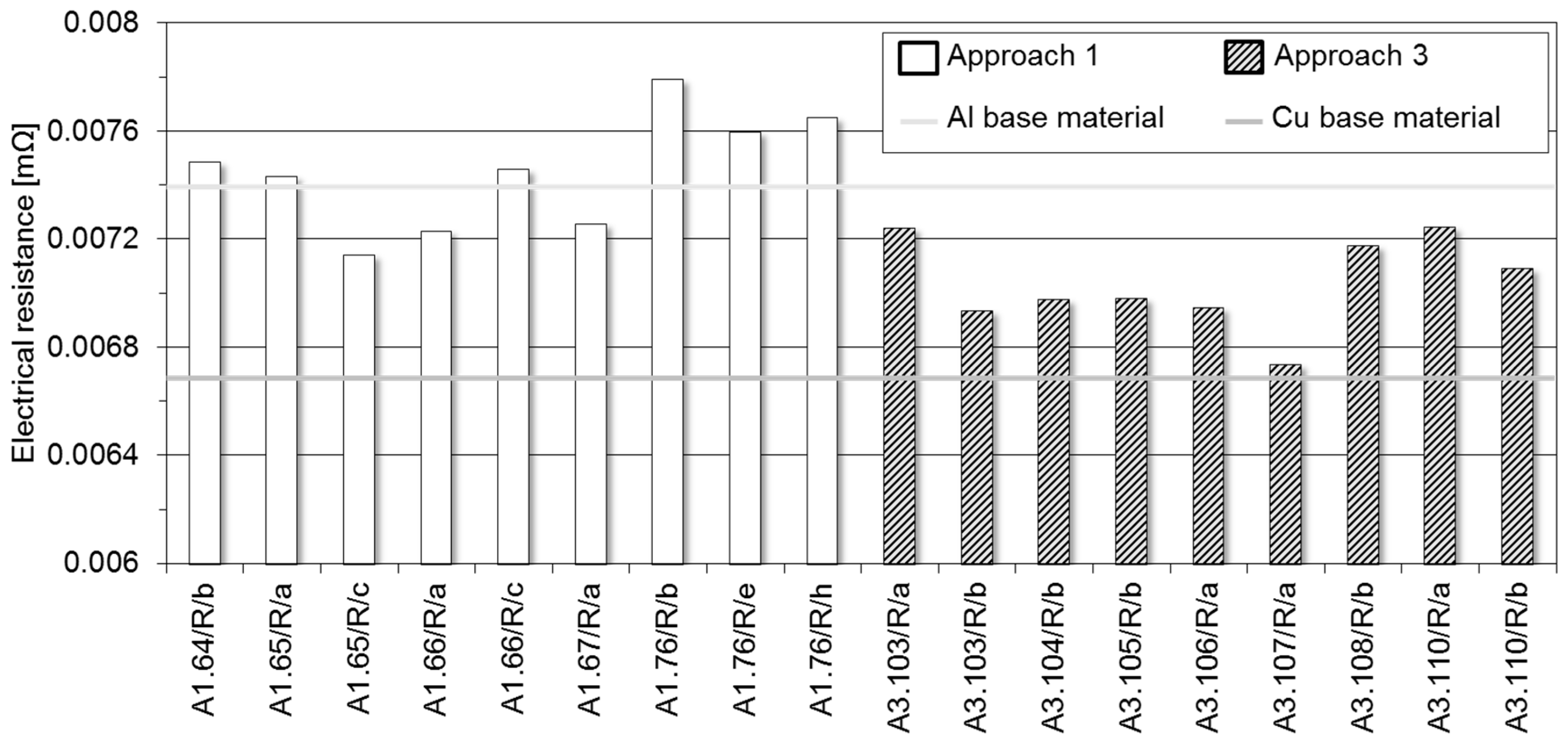

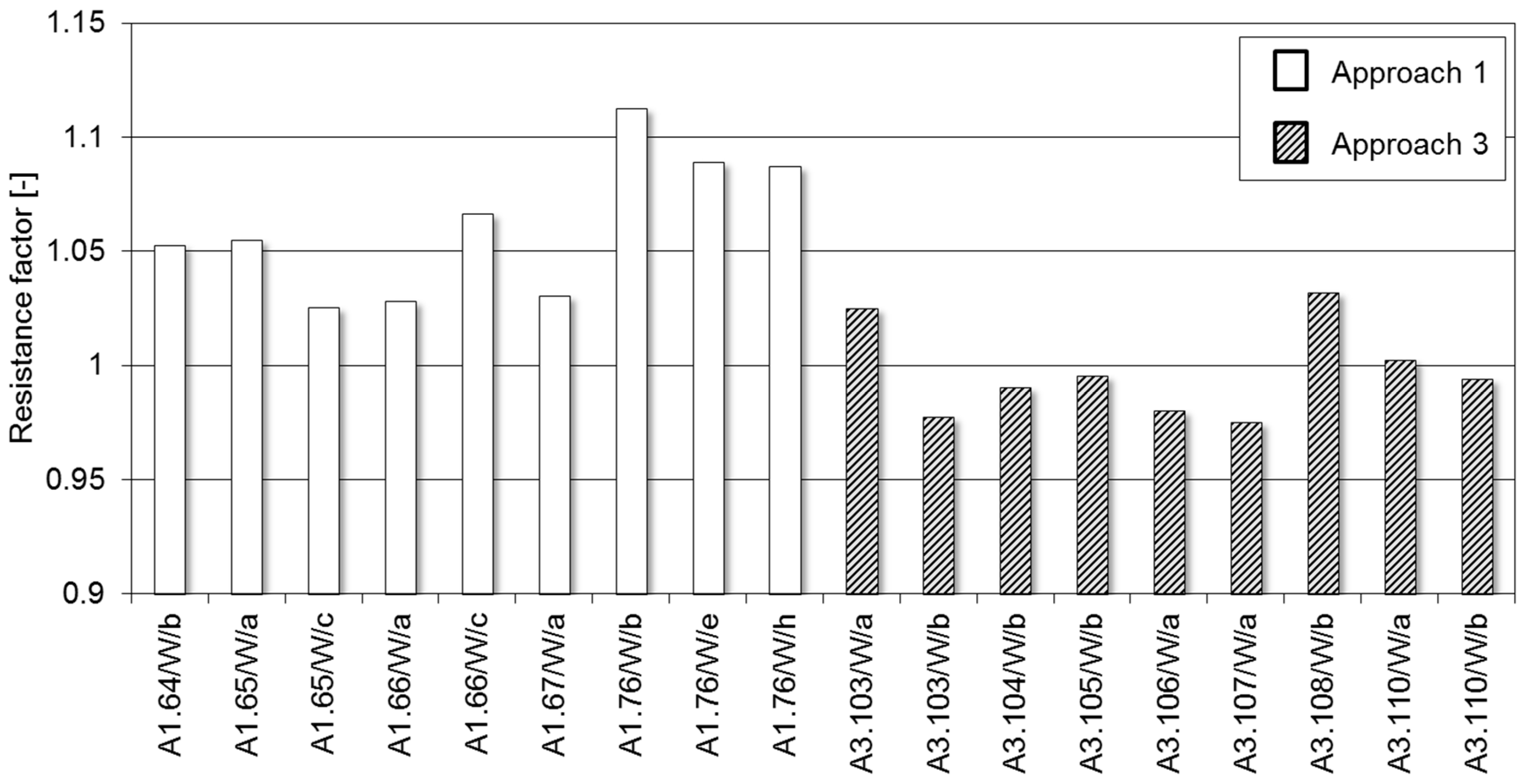

3.3. Electrical Properties of the Friction Stir Welds

4. Conclusions

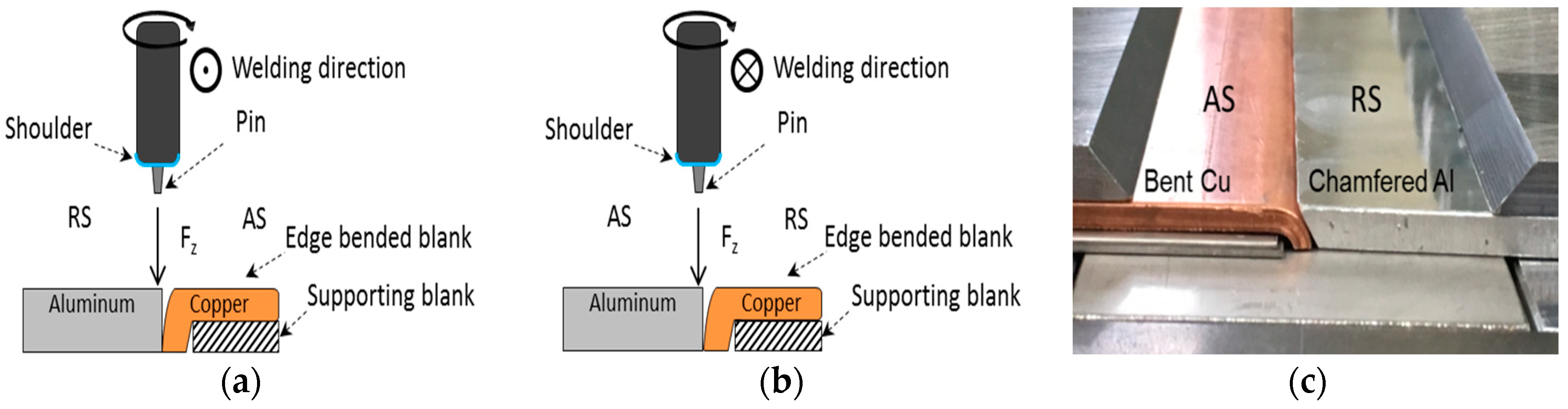

- Approach 1 included copper blanks that were edge bent on one side. These were positioned on the AS. The welds were produced with a welding speed of 450 mm/min.

- Approach 2 included copper blanks that were edge bent on one side. These were positioned on the RS. Using this approach no sound welds could be achieved. This is the reason why samples that were welded according to this approach were ignored for further analysis.

- Approach 3 included copper blanks that were edge bent on one side. These were positioned on the AS. Within this approach, the aluminum blanks were chamfered on one side to reduce the material deficit in the joining area. The welds were produced with a welding speed of 450 mm/min.

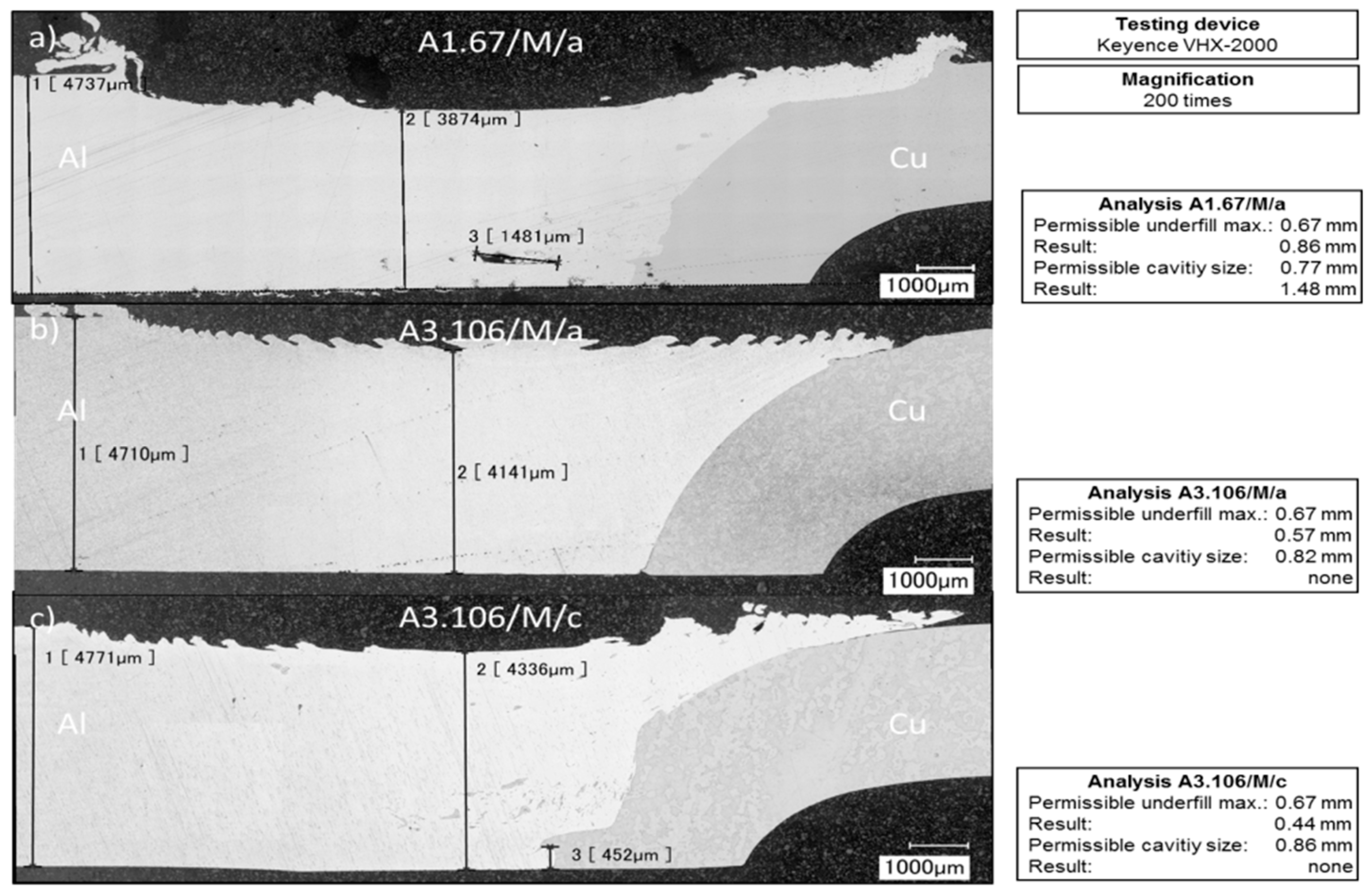

- The results of the macrostructural analysis showed a lack of penetration for both approaches and inadmissible cavities for approach 1. In general, the underfill maximum was smaller for approach 3.

- The average UTF for samples that were welded according to approach 1 was 7.78 kN while approach 3 achieved an average value of 8.89 kN. Compared to the aluminum base material, the joint efficiency was 57% for approach 1 and 65% for approach 3, respectively. The specimen with the best mechanical properties had a joint efficiency of 81%.

- The average electrical resistance for approach 1 was 0.0075 mΩ and for approach 3 the electrical resistance was 0.0070 mΩ. The calculated resistance factor for both approaches indicated a long-term stable behavior of the joints.

- In general, welds with good tensile properties lead to lower electrical resistances.

Author Contributions

Funding

Conflicts of Interest

References

- Li, X.-W.; Zhang, D.-T.; Qiu, C.; Zhang, W. Microstructure and mechanical properties of dissimilar pure copper/1350 aluminum alloy butt joints by friction stir welding. Trans. Nonferrous Met. Soc. China 2012, 22, 1298–1306. [Google Scholar] [CrossRef]

- Deutsches Kupfer-Institut e.V. Kupfer in der Elektrotechnik—Kabel und Leitungen; Deutsches Kupfer-Institut: Düsseldorf, Germany, 2000. [Google Scholar]

- Bargel, H.-J.; Schulze, G. Werkstoffkunde; Springer: Düsseldorf, Germany, 2016. [Google Scholar]

- Braunovic, M.; Myshkin, N.K.; Konchits, V.V. Electrical Contacts: Fundamentals, Applications and Technology. Taylor and Francis Distributor; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Khodir, S.A.; Ahmed, M.M.Z.; Ahmed, E.; Mohamed, S.M.R.; Abdel-Aleem, H. Effect of Intermetallic Compound Phases on the Mechanical Properties of the Dissimilar Al/Cu Friction Stir Welded Joints. J. Mater. Eng. Perform. 2016, 25, 4637–4648. [Google Scholar] [CrossRef]

- Xue, P.; Xiao, B.L.; Ni, D.R.; Ma, Z.Y. Enhanced mechanical properties of friction stir welded dissimilar Al–Cu joint by intermetallic compounds. Mater. Sci. Eng. A 2010, 527, 5723–5727. [Google Scholar] [CrossRef]

- Xue, P.; Ni, D.R.; Wang, D.; Xiao, B.L.; Ma, Z.Y. Effect of friction stir welding parameters on the microstructure and mechanical properties of the dissimilar Al–Cu joints. Mater. Sci. Eng. A 2011, 528, 4683–4689. [Google Scholar] [CrossRef]

- Barekatain, H.; Kazeminezhad, M.; Kokabi, A.H. Microstructure and Mechanical Properties in Dissimilar Butt Friction Stir Welding of Severely Plastic Deformed Aluminum AA 1050 and Commercially Pure Copper Sheets. J. Mater. Sci. Technol. 2014, 30, 826–834. [Google Scholar] [CrossRef]

- Zhang, Q.-Z.; Gong, W.-B.; Liu, W. Microstructure and mechanical properties of dissimilar Al–Cu joints by friction stir welding. Trans. Nonferrous Met. Soc. China 2015, 25, 1779–1786. [Google Scholar] [CrossRef]

- Al-Roubaiy, A.O.; Nabat, S.M.; Batako, A.D.L. Experimental and theoretical analysis of friction stir welding of Al–Cu joints. Int. J. Adv. Manuf. Tech. 2014, 71, 1631–1642. [Google Scholar] [CrossRef]

- Thomas, W.M.; Nicholas, E.D.; Needham, J.C.; Murch, M.G.; Templesmith, P.; Dawes, C.J. Improvements Relating to Friction Welding. U.S. Patent 5,460,317, 10 June 1993. [Google Scholar]

- Matthes, K.-J.; Schneider, W. Schweißtechnik. Schweißen von Metallischen Konstruktionswerkstoffen; Carl Hanser Verlag: München, Germany, 2016. [Google Scholar]

- Celik, S.; Cakir, R. Effect of Friction Stir Welding Parameters on the Mechanical and Microstructure Properties of the Al-Cu Butt Joint. Metals 2016, 6, 133. [Google Scholar] [CrossRef]

- Mishra, R.S.; De, P.S.; Kumar, N. Friction Stir Welding and Processing: Science and Engineering; Springer International Publishing: New York, NY, USA, 2014. [Google Scholar]

- Ott, M. Neues Verfahren fügt Bleche besser zusammen. Aluminium Praxis, 3 February 2017. [Google Scholar]

- Fratini, L.; Buffa, G.; Shivpuri, R. Improving friction stir welding of blanks of different thicknesses. Mater. Sci. Eng. A 2007, 459, 209–215. [Google Scholar] [CrossRef]

- Sahu, P.K.; Pal, S. Mechanical properties of dissimilar thickness aluminium alloy weld by single/double pass FSW. J. Mater. Process. Technol. 2017, 243, 442–455. [Google Scholar] [CrossRef]

- Ezumi, M. Friction Stir Welding Method of Two Members Having Different Thicknesses. Google Patent EP1825946A1, 29 August 2007. [Google Scholar]

- Weigl, M.; Feineis, A.; Sascha, C.; Kunz, M. Verfahren und Vorrichtung zum Rührreibschweißen bei Materialien unterschiedlicher Dicke und bei Kehlnähten. Google Patent DE102014001050A1, 30 July 2015. [Google Scholar]

- Werz, M.; Hoßfeld, M.; Volz, O. Verfahren zum Stumpfverschweißen sowie Bauteil und Rührreibschweißwerkzeug. Google Patent DE102013110034A1, 12 March 2015. [Google Scholar]

- Deutsches Institut für Normung e.V. Aluminium und Aluminiumlegierungen—Chemische Zusammensetzung und Form von Halbzeug—Teil 3: Chemische Zusammensetzung und Erzeugnisformen; Beuth Verlag GmbH: Berlin, Germany, 2013; DIN EN 573-3. [Google Scholar]

- Deutsches Institut für Normung e.V. Kupfer und Kupferlegierungen—Platten, Bleche und Bänder aus Kupfer für die Anwendung in der Elektrotechnik; Beuth Verlag GmbH: Berlin, Germany, 2014; DIN EN 13599. [Google Scholar]

- Deutsches Institut für Normung e.V. Rührreibschweißen—Aluminium—Teil 5: Qualitäts-und Prüfungsanforderungen; Beuth Verlag GmbH: Berlin, Germany, 2012; DIN EN ISO 25239-5. [Google Scholar]

- Deutsches Institut für Normung e.V. Zerstörende Prüfung von Schweißverbindungen an Metallischen Werkstoffen—Querzugversuch; Beuth Verlag GmbH: Berlin, Germany, 2013; DIN EN ISO 4136:2012. [Google Scholar]

- Schmidt, P.A. Laserstrahlschweissen Elektrischer Kontakte von Lithium-Ionen-Batterien in Elektro- und Hybridfahrzeugen; Herbert Utz: München, Germany, 2015. [Google Scholar]

- Essers, M.; Schiebahn, A.; Reisgen, U. Widerstandsbuckelschweißen von Al-Cu-Mischverbindungen zur Generierung elektrischer Kontaktierungen. Große Schweißtechnische Tagung, DVS-Studentenkongress, Nürnberg, Germany, 17 September 2015. [Google Scholar]

| Materials | Al | Fe | Si | Mn | Mg | Zn | Ti | Pb | Bi | Cu |

|---|---|---|---|---|---|---|---|---|---|---|

| EN AW-1050A | ≥99.50 | ≤0.40 | ≤0.25 | ≤0.05 | ≤0.05 | ≤0.07 | ≤0.05 | - | - | ≤0.05 |

| CW008A | - | - | - | - | - | - | - | ≤0.005 | ≤0.0005 | ≥99.95 |

| Approach | Rotational Speed (rpm) | Feed Rate (mm/min) | Plunge Depth (mm) | Dwell Time (s) | Tool Tilt Angle(°) | Tool Pin Length (mm) | Tool Shoulder Shape | Offset(mm) |

|---|---|---|---|---|---|---|---|---|

| A1 | 1100 | 450 | 4.25 | 2 | 4 | 3.7 | flat | 2.0 |

| A3 | 1100 | 450 | 4.20 | 2 | 3 | 3.8 | flat | 1.8 |

| Approach | FSW No. | Method | Order |

|---|---|---|---|

| A1 | 1–76 | T = Tensile testing | a–i |

| A3 | 100–110 | M = Metallographic analysis | a–c |

| - | - | R = Electrical resistance | - |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Eslami, N.; Harms, A.; Deringer, J.; Fricke, A.; Böhm, S. Dissimilar Friction Stir Butt Welding of Aluminum and Copper with Cross-Section Adjustment for Current-Carrying Components. Metals 2018, 8, 661. https://doi.org/10.3390/met8090661

Eslami N, Harms A, Deringer J, Fricke A, Böhm S. Dissimilar Friction Stir Butt Welding of Aluminum and Copper with Cross-Section Adjustment for Current-Carrying Components. Metals. 2018; 8(9):661. https://doi.org/10.3390/met8090661

Chicago/Turabian StyleEslami, Nima, Alexander Harms, Johann Deringer, Andreas Fricke, and Stefan Böhm. 2018. "Dissimilar Friction Stir Butt Welding of Aluminum and Copper with Cross-Section Adjustment for Current-Carrying Components" Metals 8, no. 9: 661. https://doi.org/10.3390/met8090661

APA StyleEslami, N., Harms, A., Deringer, J., Fricke, A., & Böhm, S. (2018). Dissimilar Friction Stir Butt Welding of Aluminum and Copper with Cross-Section Adjustment for Current-Carrying Components. Metals, 8(9), 661. https://doi.org/10.3390/met8090661