Inclusion Evolution Behavior of Ti-Mg Oxide Metallurgy Steel and Its Effect on a High Heat Input Welding HAZ

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

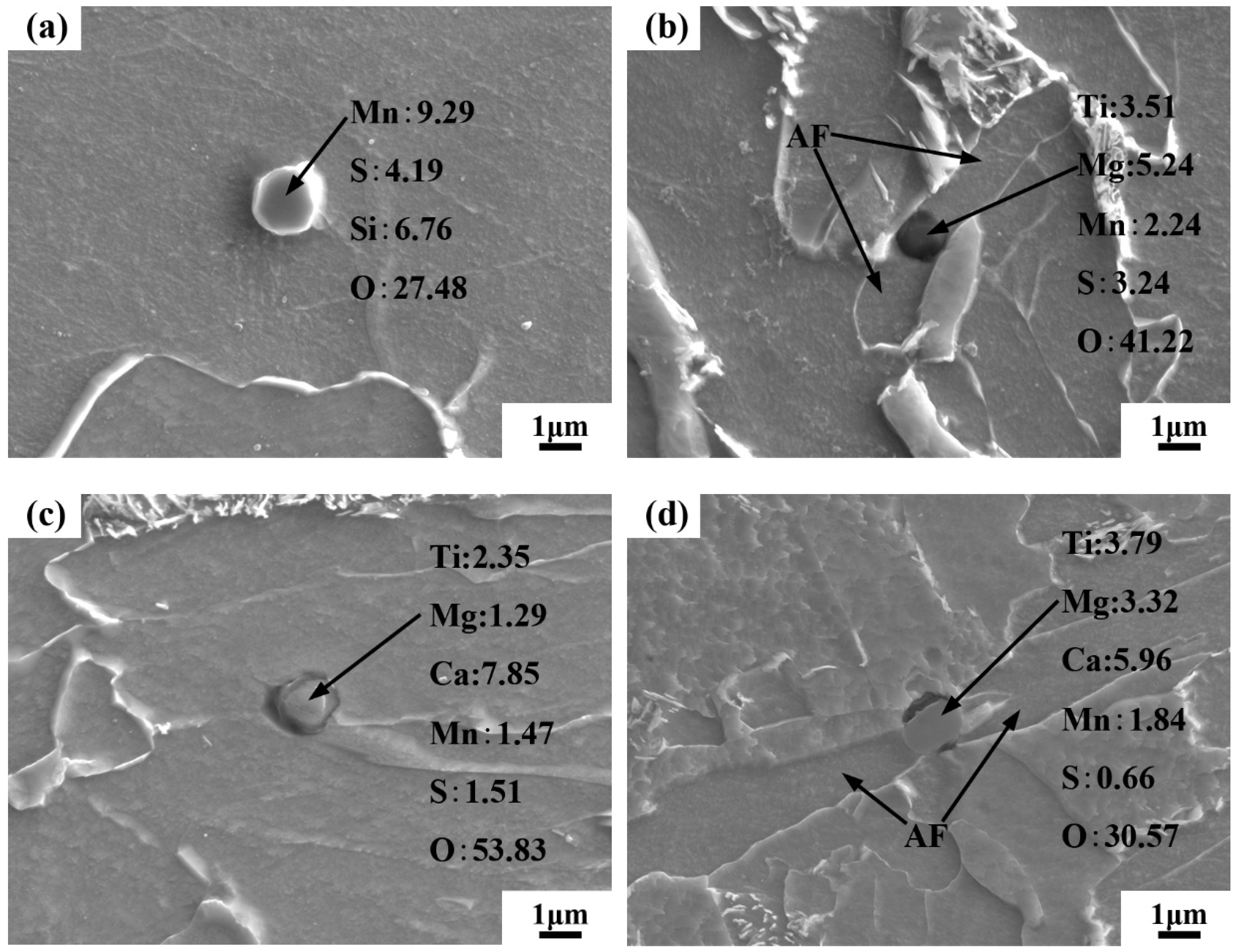

3.1. Evolution of Inclusions in EH420-Mg

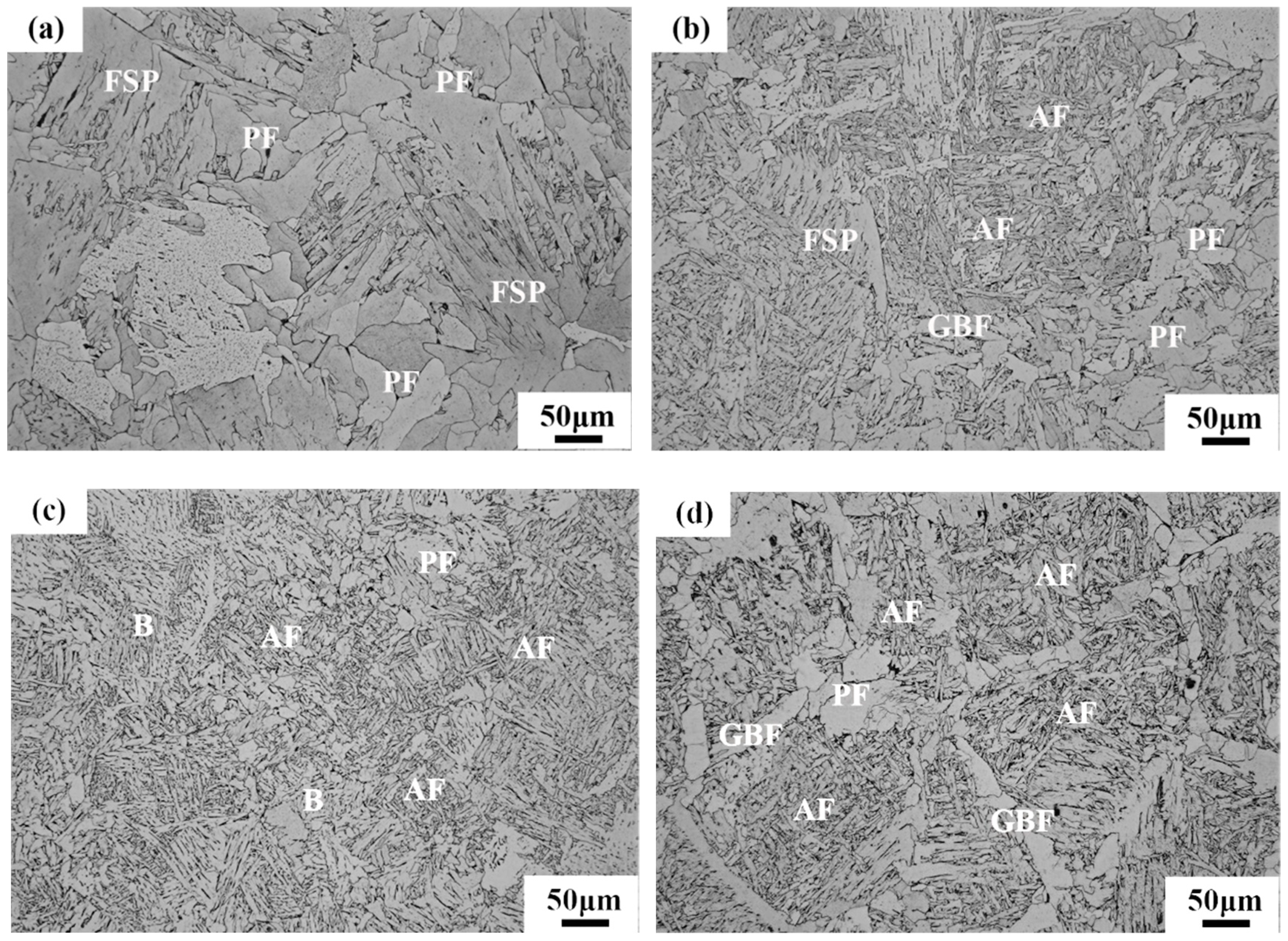

3.2. Evolution of Microstructure in EH420-Mg

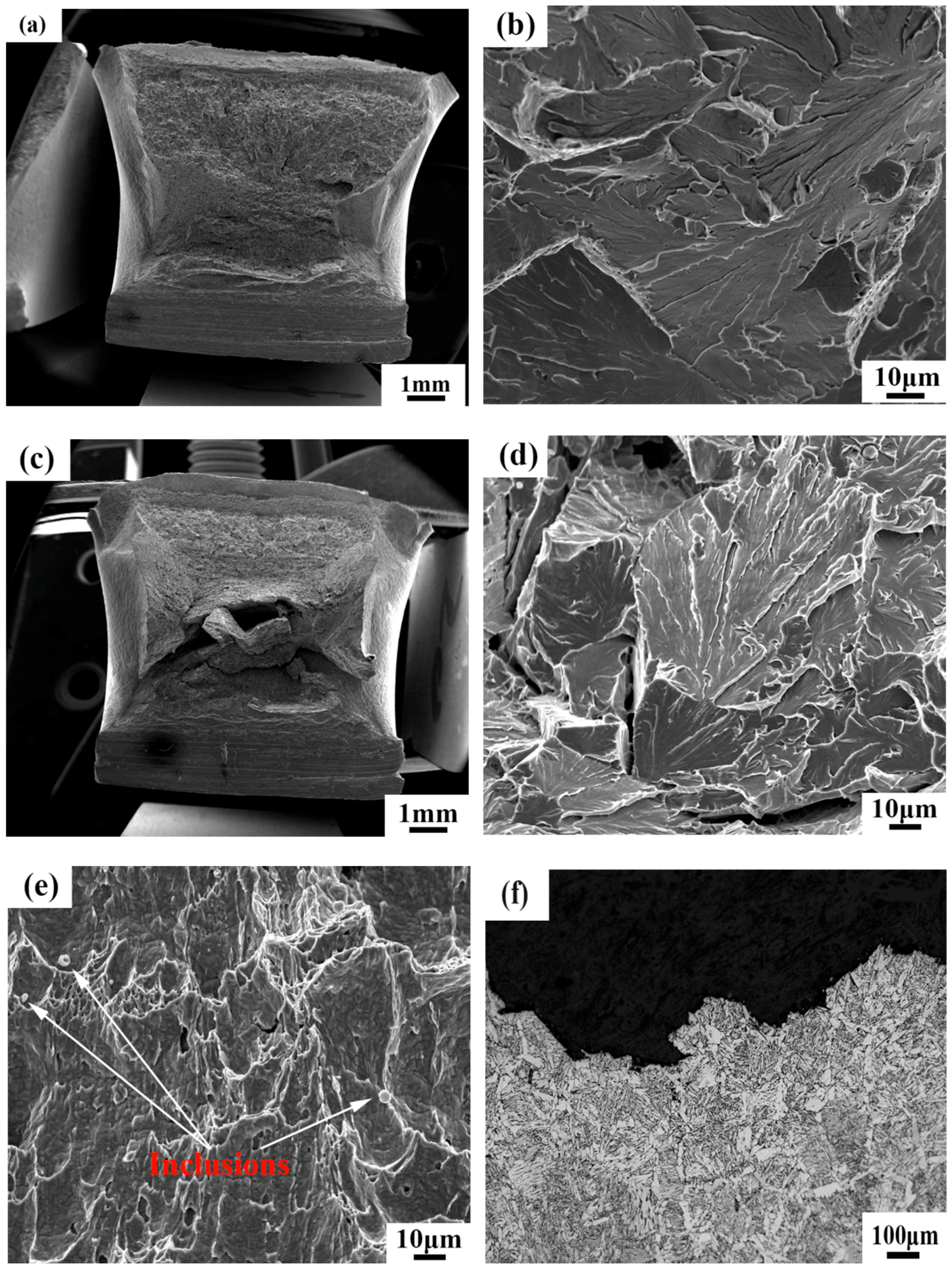

3.3. Effect of Inclusions on the HAZ after High Heat Input Welding

4. Conclusions

- The composition of inclusions in the core changed from silicomanganate and MnS (LF furnace station) to Ti-Mg-O (Ti-Mg treatment in the LF furnace) and finally to Ti-Ca-Mg-O in EH420-Mg. The corresponding average size of inclusions decreased from 0.83 μm to 0.47 μm, and the number density decreased from 1508 /mm2 to 874 /mm2. After the thermal welding simulation, the inclusions of size less than 0.4 μm disappeared.

- For EH420-Mg steel, after a continuous cooling transformation by a dilatometer, the microstructure of the LF furnace station sample was composed of FSP and PF, which then changed to AF, PF, and B (vacuum treatment in an RH furnace), while in the welded sample, the microstructure was composed of AF, GBF, and PF. A Ti-Mg-containing oxide promoted the nucleation of AF.

- An interlocking AF microstructure acts as an obstacle to the propagation of cleavage cracks. Fine-size cleavage facets, small inclusions, and dense dimples contributed to the high impact toughness in Ti-Mg oxide metallurgy steel.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Garrison, W.M.; Wojcieszynski, A.L. A discussion of the effect of inclusion volume fraction on the toughness of steel. Mater. Sci. Eng. A 2007, 464, 321–329. [Google Scholar] [CrossRef]

- Faulring, G.M.; Ramalingam, S. Oxide inclusions and tool wear in maching. Metall. Trans. A 1979, 10, 1781–1788. [Google Scholar] [CrossRef]

- Sawai, T.; Wakoh, M.; Ueshima, Y.; Mizoguchi, S. Analysis of oxide dispersion during solidification in Ti, Zr-deoxidized steels. ISIJ Int. 1992, 32, 169–173. [Google Scholar] [CrossRef]

- Ma, Z.T.; Janke, D. Oxide metallurgy-its purposes and practical approaches. Acta Metall. 1998, 22, 79–86. [Google Scholar]

- Wang, C.; Misra, R.D.K.; Shi, M.H.; Zhang, P.Y.; Wang, Z.D.; Zhu, F.X.; Wang, G.D. Transformation behavior of a Ti-Zr deoxidized steel: microstructure and toughness of simulated coarse grain heat affected zone. Mater. Sci. Eng. A 2014, 594, 218–228. [Google Scholar] [CrossRef]

- Suito, H.; Vladimirovich, K.A.; Hamada, M.; Inoue, R.; Nakajima, K. Influence of oxide particles and residual elements on microstructure and toughness in the heat-affected zone of low-carbon steel deoxidized with Ti and Zr. ISIJ Int. 2011, 51, 1151–1162. [Google Scholar] [CrossRef]

- Kim, B.; Uhm, S.; Lee, C.; Lee, J.; An, Y. Effects of inclusions and microstructures on impact energy of high heat-input submerged-arc-weld metals. J. Eng. Mater. Technol. 2005, 127, 204–213. [Google Scholar] [CrossRef]

- Wan, X.L.; Wei, R.; Wu, K.M. Effect of acicular ferrite formation on grain refinement in the coarse-grained region of heat-affected zone. Mater. Charact. 2010, 61, 726–731. [Google Scholar] [CrossRef]

- Wan, X.L.; Wu, K.M.; Huang, G.; Wei, R.; Cheng, L. In situ observation of austenite grain growth behavior in the simulated coarse-grained heat-affected zone of Ti-microalloyed steels. Int. J. Miner. Metal. Mater. 2014, 21, 878–893. [Google Scholar] [CrossRef]

- Wan, X.L.; Wu, K.M.; Huang, G.; Wei, R. In situ observations of the formation of fine-grained mixed microstructures of acicular ferrite and bainite in the simulated coarse-grained heated-affected zone. Steel Res. Int. 2014, 85, 243–250. [Google Scholar] [CrossRef]

- Zhu, K.; Yang, J.; Wang, R.Z.; Yang, Z.G. Effect of Mg addition on inhibiting austenite grain growth in heat affected zones of Ti-bearing low carbon steels. J. Iron Steel Res. Int. 2011, 18, 60–64. [Google Scholar] [CrossRef]

- Xu, L.Y.; Yang, J.; Wang, R.Z.; Wang, Y.N.; Wang, W.L. Effect of Mg content on the microstructure and toughness of heat-affected zone of steel plate after high heat input welding. Metall. Mater. Trans. A 2016, 47, 3354–3364. [Google Scholar] [CrossRef]

- KiviÖ, M.; Holappa, L. Addition of titanium oxide inclusions into liquid steel to control nonmetallic inclusions. Metall. Mater. Trans. B 2012, 43, 233–240. [Google Scholar] [CrossRef]

- Zhang, L.F. Nucleation, growth, transport, and entrapment of inclusions during steel casting. JOM 2013, 65, 1138–1144. [Google Scholar] [CrossRef]

- Chai, F.; Yang, C.F.; Su, H.; Zhang, Y.Q.; Xu, Z. Effect of magnesium on inclusion formation in Ti-killed steel and microstructural evolution in welding induced coarse-grain heat affected zone. J. Iron Steel Res. Int. 2009, 16, 69–74. [Google Scholar] [CrossRef]

- Sakata, K.; Suito, H. Grain-growth-inhibiting effects of primary inclusion particles of ZrO2 and MgO in Fe-10 mass pct Ni alloy. Metall. Mater. Trans. A 2000, 31, 1213–1223. [Google Scholar] [CrossRef]

- Holappa, L.; Hämäläinen, M.; Liukkonen, M.; Lind, M. Thermodynamic examination of inclusion modification and precipitation from calcium treatment to solidified steel. Ironmak. Steelmak. 2003, 30, 111–115. [Google Scholar] [CrossRef]

- Kimura, S.; Nakajima, K.; Mizoguchi, S. Behavior of alumina-magnesia complex inclusions and magnesia inclusions on the surface of molten low-carbon steels. Mater. Trans. A 2001, 32, 79–85. [Google Scholar] [CrossRef]

- Kim, H.S.; Lee, H.G.; Oh, K.S. Evolution of size, composition, and morphology of primary and secondary inclusions in Si/Mn and Si/Mn/Ti deoxidized steels. ISIJ Int. 2002, 42, 1404–1411. [Google Scholar] [CrossRef]

- Hou, Y.; Zheng, W.; Wu, Z.; Li, G.; Moelans, N.; Guo, M.; Khan, B.S. Study of Mn absorption by complex oxide inclusions in Al-Ti-Mg killed steels. Acta Mater. 2016, 118, 8–16. [Google Scholar] [CrossRef]

- Lifshitz, I.M.; Slyozov, V.V. The kinetics of precipitation from supersaturated solid solutions. J. Phys. Chem. Solids 1961, 19, 35–50. [Google Scholar] [CrossRef]

- Wagner, C. Theorie der Alterung von Niederschägen durch Umlösen. Z. Elektrochem. 1961, 65, 581–594. [Google Scholar]

- Gourgues, A.F.; Flower, H.M.; Lindley, T.C. Electron backscattering diffraction study of acicular ferrite, bainite, and martensite steel microstructure. Mater. Sci. Technol. 2000, 16, 26–40. [Google Scholar] [CrossRef]

- Byun, J.S.; Shim, J.H.; Cho, Y.W.; Lee, D.N. Non-metallic inclusion and intragranular nucleation of ferrite in Ti-killed C-Mn steel. Acta Mater. 2003, 51, 1593–1606. [Google Scholar] [CrossRef]

- Shim, J.H.; Cho, Y.W.; Chung, S.H.; Shim, J.D.; Lee, D.N. Nucleation of intragranular ferrite at Ti2O3 particle in low carbon steel. Acta Mater. 1999, 47, 2751–2760. [Google Scholar] [CrossRef]

- Shim, J.H.; Oh, Y.J.; Suh, J.Y.; Cho, Y.W.; Shim, J.D.; Byun, J.S.; Lee, D.N. Ferrite nucleation potency of non-metallic inclusions in medium carbon steels. Acta Mater. 2001, 49, 2115–2122. [Google Scholar] [CrossRef]

- Mabuchi, H.; Uemore, R.; Fujioka, M. The role of Mn depletion in intra-granular ferrite transformation in the heat affected zone of welded joints with large heat input in structural steels. ISIJ Int. 1996, 36, 1406–1412. [Google Scholar] [CrossRef]

- Zhang, Z.; Farrar, R.A. Role of non-metallic inclusions in formation of acicular ferrite in low alloy weld metals. Mater. Sci. Technol. 1996, 12, 237–260. [Google Scholar] [CrossRef]

- Enomoto, M. Nucleation of phase transformation at intragranular inclusions in steel. Metab. Mater. 1998, 4, 115–123. [Google Scholar] [CrossRef]

- Zhang, S.; Hattori, N.; Enomoto, M.; Tarui, T. Ferrite nucleation at ceramic/austenite interfaces. ISIJ Int. 1996, 36, 1301–1309. [Google Scholar] [CrossRef]

- Lee, T.K.; Kim, H.J.; Kang, B.Y.; Hwang, S.K. Effect of inclusion size on the nucleation of acicular ferrite in welds. ISIJ Int. 2000, 40, 1260–1268. [Google Scholar] [CrossRef]

- Moon, J.; Lee, C.; Uhm, S.; Lee, J. Coarsening kinetics of TiN particle in a low alloyed steel in weld HAZ: considering critical particle size. Acta Mater. 2006, 54, 1053–1061. [Google Scholar] [CrossRef]

- Zener, C. Theory of growth of spherical precipitates from solid solution. J. Appl. Phys. 1949, 20, 950–953. [Google Scholar] [CrossRef]

- Zhu, K.; Yang, Z. Effect of magnesium on the austenite grain growth of the heat-affected zone in low-carbon high-strength steels. Metall. Mater. Trans. A 2011, 42, 2207–2213. [Google Scholar] [CrossRef]

- Fuentes, M.D.; Mendia, A.I.; Gutiérrez, I. Analysis of different acicular ferrite microstructures in low-carbon steels by electron backscattered diffraction. Study of their toughness behavior. Metall. Mater. Trans. A 2003, 34, 2505–2516. [Google Scholar] [CrossRef]

- Kim, Y.M.; Lee, H.; Kim, N.J. Transformation behavior and microstructural characteristics of acicular ferrite in linepipe steels. Mater. Sci. Eng. A 2008, 478, 361–370. [Google Scholar] [CrossRef]

- Sung, H.K.; Sang, S.Y.; Cha, W.; Oh, K.; Lee, S.; Kim, N.J. Effects of acicular ferrite on charpy impact properties in heat affected zones of oxide-containing API X80 linepipe steels. Mater. Sci. Eng. A 2011, 528, 3350–3357. [Google Scholar] [CrossRef]

| Steel | C | Si | Mn | S | P | Ti | Ca | Nb | Mg | Ni | O | N |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| EH420 | 0.06 | 0.12 | 1.53 | 0.008 | 0.008 | 0.015 | 0.003 | 0.014 | - | 0.28 | 0.005 | 0.005 |

| EH420-Mg | 0.07 | 0.12 | 1.65 | 0.006 | 0.005 | 0.013 | 0.003 | 0.015 | 0.003 | 0.3 | 0.003 | 0.005 |

| Steel | Impact Fracture | Impact Toughness (J) | |||||

|---|---|---|---|---|---|---|---|

| Fibrous Zone (pct) | Radical Zone (pct) | Shear Lip Zone (pct) | Individual Value | Mean | |||

| EH420 | 34.6 | 35.6 | 29.8 | 176 | 157 | 170 | 168 |

| EH420-Mg | 44.3 | 22.2 | 33.5 | 252 | 264 | 271 | 262 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lou, H.-N.; Wang, C.; Wang, B.-X.; Wang, Z.-D.; Li, Y.-Q.; Chen, Z.-G. Inclusion Evolution Behavior of Ti-Mg Oxide Metallurgy Steel and Its Effect on a High Heat Input Welding HAZ. Metals 2018, 8, 534. https://doi.org/10.3390/met8070534

Lou H-N, Wang C, Wang B-X, Wang Z-D, Li Y-Q, Chen Z-G. Inclusion Evolution Behavior of Ti-Mg Oxide Metallurgy Steel and Its Effect on a High Heat Input Welding HAZ. Metals. 2018; 8(7):534. https://doi.org/10.3390/met8070534

Chicago/Turabian StyleLou, Hao-Nan, Chao Wang, Bing-Xing Wang, Zhao-Dong Wang, Yu-Qian Li, and Zi-Gang Chen. 2018. "Inclusion Evolution Behavior of Ti-Mg Oxide Metallurgy Steel and Its Effect on a High Heat Input Welding HAZ" Metals 8, no. 7: 534. https://doi.org/10.3390/met8070534

APA StyleLou, H.-N., Wang, C., Wang, B.-X., Wang, Z.-D., Li, Y.-Q., & Chen, Z.-G. (2018). Inclusion Evolution Behavior of Ti-Mg Oxide Metallurgy Steel and Its Effect on a High Heat Input Welding HAZ. Metals, 8(7), 534. https://doi.org/10.3390/met8070534