Microstructural Characterization of Surface Softening Behavior for Cu-Bearing Martensitic Steels after Laser Surface Heat Treatment

Abstract

1. Introduction

2. Materials and Experimental Procedures

2.1. Materials

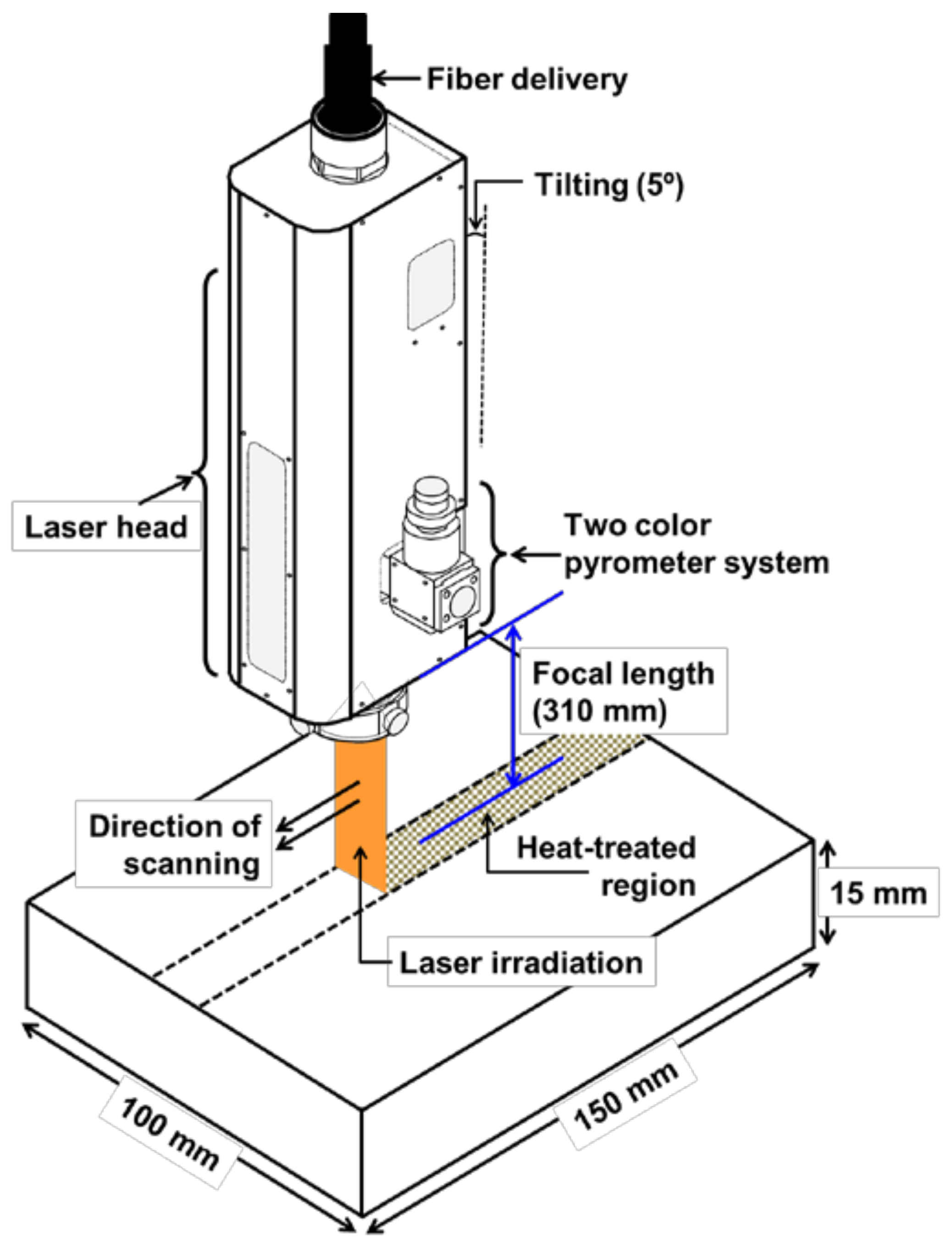

2.2. Experimental Procedures

3. Results and Discussion

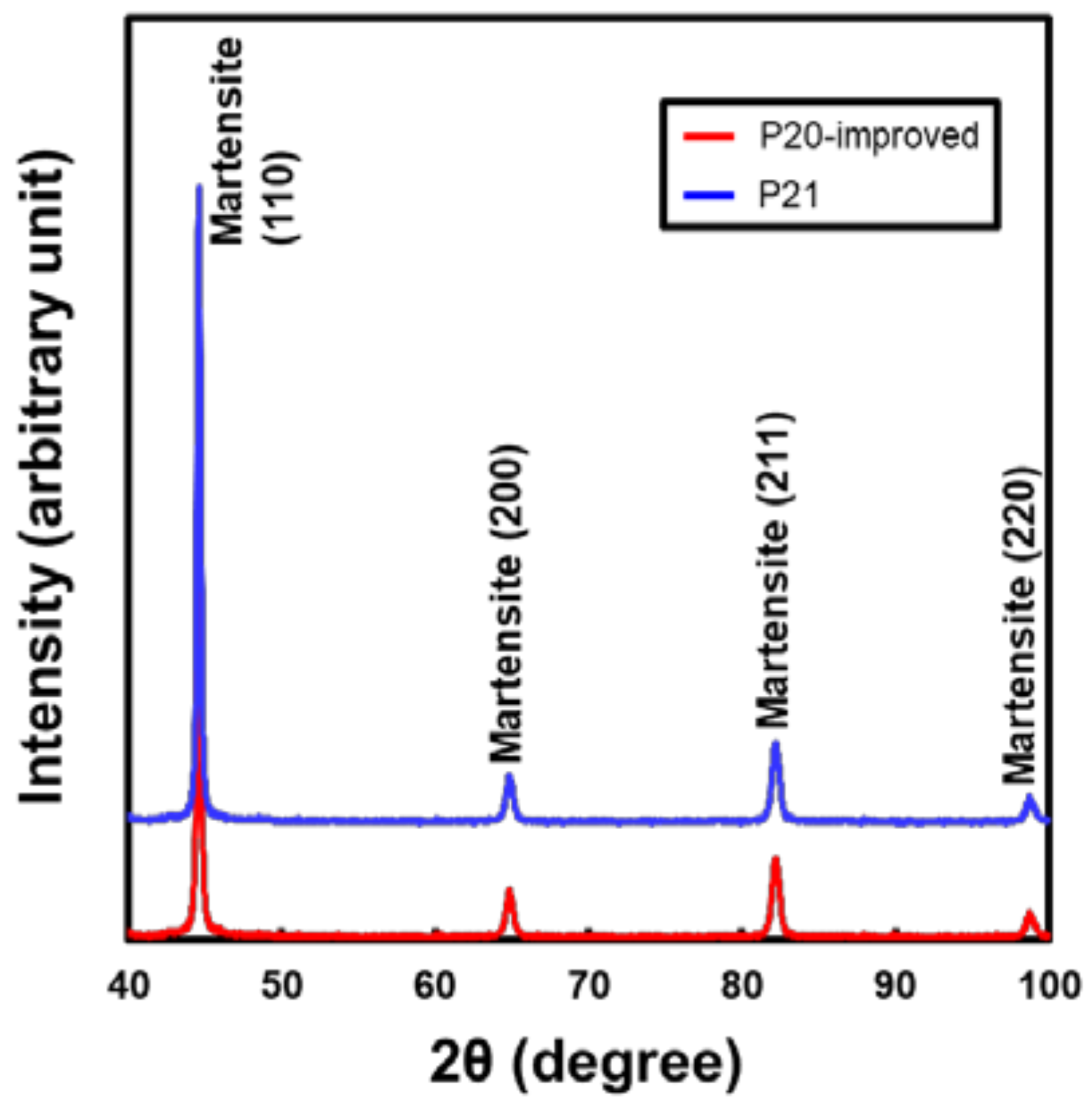

3.1. Microstructure of Base Metals (As-Recieved)

3.2. Determining Heat Treatment Conditions from Thermodynamic Calculations

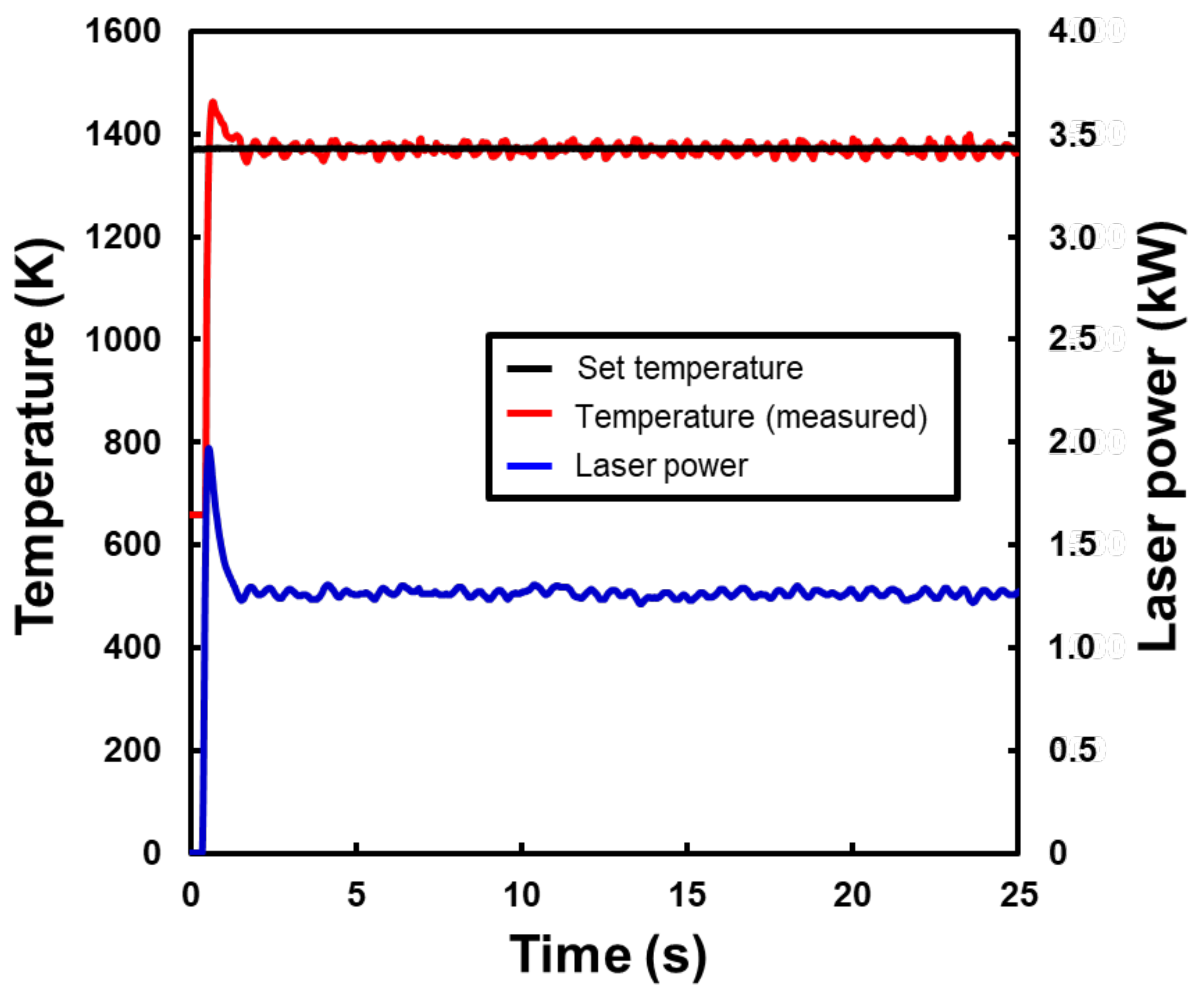

3.3. Laser Power and Surface Temperature during Laser-Assisted Heat Treatment

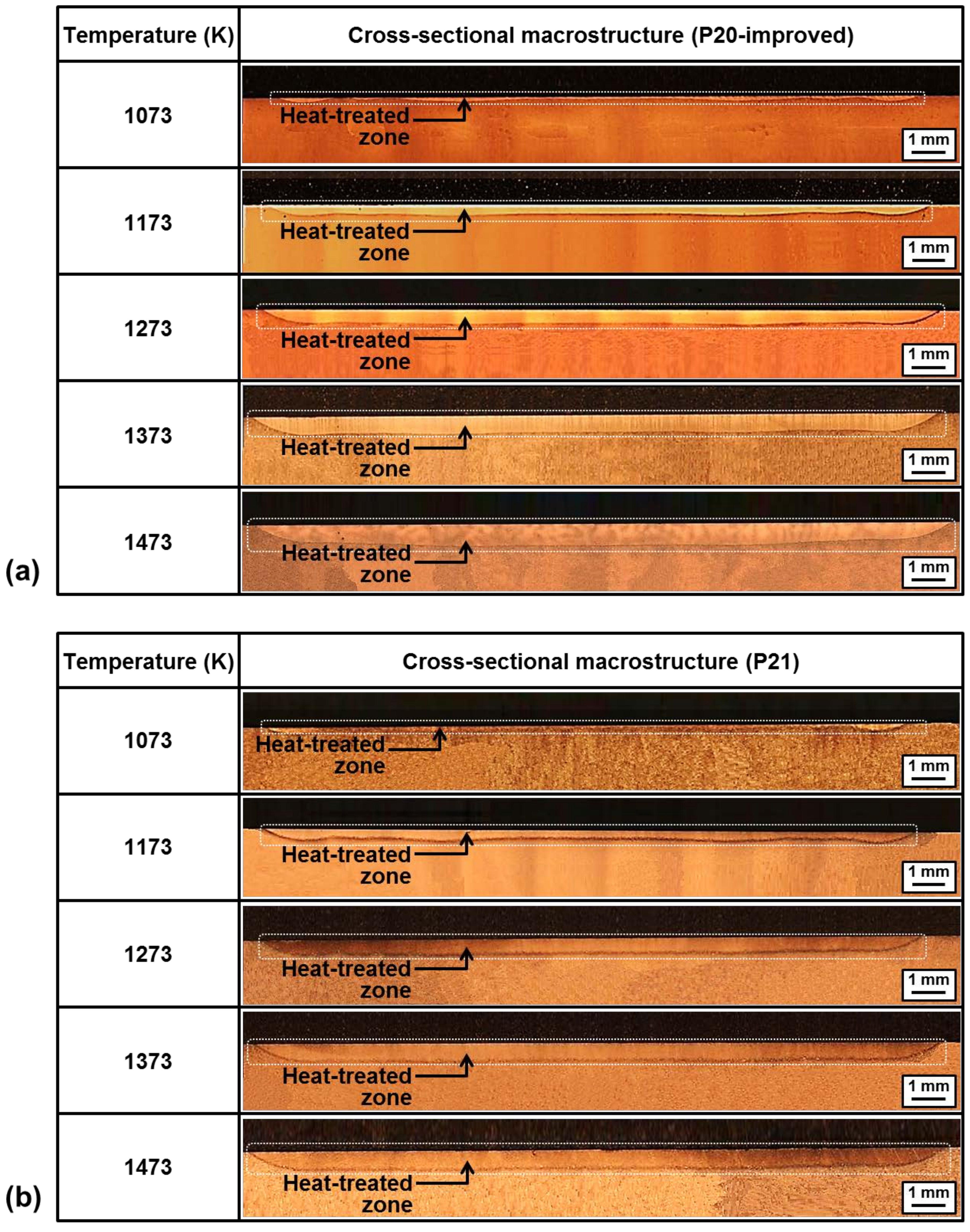

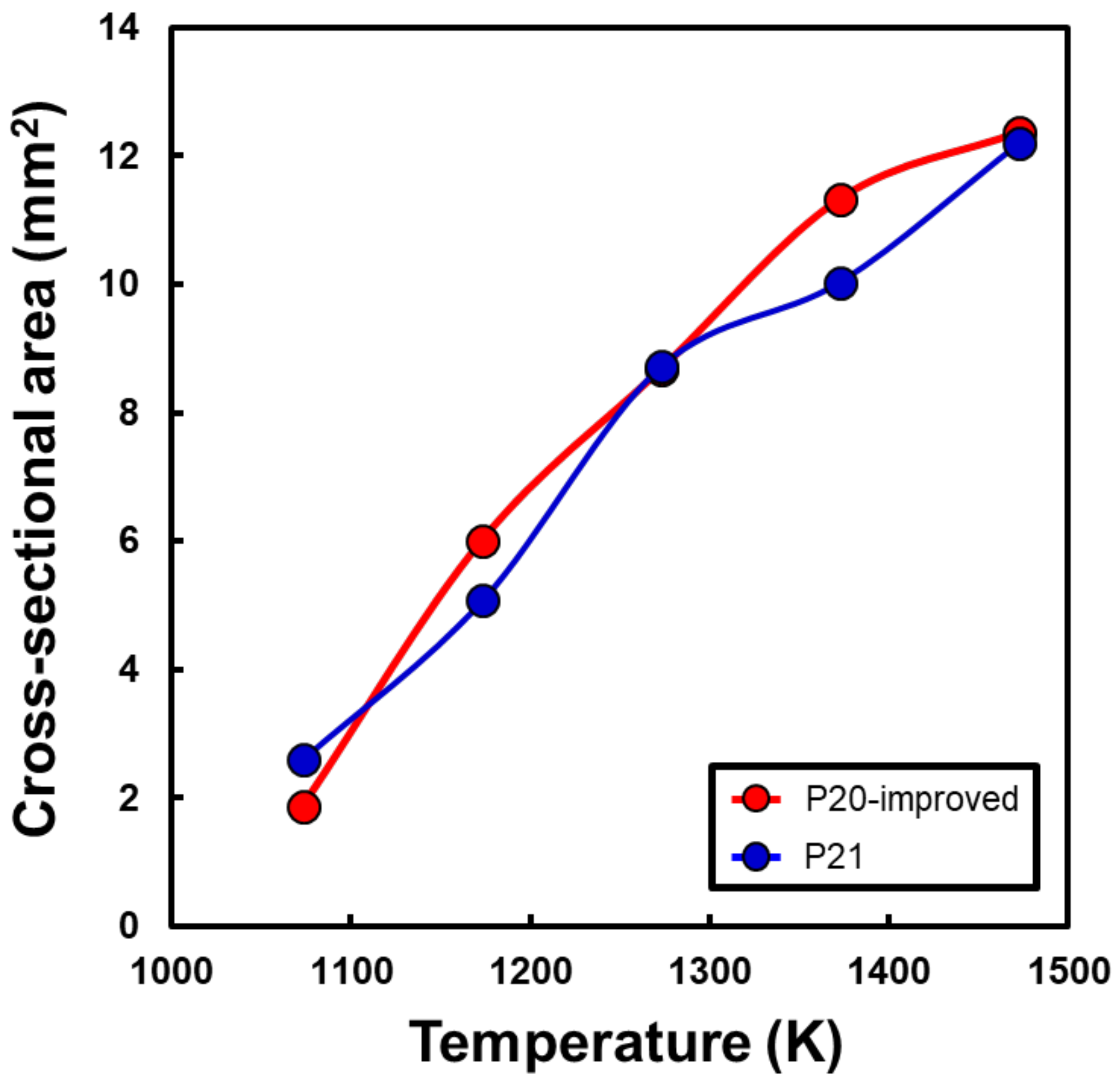

3.4. Cross-Sectional Macrostructure Variations with Temperature

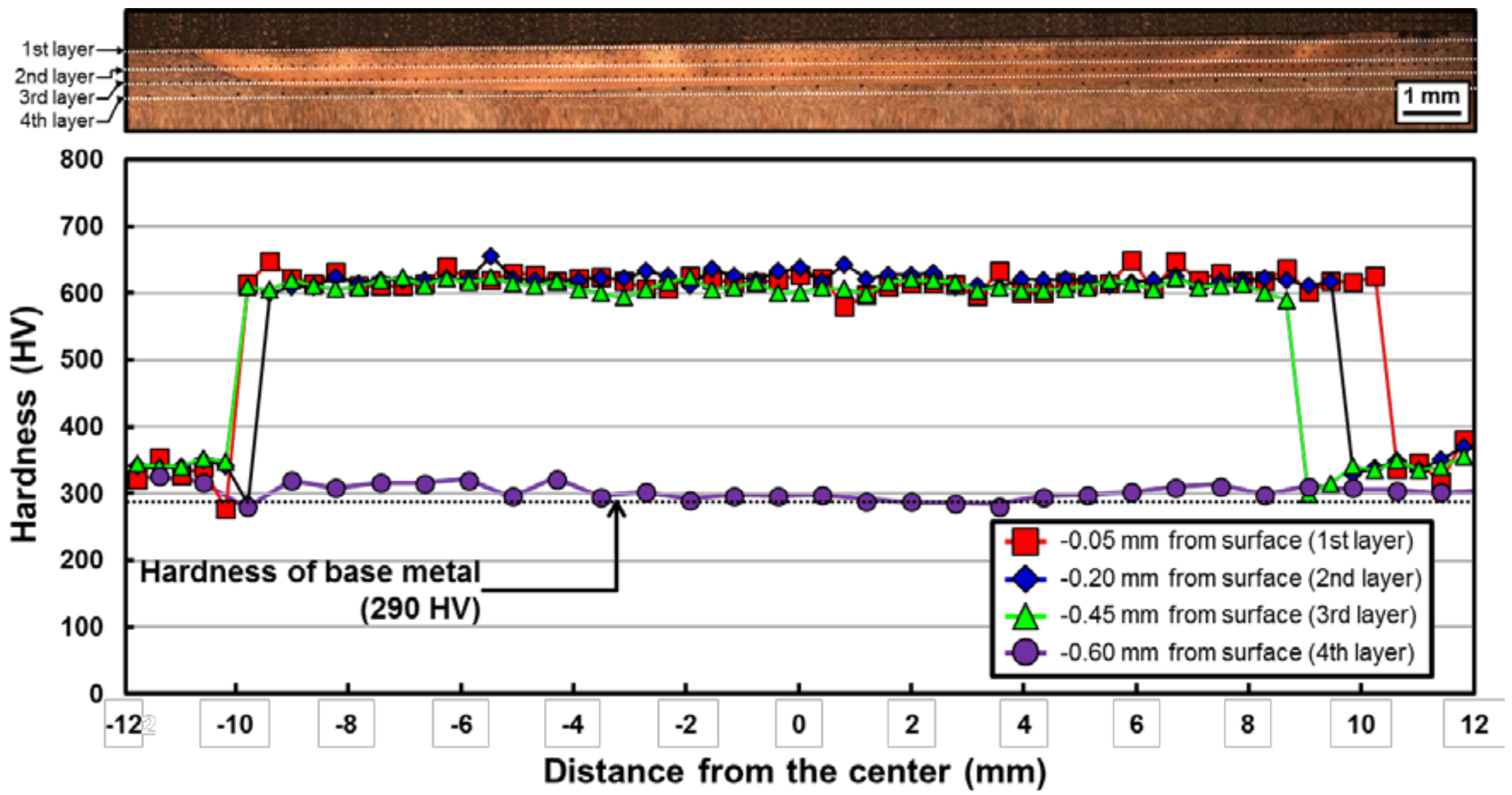

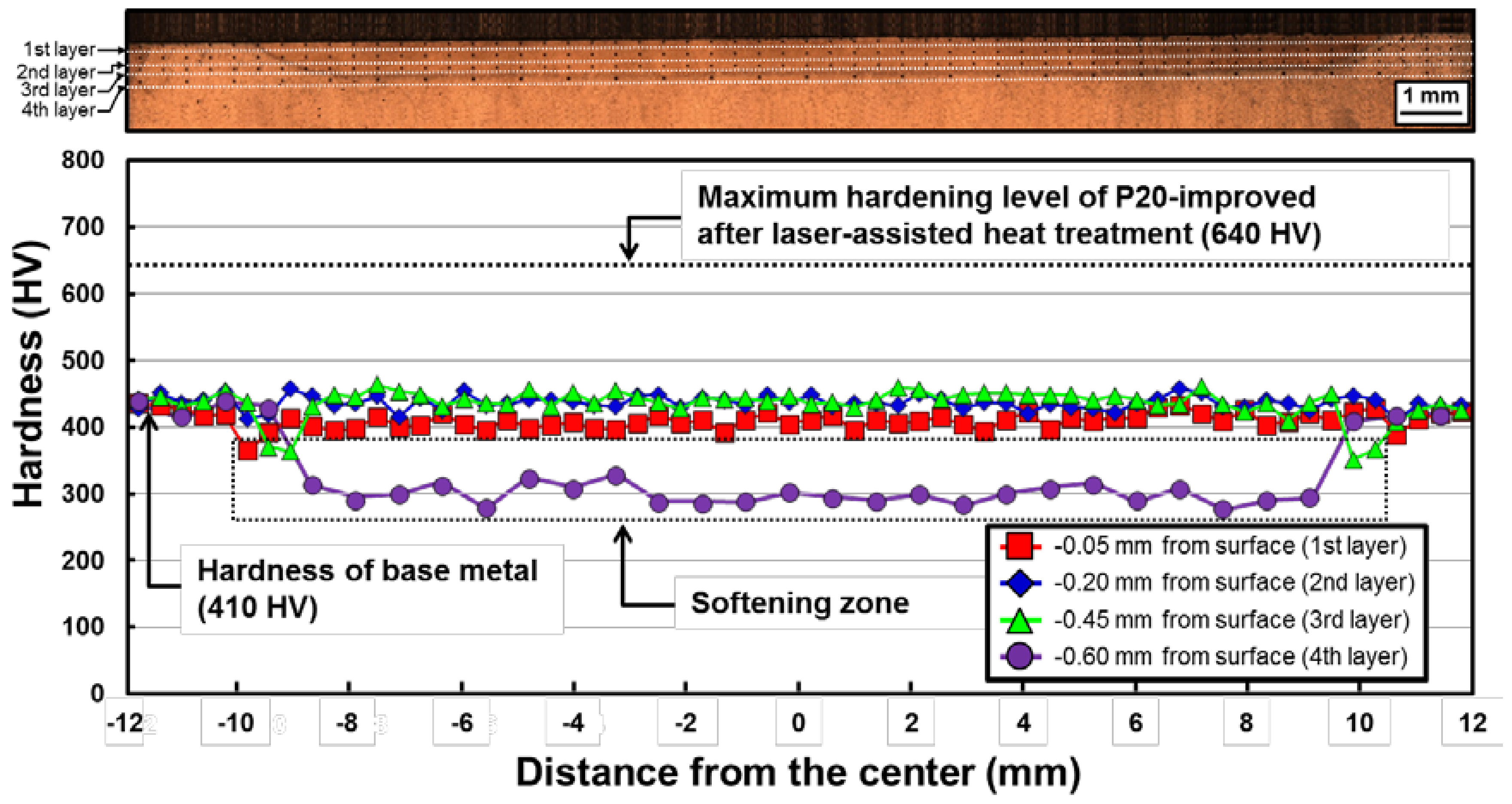

3.5. Hardening and Softening Behavior after Laser-Assisted Heat Treatment

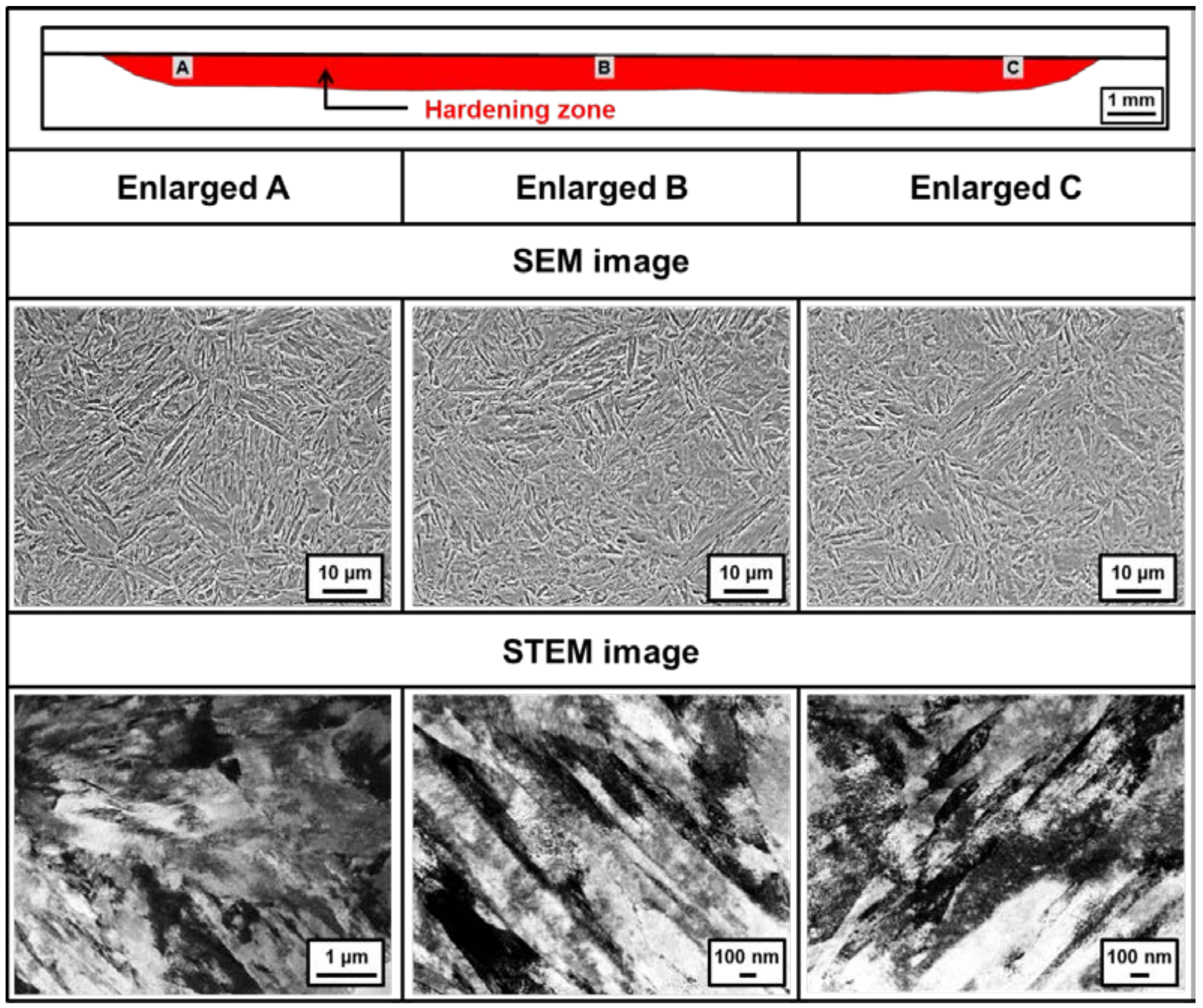

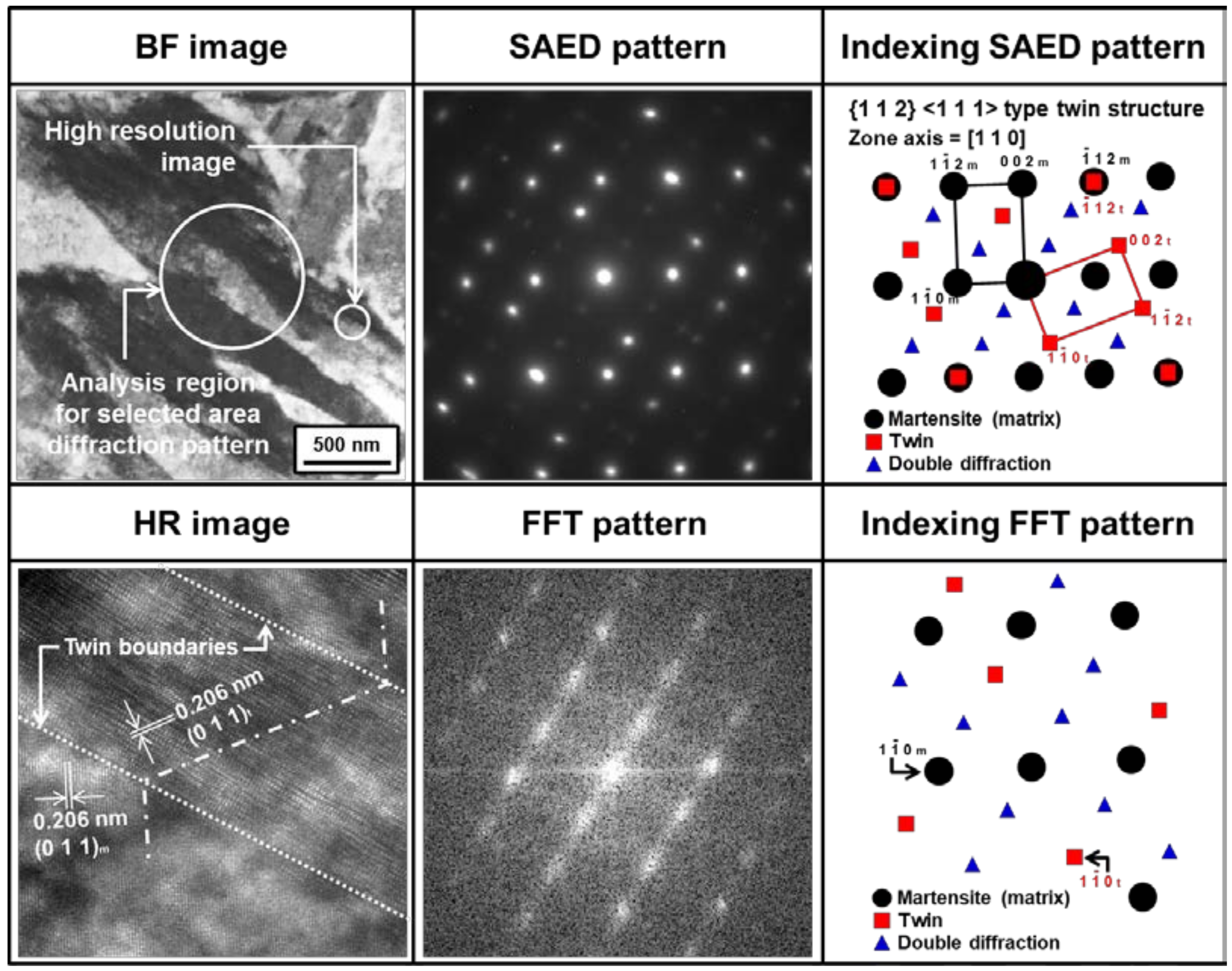

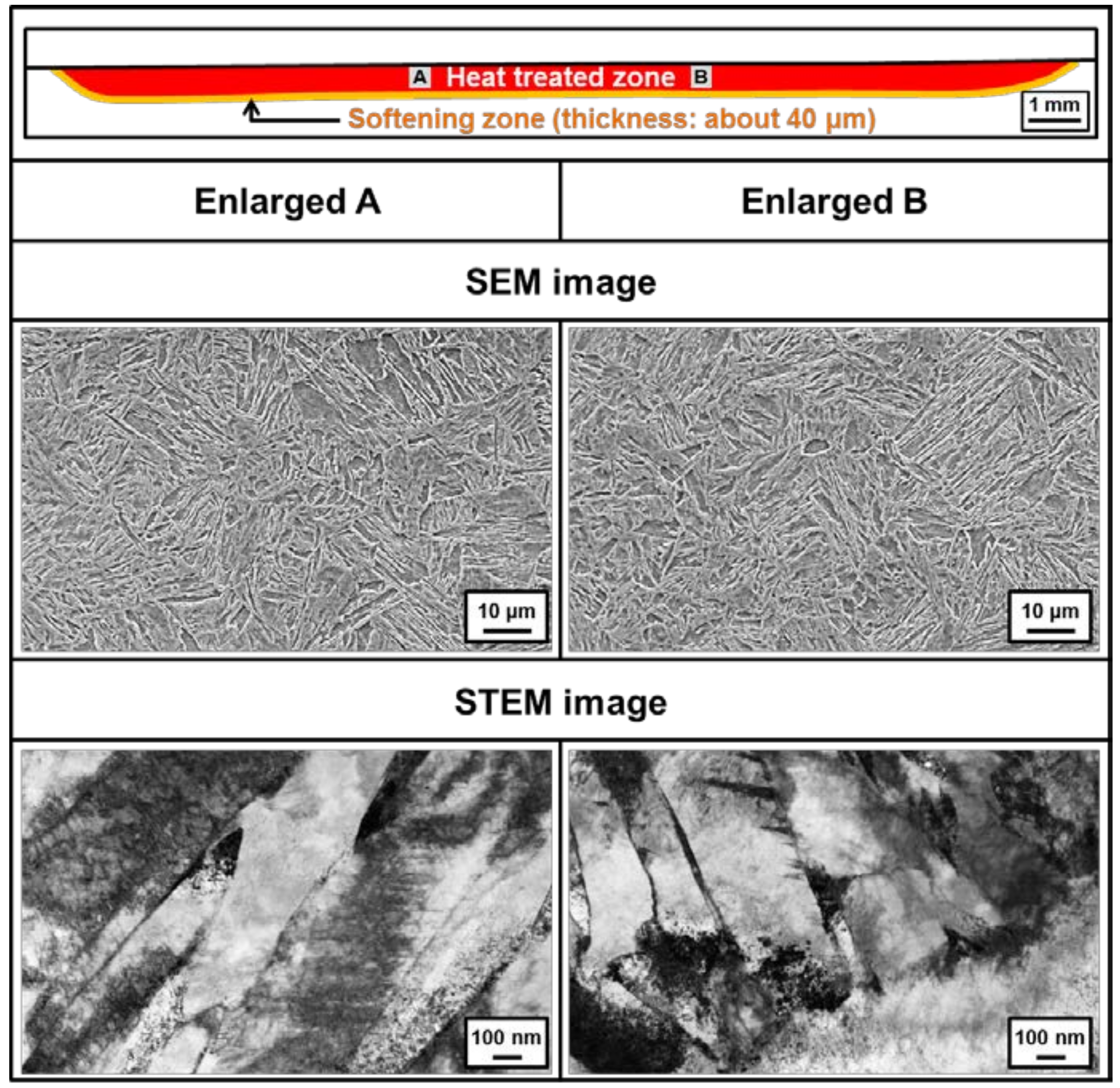

3.6. Microstructural Characterization of the Hardening Zone in P20-Improved Steel

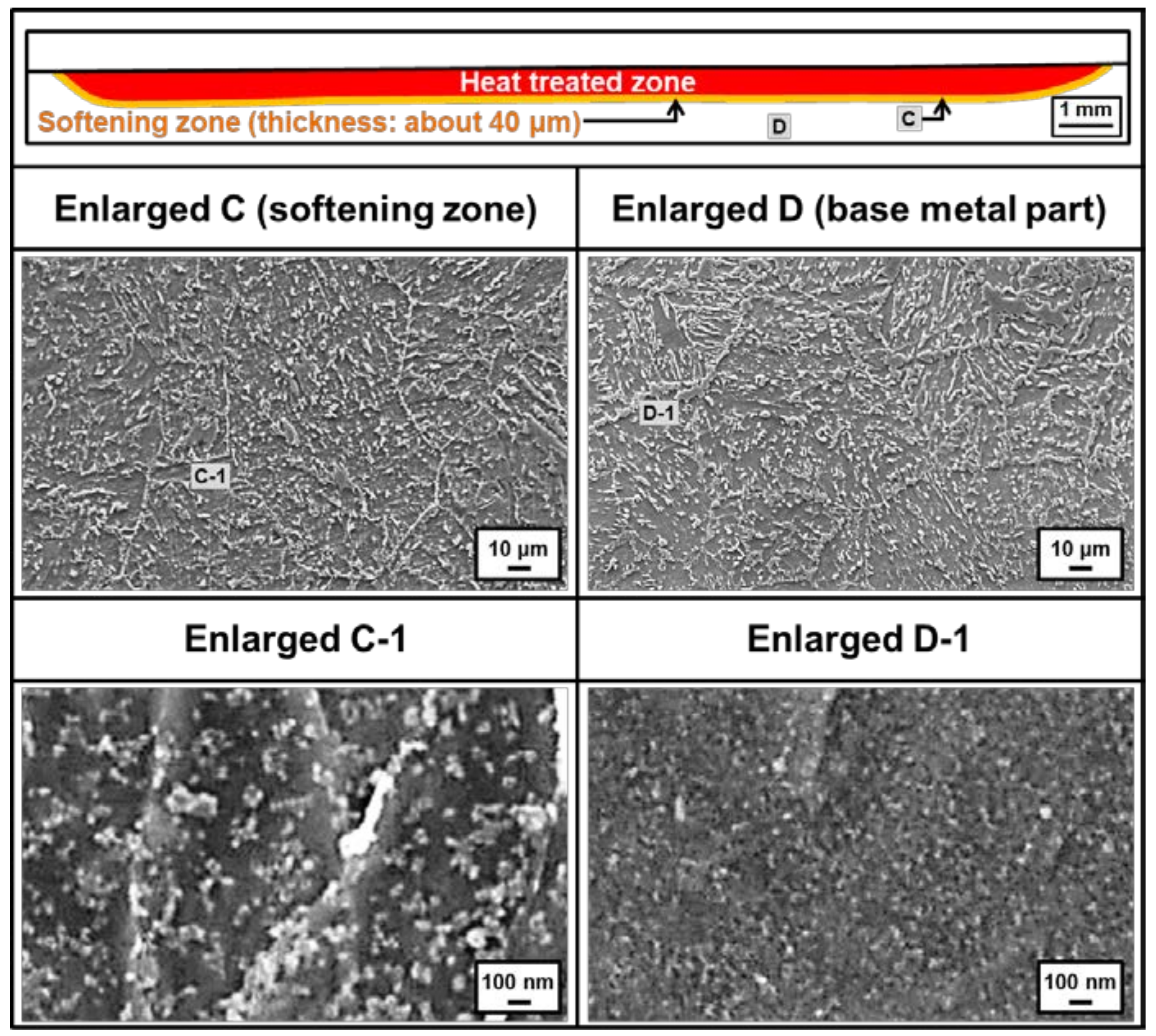

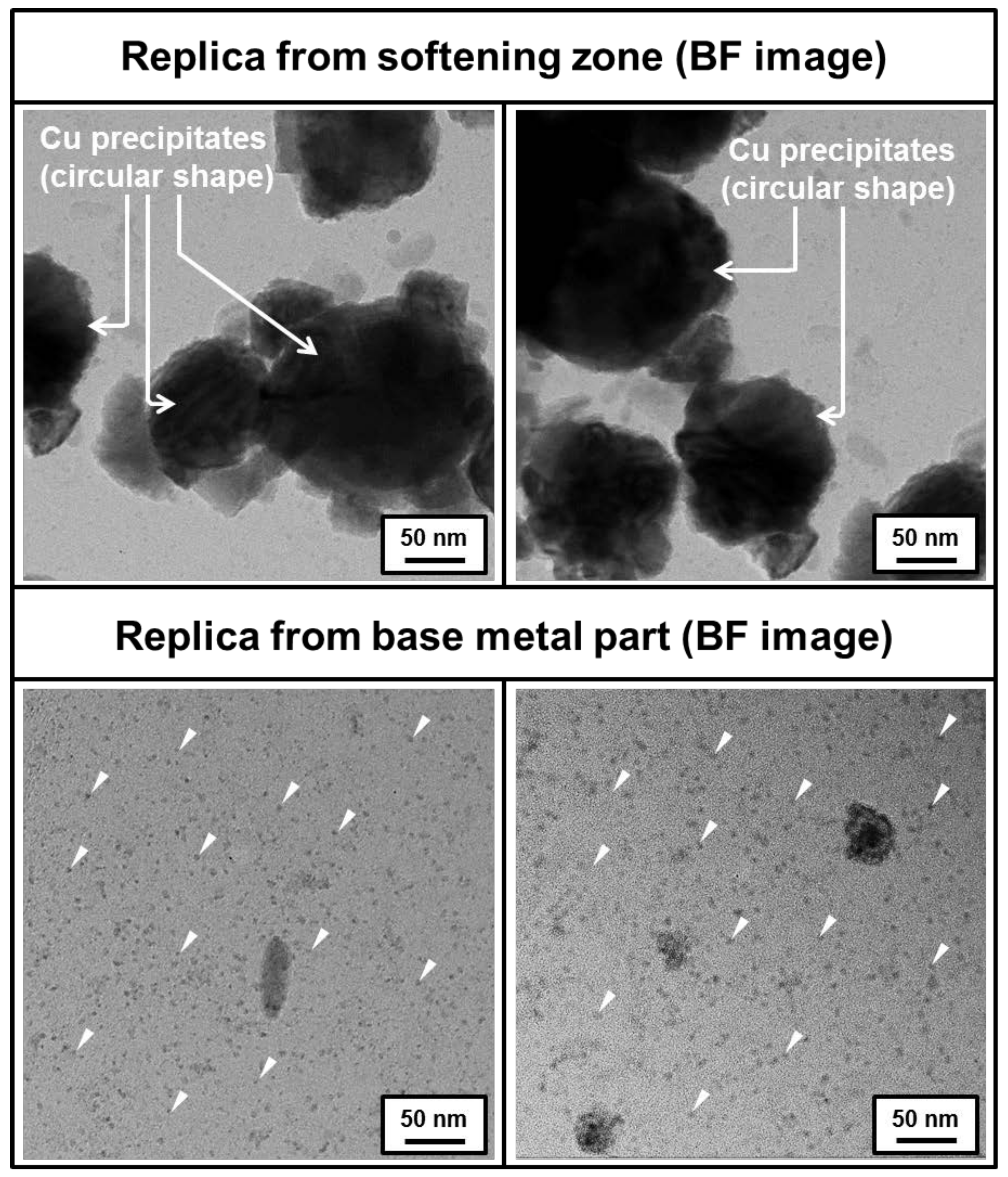

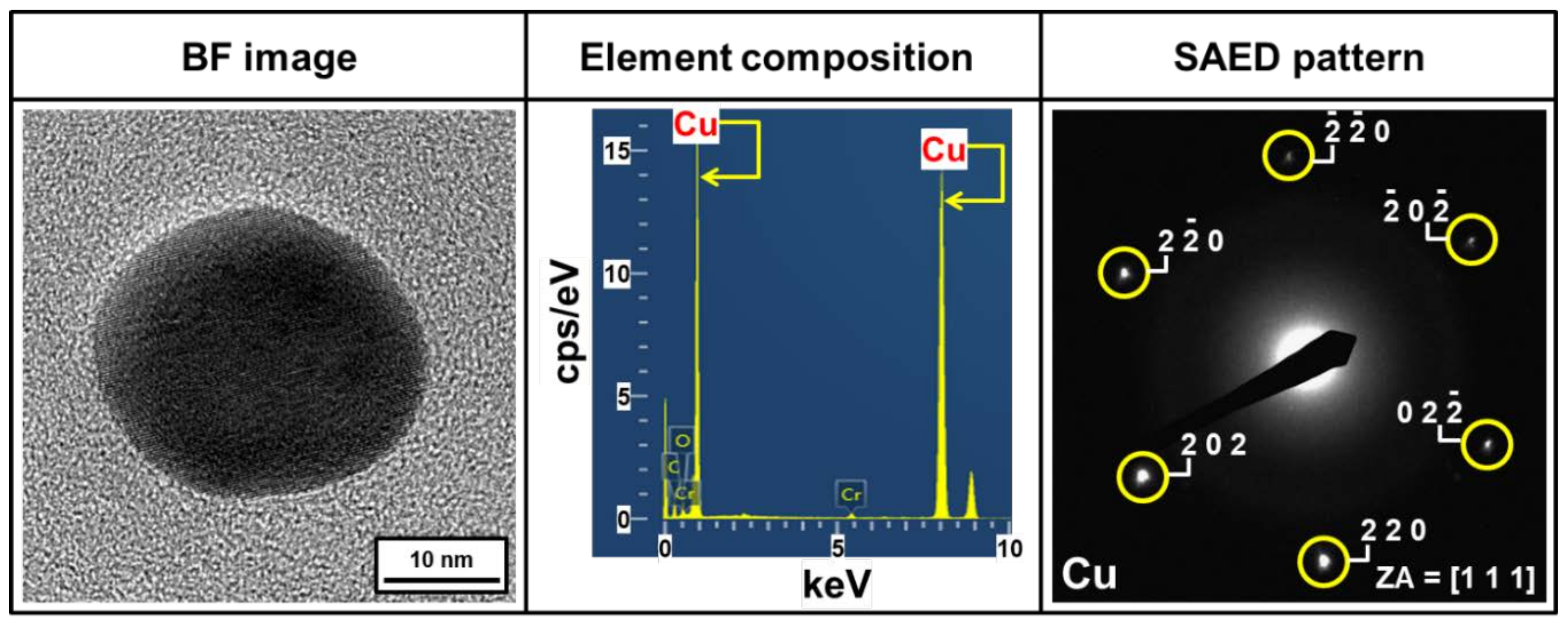

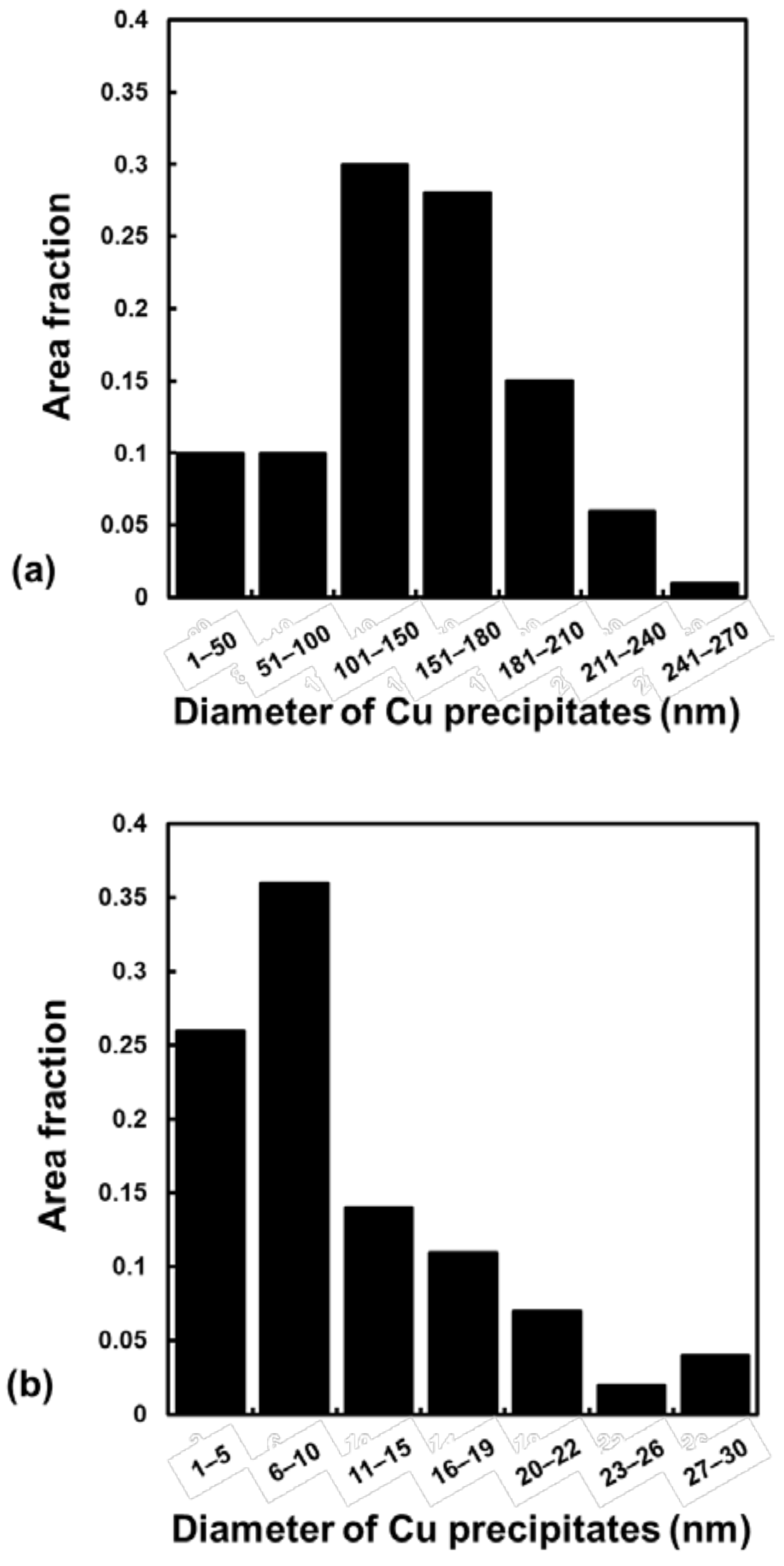

3.7. Relationship between Coarsening of Cu Precipitates and Formation of the Softening Zone in P21 Steel

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Shiou, F.J.; Cheng, C.H. Ultra-precision surface finish of NAK80 mould tool steel using sequential ball burnishing and ball polishing processes. J. Mater. Process. Technol. 2018, 201, 554–559. [Google Scholar] [CrossRef]

- Singh, G.; Verma, A. A brief review on injection moulding manufacturing process. Mater. Today-Proc. 2017, 4, 1423–1433. [Google Scholar] [CrossRef]

- Silva, F.J.G.; Martinho, R.P.; Alexandre, R.J.D.; Baptista, A.P.M. Increasing the wear resistance of molds for injection of glass fiber reinforced plastics. Wear 2011, 271, 2494–2499. [Google Scholar] [CrossRef]

- Boztepe, E.; Alvesb, A.C.; Ariza, E.; Rocha, L.A.; Cansever, N.; Toptan, F. A comparative investigation of the corrosion and tribocorrosion behavior of nitrocarburized, gas nitrided, fluidized-bed nitrided, and plasma nitride plastic mould steel. Surf. Coat. Technol. 2018, 334, 116–123. [Google Scholar] [CrossRef]

- Wen, D.C. Microstructure and corrosion resistance of the layers formed on the surface of precipitation hardenable plastic mold steel by plasma-nitriding. Appl. Surf. Sci. 2009, 256, 797–804. [Google Scholar] [CrossRef]

- Chun, E.J.; Nishimoto, K.; Saida, K. Evaluation of solidification cracking susceptibility in laser welds for type 316FR stainless steel. Weld. World 2016, 60, 217–231. [Google Scholar] [CrossRef]

- Chun, E.J.; Lee, S.J.; Suh, J.; Kang, N.; Saida, K. Solidification cracking behavior in austenitic stainless steel laser welds (part 1)—Evaluation of solidification cracking susceptibility by laser beam welding Varestraint test. J. Weld. Join. 2016, 34, 54–60. [Google Scholar] [CrossRef]

- Chun, E.J.; Lee, S.J.; Suh, J.; Kang, N.; Saida, K. Solidification cracking behavior in austenitic stainless steel laser welds (part 2)—Effects of δ–ferrite crystallization and solidification segregation behavior on solidification cracking susceptibility. J. Weld. Join. 2016, 34, 61–69. [Google Scholar] [CrossRef]

- Zhang, Z.; Yu, T.; Kovacevic, R. Erosion and corrosion resistance of laser cladded AISI 420 stainless steel reinforced with VC. Appl. Surf. Sci. 2017, 410, 225–240. [Google Scholar] [CrossRef]

- Cong, D.; Zhou, H.; Ren, Z.; Zhang, H.; Ren, L.; Meng, C.; Wang, C. Thermal fatigue resistance of hot work die steel repaired by partial laser surface remelting and alloying process. Opt. Lasers Eng. 2014, 54, 55–61. [Google Scholar] [CrossRef]

- Tong, X.; Dai, M.J.; Zhang, Z.H. Thermal fatigue resistance of H13 steel treated by selective laser surface melting and CrNi alloying. Appl. Surf. Sci. 2013, 217, 373–380. [Google Scholar] [CrossRef]

- Sun, P.; Li, S.; Yu, G.; He, X.; Zheng, C.; Ning, W. Laser surface hardening of 42CrMo cast steel for obtaining a wide and uniform hardened layer by shaped beams. Int. J. Adv. Manuf. Technol. 2014, 70, 787–796. [Google Scholar] [CrossRef]

- Wang, C.; Zhou, H.; Liang, N.; Wang, C.; Cong, D.; Meng, C.; Ren, L. Mechanical properties of several laser remelting processed steels with different unit spacings. Appl. Surf. Sci. 2014, 313, 333–340. [Google Scholar] [CrossRef]

- Lee, K.H.; Choi, S.W.; Yoon, T.J.; Kang, C.Y. Microstructure and hardness of surface melting hardened zone of mold steel, SM45C using Yb:YAG disk laser. J. Weld. Join. 2016, 34, 75–81. [Google Scholar] [CrossRef]

- Hongchao, Q. Experimental investigation of laser peening on Ti17 titanium alloy for rotor blade applications. Appl. Surf. Sci. 2015, 351, 524–530. [Google Scholar] [CrossRef]

- Hoppius, J.S.; Kukreja, L.M.; Knyazeva, M.; Pohl, F.; Walther, F.; Ostendorf, A.; Gurevich, E.L. On femtosecond laser shock peening of stainless steel AISI 316. Appl. Surf. Sci. 2018, 435, 1120–1124. [Google Scholar] [CrossRef]

- Haque, R. Quality of self-piercing riveting (SPR) joints from cross-sectional perspective: A review. Arch. Civ. Mech. Eng. 2018, 18, 83–93. [Google Scholar] [CrossRef]

- Chun, E.J.; Kim, M.S.; Nishikawa, H.; Park, C.; Suh, J. Laser-assisted selective fusing of thermal sprayed Ni-based self-fluxing alloys by using high–power diode lasers. Opt. Lasers Technol. 2018, 100, 317–324. [Google Scholar] [CrossRef]

- Syed, B.; Shariff, S.M.; Padmanabham, G.; Lenka, S.; Bhattacharya, B.; Kundu, S. Influence of laser surface hardened layer on mechanical properties of re-engineered low carbon steel sheet. Mat. Sci. Eng. A 2017, 685, 168–177. [Google Scholar] [CrossRef]

- Guarino, S.; Barletta, M.; Afilal, A. High power diode laser (HPDL) surface hardening of low carbon steel: Fatigue life improvement analysis. J. Manuf. Process. 2017, 28, 266–271. [Google Scholar] [CrossRef]

- Telasang, G.; Majumdar, J.D.; Padmanabham, G.; Manna, I. Wear and corrosion behavior of laser surface engineered AISI H13 hot working tool steel. Surf. Coat. Technol. 2015, 261, 69–78. [Google Scholar] [CrossRef]

- Telasang, G.; Majumdar, J.D.; Padmanabham, G.; Manna, I. Structure-property correlation in laser surface treated AISI H13 tool steel for improved mechanical properties. Mat. Sci. Eng. A 2014, 599, 255–267. [Google Scholar] [CrossRef]

- Shariff, S.M.; Pal, T.K.; Padmanabham, G.; Joshi, S.V. Influence of chemical composition and prior microstructure on diode laser hardening of railroad steels. Surf. Coat. Technol. 2013, 228, 14–26. [Google Scholar] [CrossRef]

- Santhanakrishnan, S.; Kovacevic, R. Hardness prediction in multi-pass direct diode laser heat treatment by on-line surface temperature monitoring. J. Mater. Process. Technol. 2012, 212, 2261–2271. [Google Scholar] [CrossRef]

- Li, R.; Jin, Y.; Li, Z.; Qi, K. A Comparative study of high-power diode laser and CO2 laser surface hardening of AISI 1045 steel. J. Mater. Eng. Perform. 2014, 23, 3085–3091. [Google Scholar] [CrossRef]

- Soriano, C.; Leunda, J.; Lambarri, J.; Navas, V.G.; Sanz, C. Effect of laser surface hardening on the microstructure, hardness and residual stressed of austempered ductile iron grades. Appl. Surf. Sci. 2011, 257, 7101–7106. [Google Scholar] [CrossRef]

- Järvenpää, A.; Jaskari, M.; Hietala, M.; Mäntyjärvi, K. Local laser heat treatments of steel sheets. Phys. Proc. 2015, 78, 296–304. [Google Scholar] [CrossRef]

- Qiu, F.; Uusitalo, J.; Kujanpaa, V. Laser transformation hardening of carbon steel: Microhardness analysis on microstructural phases. Surf. Eng. 2013, 29, 34–40. [Google Scholar] [CrossRef]

- Farshidianfar, M.H.; Khajepouhor, A.; Gerlich, A. Real time monitoring and prediction of martensite formation and hardening depth during laser heat treatment. Surf. Coat. Technol. 2017, 315, 326–334. [Google Scholar] [CrossRef]

- Hsiao, C.N.; Yang, J.R. Age hardening in martensitic/bainitic matrices in a copper-bearing steel. Mater. Trans. 2000, 41, 1312–1321. [Google Scholar] [CrossRef]

- Jung, J.G.; Jung, M.; Kang, S.; Lee, Y.K. Precipitation behaviors of carbides and Cu during continuous heating for tempering in Cu-bearing medium C martensitic steel. J. Mater. Sci. 2014, 49, 2204–2212. [Google Scholar] [CrossRef]

- Yao, C.; Xu, B.; Huang, J.; Zhang, P.; Wu, Y. Study on the softening in overlapping zone by laser-overlapping scanning surface hardening for carbon and alloyed steel. Opt. Laser Eng. 2010, 48, 20–26. [Google Scholar] [CrossRef]

- Bouquet, J.; Camp, D.V.; Malek, O.; Haaf, P.T.; Vanmeensel, K.; Lauwers, B. Aiming for improved lifetime of die and mold components through an integrated laser hardening operation, combining machining and a selective heat treatment in one setup. Proc. CIRP 2016, 46, 541–544. [Google Scholar] [CrossRef]

- Kwok, C.T.; Leong, K.I.; Cheng, F.T.; Man, H.C. Microstructural and corrosion characteristics of laser surface-melted plastics mold steels. Mater. Sci. Eng. A 2003, 357, 93–103. [Google Scholar] [CrossRef]

| Materials | C | Ni | Si | Mn | Cr | Mo | Cu | Fe |

|---|---|---|---|---|---|---|---|---|

| AISI P20 improved | 0.38 | 0.12 | 0.26 | 1.02 | 1.72 | 0.46 | - | Bal. |

| AISI P21 | 0.15 | 3.00 | 0.30 | 1.60 | 0.30 | 0.30 | 1.03 | Bal. |

| Parameters | Values |

|---|---|

| Oscillator | 4 kW direct diode laser |

| Wavelength of laser beam (nm) | 970 |

| Beam dimension (mm) | 24 × 1 |

| Maximum laser power density (W/cm2) | 2.5 × 103 |

| Direction of beam irradiation | 5° tilting from normal direction of specimen |

| Focal length (mm) | 310 |

| Defocus distance (mm) | 0 |

| Scan speed of laser beam (mm/s) | 5 |

| Temperature of heat treatment (K) | 1073–1473 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chun, E.-J.; Sim, A.; Kim, M.-S.; Kang, N. Microstructural Characterization of Surface Softening Behavior for Cu-Bearing Martensitic Steels after Laser Surface Heat Treatment. Metals 2018, 8, 470. https://doi.org/10.3390/met8060470

Chun E-J, Sim A, Kim M-S, Kang N. Microstructural Characterization of Surface Softening Behavior for Cu-Bearing Martensitic Steels after Laser Surface Heat Treatment. Metals. 2018; 8(6):470. https://doi.org/10.3390/met8060470

Chicago/Turabian StyleChun, Eun-Joon, Ahjin Sim, Min-Su Kim, and Namhyun Kang. 2018. "Microstructural Characterization of Surface Softening Behavior for Cu-Bearing Martensitic Steels after Laser Surface Heat Treatment" Metals 8, no. 6: 470. https://doi.org/10.3390/met8060470

APA StyleChun, E.-J., Sim, A., Kim, M.-S., & Kang, N. (2018). Microstructural Characterization of Surface Softening Behavior for Cu-Bearing Martensitic Steels after Laser Surface Heat Treatment. Metals, 8(6), 470. https://doi.org/10.3390/met8060470